Theoretical Analysis of Bearing Mechanism of Pipe Sheds

-

摘要:

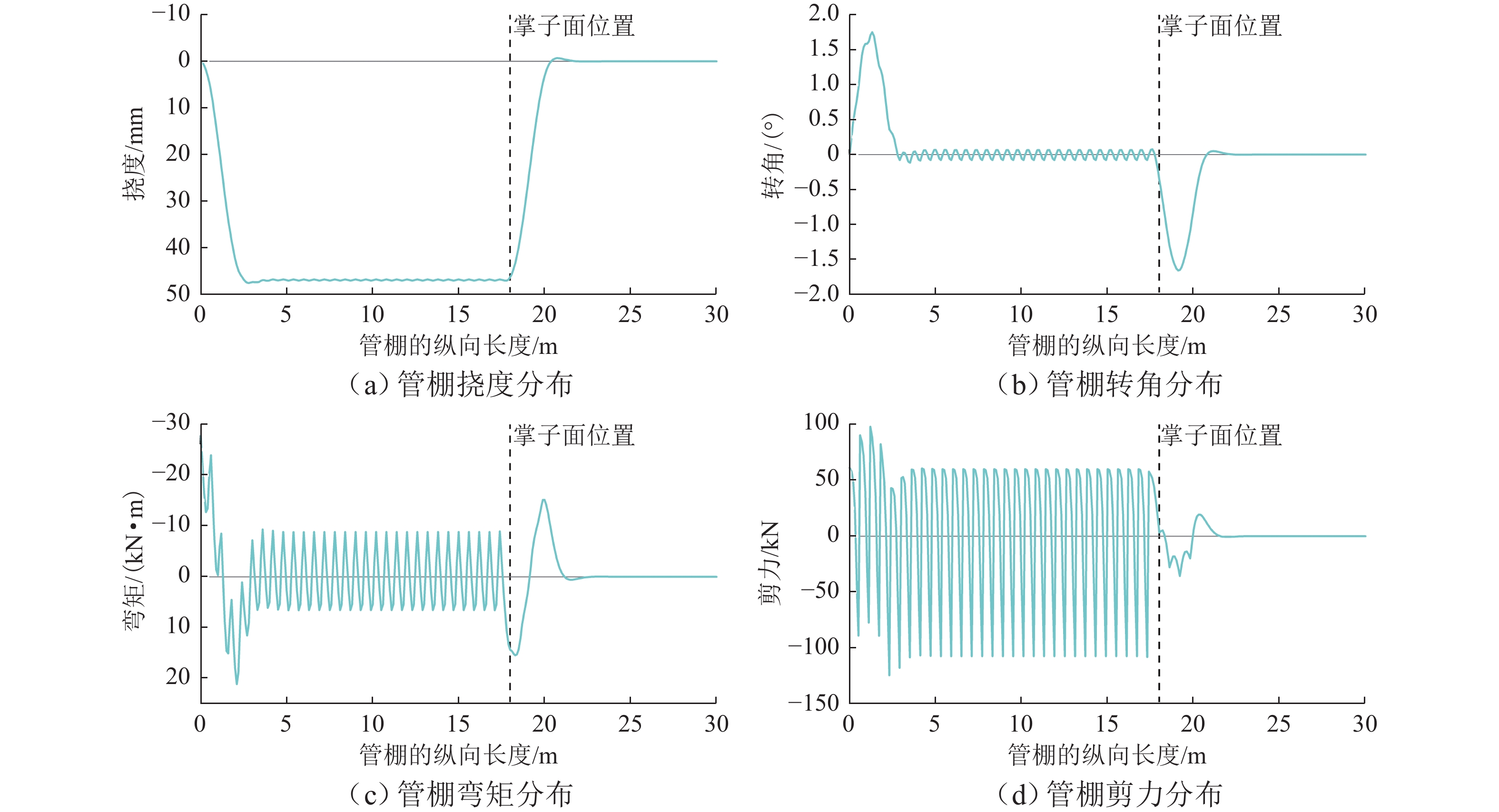

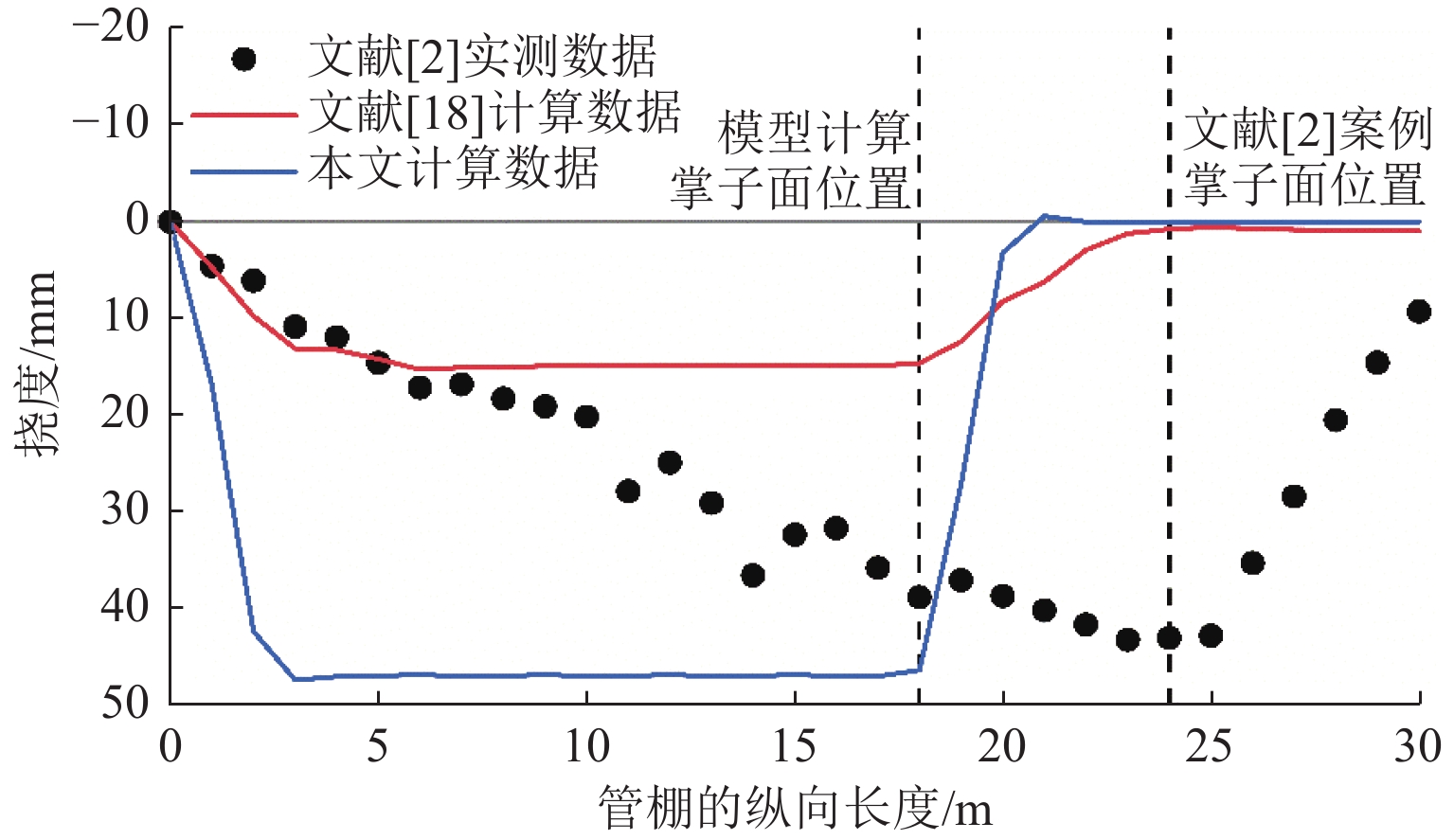

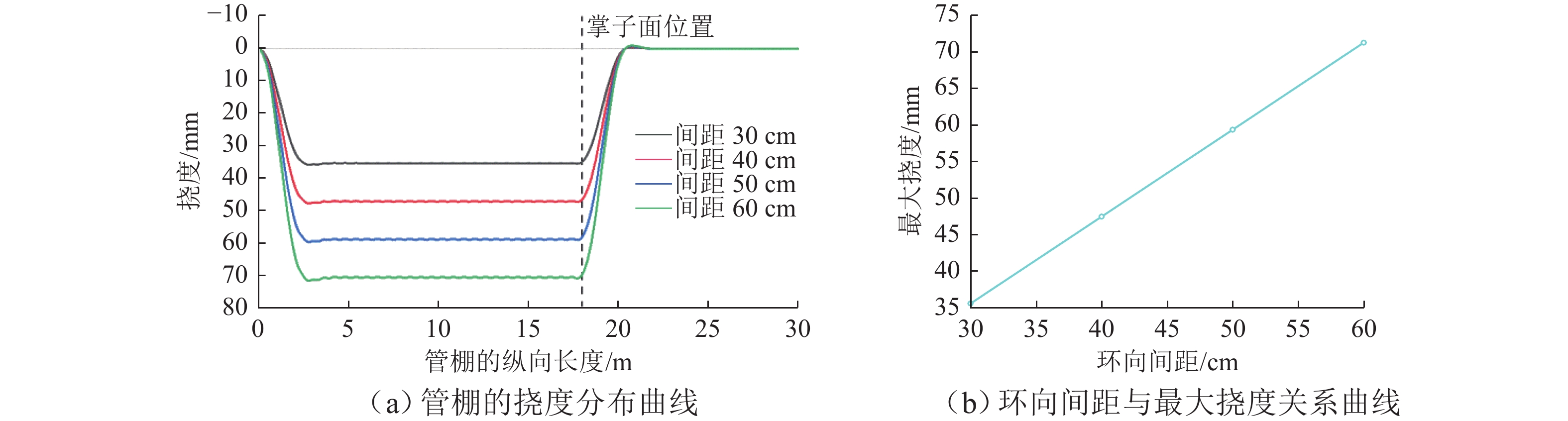

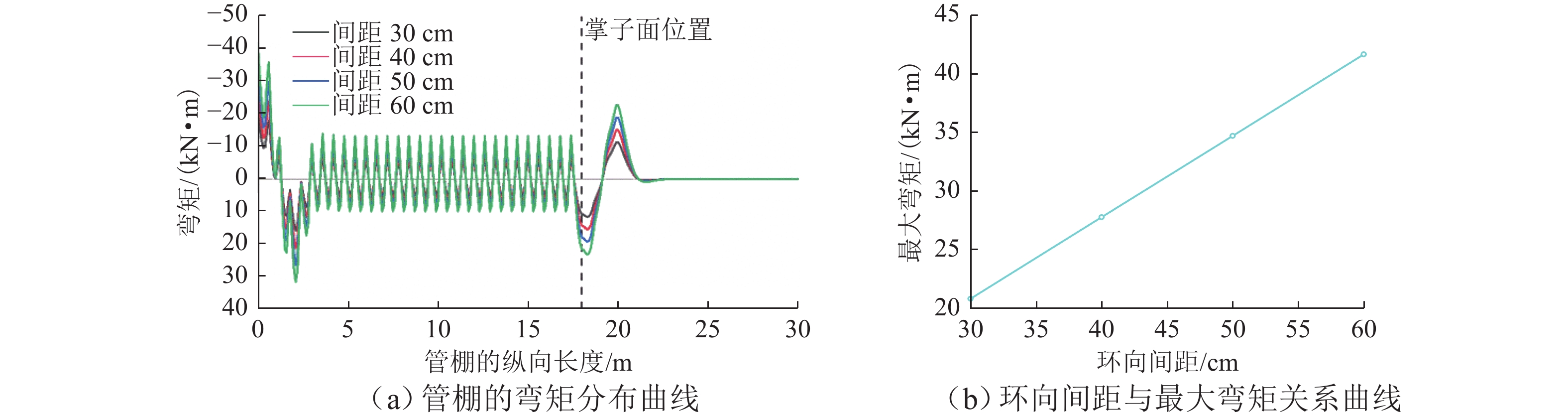

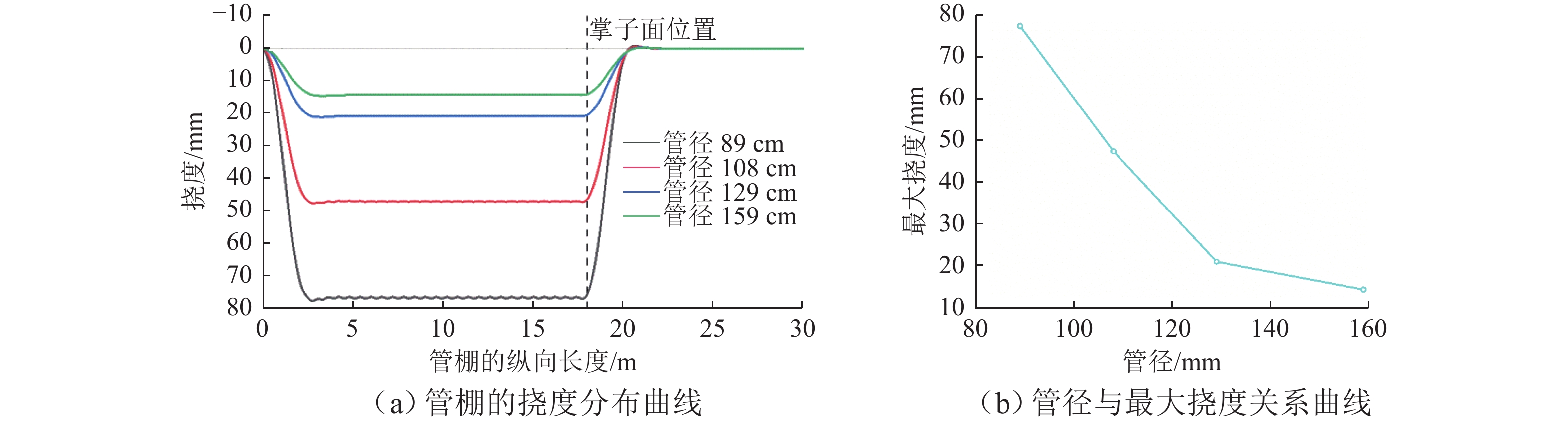

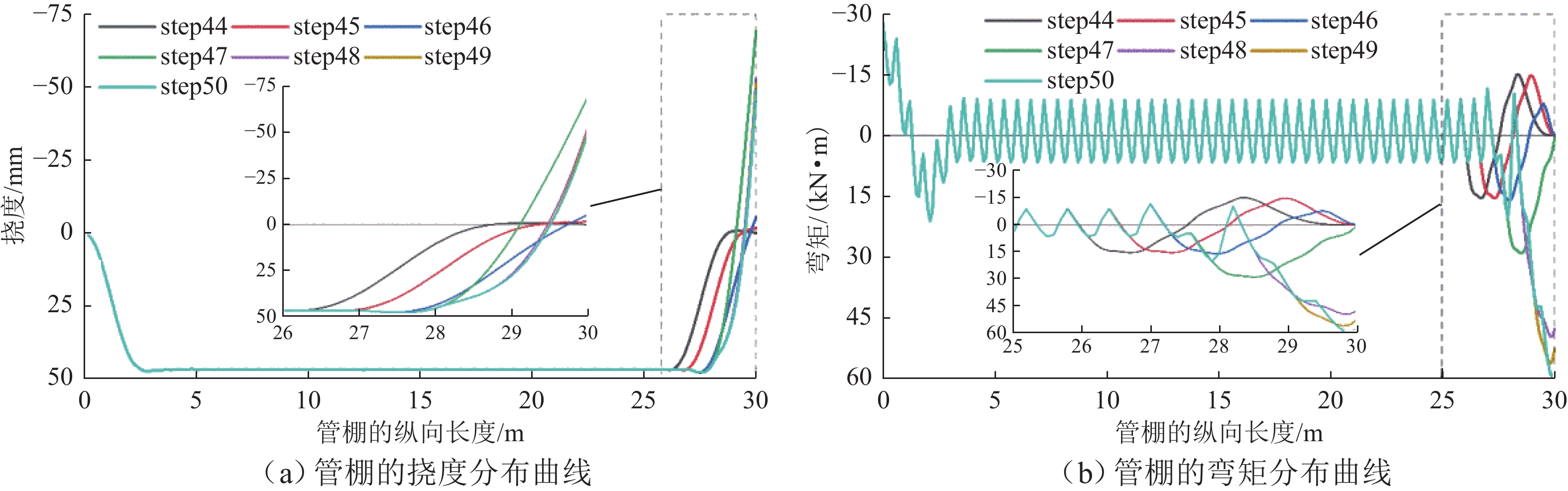

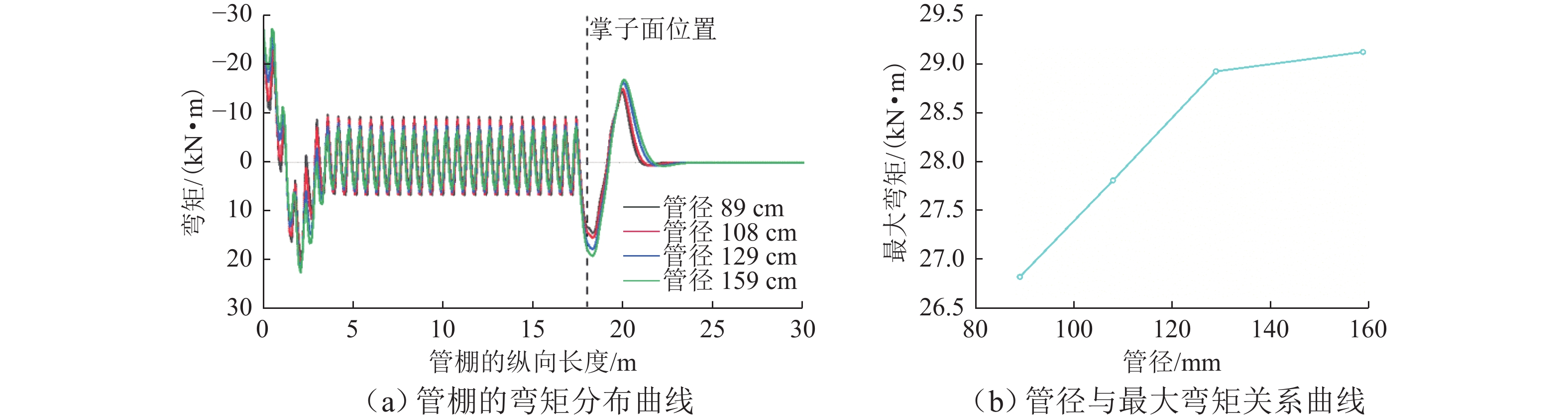

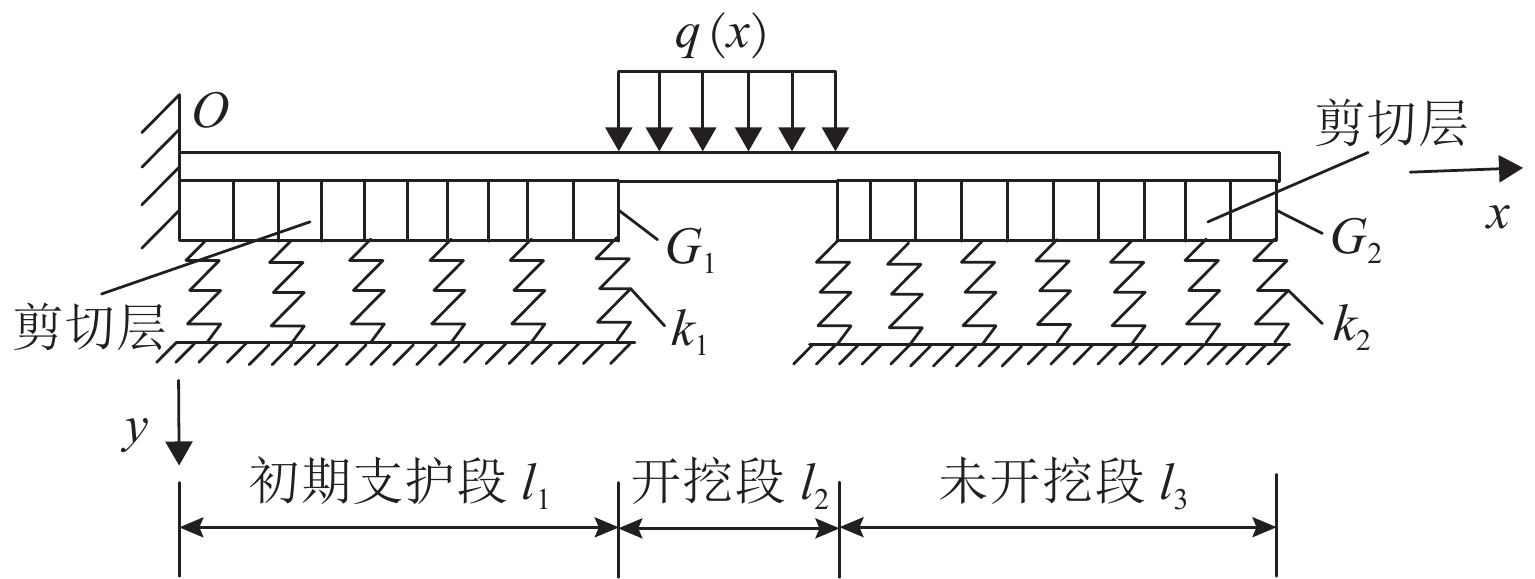

建立合理准确的管棚理论分析模型并对其进行求解,对推动管棚预支护技术的进一步发展具有重要意义. 本文在隧道开挖、支护的施工过程以及未开挖段由于掌子面扰动而导致管棚约束反力有所降低的基础上,建立了基于Euler-Bernoulli梁理论的管棚荷载结构模型,同时引入Pasternak弹性地基模型来确定初期支护及掌子面前方岩体对管棚的约束反力,推导出每一循环隧道开挖支护过程中管棚的受力和变形解析表达式,并通过叠加法求解掌子面掘进至任意位置时管棚的受力和变形分布;通过案例比对,验证了本文建立模型的合理性和有效性. 研究结果表明:管棚钢管环向间距越小、直径越大越有利于提升管棚的预加固能力;管棚合理搭接长度为1.8 m.

Abstract:Establishing a reasonable and accurate theoretical analysis model for pipe sheds and solving it are of great significance to promoting the development of pipe shed pre-support technology. By analyzing the construction process of tunnel excavation and support and the reduction of the restraining reaction force of the pipe shed due to the disturbance of the tunnel face in the unexcavated section, a load structure model of the pipe shed based on the Euler-Bernoulli beam theory was established. The Pasternak elastic foundation model was introduced to determine the initial support and the restraining reaction force of the rock mass in front of the tunnel face on the pipe shed, and the analytical expressions of the stress and deformation of the pipe shed during each cycle of tunnel excavation and support were derived. In addition, the superposition method was used to solve the stress and deformation distribution of the pipe shed when the tunnel face was tunneled to any position. Through case comparison, the rationality and effectiveness of the model were verified. The research results show that smaller circumferential spacing and larger diameter of the pipe shed steel pipes are helpful in improving the pre-reinforcement capacity of the pipe shed, and the reasonable lap length of the pipe shed is 1.8 m.

-

Key words:

- tunnel engineering /

- pipe shed /

- design parameter /

- analytical solution

-

表 1 Pasternak弹性地基参数

Table 1. Pasternak elastic foundation parameters

项目 基床系数/(kN·m−3) 地基剪切模量/(kN·m−1) 初期支护 7.84 × 107 9.51 × 104 岩体 1.64 × 105 1.63 × 103 -

[1] 师晓权. 软弱围岩隧道掌子面稳定性控制及预加固技术研究[D]. 成都:西南交通大学,2012. [2] 王道远,袁金秀,李俊,等. 考虑施工特性的浅埋软弱洞口段管棚变形量预测及工程应用[J]. 岩石力学与工程学报,2017,36(3): 716-724.WANG Daoyuan, YUAN Jinxiu, LI Jun, et al. Deformation prediction of pipe roof in shallow soft portal section of tunnels considering construction feature[J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(3): 716-724. [3] 李化云,张志强,王志杰,等. 浅埋大跨隧道预加固措施相似模型试验研究[J]. 岩土力学,2012,33(增2):133-138.LI Huayun, ZHANG Zhiqiang, WANG Zhijie, et al. Similar model test study on pre-reinforcement measures of shallow-buried long-span tunnel[J]. Rock and Soil Mechanics, 2012, 33(S2):133-138. [4] HISATAKE M, OHNO S. Effects of pipe roof supports and the excavation method on the displacements above a tunnel face[J]. Tunnelling and Underground Space Technology, 2008, 23(2): 120-127. doi: 10.1016/j.tust.2007.02.002 [5] SONG K I, CHO G C, CHANG S B, et al. Beam-spring structural analysis for the design of a tunnel pre-reinforcement support system[J]. International Journal of Rock Mechanics and Mining Sciences, 2013, 59: 139-150. doi: 10.1016/j.ijrmms.2012.12.017 [6] 周顺华. 软弱地层浅埋暗挖施工中管棚法的棚架原理[J]. 岩石力学与工程学报,2005,24(14): 2565-2570.ZHOU Shunhua. Principles of pipe roof applied to shallow-buried tunnels in soft ground[J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(14): 2565-2570. [7] HOUNYEVOU KLOTOÉ C, BOURGEOIS E. Three dimensional finite element analysis of the influence of the umbrella arch on the settlements induced by shallow tunneling[J]. Computers and Geotechnics, 2019, 110: 114-121. doi: 10.1016/j.compgeo.2019.02.017 [8] 高文山,王立川,章慧健,等. 超前加固和初期支护对浅埋隧道地表沉降控制的贡献率分析[J]. 铁道科学与工程学报,2021,18(3): 720-727.GAO Wenshan, WANG Lichuan, ZHANG Huijian, et al. Analysis of the contribution of face support and primary support to the surface settlement control of shallow tunnel[J]. Journal of Railway Science and Engineering, 2021, 18(3): 720-727. [9] 赵凯. 隧道洞口软岩段超前支护围岩变形控制及施工方法研究[D]. 西安:西安科技大学,2020. [10] MOROVATDAR A, PALASSI M, ASHTIANI R S. Effect of pipe characteristics in umbrella arch method on controlling tunneling-induced settlements in soft grounds[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2020, 12(5): 984-1000. doi: 10.1016/j.jrmge.2020.05.001 [11] 李沛莹. 管棚受力特性及其与后续工法配合效果分析[D]. 武汉:华中科技大学,2011. [12] BAGHERZADEH P, GOSHTASBI K, KASHEF M. Umbrella arch method performance, structural behavior and design elements utilizing in collapsing zones[J]. Environmental Earth Sciences, 2020, 79(23): 521.1-521.15. doi: 10.1007/s12665-020-09266-y [13] 董新平,周顺华,胡新朋. 软弱地层管棚法施工中管棚作用空间分析[J]. 岩土工程学报,2006,28(7): 841-846.DONG Xinping, ZHOU Shunhua, HU Xinpeng. 3D analysis of function of piperoof applied in soft ground[J]. Chinese Journal of Geotechnical Engineering, 2006, 28(7): 841-846. [14] 宋战平,田小旭,周冠南,等. 隧道洞内管棚超前预支护力学行为的理论分析[J]. 中国公路学报,2020,33(4):89-98.SONG Zhanping, TIAN Xiaoxu, ZHOU Guannan, et al. Theoretical analysis of mechanical behavior of advanced pre-support of pipe-roof in tunnel[J]. China Journal of Highway and Transport, 2020, 33(4):89-98. [15] 武松,汤华,罗红星,等. 浅埋软岩公路隧道超前管棚支护机制与工程应用研究[J]. 岩石力学与工程学报,2019,38(增1):3080-3091.WU Song, TANG Hua, LUO Hongxing, et al. Study on advanced pipe-shed support mechanism and engineering application of shallow-buried soft rock highway tunnel[J]. Chinese Journal of Rock Mechanics and Engineering,2019,38(S1):3080-3091. [16] 黄华,巩江峰,邸成,等. 铁路隧道超前管棚变形规律及参数研究[J]. 铁道工程学报,2019,36(12): 65-70.HUANG Hua, GONG Jiangfeng, DI Cheng, et al. Research on the deformation law and parameters of advanced pipe shed for railway tunnel[J]. Journal of Railway Engineering Society, 2019, 36(12): 65-70. [17] 王炳智. 软弱围岩隧道管棚超前预支护技术[D]. 重庆:重庆交通大学,2018. [18] ZHANG Z Q, LI H Y, LIU H Y, et al. Load transferring mechanism of pipe umbrella support in shallow-buried tunnels[J]. Tunnelling and Underground Space Technology, 2014, 43: 213-221. doi: 10.1016/j.tust.2014.05.018 [19] 卢新建. 基于变基床系数下双参数模型的管棚力学机理研究[J]. 福建建筑,2016(6): 58-62.LU Xinjian. Mechanical mechanism of piperoofs based on the Pasternak model with variable coefficient of subgrade reaction[J]. Fujian Architecture & Construction, 2016(6): 58-62. -

-

下载:

下载: