Determination Method of Rock Strength Based on Digital Drilling Parameters

-

摘要:

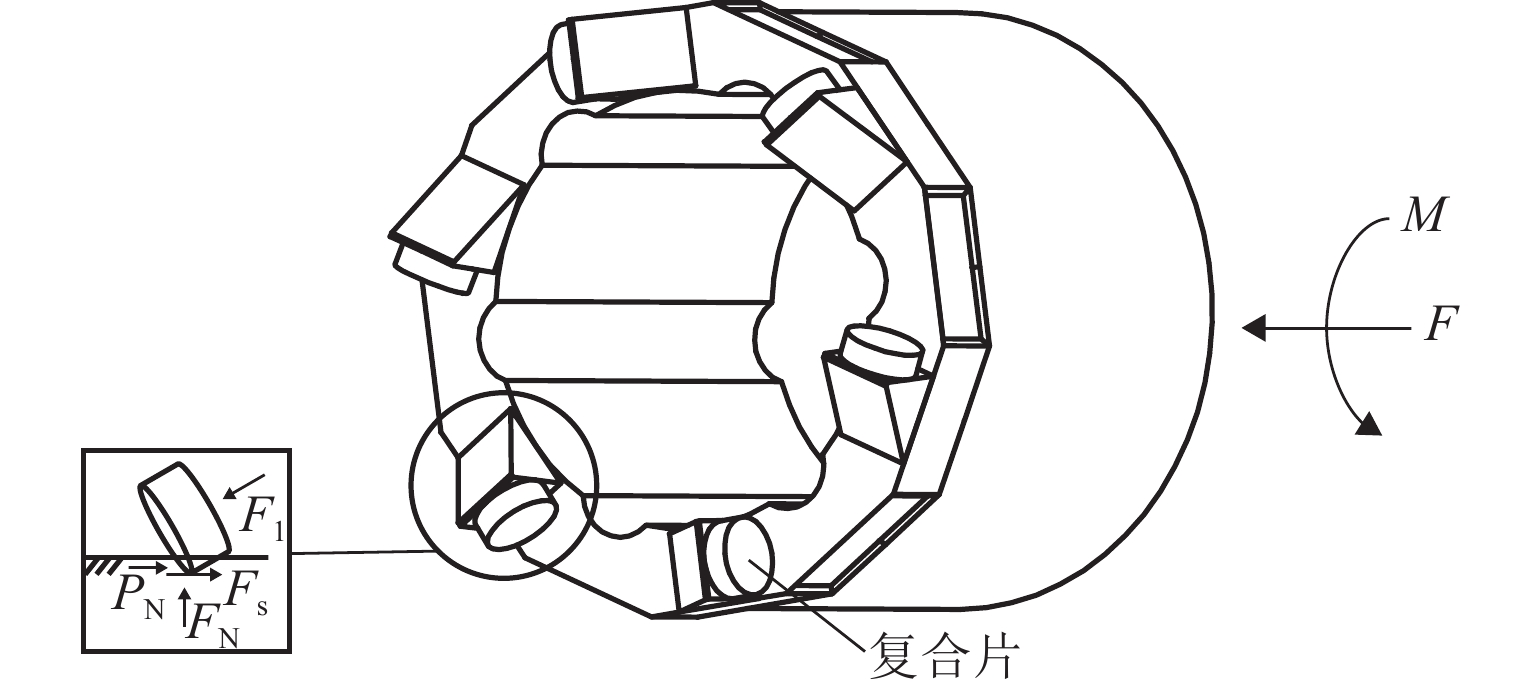

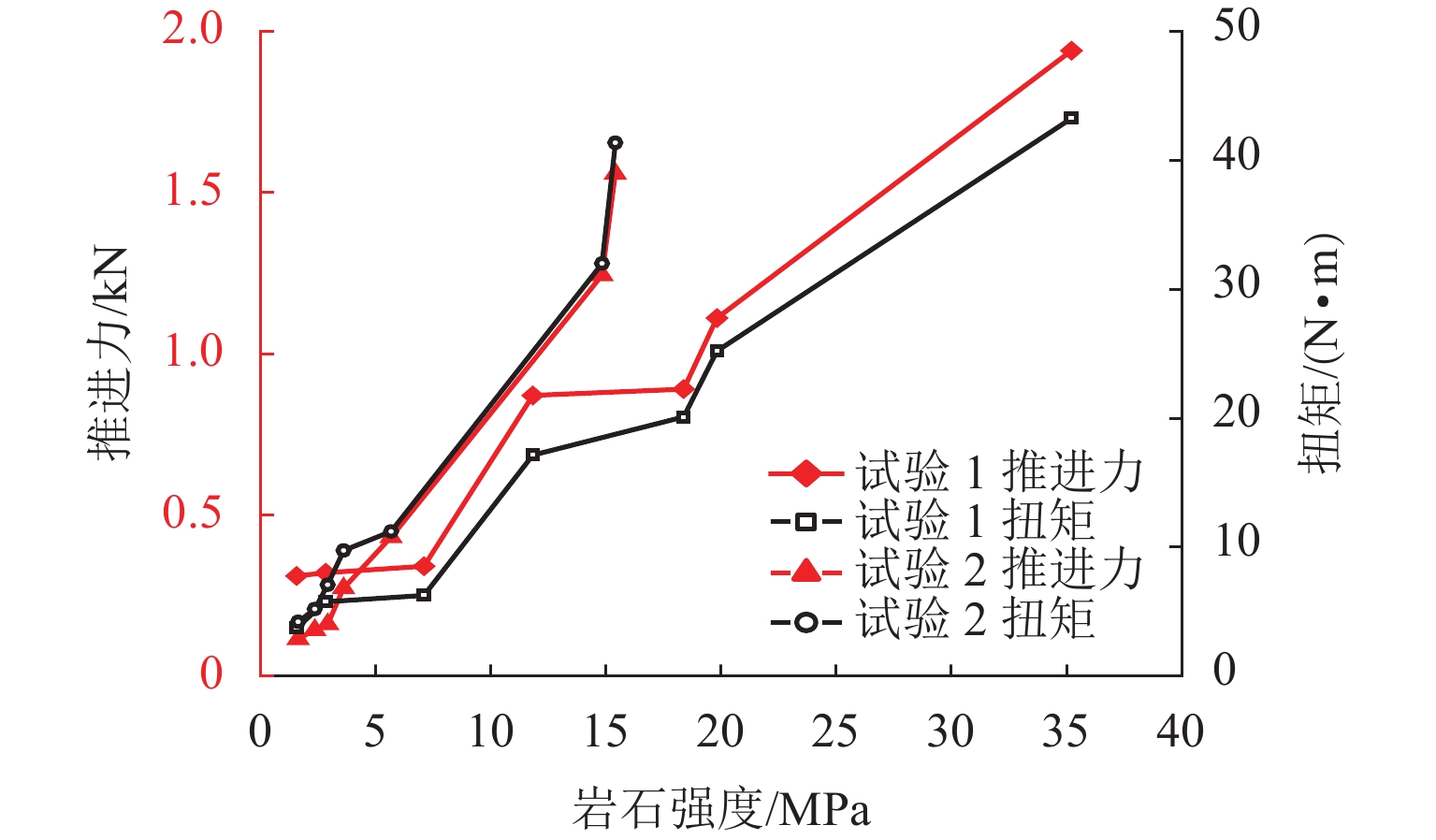

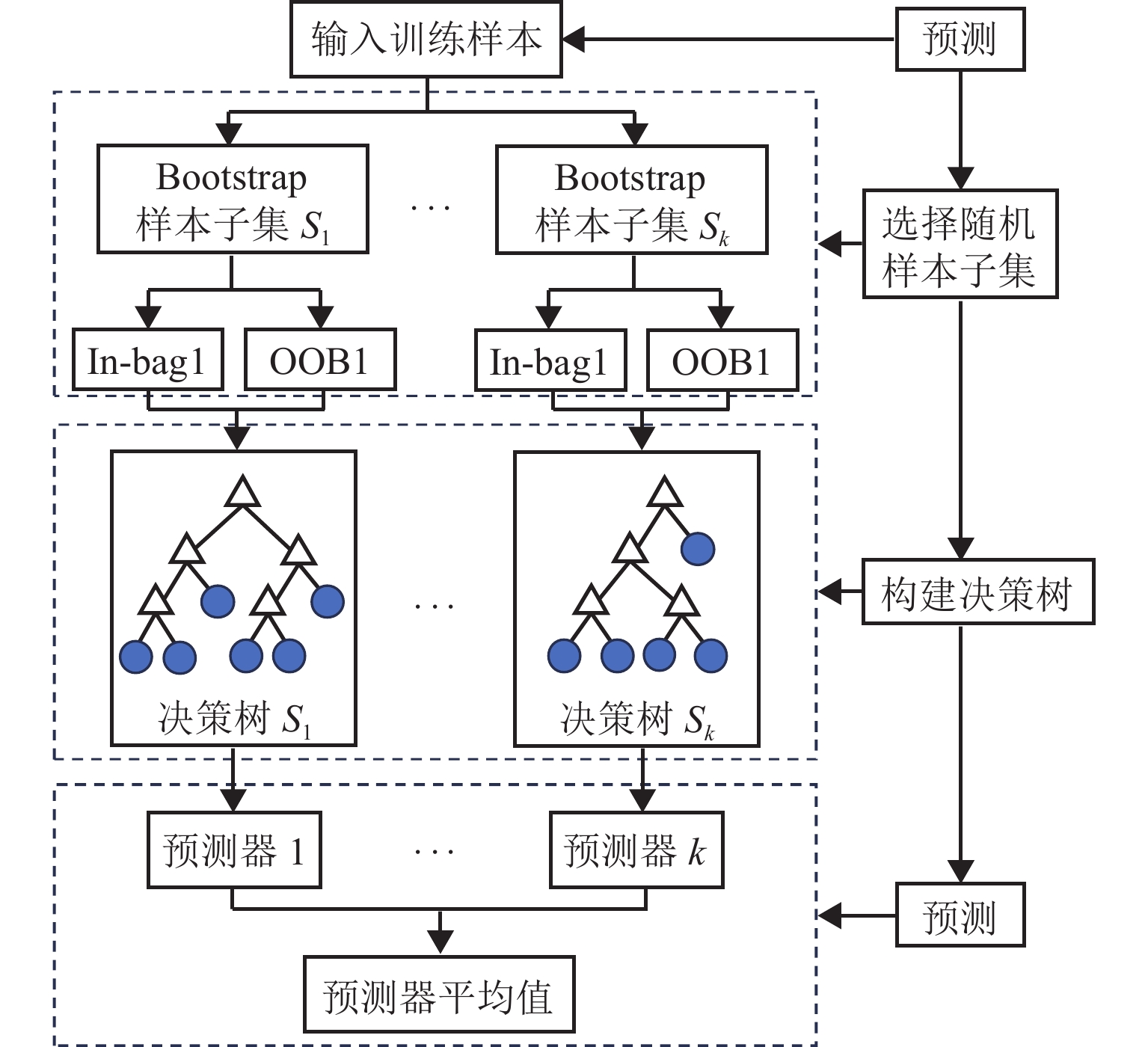

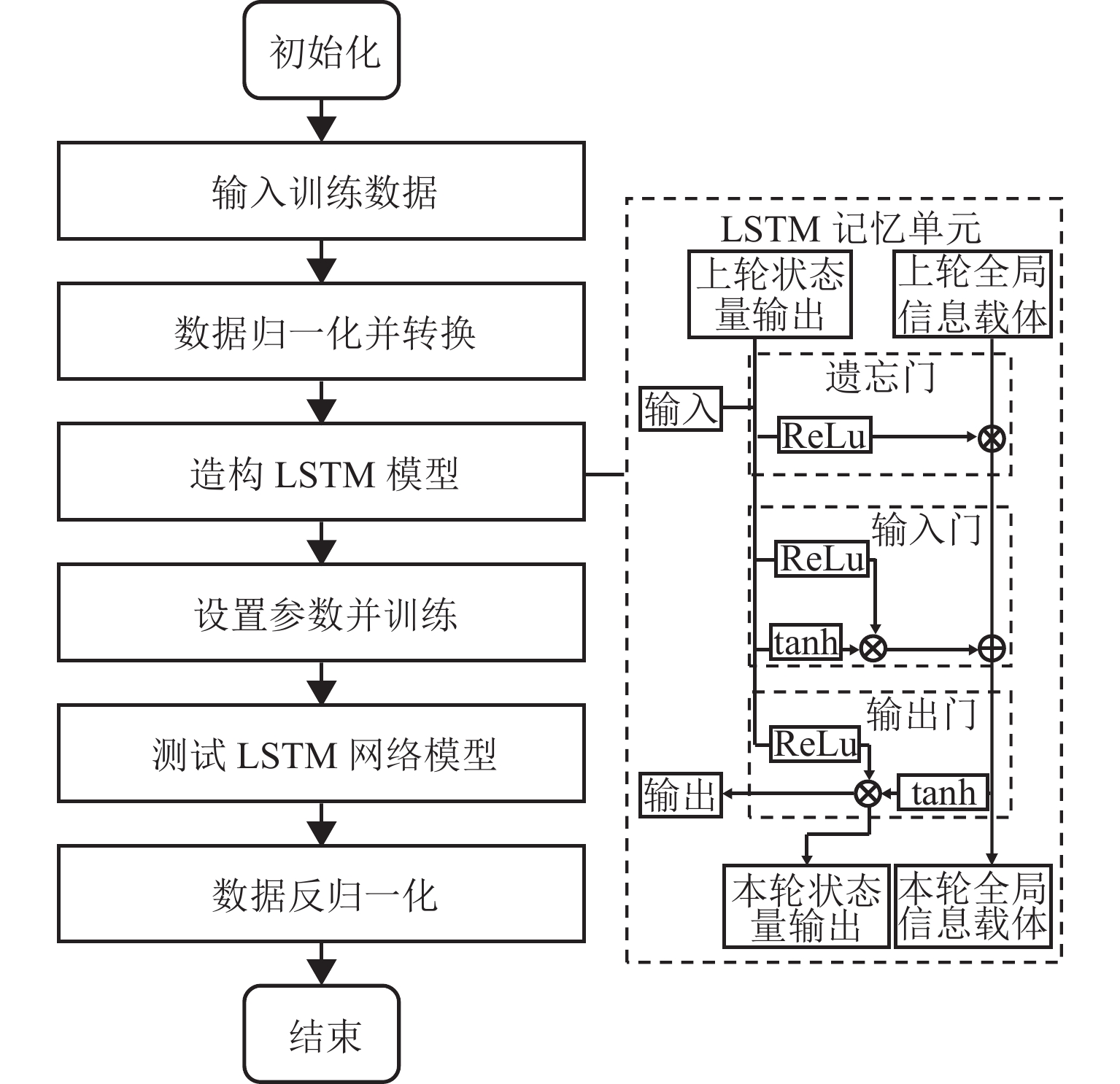

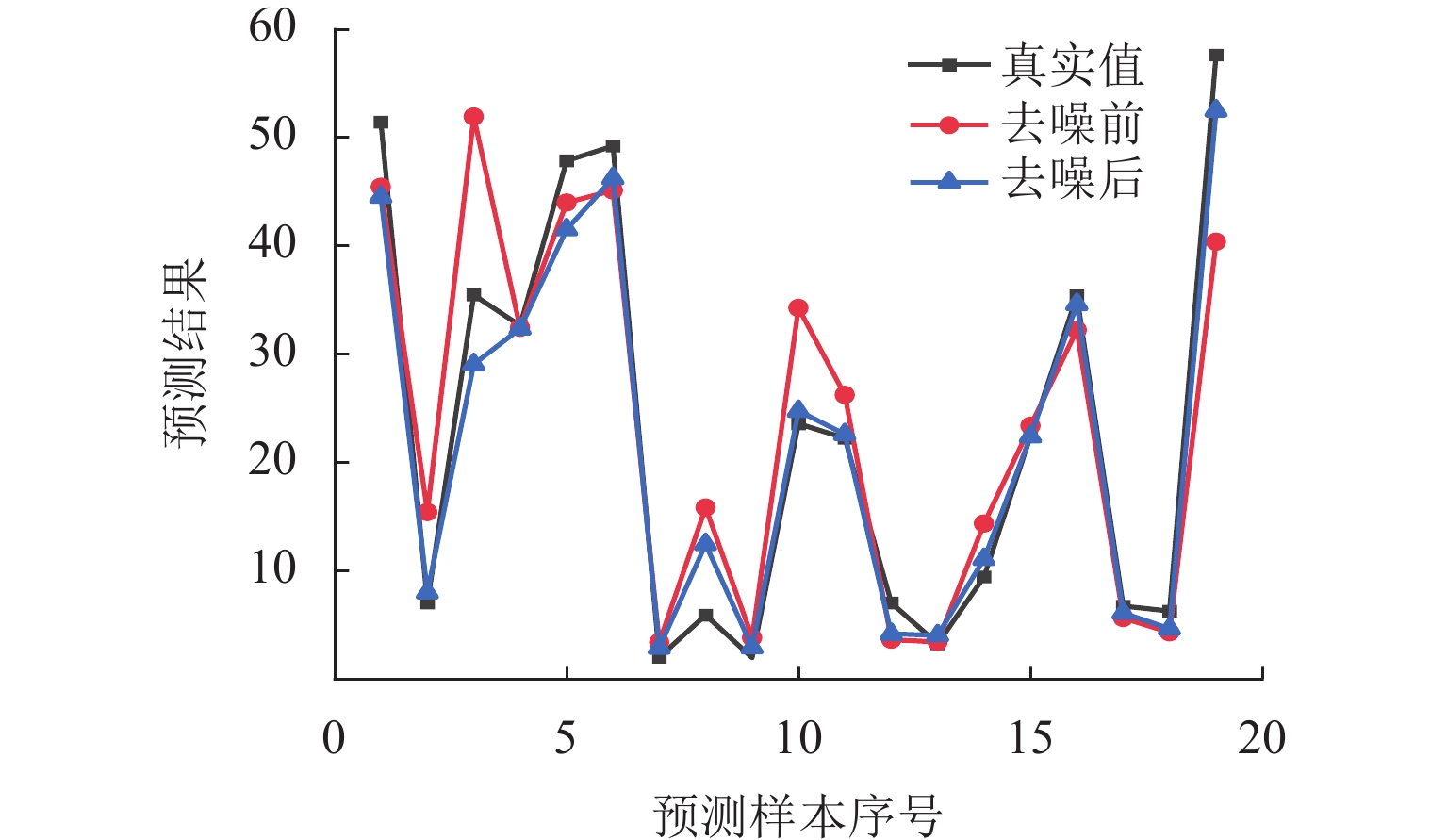

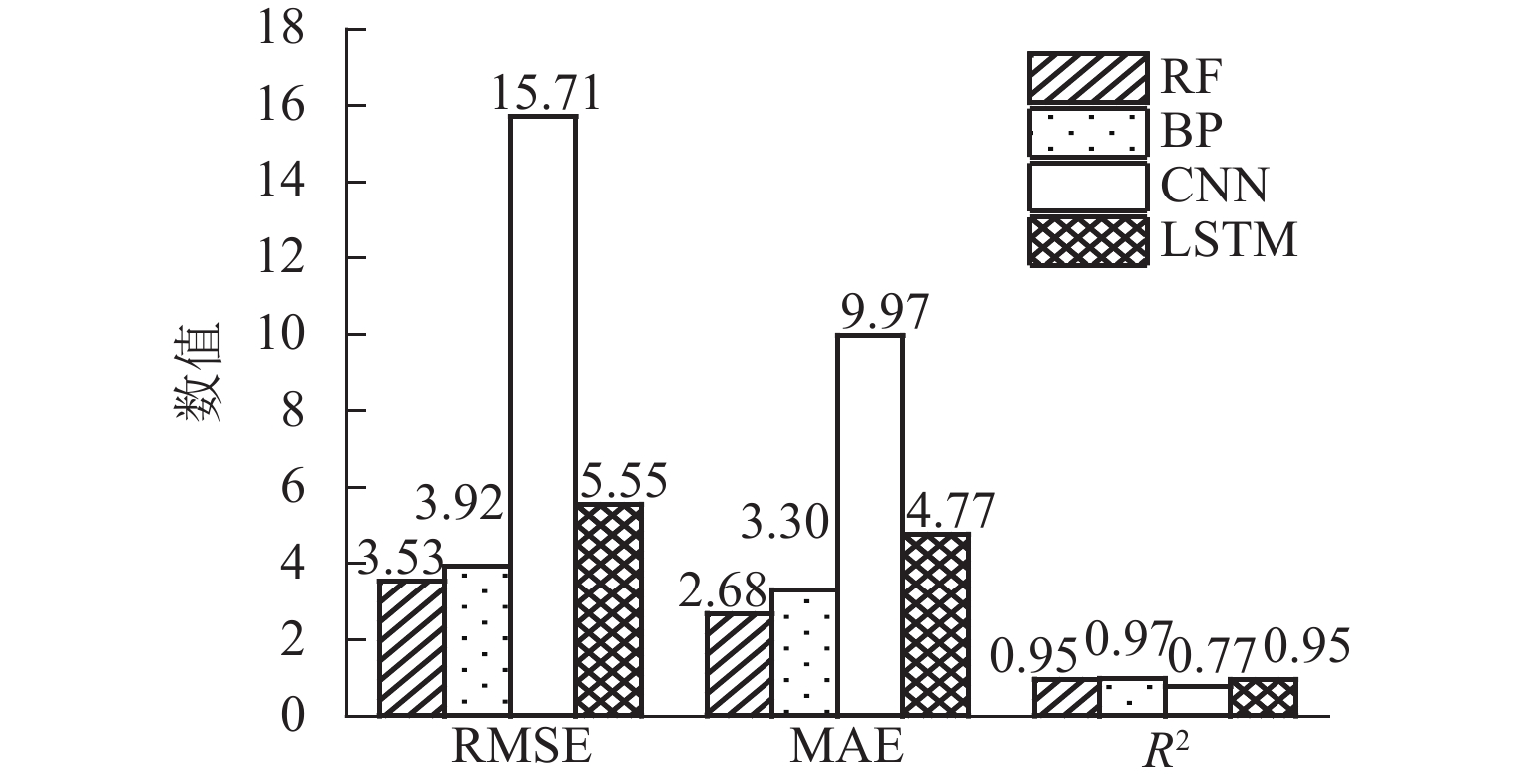

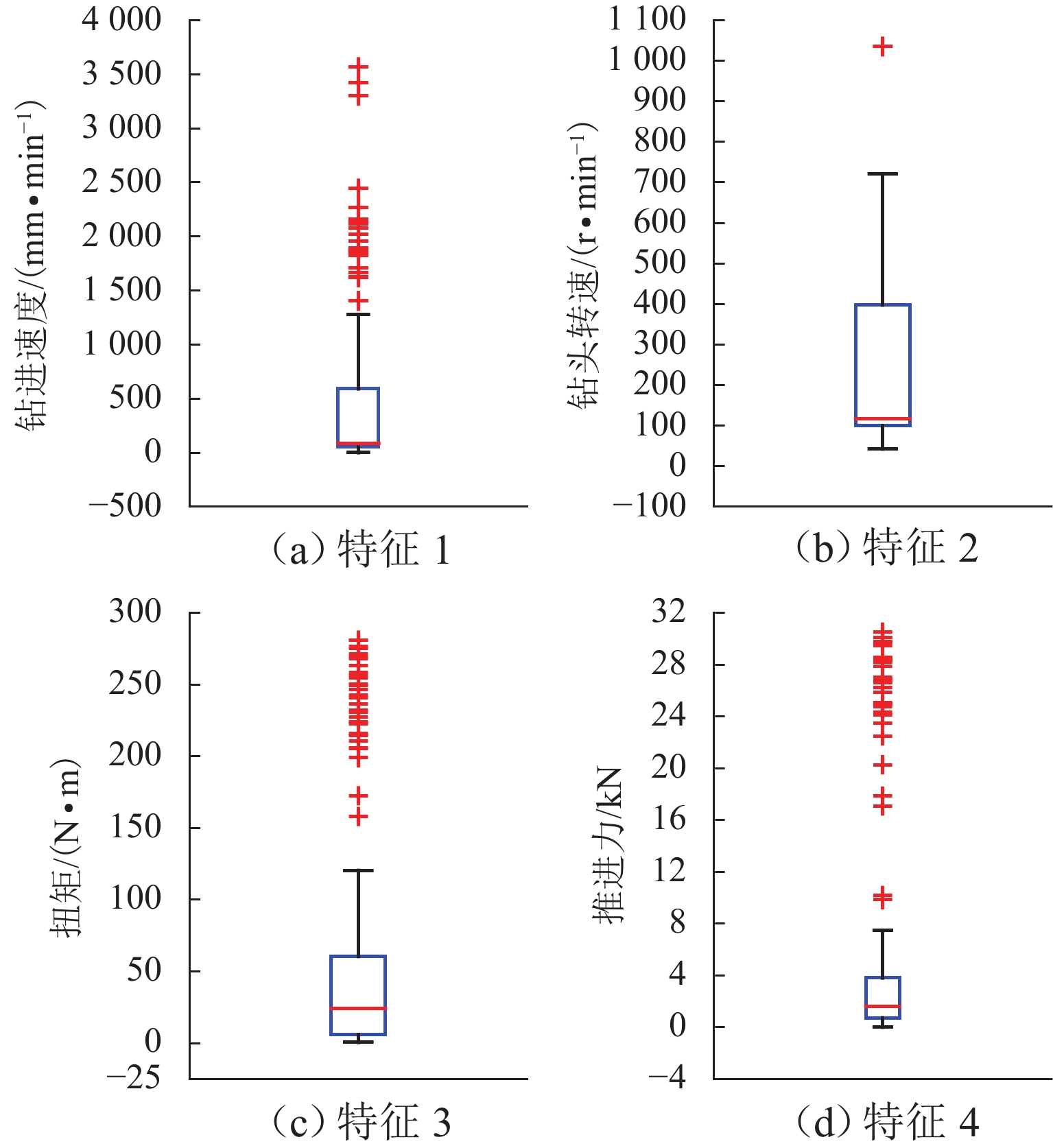

岩石强度是衡量岩石稳定性和安全性的关键参数,而高效准确地预测岩石强度可以有效指导隧道的开挖和支护工作. 本文收集分析源于不同设备的数字钻进参数和岩石力学性质相关数据,基于钻进过程中的能量传递分析建立数字钻进参数与单轴抗压强度的定量关系;采用机器学习方法建立基于钻进参数的岩石强度预测模型,选择BP (back-propagation)神经网络、随机森林、卷积神经网络和长短期记忆网络4种算法比较不同算法的预测效果,最终确定最优模型. 结果显示:相对于理论公式和其他3种机器学习算法,BP神经网络算法在岩石强度预测中表现优秀,其预测结果的均方根误差为5.794,平均绝对误差为4.129,相关系数为

0.9749 .Abstract:Rock strength is a critical parameter for assessing rock stability and safety. Efficient and accurate prediction of rock strength can effectively guide tunnel excavation and support. Digital drilling parameters and mechanical property data of rock were collected from various devices. By analyzing energy transfer during the drilling process, a quantitative relationship between digital drilling parameters and uniaxial compressive strength (UCS) was established. Meanwhile, machine learning methods were employed to develop a rock strength prediction model based on drilling parameters. Four algorithms, including a back-propagation (BP) neural network, random forest, convolutional neural network (CNN), and long short-term memory network were chosen to compare their prediction effects and identify the optimal model. The results indicate that compared to the theoretical formulas and the other three machine learning algorithms, the BP neural network algorithm excels in rock strength prediction, with a root mean square error of 5.794, a mean absolute error of 4.129, and a correlation coefficient of

0.9749 .-

Key words:

- drilling parameters /

- energy method /

- compressive strength /

- neural networks /

- random forests

-

表 1 232组数字钻进样本

Table 1. 232 groups of digital drilling samples

组数 来源 强度/MPa 岩石类型 30 组 文献[9] 49.80~61.91 较硬砂岩 1.90~30.81 砂浆试件 45 组 文献[10] 1.98~116.09 砂岩 51 组 文献[11] 2.50~9.00 砂浆试件 36 组 文献[12] 49.80~61.91 较硬砂岩 1.90~35.21 砂浆试件 24 组 文献[13] 48.35~55.68 较硬砂岩 1.56~36.05 砂浆试件 6 组 文献[14] 81.90/69.20/

49.80/49.20完整花岗岩/灰岩/

粉砂岩/砂岩9.40 破碎砂岩 28.10 注浆砂岩 15 组 文献[15] 58.29/约10.89/19.98 完整/破碎/注浆砂岩 75.23/约13.44/21.23 完整/破碎/注浆灰岩 约9.11/约33.45/18.99 完整/破碎/注浆泥岩 1.59~16.49 砂浆试件 25 组 文献[16-17] 1.63~20.80 砂浆试件 表 2 部分样本数据

Table 2. Part of sample data

序号 V/

( mm·min−1)N/

(r·min−1)M/

(N·m)F/

kN岩石强

度/MPa1 105.70 100.00 6.19 0.03 3.29 2 87.94 100.00 7.30 0.02 2.58 3 138.95 100.00 8.38 0.05 3.22 4 124.80 50.00 17.01 0.03 2.37 5 118.08 100.00 21.44 2.07 10.60 6 132.05 100.00 22.34 2.15 10.54 7 83.85 50.00 28.77 2.79 10.23 8 85.18 99.71 48.25 3.86 28.10 表 3 数据集样本参数统计

Table 3. Dataset sample parameters

取值类型 F/kN M/(N·m) V/

(mm·min−1)N/

(r·min−1)UCS/

MPa最小值 0.01 0.42 0.19 41.92 1.59 最大值 30.51 280.95 3566.00 1035.00 194.58 中位值 1.49 22.34 85.66 100.32 16.24 平均值 6.34 63.40 468.23 222.84 30.69 标准差 9.96 88.01 757.52 192.39 37.30 表 4 岩石强度计算结果

Table 4. Results of rock strength calculation

序号 真实值/MPa 计算值/MPa 相对误差/% 1 3.29 2.61 10.10 2 2.58 3.14 21.80 3 3.22 2.29 28.93 4 2.37 15.89 24.81 5 10.60 2.21 32.76 6 10.54 4.27 38.98 7 10.23 1.97 30.54 8 28.10 1.07 31.62 表 5 预测结果对比

Table 5. Comparison of prediction results

序号 真实值/

MPa理论计算

值/MPaBP 预测

值/MPa理论计算

误差/%机器学习

误差/%1 3.29 2.23 4.58 32.20 8.93 2 2.58 3.15 5.11 22.27 20.60 3 3.22 2.32 5.06 27.99 5.04 4 2.37 2.63 1.95 10.86 17.52 5 10.60 7.30 11.89 31.18 12.19 6 10.54 7.21 12.33 31.60 16.96 7 10.23 8.40 7.45 17.93 17.40 8 28.10 19.81 34.35 29.51 22.24 -

[1] 王玉杰,佘磊,赵宇飞,等. 基于数字钻进技术的岩石强度参数测定试验研究[J]. 岩土工程学报,2020,42(9): 1669-1678.WANG Yujie, SHE Lei, ZHAO Yufei, et al. Experimental study on measurement of rock strength parameters based on digital drilling technology[J]. Chinese Journal of Geotechnical Engineering, 2020, 42(9): 1669-1678. [2] 佘磊. 岩石强度与耐磨性参数的数字钻进测定技术研究[D]. 西安:西安理工大学,2019. [3] 谭卓英. 金刚石钻进能量在风化花岗岩地层中的变化特征[J]. 岩土工程学报,2007,29(9): 1303-1306.TAN Zhuoying. Variation characteristics of penetrating energy for diamond drilling in weathered granite formation[J]. Chinese Journal of Geotechnical Engineering, 2007, 29(9): 1303-1306. [4] 田昊,李术才,薛翊国,等. 基于钻进能量理论的隧道凝灰岩地层界面识别及围岩分级方法[J]. 岩土力学,2012,33(8): 2457-2464.TIAN Hao, LI Shucai, XUE Yiguo, et al. Identification of interface of tuff stratum and classfication of surrounding rock of tunnel using drilling energy theory[J]. Rock and Soil Mechanics, 2012, 33(8): 2457-2464. [5] MUNOZ H, TAHERI A, CHANDA E K. Rock drilling performance evaluation by an energy dissipation based rock brittleness index[J]. Rock Mechanics and Rock Engineering, 2016, 49(8): 3343-3355. doi: 10.1007/s00603-016-0986-0 [6] 王琦,孙会彬,江贝,等. 基于数字钻探和支持向量机预测岩体单轴抗压强度的方法[J]. 岩土力学,2019,40(3): 1221-1228.WANG Qi, SUN Huibin, JIANG Bei, et al. A method for predicting uniaxial compressive strength of rock mass based on digital drilling test technology and support vector machine[J]. Rock and Soil Mechanics, 2019, 40(3): 1221-1228. [7] 陈庆贺. 岩石力学参数随钻预测实验研究[D]. 徐州:中国矿业大学,2022. [8] 宋超,赵腾远,许领. 基于贝叶斯高斯过程回归与模型选择的岩石单轴抗压强度估计方法[J]. 岩土工程学报,2023,45(8): 1664-1673.SONG Chao, ZHAO Tengyuan, XU Ling. Estimation of uniaxial compressive strength based on fully Bayesian Gaussian process regression and model class selection[J]. Chinese Journal of Geotechnical Engineering, 2023, 45(8): 1664-1673. [9] 江贝,马凤林,王琦,等. 基于切削理论的数字钻探参数与岩石单轴抗压强度关系研究[J]. 中南大学学报(自然科学版),2021,52(5): 1601-1609.JIANG Bei, MA Fenglin, WANG Qi, et al. Study on the relationship between digital drilling parameters and uniaxial compressive strength of rock based on cutting theory[J]. Journal of Central South University (Science and Technology), 2021, 52(5): 1601-1609. [10] 何明明. 基于旋切触探技术的岩体力学参数预报研究[D]. 西安:西安理工大学,2017. [11] 牛钢钢. 基于钻机响应特征的岩体质量评价理论与应用[D]. 徐州:中国矿业大学,2022. [12] 高松. 岩石力学参数数字钻探快速预测技术研究[D]. 济南:山东大学,2018. [13] GAO H K, WANG Q, JIANG B, et al. Relationship between rock uniaxial compressive strength and digital core drilling parameters and its forecast method[J]. International Journal of Coal Science & Technology, 2021, 8(4): 605-613. [14] 王琦,高红科,蒋振华,等. 地下工程围岩数字钻探测试系统研发与应用[J]. 岩石力学与工程学报,2020,39(2): 301-310.WANG Qi, GAO Hongke, JIANG Zhenhua, et al. Development and application of a surrounding rock digital drilling test system of underground engineering[J]. Chinese Journal of Rock Mechanics and Engineering, 2020, 39(2): 301-310. [15] WANG Q, GAO H K, YU H C, et al. Method for measuring rock mass characteristics and evaluating the grouting-reinforced effect based on digital drilling[J]. Rock Mechanics and Rock Engineering, 2019, 52(3): 841-851. doi: 10.1007/s00603-018-1624-9 [16] 孙鑫,张少华,程敬义,等. 基于MLR-RBF的岩石强度智能随钻识别实验研究[J]. 采矿与安全工程学报,2022,39(5): 981-991. [17] 孙鑫. 基于锚固孔随钻参数的岩石强度量化识别研究[D]. 徐州:中国矿业大学,2021. [18] 李田军. PDC钻头破碎岩石的力学分析与机理研究[D]. 武汉:中国地质大学,2012. [19] 李骞. 岩石的切削强度特性及岩体力学参数的旋切触探试验研究[D]. 西安:西安理工大学,2016. [20] INABA T, NISHIDA M, KANEKO K, et al. Static rock breaker using shape memory alloy[J]. 7th ISRM Congress, 1991, 2: 1005-1008 [21] 谭卓英,岳中琦,蔡美峰. 风化花岗岩地层旋转钻进中的能量分析[J]. 岩石力学与工程学报,2007,26(3): 478-483.TAN Zhuoying, YUE Zhongqi, CAI Meifeng. Analysis of energy for rotary drilling in weathered granite formation[J]. Chinese Journal of Rock Mechanics and Engineering, 2007, 26(3): 478-483. [22] GOWIDA A, ELKATATNY S, GAMAL H. Unconfined compressive strength (UCS) prediction in real-time while drilling using artificial intelligence tools[J]. Neural Computing and Applications, 2021, 33(13): 8043-8054. doi: 10.1007/s00521-020-05546-7 -

下载:

下载: