Seismic Performance of Concrete Composite Columns of Ultra-High Performance Concrete Precast Pipe

-

摘要:

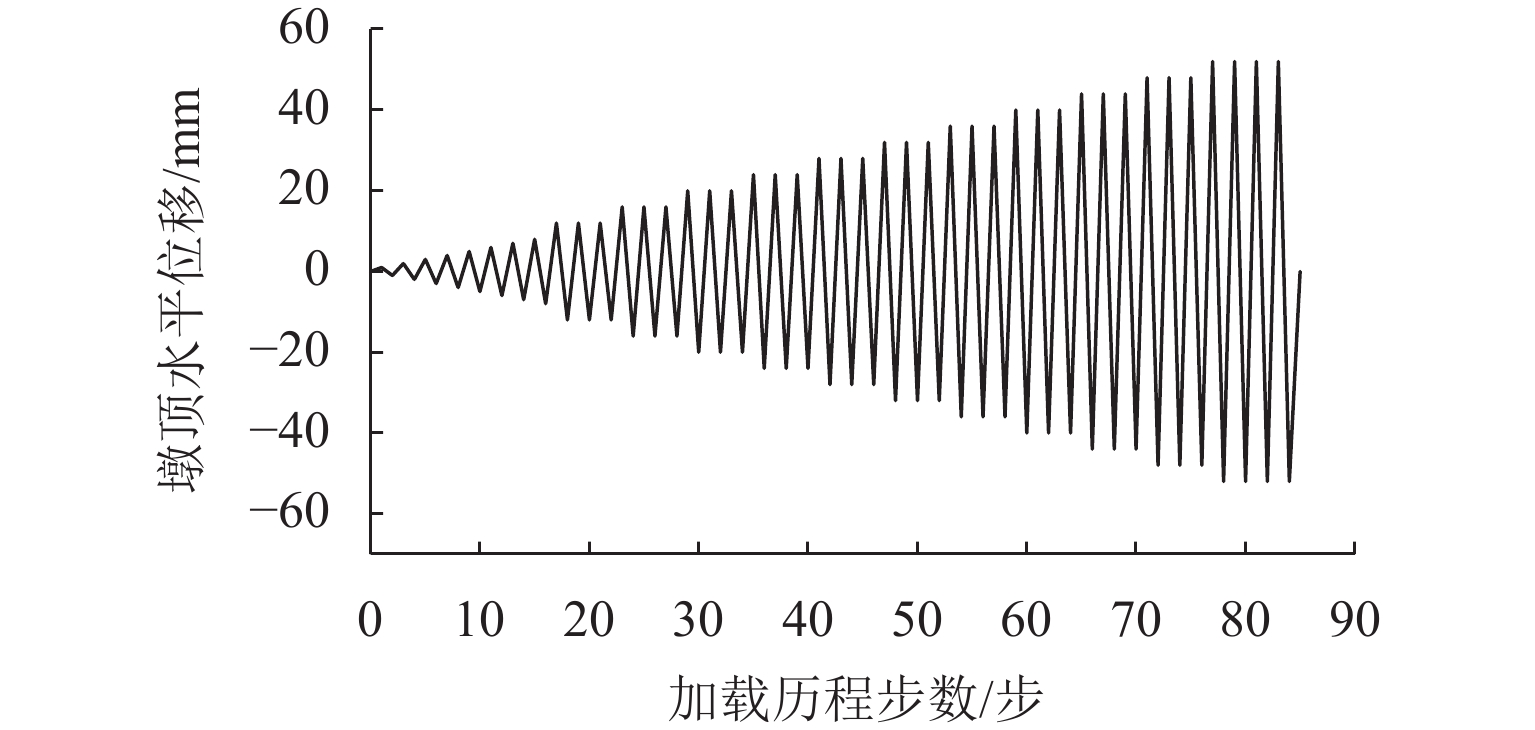

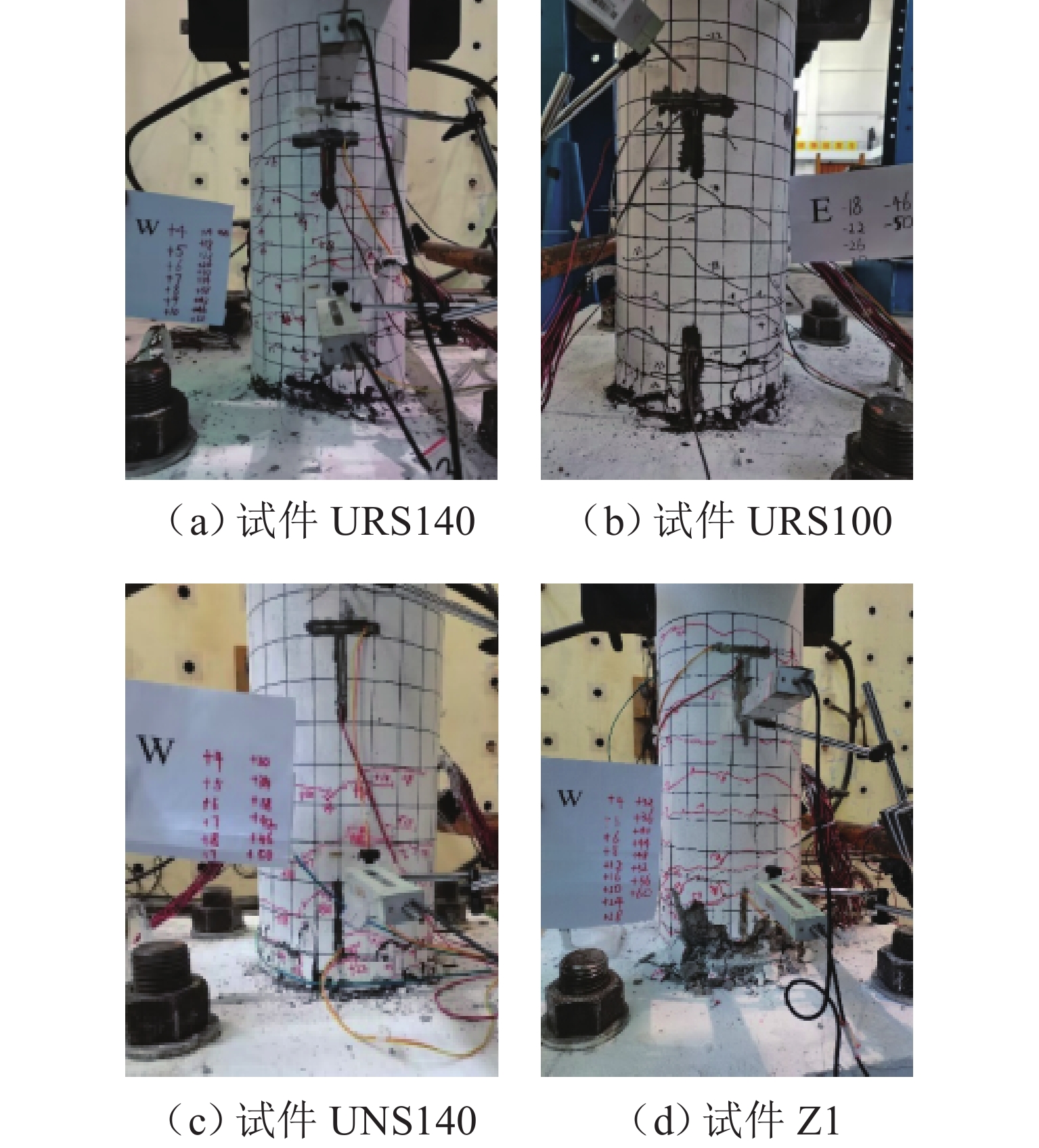

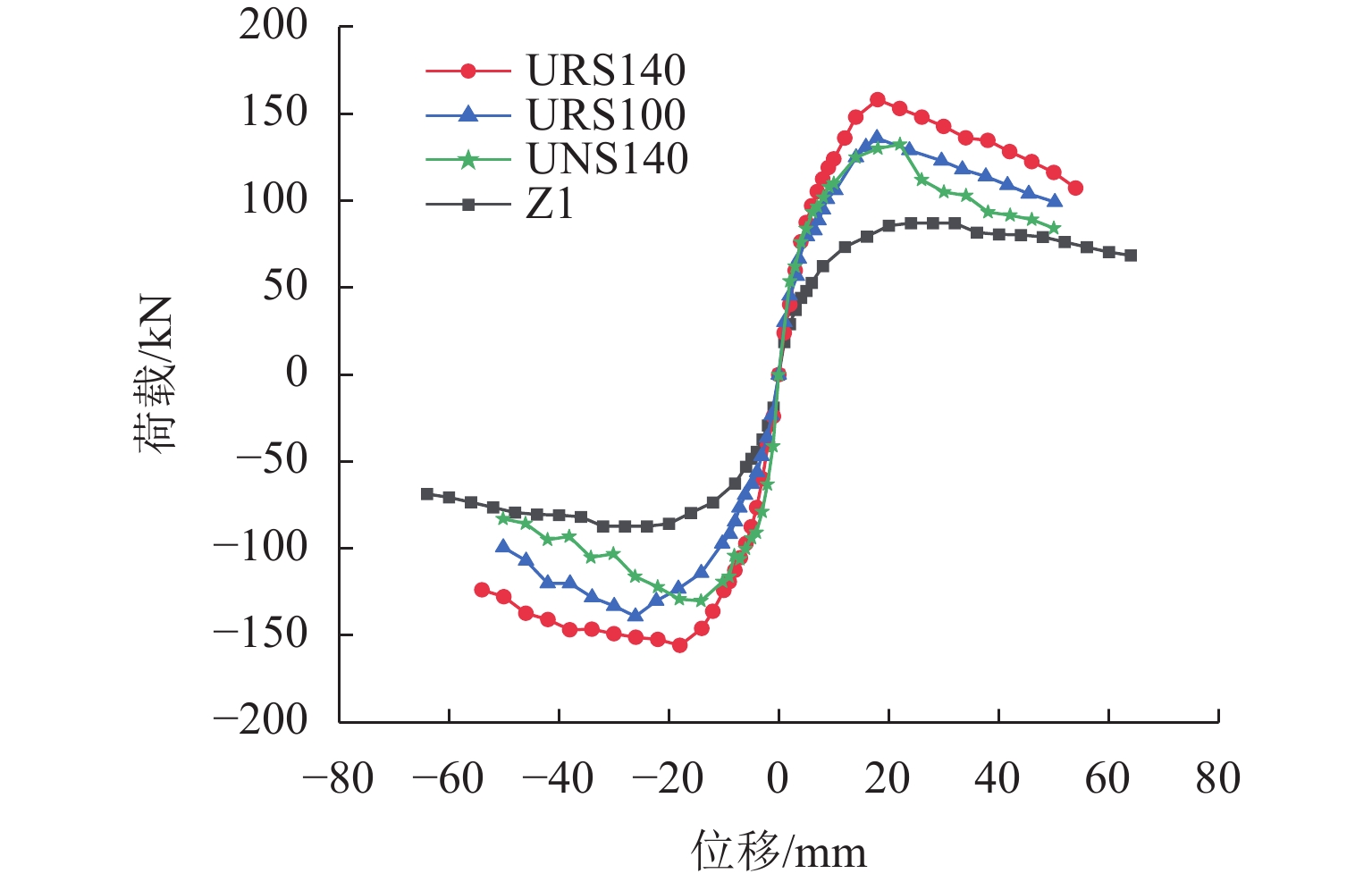

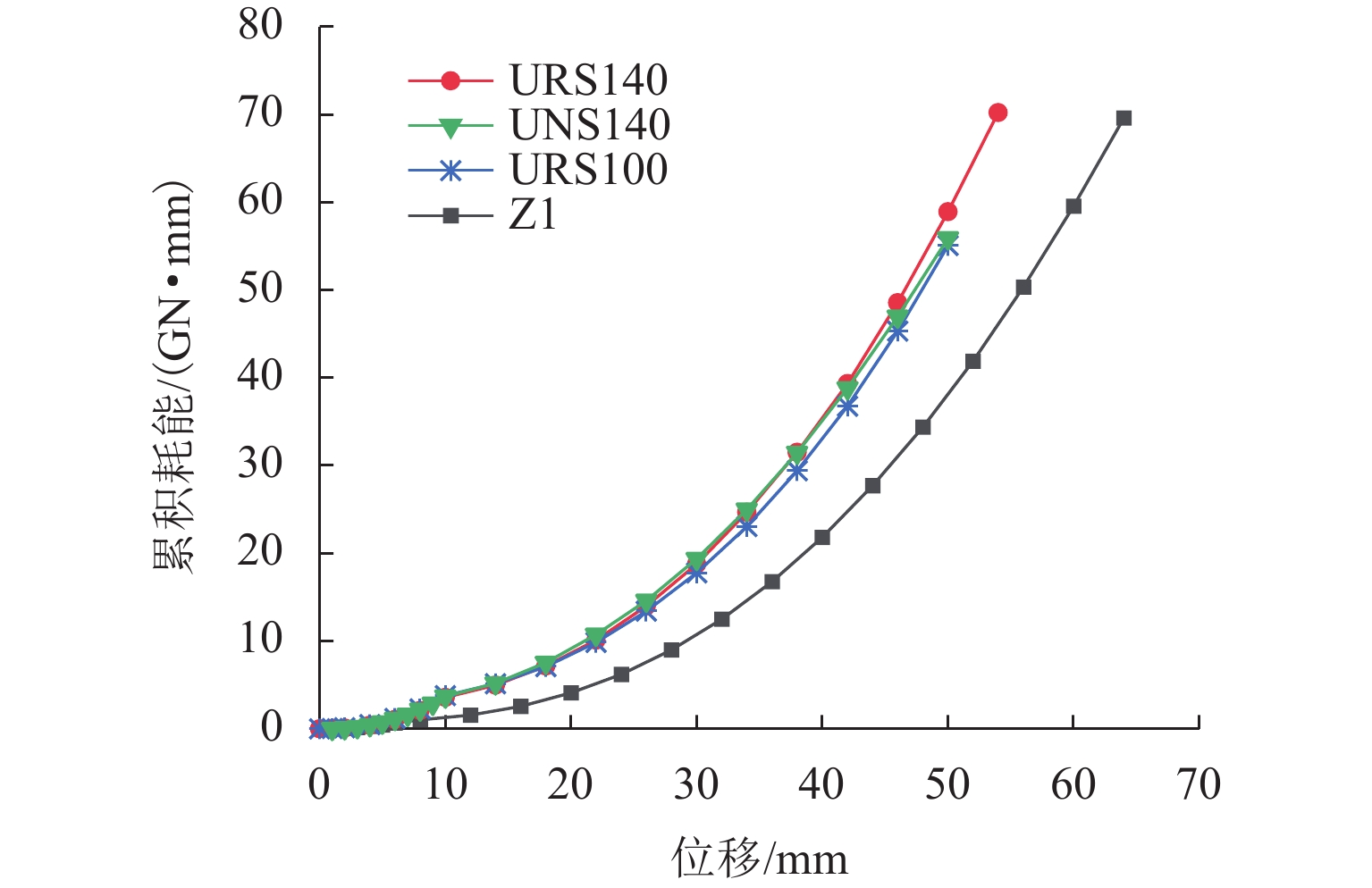

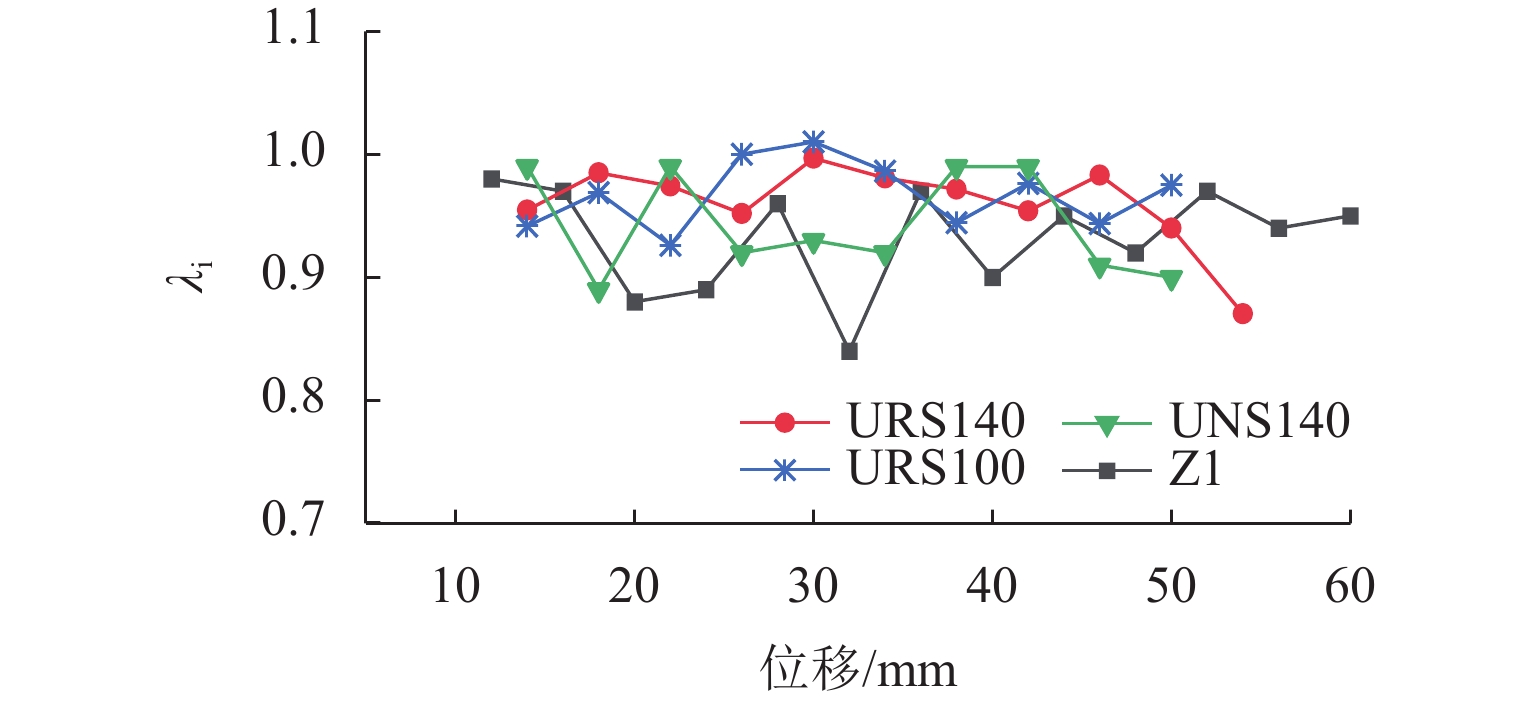

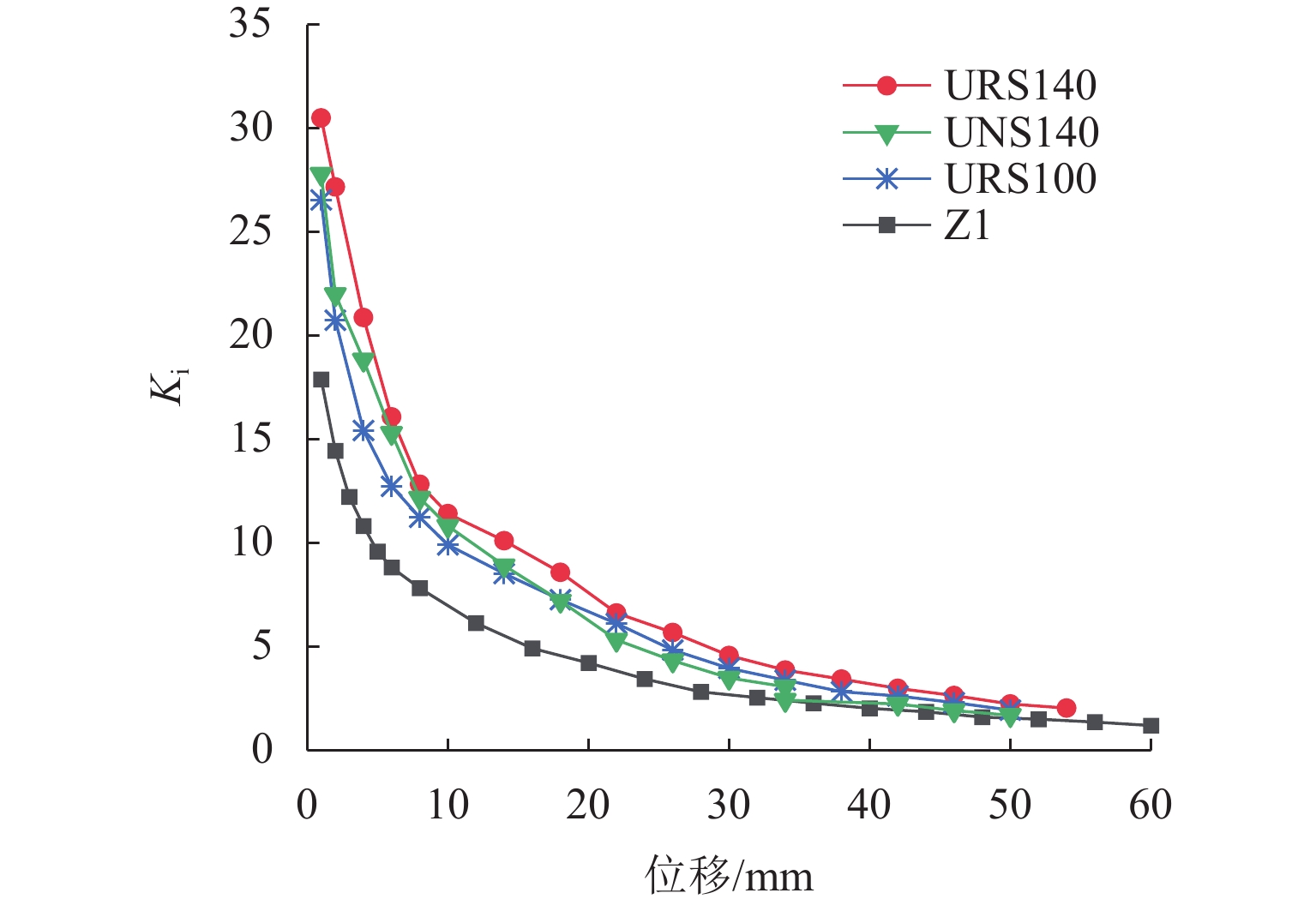

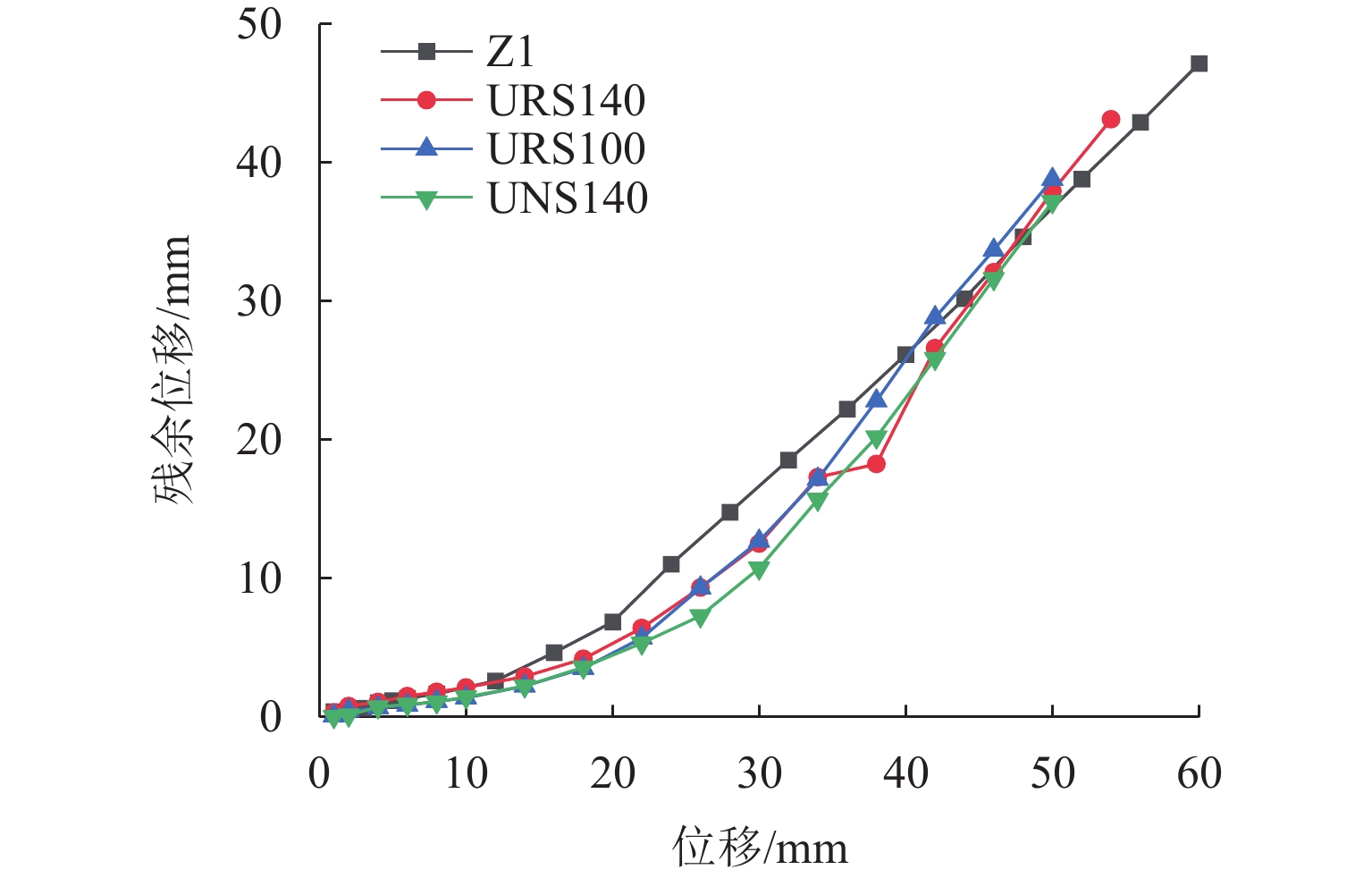

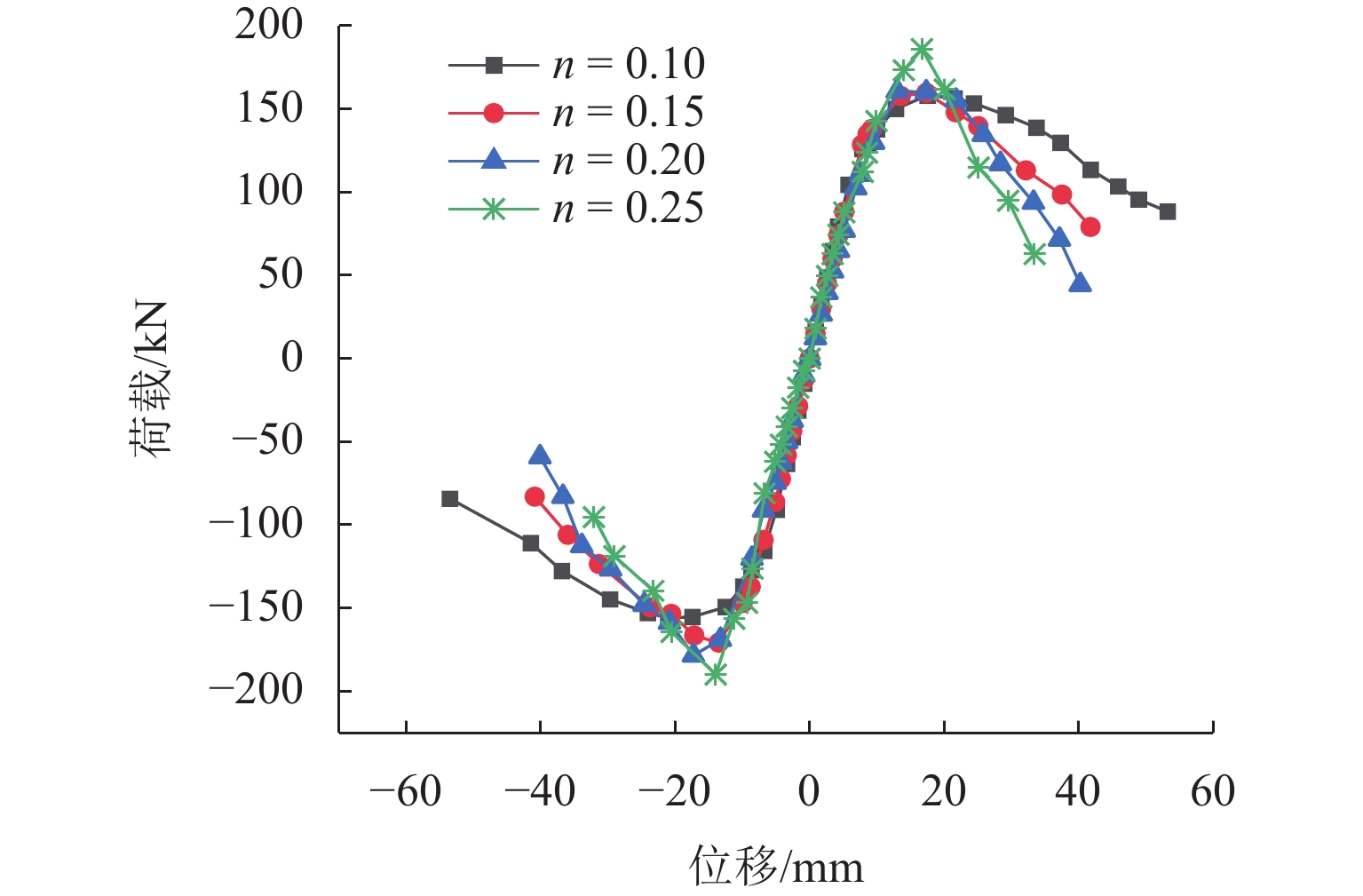

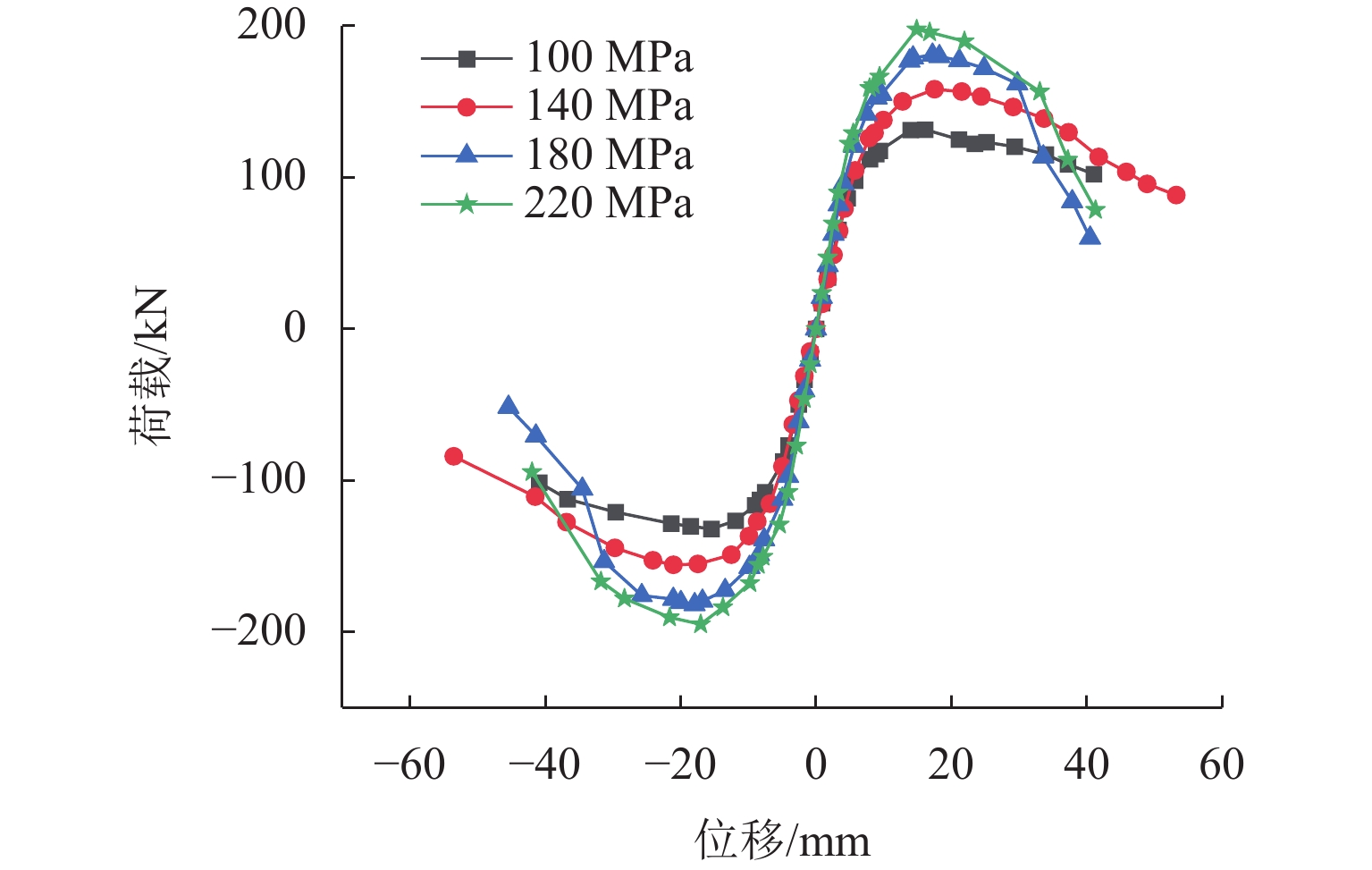

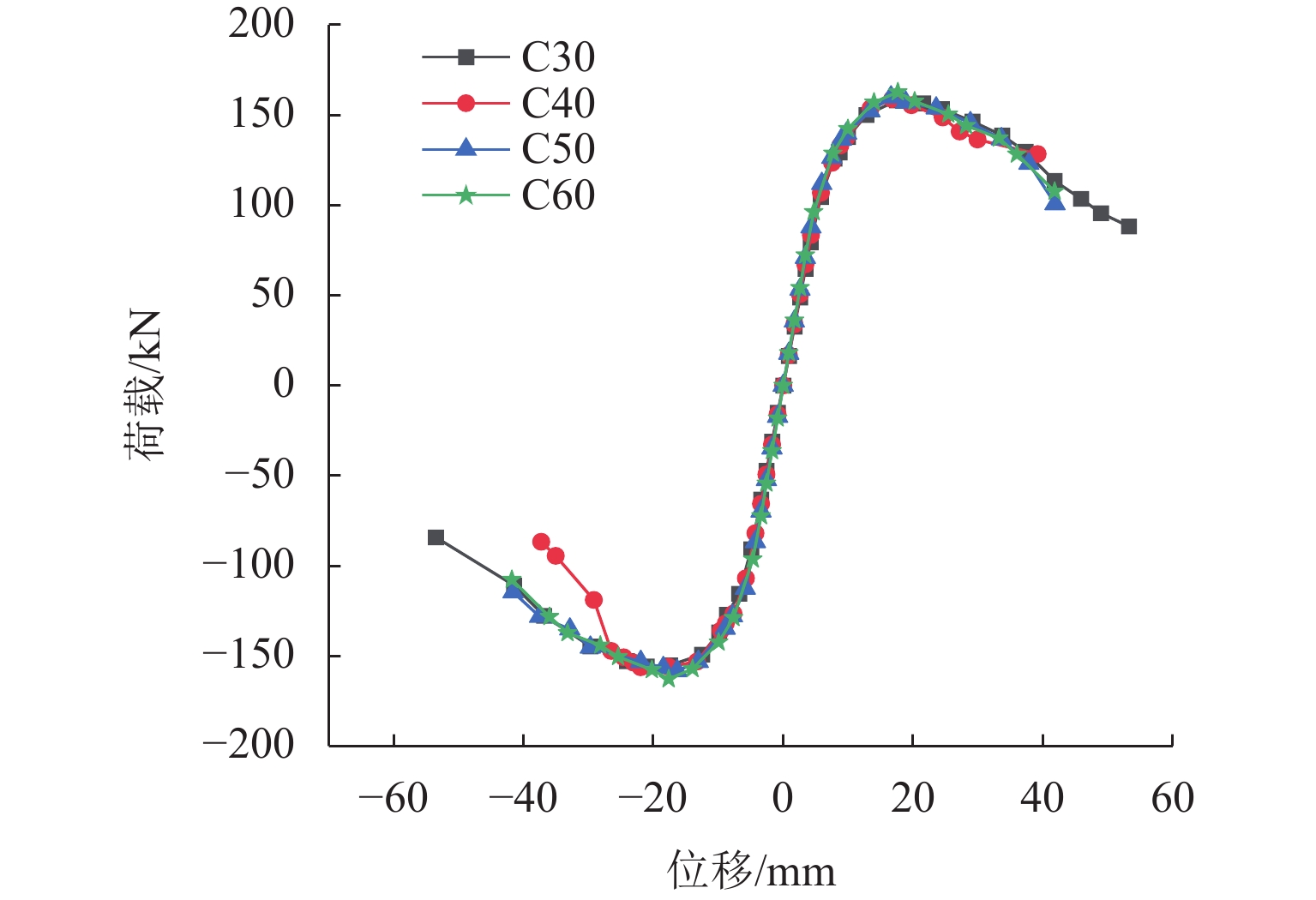

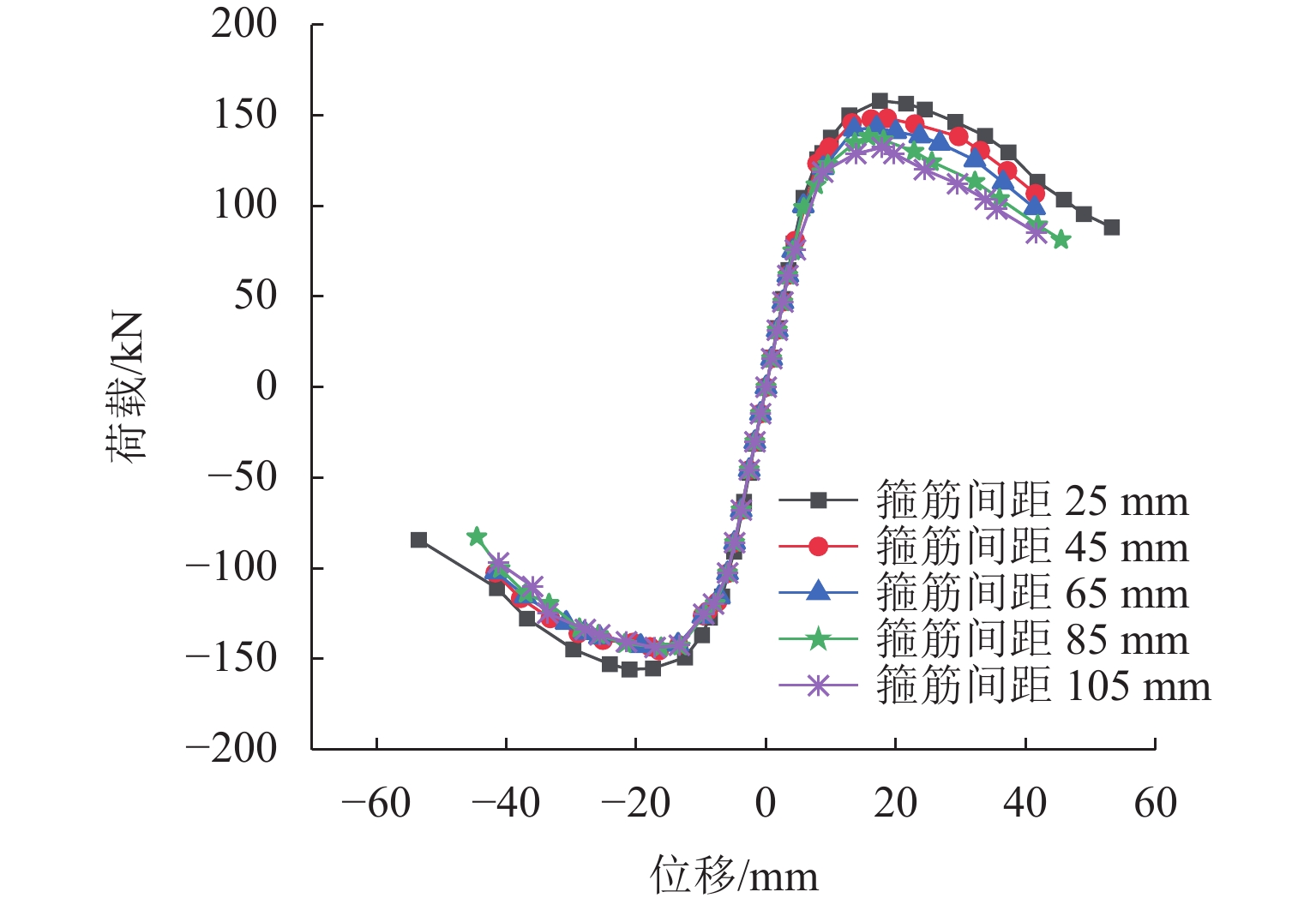

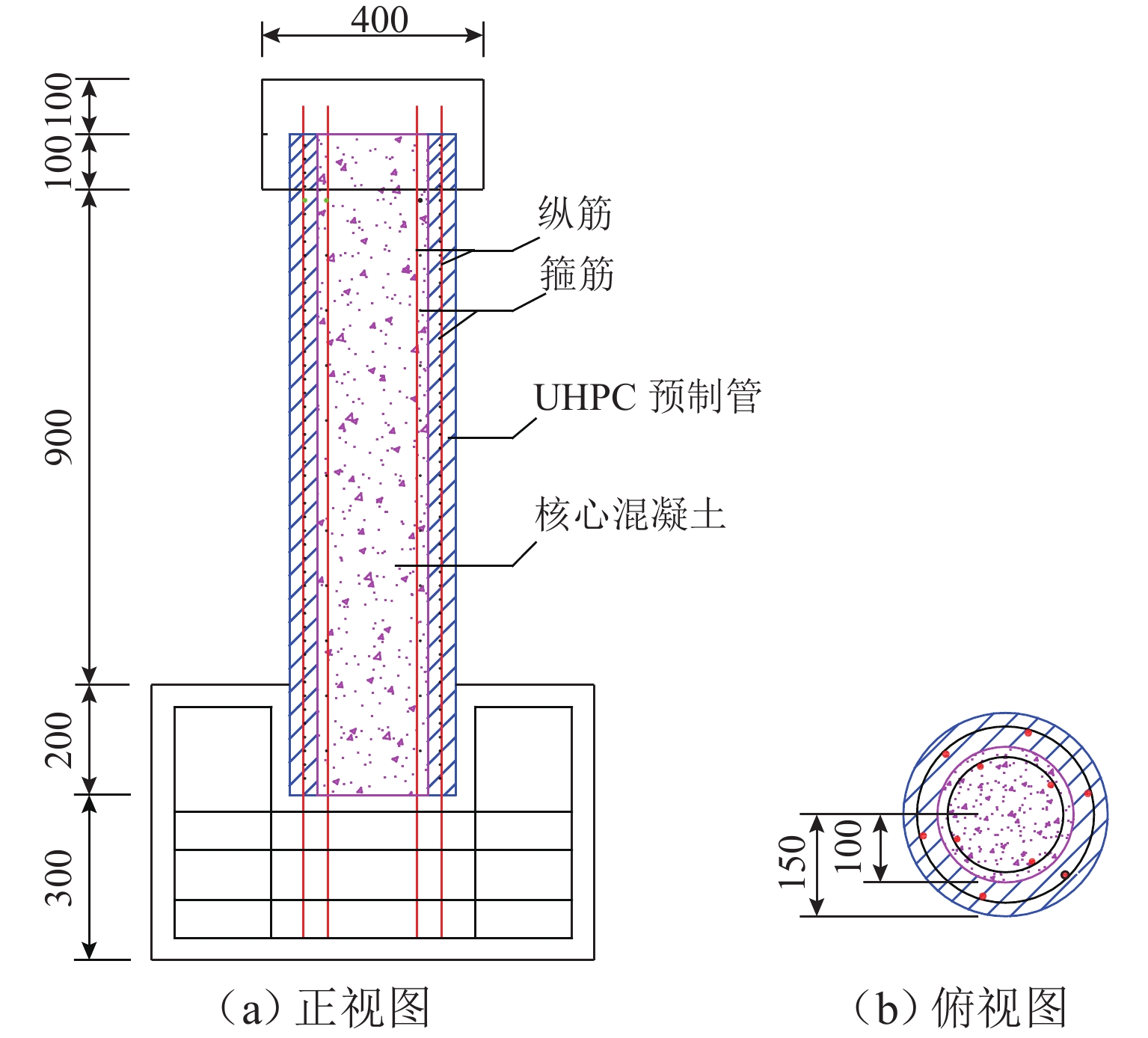

为研究在低周反复荷载下超高性能混凝土(UHPC)预制管混凝土组合柱的抗震性能,进行共计3根UHPC预制管混凝土组合柱和1根钢筋混凝土柱的拟静力试验,分析在不同UHPC强度和核心混凝土有无配筋情况下,各组合柱试件的破坏模式、位移延性、耗能能力、刚度退化等方面抗震性能. 分析结果表明:UHPC预制管混凝土组合柱试件的滞回曲线较为饱满,破坏形态基本相同,均为整体压弯破坏;与传统钢筋混凝土(RC)柱相比,UHPC预制管混凝土组合柱刚度、屈服荷载、延性性能均有提升;随着UHPC强度增大,组合柱试件的滞回曲线更为饱满,耗能能力增强,残余位移小,水平峰值荷载和位移延性系数分别提高了20.60%和6.40%,表现出良好的整体抗震性能;采用ABAQUS程序建立组合柱的有限元分析模型,计算结果与试验结果吻合良好;轴压比、长细比、UHPC强度是影响UHPC预制管混凝土组合柱抗震性能的重要参数,可为同类工程设计提供参考.

-

关键词:

- 超高性能混凝土(UHPC) /

- 组合柱 /

- 抗震性能 /

- 拟静力试验 /

- 有限元分析

Abstract:To investigate the seismic performance of concrete composite columns of ultra-high performance concrete (UHPC) precast pipe under low-cycle repeated loads, three concrete composite columns of UHPC precast pipes and one reinforced concrete (RC) column were subjected to quasi-static tests, so as to analyze the seismic performance of each composite column specimen in terms of damage mode, displacement ductility, energy dissipation capacity, and stiffness degradation under different UHPC strengths and core concrete with or without reinforcement. The analysis results show that the hysteresis curves of the concrete composite column specimens of UHPC precast pipe are fuller, and their damage patterns are basically the same, which are both integral compression-bending damage. Compared with those of the conventional RC columns, the stiffness, yield load, and ductility of the concrete composite column of UHPC precast pipe are improved. With the increase in UHPC strength, the hysteresis curves of the composite column specimens are fuller, and the energy dissipation capacity is enhanced. The residual displacement is small, and the horizontal peak load and displacement ductility coefficient increase by 20.6% and 6.4%, which shows good overall seismic performance. The finite element analysis model of the composite column is established by the ABAQUS program, and the calculation results are in good agreement with the test results. Different axial compression ratios, slenderness ratios, and UHPC strengths are important parameters affecting the seismic performance of concrete composite columns of UHPC precast pipes, which can provide a reference for similar engineering designs.

-

表 1 试件编号与参数

Table 1. Numbers and parameters of specimens

试件编号 h/mm d/mm fu/MPa 有无配筋 URS100 900 300 100 有 URS140 140 有 UNS140 140 无 Z1 表 2 混凝土材料性能表

Table 2. Concrete material properties

MPa 材料 弹性模量 抗压强度 C40 3.34 × 104 41.9 UHPC100 4.01 × 104 101.6 UHPC140 4.35 × 104 140.5 表 3 钢筋材料性能表

Table 3. Reinforcement material properties

MPa 材料 弹性模量 屈服强度 极限强度 箍筋 2.06 × 105 415.6 554.5 纵筋 1.98 × 105 452.2 613.2 表 4 试验与数值模拟骨架曲线特征值对比

Table 4. Comparison of skeleton curve eigenvalues of experimental and numerical simulation results

试件编号 弹性刚度/(kN·mm−1) 屈服荷载/kN 水平峰值荷载/kN 峰值荷载位移/mm 试验值 模拟值 误差/% 试验值 模拟值 误差/% 试验值 模拟值 误差/% 试验值 模拟值 误差/% Z1 5.9 6.1 −3.8 73.6 70.4 4.30 87.3 82.4 5.0 32.00 30.04 6.1 URS140 14.5 15.5 −6.9 134.8 134.6 0.14 158.1 157.4 0.4 18.03 17.56 2.6 URS100 12.7 12.4 2.4 109.2 109.6 −0.30 128.3 123.5 3.7 22.10 20.60 6.7 UNS140 15.9 15.4 3.1 107.6 106.8 0.70 131.3 129.8 1.1 18.10 17.60 2.7 表 5 试件位移延性系数

Table 5. Displacement ductility coefficient of specimens

试件编号 Z1 URS140 URS100 UNS140 位移延性系数 5.12 4.63 4.58 4.05 表 6 刚度退化特征值表

Table 6. Stiffness degradation eigenvalue

试件 起始刚度/

(kN·mm−1)最终刚度/

(kN·mm−1)刚度退化率/% URS140 30.52 2.04 93 UNS140 27.83 1.69 94 URS100 26.55 1.94 92 Z1 17.96 1.21 93 -

[1] 徐子兵. UHPC预制管混凝土组合柱收缩徐变性能研究[D]. 长沙:湖南大学,2021. [2] 徐海宾,邓宗才. 超高性能混凝土在桥梁工程中的应用[J]. 世界桥梁,2012,40(3): 63-67.XU Haibin, DENG Zhongcai. Application of ultra-high performance concrete in bridge engineering[J]. World Bridge, 2012, 40(3): 63-67. [3] 张锡治,章少华,牛四欣. 装配式建筑中预制混凝土管柱的研究与展望[J]. 建筑结构,2018,48(7): 79-86.ZHANG Xizhi, ZHANG Shaohua, NIU Sixin. Research and prospect of precast concrete tubular column in prefabricated buildings[J]. Building Structure, 2018, 48(7): 79-86. [4] 韦建刚,罗霞,谢志涛. 圆高强钢管超高性能混凝土轴压柱稳定性能试验研究[J]. 建筑结构学报,2019,40(增1): 200-206.WEI Jiangang, LUO Xia, XIE Zhitao. Stability of ultra-high performance concrete filled high-strength steel tube columns subjected to axial load[J]. Journal of Building Structures, 2019, 40(S1): 200-206. [5] HUNG C C, CHUEH C Y. Cyclic behavior of UHPFRC flexural members reinforced with high-strength steel rebar[J]. Engineering Structures, 2016, 122(6): 108-120. [6] 邓宗才,贺少锋,姚军锁. 配筋UHPC柱的抗震性能及影响因素分析[J]. 哈尔滨工业大学学报,2021,53(4): 51-61. doi: 10.11918/202005107DENG Zongcai, HE Shaofeng, YAO Junsuo. Analysis of seismic behavior and influencing factors of reinforced UHPC columns[J]. Journal of Harbin Institute of Technology, 2021, 53(4): 51-61. doi: 10.11918/202005107 [7] 何乐. UHPC-ST-NC组合桥墩抗震性能研究[D]. 福州:福建工程学院,2022. [8] 梁兴文,史纪从,于婧,等. 免拆超高性能混凝土模板钢筋混凝土柱抗震性能研究[J]. 地震工程学报,2020,42(3): 579-588,606. doi: 10.3969/j.issn.1000-0844.2020.03.579LIANG Xingwen, SHI Jicong, YU Jing, et al. Seismic behavior of reinforced concrete columns with permanent template of ultra-high-performance concrete[J]. China Earthquake Engineering Journal, 2020, 42(3): 579-588,606. doi: 10.3969/j.issn.1000-0844.2020.03.579 [9] 施路遥. 基于UHPC环箍约束的混凝土桥墩抗震加固研究[D]. 南京:东南大学,2018. [10] 贺斌. RPC预制管混凝土组合柱在火灾作用后的抗震性能试验研究[D]. 长沙:湖南大学,2018. [11] 温帅. 新型高强钢筋增强UHPC-NC组合柱抗震性能数值研究[D]. 南昌:华东交通大学,2020. [12] 中国建筑科学研究院有限公司. 混凝土物理力学性能试验方法标准:GB/T 50081—2019[S]. 北京:中国建筑工业出版社,2019. [13] 钢铁研究总院,冶金工业信息标准研究院. 金属材料拉伸试验第1部分:室温试验方法:GB/T-228.1—2021[S]. 北京:中国标准出版社,2021. [14] 中华人民共和国住房和城乡建设部. 建筑抗震试验规程:JGJ/T 101—2015[S]. 北京:中国建筑工业出版社,2015. [15] 马亚峰. 活性粉末混凝土(RPC200)单轴受压本构关系研究[D]. 北京:北京交通大学,2006. [16] 方自虎,甄翌,李向鹏. 钢筋混凝土结构的钢筋滞回模型[J]. 武汉大学学报(工学版),2018,51(7): 613-619.FANG Zihu, ZHEN Yi, LI Xiangpeng. Steel hysteretic model of reinforced concrete structures[J]. Engineering Journal of Wuhan University, 2018, 51(7): 613-619. -

下载:

下载: