Freeze-Thaw Resistance of Red Mud-Based Stabilized Crushed Stone

-

摘要:

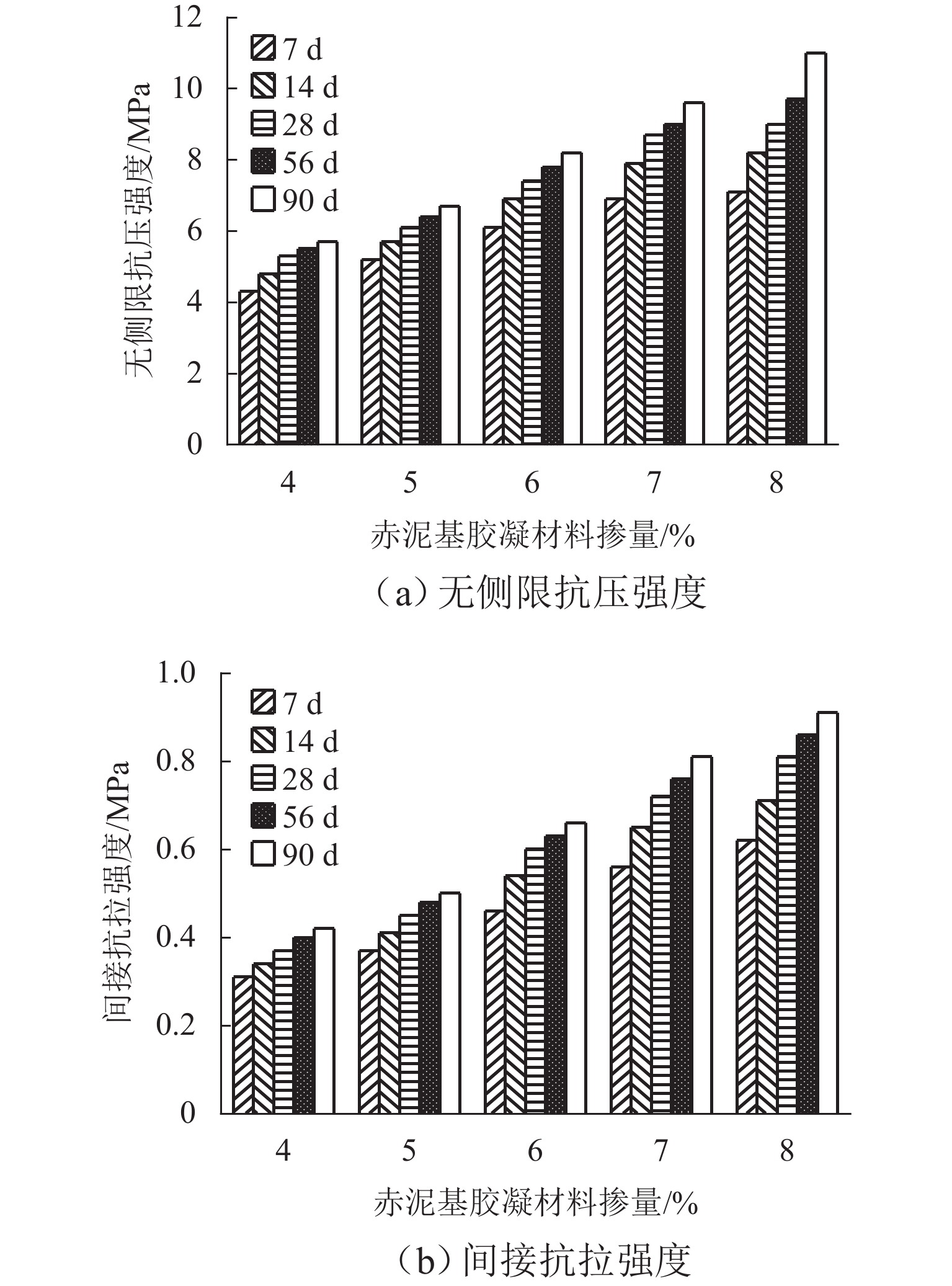

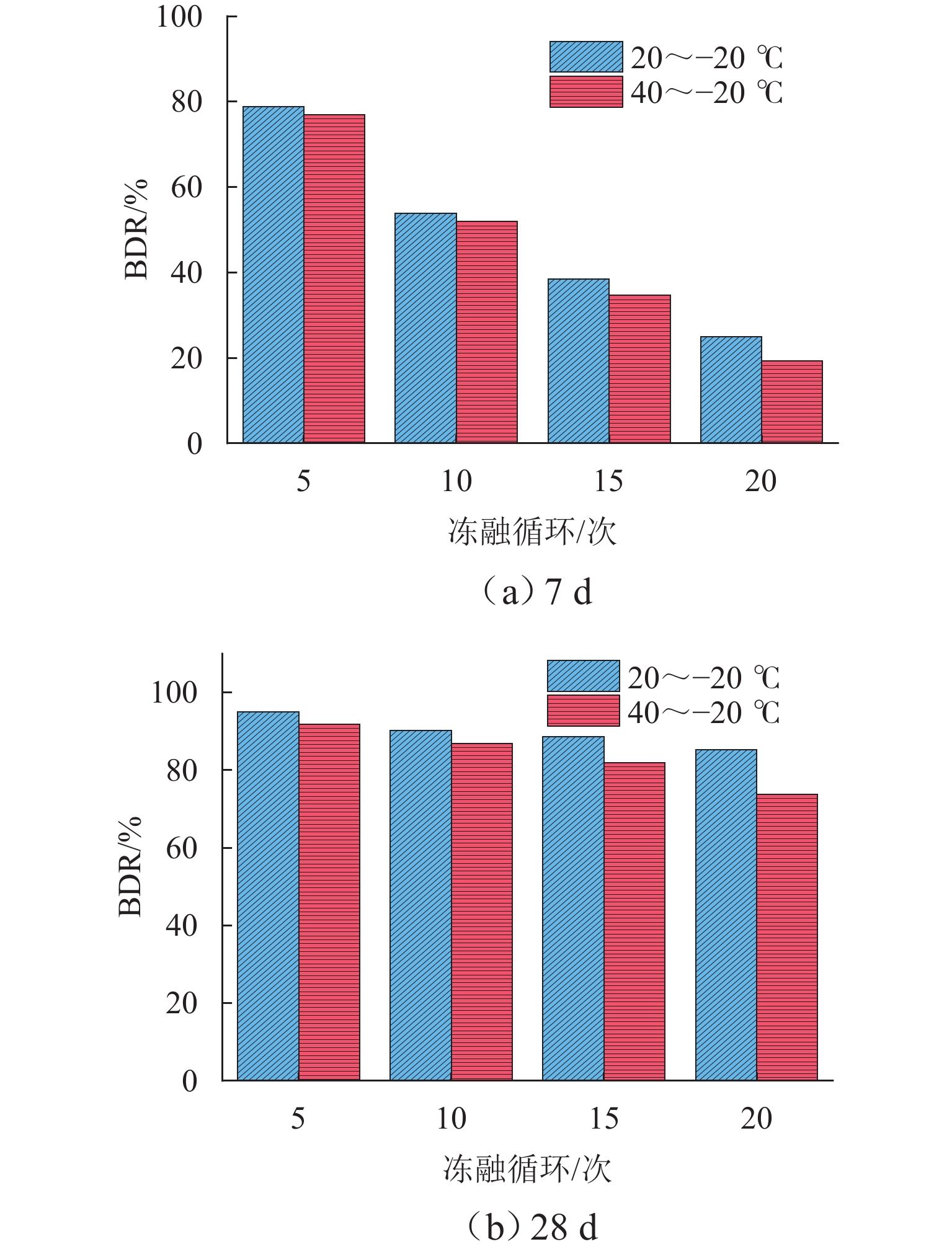

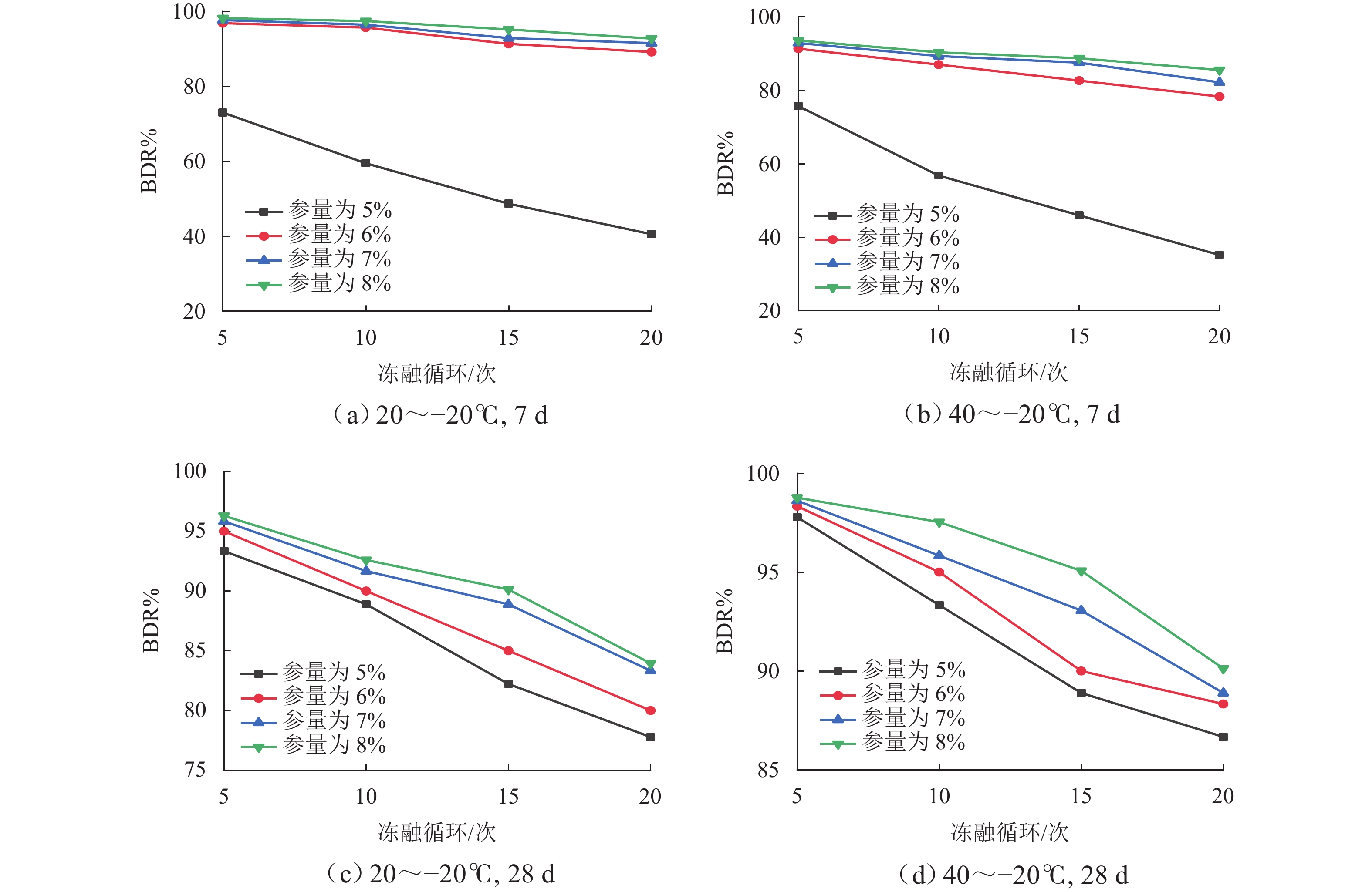

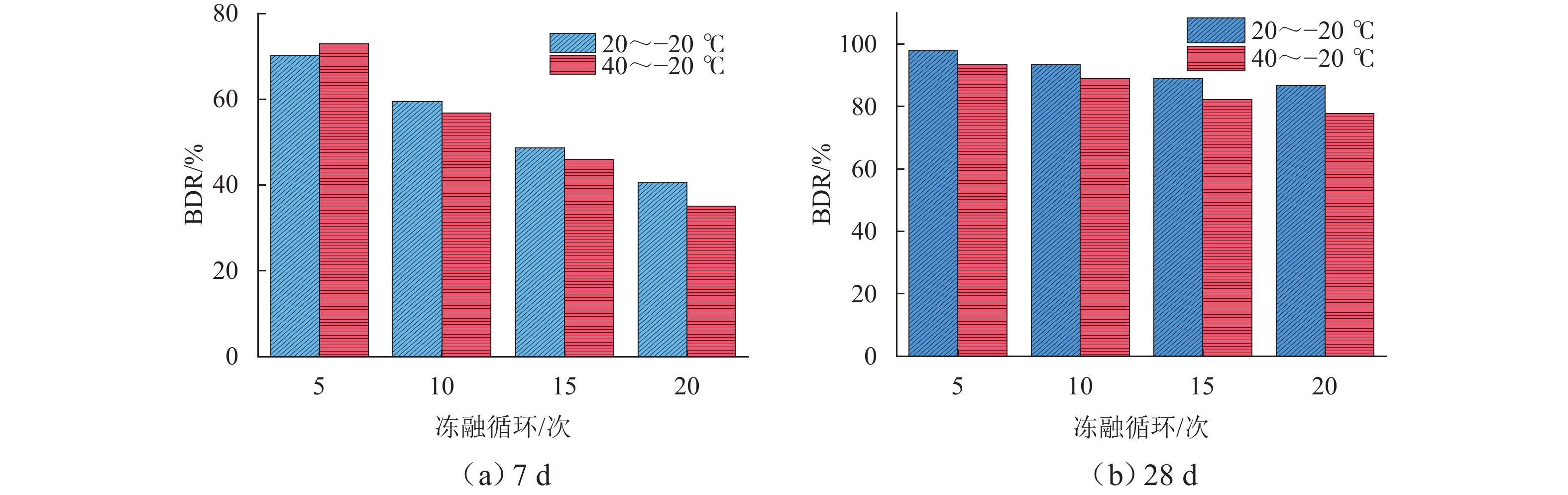

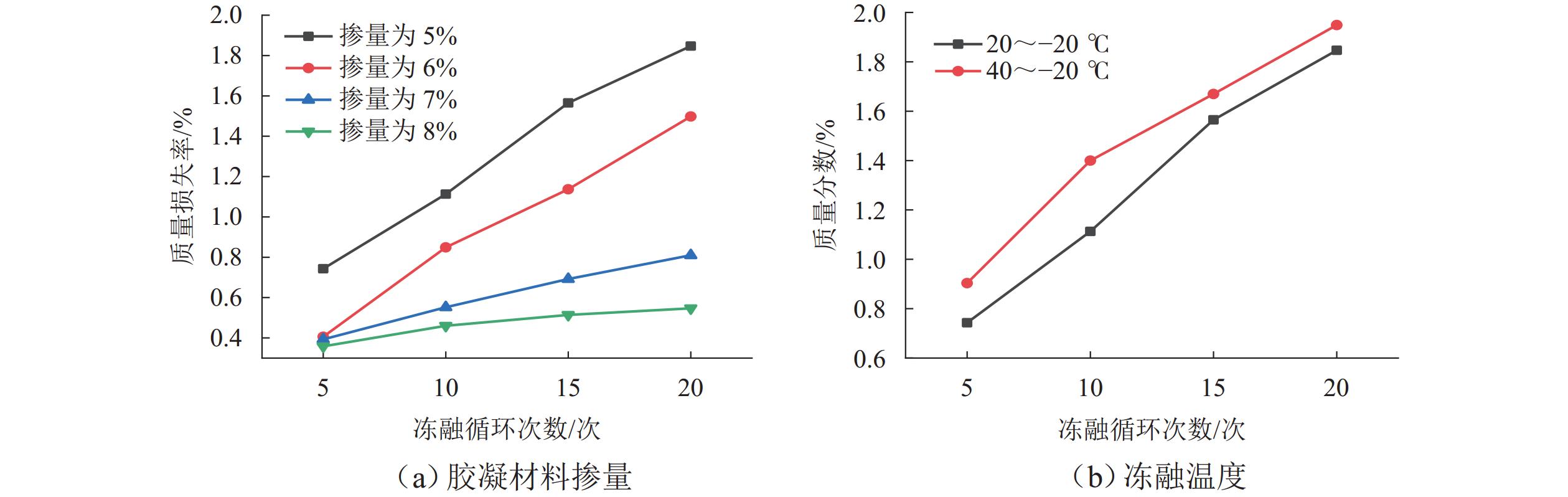

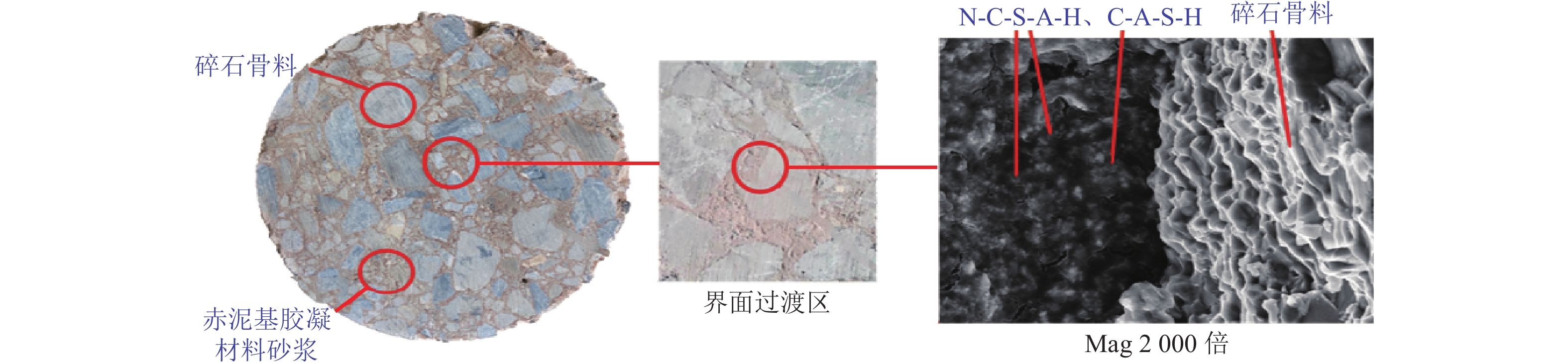

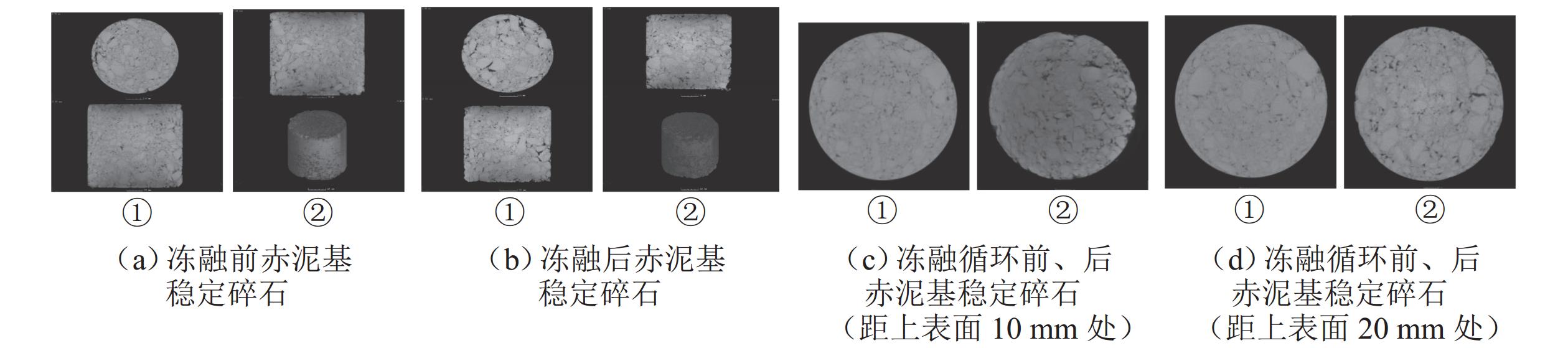

为实现赤泥基胶凝材料在道路工程中的安全应用,研究赤泥基稳定碎石基层在冻融循环作用下力学性能与质量的变化规律,采用工业CT扫描、扫描式电子显微镜与能谱仪(SEM-EDS)等方式探究冻融温度与次数对力学性能和质量损失的作用机制. 研究表明:20~−20 ℃、28 d条件下胶凝材料5%掺量最大质量损失率为1.85%;5%和6%赤泥基胶凝材料掺量下稳定碎石质量损失率变化幅度高于掺量7%和8%掺量下的变化幅度,且随着冻融循环次数的增加,质量损失率不断增加;通过工业CT与SEM-EDS微观分析,随着冻融循环次数增加,稳定碎石孔隙率增大,养生28 d、6%掺量稳定碎石经历20次冻融循环后,孔隙率增长1.53%,内部裂缝损伤增多并不断积累,呈现由少变多、由窄变宽的变化规律;研究结果对交通工程绿色建设和赤泥大宗量利用具有积极推动作用.

Abstract:In order to achieve the safe application of red mud-based cementitious materials in road engineering, the mechanical properties and quality of red mud-based stabilized crushed stone base under freeze-thaw cycles were studied. The influence of freeze-thaw cycle temperature and number on mechanical properties and quality loss was explored by industrial CT scanning and SEM-EDS. Research has shown that when the temperature ranges from 20 ℃ to −20 ℃ for 28 days, the maximum quality loss rate of the cementitious material with a 5% dosage is 1.85%. The change in quality loss rate of stabilized crushed stone with 5% and 6% red mud-based cementitious materials is higher than that with 7% and 8% red mud-based cementitious materials. In addition, with the increase in freeze-thaw cycles, the quality loss rate continues to increase. Through industrial CT and SEM-EDS microscopic analysis, as the number of freeze-thaw cycles increases, the porosity of stabilized crushed stone increases. After the stabilized crushed stone undergoes 28 days of curing and 20 freeze-thaw cycles with a 6% dosage, the porosity increases by 1.53%, and internal crack damage increases and accumulates continuously, showing a changing pattern from less to more and from narrow to wide. The research results have a positive role in promoting the green construction of transportation engineering and the large-scale application of red mud.

-

表 1 原料化学组成(质量分数)

Table 1. Chemical composition of raw materials (mass fraction)

% 类型 Fe2O3 Al2O3 SiO2 TiO2 Na2O CaO SO3 ZrO2 P2O5 MgO Cr2O3 MnO K2O 赤泥 53.63 19.48 8.30 7.26 4.86 4.65 0.42 0.42 0.24 0.23 0.19 0.11 0.08 矿粉 2.36 16.71 25.51 0.99 0.50 45.09 1.25 0.11 0.04 5.67 0.46 1.04 表 2 赤泥基胶凝材料主要技术指标

Table 2. Technical specifications of red mud-based cementitious materials

标准稠度用水量/% 凝结时间/min 28 d 抗折强度/MPa 28 d 抗压强度/MPa 27.36 初凝 226,终凝 366 9.64 24.50 表 3 碎石骨料物理性质

Table 3. Physical properties of crushed stone aggregate

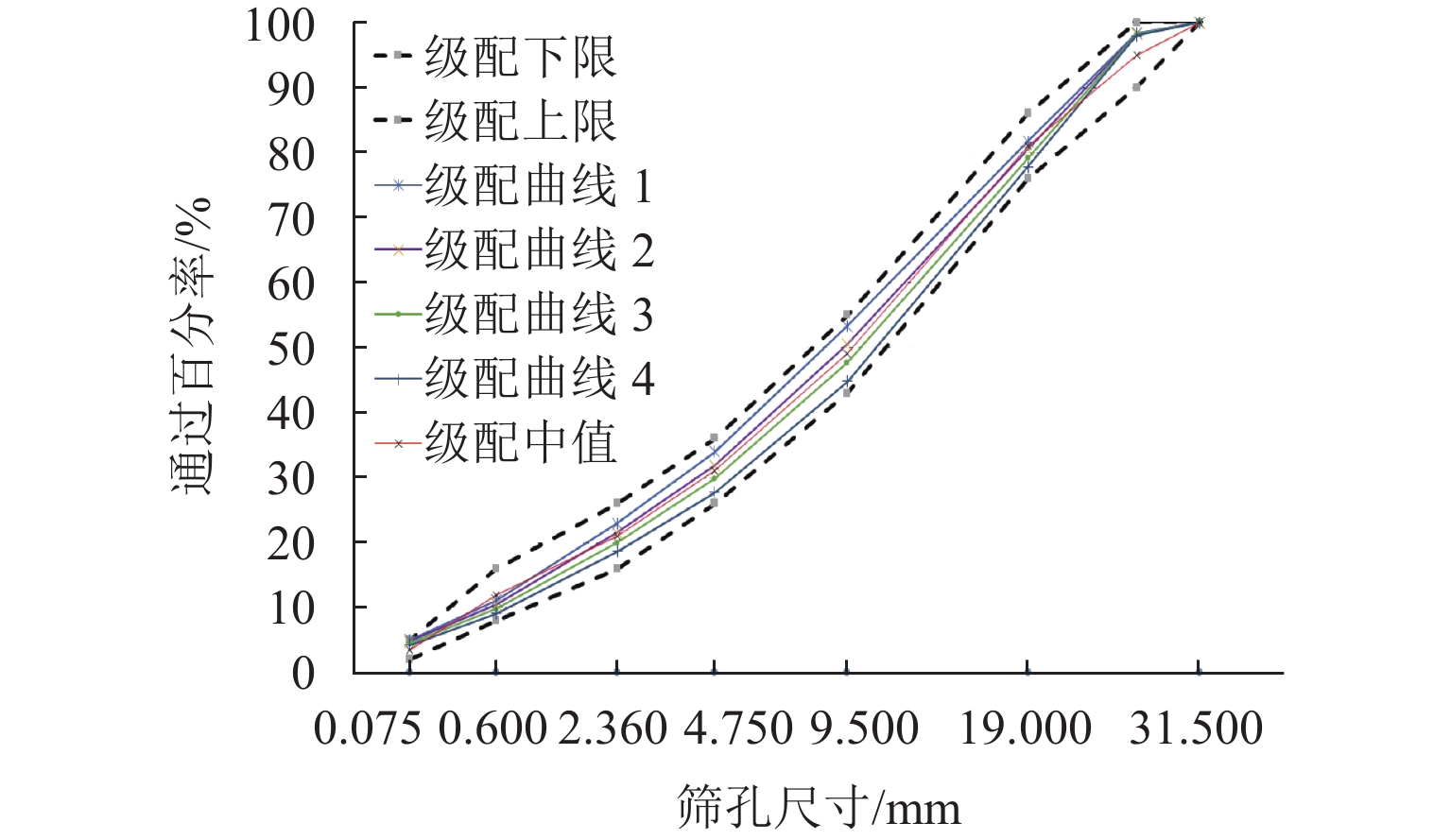

类型 压碎值/% 针片状含量/% 小于 0.075 mm 颗粒含量/% 表观相对密度 毛体积相对密度 吸水率/% 碎石 A 5.8 0.1 2.738 2.714 0.33 碎石 B 21.8 7.7 0.8 2.721 2.700 0.40 碎石 C 9.9 0.6 2.712 2.693 0.62 石粉 14.9 2.703 表 4 骨料各筛孔通过百分率

Table 4. Passing percentage of aggregates for each sieve opening

% 类型 粒径/mm 31.50 26.50 19.00 9.50 4.75 2.36 0.60 0.08 碎石 A 100.0 87.4 3.4 0.1 0.1 0.1 0.1 0.1 碎石 B 100.0 100.0 84.0 7.1 0.8 0.8 0.8 0.8 碎石 C 100.0 100.0 100.0 98.9 15.6 1.2 0.6 0.6 石粉 100.0 100.0 100.0 100.0 98.8 72.2 34.6 14.9 表 5 最大干密度、最佳含水率和7 d无侧限抗压强度

Table 5. Maximum dry density, optimal water content, and 7 d unconfined compressive strength

级配名称 最佳含水率/% 最大干密度/

(g•cm−3)7 d 无侧限抗压强度/MPa 合成级配 1 4.4 2.316 5.32 合成级配 2 4.8 2.400 6.19 合成级配 3 4.6 2.356 6.09 合成级配 4 4.8 2.373 5.76 表 6 不同冻融循环条件下的元素及质量分数

Table 6. Element content and mass fraction under different freeze-thaw cycle conditions

% 冻融条件 点位 Ca Si Na Al Ca/Al Ca/Si Si/Al Na/Si Na/Al 20~−20 ℃,冻融 5 次 1 27.21 2.22 0.80 1.21 22.50 12.26 1.83 0.36 0.66 2 42.91 1.96 0.40 1.21 35.50 21.89 1.62 0.20 0.33 3 40.69 0.87 0.18 0.43 94.60 46.77 2.02 0.21 0.42 4 37.48 2.77 0.67 1.66 22.60 13.53 1.67 0.24 0.40 5 45.95 0.90 0.23 0.31 148.00 51.06 2.90 0.26 0.74 20~−20 ℃,冻融 20 次 1 18.47 9.48 2.63 4.45 4.15 1.94 2.13 0.28 0.59 2 27.72 12.31 1.03 10.33 2.68 2.25 1.19 0.08 0.10 3 10.47 9.25 4.48 10.29 1.02 1.13 0.90 0.48 0.44 4 24.12 12.97 1.01 9.77 2.47 1.86 1.33 0.08 0.10 5 41.97 17.74 0.20 0.84 50.00 2.36 21.10 0.01 0.24 40~−20 ℃,冻融 5 次 1 14.33 14.95 0.86 7.23 1.98 0.95 2.07 0.06 0.12 2 22.49 5.78 2.30 4.03 5.58 3.89 1.43 0.40 0.57 3 23.61 4.56 1.45 2.32 10.20 5.17 1.97 0.32 0.63 4 25.08 5.44 1.45 2.62 9.57 4.61 2.08 0.27 0.55 5 15.65 12.69 3.66 7.86 1.99 1.23 1.61 0.29 0.47 40~−20 ℃,冻融 20 次 1 0.19 2.40 2.20 0.65 0.29 0.08 3.69 0.92 3.38 2 0.10 1.95 1.34 0.42 0.24 0.05 4.64 0.69 3.19 3 0.37 7.32 2.28 4.11 0.09 0.05 1.78 0.31 0.55 4 0.21 8.73 5.68 0.34 0.62 0.02 25.70 0.65 16.70 5 0.59 4.80 2.27 0.84 0.70 0.12 5.71 0.47 2.70 -

[1] 刘志强. 交通大国阔步迈向交通强国[N]. 2022-05-02. [2] 黄晓明. 路基路面工程[M]. 6版. 北京: 人民交通出版社, 2019. [3] 沈卫国, 郑小平, 李洪震, 等. 路面基层材料的分类及其服役状况综述[J]. 武汉理工大学学报, 2021, 43(9): 1-5.SHEN Weiguo, ZHENG Xiaoping, LI Hongzhen, et al. Review on classification and service status of road base cours[J]. Journal of Wuhan University of Technology, 2021, 43(9): 1-5. [4] 马淑杰, 张英健, 罗恩华, 等. 双碳背景下“十四五”大宗固废综合利用建议[J]. 中国投资(中英文), 2021(Z8): 22-25. [5] ZHANG J Z, YAO Z Y, WANG K, et al. Sustainable utilization of bauxite residue (red mud) as a road material in pavements: a critical review[J]. Construction and Building Materials, 2021, 270: 121419.1-121419.18. [6] XUE S G, JIANG Y F, ZHU F. Ecological disposal and large-scale utilization of bauxite residue: a long way to go[J]. Bulletin of Environmental Contamination and Toxicology, 2022, 109(1): 1-2. doi: 10.1007/s00128-022-03578-4 [7] 李帅, 周斌, 刘万超, 等. 赤泥综合利用产业化现状、存在问题及解决方略探讨[J]. 中国有色冶金, 2022, 51(5): 32-36.LI Shuai, ZHOU Bin, LIU Wanchao, et al. Status-quo, problems and solutions of red mud comprehensive utilization[J]. China Nonferrous Metallurgy, 2022, 51(5): 32-36. [8] CHEN R F, CAI G J, DONG X Q, et al. Mechanical properties and micro-mechanism of loess roadbed filling using by-product red mud as a partial alternative[J]. Construction and Building Materials, 2019, 216: 188-201. doi: 10.1016/j.conbuildmat.2019.04.254 [9] 陈瑞锋, 田高源, 米栋云, 等. 赤泥改性黄土的基本工程性质研究[J]. 岩土力学, 2018, 39(增1): 89-97.CHEN Ruifeng, TIAN Gaoyuan, MI Dongyun, et al. Study of basic engineering properties of loess modified by red mud[J]. Rock and Soil Mechanics, 2018, 39(S1): 89-97. [10] WANG C M, LIU H L, WU D, et al. Engineering and environmental evaluation of red mud amended volcanic ash as a sustainable subgrade material[J]. Journal of Cleaner Production, 2023, 393: 136353.1-136353.18. [11] 齐建召, 杨家宽, 王梅, 等. 赤泥做道路基层材料的试验研究[J]. 公路交通科技, 2005, 22(6): 30-33. doi: 10.3969/j.issn.1002-0268.2005.06.009QI Jianzhao, YANG Jiakuan, WANG Mei, et al. Experiment research on road base materi al of red mud[J]. Journal of Highway and Transportation Research and Development, 2005, 22(6): 30-33. doi: 10.3969/j.issn.1002-0268.2005.06.009 [12] 梁乃兴, 张登良, 颜祖兴. 水泥赤泥混凝土路用性能研究[J]. 中国公路学报, 1996(2): 6-11.LIANG Naixing, ZHANG Dengliang, YAN Zuxing. Research on properties of cement red mud concrete in highway pavement[J]. China Journal of Highway and Transport, 1996(2): 6-11. [13] LIU S T, LI Z Z, LI Y Y, et al. Strength properties of bayer red mud stabilized by lime-fly ash using orthogonal experiments[J]. Construction and Building Materials, 2018, 166: 554-563. doi: 10.1016/j.conbuildmat.2018.01.186 [14] 梁旭, 梁乃兴, 曾建民, 等. 水泥赤泥稳定级配碎石基层的性能研究[J]. 重庆交通大学学报(自然科学版), 2008, 27(6): 1086-1089.LIANG Xu, LIANG Naixing, ZENG Jianmin, et al. Performance study on cement and red mud stabilized graded crushed stones[J]. Journal of Chongqing Jiaotong University (Natural Science), 2008, 27(6): 1086-1089. [15] 唐双美, 张立明, 梁高荣, 等. 赤泥掺量对水泥稳定碎石基层性能影响[J]. 公路, 2022, 67(4): 91-94.TANG Shuangmei, ZHANG Liming, LIANG Gaorong, et al. Influence of red mud content on performance of cement stabilize macadam base[J]. Highway, 2022, 67(4): 91-94. [16] DEELWAL K, DHARAVATH K, KULSHRESHTHA M. Stabilization of red mud by lime, gypsum and investigating its possible use as a geotechnical material in the civil construction[J]. International Journal of Advances in Engineering & Technology, 2014, 7(4): 1238-1244. [17] SARATH CHANDRA K, KRISHNAIAH S. Strength and leaching characteristics of red mud (bauxite residue) as a geomaterial in synergy with fly ash and gypsum[J]. Transportation Research Interdisciplinary Perspectives, 2022, 13: 100566.1-100566.6. [18] ZHANG J, LI S C, LI Z F. Investigation the synergistic effects in quaternary binder containing red mud, blast furnace slag, steel slag and flue gas desulfurization gypsum based on artificial neural networks[J]. Journal of Cleaner Production, 2020, 273: 122972.1-122972.12. [19] 中华人民共和国交通运输部. 公路工程水泥及水泥混凝土试验规程: JTG 3420—2020[S]. 北京: 人民交通出版社, 2020. [20] 中华人民共和国交通运输部. 公路路面基层施工技术细则: JTG/T F20—2015[S]. 北京: 人民交通出版社, 2015. [21] 山东省市场监督管理局. 水泥稳定碎石基层施工技术规范: DB37/T 3577—2019[S]. 北京: 人民交通出版社, 2019. [22] 中华人民共和国交通运输部. 公路工程无机结合料稳定材料试验规程: JTG 3441—2024[S]. 北京: 人民交通出版社, 2024. [23] 杨利香, 宋兴福, 陆美荣, 等. 基于再生粗骨料裹浆厚度的含砂透水混凝土配合比设计方法[J]. 材料导报, 2022, 36(4): 111-117.YANG Lixiang, SONG Xingfu, LU Meirong, et al. The mixture proportioning design of sand-containing pervious concrete based on mortar thickness of recycled coarse aggregate[J]. Materials Reports, 2022, 36(4): 111-117. [24] LI S C, ZHANG J, LI Z F, et al. Feasibility study of red mud-blast furnace slag based geopolymeric grouting material: effect of superplasticizers[J]. Construction and Building Materials, 2021, 267: 120910.1-120910.13. [25] 夏冬桃, 吴晨, 崔凯, 等. 粉煤灰和硅灰取代率对碱矿渣混凝土力学性能影响分析[J]. 西南交通大学学报, 2024, 59(5): 1113-1122.XIA Dongtao, WU Chen, CUI Kai, et al. Effect of fly ash and silica fume contents on mechanical properties of alkali-activated slag-based concrete [J]. Journal of Southwest Jiaotong University, 2024, 59(5): 1113-1122. [26] 李茂红, 张雨杰, 陈航, 等. 粉煤灰矿渣掺量对劣级配砂配制混凝土性能的影响[J]. 西南交通大学学报, 2015, 50(2): 342-346, 353. doi: 10.3969/j.issn.0258-2724.2015.02.021LI Maohong, ZHANG Yujie, CHEN Hang, et al. Effect of dosage of fly ash and blast furnace slag on performance of concrete prepared with poorly graded sand[J]. Journal of Southwest Jiaotong University, 2015, 50(2): 342-346, 353. doi: 10.3969/j.issn.0258-2724.2015.02.021 [27] 赵人达, 杨世玉, 贾文涛, 等. 粉煤灰基地聚物混凝土的耐久性研究新进展[J]. 西南交通大学学报, 2021, 56(5): 1065-1074.ZHAO Renda, YANG Shiyu, JIA Wentao, et al. Review of recent progress in durability of fly ash based geopolymer concrete[J]. Journal of Southwest Jiaotong University, 2021, 56(5): 1065-1074. [28] 王一琪. 荷载-冻融作用下水泥稳定碎石基层材料损伤研究[D]. 哈尔滨: 哈尔滨工业大学, 2017. -

下载:

下载: