Optimization of JM3 Wheel Profile Considering Equivalent Conicity Dispersion

-

摘要:

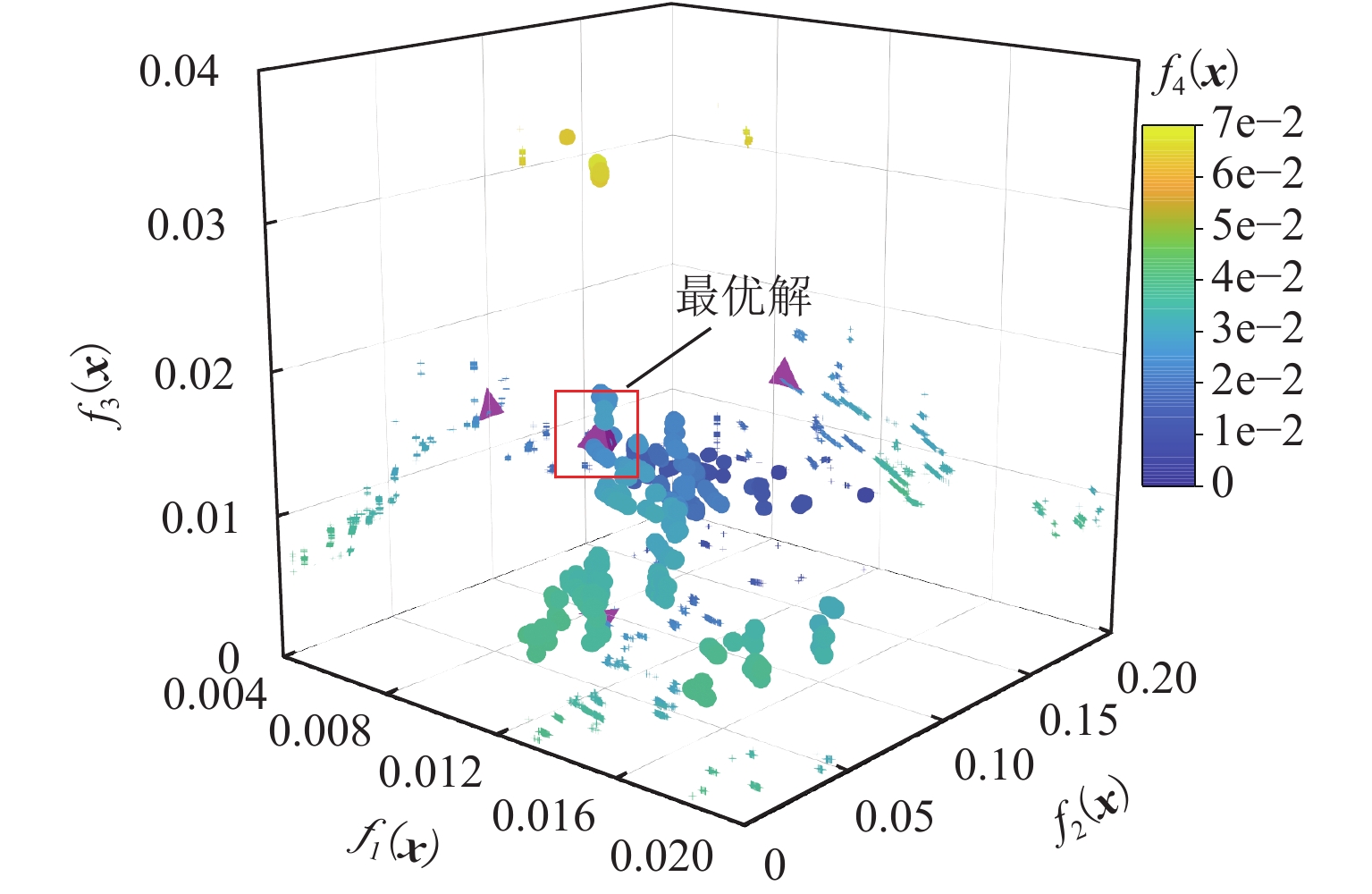

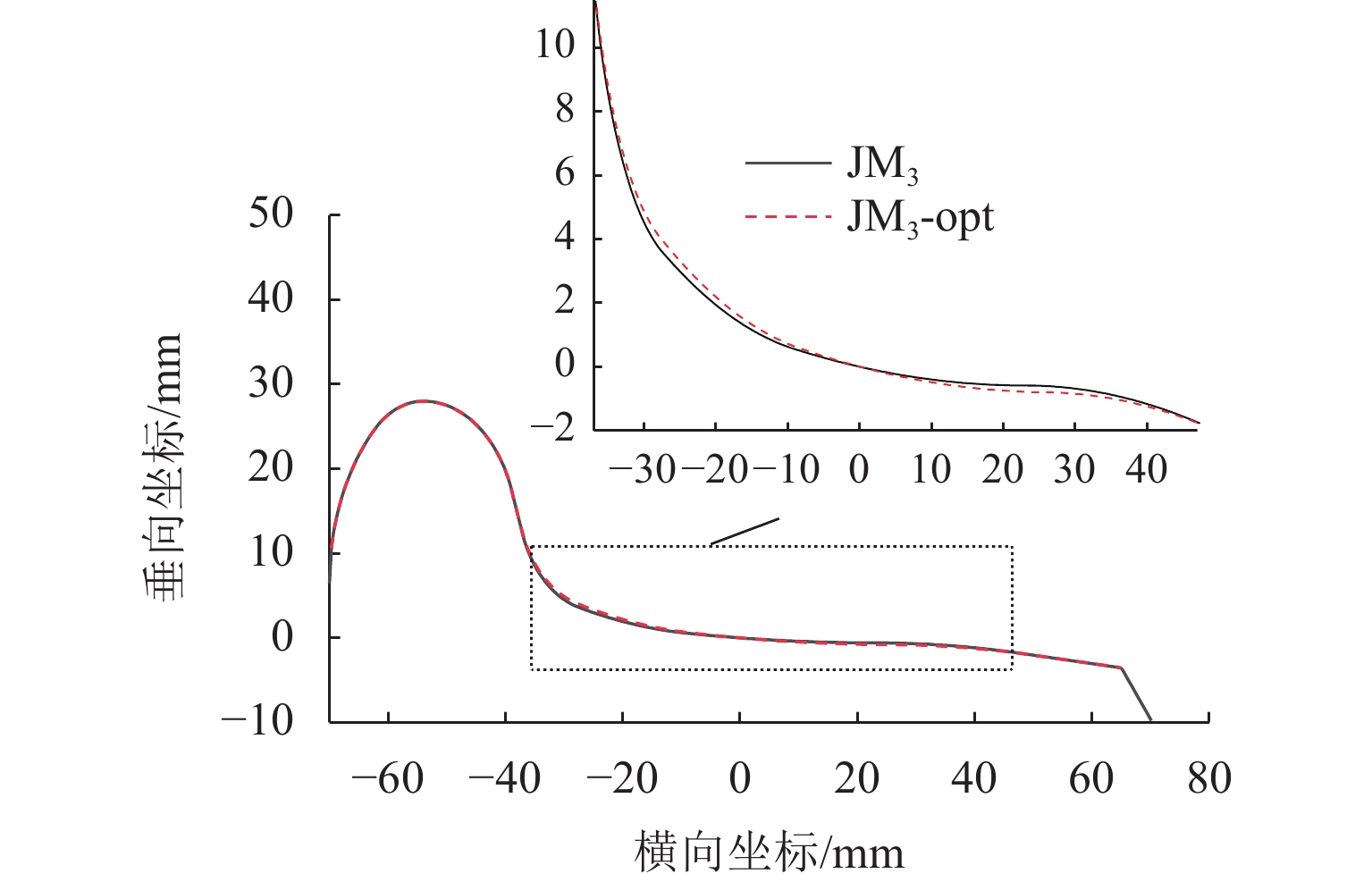

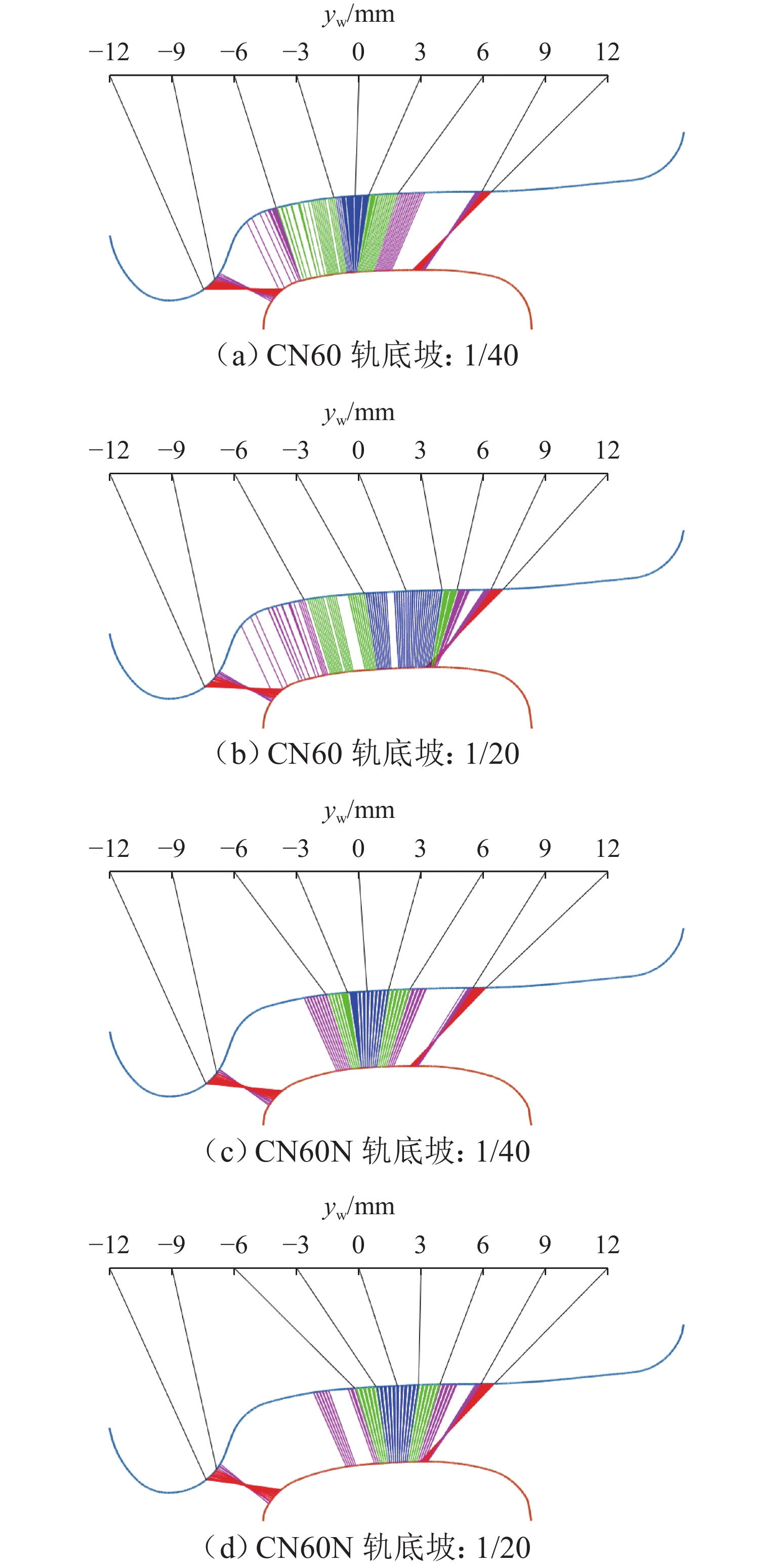

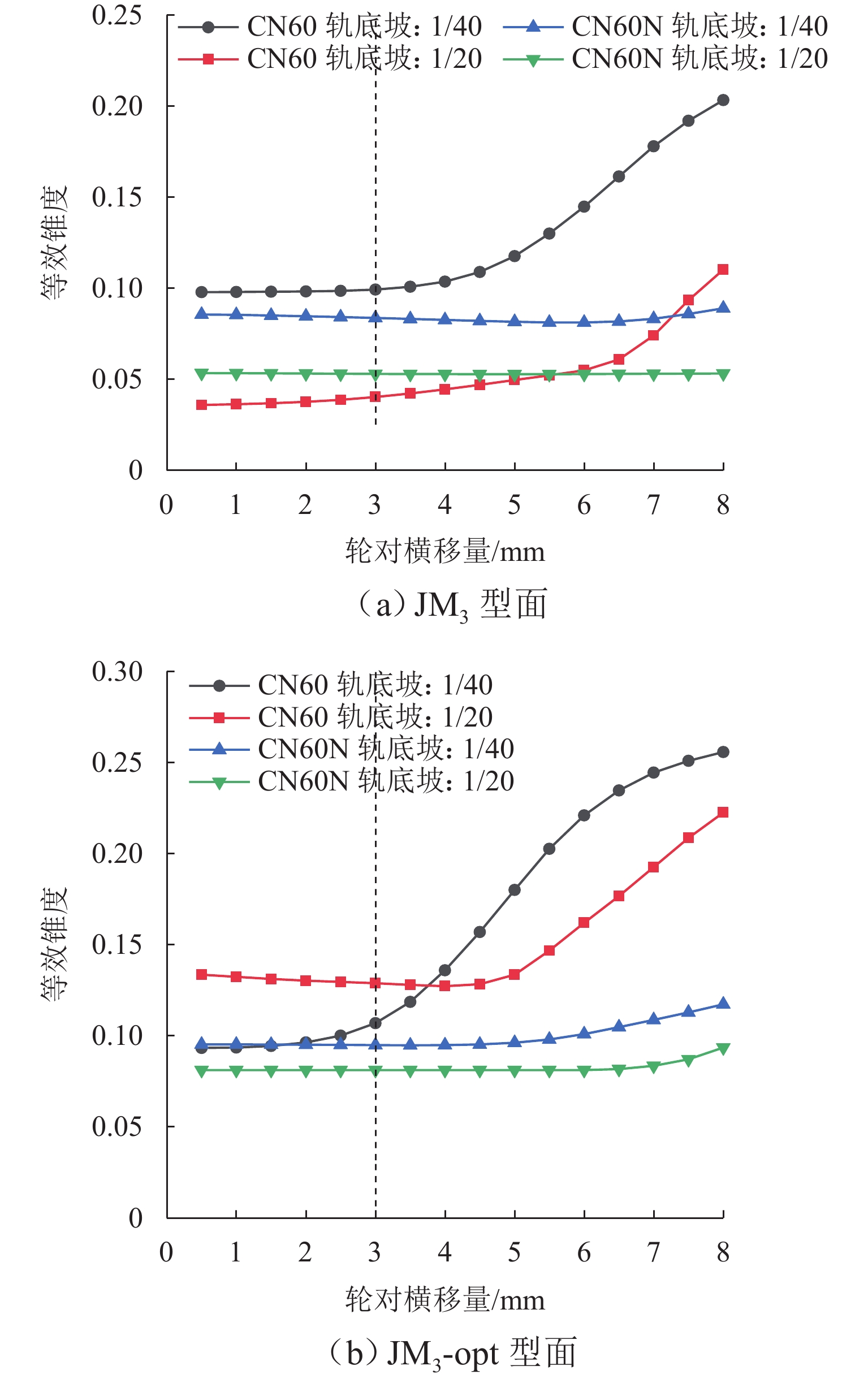

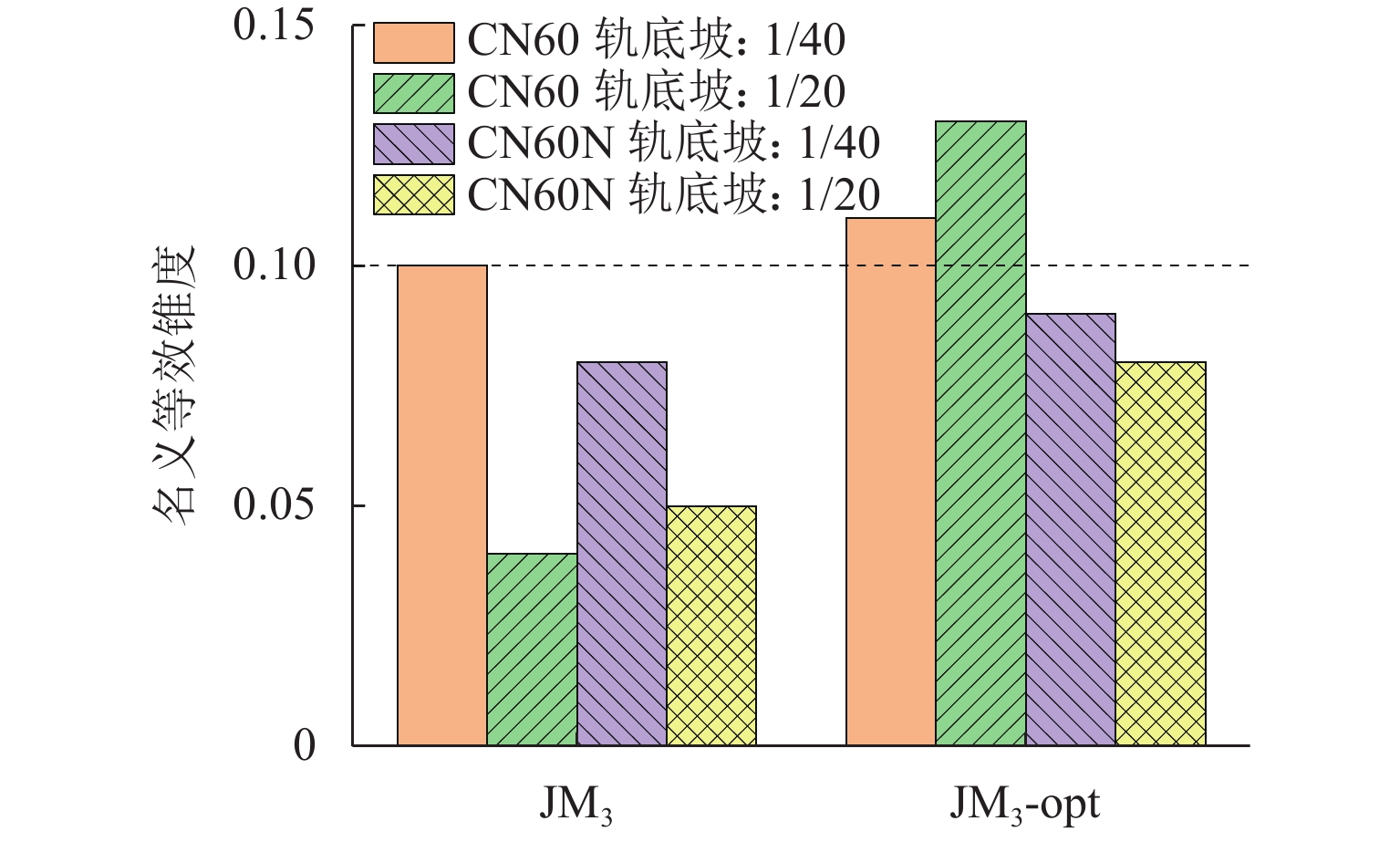

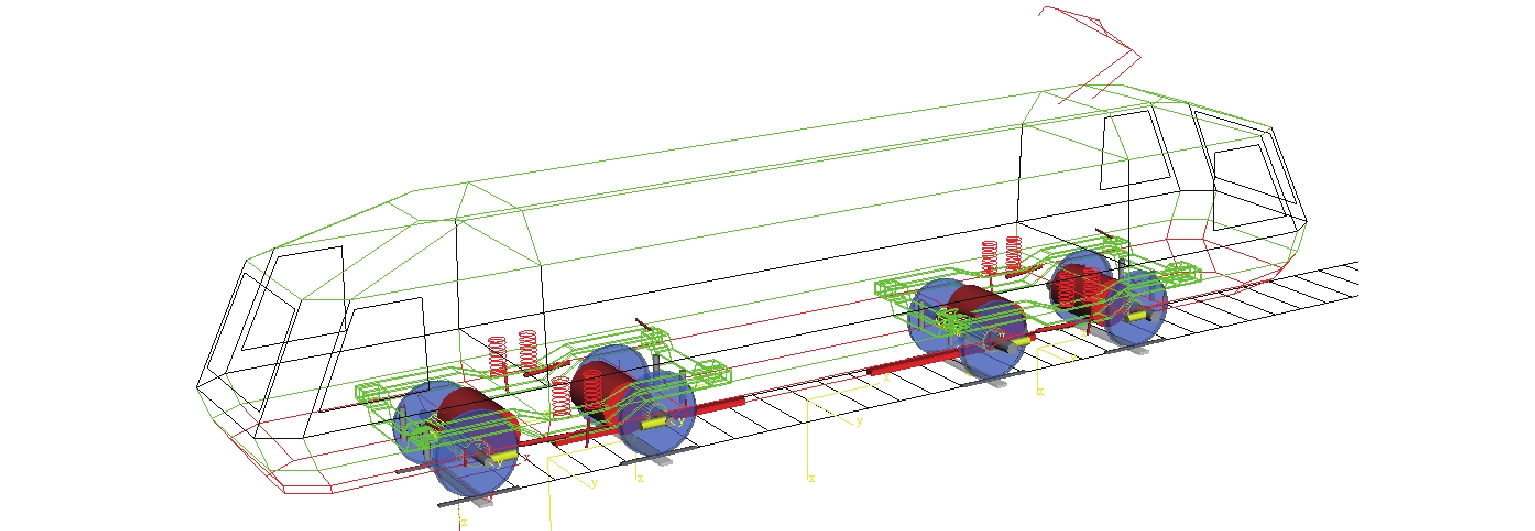

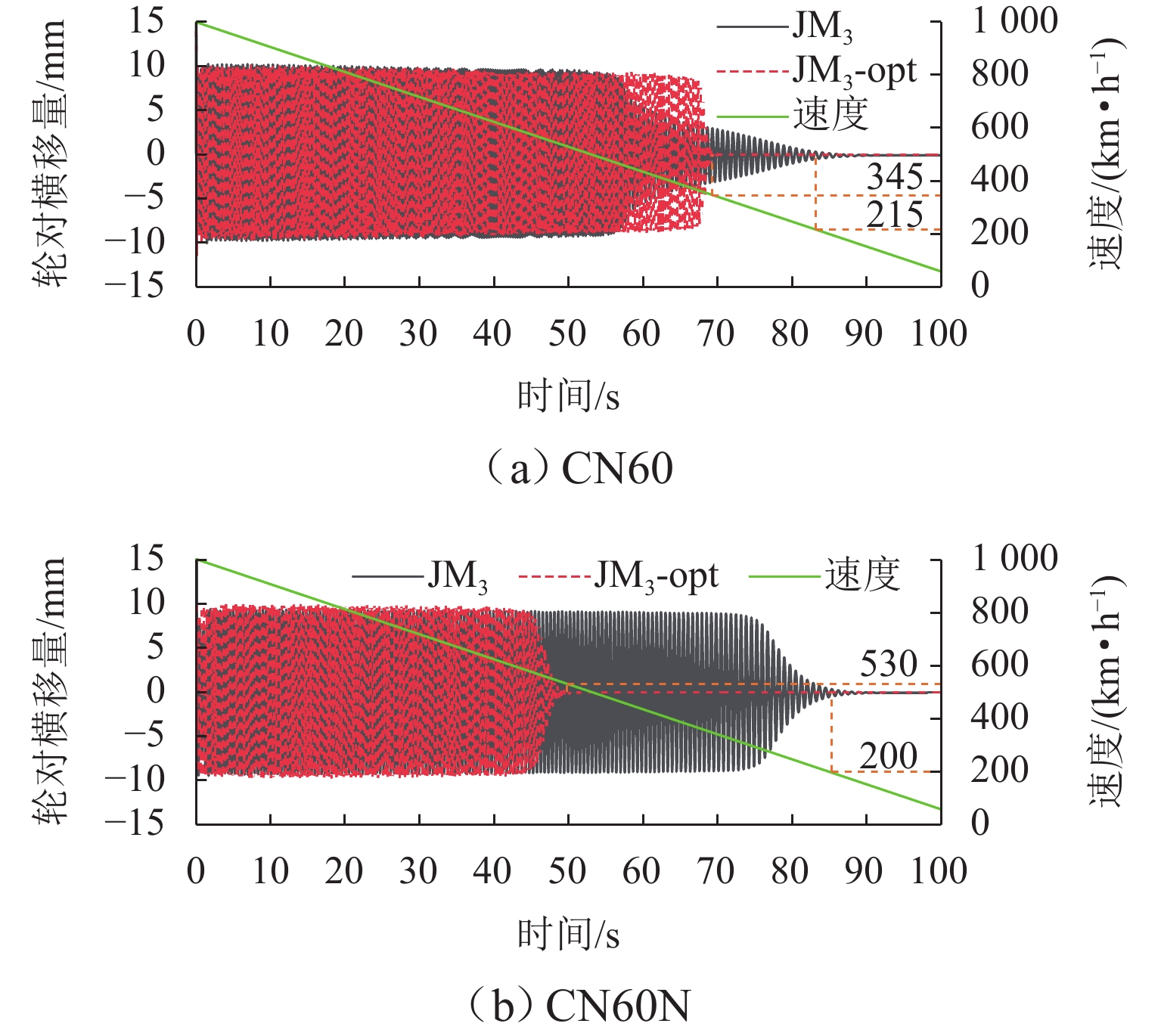

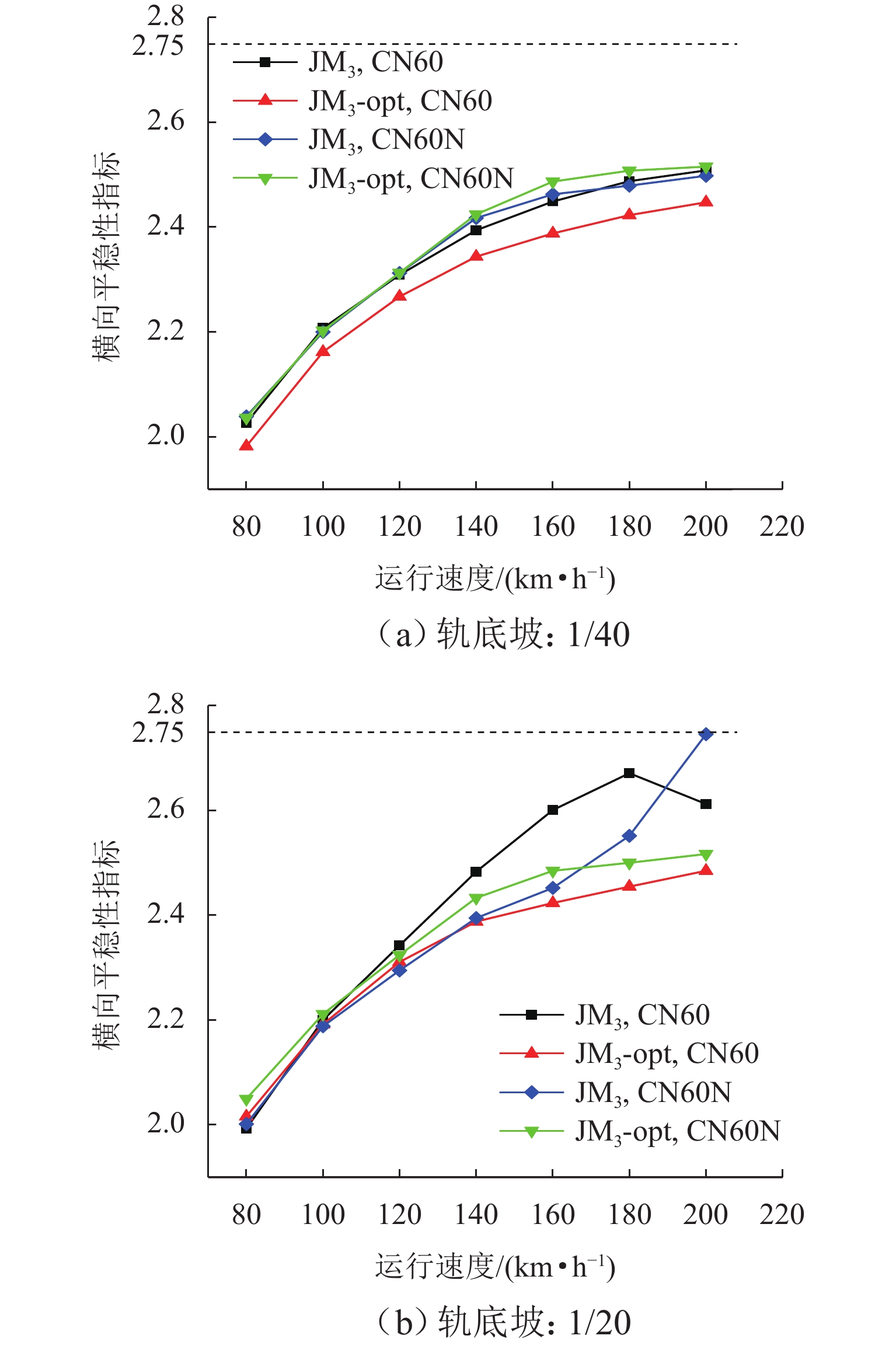

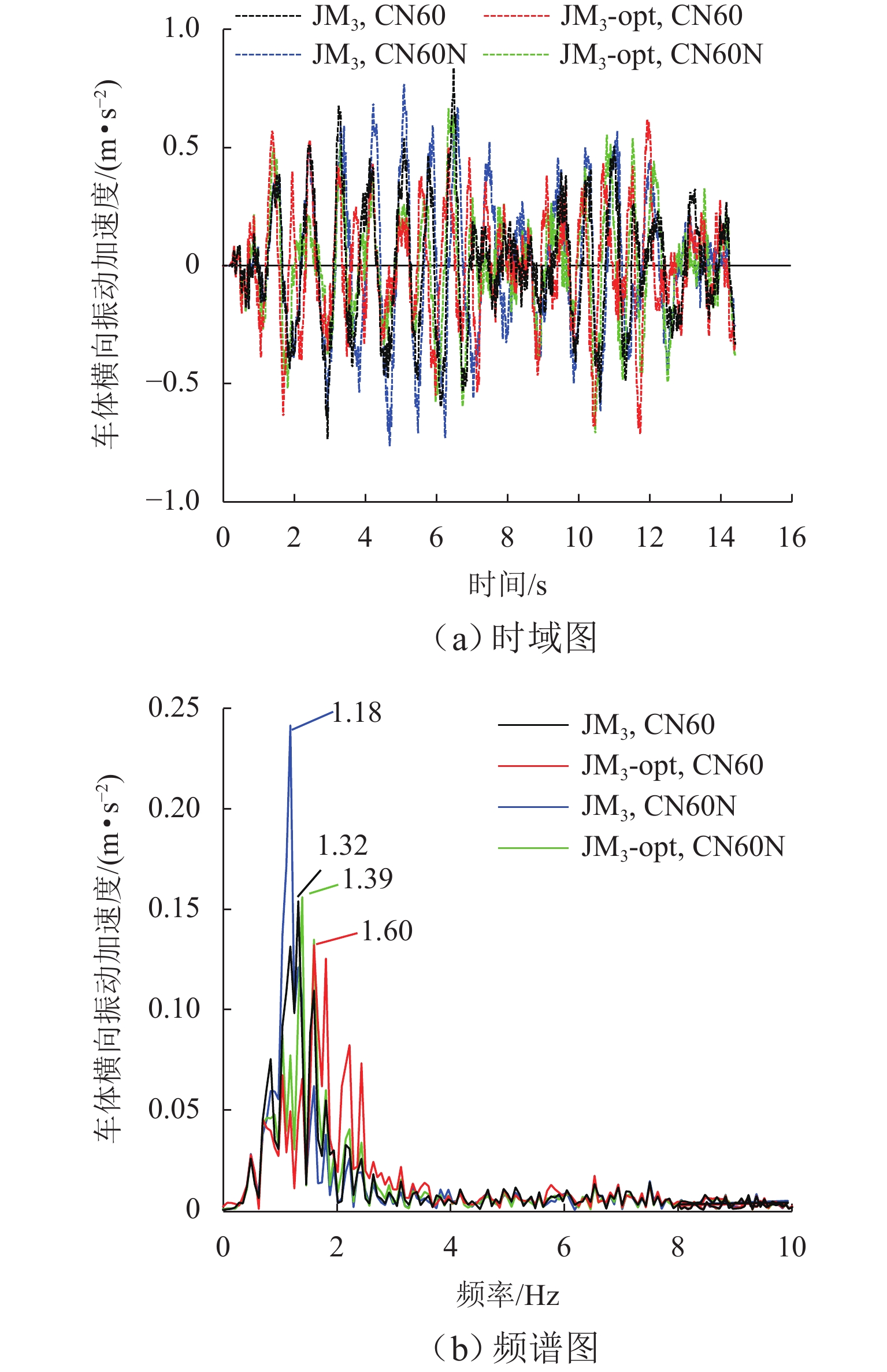

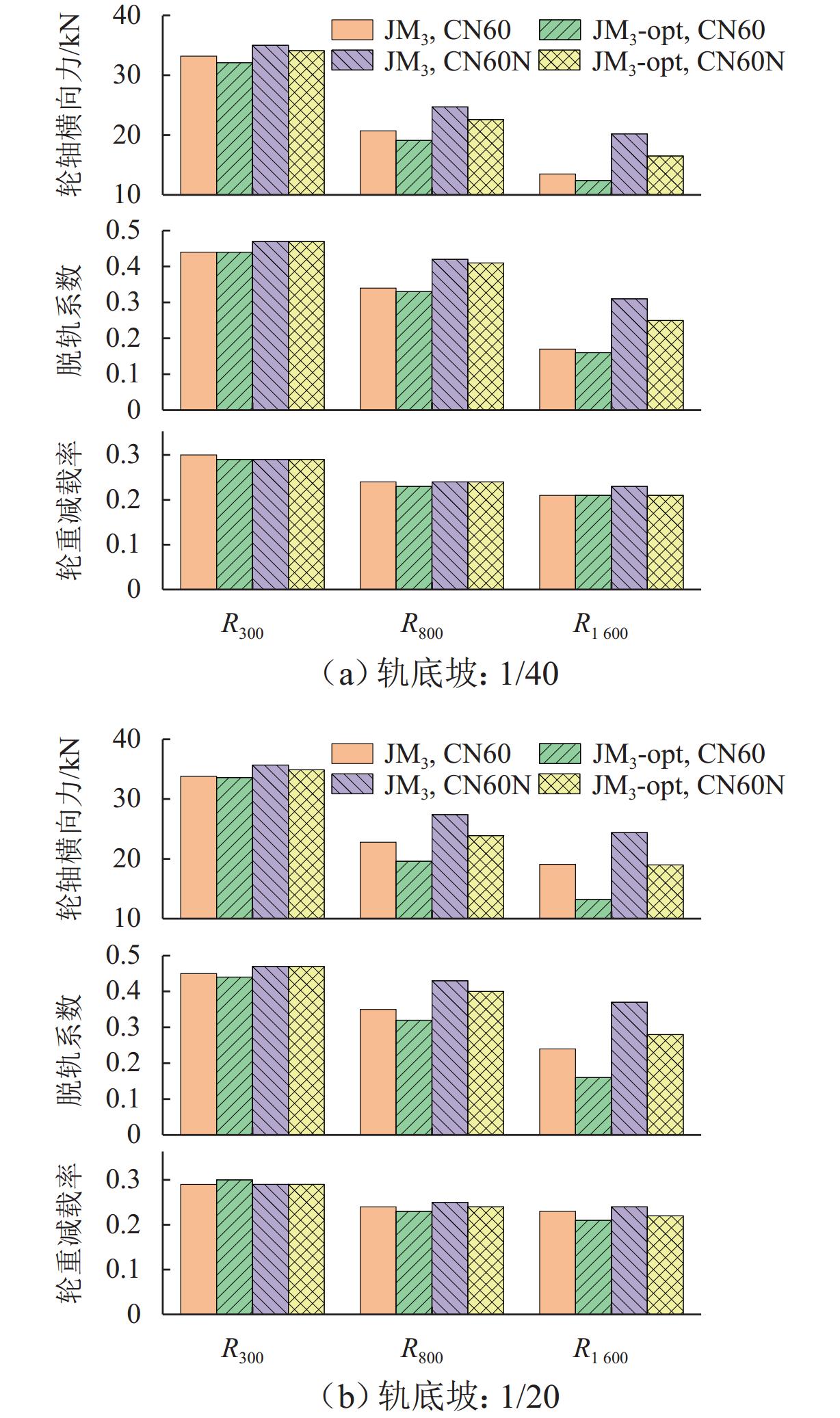

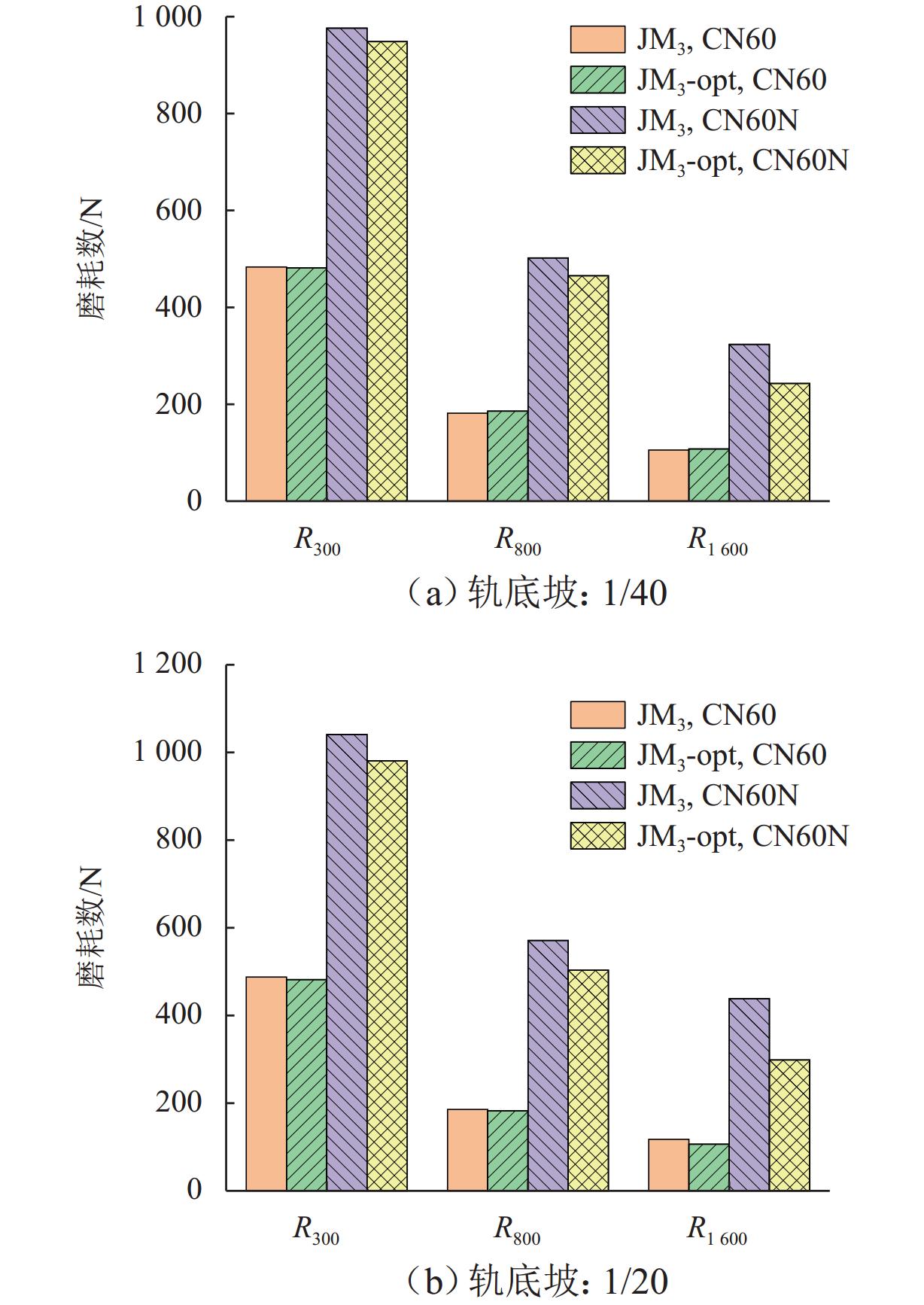

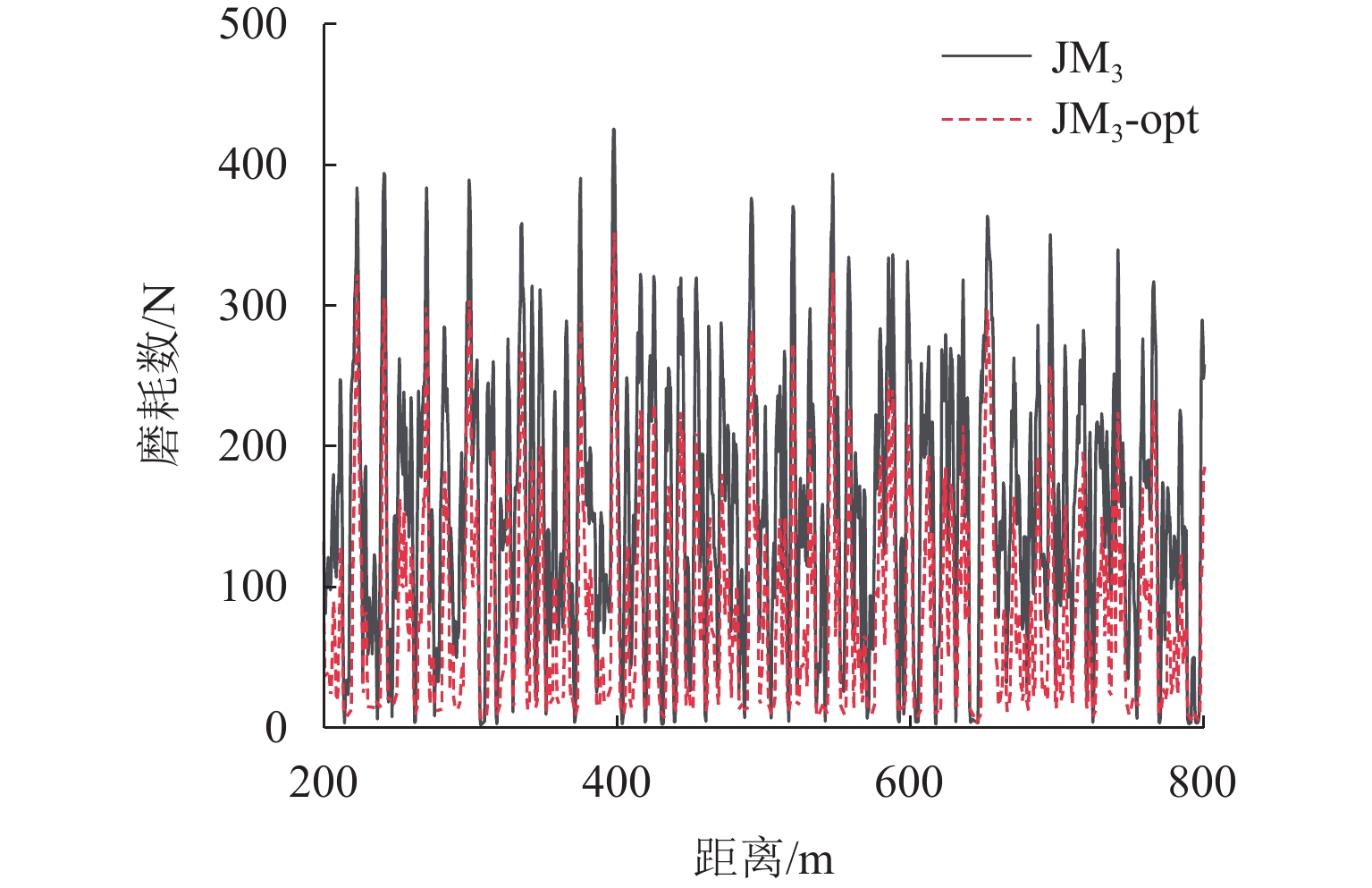

轮轨匹配对轨道车辆动力学性能有着重要影响,针对现行标准JM3车轮型面与国内不同类型钢轨廓形匹配时等效锥度差异过大,以及在大轨底坡条件下匹配打磨钢轨时因等效锥度过低而引发机车晃车的问题,本文以减小车轮型面在不同轨底坡条件下与CN60型和CN60N型2种钢轨匹配对应的等效锥度离散度为优化目标,采用圆弧、直线组合的车轮型面描述方法,应用NSGA-Ⅱ遗传算法优化滚动圆附近两段圆弧圆心横向位置参数,对JM3型面进行优化,并对优化前后的车轮型面进行轮轨接触特性和机车动力学性能仿真对比分析. 结果表明:优化型面在与上述钢轨匹配时,轮对3 mm横移量处的名义等效锥度均在0.1左右,显著降低原JM3踏面等效锥度离散度,提高了车轮型面对不同钢轨廓形和线路条件的适应性;同时,优化后的型面对应机车蛇行稳定性、横向平稳性、曲线通过性能和磨耗性能指标较原型面均得到提升,消除了特定线路机车的低频晃车现象.

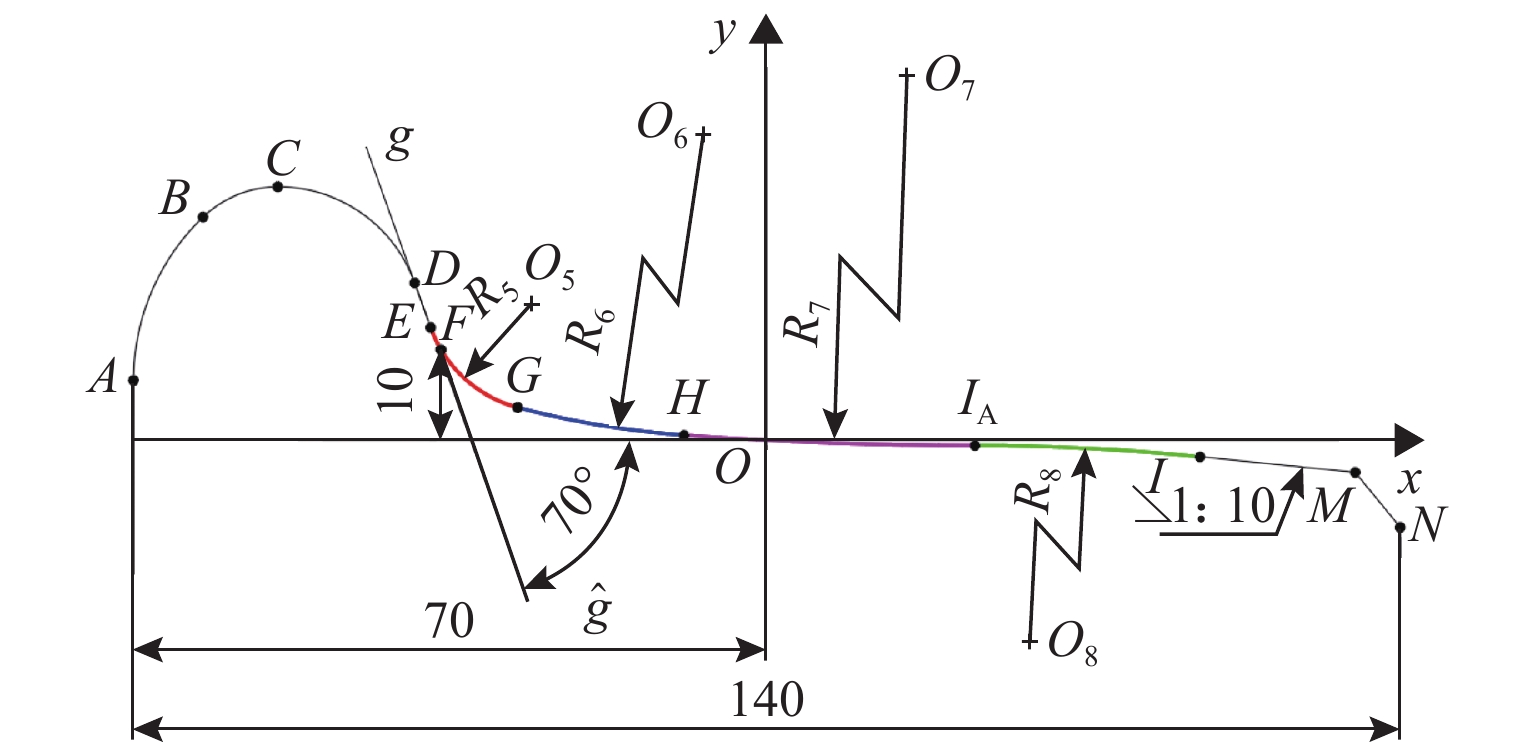

Abstract:Wheel-rail profile compatibility has an important influence on the dynamic performance of rail vehicles. The present standard JM3 wheel profile has a large difference in equivalent conicity when it is matched with different types of rail profiles in China. It has the problem of locomotive swaying caused by too low equivalent conicity when the profile is matched with the grinding rail with large rail cant. To address these issues, the optimization objective of reducing the equivalent conicity dispersion of the wheel profile matched with CN60 and CN60N rail profiles under different rail cants was set. The wheel profile was described by a method combining arcs and straight lines. The JM3 wheel profile was optimized by utilizing NSGA-II genetic algorithm to improve the lateral position parameters of the two arc centers near the rolling circle. The wheel-rail contact characteristics and the locomotive dynamic simulation of the wheel profile before and after optimization were compared. The results show that when the optimized wheel profile is matched with the rails above, the nominal equivalent conicities at the 3 mm transverse displacement of the wheelset are all about 0.1, which reduces the equivalent conicity dispersion of the original JM3 wheel profile and improves the adaptability of the wheel profile to different rail profiles and line conditions. At the same time, the locomotive hunting stability, lateral stability, curving performance, and wear performance index of the optimized profile are all improved compared with the original wheel profile. In addition, the phenomenon of low-frequency swaying of locomotives on specific lines is eliminated.

-

表 1 设计变量上下限

Table 1. Upper and lower limits of design variables

mm 圆弧参数 下限 上限 $x_{O_6} $ −9.0 −0.5 $x_{O_7} $ 10.0 30.0 表 2 计算等效锥度的匹配条件

Table 2. Matching conditions for calculating equivalent conicity

序号 钢轨 轨底坡 λi 1 CN60 1/40 λ1 2 1/20 λ2 3 CN60N 1/40 λ3 4 1/20 λ4 表 3 不同匹配条件的非线性临界速度

Table 3. Nonlinear critical speeds under different matching conditions

km/h 钢轨 轨底坡 JM3 JM3-opt CN60 1/40 395 390 1/20 215 345 CN60N 1/40 660 670 1/20 200 530 -

[1] PERSSON I, IWNICKI S. Optimisation of railway wheel profiles using a genetic algorithm[J]. Vehicle System Dynamics, 2004, 41: 517-526. [2] 李立,崔大宾,金学松. 车轮型面优化的研究进展[J]. 西南交通大学学报,2009,44(1): 13-19.LI Li, CUI Dabin, JIN Xuesong. State of arts of research on railway wheel profile optimization[J]. Journal of Southwest Jiaotong University, 2009, 44(1): 13-19. [3] 吴磊,康彦兵,董勇,等. 考虑打磨量的重载钢轨打磨廓形优化设计[J]. 西南交通大学学报,2022,57(4): 805-812.WU Lei, KANG Yanbing, DONG Yong, et al. Optimal design of heavy-haul rail grinding profile considering grinding amount[J]. Journal of Southwest Jiaotong University, 2022, 57(4): 805-812. [4] SHEVTSOV I Y, MARKINE V L, ESVELD C. Optimal design of wheel profile for railway vehicles[J]. Wear, 2005, 258(7/8): 1022-1030. [5] 成棣,王成国,刘金朝,等. 以圆弧参数为设计变量的车轮型面优化数学模型研究[J]. 中国铁道科学,2011,32(6): 107-113.CHENG Di, WANG Chengguo, LIU Jinzhao, et al. Research on the mathematical model for wheel profile optimization with arc parameters as design variables[J]. China Railway Science, 2011, 32(6): 107-113. [6] YE Y G, QI Y Y, SHI D C, et al. Rotary-scaling fine-tuning (RSFT) method for optimizing railway wheel profiles and its application to a locomotive[J]. Railway Engineering Science, 2020, 28(2): 160-183. doi: 10.1007/s40534-020-00212-z [7] SHEN G, AYASSE J B, CHOLLET H, et al. A unique design method for wheel profiles by considering the contact angle function[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2003, 217(1): 25-30. doi: 10.1243/095440903762727320 [8] JAHED H, FARSHI B, ESHRAGHI M A, et al. A numerical optimization technique for design of wheel profiles[J]. Wear, 2008, 264(1/2): 1-10. [9] POLACH O. Wheel profile design for target conicity and wide tread wear spreading[J]. Wear, 2011, 271(1/2): 195-202. [10] CUI D B, LI L, JIN X S, et al. Optimal design of wheel profiles based on weighed wheel/rail gap[J]. Wear, 2011, 271(1/2): 218-226. [11] SANTAMARIA J, HERREROS J, VADILLO E G, et al. Design of an optimised wheel profile for rail vehicles operating on two-track gauges[J]. Vehicle System Dynamics, 2013, 51(1): 54-73. doi: 10.1080/00423114.2012.711478 [12] 干锋,戴焕云,池茂儒,等. 铁道车辆车轮踏面反向优化设计方法[J]. 铁道学报,2015,37(9): 17-24.GAN Feng, DAI Huanyun, CHI Maoru, et al. A reverse optimal design method for wheel tread of railway vehicle[J]. Journal of the China Railway Society, 2015, 37(9): 17-24. [13] 成棣,孙琛,胡晓依,等. 面向低锥度晃车的CRH3平台动车组车轮型面优化[J]. 中国铁道科学,2020,41(6): 135-144.CHENG Di, SUN Chen, HU Xiaoyi, et al. Wheel profile optimization of CRH3 EMU oriented to carbody shaking caused by low equivalent conicity[J]. China Railway Science, 2020, 41(6): 135-144. [14] 祁亚运,戴焕云,干锋,等. 基于车轮磨耗和舒适度的CRH3型动车组型面优化研究[J]. 振动与冲击,2021,40(18): 148-155.QI Yayun, DAI Huanyun, GAN Feng, et al. Wheel profile optimization of CRH3 type of EMU based on wheel wear and passenger comfort[J]. Journal of Vibration and Shock, 2021, 40(18): 148-155. [15] 杜星,陶功权,杨城,等. 轨底坡变化对高速车辆运行行为的影响[J]. 西南交通大学学报,2022,57(2): 286-294.DU Xing, TAO Gongquan, YANG Cheng, et al. Influence of different rail cants on dynamical characteristics of high-speed railway vehicles[J]. Journal of Southwest Jiaotong University, 2022, 57(2): 286-294. [16] SUN J F, CHI M R, JIN X S, et al. Experimental and numerical study on carbody hunting of electric locomotive induced by low wheel–rail contact conicity[J]. Vehicle System Dynamics, 2021, 59(2): 203-223. doi: 10.1080/00423114.2019.1674344 [17] 宋志坤,孙琛,成棣,等. 车轮型面圆弧参数及其对轮轨接触和车辆动力学影响研究[J]. 中国铁道科学,2019,40(6):104-113.SONG Zhikun, SUN Chen, CHENG Di, et al. Research on arc parameters of wheel profile and its influence on wheel-rail contact and vehicle dynamics[J]. China Railway Science, 2019, 40(6):104-113. [18] 国家铁路局. 机车车辆车轮轮缘踏面外形:TB/T 449—2016[S]. 北京:中国铁道出版社,2016. [19] 孙琛. CRH3型平台高速动车组车轮型面多目标优化研究[D]. 北京:北京交通大学,2020. [20] 张维煜,李凯,杨鑫. 基于参数优先级划分的飞轮电机多目标优化[J]. 西南交通大学学报,2023,58(4): 922-932.ZHANG Weiyu, LI Kai, YANG Xin. Multi-objective optimization for flywheel motors based on parameter priority division[J]. Journal of Southwest Jiaotong University, 2023, 58(4): 922-932. [21] 石怀龙,罗仁,曾京. 国内外高速列车动力学评价标准综述[J]. 交通运输工程学报,2021,21(1): 36-58.SHI Huailong, LUO Ren, ZENG Jing. Review on domestic and foreign dynamics evaluation criteria of high-speed train[J]. Journal of Traffic and Transportation Engineering, 2021, 21(1): 36-58. [22] BRACCIALI A, MEGNA G. Contact mechanics issues of a vehicle equipped with partially independently rotating wheelsets[J]. Wear, 2016, 366/367: 233-240. doi: 10.1016/j.wear.2016.03.037 -

下载:

下载: