Calculation Method for Reinforcement Stress in Ultra-High Performance Concrete Beams Considering Bond-Slip Effect

-

摘要:

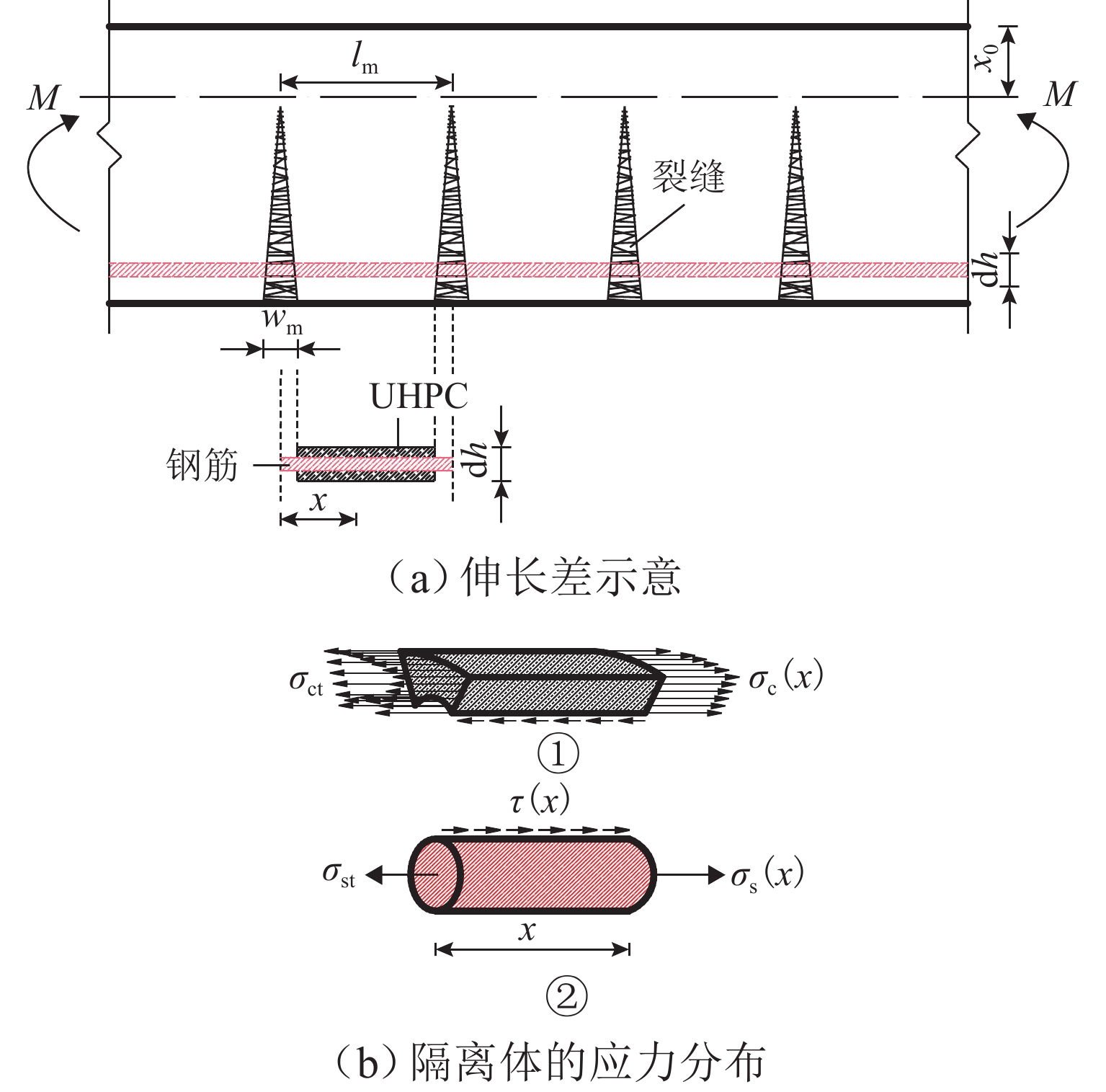

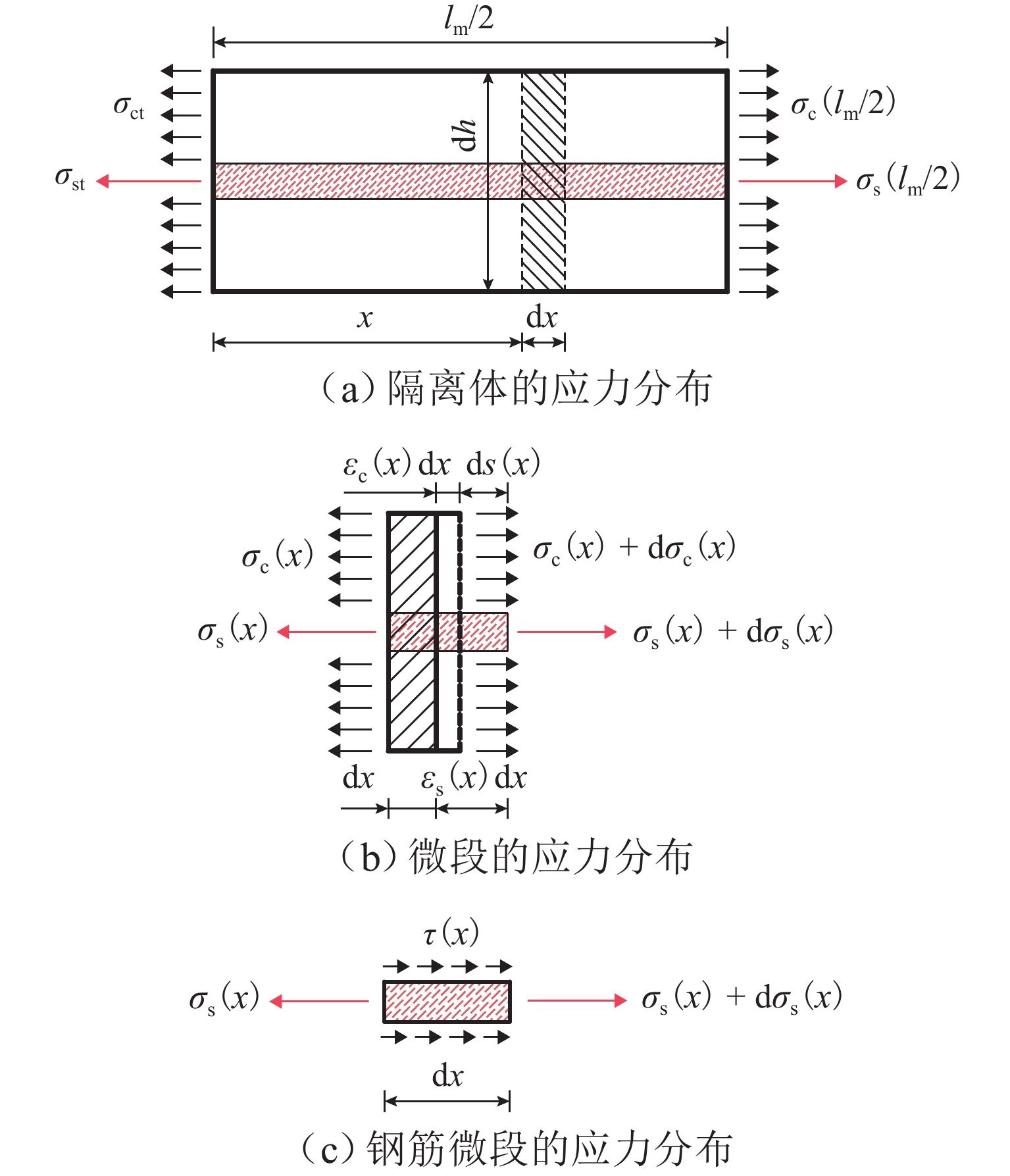

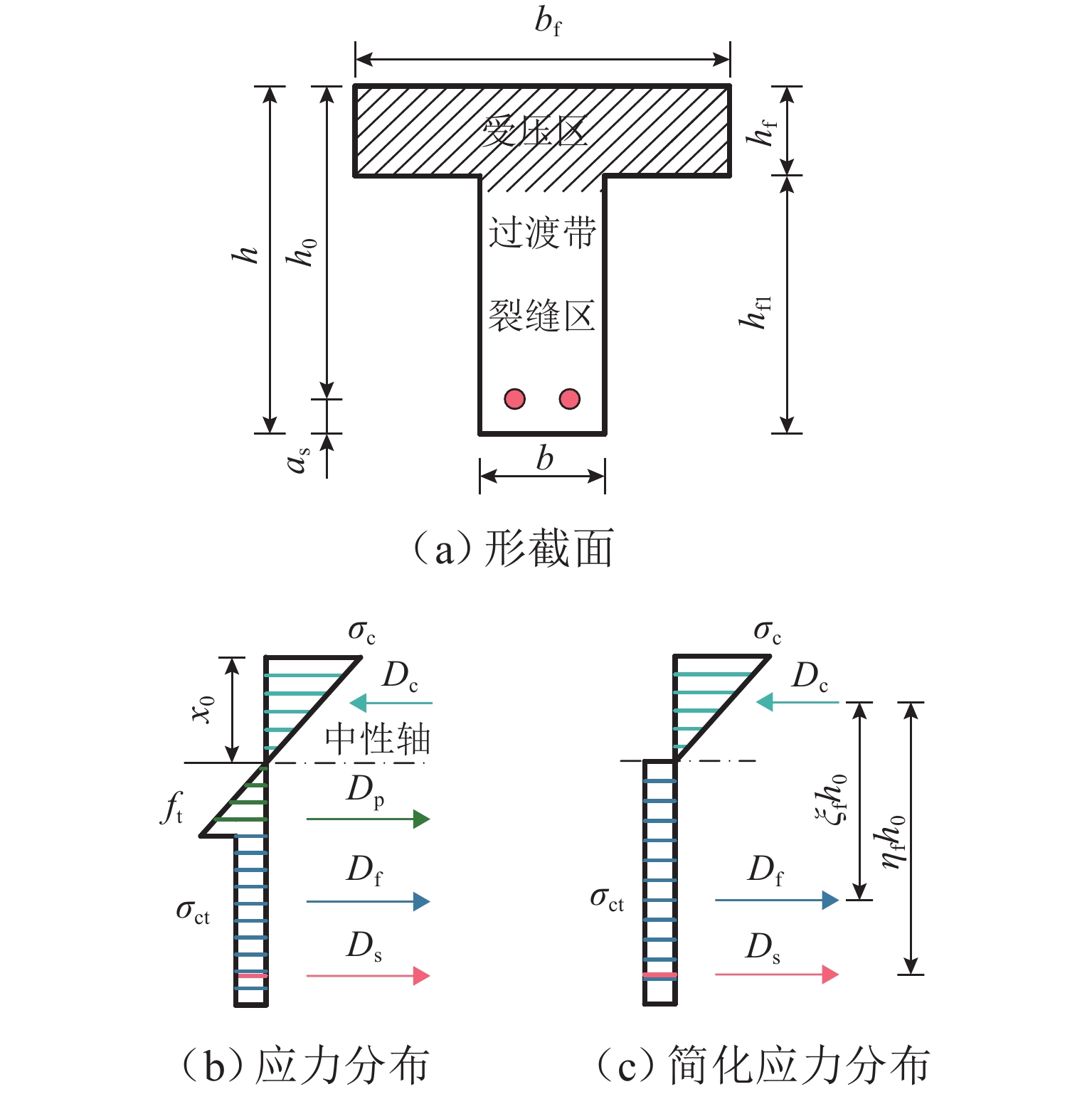

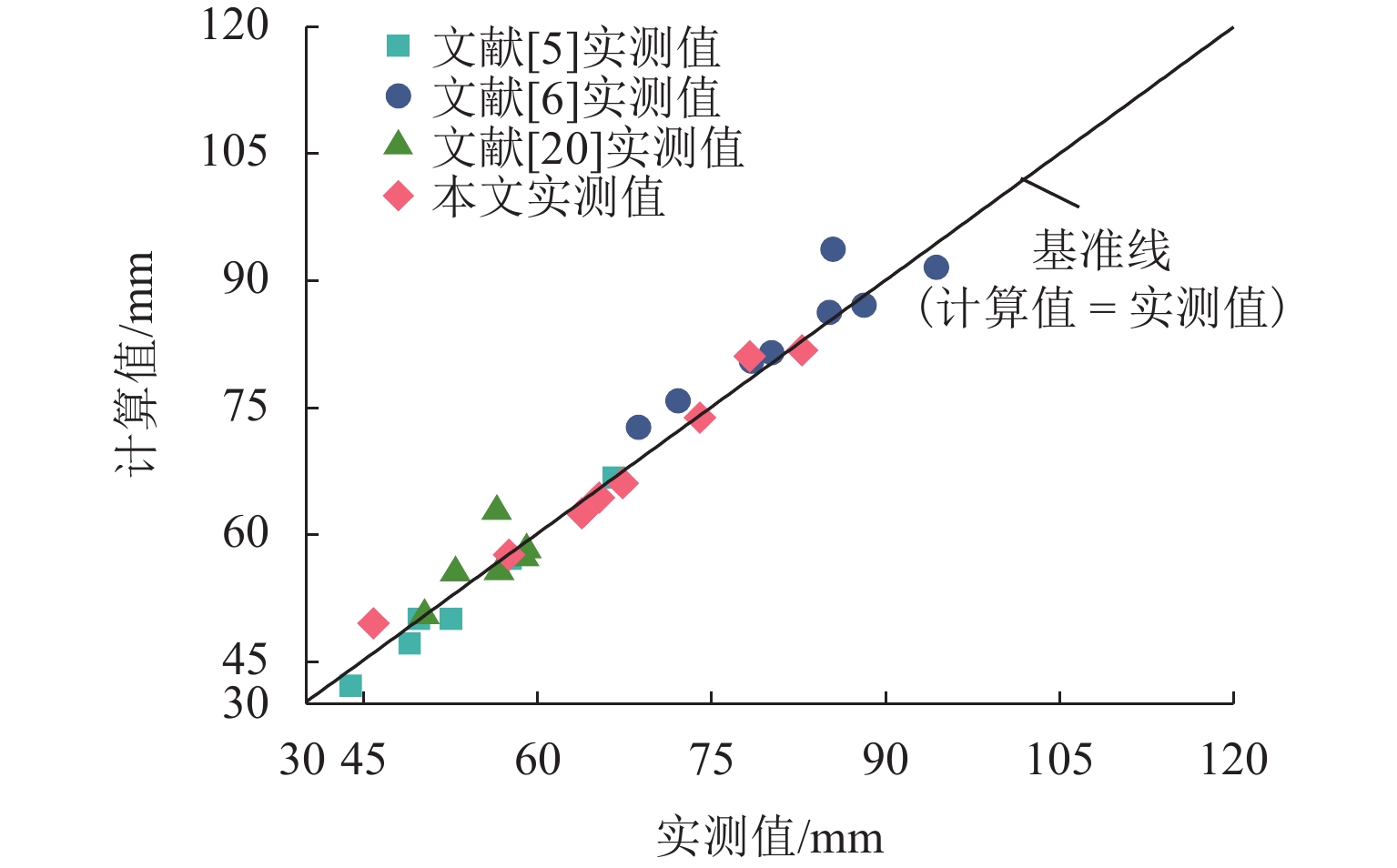

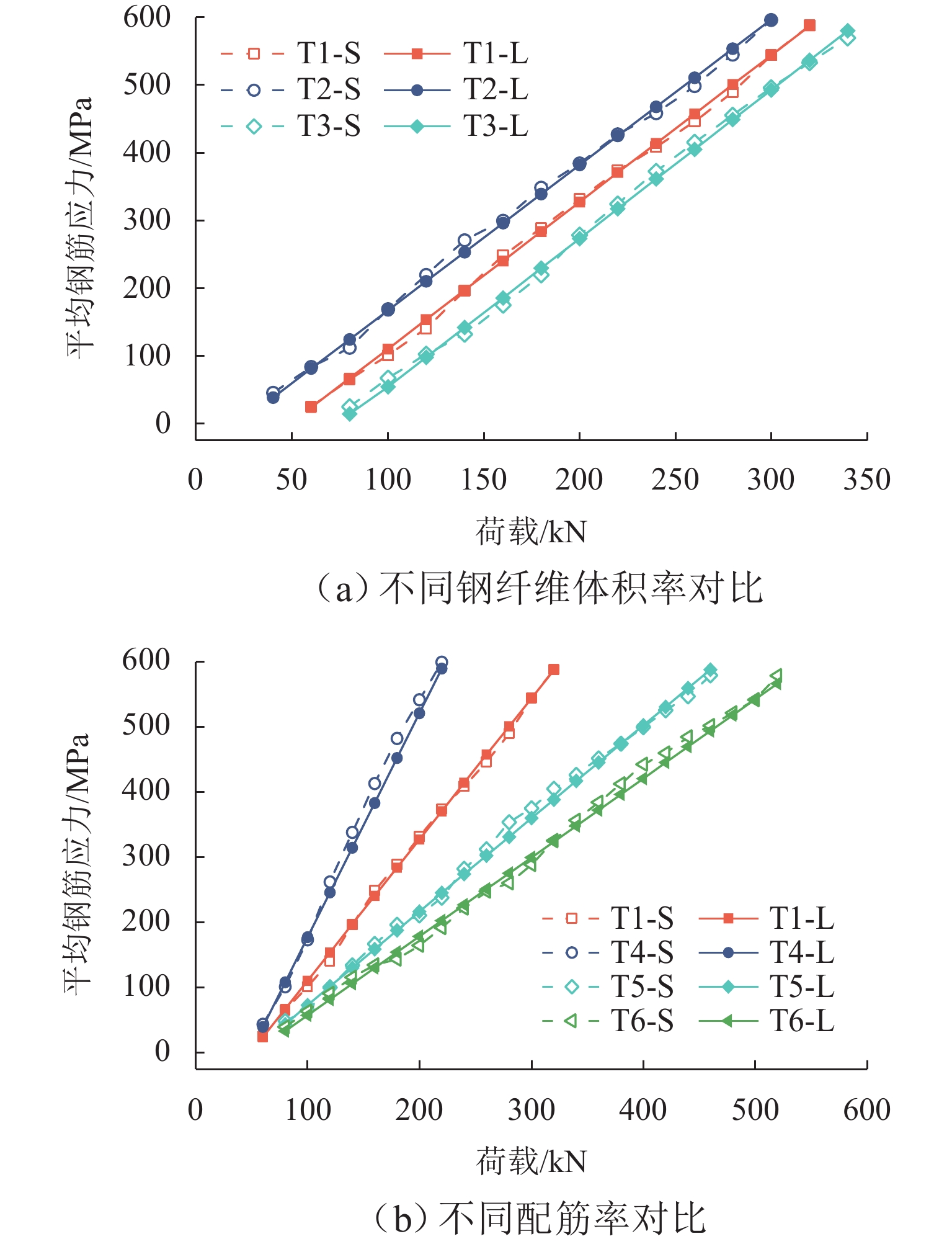

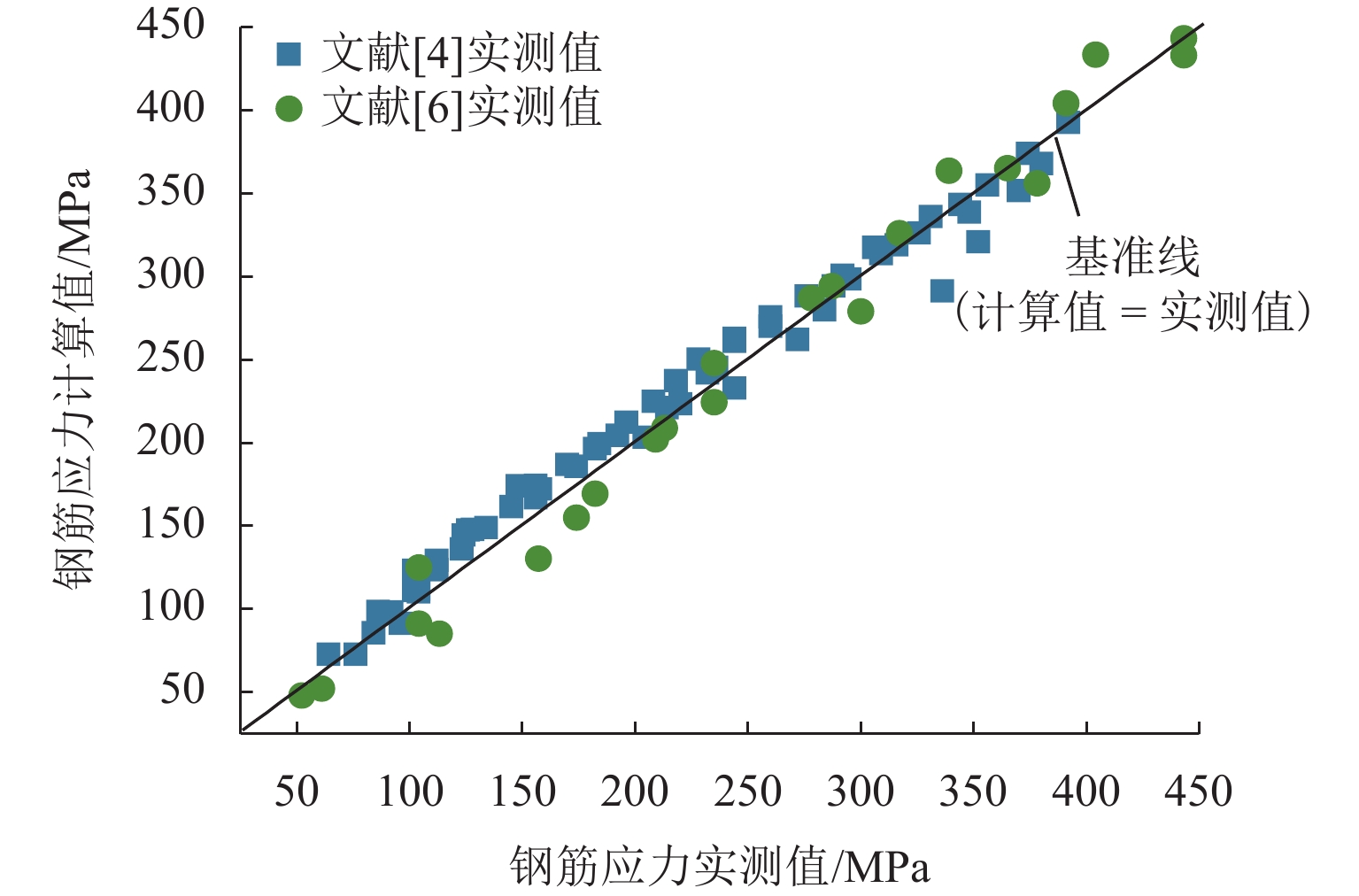

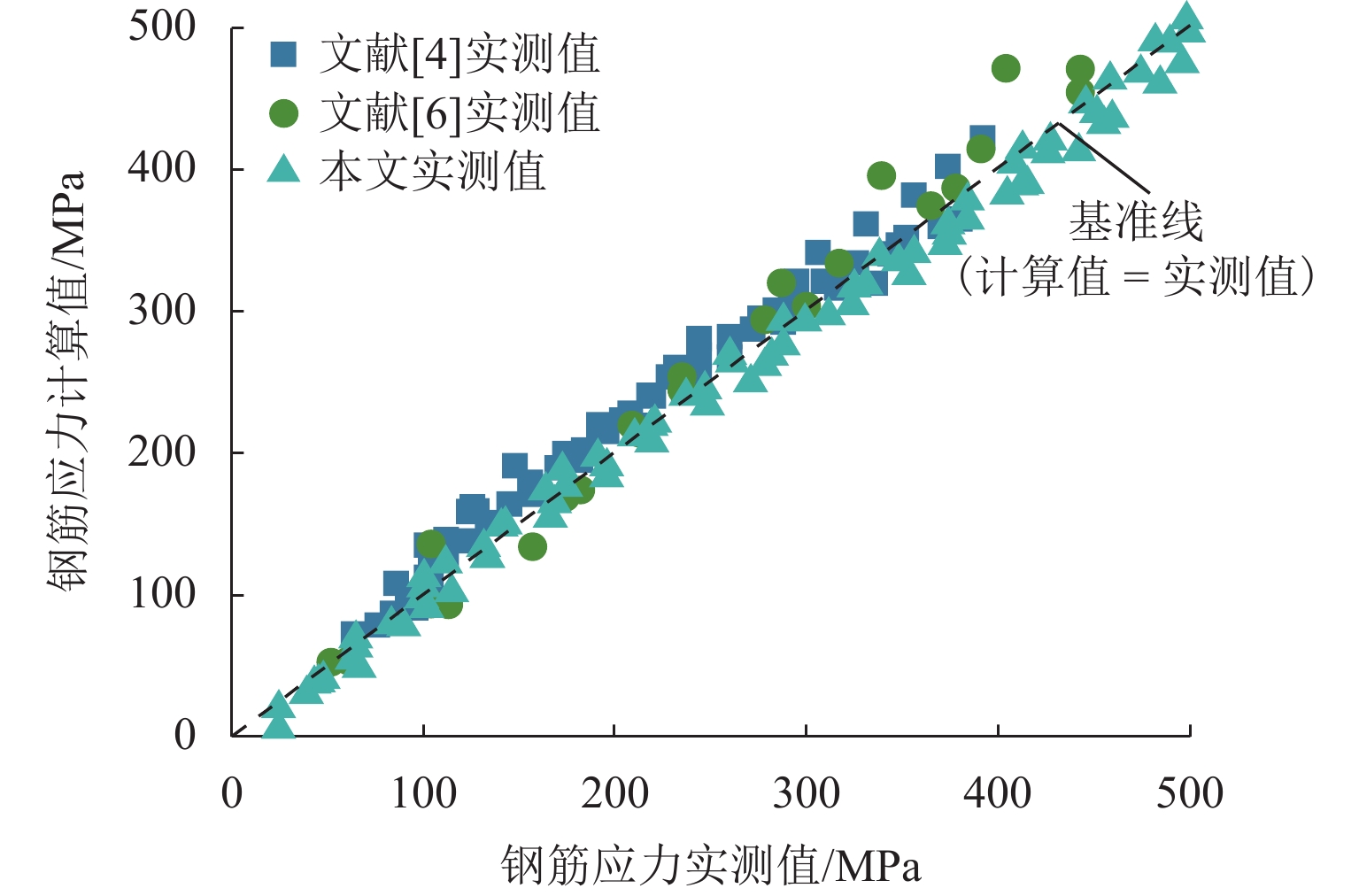

为建立适用于配筋超高性能混凝土(UHPC)梁的钢筋应力计算方法,对6片UHPC-T形截面梁开展四点弯曲试验,研究钢筋应力的变化规律. 从钢筋-UHPC受力平衡与变形协调机理出发,应用微元体建立平衡、变形以及黏结-滑移微分方程,导出能综合反映钢筋与UHPC界面黏结-滑移影响及钢纤维抗拉贡献的钢筋应力计算公式,并通过简化应变不均匀系数与裂缝截面钢筋应力计算,提出便于工程应用的钢筋应力简化公式. 研究表明:单位荷载下钢筋应力的增幅随配筋率的提高而减小,而与钢纤维体积率的变化无关;与普通混凝土梁相比,UHPC梁的钢筋应力在开裂截面处偏小,但其分布在相邻裂缝间的不均匀程度更高;钢筋应力建议公式计算值与本文、既有文献的试验值均吻合良好;钢筋应力简化公式计算值与试验值之比的均值为1.03,变异系数为0.06,表明该简化式可用于UHPC梁的钢筋应力计算.

-

关键词:

- 超高性能混凝土(UHPC) /

- 钢筋应力 /

- 黏结-滑移 /

- 应变不均匀系数 /

- 微元体

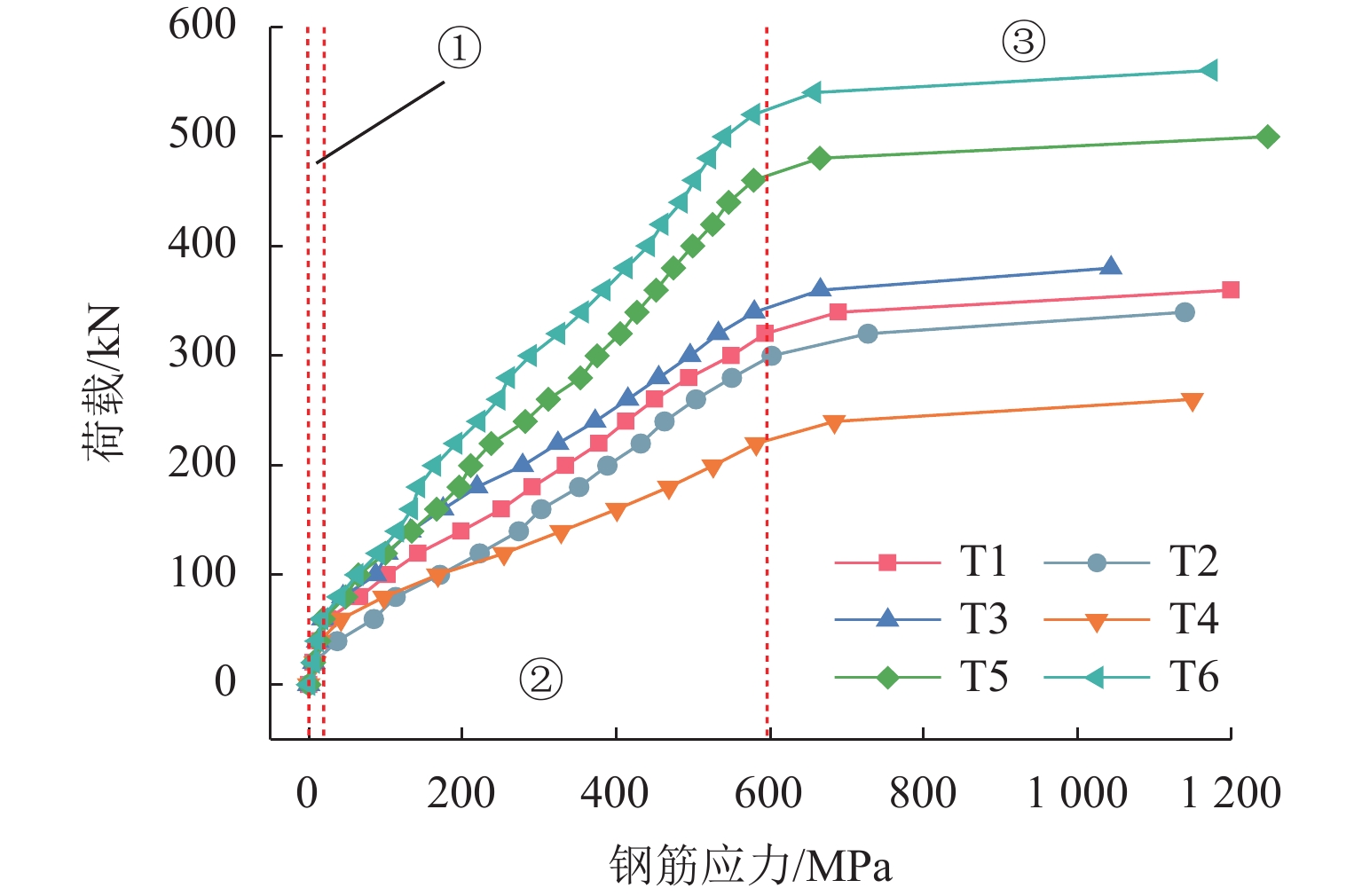

Abstract:Four-point bending tests were conducted on six ultra-high performance concrete T-shaped (UHPC-T) section beams to establish a reinforcement stress calculation method for reinforced UHPC beams and study the variation law of reinforcement stress. Based on the mechanism of force balance and deformation coordination between reinforcement and UHPC, a reinforcement stress calculation formula was derived using the differential equations of equilibrium, deformation, and bond-slip established by micro elements, which could comprehensively reflect the influence of bond-slip between reinforcement and UHPC interfaces and the contribution of steel fibers to tensile strength. By simplifying the calculation of the strain non-uniformity coefficient and the reinforcement stress in cracked sections, a simplified formula for reinforcement stress suitable for engineering applications was proposed. The results show that the increase in reinforcement stress under unit load decreases with the increase in reinforcement ratio, but it is not related to the change in steel fiber volume fraction. Compared with ordinary concrete beams, the reinforcement stress in UHPC beams is relatively small in the cracked section, but the uneven distribution of reinforcement stress between adjacent cracks is intensified. The calculation value of the suggested formula for reinforcement stress is in good agreement with the experimental values in this article and existing literature. The average ratio of the calculated value of the simplified formula for reinforcement stress to the experimental value is 1.03, and the coefficient of variation is 0.06, indicating that this simplified formula can be used for calculating reinforcement stress in UHPC beams.

-

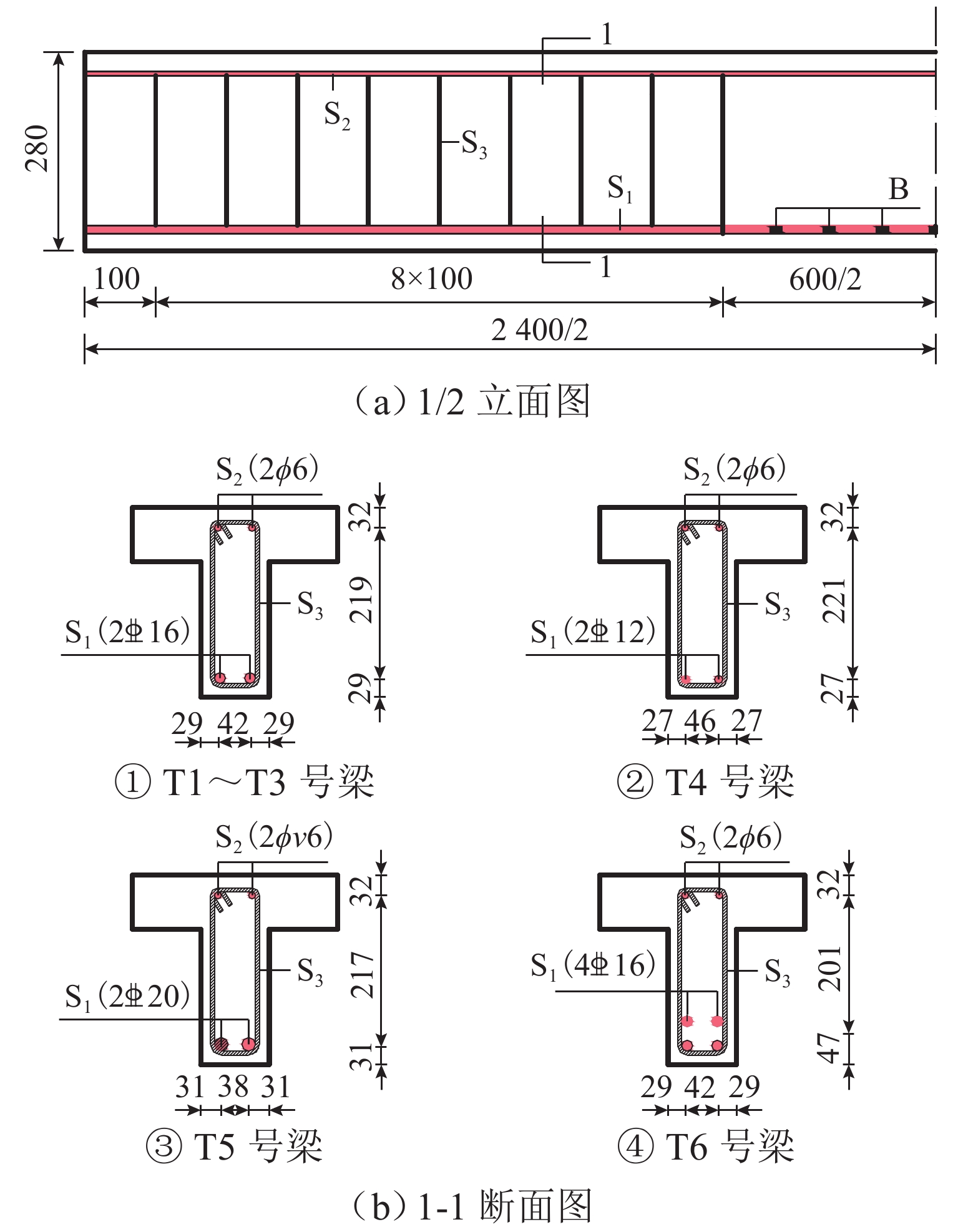

表 1 试件的编号与参数

Table 1. Number and parameters of specimens

变量 梁号 Vf/% 纵筋配置 ρs/% c/mm 标准梁 T1 2 2

1.60 15 钢纤维

体积率T2 1 2

1.60 T3 3 配筋率 T4 2 2

0.89 T5 2

2.51 T6 4

3.20 表 2 基本力学指标

Table 2. Basic mechanical indicators

Vf/% fcu/MPa fc/MPa ft/MPa Ec/GPa 1 121.22 83.72 6.35 41 2 133.71 89.14 7.84 42 3 141.53 97.82 9.32 44 表 3 钢筋应力的实测结果

Table 3. Measured results of reinforcement stress

梁号 Fcr/kN Ft/kN σcr/MPa σt/MPa Vm/(MPa•kN−1) T1 55.24 321.42 37.77 593.75 2.09 T2 37.27 311.31 32.23 602.22 2.08 T3 69.72 334.27 44.53 579.63 2.02 T4 43.43 218.51 41.82 581.70 3.08 T5 60.67 454.88 48.34 579.06 1.35 T6 61.14 529.20 39.25 578.51 1.15 表 4 系数n与S1的取值

Table 4. Values of coefficients n and S1

梁号 n S1 T1 0.64 1.10 T2 0.66 0.90 T3 0.60 0.99 T4 0.62 1.17 T5 0.64 0.95 T6 0.71 0.87 -

[1] SHIRAI K, YIN H, TEO W. Flexural capacity prediction of composite RC members strengthened with UHPC based on existing design models[J]. Structures, 2020, 23: 44-55. doi: 10.1016/j.istruc.2019.09.017 [2] ELSAYED M, BADAWY S, TAYEH B A, et al. Shear behaviour of ultra-high performance concrete beams with openings[J]. Structures, 2022, 43(6): 546-558. [3] WANG J Q, QI J N, TONG T, et al. Static behavior of large stud shear connectors in steel-UHPC composite structures[J]. Engineering Structures, 2019, 178: 534-542. doi: 10.1016/j.engstruct.2018.07.058 [4] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范:GB 50010—2010[S]. 北京:中国建筑工业出版社,2010. [5] 邱明红,邵旭东,胡伟业,等. 钢筋UHPC受弯构件裂缝宽度计算方法研究[J]. 土木工程学报,2020,53(10): 89-98,119.QIU Minghong, SHAO Xudong, HU Weiye, et al. Calculation method for crack width of reinforced UHPC flexural components[J]. China Civil Engineering Journal, 2020, 53(10): 89-98,119. [6] 邱明红,邵旭东,胡伟业,等. 钢筋UHPC矩形截面受弯构件的钢筋应力简化计算[J]. 中国公路学报,2021,34(8): 106-117.QIU Minghong, SHAO Xudong, HU Weiye, et al. Simplified calculation of reinforcement stress in reinforced UHPC bending members with rectangular sections[J]. China Journal of Highway and Transport, 2021, 34(8): 106-117. [7] 郑文忠,李莉,卢姗姗. 钢筋活性粉末混凝土简支梁正截面受力性能试验研究[J]. 建筑结构学报,2011,32(6): 125-134.ZHENG Wenzhong, LI Li, LU Shanshan. Experimental research on mechanical performance of normal section of reinforced reactive powder concrete beam[J]. Journal of Building Structures, 2011, 32(6): 125-134. [8] 赵国藩,王清湘. 钢筋混凝土构件裂缝宽度分析的应力图形和计算模式[J]. 大连工学院学报,1984,24(4): 87-94.ZHAO Guofan, WANG Qingxiang. Stress distribution and calculation formula for crack width analysis of reinforced concrete members[J]. Journal of Dalian University of Technology, 1984, 24(4): 87-94. [9] 朱虹,董志强,吴刚,等. FRP筋混凝土梁的刚度试验研究和理论计算[J]. 土木工程学报,2015,48(11): 44-53.ZHU Hong, DONG Zhiqiang, WU Gang, et al. Experimental study and theoretical calculation on the flexural stiffness of concrete beams reinforced with FRP bars[J]. China Civil Engineering Journal, 2015, 48(11): 44-53. [10] 贾方方. 钢筋与活性粉末混凝土粘结性能的试验研究[D]. 北京:北京交通大学,2013. [11] 徐海宾,邓宗才. UHPC梁开裂弯矩和裂缝试验[J]. 哈尔滨工业大学学报,2014,46(4): 87-92.XU Haibin, DENG Zongcai. Cracking moment and crack width of ultra-high performance concrete beams[J]. Journal of Harbin Institute of Technology, 2014, 46(4): 87-92. [12] YOO D Y, YOON Y S. A review on structural behavior, design, and application of ultra-high-performance fier-reinforced concrete[J]. International Journal of Concrete Structures and Materials, 2016, 10(2): 125-142. doi: 10.1007/s40069-016-0143-x [13] HASGUL U, TURKER K, BIROL T, et al. Flexural behavior of ultra-high-performance fiber reinforced concrete beams with low and high reinforcement ratios[J]. Structural Concrete, 2018, 19(6): 1577-1590. doi: 10.1002/suco.201700089 [14] AHMED K S, HABIB M A, ASEF M F. Flexural response of stainless steel reinforced concrete beam[J]. Structures, 2021, 34: 589-603. doi: 10.1016/j.istruc.2021.08.019 [15] 中华人民共和国住房和城乡建设部. 活性粉末混凝土:GB/T 31387—2015 [S]. 北京:中国标准出版社,2015. [16] 中国建筑科学研究院. 混凝土结构试验方法标准:GB/T 50152—2012[S]. 北京:中国建筑工业出版社,2012. [17] 高丹盈,张明,赵军. 疲劳荷载下钢纤维高强混凝土梁裂缝宽度的计算方法[J]. 土木工程学报,2013,46(3): 40-48.GAO Danying, ZHANG Ming, ZHAO Jun. Calculating method for crack width of steel fiber reinforced high-strength concrete beams under fatigue loads[J]. China Civil Engineering Journal, 2013, 46(3): 40-48. [18] 宁喜亮,丁一宁. 钢筋钢纤维自密实混凝土梁裂缝宽度试验研究[J]. 工程力学,2017,34(4): 116-124.NING Xiliang, DING Yining. Experimental research on crack width of steel fibers reinforced self-consolidating concrete beams[J]. Engineering Mechanics, 2017, 34(4): 116-124. [19] 高丹盈,刘建秀. 钢纤维混凝土基本理论[M]. 北京:科学技术文献出版社,1994. [20] 贾方方,安明喆,余自若,等. 钢筋与活性粉末混凝土黏结性能的梁式试验研究[J]. 铁道学报,2012,34(6): 83-87.JIA Fangfang, AN Mingzhe, YU Ziruo, et al. Beam test of bond behavior between steel bars and reactive powder concrete[J]. Journal of the China Railway Society, 2012, 34(6): 83-87. [21] BABY F, MARCHAND P, ATRACH M, et al. Analysis of flexure-shear behavior of UHPFRC beams based on stress field approach[J]. Engineering Structures, 2013, 56: 194-206. doi: 10.1016/j.engstruct.2013.04.024 [22] 徐明雪,梁兴文,汪萍,等. 超高性能混凝土梁正截面受弯承载力理论研究[J]. 工程力学,2019,36(8): 70-78.XU Mingxue, LIANG Xingwen, WANG Ping, et al. Theoretical investigation on normal section flexural capacity of uhpc beams[J]. Engineering Mechanics, 2019, 36(8): 70-78. [23] BAE B I, CHOI H K, CHOI C S. Flexural strength evaluation of reinforced concrete members with ultra high performance concrete[J]. Advances in Materials Science and Engineering, 2016, 2016: 2815247.1-2815247.11. [24] 王景全,戚家南,刘加平. 基于细观本构模型的UHPC梁受弯全过程分析[J]. 建筑结构学报,2020,41(9): 137-144.WANG Jingquan, QI Jianan, LIU Jiaping. Flexural analysis of UHPC beams based on a mesoscale constitutive model[J]. Journal of Building Structures, 2020, 41(9): 137-144. [25] 周建民,王眺,赵勇,等. 高强钢筋混凝土受弯构件裂缝宽度计算方法的研究[J]. 土木工程学报,2010,43(9): 69-76.ZHOU Jianmin, WANG Tiao, ZHAO Yong, et al. Research on the calculation of crack width for RC flexural member using high-strength bars[J]. China Civil Engineering Journal, 2010, 43(9): 69-76. [26] 程东辉,范永萱,王彦松. RC类活性粉末混凝土钢筋粘结-滑移本构模型[J]. 吉林大学学报(工学版),2021,51(4): 1317-1330.CHENG Donghui, FAN Yongxuan, WANG Yansong. Bond-slip constitutive model of steel bars and reactive powder concrete under standard curing[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(4): 1317-1330. [27] 张哲,李帅帅,朱平,等. 钢筋-超高性能混凝土界面黏结性能试验[J]. 湖南大学学报(自然科学版),2022,49(11): 105-115.ZHANG Zhe, LI Shuaishuai, ZHU Ping, et al. Test on interface bonding behavior between steel rebar and ultra-high performance concrete[J]. Journal of Hunan University (Natural Sciences), 2022, 49(11): 105-115. [28] 梁芮,黄远. 高强钢筋与超高性能混凝土黏结性能试验研究[J]. 建筑结构学报,2022,43(9): 294-302.LIANG Rui, HUANG Yuan. Experimental study on bond performance between high strength steel rebar and ultra-high performance concrete[J]. Journal of Building Structures, 2022, 43(9): 294-302. -

下载:

下载: