Experimental Study on Injection Stability of Common Rail Injector Based on Spray Momentum Method

-

摘要:

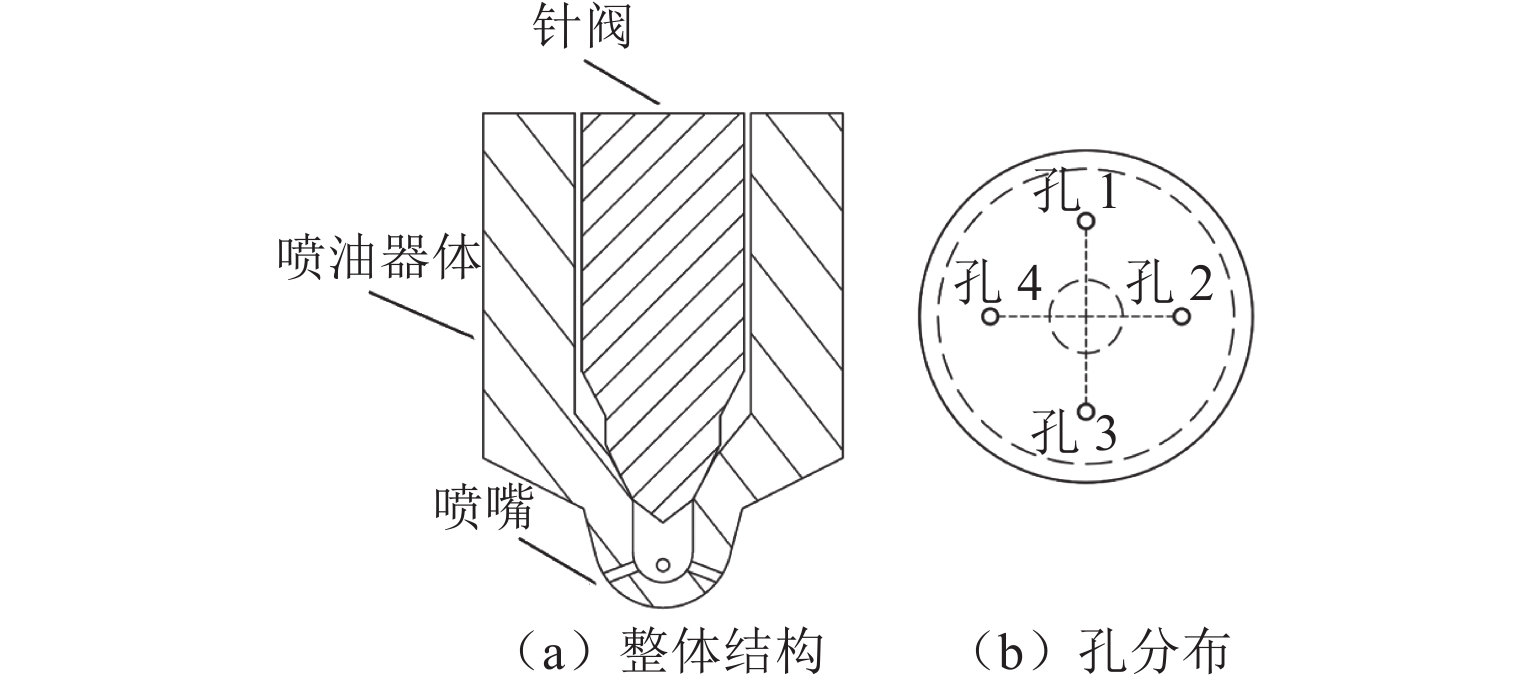

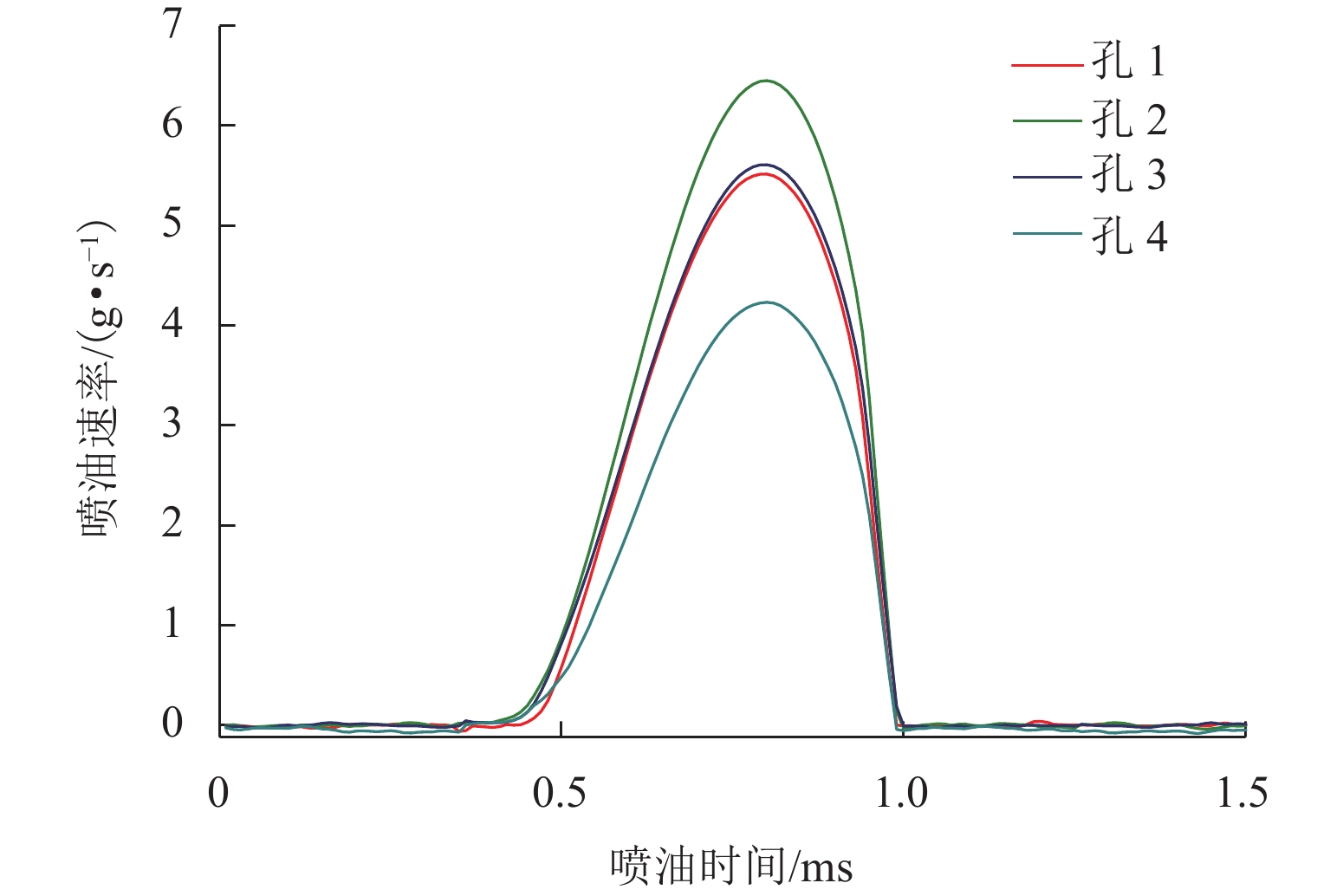

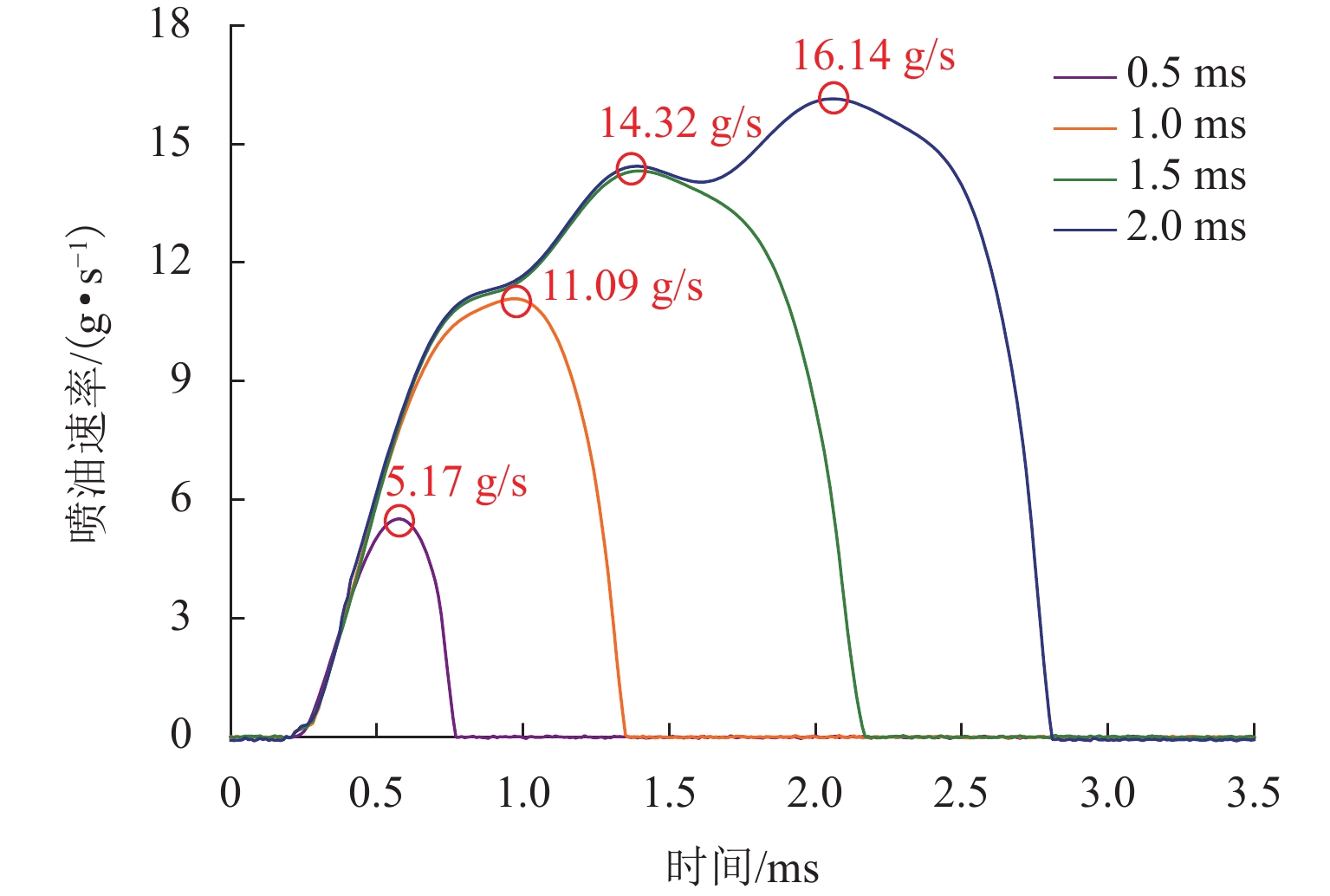

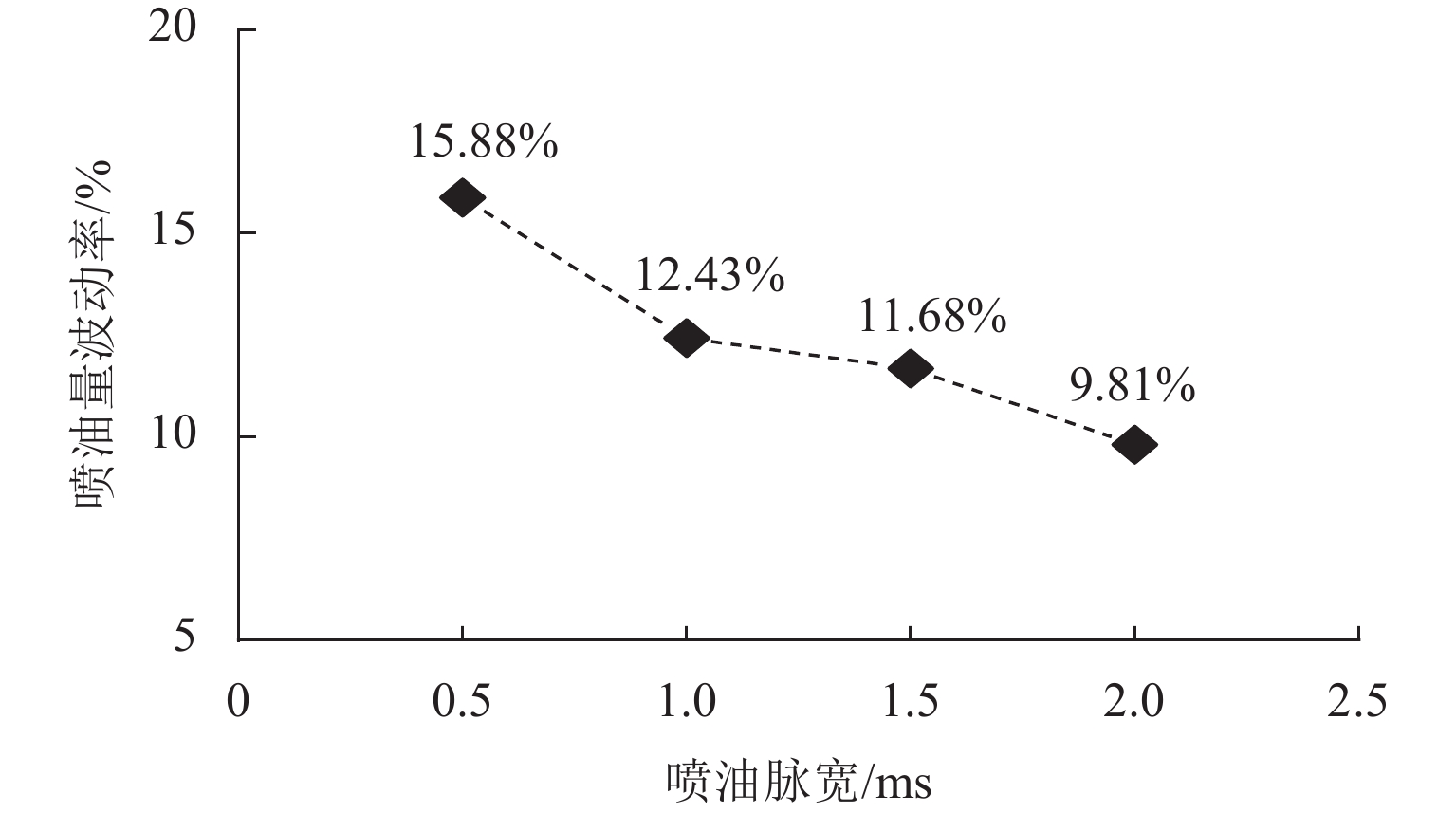

为研究共轨喷油器各喷孔喷油规律,根据动量法研发了多孔喷油器喷油规律测量装置;在不同的负荷工况下,使用研发的装置测量喷油器各喷孔的喷油量差异性,并与商业单次喷射仪EMI 2的测量结果进行对比;在不同的喷油压力下,针对单一喷孔进行喷孔喷油稳定性研究. 研究结果表明:在低喷油压力下,喷油量波动率随着喷油脉宽的增加而降低,整体上喷油量波动率为10%~20%,此时针阀无法完全打开,针阀-针阀座之间燃油的不稳定流动会造成较大的喷油量波动;在高喷油压力下,针阀更容易达到最大升程,喷孔参数间的不一致性是导致喷孔喷油量波动的关键因素,在0.5~2.0 ms的喷油脉宽范围内,喷油量波动率处于5%之内,远小于相同条件低喷油压力下的喷孔喷油量波动率,针阀无法达到最大升程是导致共轨喷油器喷油不稳定性的主要原因.

Abstract:In order to study the injection law of each nozzle hole of the common rail injector, an injection pattern measuring device for multi-hole injectors was developed based on the momentum method. Under different load conditions, the developed device was used to measure the injection rate of each nozzle hole of the injector, and the difference was compared with the measurement results of the commercial single injection instrument EMI 2. Under different injection pressures, the injection stability of the single injection hole was studied. The research findings indicate that at low injection pressure, the fluctuation rate of the injection decreases with increasing injection pulse width, with an overall fluctuation rate of 10%–20%. At this point, the needle valve cannot fully open, leading to significant fluctuations in the injection due to unstable fuel flow between the needle valve and its seat. At high injection pressure, the needle valve is more likely to reach maximum lift, and thus the inconsistency in nozzle hole parameters becomes the key factor causing fluctuations in the nozzle hole injection. Within the range of injection pulse width of 0.5–2.0 ms, the fluctuation rate of the injection is within 5%, much lower than the fluctuation rate of nozzle hole injection under low injection pressure conditions. This indicates that the inability of the needle valve to reach maximum lift is the primary cause of injection instability in common rail injectors.

-

表 1 力传感器主要性能指标

Table 1. Main performance indicators of force sensor

指标 数值 量程/N 0~20 输出精度/% 0.05 响应频率/kHz 10 工作温度/℃ −20~80 -

[1] SHAHANGIAN N, SHARIFIAN L, UEHARA K, et al. Transient nozzle flow simulations of gasoline direct fuel injectors[J]. Applied Thermal Engineering, 2020, 175: 115356.1-115356.12. [2] FENG Z H, ZHAN C, TANG C L, et al. Experimental investigation on spray and atomization characteristics of diesel/gasoline/ethanol blends in high pressure common rail injection system[J]. Energy, 2016, 112: 549-561. doi: 10.1016/j.energy.2016.06.131 [3] GUI H X, XUE J, LI Y, et al. Research on carbon emissions reduction strategy considering government subsidy and free riding behavior[J]. Environmental Engineering Science, 2022, 39(4): 329-341. doi: 10.1089/ees.2021.0192 [4] LEE C. An experimental study on advanced injection rate measurement of a marine engine using the Zeuch method[J]. Journal of Thermal Science and Technology, 2016, 11(2): JTST0026.1-JTST0026.11. [5] BOSCH W. The fuel rate indicator: a new measuring instrument for display of the characteristics of individual injection[C]//SAE Technical Paper Series. Warrendale: SAE International, 1966: 641-622. [6] MARCIC M. New diesel injection nozzle flow measuring device[J]. Review of Scientific Instruments, 2000, 71(4): 1876-1882. doi: 10.1063/1.1150556 [7] SUH H K, PARK S W, LEE C S. Effect of piezo-driven injection system on the macroscopic and microscopic atomization characteristics of diesel fuel spray[J]. Fuel, 2007, 86(17/18): 2833-2845. [8] PAYRI R, GARCÍA A, DOMENECH V, et al. An experimental study of gasoline effects on injection rate, momentum flux and spray characteristics using a common rail diesel injection system[J]. Fuel, 2012, 97: 390-399. doi: 10.1016/j.fuel.2011.11.065 [9] POSTRIOTI L, BUITONI G, PESCE F C, et al. Zeuch method-based injection rate analysis of a common-rail system operated with advanced injection strategies[J]. Fuel, 2014, 128: 188-198. doi: 10.1016/j.fuel.2014.03.006 [10] CAVICCHI A, POSTRIOTI L. Simultaneous needle lift and injection rate measurement for GDI fuel injectors by laser Doppler vibrometry and Zeuch method[J]. Fuel, 2021, 285: 119021.1-119021.9. [11] DESANTES J M, PAYRI R, GARCÍA A, et al. Experimental study of biodiesel blends’ effects on diesel injection processes[J]. Energy & Fuels, 2009, 23(6): 3227-3235. [12] LUO F Q, CUI H F, DONG S F. Transient measuring method for injection rate of each nozzle hole based on spray momentum flux[J]. Fuel, 2014, 125: 20-29. doi: 10.1016/j.fuel.2014.02.011 [13] FAGHANI E, KIRCHEN P, ROGAK S N. Application of fuel momentum measurement device for direct injection natural gas engines[C]//SAE Technical Paper Series. Warrendale: SAE International, 2015: 1-11. [14] DOCQUIER N. Influence of fresh charge preparation and composition on auto-ignition delays and combustion development in an optical HCCI direct injection diesel engine[C]//SAE Technical Paper Series. Warrendale: SAE International, 2003: 1-14. [15] SHAO L M, LIU Z M, ZHOU J D, et al. Study on the influence of electronic injector nozzle geometry on the injection rate[C]//2009 9th International Conference on Electronic Measurement & Instruments. Beijing: IEEE, 2009: 773-777. [16] 杨朝盛. 测量系统分析(MSA)实用指南[M]. 北京:机械工业出版社,2020. [17] PAYRI R, BRACHO G, SORIANO J A, et al. Nozzle rate of injection estimation from hole to hole momentum flux data with different fossil and renewable fuels[J]. Fuel, 2020, 279: 118404.1-118404.10. -

下载:

下载: