Comparison of Shear Behaviors of Different Concrete-Filled High-Strength Steel Tubes

-

摘要:

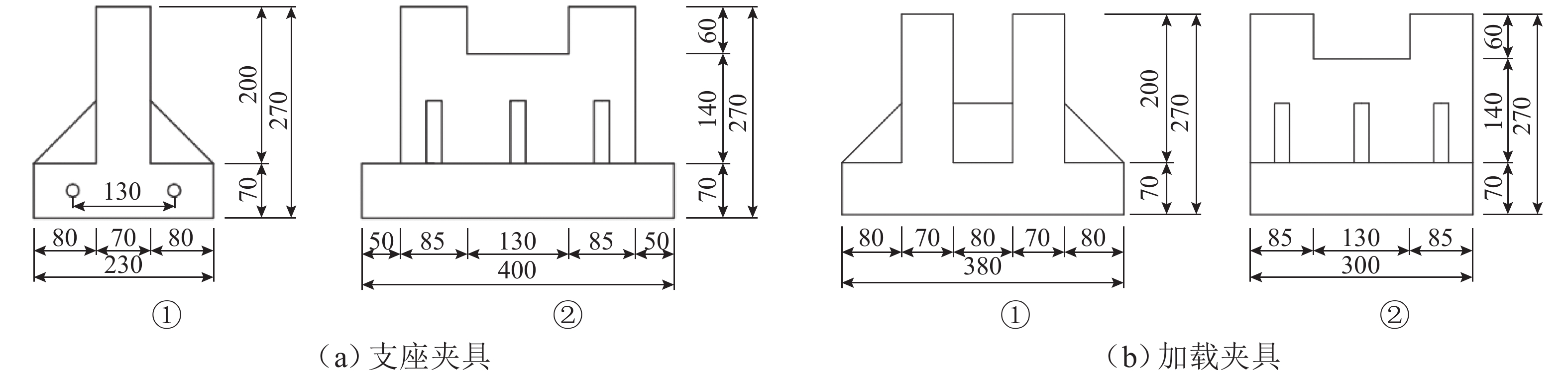

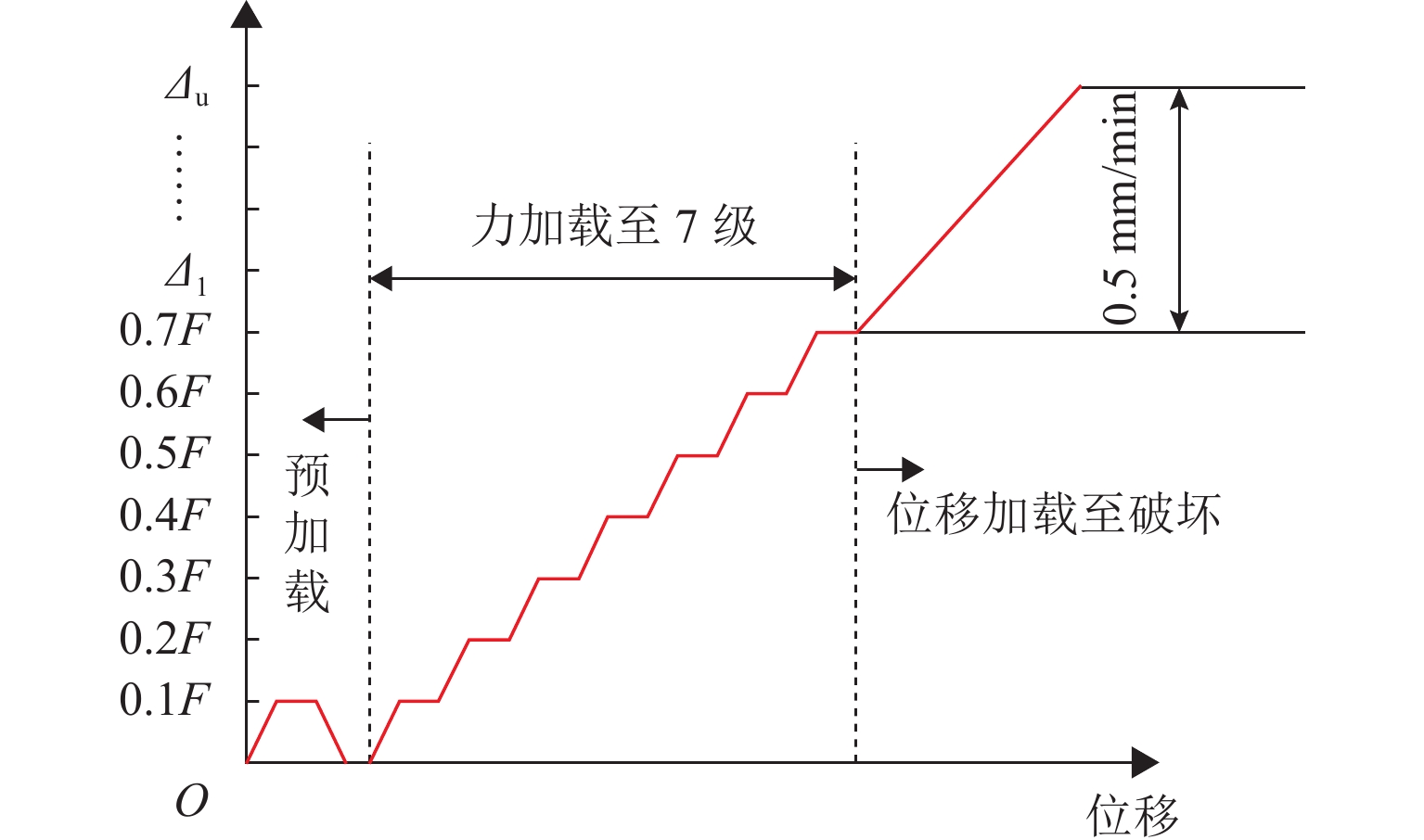

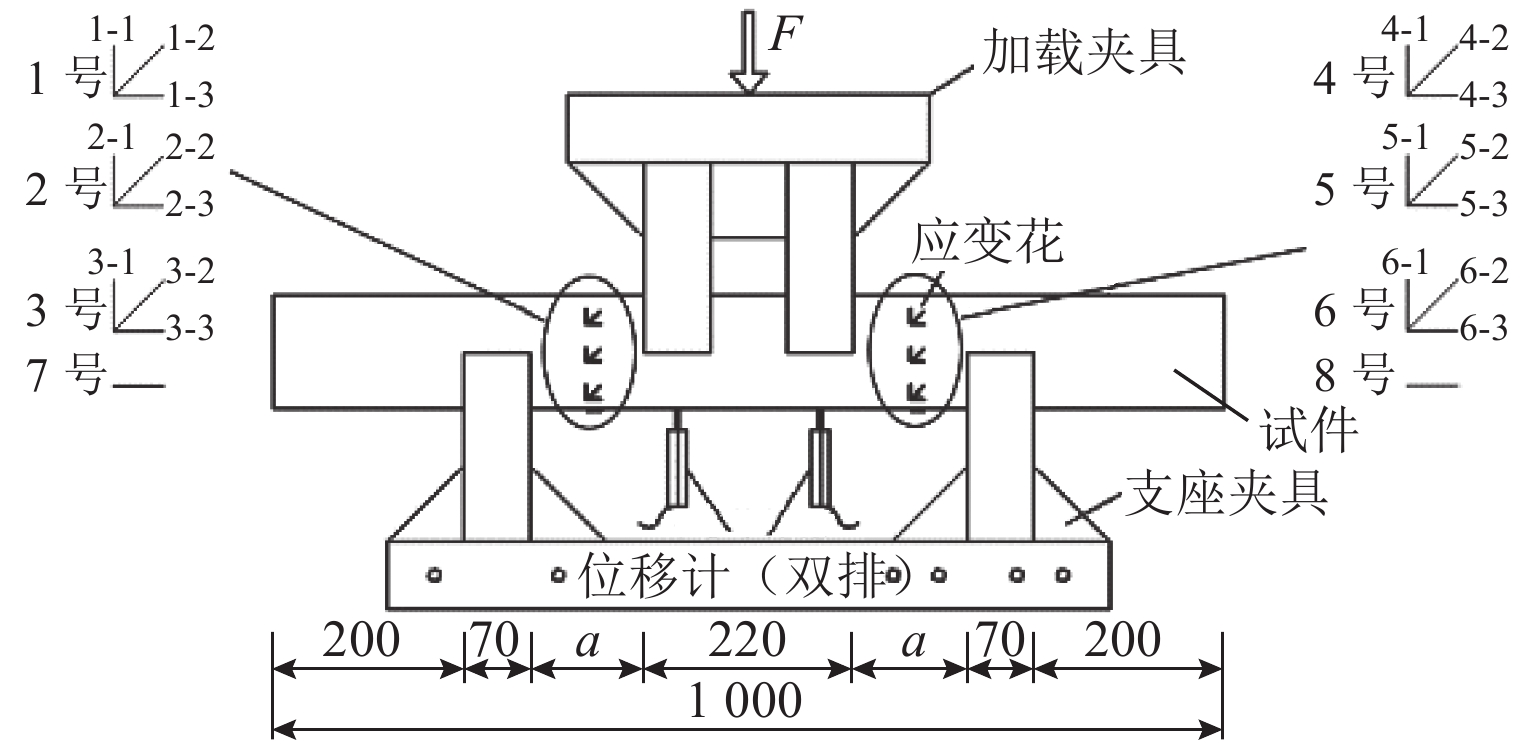

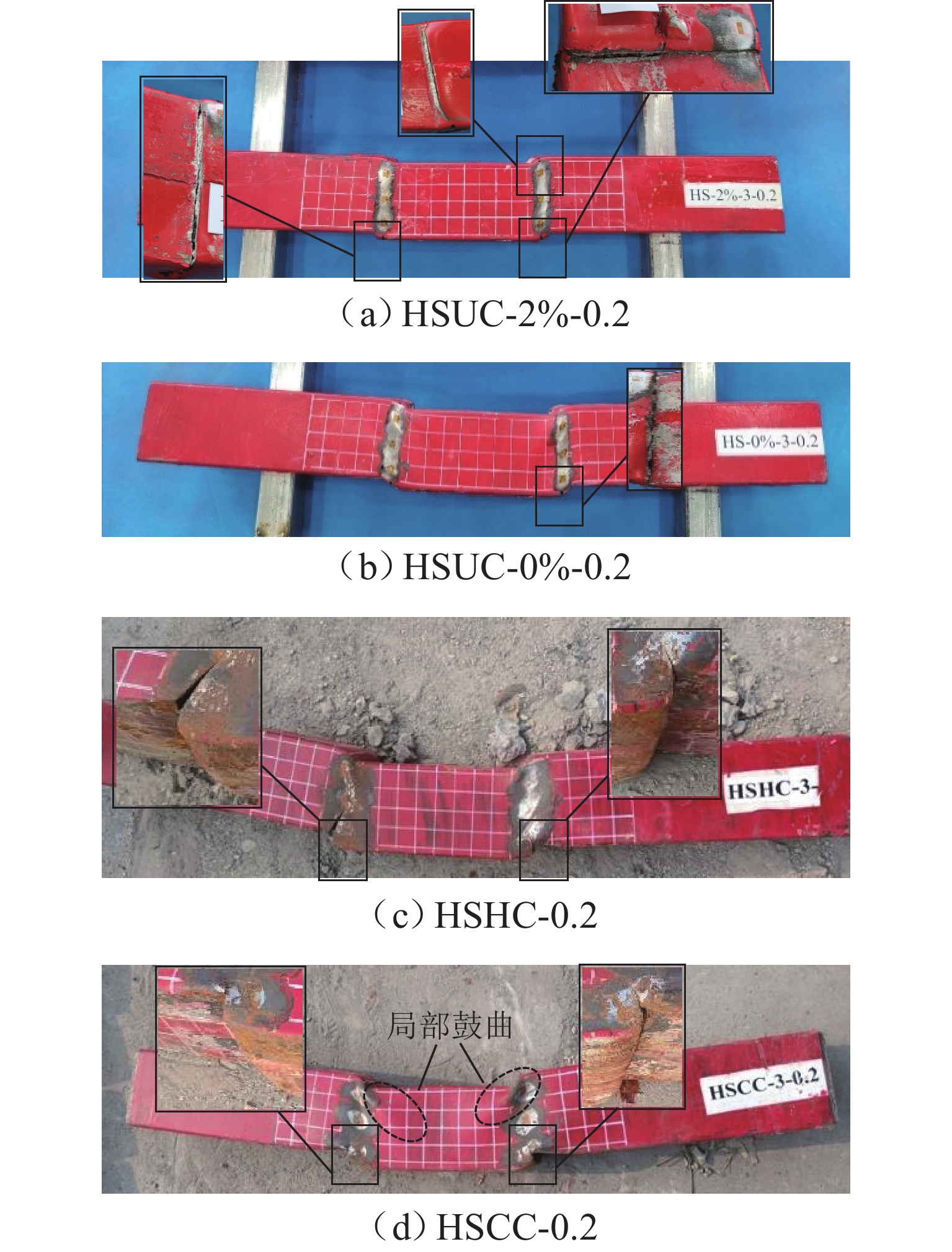

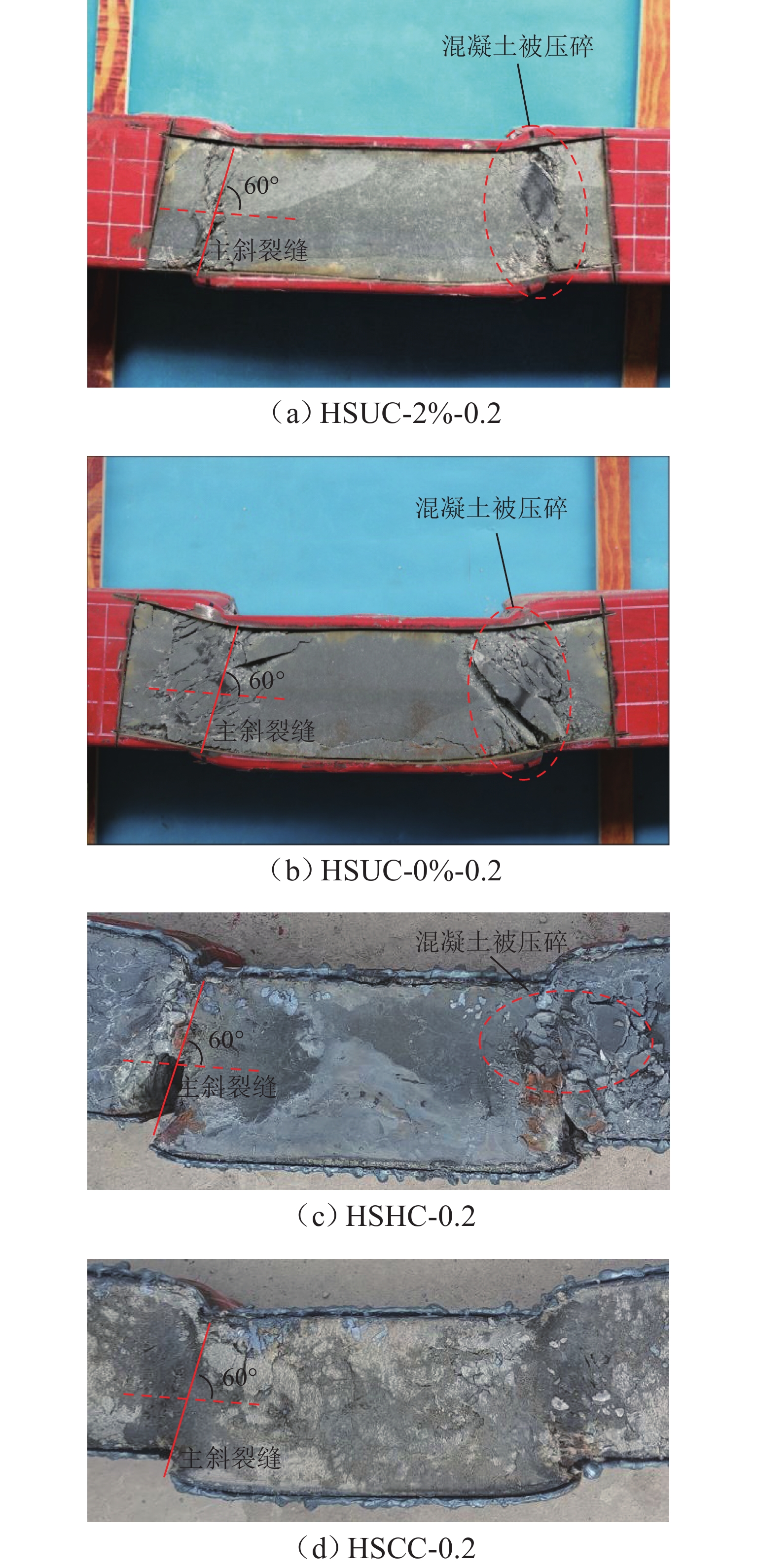

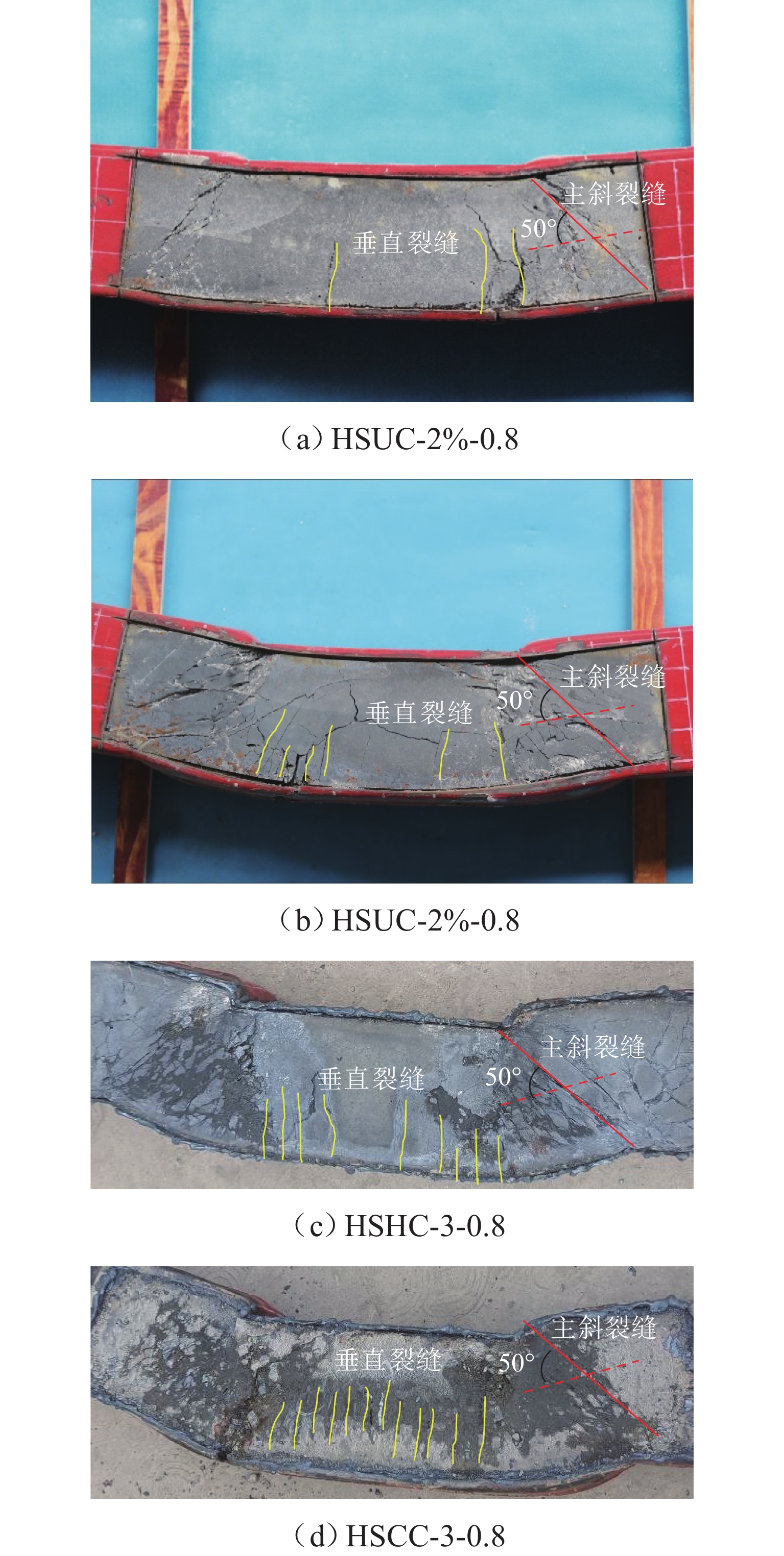

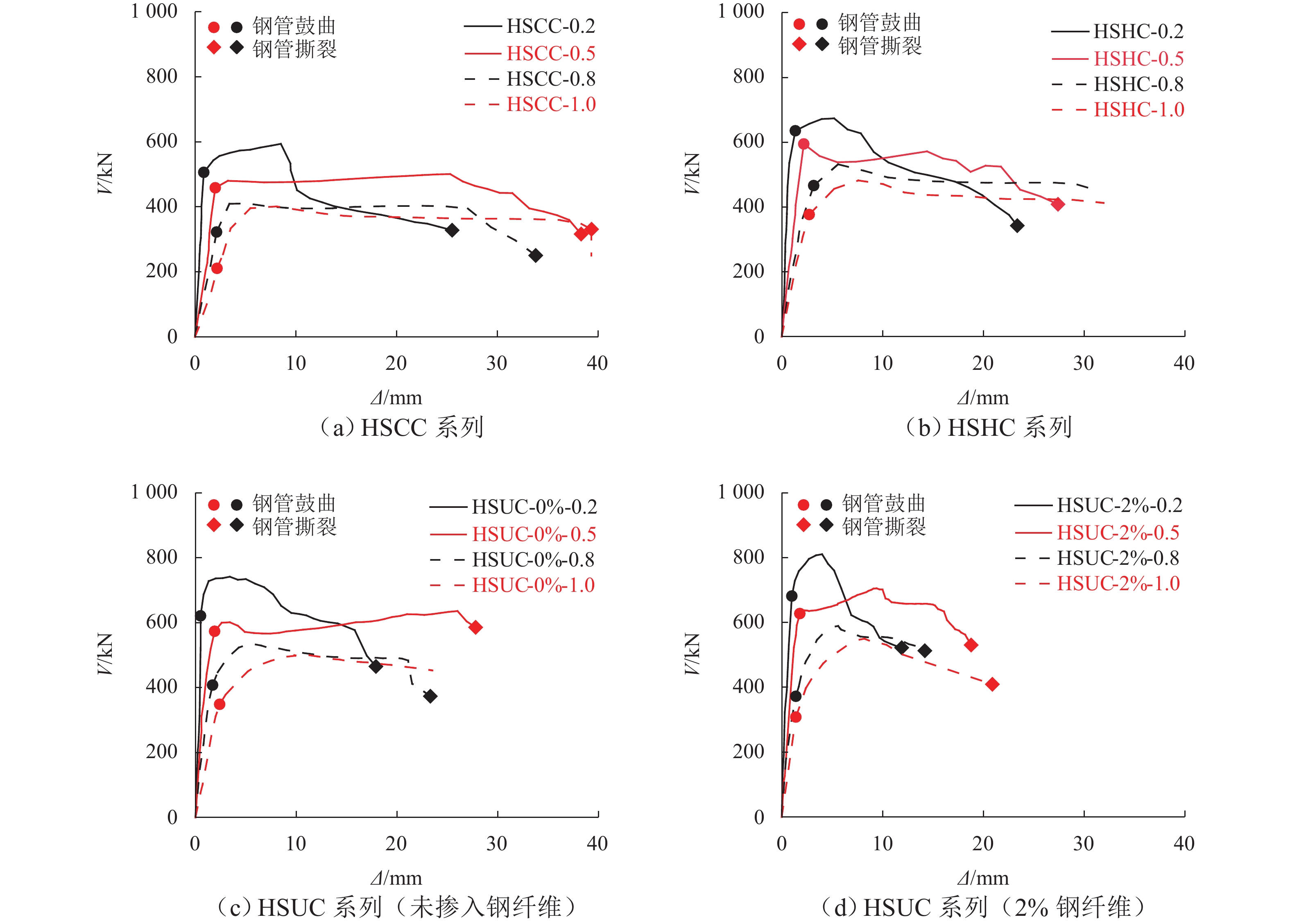

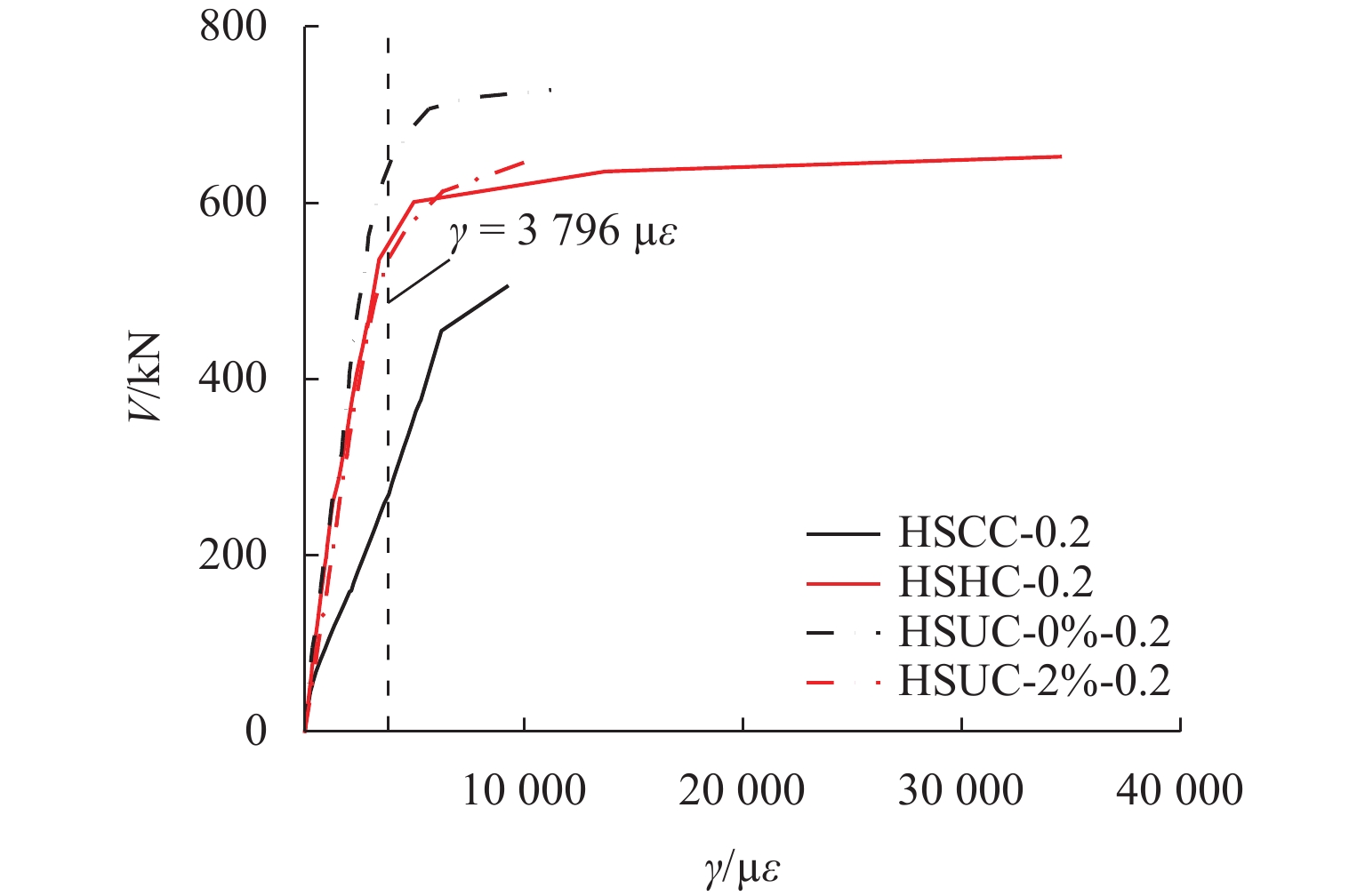

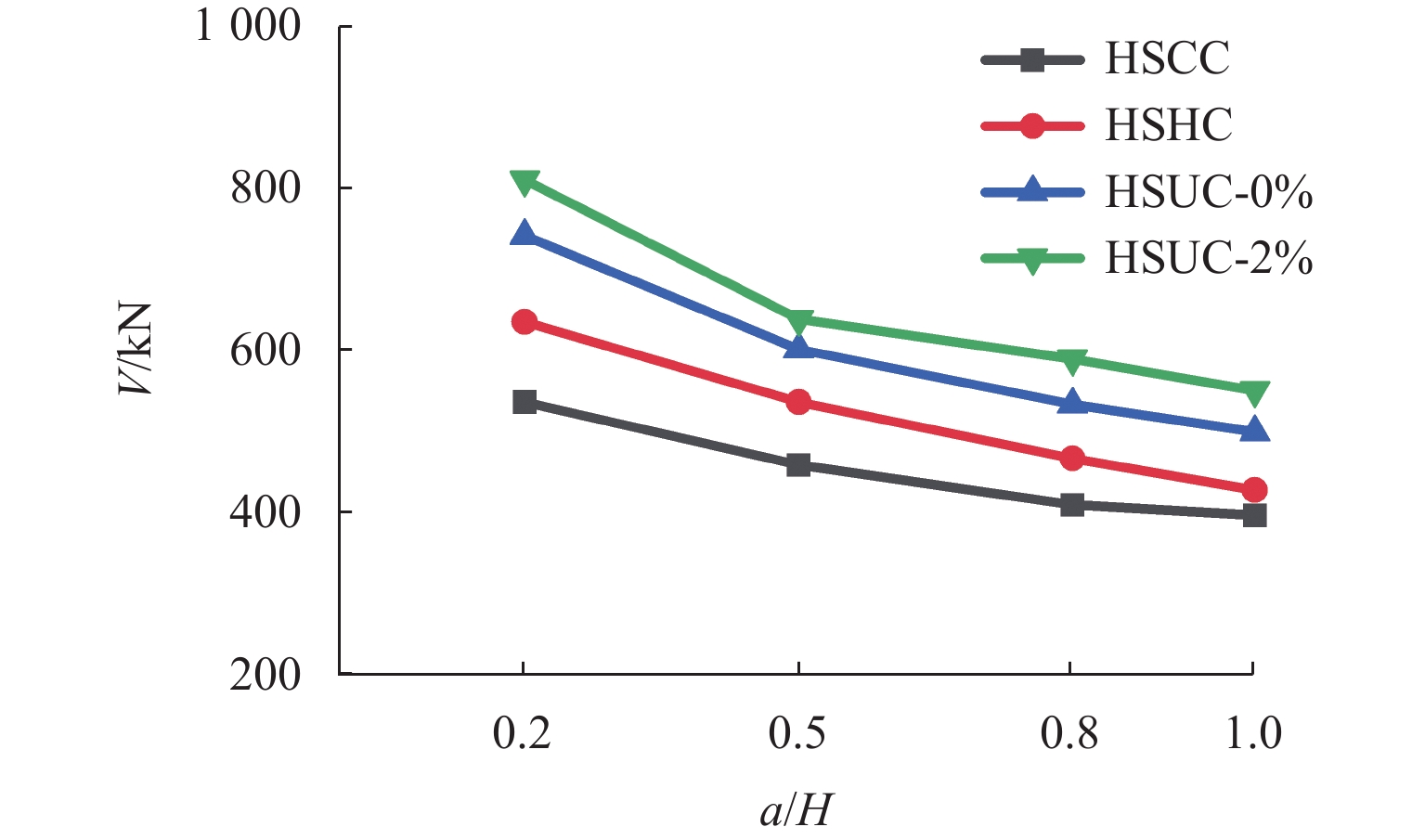

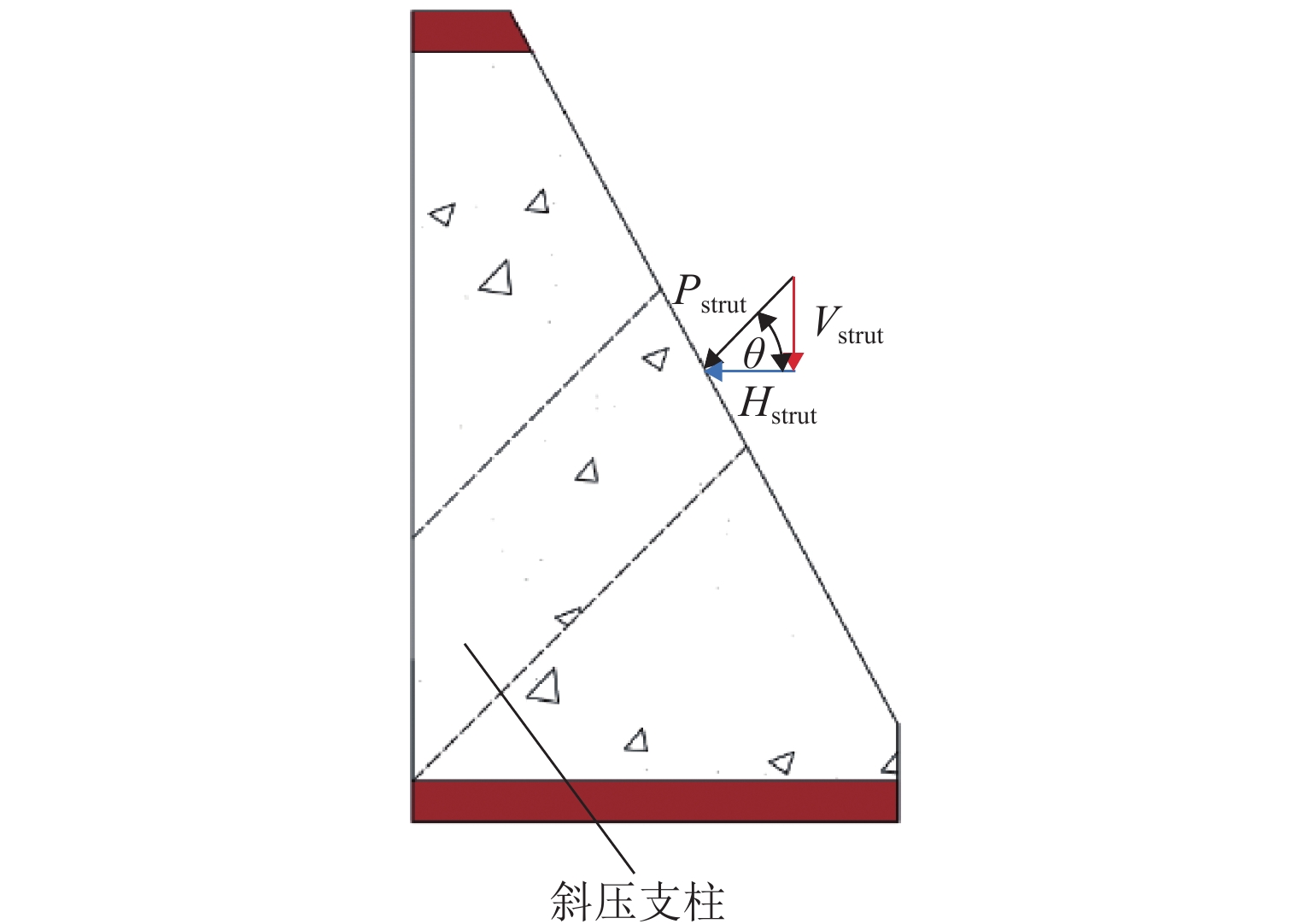

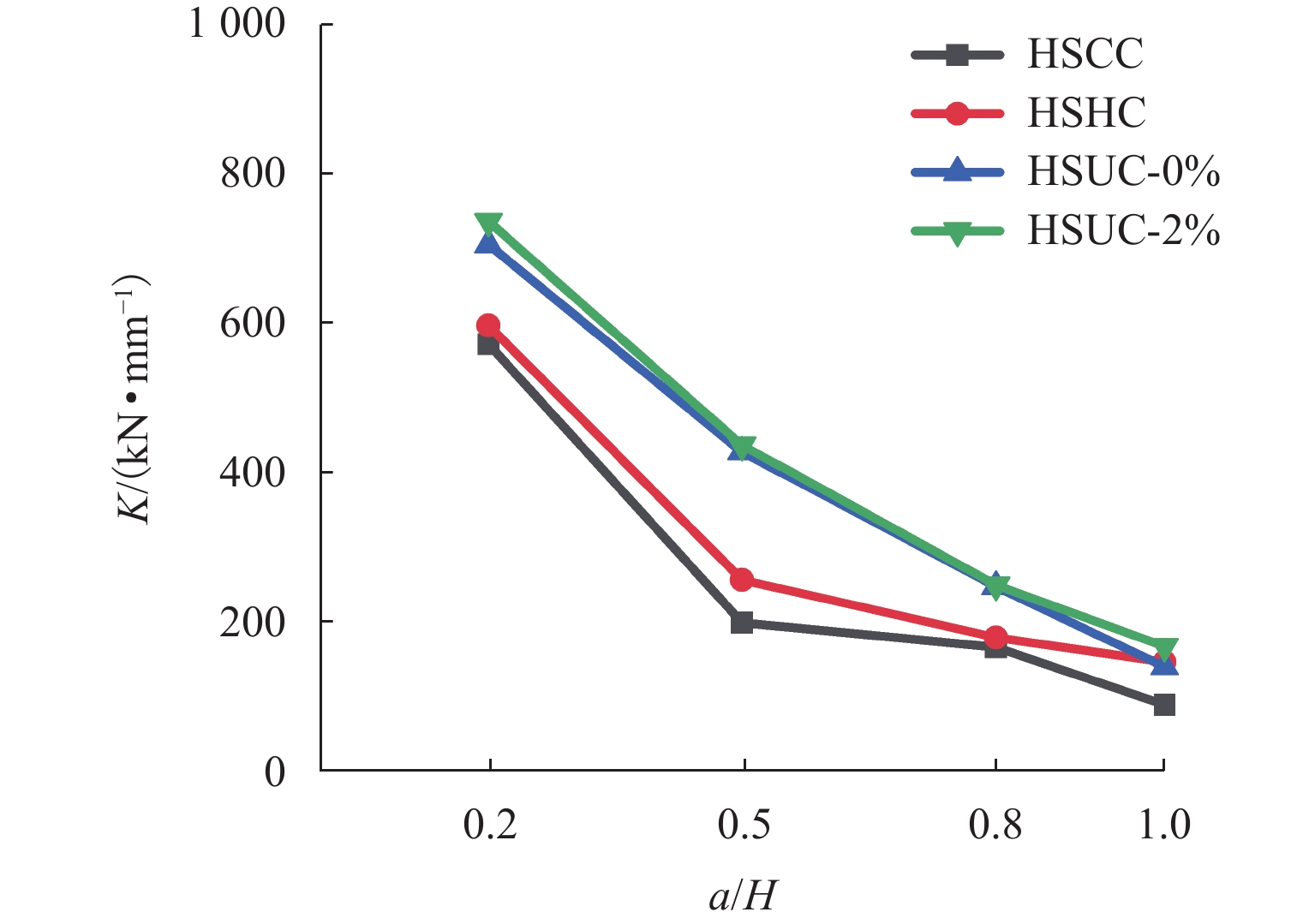

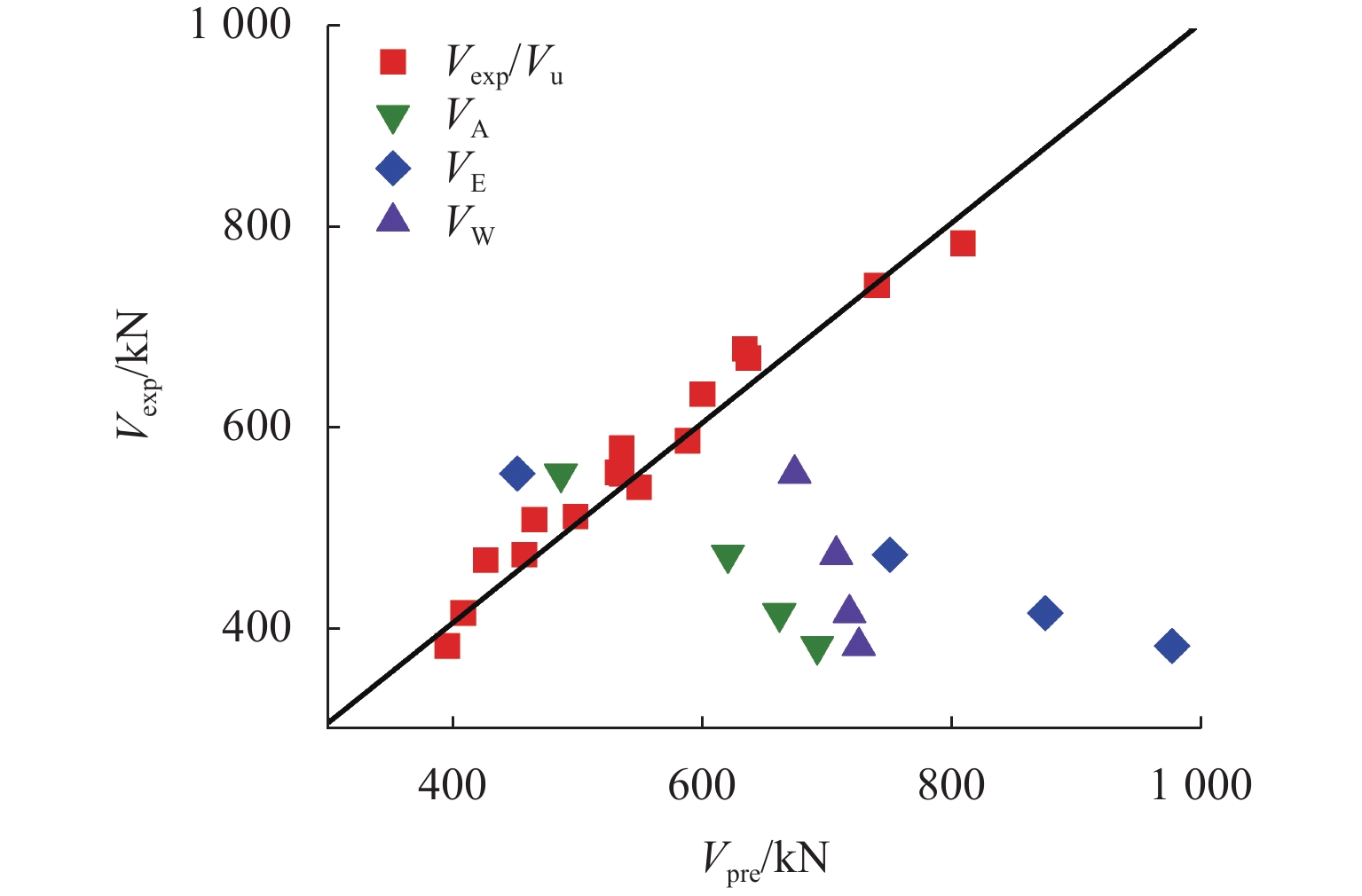

为研究剪跨比和混凝土强度对高强方钢管混凝土试件抗剪性能的影响,共设计16个高强方钢管混凝土试件. 通过试验获得试件的破坏模式和剪力-位移曲线,对比剪跨比、核心混凝土强度等参数对破坏模式、剪力-位移曲线、剪力-剪应变曲线、抗剪强度和刚度的影响. 研究结果表明:与普通钢管混凝土试件一致,剪跨比是控制高强方钢管混凝土试件破坏模式的主要参数,当剪跨比为0.2或0.5时,发生剪切破坏;当剪跨比为0.8或1.0时,发生弯剪破坏;采用超高性能混凝土填充高强方钢管(剪跨比为1.0),试件的变形能力降低61.4%,抗剪强度和刚度分别提高了38.9%和85.7%,且有效延缓钢管局部屈曲和降低试件的破坏程度;核心混凝土主斜裂缝产生的倾角随剪跨比增大而减小,但不受混凝土强度影响. 本文抗剪强度试验值/抗剪强度计算值(

V exp/V u)的均值为0.97,方差为0.03,精度高,离散性小,认为该公式可较准确地预测高强钢管混凝土的抗剪强度.Abstract:A total of 16 concrete-filled high-strength steel tube specimens were designed to evaluate the effects of shear-to-span ratio and concrete strength on the shear behavior of concrete-filled high-strength steel tube specimens. The failure mode and shear-displacement curve of the specimens were obtained through the test, and the effects of shear-to-span ratio, core concrete strength, and other parameters on the failure mode, shear-displacement curve, shear-shear strain curve, shear strength, and shear stiffness were compared. The results show that similar to conventional concrete-filled steel tube specimens, the shear-to-span ratio is the key parameter controlling the failure mode of the concrete-filled high-strength steel tube specimens. When the shear-to-span ratio is 0.2 or 0.5, shear failure occurs; when the shear-to-span ratio is 0.8 or 1.0, shear-flexural failure occurs. By implementing ultra-high performance concrete (UHPC), the deformation capacity of the concrete-filled high-strength steel tube specimens (with a shear-to-span ratio of 1.0) is reduced by 61.4%. However, shear strength and stiffness increase by 38.9% and 85.7%, respectively. Additionally, local buckling of the steel tubes is effectively delayed, and the damage degree of the specimens is reduced. The inclination angle of the main diagonal cracks in the core concrete decreases with an increase in the shear-to-span ratio but is not affected by the concrete strength. The average value of tested shear strength/calculated shear strength (

V exp/V u) is 0.97, with a deviation of 0.03, showing higher accuracy and smaller dispersion. It is considered that the formula can accurately predict the shear strength of concrete-filled high-strength steel tubes.-

Key words:

- concrete-filled steel tube /

- high-strength steel tube /

- shear behavior /

- failure mode /

- design method

-

表 1 试件主要参数

Table 1. Main parameters of specimens

序号 试件编号 L/mm B/mm H/mm $\rho $/% $f_{\mathrm{y}} $/MPa $f_{{\mathrm{c}}1} $/MPa t/mm $E_{\mathrm{s}} $/GPa $E_{\mathrm{c}} $/GPa 1 HSCC-0.2 1000 120 120 747 30 3 206 32.7 2 HSCC-0.5 1000 120 120 747 30 3 206 32.7 3 HSCC-0.8 1000 120 120 747 30 3 206 32.7 4 HSCC-1.0 1000 120 120 747 30 3 206 32.7 5 HSHC-0.2 1000 120 120 782 90 3 206 43.4 6 HSHC-0.5 1000 120 120 782 90 3 206 43.4 7 HSHC-0.8 1000 120 120 782 90 3 206 43.4 8 HSHC-1.0 1000 120 120 782 90 3 206 43.4 9 HSUC-0%-0.2 1000 120 120 747 115 3 206 41.9 10 HSUC-0%-0.5 1000 120 120 747 115 3 206 41.9 11 HSUC-0%-0.8 1000 120 120 747 115 3 206 41.9 12 HSUC-0%-1.0 1000 120 120 747 115 3 206 41.9 13 HSUC-2%-0.2 1000 120 120 2 775 135.4 3 206 44.8 14 HSUC-2%-0.5 1000 120 120 2 775 135.4 3 206 44.8 15 HSUC-2%-0.8 1000 120 120 2 775 135.4 3 206 44.8 16 HSUC-2%-1.0 1000 120 120 2 775 135.4 3 206 44.8 表 2 混凝土配合比

Table 2. Concrete mix proportions

kg/m3 混凝土类别 水 水泥 硅灰 粗骨料 细骨料 减水剂 钢纤维体积掺量/% 普通(C30) 180.0 370.0 1042.0 766.0 7.40 高强(C90) 156.8 579.4 102.2 1050.8 617.2 15.48 UHPC (无钢纤维) 221.7 852.5 255.7 920.7 80.1 21.30 UHPC (2% 钢纤维) 221.7 852.5 255.7 920.7 80.1 21.30 2 表 3 试验结果

Table 3. Test results

试件编号 Vexp/

kN$\varDelta_{\mathrm{y}} $/

mm$\varDelta_{\mathrm{u}} $/

mmK/

(kN·mm−1)破坏模式 HSCC-0.2 536 0.9 9.5 573 剪切破坏 HSCC-0.5 458 2.3 28.4 201 剪切破坏 HSCC-0.8 409 2.4 29.7 168 弯剪破坏 HSCC-1.0 396 4.4 >30.0 91 弯剪破坏 HSHC-0.2 635 1.1 7.2 598 剪切破坏 HSHC-0.5 536 2.1 22.6 258 剪切破坏 HSHC-0.8 466 2.5 27.7 181 弯剪破坏 HSHC-1.0 427 2.9 >30.0 148 弯剪破坏 HSUC-0%-0.2 741 1.1 14.5 706 剪切破坏 HSUC-0%-0.5 601 1.4 27.8 429 剪切破坏 HSUC-0%-0.8 533 2.1 21.2 249 弯剪破坏 HSUC-0%-1.0 499 3.5 23.5 142 弯剪破坏 HSUC-2%-0.2 810 1.1 6.1 737 剪切破坏 HSUC-2%-0.5 638 1.6 14.2 438 剪切破坏 HSUC-2%-0.8 589 2.3 22.4 251 弯剪破坏 HSUC-2%-1.0 550 3.3 23.3 169 弯剪破坏 表 4 试验值与计算值比较

Table 4. Comparison between the tested and calculated values

试件编号 Vexp/kN 文献[20] 文献[21] 文献[22] 文献[23] Vu/kN Vexp/Vu VA/kN Vexp/VA VE/kN Vexp/VE VW/kN Vexp/VW HSCC-0.2 536 553.5 0.97 487.2 1.10 452.3 1.19 675.0 0.79 HSCC-0.5 458 472.4 0.97 487.2 0.94 452.3 1.01 675.0 0.68 HSCC-0.8 409 414.0 0.99 487.2 0.84 452.3 0.90 675.0 0.61 HSCC-1.0 396 381.1 1.01 487.2 0.81 452.3 0.88 675.0 0.59 HSHC-0.2 635 678.0 0.94 621.3 1.02 751.4 0.85 708.5 0.90 HSHC-0.5 536 578.8 0.93 621.3 0.86 751.4 0.71 708.5 0.76 HSHC-0.8 466 507.2 0.92 621.3 0.75 751.4 0.62 708.5 0.66 HSHC-1.0 427 466.9 0.91 621.3 0.69 751.4 0.57 708.5 0.60 HSUC-0%-0.2 741 741.4 1.00 662.6 1.12 876.1 0.85 718.9 1.03 HSUC-0%-0.5 601 632.8 0.95 662.6 0.91 876.1 0.69 718.9 0.84 HSUC-0%-0.8 533 554.6 0.96 662.6 0.80 876.1 0.61 718.9 0.74 HSUC-0%-1.0 499 510.5 0.98 662.6 0.75 876.1 0.57 718.9 0.69 HSUC-2%-0.2 810 783.7 1.03 693.1 1.17 977.8 0.83 726.5 1.11 HSUC-2%-0.5 638 669.0 0.95 693.1 0.92 977.8 0.65 726.5 0.88 HSUC-2%-0.8 589 586.3 1.00 693.1 0.85 977.8 0.60 726.5 0.81 HSUC-2%-1.0 550 539.7 1.02 693.1 0.79 977.8 0.56 726.5 0.76 均值 0.97 0.90 0.75 0.78 方差 0.03 0.14 0.18 0.15 -

[1] 韩林海. 钢管混凝土结构:理论与实践[M]. 2版. 北京:科学出版社,2007. [2] LAI Z C, VARMA A H, GRIFFIS L G. Analysis and design of noncompact and slender CFT beam-columns[J]. Journal of Structural Engineering, 2016, 142(1): 04015097.1-04015097.14. [3] WANG Y, LIN H, LAI Z C, et al. Flexural behavior of high-strength rectangular concrete-filled steel tube members[J]. Journal of Structural Engineering, 2022, 148(1): 4021230.1-4021230.15. [4] WANG F Y, ZHAO O, YOUNG B. Testing and numerical modelling of S960 ultra-high strength steel angle and channel section stub columns[J]. Engineering Structures, 2020, 204: 109902.1-109902.12. [5] RICHARD P, CHEYREZY M. H. Reactive powder concretes with high ductility and 200-800 MPa compressive strength[J]. Special Publications, 1994, 144(24): 507-518. [6] 管民生,黄献奇,杜宏彪,等. 矩形钢管高强混凝土框架抗震性能分析[J]. 西南交通大学学报,2019,54(3): 483-491. doi: 10.3969/j.issn.0258-2724.20170809GUAN Minsheng, HUANG Xianqi, DU Hongbiao, et al. Seismic behavior of rectangular high-strength concrete-filled steel tube frame structure[J]. Journal of Southwest Jiaotong University, 2019, 54(3): 483-491. doi: 10.3969/j.issn.0258-2724.20170809 [7] YE Y, HAN L H, TAO Z, et al. Experimental behaviour of concrete-filled steel tubular members under lateral shear loads[J]. Journal of Constructional Steel Research, 2016, 122: 226-237. doi: 10.1016/j.jcsr.2016.03.012 [8] 黄勇,陈伟刚,段莉. 钢管混凝土短柱(剪力键)受剪性能试验研究[J]. 建筑结构学报,2011,32(12): 178-185.HUANG Yong, CHEN Weigang, DUAN Li. Experimental study on shear resistance performance of concrete filled steel tube shear block stub columns[J]. Journal of Building Structures, 2011, 32(12): 178-185. [9] 李志强,陈以一,王伟. 矩形钢管混凝土中短柱弯-剪性能试验研究[J]. 建筑结构学报,2015,36(7): 1-9.LI Zhiqiang, CHEN Yiyi, WANG Wei. Experimental research on bending and shearing behavior of middle and short concrete filled steel tubular columns[J]. Journal of Building Structures, 2015, 36(7): 1-9. [10] 史艳莉,周绪红,鲜威,等. 无端板矩形钢管混凝土构件基本剪切性能研究[J]. 工程力学,2018,35(12): 25-33.SHI Yanli, ZHOU Xuhong, XIAN Wei, et al. Research on basic shear performance of concrete filled rectangular steel tubular members without end-plate[J]. Engineering Mechanics, 2018, 35(12): 25-33. [11] 丁威. 矩形钢管混凝土双剪截面研究及其工程应用[D]. 广东:广东工业大学,2019. [12] MANSOURI A. Shear strength of concrete-filled steel tubes based on experimental results[J]. Journal of Structural Engineering, 2020, 146(6): 04020097.1-04020097.14. [13] LEHMAN D, ROEDER C, HEID A, et al. Shear response of concrete filled tubes part 1: experiments[J]. Journal of Constructional Steel Research, 2018, 150: 528-540. doi: 10.1016/j.jcsr.2018.08.027 [14] LEHMAN D, ROEDER C, HEID A, et al. Shear response of concrete filled tubes part Ⅱ: analytical study[J]. Journal of Constructional Steel Research, 2019, 153: 169-178. doi: 10.1016/j.jcsr.2018.08.019 [15] 颜燕祥,徐礼华,蔡恒,等. 高强方钢管超高性能混凝土短柱轴压承载力计算方法研究[J]. 建筑结构学报,2019,40(12): 128-137.YAN Yanxiang, XU Lihua, CAI Heng, et al. Calculation methods of axial bearing capacity of short square UHPC filled high strength steel tubular columns[J]. Journal of Building Structures, 2019, 40(12): 128-137. [16] 操礼林,石启印,王震,等. 高强U形外包钢-混凝土组合梁受弯性能[J]. 西南交通大学学报,2014,49(1): 72-78. doi: 10.3969/j.issn.0258-2724.2014.01.012CAO Lilin, SHI Qiyin, WANG Zhen, et al. Bending performances of high-strength steel-encased composite beams[J]. Journal of Southwest Jiaotong University, 2014, 49(1): 72-78. doi: 10.3969/j.issn.0258-2724.2014.01.012 [17] YAN Y X, XU L H, LI B, et al. Axial behavior of ultra-high performance concrete (UHPC) filled stocky steel tubes with square sections[J]. Journal of Constructional Steel Research, 2019, 158: 417-428. doi: 10.1016/j.jcsr.2019.03.018 [18] HU J Y, HUANG Y F, LI W J, et al. Compressive behaviour of UHPC-filled square high-strength steel tube stub columns under eccentric loading[J]. Journal of Constructional Steel Research, 2022, 198: 107558.1-107558.15. [19] LAI Z C, ZHOU W S, WANG Y, et al. Flexural behavior and design of rectangular ultra-high performance concrete-filled high-strength steel tube members[J]. Engineering Structures, 2023, 286: 116125.1-116125.15. [20] 哈尔滨工业大学,中国建筑科学研究院. 钢管混凝土结构技术规程:CECS 28—2012[S]. 北京:中国计划出版社,2012. [21] American Association of State Highway and Transportation Officials (AASHTO). AASHTO LRFD bridge design specifications[S]. Washington, D. C.: AASHTO, 2014. [22] CEN. Design of composite steel and concrete structures part 1-1: general rules and rules for buildings: DS/EN 1994-1-1[S]. Belgium: [s.n.], 1994. [23] WSDOT. Bridge design manual LRFD[S]. Olympia: [s.n.], 2018. [24] KENARANGI H, BRUNEAU M. Shear strength of composite circular reinforced concrete-filled steel tubes[J]. Journal of Structural Engineering, 2020, 146(1): 04019180.1-04019180.15. -

下载:

下载: