Flexural Bearing Performance of Prestressed Concrete Pipe Piles with Hybrid Reinforcement under Influence of Prestressed Control Level and Hybrid Reinforcement

-

摘要:

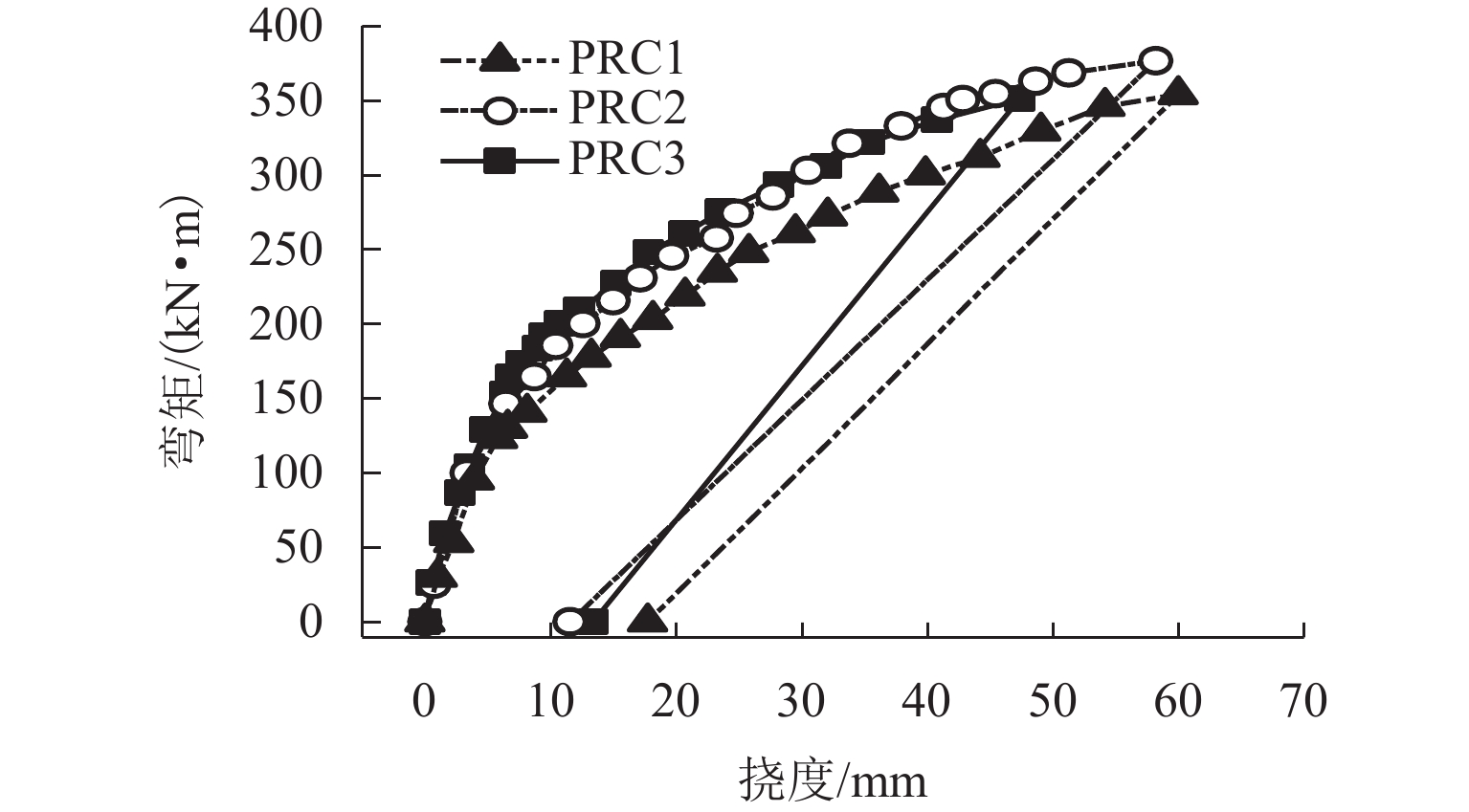

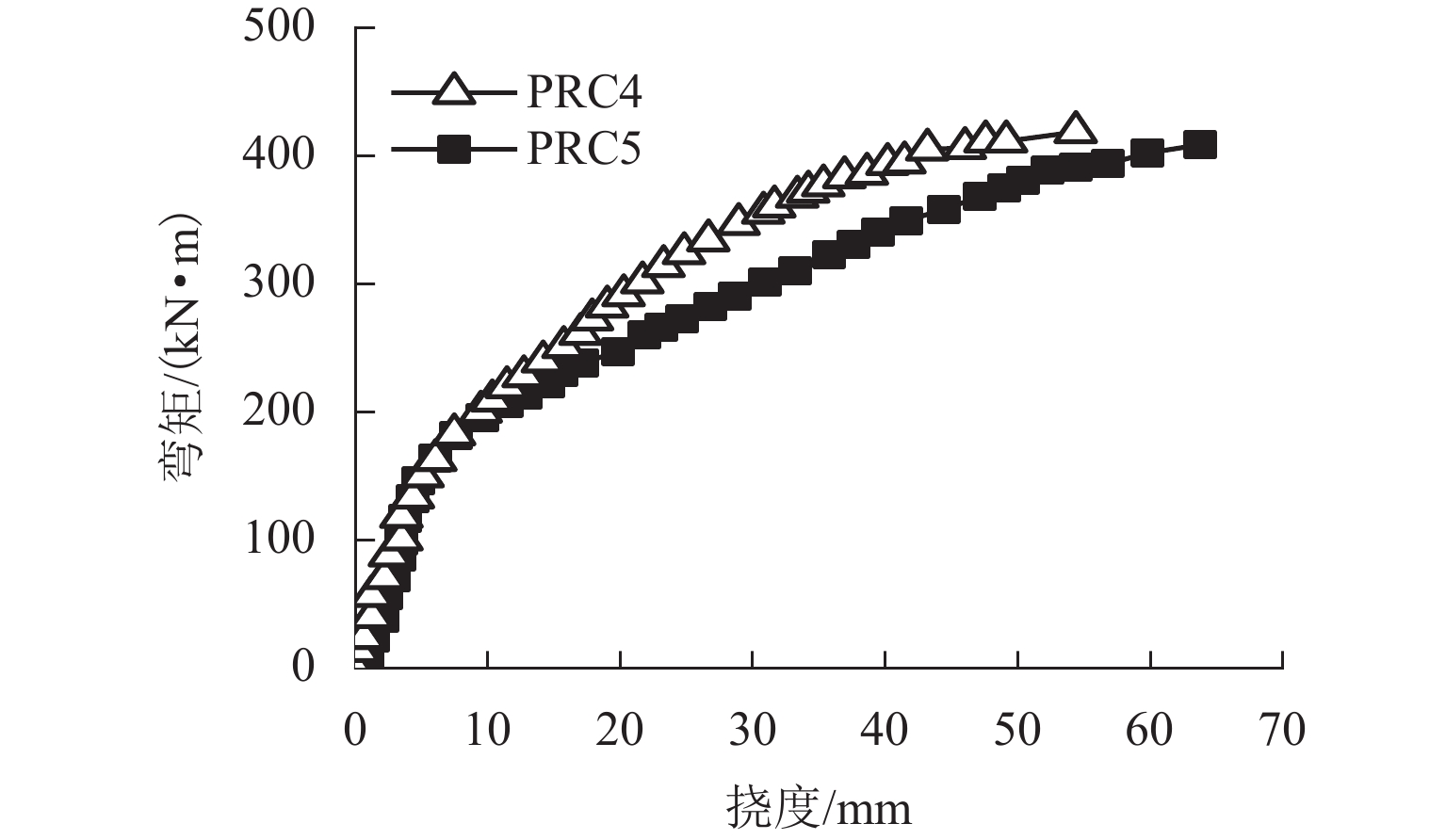

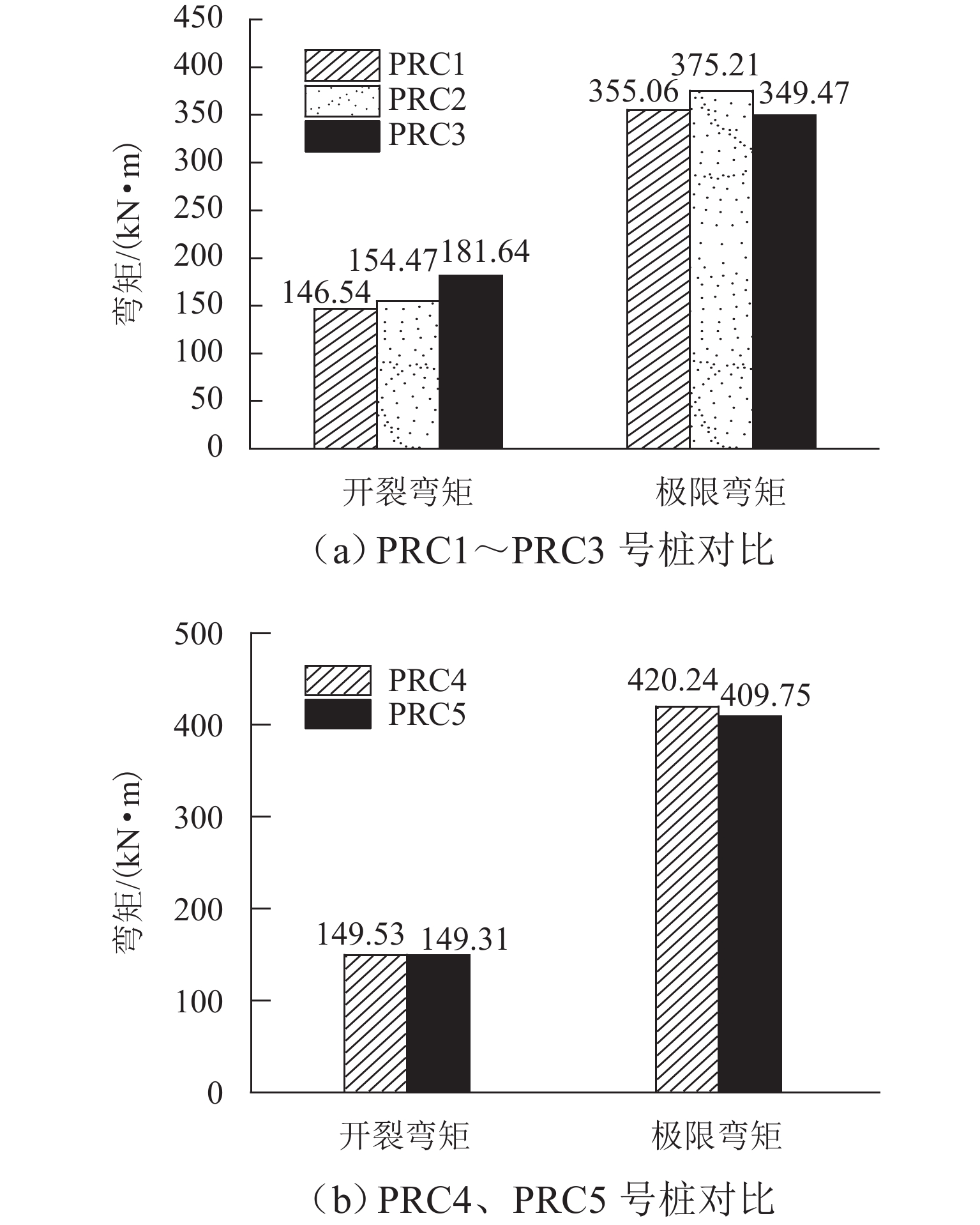

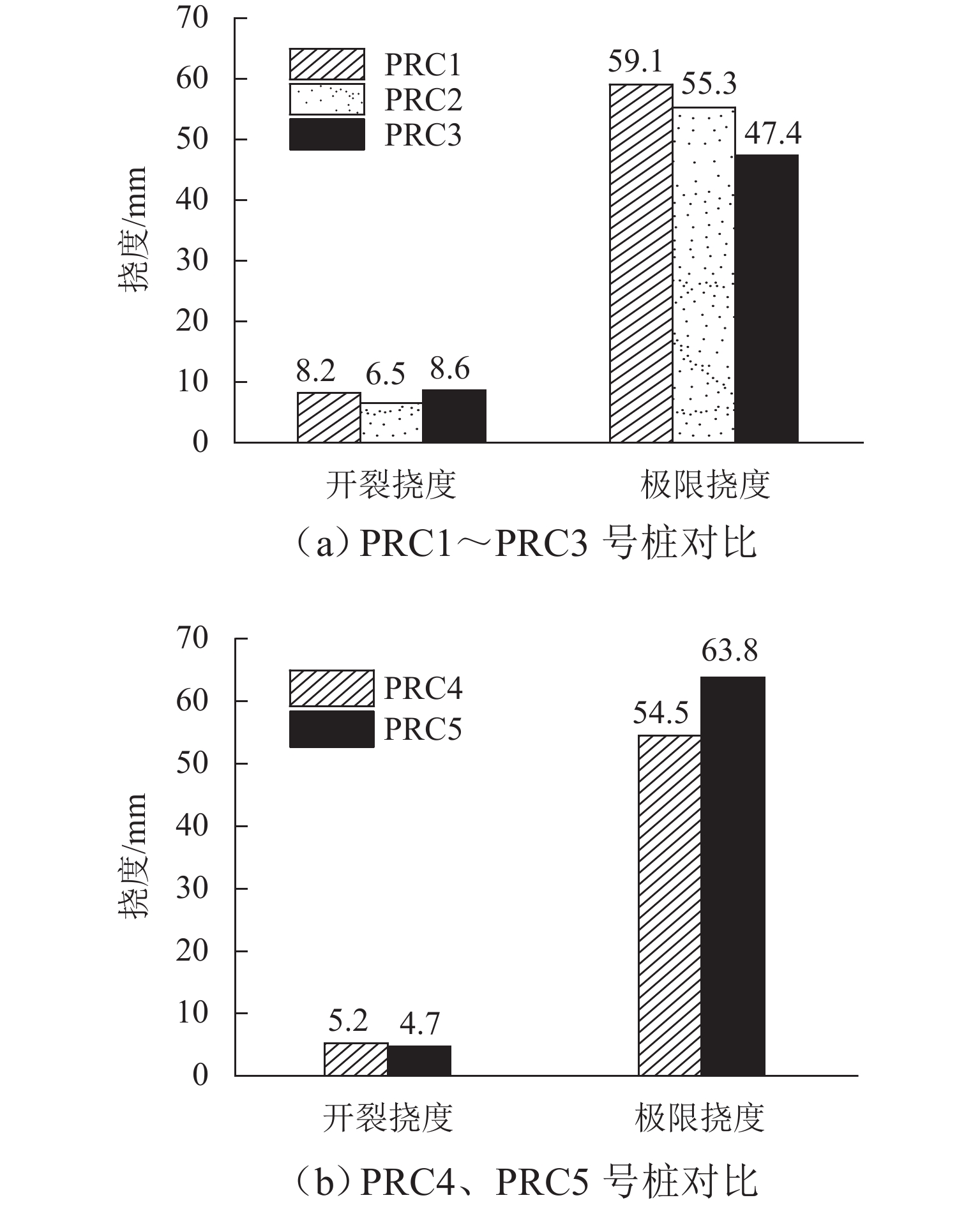

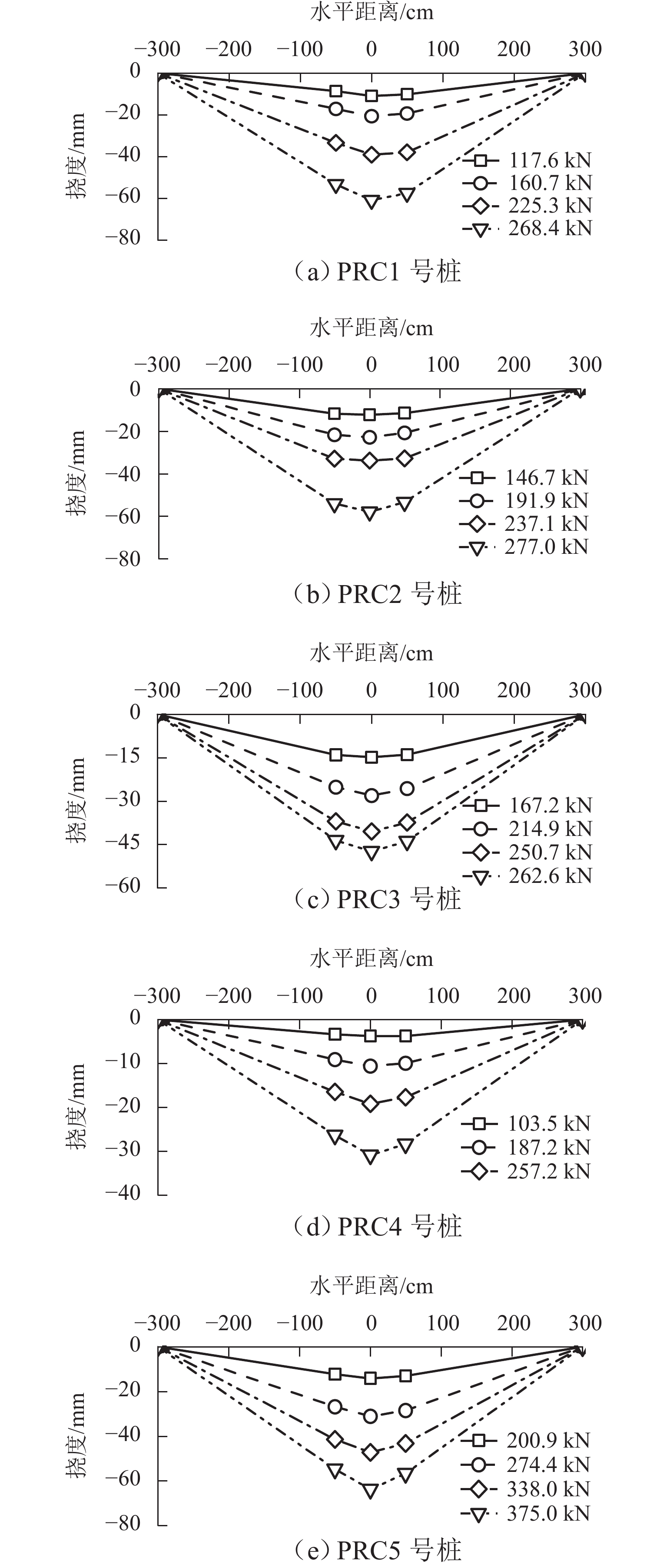

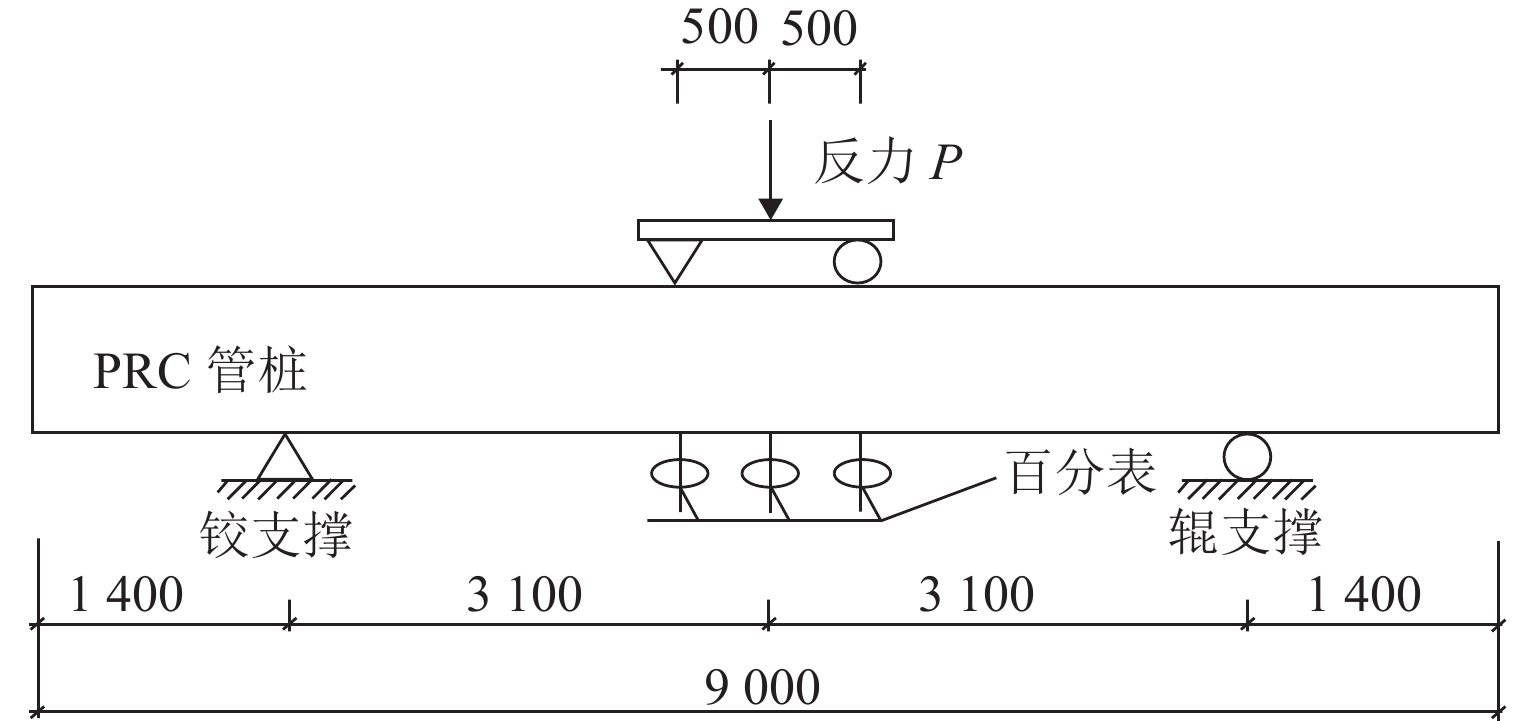

混合配筋预应力混凝土(PRC)管桩受预应力控制水平、混合配筋等因素影响,实际抗弯承载力与理论设计值存在偏差,致使其服役过程中存在桩身破坏或性能退化等潜在风险. 为研究PRC管桩实际抗弯承载性能表现,开展不同预应力水平、混合配筋情况下PRC管桩抗弯载荷试验研究. 荷载试验采用单调连续加载方式,记录不同PRC管桩桩身弯矩-挠度曲线,确定其抗弯载荷变化规律,最终对试验所得数据与现行标准中相关弯矩承载力理论计算值进行对比验证. 研究结果表明:混合配筋方式提高了桩身承载力及延性,初始预应力张拉控制比例越高,试件的弹性变形段越长,开裂弯矩越大,裂缝出现延后,初始预应力为0.5倍张拉力时试件的延性最好,弯曲变形延性大于10,最大挠度超过54 mm,裂缝宽度为1.05~1.50 mm;预应力混凝土(PC)钢棒和螺纹钢同时张拉的构件变形相对趋缓,延性和韧性更好;非预应力钢棒参与预应力贡献时,极限弯矩提高约2.5%,弹性阶段结束时的开裂挠度更大;不同预应力PRC桩开裂弯矩实测值为设计理论值的1.25倍~1.50倍,极限弯矩实测值为理论值的0.96倍~1.07倍.

Abstract:The actual flexural bearing capacity of prestressed concrete pipe piles with hybrid reinforcement (PRC pipe piles) is different from the theoretical design value due to the influence of prestressed control level and hybrid reinforcement, which leads to the potential risk of pile body damage or performance degradation during its service. In order to study the actual flexural bearing capacity of PRC pipe piles, the flexural load test of PRC pipe piles under different prestressed levels and hybrid reinforcement was carried out. The monotone continuous loading method was adopted in the load test. The bending moment-deflection curves of different PRC pipe piles were recorded to determine the flexural load variation rule. Finally, the experimental data were compared with the theoretical calculation value of relevant bending moment bearing capacity in current standards. The results show that the deformation of the hybrid reinforcement method improves the bearing capacity and ductility of the pile body. A higher initial prestress-to-tension control ratio indicates a longer elastic deformation section of the specimen, a larger cracking moment, and a delay in crack occurrence. When the initial prestress is 0.5 times the tensile force, the ductility of the specimen is the best; the bending deformation ductility is greater than 10; the maximum deflection is more than 54 mm, and the crack width is 1.05–1.5 mm. The member deformation under simultaneous tension of steel bars for prestressed concrete (PC steel bar) and screw-thread steel is relatively slow, and ductility and toughness are better. When the non-prestressed steel bars contribute to the prestress, the ultimate bending moment is increased by about 2.5%, and the cracking deflection at the end of the elastic stage is larger. The measured cracking moment of different PRC pipe piles is 1.25–1.50 times the design theoretical value, and the measured ultimate bending moment is 0.96–1.07 times the theoretical value.

-

表 1 试件基本情况

Table 1. Specimen basic information

试件编号 外径/mm 壁厚/mm 长度/mm 张拉控

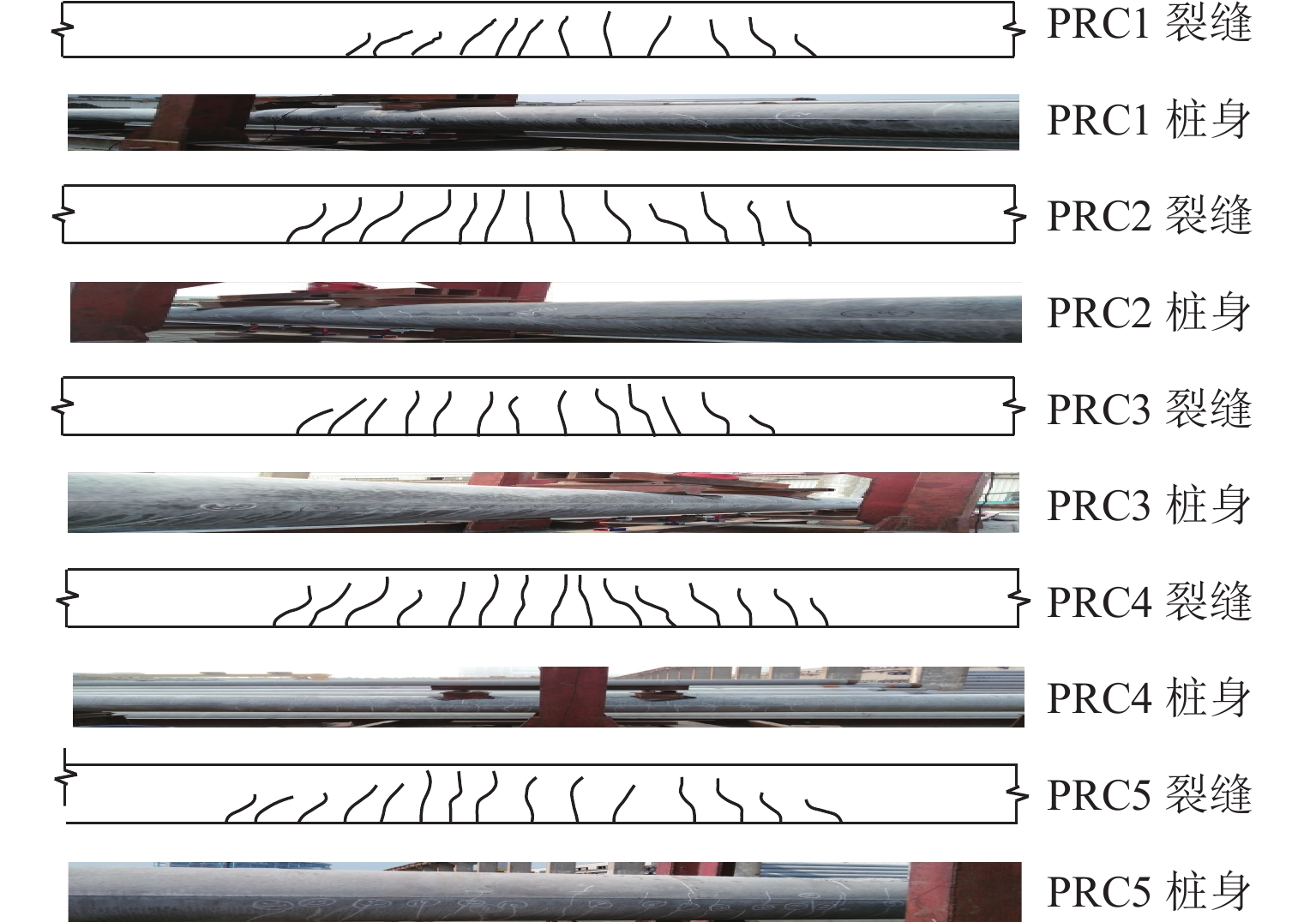

制比例非预应力钢筋贡献 PRC1 500 100 9 000 0.3 有 PRC2 0.5 有 PRC3 0.7 有 PRC4 0.5 无 PRC5 0.5 有 表 2 桩身裂缝及弯曲延性情况统计

Table 2. Statistics of pile body cracks and ductility

桩身编号 裂缝数量/条 最大裂缝宽度/mm 延性系数 μ PRC1 25 0.90 6.8 PRC2 22 0.95 8.5 PRC3 18 0.75 5.5 PRC4 27 1.05 10.6 PRC5 27 1.50 13.6 表 3 开裂弯矩理论与实测值对比结果

Table 3. Comparison of theoretical and measured cracking moments

桩身编号 初始预应力比例 理论值/

(kN·m)实测值/

(kN·m)实测值/

理论值PRC1 0.3 98.1 146.5 1.50 PRC2 0.5 121.6 154.5 1.28 PRC3 0.7 145.2 181.6 1.25 PRC4 0.5 119.3 149.3 1.39 PRC5 0.5 119.3 149.5 1.37 表 4 极限弯矩理论与实测比较

Table 4. Comparison of theoretical and measured ultimate bending moments

构件 初始预应力比例 实测值/

(kN·m)理论值 1/

(kN·m)理论值 2/

(kN·m)PRC1 0.3 355.0 310 354 PRC2 0.5 375.0 320 360 PRC3 0.7 349.5 330 363 PRC4 0.5 420.2 307 392 PRC5 0.5 409.8 307 392 -

[1] 赵升峰, 黄广龙, 马世强, 等. 预制混凝土支护管桩在深基坑工程中的应用[J]. 岩土工程学报, 2014, 36(增1): 91-96.ZHAO Shengfeng, HUANG Guanglong, MA Shiqiang, et al. Application of precast concrete pipe piles in a deep excavation project[J]. Journal of Geotechnical Engineering, 2014, 36(S1): 91-96. [2] LIU H L, KONG G Q, DING X M, et al. Performances of large-diameter cast-in-place concrete pipe piles and pile groups under lateral loads[J]. Journal of Performance of Constructed Facilities, 2013, 27(2): 191-202. doi: 10.1061/(ASCE)CF.1943-5509.0000304 [3] 郭杨, 吴平. 玻璃纤维筋与钢筋复合配筋预应力混凝土管桩承载性能试验研究[J]. 建筑结构学报, 2018, 39(2): 162-167.GUO Yang, WU Ping. Experimental study on bearing capacity of compositely reinforced with GFRP prestressed concrete pipe pile[J]. Journal of Building Structures, 2018, 39(2): 162-167. [4] 姚大立, 贾金青, 余芳. 有腹筋预应力超高强混凝土梁受剪承载力试验研究[J]. 湖南大学学报(自然科学版), 2015, 42(3): 23-30.YAO Dali, JIA Jinqing, YU Fang. Experimental study of the shear capacity of prestressed ultra-high reinforced concrete beams with stirrups[J]. Journal of Hunan University (Natural Sciences), 2015, 42(3): 23-30. [5] 王铁成, 杨志坚, 赵海龙, 等. PHC管桩与承台连接节点试验研究与有限元分析[J]. 天津大学学报(自然科学与工程技术版), 2015, 48(6): 527-534.WANG Tiecheng, YANG Zhijian, ZHAO Hailong, et al. Experimental investigation and finite element analysis of prestressed high strength concrete pile-pile cap connections[J]. Journal of Tianjin University (Science and Technology), 2015, 48(6): 527-534. [6] IKEDA S. Ductility improvement of prestressed concrete piles[J]. Transactions of the Japan Concrete Institute, 1982, 4: 531-538. [7] YANG Z J, LI G C, WANG W J. Experimental investigation and nonlinear finite element analysis on seismic performance of PHC piles[J]. Structural Engineering International, 2018, 28(4): 475-488. doi: 10.1080/10168664.2018.1462672 [8] CARBONELL-MÁRQUEZ J F, GIL-MARTÍN L M, ALEJANDRO FERNÁNDEZ-RUÍZ M, et al. Effective area in tension stiffening of reinforced concrete piles subjected to flexure according to Eurocode 2[J]. Engineering Structures, 2014, 76: 62-74. doi: 10.1016/j.engstruct.2014.06.041 [9] 王新玲, 高会宗, 周同和, 等. 新型混合配筋预应力混凝土管桩抗弯性能试验研究[J]. 工业建筑, 2012, 42(8): 64-68.WANG Xinling, GAO Huizong, ZHOU Tonghe, et al. Experimental studies of flexural behavior of new type prestressed concrete pipe pile with compound unprestressed reinforcement[J]. Industrial Construction, 2012, 42(8): 64-68. [10] 杜新喜, 胡锐, 袁焕鑫, 等. 混合配筋预应力混凝土管桩抗弯承载性能研究[J]. 土木工程学报, 2019, 52(1): 44-52.DU Xinxi, HU Rui, YUAN Huanxin, et al. Study on flexural behavior of prestressed concrete pipe pile with hybrid reinforcement[J]. China Civil Engineering Journal, 2019, 52(1): 44-52. [11] 刘畅, 孙雅楠, 郑刚, 等. 复合配筋管桩抗震性能试验研究[J]. 土木工程学报, 2018, 51(4): 77-86.LIU Chang, SUN Yanan, ZHENG Gang, et al. Experimental study on the seismic performance of the prestressed high-strength concrete pipe pile reinforced with non-prestressed steel bars[J]. China Civil Engineering Journal, 2018, 51(4): 77-86. [12] 徐金, 窦远明. 混合配筋管桩拟静力试验研究[J]. 建筑结构, 2019, 49(14): 113-116, 125.XU Jin, DOU Yuanming. Pseudo static test study on hybrid reinforced concrete pipe pile[J]. Building Structure, 2019, 49(14): 113-116, 125. [13] 郭杨, 吴平. 复合配筋预应力混凝土管桩受弯与受剪性能试验研究[J]. 施工技术, 2021, 50(2): 95-101.GUO Yang, WU Ping. Experimental study on flexural and shear behaviors of pre-stressed concrete pipe with hybrid reinforcement[J]. Construction Technology, 2021, 50(2): 95-101. [14] 张忠苗, 刘俊伟, 谢志专, 等. 新型混凝土管桩抗弯剪性能试验研究[J]. 岩土工程学报, 2011, 33(增2): 271-277.ZHANG Zhongmiao, LIU Junwei, XIE Zhizhuan, et al. Experimental study on flexural and shearing properties of modified concrete pipe piles[J]. Chinese Journal of Geotechnical Engineering, 2011, 33(S2): 271-277. [15] 朱俊涛, 代天昊, 李可. 变预应力度混合配筋混凝土管桩受弯性能[J]. 建筑结构学报, 2024, 45(1): 159-169.ZHU Juntao, DAI Tianhao, LI Ke. Flexural behavior of concrete pipe pile with various levels of prestress[J]. Journal of Building Structures, 2024, 45(1): 159-169. [16] 刘凯, 马维尼. 混合配筋超高强混凝土管桩抗弯性能试验研究[J]. 水利与建筑工程学报, 2022, 20(6): 155-162. doi: 10.3969/j.issn.1672-1144.2022.06.023LIU Kai, MA Weini. Experimental study on flexural performance of ultra-high strength concrete PRC pipe pile[J]. Journal of Water Resources and Architectural Engineering, 2022, 20(6): 155-162. doi: 10.3969/j.issn.1672-1144.2022.06.023 [17] 刘永超, 刘岩, 李兵兵, 等. 基于基坑支护工程的区段复式配筋预应力管桩抗弯试验及数值模拟[J]. 岩土工程学报, 2024, 46(2): 406-414. doi: 10.11779/CJGE20221359LIU Yongchao, LIU Yan, LI Bingbing, et al. Flexural tests and numerical simulations of prestressed concrete pipe piles with partial hybrid reinforcement based on support of foundation pits[J]. Chinese Journal of Geotechnical Engineering, 2024, 46(2): 406-414. doi: 10.11779/CJGE20221359 [18] 王新玲, 杜琳, 黄伟东. 混合配筋预应力混凝土管桩抗弯刚度模型研究[J]. 郑州大学学报(工学版), 2013, 34(6): 80-84. doi: 10.3969/j.issn.1671-6833.2013.06.020WANG Xinling, DU Lin, HUANG Weidong. Stiffness study of prestressed and reinforced concrete compounded pipe pile[J]. Journal of Zhengzhou University (Engineering Science), 2013, 34(6): 80-84. doi: 10.3969/j.issn.1671-6833.2013.06.020 [19] 郭杨, 吴平, 韩磊, 等. 复合配筋预应力混凝土管桩抗弯性能试验和数值分析[J]. 地下空间与工程学报, 2019, 15(2): 481-488.GUO Yang, WU Ping, HAN Lei, et al. Experimental study and numerical analysis on bending capability of compositely reinforced (GFRP) prestressed concrete pipe pile[J]. Chinese Journal of Underground Space and Engineering, 2019, 15(2): 481-488. [20] 傅传国, 商圣强, 王玉镯, 等. 火灾下预应力型钢混凝土梁抗弯承载力计算[J]. 西南交通大学学报, 2013, 48(4): 625-631, 658. doi: 10.3969/j.issn.0258-2724.2013.04.006FU Chuanguo, SHANG Shengqiang, WANG Yuzhuo, et al. Bending bearing capacity calculation of prestressed steel reinforced concrete beam under fire[J]. Journal of Southwest Jiaotong University, 2013, 48(4): 625-631, 658. doi: 10.3969/j.issn.0258-2724.2013.04.006 [21] 李福海, 胡丁涵, 余泳江, 等. PP-ECC梁抗弯性能试验研究[J]. 西南交通大学学报, 2021, 56(2): 272-281.LI Fuhai, HU Dinghan, YU Yongjiang, et al. Experimental study on flexural capacity of PP-ECC beam[J]. Journal of Southwest Jiaotong University, 2021, 56(2): 272-281. [22] 中国建筑材料联合会. 先张法预应力混凝土管桩: GB/T 13476—2009[S]. 北京: 中国标准出版社, 2010. [23] 河南省住房和城乡建设厅. 混合配筋预应力混凝土管桩: DBJT 19-34—2009[S]. 郑州: 河南科学技术出版社, 2010. -

下载:

下载: