Modeling and Characteristic Analysis of an Electromagnetic Isolation System with High Static Stiffness and Low Dynamic Stiffness

-

摘要:

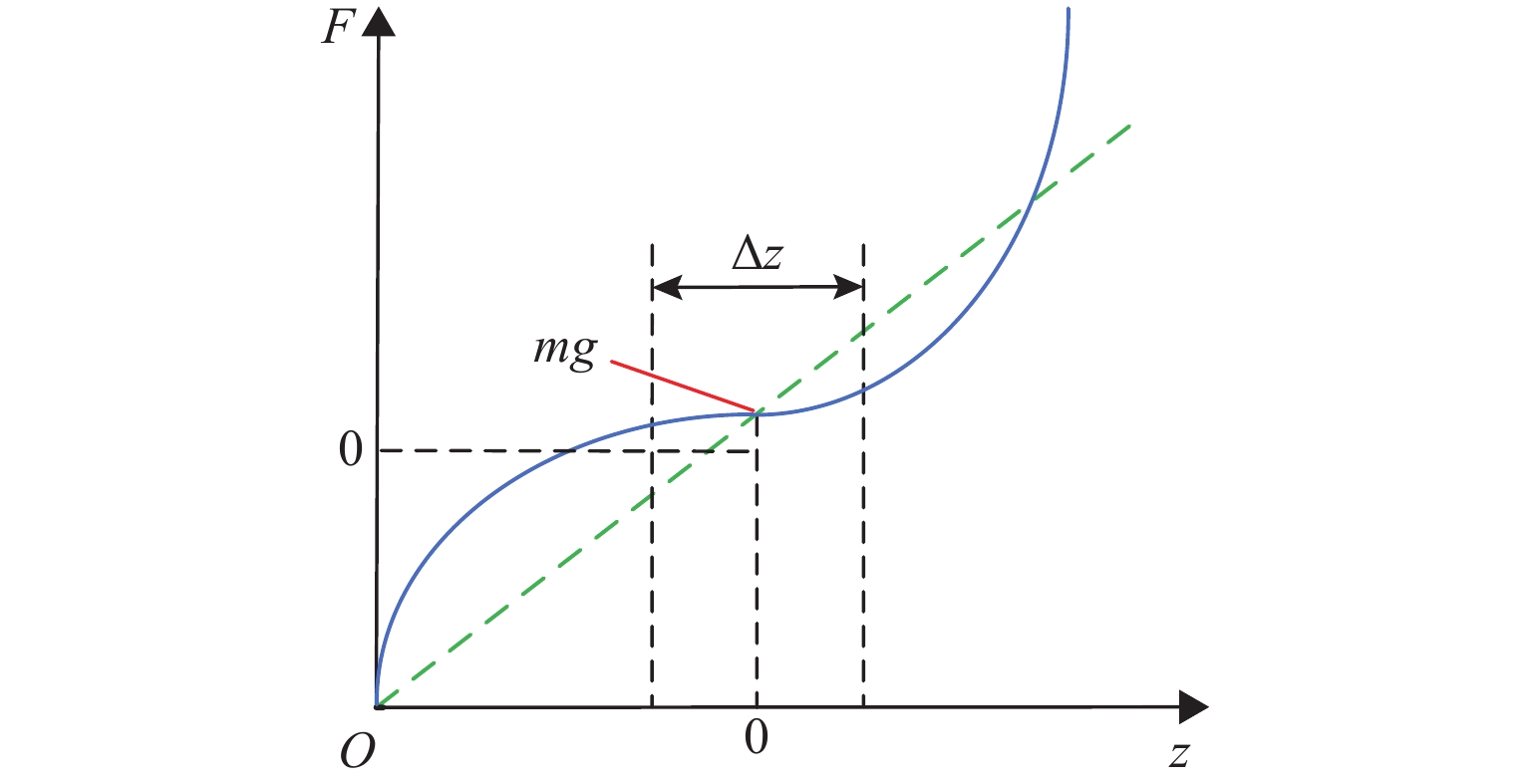

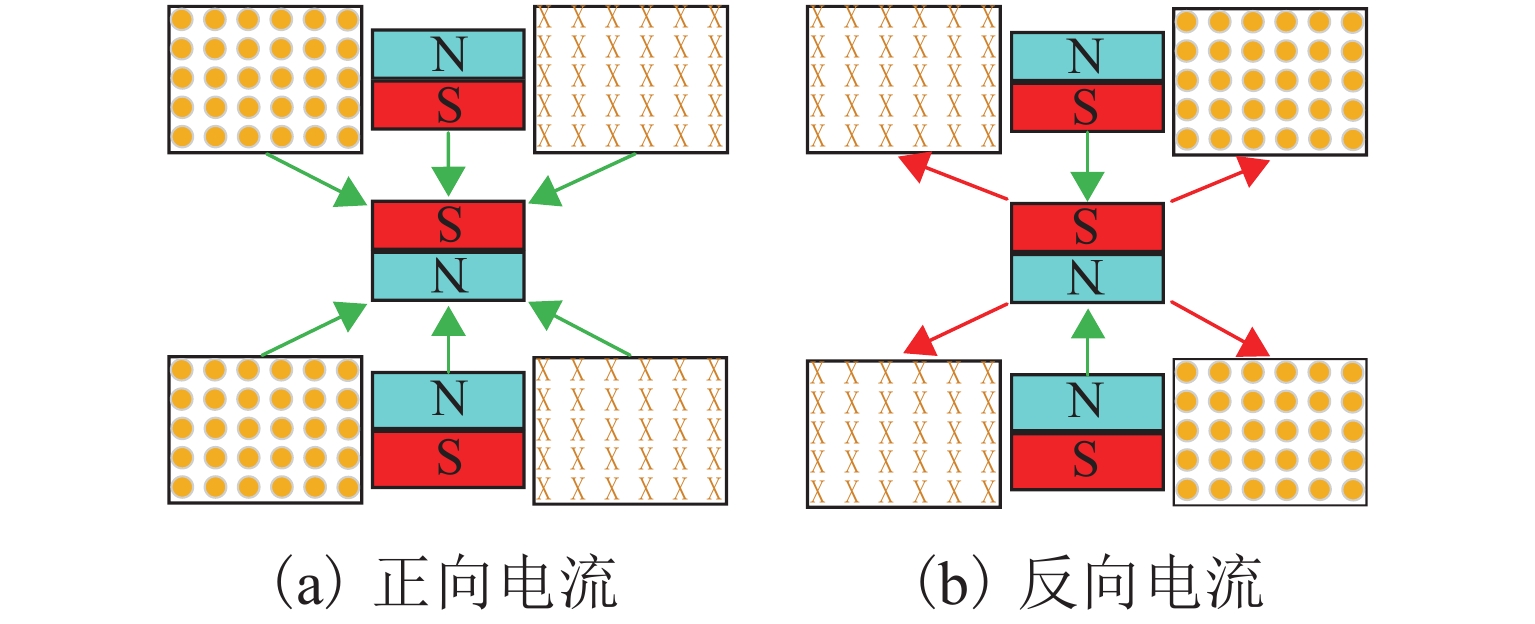

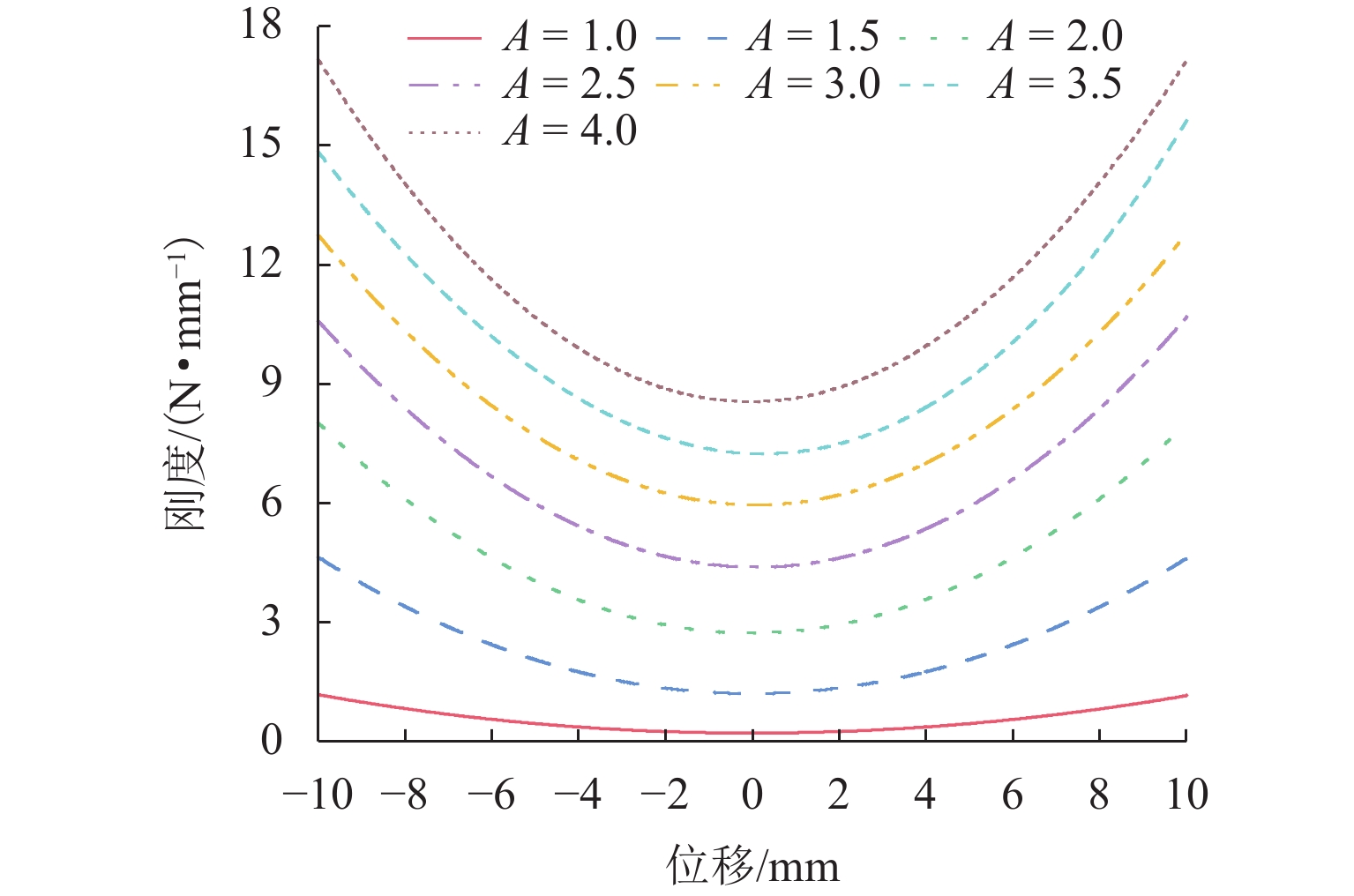

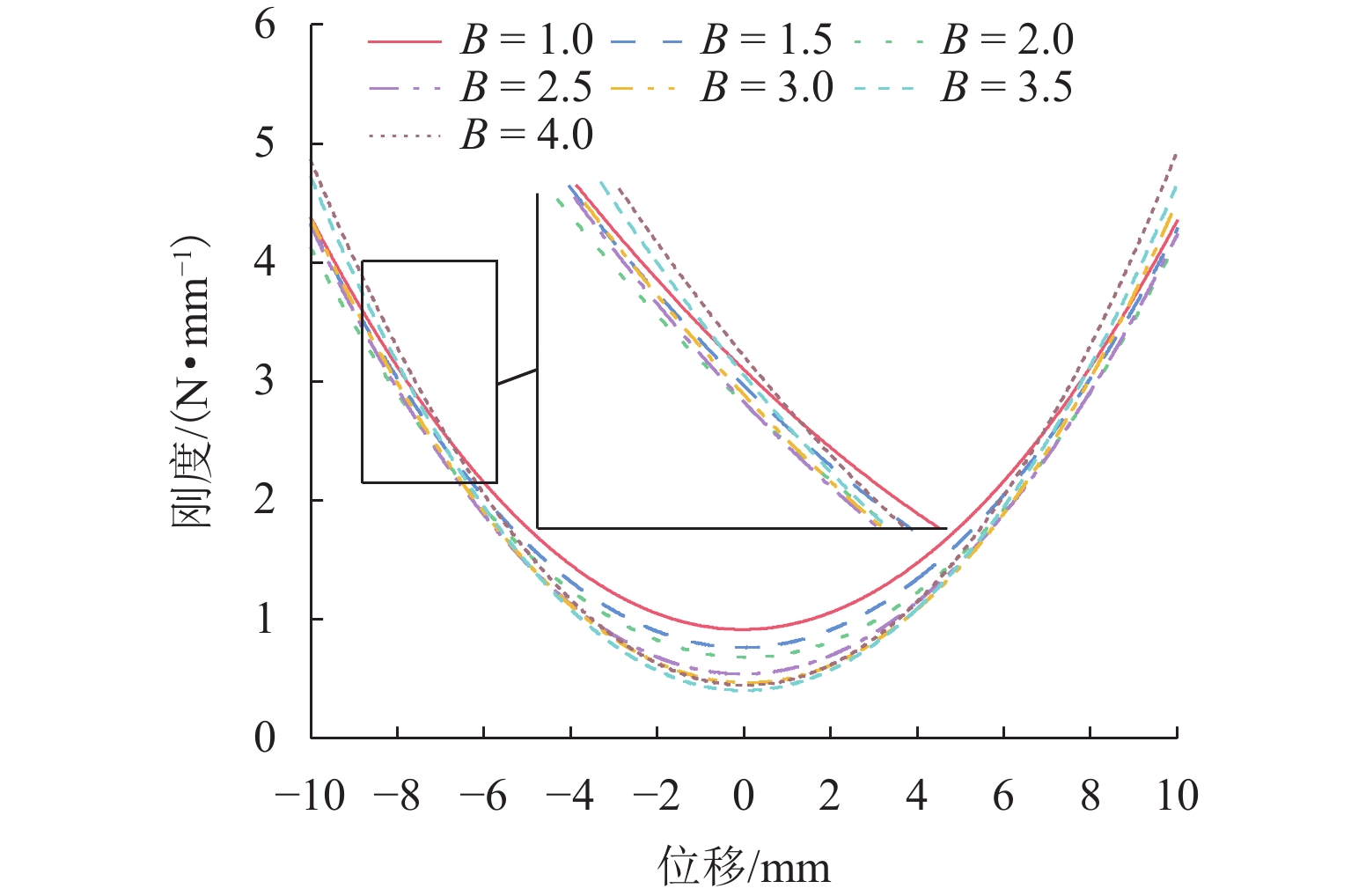

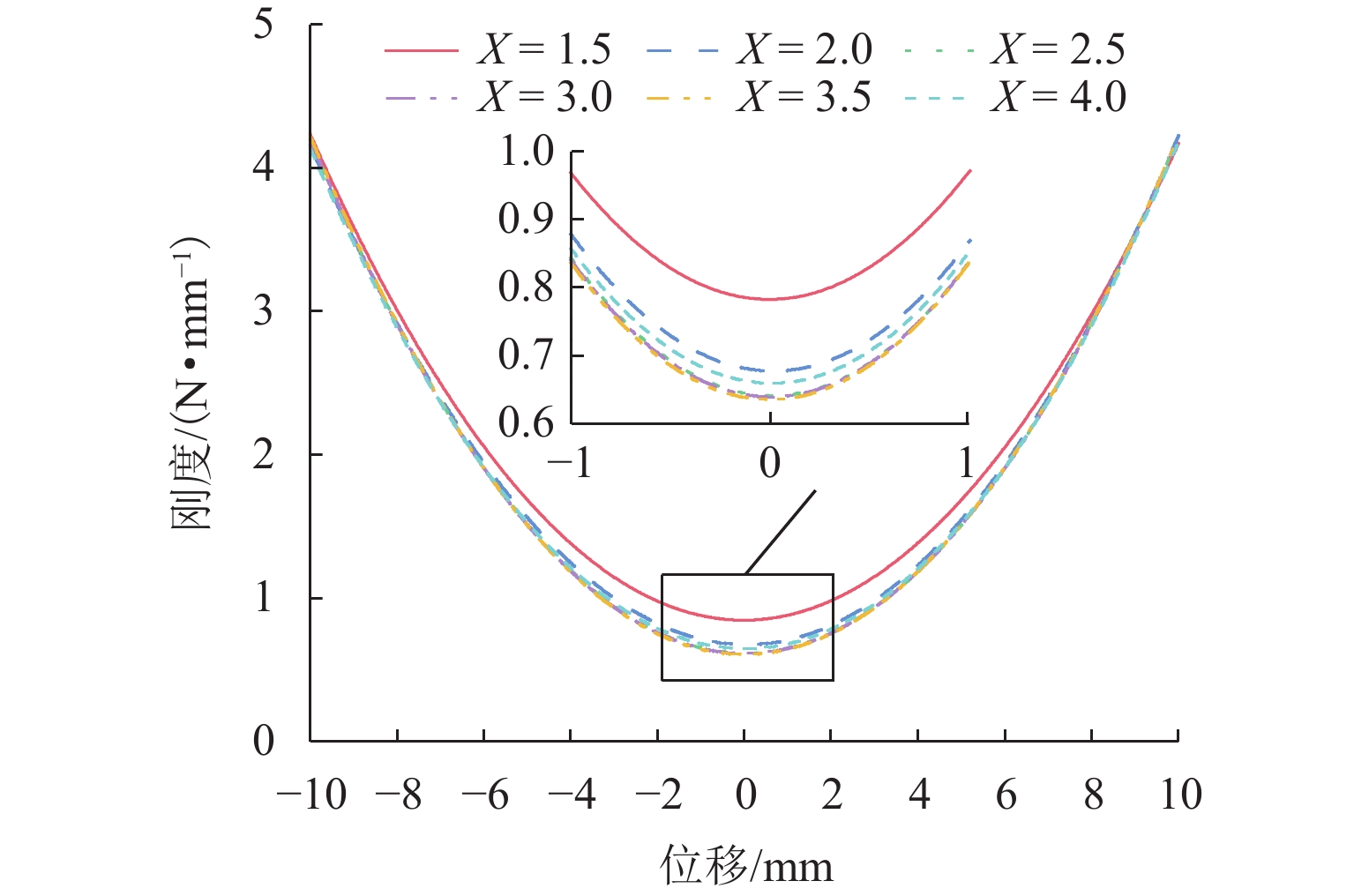

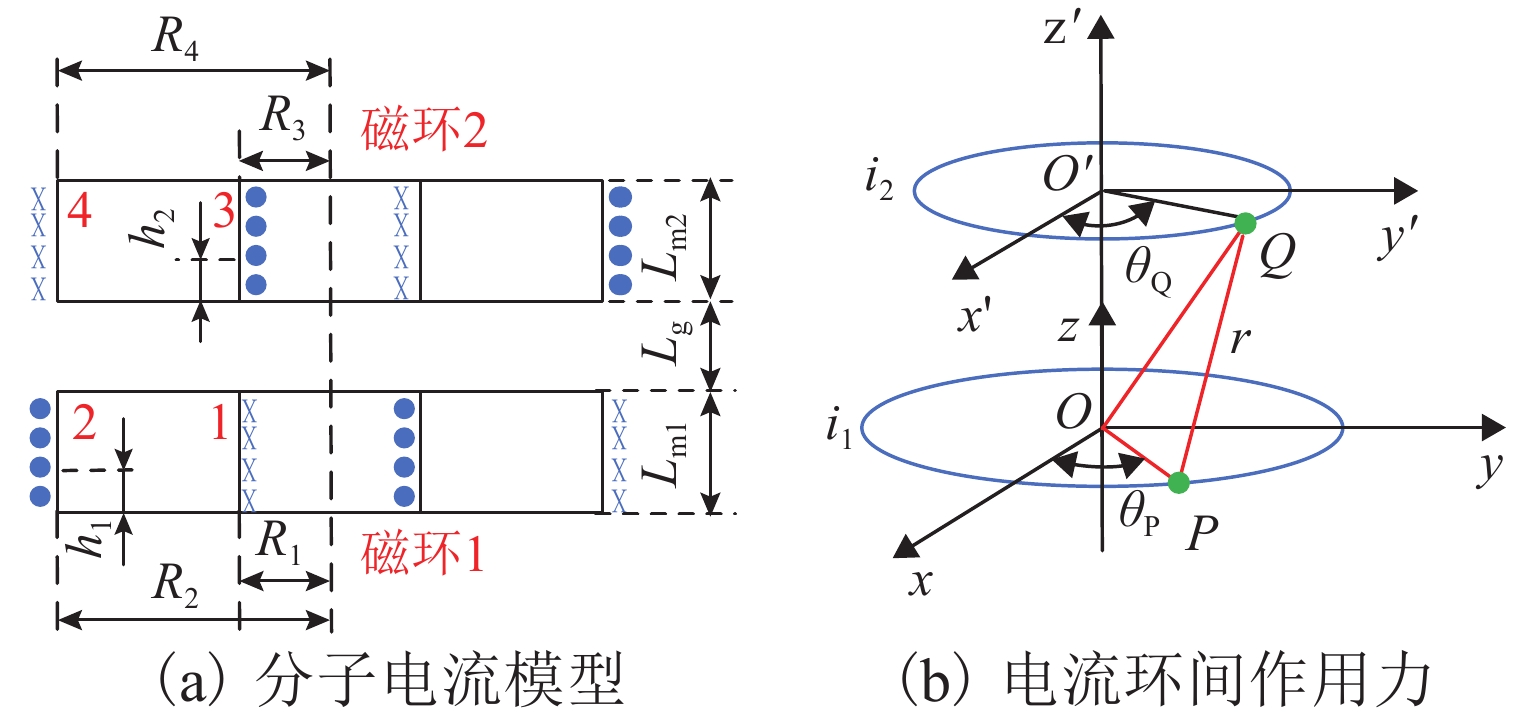

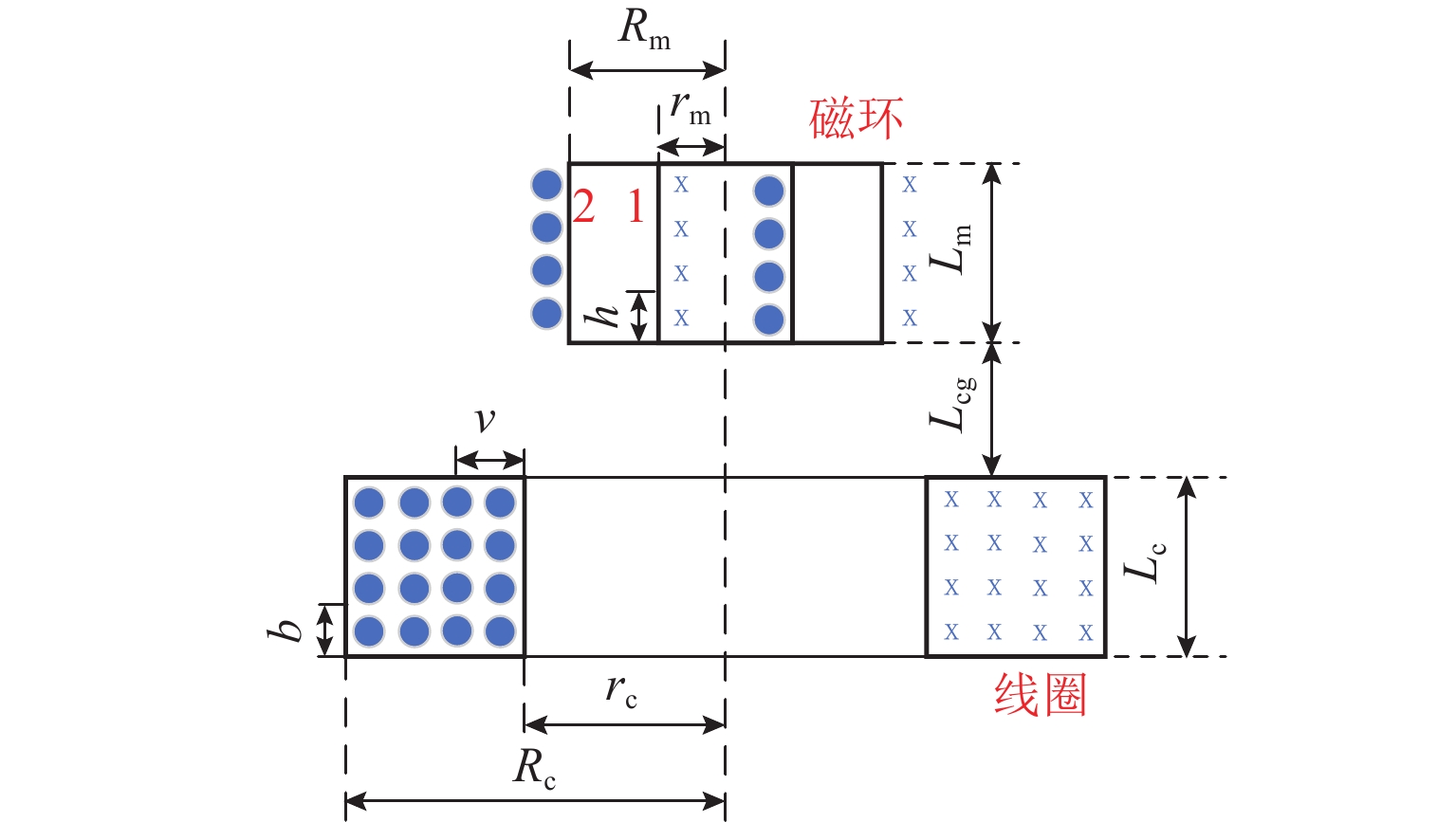

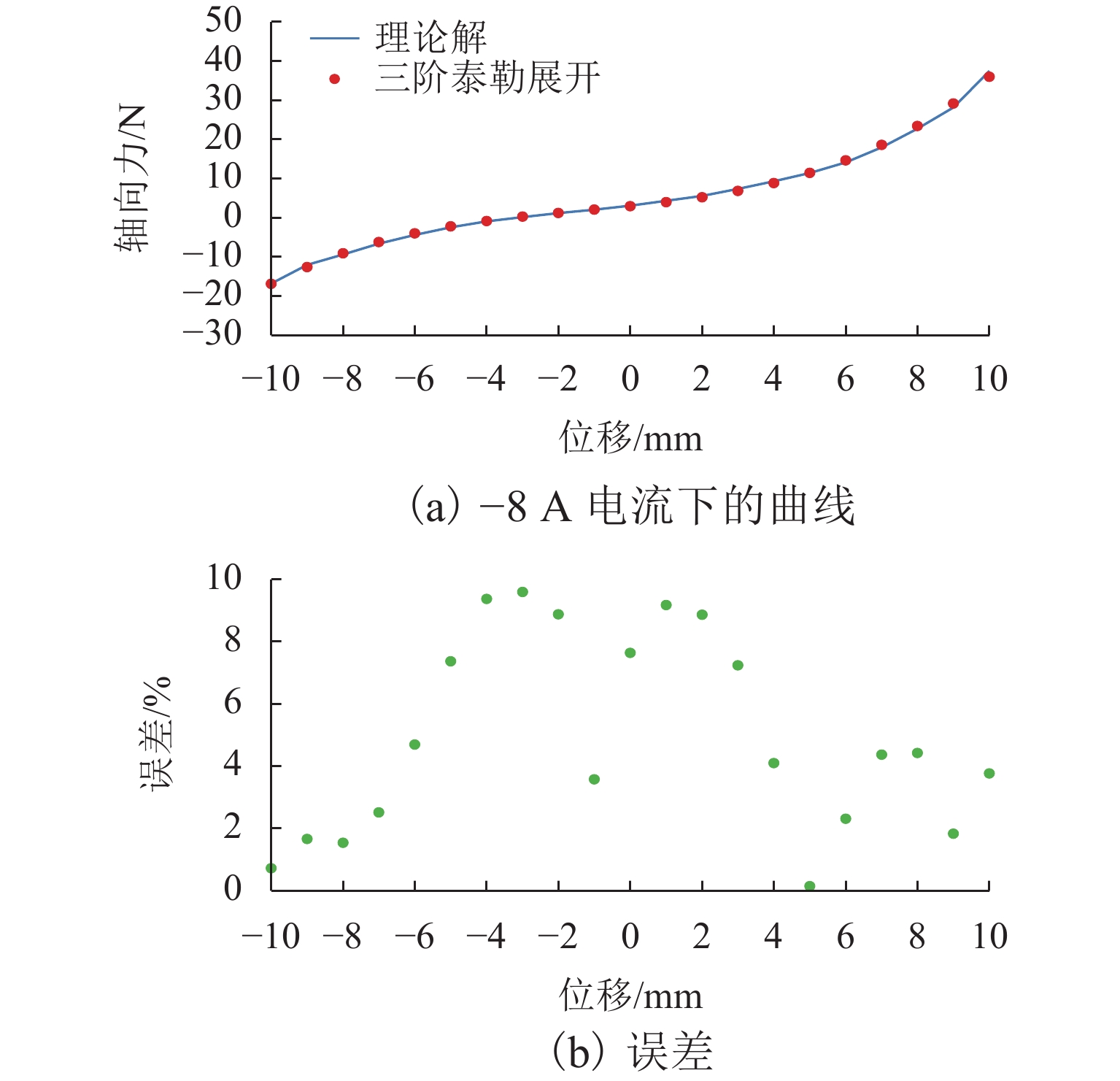

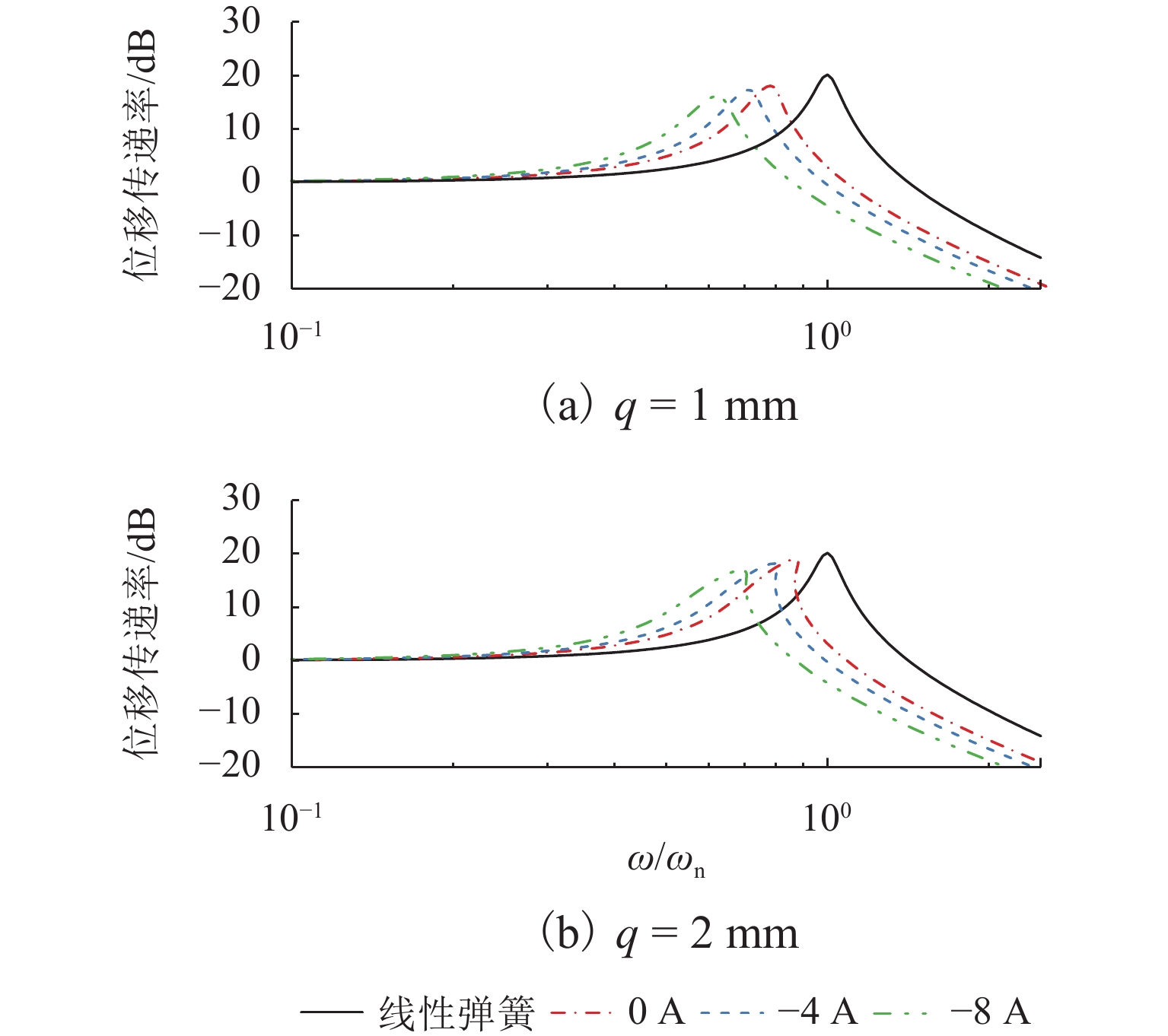

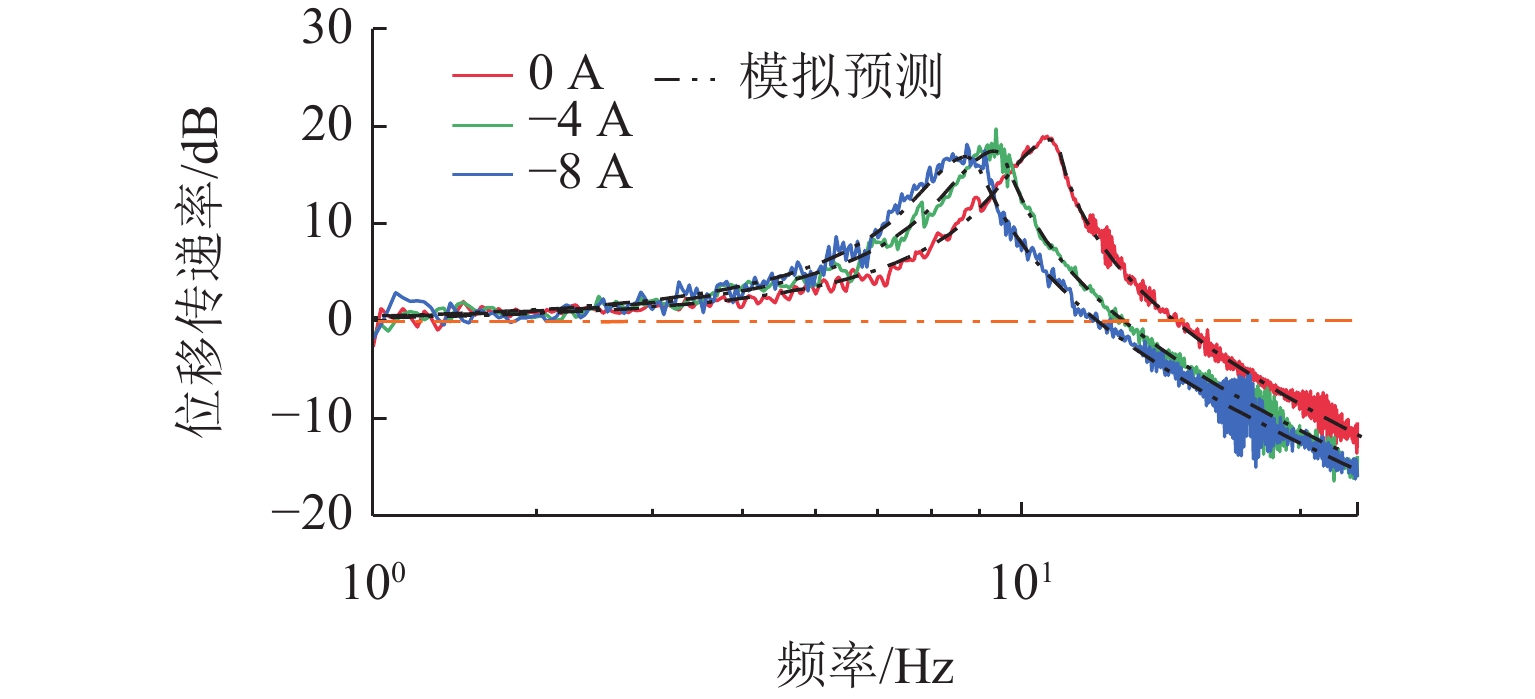

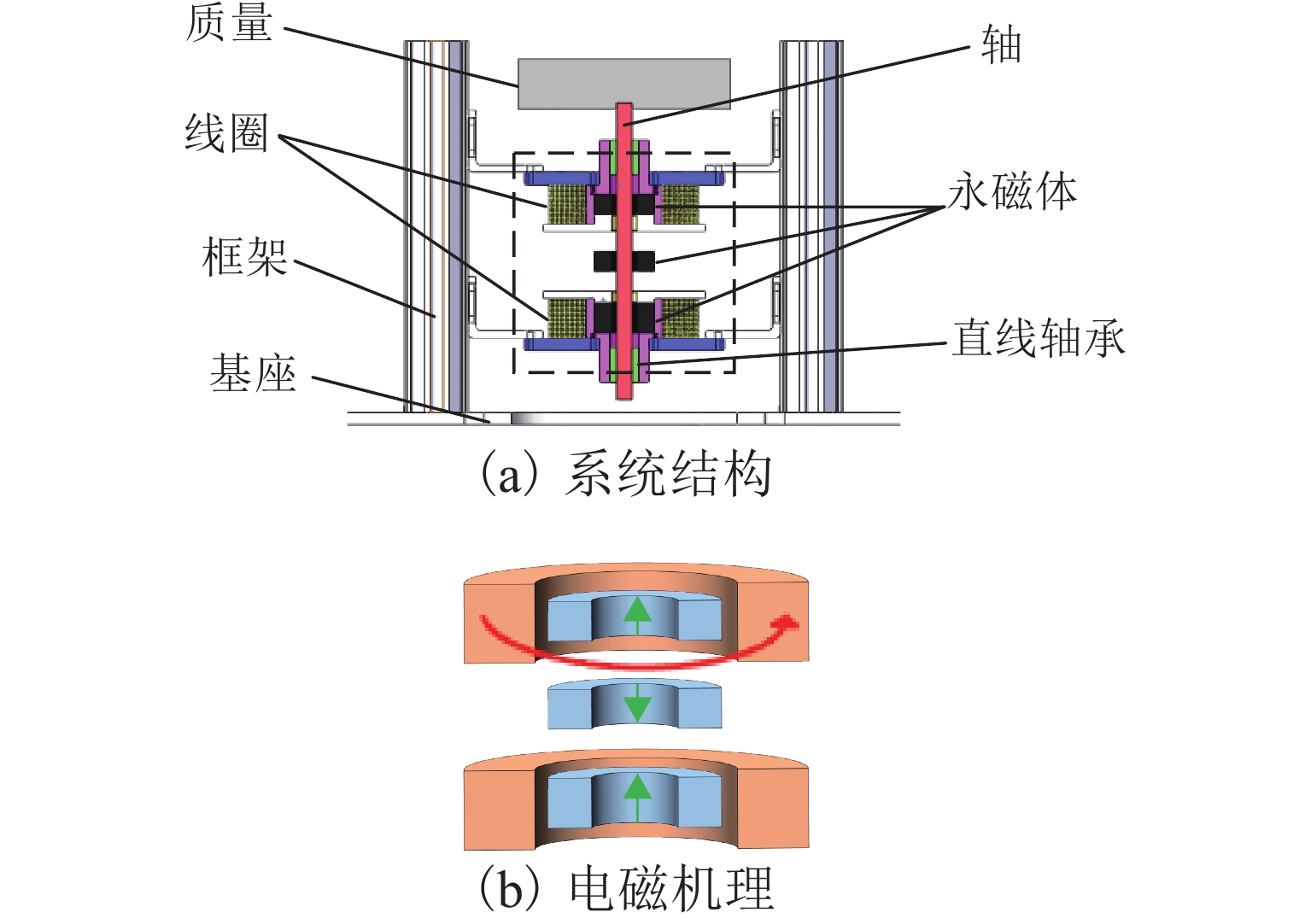

为改善传统线性隔振系统尺寸参数确定后就无法取得更低起始隔振频率的缺陷,基于电磁线圈嵌套永磁体结构,提出一种具有高静-低动刚度特性的电磁式可变刚度隔振系统. 采用分子电流法建立隔振系统磁力的数学模型;充分考虑隔振系统力学模型中二次与三次非线性刚度项的影响,建立单自由度被动隔振系统强非线性动力学模型;采用增量谐波平衡法(IHB)求解动力学模型,分析激励、电流等对隔振系统位移传递率的影响规律;构建实验测试系统,验证所提出新型隔振系统的有效性. 实验结果和理论计算表明:通入电流比未通入电流时隔振系统的起始隔振频率降低了19.25%,拓宽了隔振频带,实现了其对不同振源的适应性.

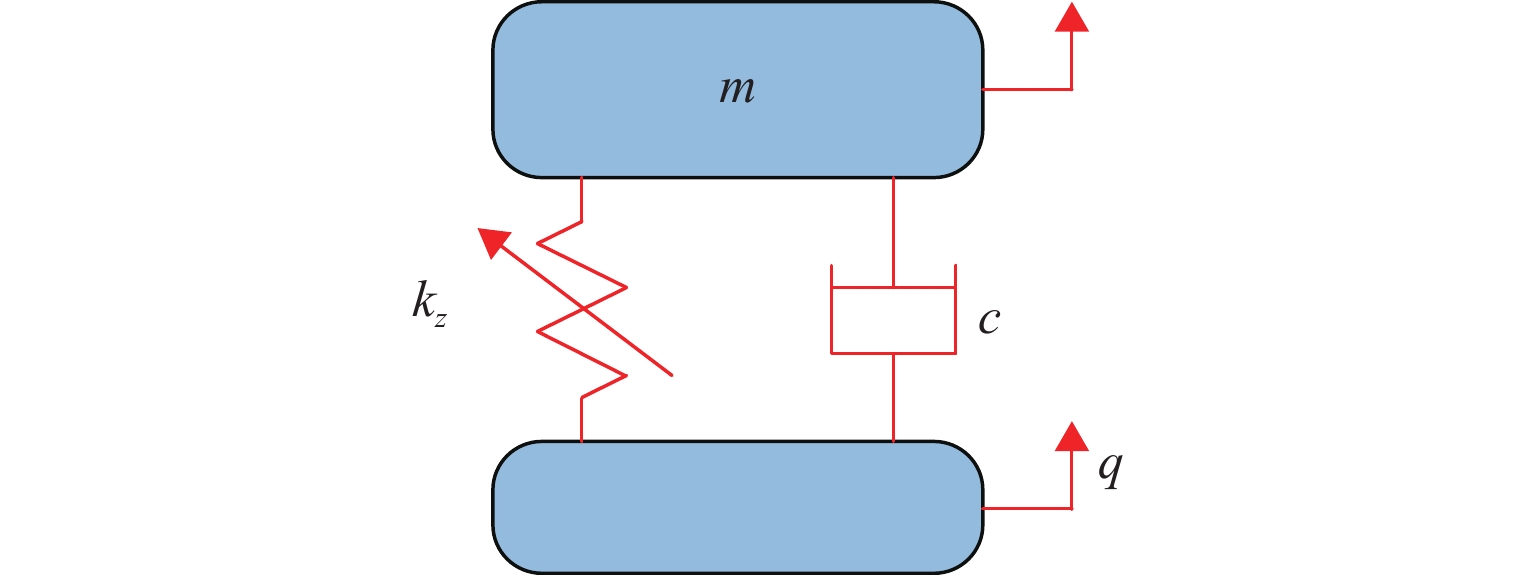

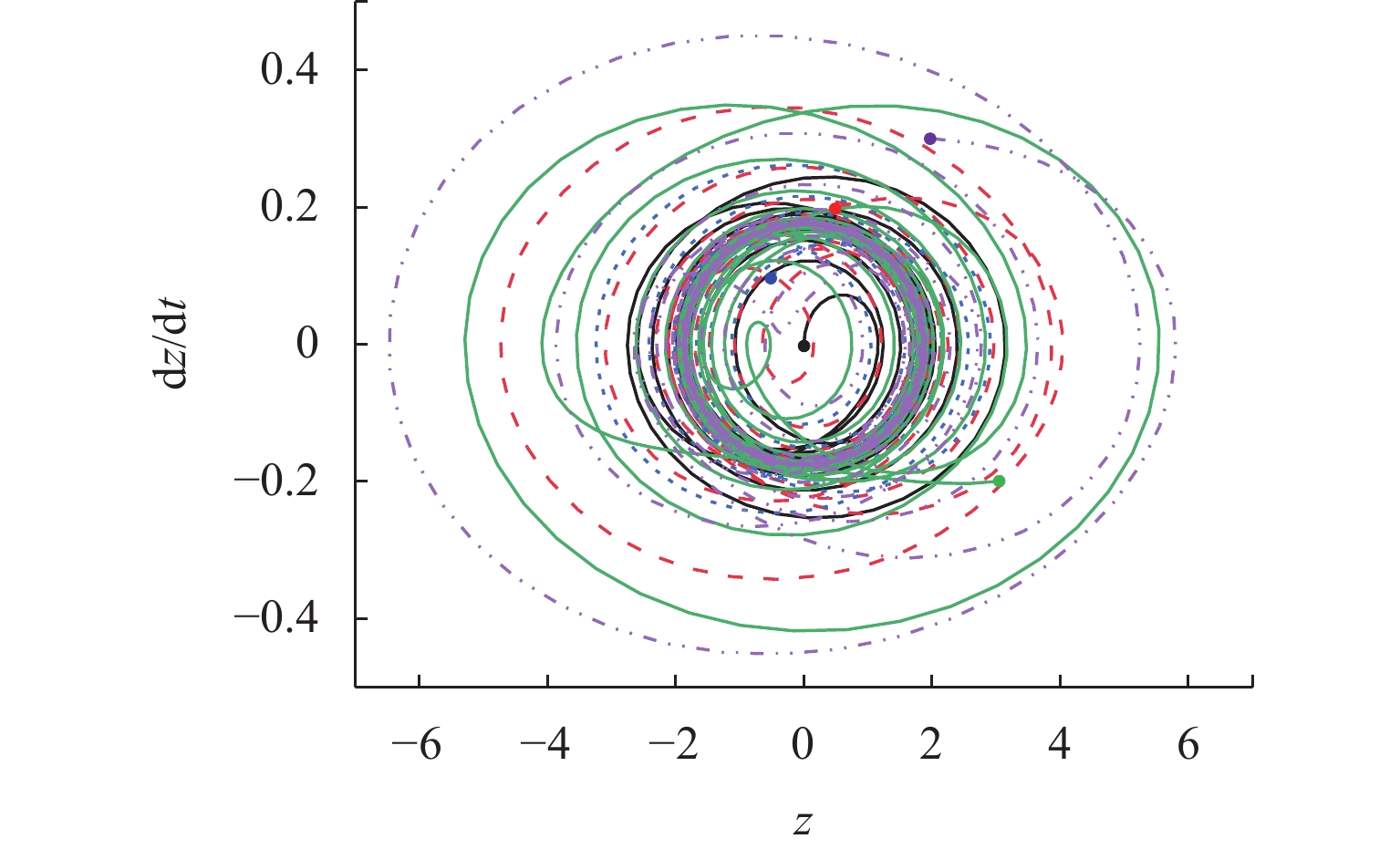

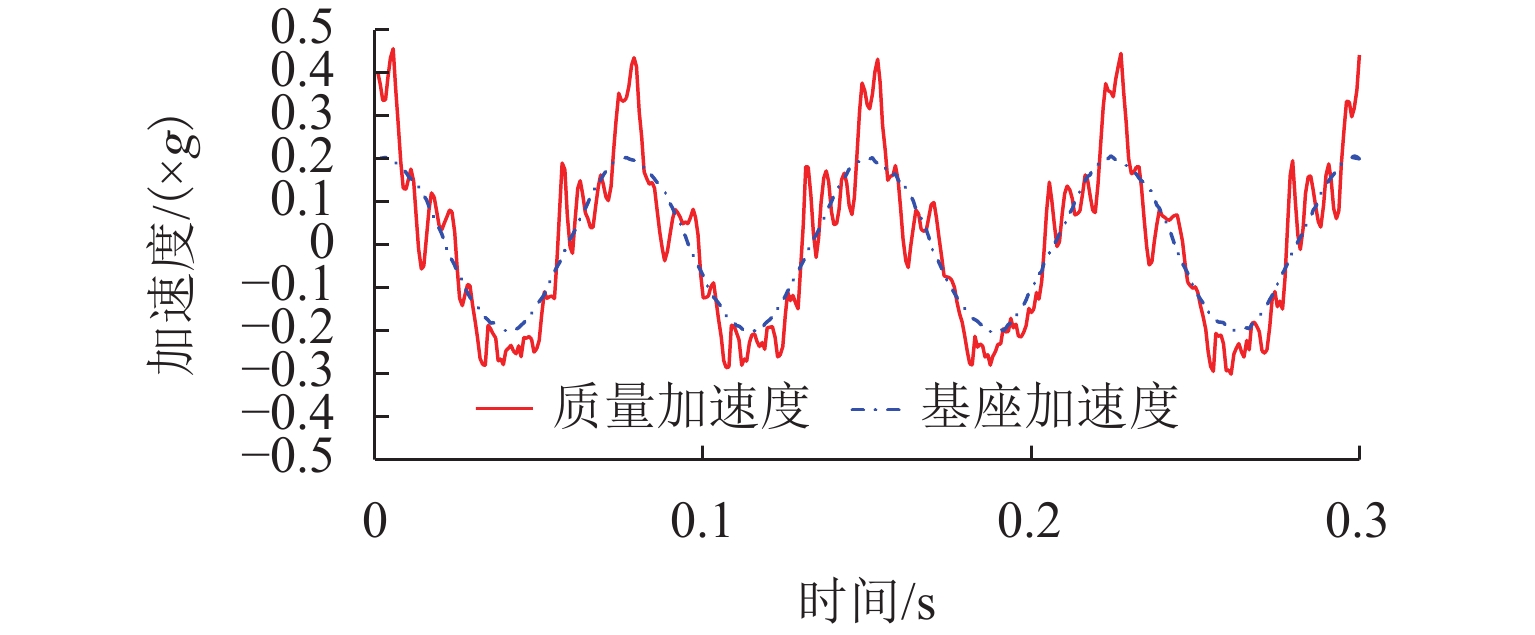

Abstract:Traditional linear vibration isolation system fails to achieve a lower initial vibration isolation frequency after setting the dimensional parameters. To address this issue, this article presented an electromagnetic vibration isolation system with variable stiffness based on the structure of a permanent magnet nested in an electromagnetic coil. To be specific, the system was characterized by high static stiffness and low dynamic stiffness. The mathematical model of the magnetic force of the system was created using the molecular current method. In addition, the strongly nonlinear dynamic model of the single-degree-of-freedom passive vibration isolation system was established by fully considering the quadratic and cubic nonlinear stiffness terms in the mechanical model of the vibration isolation system. The article used the incremental harmonic balance (IHB) method to solve the dynamic model and analyze the influence of excitation, current, and other factors on the displacement transmissibility of the system. An experimental test system was then created to validate the effectiveness of the proposed vibration isolation system. The experimental results and theoretical calculation demonstrate that the initial vibration isolation frequency of the system is reduced by 19.25% after introducing the current. This expands the frequency range of vibration isolation and improves system adaptability to different vibration sources.

-

表 1 结构参数

Table 1. Structural parameters

mm 参数 数值 磁环内径 5 磁环外径 12 磁环厚度 8(上、中),12(下) 线圈内径 15 线圈外径 30 线圈厚度 16 工作气隙 Z 15 线径 s 1 -

[1] 翟明达,张博,李晓龙,等. 基于模糊PID控制的准零刚度磁悬浮隔振平台的设计与实现[J]. 西南交通大学学报,2023,58(4): 886-895.ZHAI Mingda, ZHANG Bo, LI Xiaolong, et al. Design and implementation of magnetic suspension vibration isolation platform with quasi-zero stiffness based on fuzzy PID control[J]. Journal of Southwest Jiaotong University, 2023, 58(4): 886-895. [2] 韩俊淑,孙景工,孟令帅. 一种曲面-弹簧-滚子机构的非线性隔振器特性分析[J]. 振动与冲击,2019,38(3): 170-178.HAN Junshu, SUN Jinggong, MENG Lingshuai. Design and characteristics analysis of a nonlinear vibration isolator using a curved surface-spring-roller mechanism as negative stiffness element[J]. Journal of Vibration and Shock, 2019, 38(3): 170-178. [3] SUN Y, ZHAO J L, WANG M, et al. High-static–low-dynamic stiffness isolator with tunable electromagnetic mechanism[J]. IEEE/ASME Transactions on Mechatronics, 2020, 25(1): 316-326. doi: 10.1109/TMECH.2019.2954910 [4] CARRELLA A, BRENNAN M J, KOVACIC I, et al. On the force transmissibility of a vibration isolator with quasi-zero-stiffness[J]. Journal of Sound and Vibration, 2009, 322(4/5): 707-717. [5] CARRELLA A, BRENNAN M J, WATERS T P, et al. Force and displacement transmissibility of a nonlinear isolator with high-static—low-dynamic-stiffness[J]. International Journal of Mechanical Sciences, 2012, 55(1): 22-29. doi: 10.1016/j.ijmecsci.2011.11.012 [6] 周加喜,王心龙,徐道临,等. 含凸轮-滚轮机构的准零刚度系统隔振特性实验研究[J]. 振动工程学报,2015,28(3): 449-455.ZHOU Jiaxi, WANG Xinlong, XU Daolin, et al. Experimental study on vibration isolation characteristics of the quasi-zero stiffness isolator with cam-roller mechanism[J]. Journal of Vibration Engineering, 2015, 28(3): 449-455. [7] 刘兴天,张志谊,华宏星. 新型低频隔振器的特性研究[J]. 振动与冲击,2012,31(5): 161-164.LIU Xingtian, ZHANG Zhiyi, HUA Hongxing. Characteristics of a novel low-frequency isolator[J]. Journal of Vibration and Shock, 2012, 31(5): 161-164. [8] 陆文昌,杨帆,汪少华,等. 气动可调阻尼同轴一体式减振支柱阻尼特性研究[J]. 振动与冲击,2015,34(20): 115-119,128.LU Wenchang, YANG Fan, WANG Shaohua, et al. Damping characteristics of a coaxial integrated strut with adjustable pneumatic damping[J]. Journal of Vibration and Shock, 2015, 34(20): 115-119,128. [9] ZHANG F, SHAO S B, TIAN Z, et al. Active-passive hybrid vibration isolation with magnetic negative stiffness isolator based on Maxwell normal stress[J]. Mechanical Systems and Signal Processing, 2019, 123: 244-263. doi: 10.1016/j.ymssp.2019.01.022 [10] 高双,朱翔,谌宗琦,等. 基于欧拉梁的准零刚度隔振系统动力特性分析[J]. 中国机械工程,2016,27(21): 2869-2876.GAO Shuang, ZHU Xiang, CHEN Zongqi, et al. Analyses on dynamics characteristics of a quasi-zero-stiffness vibration isolation system based on Euler beam[J]. China Mechanical Engineering, 2016, 27(21): 2869-2876. [11] 李爽,楼京俊,杨庆超,等. 双环永磁体型高静低动刚度隔振器设计、建模与试验研究[J]. 振动工程学报,2019,32(4): 675-684.LI Shuang, LOU Jingjun, YANG Qingchao, et al. Design and experiment of a vibration isolator using double-ring permanent magnets springs with negative stiffness[J]. Journal of Vibration Engineering, 2019, 32(4): 675-684. [12] ZHOU N, LIU K. A tunable high-static–low-dynamic stiffness vibration isolator[J]. Journal of Sound and Vibration, 2010, 329(9): 1254-1273. doi: 10.1016/j.jsv.2009.11.001 [13] ZHOU N B, LIU K F. Characterization of an electromagnetic vibration isolator[J]. Journal of Electromagnetic Analysis and Applications, 2011, 3(12): 519-528. [14] 陈树辉. 强非线性振动系统的定量分析方法[M]. 北京:科学出版社,2007:167-180. [15] 王洪昌,蒋书运,梁玉飞. 基于分子电流法轴向永磁轴承轴向刚度的分析[J]. 机械工程学报,2009,45(5): 102-107. doi: 10.3901/JME.2009.05.102WANG Hongchang, JIANG Shuyun, LIANG Yufei. Analysis of axial stiffness of permanent magnet bearings by using the equivalent surface currents method[J]. Journal of Mechanical Engineering, 2009, 45(5): 102-107. doi: 10.3901/JME.2009.05.102 [16] 张海波,邱玉江,蒋书运. 永磁轴承承载能力分子电流模型的积分定义求解方法[J]. 机械工程学报,2016,52(7): 54-59. doi: 10.3901/JME.2016.07.054ZHANG Haibo, QIU Yujiang, JIANG Shuyun. Analysis of the equivalent surface current model for the permanent magnet bearing by using the integral definition[J]. Journal of Mechanical Engineering, 2016, 52(7): 54-59. doi: 10.3901/JME.2016.07.054 [17] LAU S L, ZHANG W S. Nonlinear vibrations of piecewise-linear systems by incremental harmonic balance method[J]. Journal of Applied Mechanics, 1992, 59(1): 153-160. doi: 10.1115/1.2899421 [18] ZHOU J X, ZHANG L. Incremental harmonic balance method for predicting amplitudes of a multi-d. o. f. non-linear wheel shimmy system with combined Coulomb and quadratic damping[J]. Journal of Sound and Vibration, 2005, 279(1/2): 403-416. -

下载:

下载: