Calculations for Transition Displacement and Design Optimization for Moveable Point Frog

-

摘要:

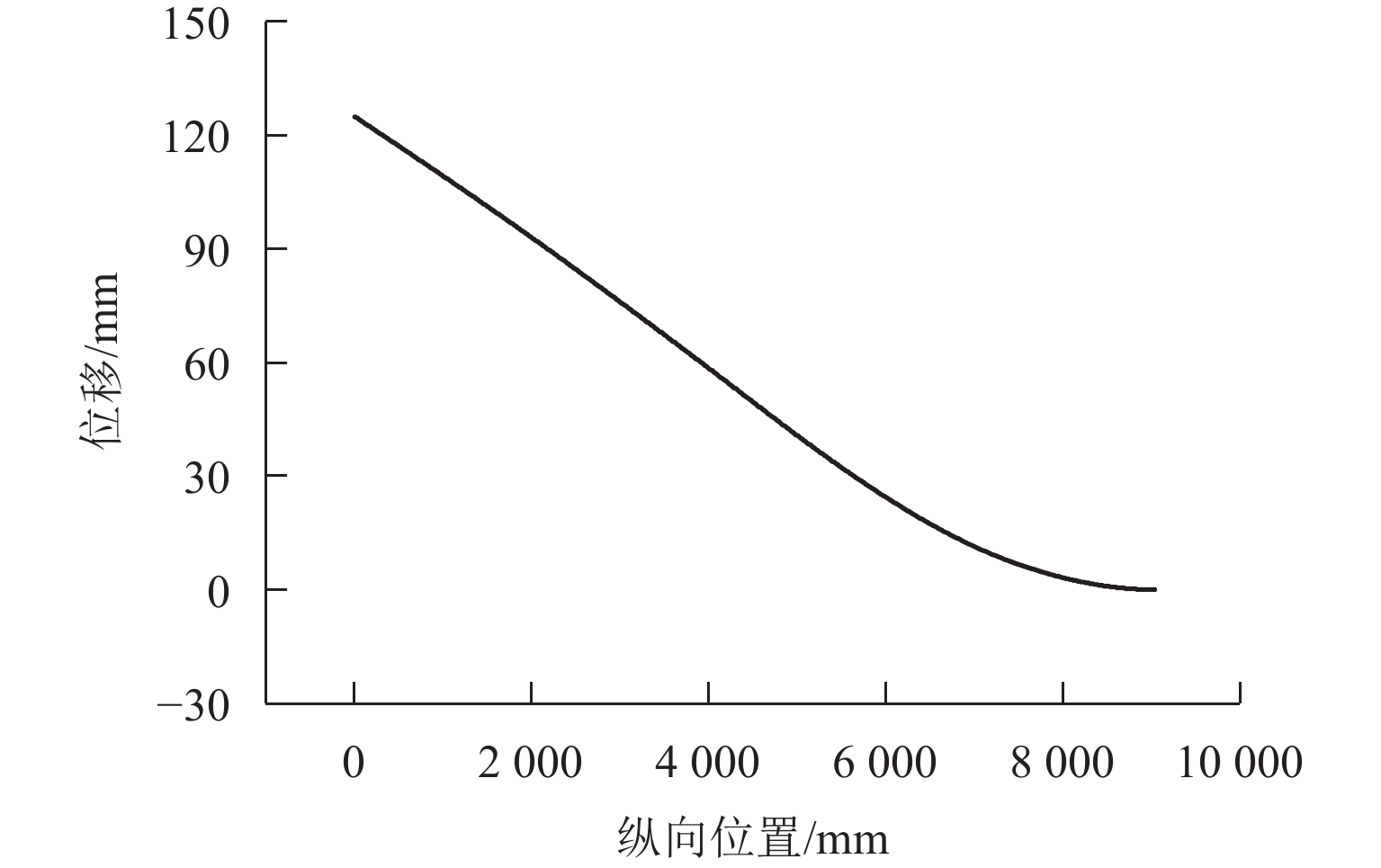

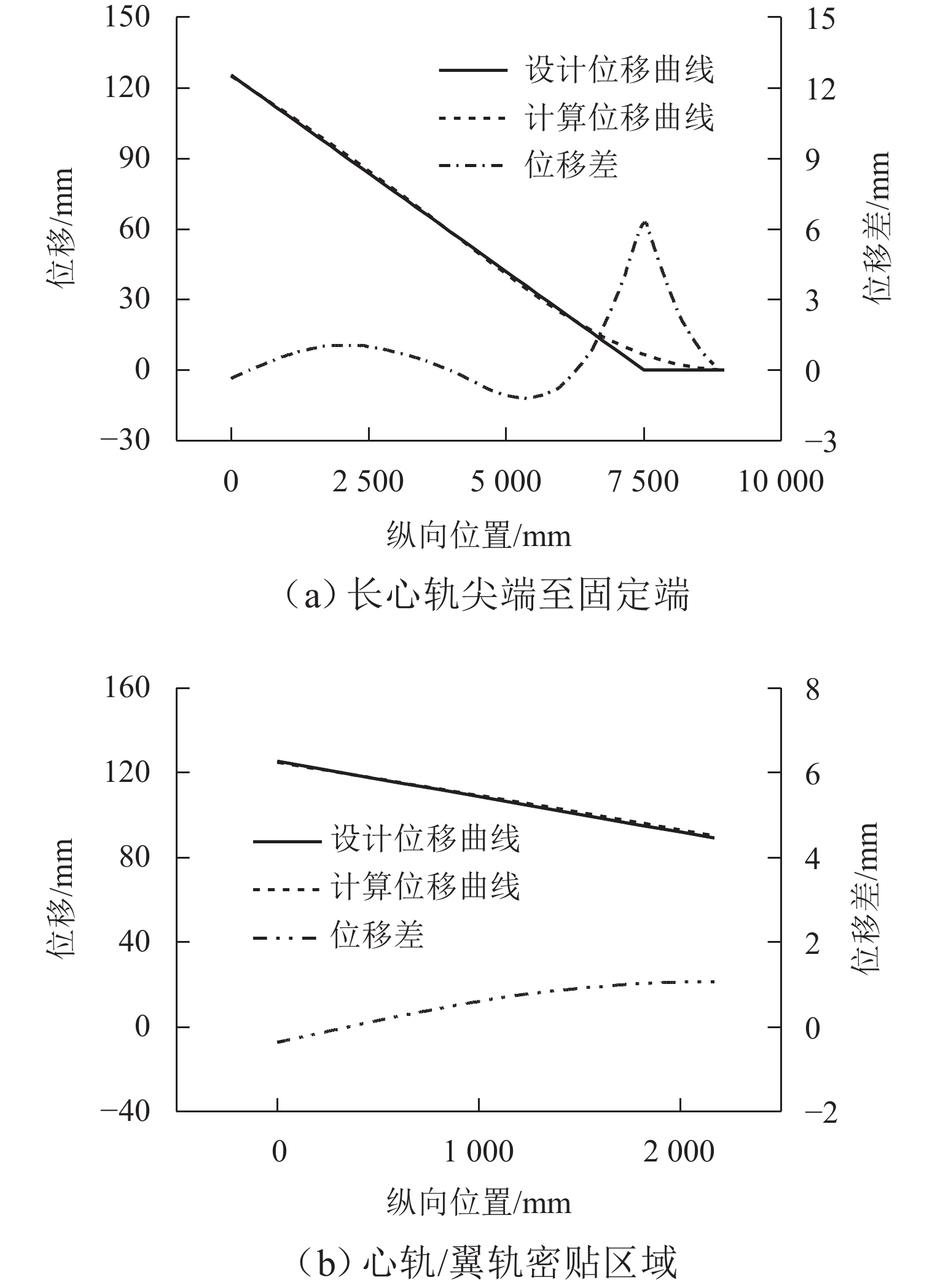

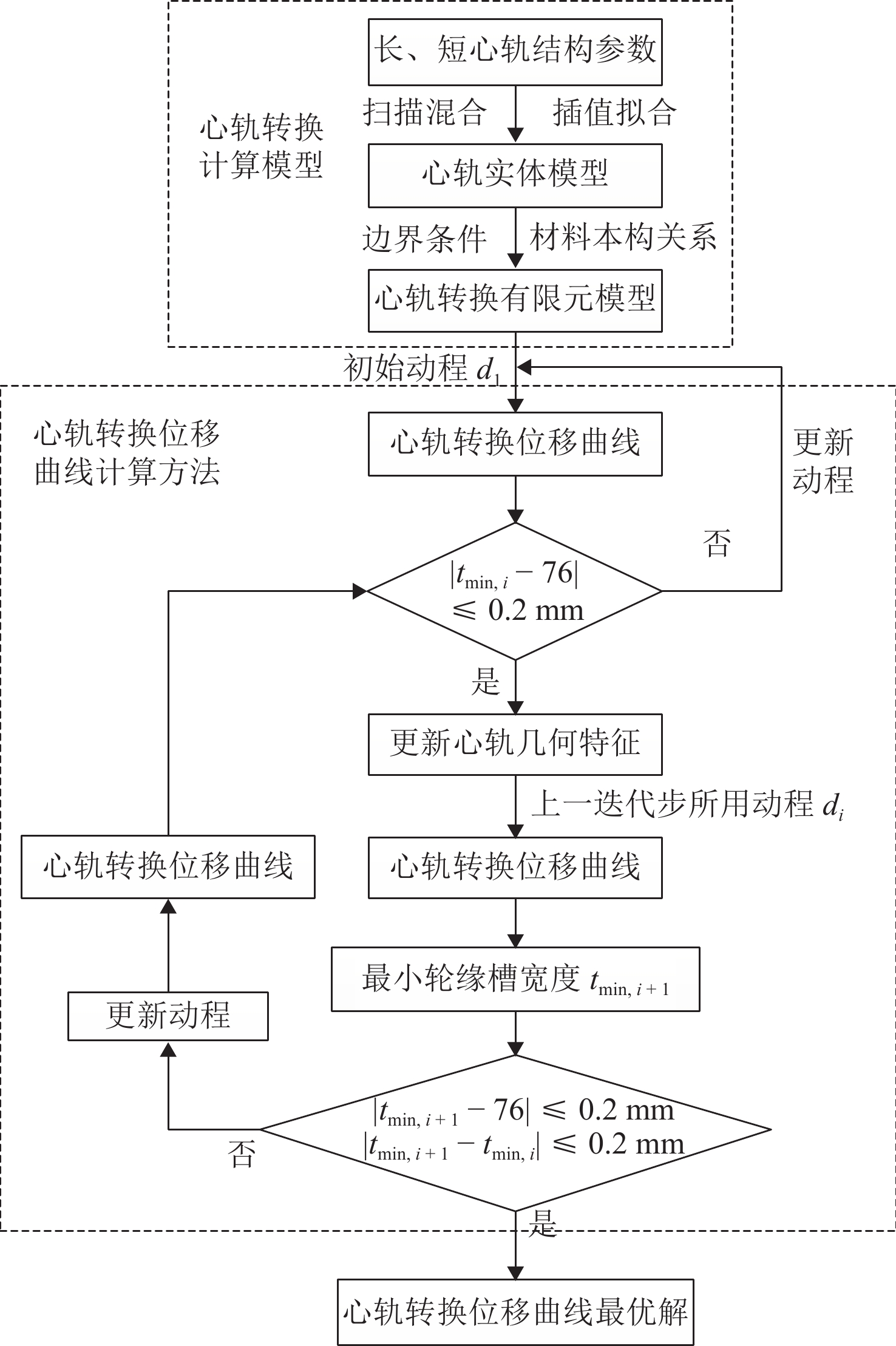

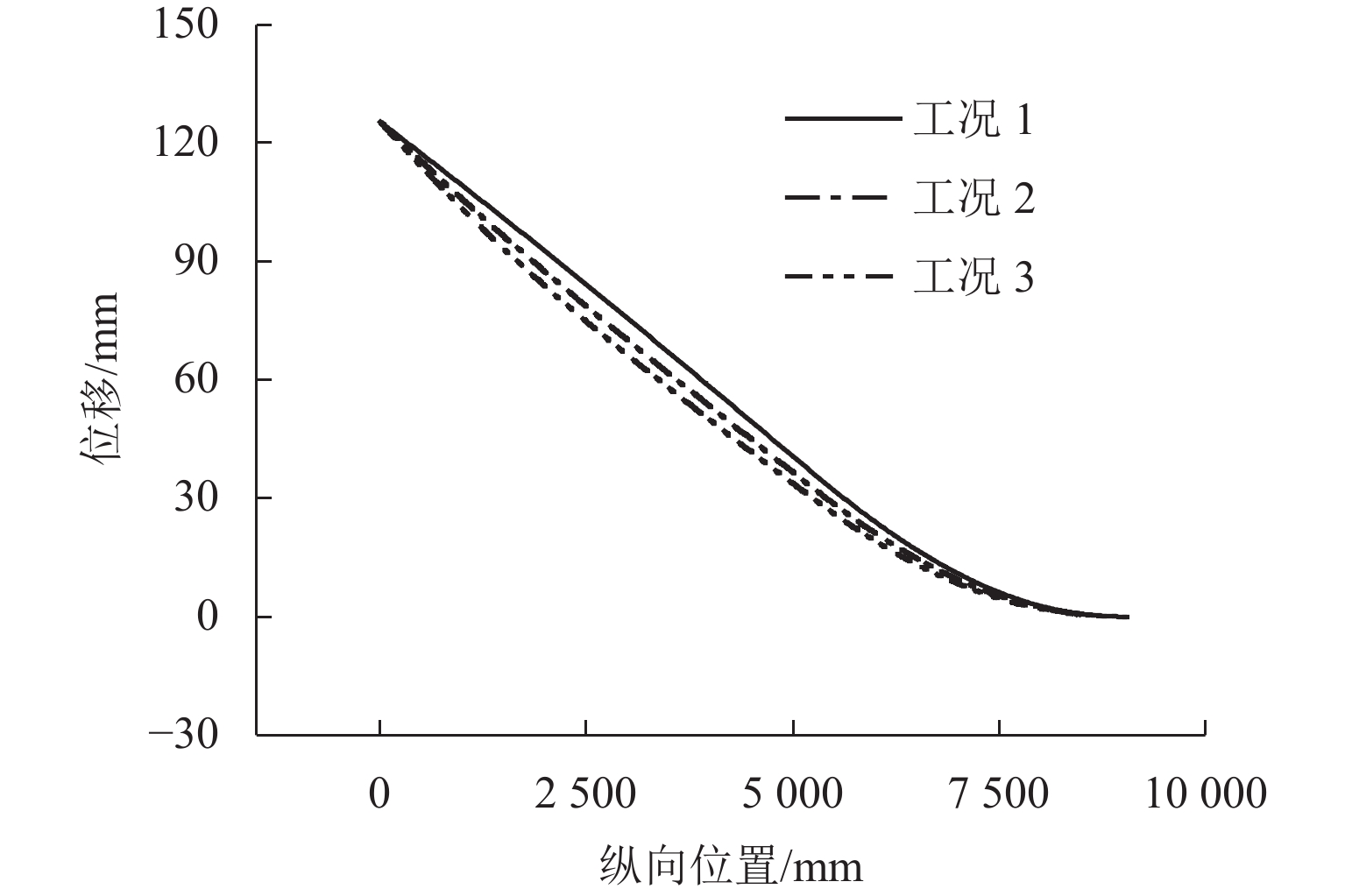

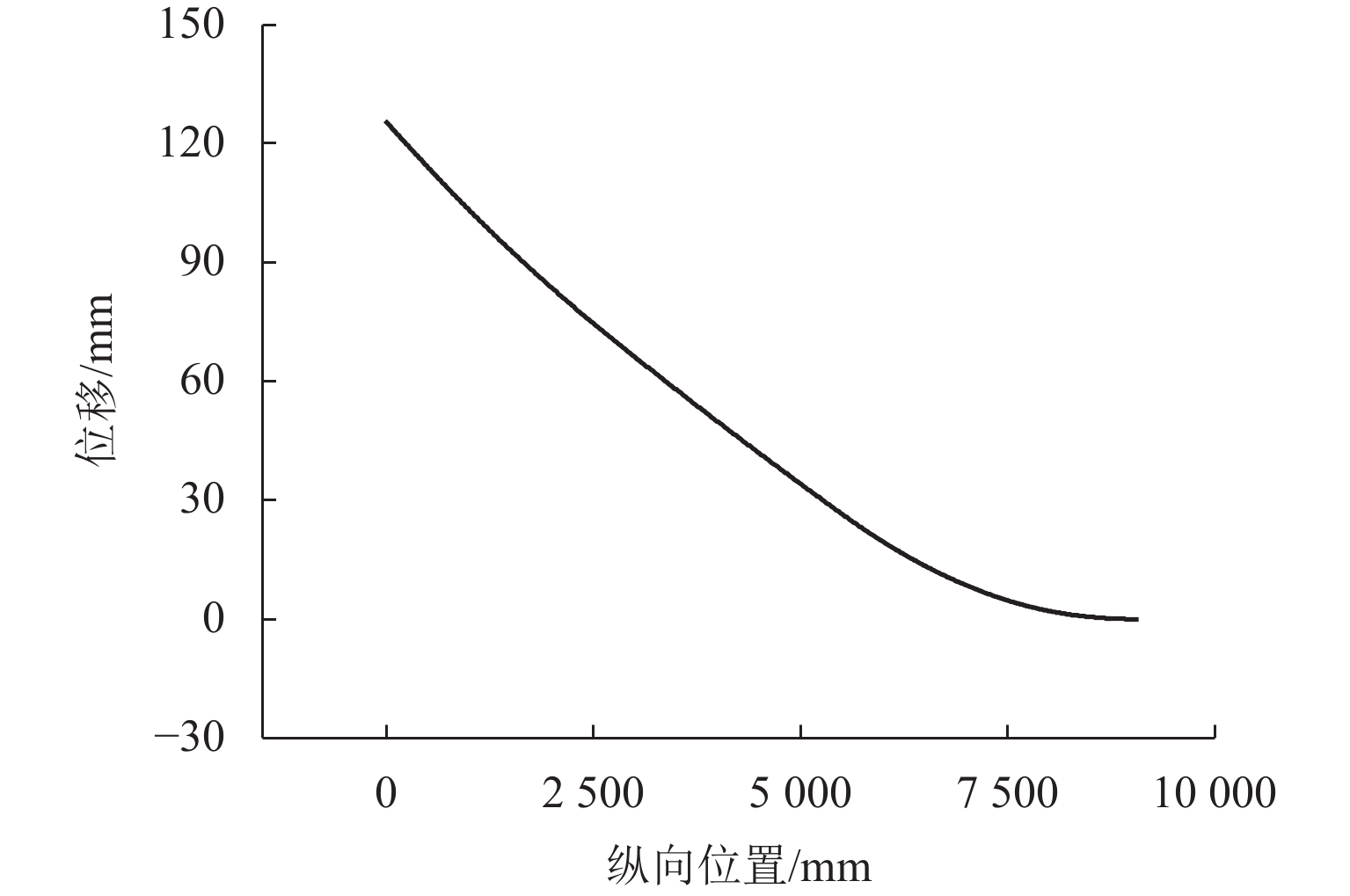

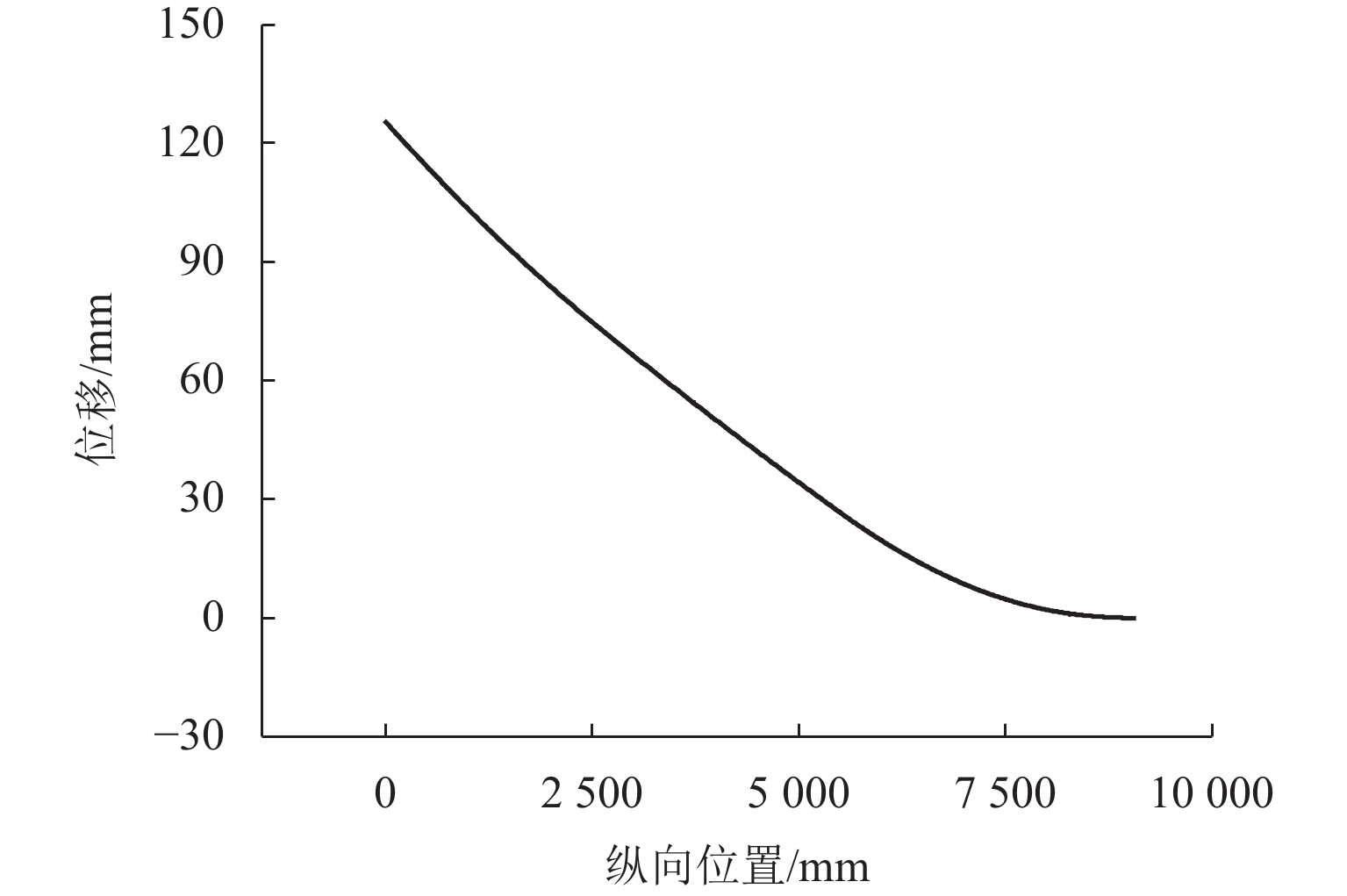

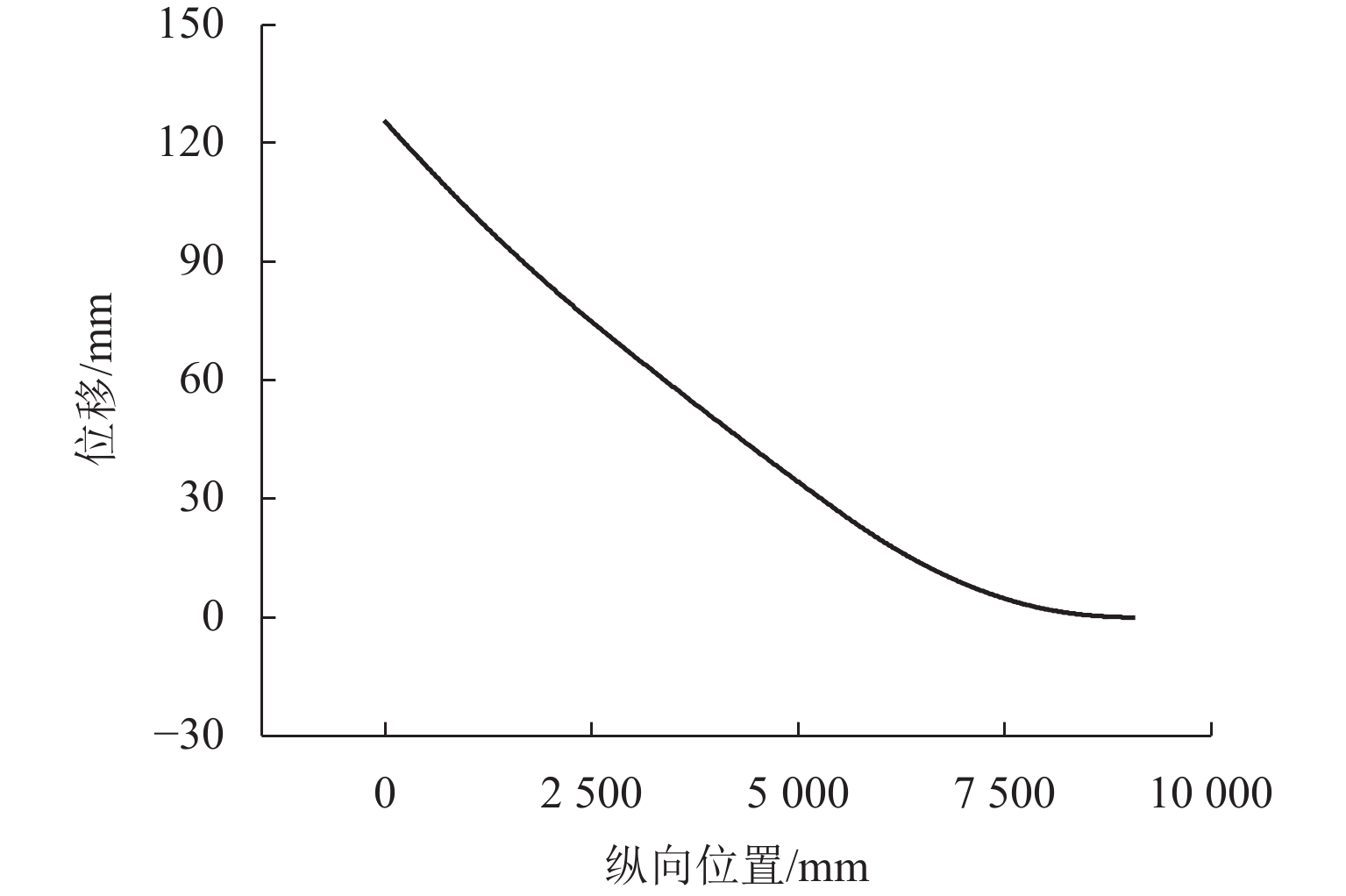

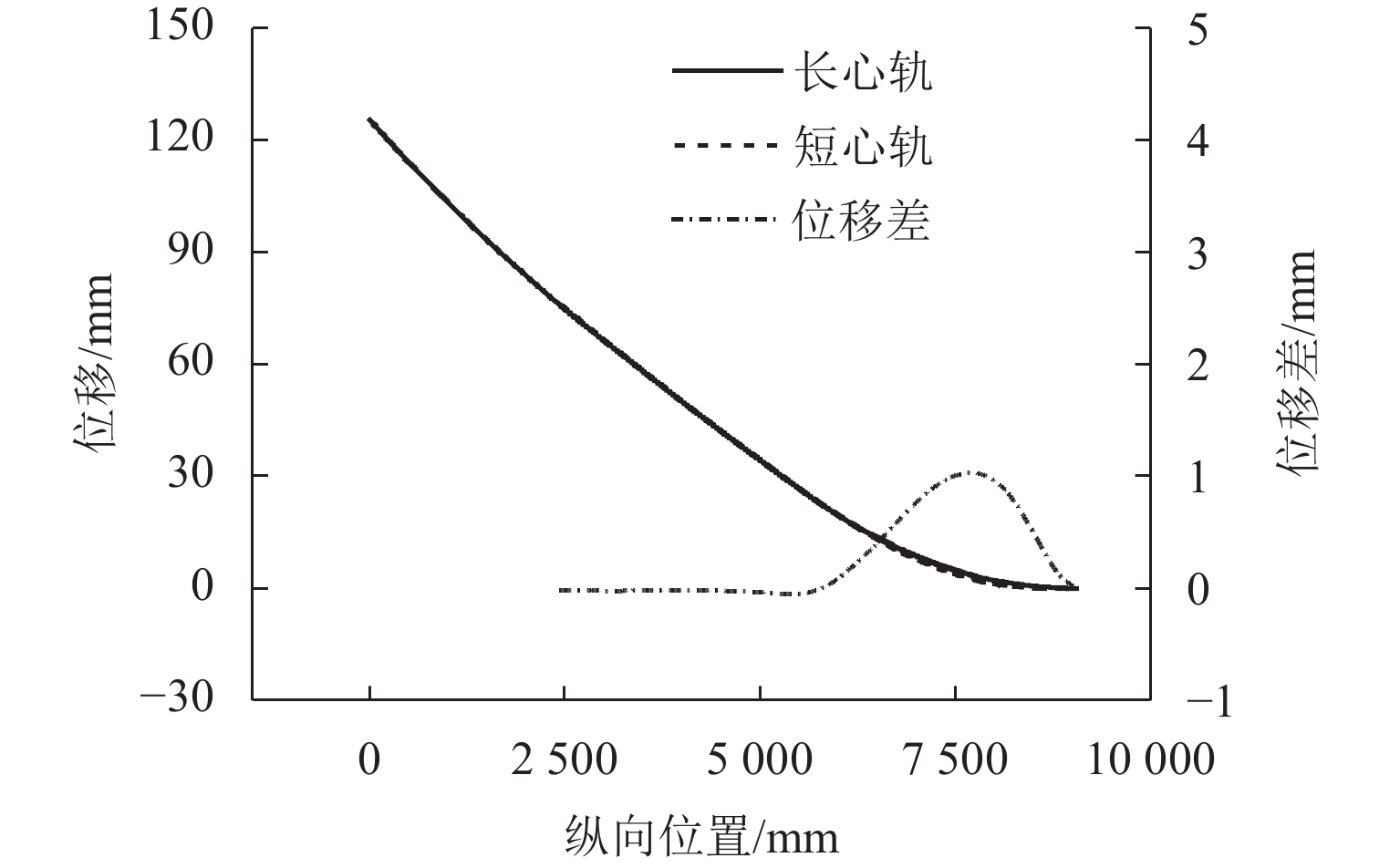

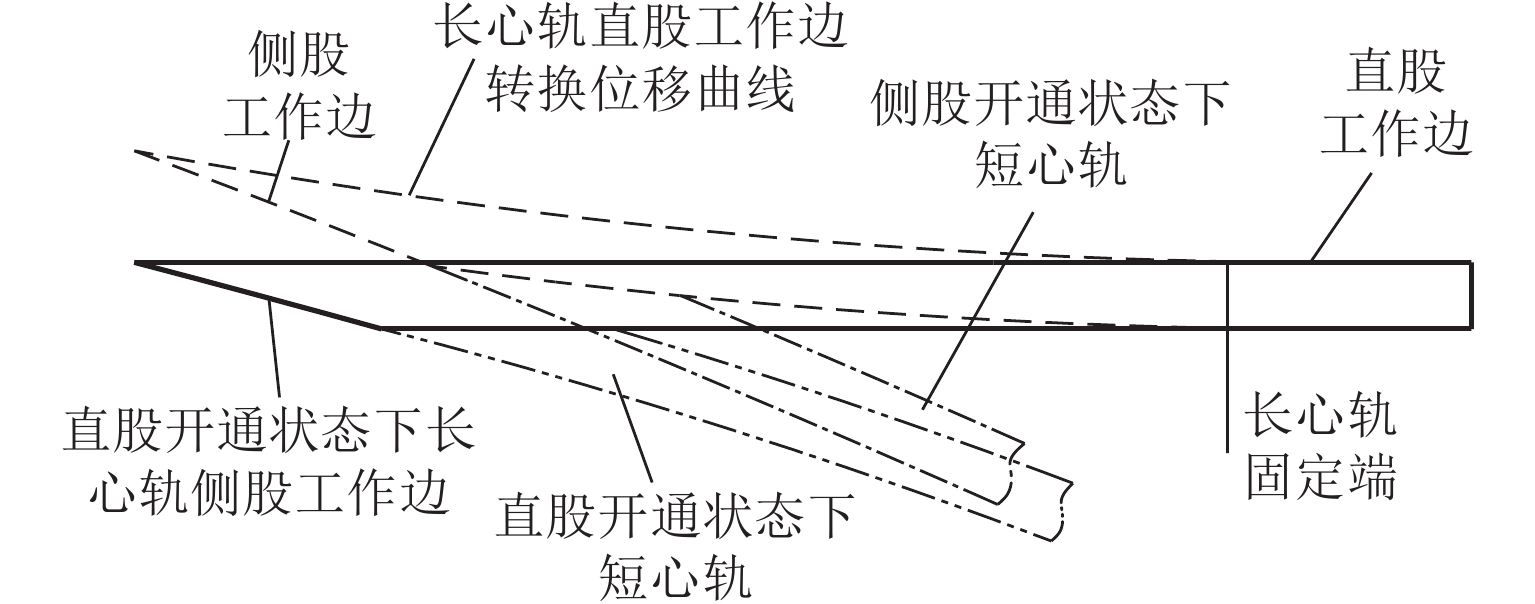

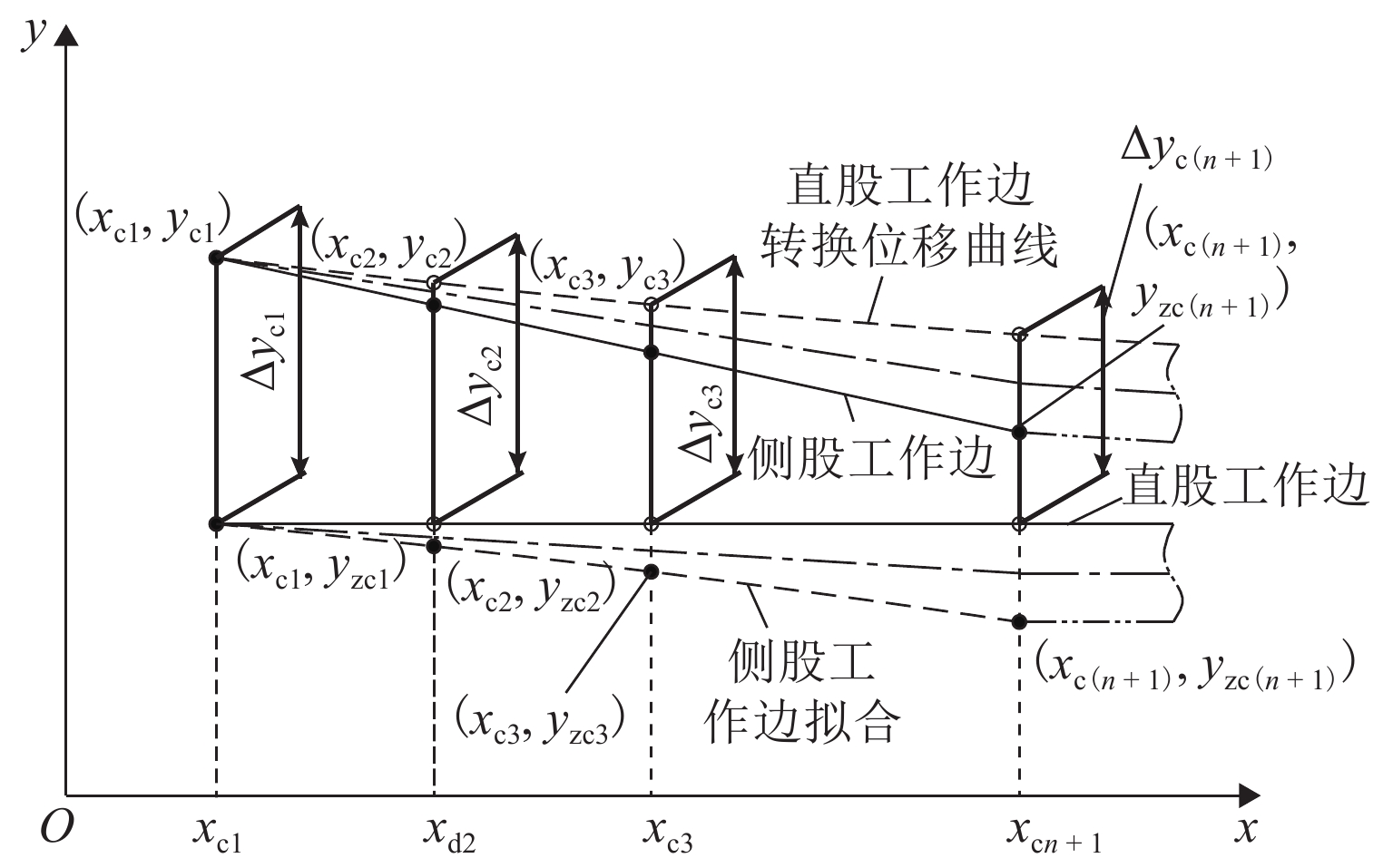

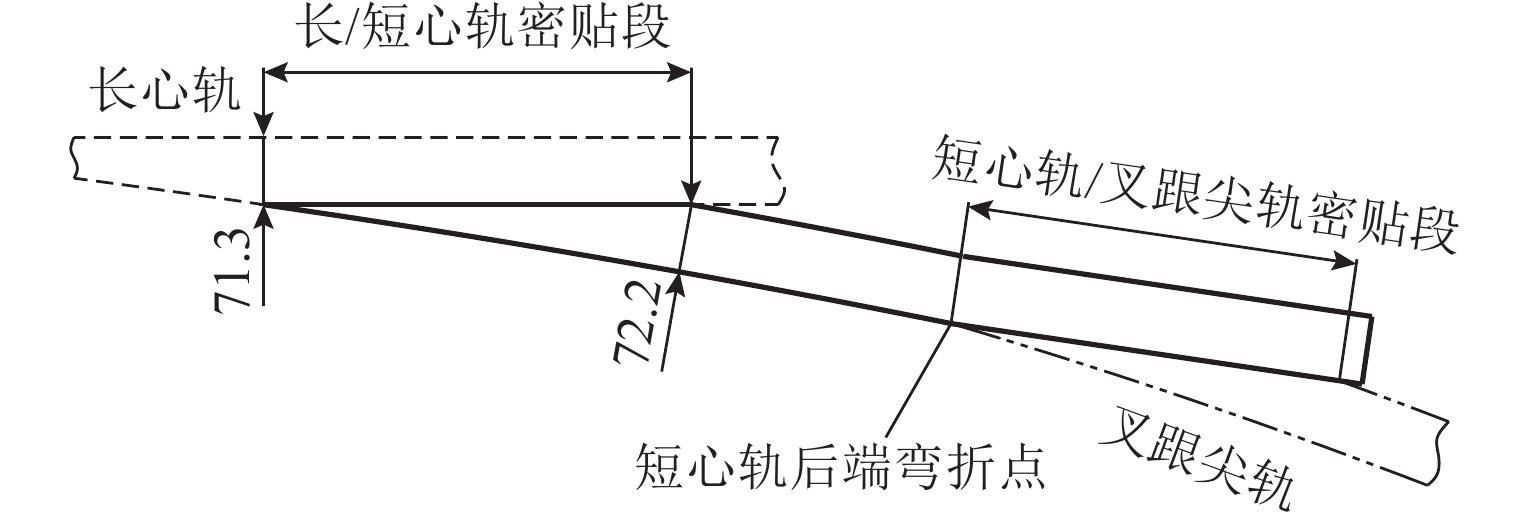

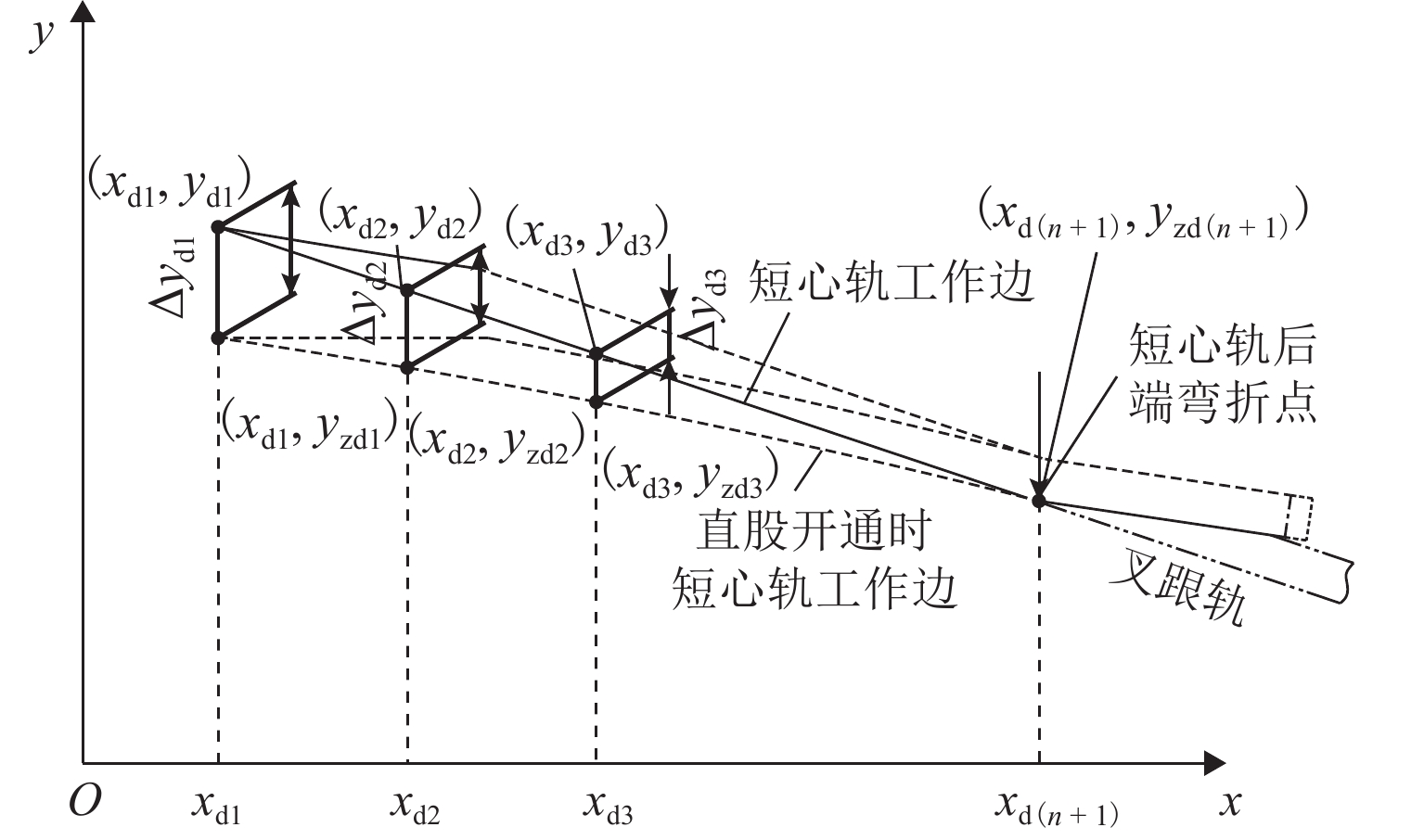

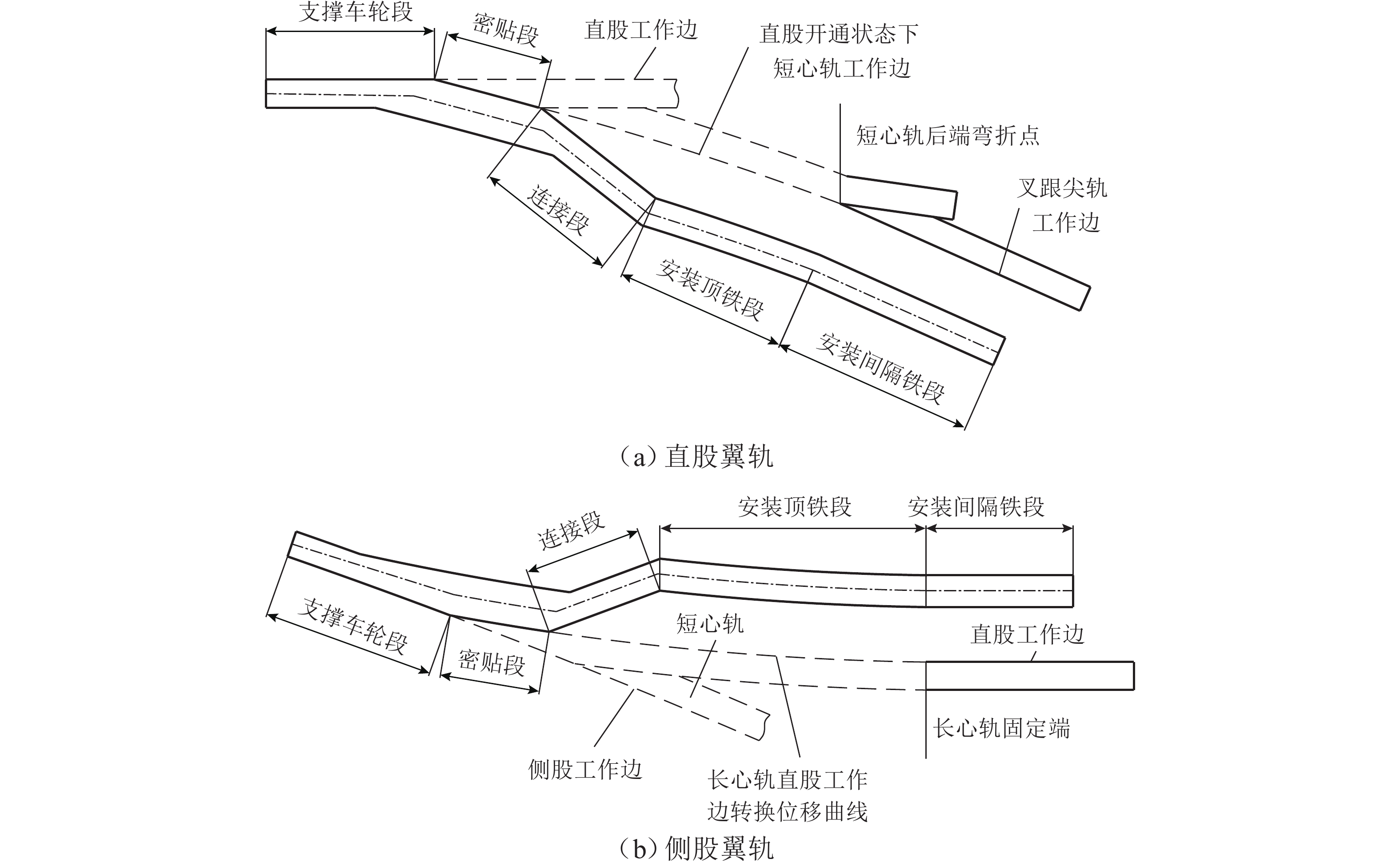

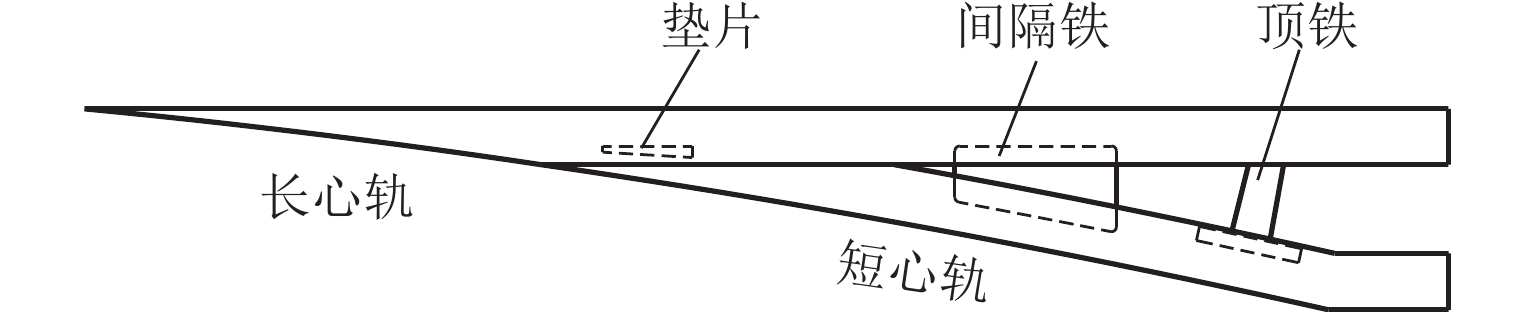

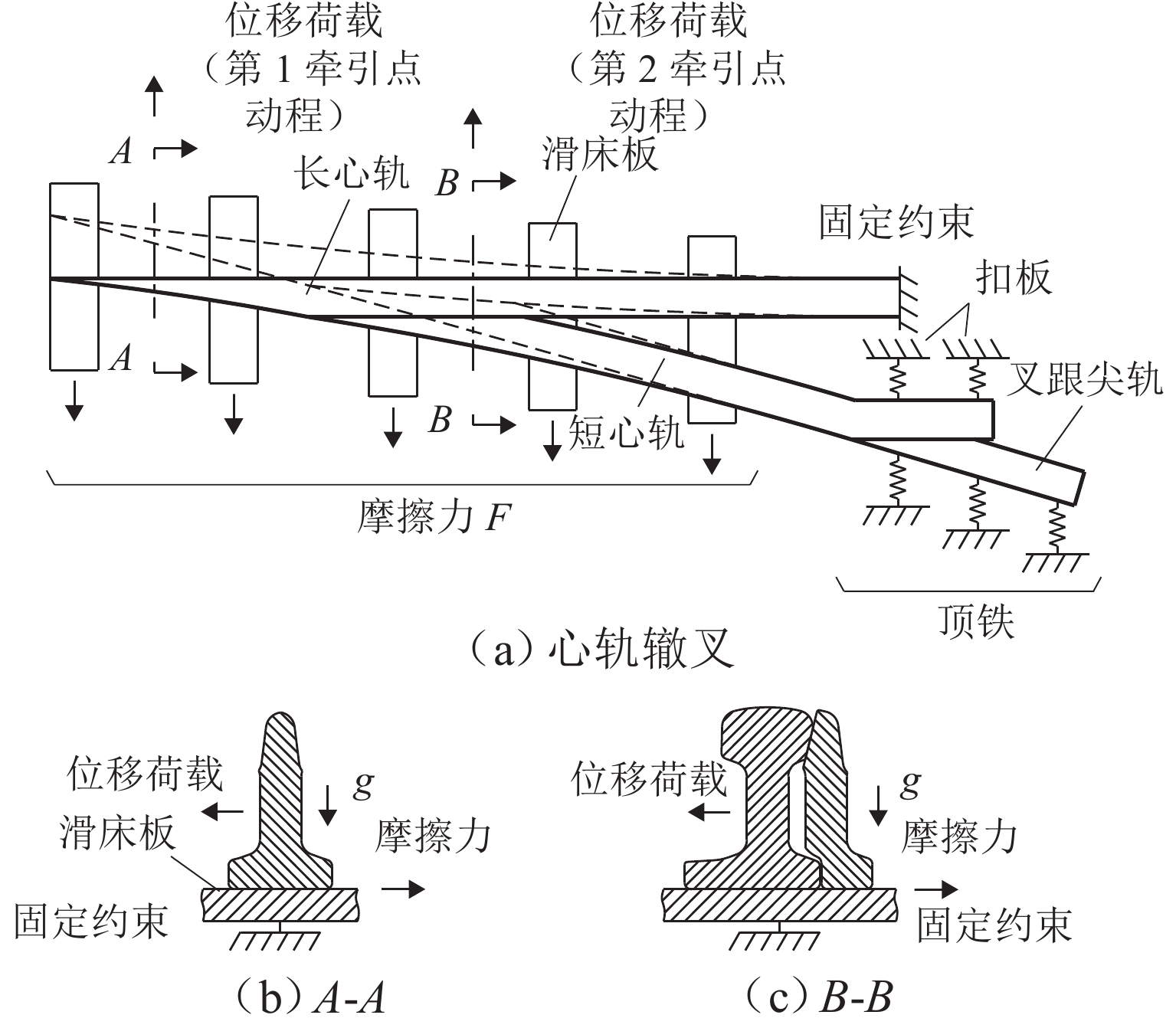

为减小可动心轨辙叉心轨/翼轨密贴区域不足位移、降低心轨牵引点转换力、提高辙叉直向平顺性,提出可动心轨辙叉的设计参数和关键部件优化设计方法. 以18号可动心辙叉最小轮缘槽宽度为优化目标,基于既有结构尺寸和有限元方法建立心轨转换计算模型,并采用逐次逼近法优化心轨转换位移曲线的设计方法;在满足辙叉直、侧向不同形位公差条件下,提出第2牵引点动程为50.7 mm的优化设计方案和直向开通状态下辙叉关键部件的结构设计方法. 研究表明:心轨计算转换位移与设计转换位移最大偏差为6.64 mm,位于弹性可弯中心;最小轮缘宽度计算值(90.7 mm)与实测平均值(90.9 mm)差异较小,满足车辆安全通过要求;第2牵引点动程较既有辙叉减小8.3 mm,减小了第2牵引点转换力.

Abstract:To reduce insufficient displacement in the contact area between the movable point frog’s point rail and wing rail, minimize transition force at the transition points of point rail, and improve the frog’s longitudinal smoothness, an optimization method for the design parameters and key components of movable point frogs was proposed. The minimum flangeway width of the No.18 movable point frog was selected as the optimization target. Based on the existing structural parameters and finite element method, a model for point rail transition calculation was established, and the method of successive approximation was used to optimize the design method of the transition displacement curve of the point rail. Under the different frog form and position tolerances for both straight/diverging lines, an optimized design was proposed with a second traction point stroke of 50.7 mm, along with the structural design scheme for key components of the frog in the straight-through state. The results show that the maximum deviation between calculated and designed point rail transition displacements is 6.64 mm, occurring at the elastic bending center. The computed minimum flangeway width (90.7 mm) closely matches the measured average value (90.9 mm), ensuring safe vehicle passage. Additionally, the second traction point stroke is reduced by 8.3 mm compared to existing frog designs, lowering the required transition force at the second traction point.

-

Key words:

- moveable point frog /

- finite element method /

- transition displacement /

- calculations /

- design

-

表 1 18号可动心轨辙叉关键结构参数

Table 1. Key structure parameters for No. 18 movable point frog

结构参数 取值/mm 长心轨轨头加工长度 2169 短心轨轨头加工长度 2075 短心轨长度 8215 长心轨可动段长度 9055 弹性可弯中心距心轨理论尖端距离 7505 咽喉宽度 125 距心轨理论尖端距离 390 动程(第 1 牵引点) 119 距心轨理论尖端距离 3955 动程(第 2 牵引点) 59 表 2 长心轨/翼轨间顶铁尺寸偏差

Table 2. Dimensional deviation for distance blocks between long point rail and wing rail

mm 序号 a b 修正值 计算值 偏差 修正值 计算值 偏差 8# 95 94 1 97 97 0 10# 124 124 0 127 127 0 12# 113 114 −1 116 116 0 14# 152 153 −1 155 155 0 16# 159 161 −2 159 161 −2 19# 159 160 −1 159 159 0 21# 157 157 0 157 156 1 23# 154 154 0 154 155 −1 表 3 18# 可动心轨辙叉最小轮缘槽宽度

Table 3. Minimum flangeway width for No. 18 movable point frog

序号 1# 2# 3# 4# 5# 平均 检测值/mm 91.0 90.6 90.9 90.6 91.3 90.9 表 4 数值计算工况

Table 4. Numerical calculation conditions

mm 工况 第 2 牵引点动程 最小轮缘槽宽度 1(初始设计) 59.0 90.7 2 54.0 81.9 3 50.5 76.1 表 5 初始模型和修正模型1关键结构参数

Table 5. Key structure parameters for initial model and refined model 1

mm 关键参数 长心轨轨头

加工长短心轨轨头

加工长短心轨长 初始模型 2169 2075 8215 修正模型 1 2425 2056 7959 表 6 修正模型1和修正模型2关键结构参数

Table 6. Key structure parameters for refined model 1 and refined model 2

mm 关键参数 长心轨轨头

加工长短心轨轨头

加工长短心轨长 修正模型 1 2425 2056 7959 修正模型 2 2427 2020 7957 表 7 关键结构参数比较

Table 7. Key structure parameter comparison

mm 关键参数 修正模型 2 工况 6 长心轨轨头加工长 2427 2427 短心轨轨头加工长 2020 2020 短心轨长 7957 7957 -

[1] 徐井芒,郑兆光,赖军,等. 轨道参数对高速道岔轮轨接触行为的影响[J]. 西南交通大学学报,2022,57(5): 990-999. doi: 10.3969/j.issn.0258-2724.20210449XU Jingmang, ZHENG Zhaoguang, LAI Jun, et al. Influence of track parameters on wheel/rail contact behavior of high-speed turnout[J]. Journal of Southwest Jiaotong University, 2022, 57(5): 990-999. doi: 10.3969/j.issn.0258-2724.20210449 [2] 郝瀛. 铁道工程[M]. 北京:中国铁道出版社,2000:98. [3] 国家铁路局. 高速铁路道岔制造技术条件. 第1部分:制造与组装:TB/T 3307.1—2020[S]. 北京:中国铁道出版社,2020. [4] 国家铁路局. 标准轨距铁路道岔:TB/T 412—2020[S]. 北京:中国铁道出版社,2020. [5] 国家铁路局. 高速铁路无砟轨道线路维修规则(试行): TG/GW 115—2012[Z]. 北京:中国铁道出版社,2012. [6] 国家铁路局. 高速铁路有砟轨道线路维修规则(试行): TG/GW 116—2013[Z]. 北京:中国铁道出版社,2013. [7] 国家铁路局. 普速铁路线路修理规则:TG/GW 102—2019[Z]. 北京: 中国铁道出版社,2020. [8] 王树国,王璞,赵振华,等. 高铁正线道岔专项评估整治调研报告[R]. 北京:中国铁道科学研究院集团有限公司,2022. [9] 蔡小培,李成辉. 高速道岔心轨扳动力和不足位移控制研究[J]. 铁道学报,2008,30(2): 48-51. doi: 10.3321/j.issn:1001-8360.2008.02.010CAI Xiaopei, LI Chenghui. Study on controlling the swiching force and scant displacement of the point rail of the high speed turnout[J]. Journal of the China Railway Society, 2008, 30(2): 48-51. doi: 10.3321/j.issn:1001-8360.2008.02.010 [10] 曾瑞东,王树国,王璞,等. 跟端轨底刨切对尖轨转换影响的有限元分析[J]. 铁道建筑,2019,59(2): 140-142,146. doi: 10.3969/j.issn.1003-1995.2019.02.33ZENG Ruidong, WANG Shuguo, WANG Pu, et al. FEM simulation analysis about influence of rail bottom slicing on switch rail transformation[J]. Railway Engineering, 2019, 59(2): 140-142,146. doi: 10.3969/j.issn.1003-1995.2019.02.33 [11] 马晓川,王平. 小号码道岔扳动力随密贴段刚度变化规律研究[J]. 铁道标准设计,2014,58(5): 12-14,20.MA Xiaochuan, WANG Ping. Study on change rule of switching force of small-sized turnout with the change of closure section’s stiffness[J]. Railway Standard Design, 2014, 58(5): 12-14,20. [12] 司道林,赵振华,王树国,等. 新型50 kg•m−1钢轨9号道岔尖轨转换特性研究[J]. 中国铁道科学,2021,42(4): 27-33. doi: 10.3969/j.issn.1001-4632.2021.04.04SI Daolin, ZHAO Zhenhua, WANG Shuguo, et al. Study on switching characteristics of switch rail for No. 9 turnout of new 50 kg•m−1 rail[J]. China Railway Science, 2021, 42(4): 27-33. doi: 10.3969/j.issn.1001-4632.2021.04.04 [13] Čedomir I, Mirjana Tomičić-Torlaković, Gordan Radivojević. Modelling the swing nose frog of turnout[J]. Architecture and Civil Engineer Vol.1, 1997, 4: 533-539. [14] 井国庆. 18号可动心轨道岔心轨不足位移仿真分析[D]. 成都:西南交通大学,2006. [15] 王树国. 我国铁路道岔现状与发展[J]. 铁道建筑,2015,55(10): 42-46. doi: 10.3969/j.issn.1003-1995.2015.10.08WANG Shuguo. Current status and future development trend of railway turnouts in China[J]. Railway Engineering, 2015, 55(10): 42-46. doi: 10.3969/j.issn.1003-1995.2015.10.08 [16] 沈长耀,王明治,许有全,等. 提速道岔平面及结构设计[J]. 铁道标准设计,1997(3): 7-13. [17] 葛晶,杨东升,等. 全路铁路道岔型号梳理[R]. 北京:中国铁道科学研究院集团有限公司,2022. [18] 王璞,杨东升,赵振华,等. 60 kg/m钢轨12号单开道岔转换优化数值分析与试验研究[J]. 工程力学,2023,40(7):249-256.WANG Pu, YANG Dongsheng, ZHAO Zhenhua , et al. Numerical analysis and experimental research on switching optimization of the No. 12 single turnout with 60 kg/m rails[J]. Engineering Mechanics, 2023, 40(7):249-256. [19] 蔡小培,李成辉,王平. 滑床板摩擦力对尖轨不足位移的影响[J]. 中国铁道科学,2007,28(1): 8-12. doi: 10.3321/j.issn:1001-4632.2007.01.002CAI Xiaopei, LI Chenghui, WANG Ping. Effect on the scant displacement of switch rail induced by friction of slide baseplate[J]. China Railway Science, 2007, 28(1): 8-12. doi: 10.3321/j.issn:1001-4632.2007.01.002 [20] 于浩,王平,温静,等. 可动心轨转换锁闭力仿真研究[J]. 铁道科学与工程学报,2020,17(3): 533-539.YU Hao, WANG Ping, WEN Jing, et al. Simulation and analysis of the movable rail conversion and locking force[J]. Journal of Railway Science and Engineering, 2020, 17(3): 533-539. [21] 赵振华. 自主研发高速道岔制造标准化研究报告[R]. 北京:中国铁道科学研究院集团有限公司,2021. [22] 王平,刘学毅,陈嵘. 我国高速铁路道岔技术的研究进展[J]. 高速铁路技术,2010,1(2): 6-13. doi: 10.3969/j.issn.1674-8247.2010.02.002WANG Ping, LIU Xueyi, CHEN Rong. Progress of turnout technology for China’s high speed railway[J]. High Speed Railway Technology, 2010, 1(2): 6-13. doi: 10.3969/j.issn.1674-8247.2010.02.002 -

下载:

下载: