Analysis of Longitudinal Force Distribution Characteristics and Arching Mechanism of Longitudinally Connected Track Slabs in Bridge-Subgrade Transition Section

-

摘要:

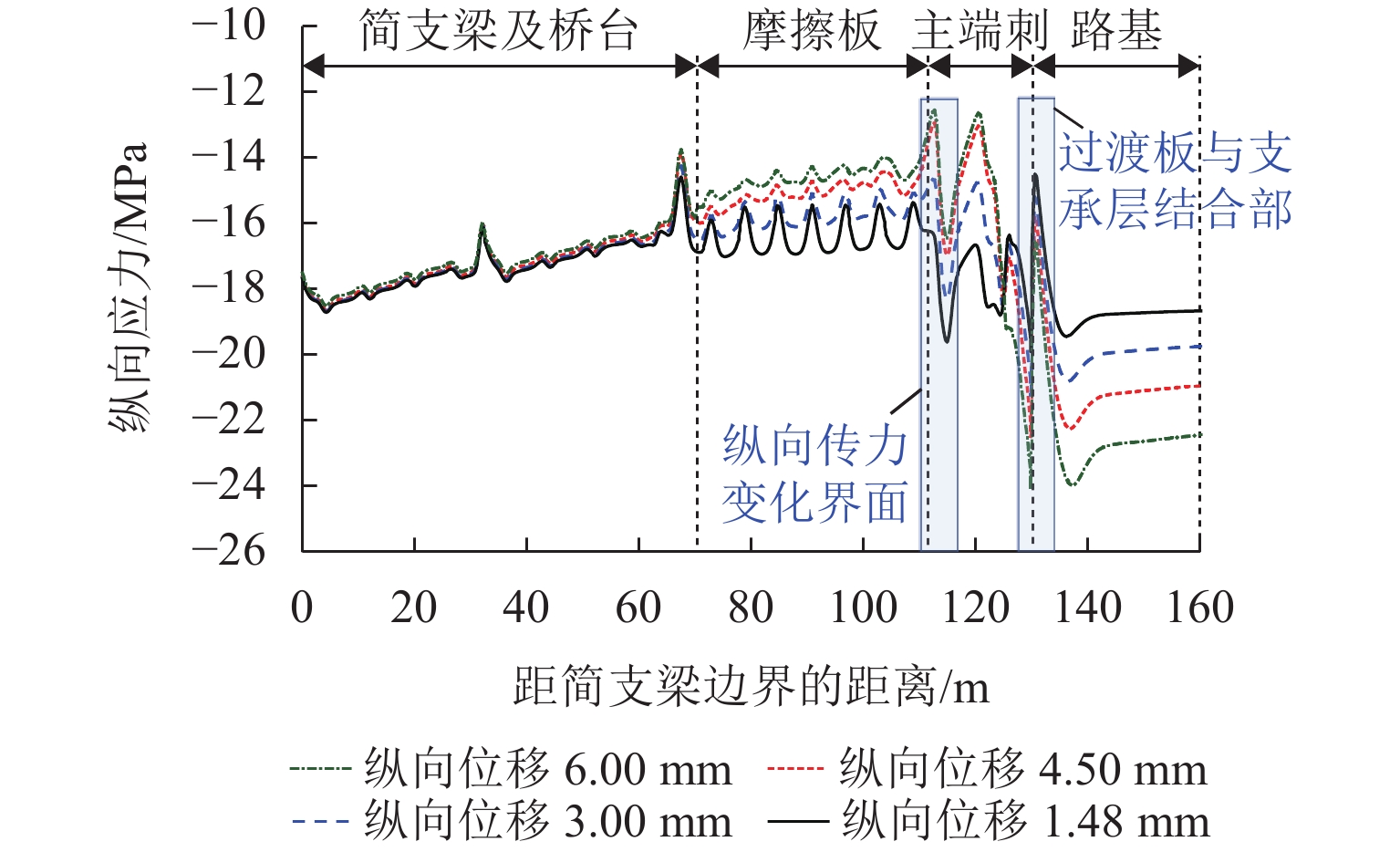

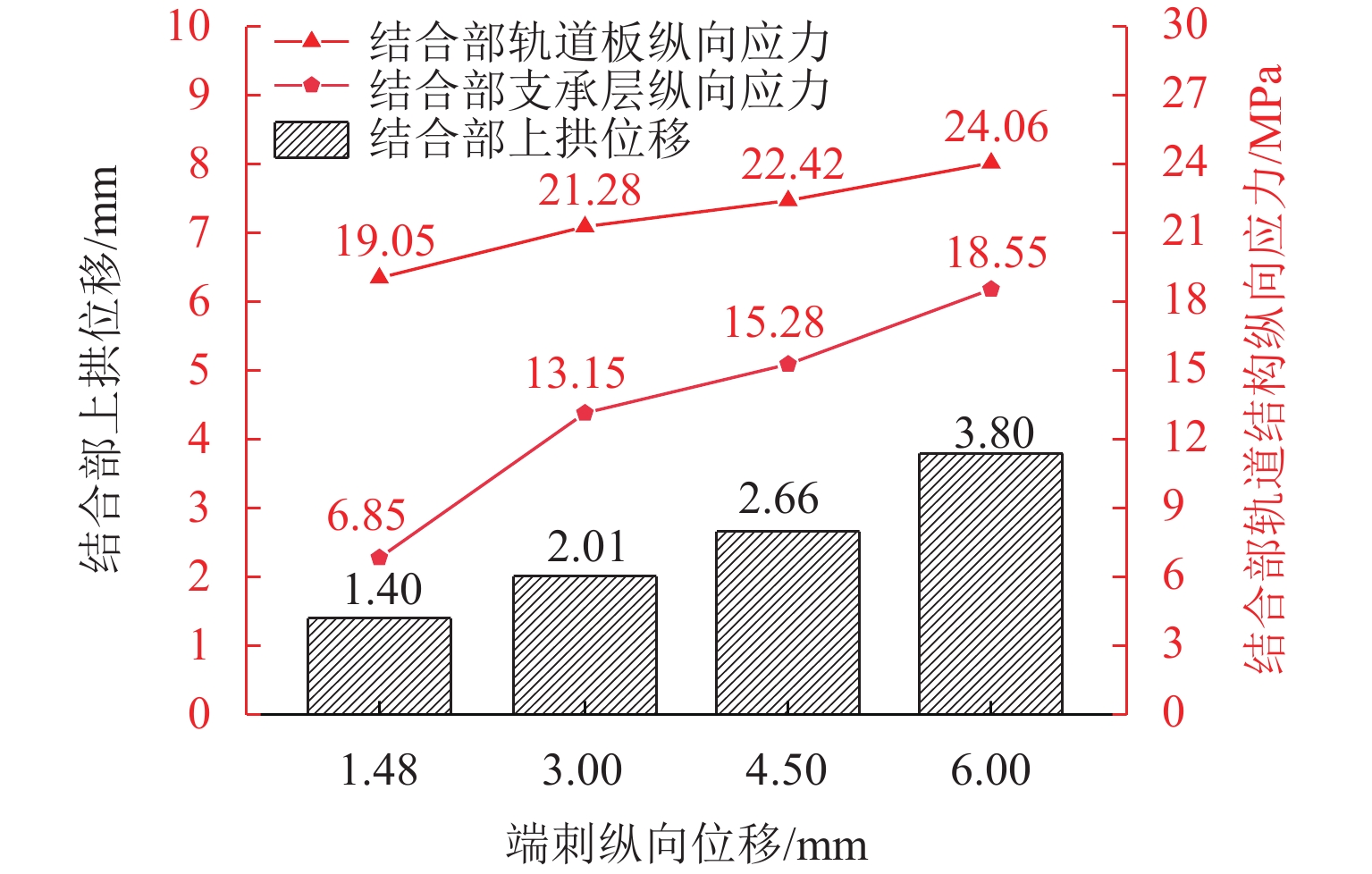

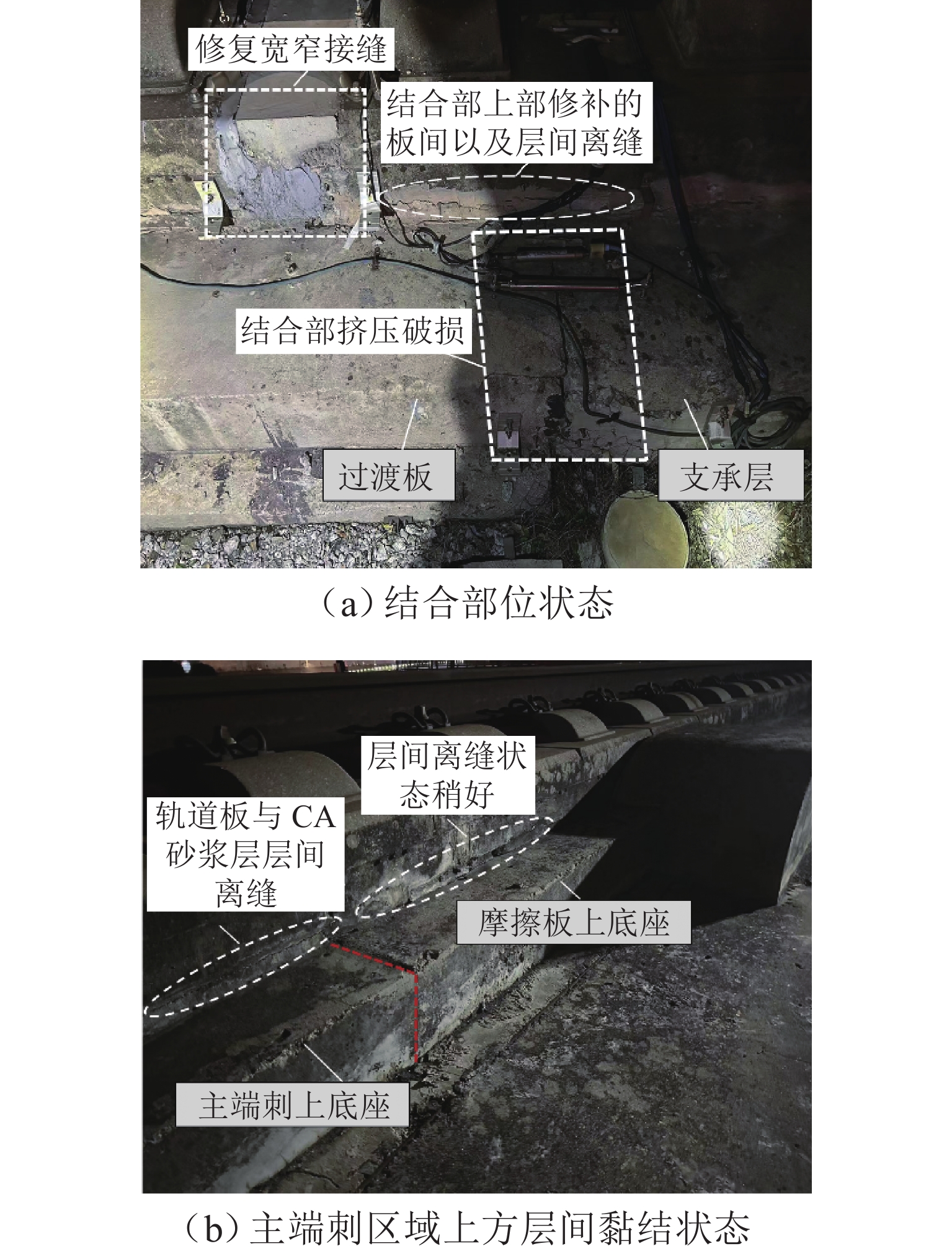

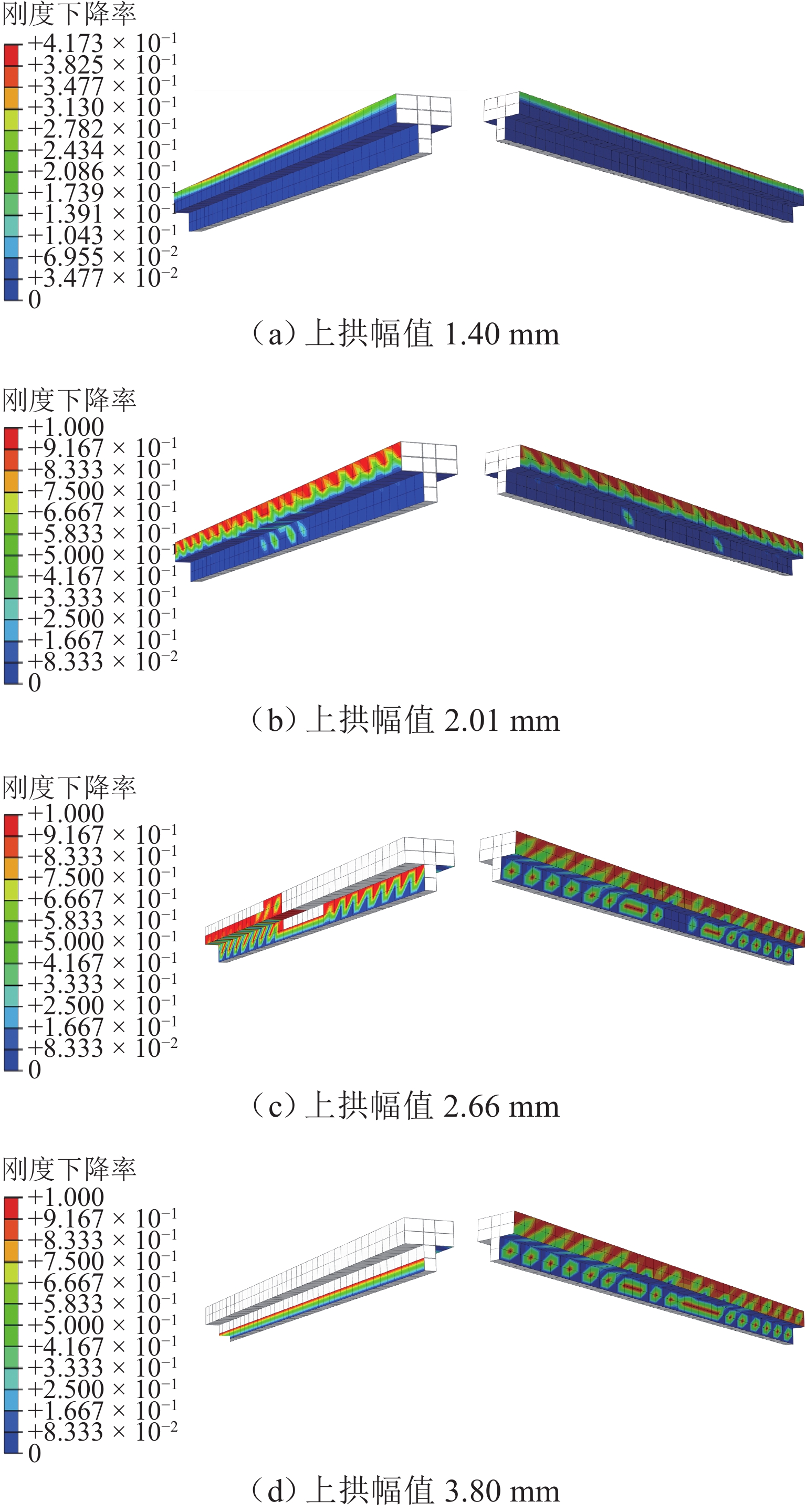

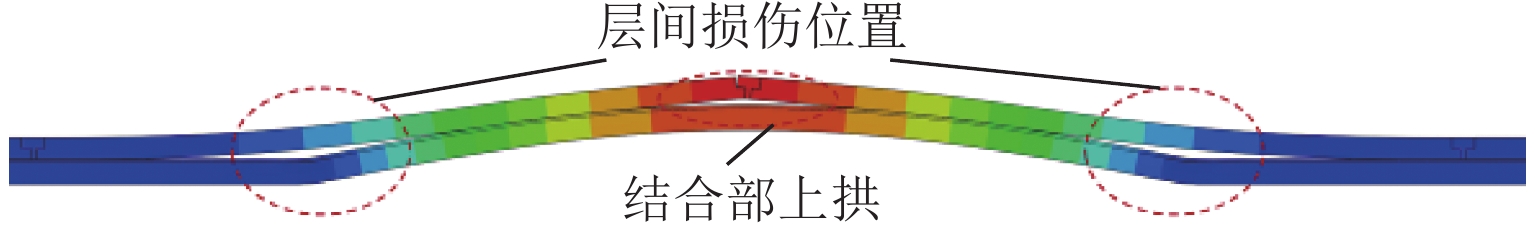

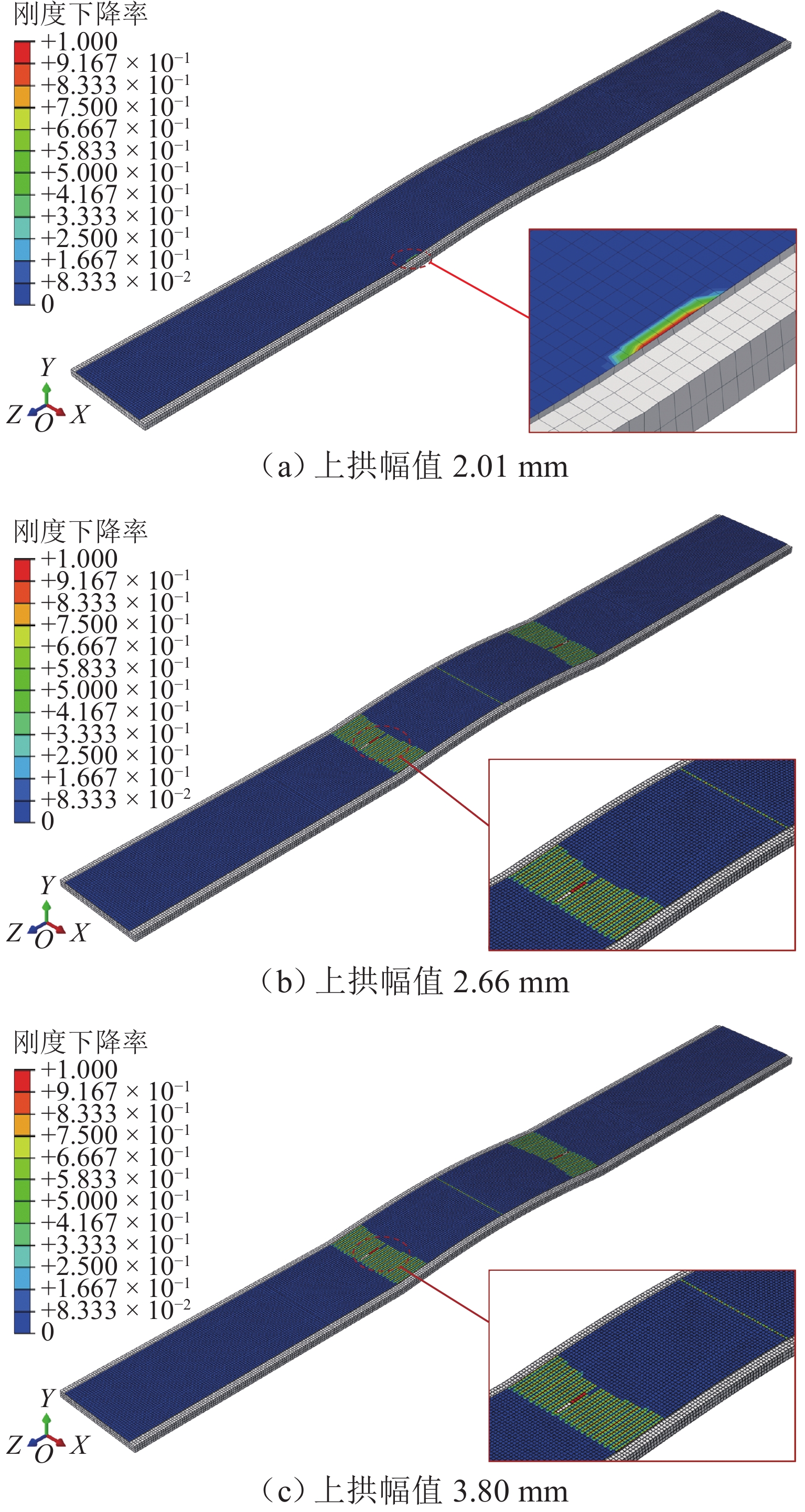

纵连板式无砟轨道在路桥过渡段区域力学行为复杂,且上拱病害频繁,以路桥过渡段 П 型端刺无砟轨道为研究对象,建立轨道-桥梁-端刺-路基一体化有限元模型;并引入双线性内聚力模型模拟板间及层间黏结关系,分析路桥过渡段纵连轨道板在不同温度荷载和端刺位移下的纵向力分布规律;并研究端刺应力敏感区域,即过渡段与支承层结合部的轨道板纵向应力特征以及结合部挤压变形与上拱变形的关系. 研究结果表明:在主端刺及过渡板与支承层结合部的轨道板纵向压应力水平最高,极端正温梯下的最大值为19.91 MPa,摩擦板及桥梁段较小,与端刺各结构组成的限位能力相对应;随着路基材料劣化脱空等病害发展,其纵向抵抗和层间摩阻不断降低,导致端刺纵向变形不断增加,端刺区轨道板的纵向应力降低,结合部支承层的纵向应力增加,当纵向变形达到6 mm时,结合部支承层的纵向压应力达到18.55 MPa,结构的压碎风险极高;结合部位的挤压上拱显著影响轨道结构板间和层间黏结状态,增加上拱病害的风险;研究成果可进一步优化和整治纵连板式无砟轨道过渡段病害,保障高铁安全平稳运行提供参考.

-

关键词:

- CRTSⅡ型板式无砟轨道 /

- 内聚力模型 /

- 应力分析 /

- 损伤

Abstract:The mechanical behavior of longitudinally connected ballastless track slabs in the transition section of subgrade and bridge is complex, and arching disease is frequent. The П-type end spine ballastless track in the transition section of subgrade and bridge was taken as the research object, and a track-bridge-end spine-subgrade integrated finite element model was established. The bilinear cohesive force model was introduced to simulate the bonding relationship between the slabs and the interlayers, and the longitudinal force distribution of the longitudinally connected track slabs in the transition section of subgrade and bridge under different temperature loads and end spine displacements was analyzed. The stress-sensitive area of the end spine, namely, the longitudinal stress characteristics of the track slabs at the junction of the transition section and the supporting layer and the relationship between the extrusion deformation of the junction and the arching deformation, were studied. The results show that the longitudinal compressive stress level of the track slabs at the main end spine and the junction of the transition plate and the supporting layer is the highest, and the maximum value under the extreme positive temperature gradient is 19.91 MPa. The friction plate and the bridge section are small, which corresponds to the limit capacity of each structure of the end spine. With the development of diseases such as deterioration and void of subgrade materials, the longitudinal resistance and interlayer friction decrease continuously, which leads to the increase in longitudinal deformation of the end spine, the decrease in longitudinal stress of the track slabs in the end spine area, and the increase in longitudinal stress of the supporting layer of the junction. When the longitudinal deformation reaches 6 mm, the longitudinal compressive stress of the supporting layer of the junction reaches 18.55 MPa, and the crushing risk of the structure is very high. The compressive arching of the junction greatly affects the bonding between the slabs and the layers of the track structure and increases the risk of arching disease. The research results can provide a reference for further optimizing and renovating the diseases of the transition section of the longitudinally connected ballastless track slabs and ensuring the safe and stable operation of high-speed railways.

-

Key words:

- CRTSⅡ ballastless track slab /

- cohesive force model /

- stress analysis /

- damage

-

表 1 路基模型计算参数

Table 1. Calculation parameters of subgrade model

部件 密度/(kg•m−3) 弹性模量/MPa 泊松比 黏聚力/(kN•m−2) 剪切角/(°) 剪切膨胀角/(°) 级配碎石 2200 200 0.20 35 30 5 AB 组填料 2100 120 0.25 15 20 8 表 2 内聚力模型参数

Table 2. Cohesive force model parameters

黏结界面 法向抗拉

强度/MPa剪切强度/MPa 法向刚度/

(MPa•mm−1)切向刚度/

(MPa•mm−1)法向断裂

能/(J•m2)切向断裂

能/(J•m2)轨道板与宽窄接缝 1.700 1.600 500.0 150.0 35.00 15.20 轨道板与 CA 砂浆层 1.792 0.956 716.8 62.9 25.24 18.70 -

[1] CAI X P, LUO B C, ZHONG Y L, et al. Arching mechanism of the slab joints in CRTS Ⅱ slab track under high temperature conditions[J]. Engineering Failure Analysis, 2019, 98: 95-108. doi: 10.1016/j.engfailanal.2019.01.076 [2] 张鹏飞. 复杂荷载条件下桥上CRTS Ⅱ型板式无砟轨道无缝线路纵向力研究[D]. 北京:北京交通大学,2018. [3] 戴公连,葛浩,刘文硕,等. 实测温度下大跨度桥上纵连无砟轨道受力研究[J]. 铁道工程学报,2017,34(5): 26-31,93.DAI Gonglian, GE Hao, LIU Wenshuo, et al. Analysis of longitudinally connected ballastless track on the high-speed railway long-span bridge based on the actual measured temperature[J]. Journal of Railway Engineering Society, 2017, 34(5): 26-31,93. [4] 徐庆元,张旭久. 高速铁路博格纵连板桥上无砟轨道纵向力学特性[J]. 中南大学学报(自然科学版),2009,40(2): 526-532.XU Qingyuan, ZHANG Xujiu. Longitudinal forces characteristic of Bogl longitudinal connected ballastless track on high-speed railway bridge[J]. Journal of Central South University (Science and Technology), 2009, 40(2): 526-532. [5] ZHANG Q, CAI X P, ZHONG Y L, et al. Temperature field and thermal effects of the longitudinal connected slab track based on the measurement data and thermal-fluid-structure coupling analysis[J]. Construction and Building Materials, 2022, 343: 128121.1-128121.14. [6] 高亮,何宁,任西冲,等. 无砟轨道板端上拱变形影响规律研究[J]. 华中科技大学学报(自然科学版),2020,48(3): 92-97.GAO Liang, HE Ning, REN Xichong, et al. Research on effect law of arch deformation of ballastless track slab[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2020, 48(3): 92-97. [7] 周凌宇,张广潮,余志武,等. 循环温度荷载下无砟轨道结构模型试验研究[J]. 铁道学报,2020,42(1): 82-88.ZHOU Lingyu, ZHANG Guangchao, YU Zhiwu, et al. Model experiments of ballastless track-bridge structure under cyclic temperature load[J]. Journal of the China Railway Society, 2020, 42(1): 82-88. [8] 钟垚,何越磊,路宏遥,等. 持续高温作用下CRTSⅡ型无砟轨道层间离缝分析[J]. 铁道科学与工程学报,2018,15(5): 1128-1133.ZHONG Yao, HE Yuelei, LU Hongyao, et al. Analysis of interface seam of CRTSⅡ slab track under sustained high temperature[J]. Journal of Railway Science and Engineering, 2018, 15(5): 1128-1133. [9] 赵国堂,刘钰. CRTSⅡ型板式无砟轨道结构层间离缝机理研究[J]. 铁道学报,2020,42(7): 117-126.ZHAO Guotang, LIU Yu. Mechanism analysis of delamination of CRTS Ⅱ slab ballastless track structure[J]. Journal of the China Railway Society, 2020, 42(7): 117-126. [10] 张乾,蔡小培,钟阳龙,等. 无砟轨道路基不均匀沉降区高速列车动力特性[J]. 西南交通大学学报,2023,58(1): 133-140. doi: 10.3969/j.issn.0258-2724.20210830ZHANG Qian, CAI Xiaopei, ZHONG Yanglong, et al. Dynamic characteristics of high-speed trains in differential subgrade settlement zone of ballastless track[J]. Journal of Southwest Jiaotong University, 2023, 58(1): 133-140. doi: 10.3969/j.issn.0258-2724.20210830 [11] 刘笑凯,刘学毅,肖杰灵,等. 温升作用下CRTSⅡ型板宽窄接缝受力及损伤分析[J]. 西南交通大学学报,2024,58(1): 273-280.LIU Xiaokai, LIU Xueyi, XIAO Jieling, etal. Analysis of internal forces and damage of broad-narrow joint of CRTSⅡ slab track under temperature rise[J]. Journal of Southwest Jiaotong University, 2024, 58(1): 273-280. [12] 张鹏飞,涂建,桂昊,等. 温梯荷载下桥上CRTSⅡ型板式无砟轨道的力学特性[J]. 西南交通大学学报,2021,56(5): 945-952.ZHANG Pengfei, TU Jian, GUI Hao, et al. Mechanical properties of CRTSⅡ slab ballastless track on bridge under temperature gradient loads[J]. Journal of Southwest Jiaotong University, 2021, 56(5): 945-952. [13] CUI X H, GUO G R, DU B W, et al. Effects of lateral differential settlement of the subgrade on deformation behavior and damage evolution of CRTS Ⅱ slab track[J]. Engineering Failure Analysis, 2021, 129: 105674.1-105674.18. [14] XU Y D, YAN D B, ZHU W J, et al. Study on the mechanical performance and interface damage of CRTS Ⅱ slab track with debonding repairment[J]. Construction and Building Materials, 2020, 257: 119600.1-119600.16. [15] 王军,卢朝辉,张玄一,等. CRTSⅡ型轨道板/CA砂浆界面内聚力模型研究[J]. 工程力学,2022,39(9): 72-80,109. doi: 10.6052/j.issn.1000-4750.2021.05.0336WANG Jun, LU Chaohui, ZHANG Xuanyi, et al. Research on cohesive zone model of the interface between CRTS Ⅱ track slab and CA mortar[J]. Engineering Mechanics, 2022, 39(9): 72-80,109. doi: 10.6052/j.issn.1000-4750.2021.05.0336 [16] LIU G Y, BAO H C, TANG K L. Damage prediction in notched fiber-reinforced composite laminates[J]. Composite Interfaces, 2016, 24(3): 279-290. [17] 刘学毅,苏成光,刘丹,等. 轨道板与砂浆粘结试验及内聚力模型参数研究[J]. 铁道工程学报,2017,34(3): 22-28. doi: 10.3969/j.issn.1006-2106.2017.03.005LIU Xueyi, SU Chengguang, LIU Dan, et al. Research on the bond properties between slab and CA mortar and the parameters study of cohesive model[J]. Journal of Railway Engineering Society, 2017, 34(3): 22-28. doi: 10.3969/j.issn.1006-2106.2017.03.005 [18] ZHOU R, YUAN W H, LIU W B, et al. Thermal performance of CRTS Ⅱ slab track-bridge structure under extreme temperatures: numerical simulation[J]. Construction and Building Materials, 2023, 377: 131147.1-131147.13. [19] 钟阳龙,高亮,王璞,等. 温度荷载下CRTSⅡ型轨道板与CA砂浆界面剪切破坏机理[J]. 工程力学,2018,35(2):230-238.ZHONG Yanglong, GAO Liang, WANG Pu, et al. Mechanism of interfacial shear failure between CRTS Ⅱ slab and ca mortar under temperature loading[J]. Engineering Mechanics, 2018, 35(2):230-238. [20] 闫斌,程瑞琦,谢浩然,等. 极端温度作用下桥上CRTSⅡ型无砟轨道受力特性[J]. 铁道科学与工程学报,2021,18(4): 830-836.YAN Bin, CHENG Ruiqi, XIE Haoran, et al. Mechanical characteristics of CRTSⅡ ballastless track on bridge due to extreme temperature load[J]. Journal of Railway Science and Engineering, 2021, 18(4): 830-836. [21] 国家铁路局. 高速铁路设计规范:TB 10621—2014[S]. 北京:中国铁道出版社,2015. [22] YAN D B, XU Y, ZHU W J. Effects of debonding repairment on interfacial damage and thermal deformation of CRTS Ⅱ slab ballastless track[J]. Construction and Building Materials, 2023, 389: 131793.1-131793.13. [23] ZHONG Y L, GAO L, ZHANG Y R. Effect of daily changing temperature on the curling behavior and interface stress of slab track in construction stage[J]. Construction and Building Materials, 2018, 185: 638-647. doi: 10.1016/j.conbuildmat.2018.06.224 [24] 朱永见,赵国堂,郑建. CRTS Ⅱ型板式无砟轨道层间离缝产生原因分析[J]. 铁道学报,2021,43(2): 111-117. doi: 10.3969/j.issn.1001-8360.2021.02.014ZHU Yongjian, ZHAO Guotang, ZHENG Jian. Analysis on causes of gap under CRTS Ⅱ slab ballastless track[J]. Journal of the China Railway Society, 2021, 43(2): 111-117. doi: 10.3969/j.issn.1001-8360.2021.02.014 [25] SONG L, LIU H B, CUI C X, et al. Thermal deformation and interfacial separation of a CRTS Ⅱ slab ballastless track multilayer structure used in high-speed railways based on meteorological data[J]. Construction and Building Materials, 2020, 237: 117528.1-117528.16. -

下载:

下载: