Mesoscopic Study on Mechanical and Deformation Behaviors of Reinforced Buried Pipelines Under Vertical Loads

-

摘要:

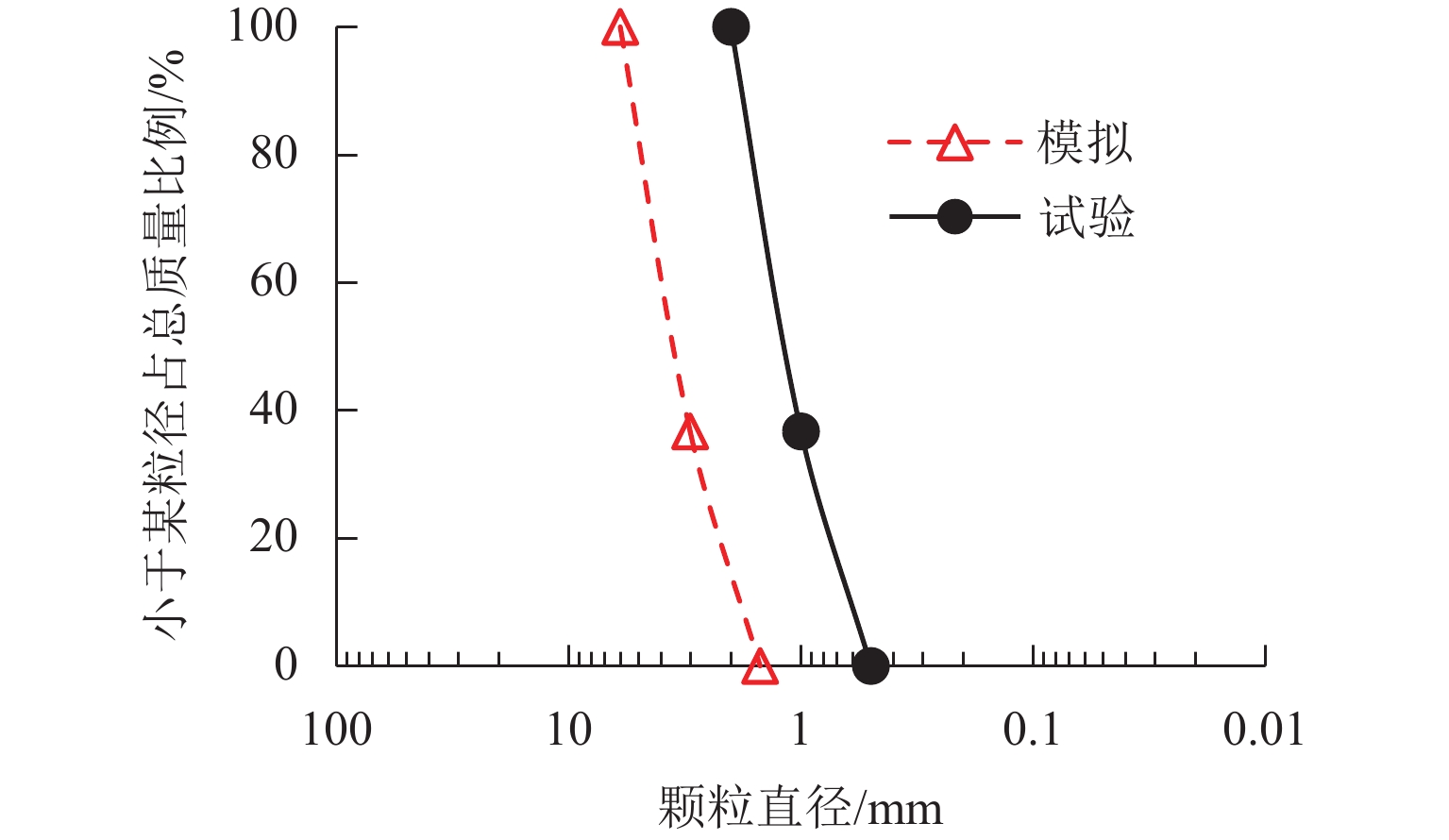

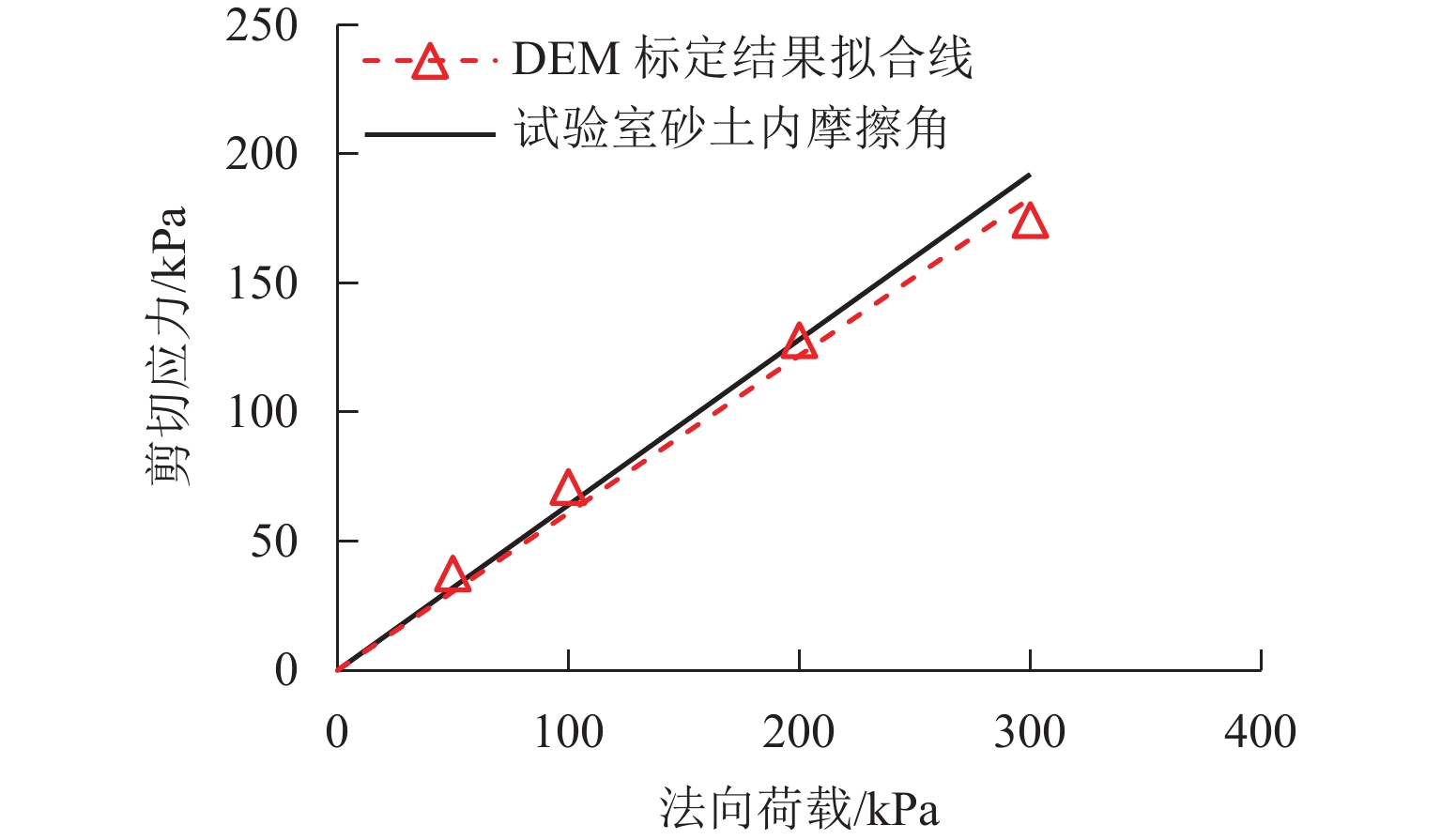

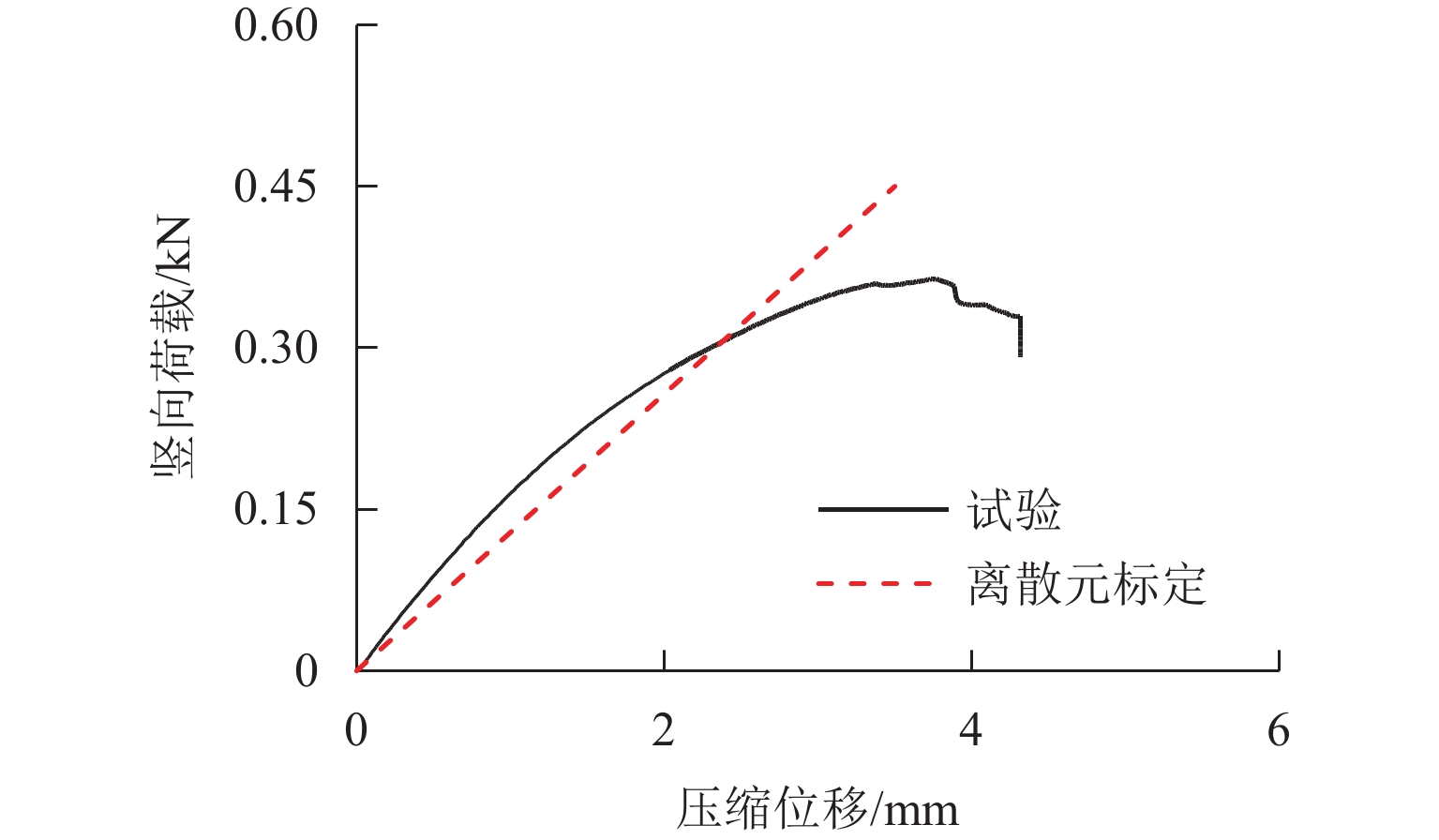

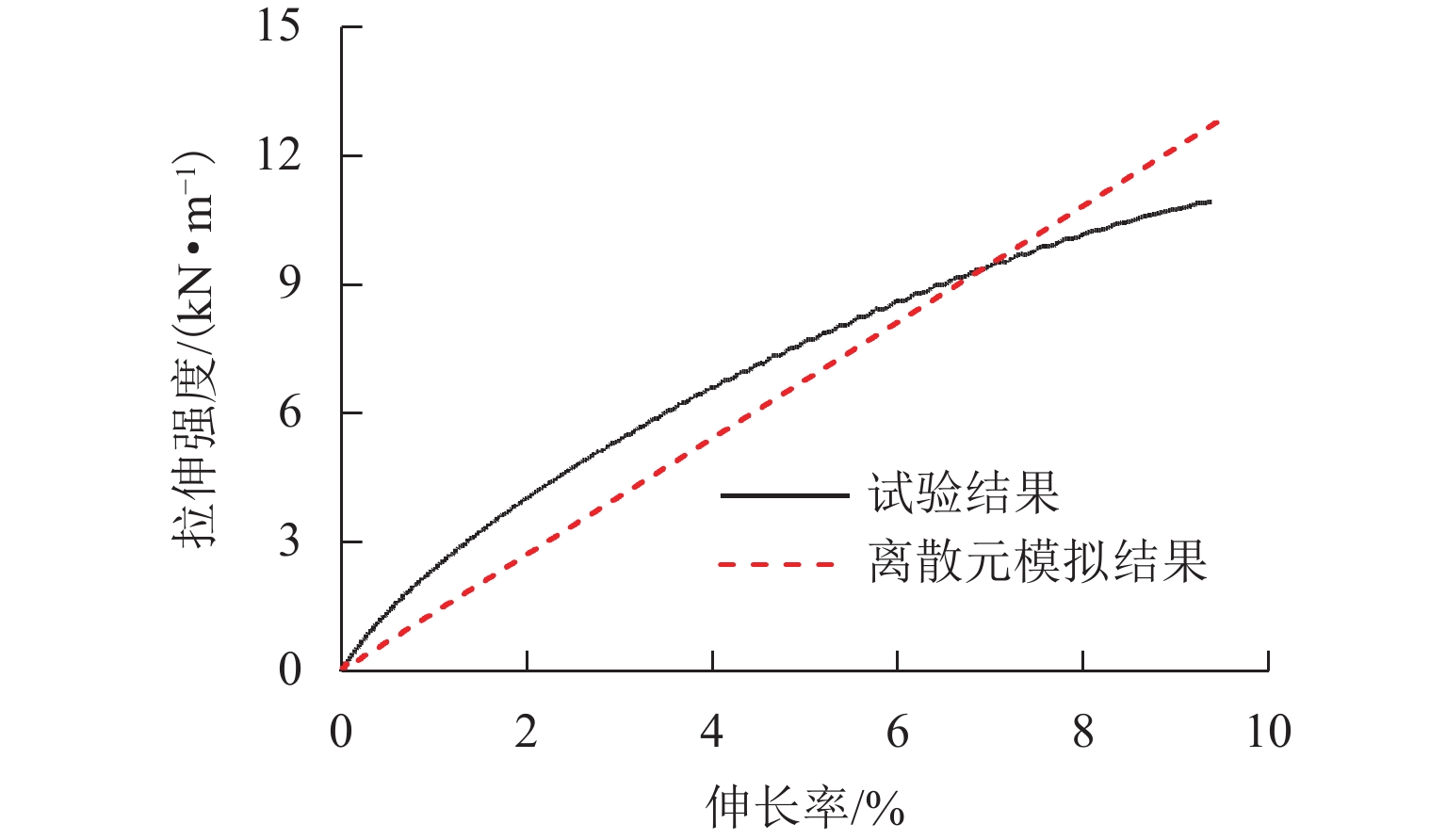

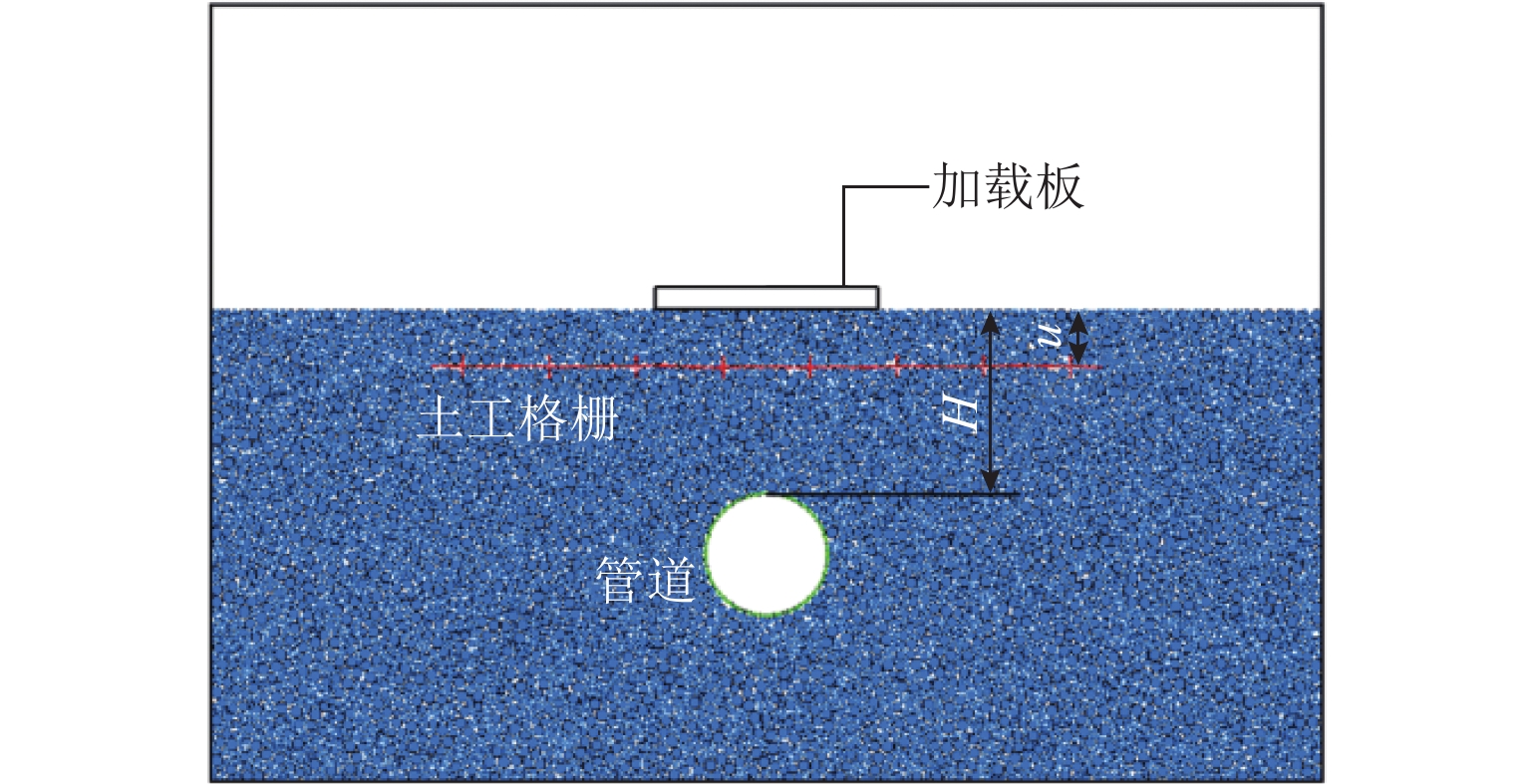

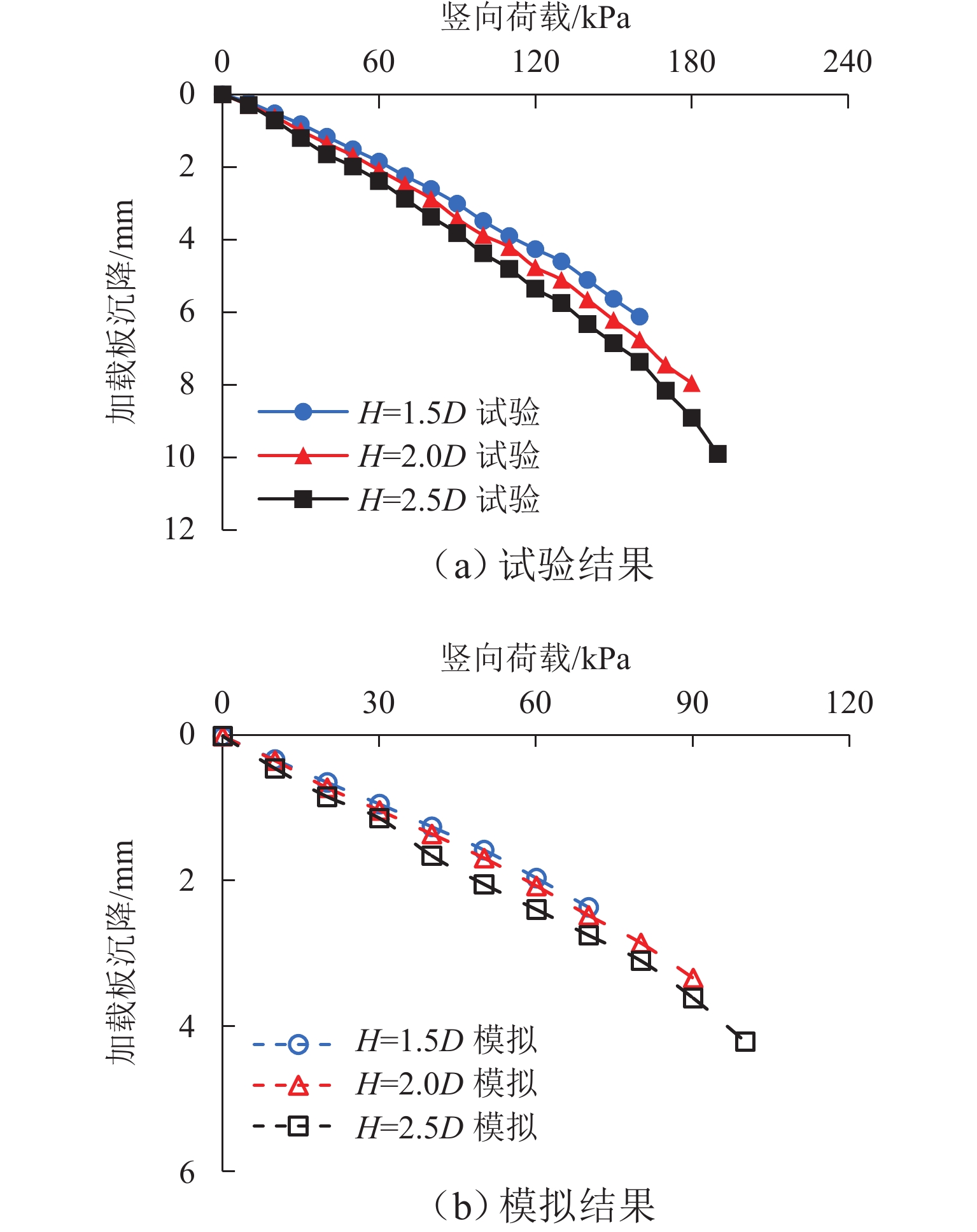

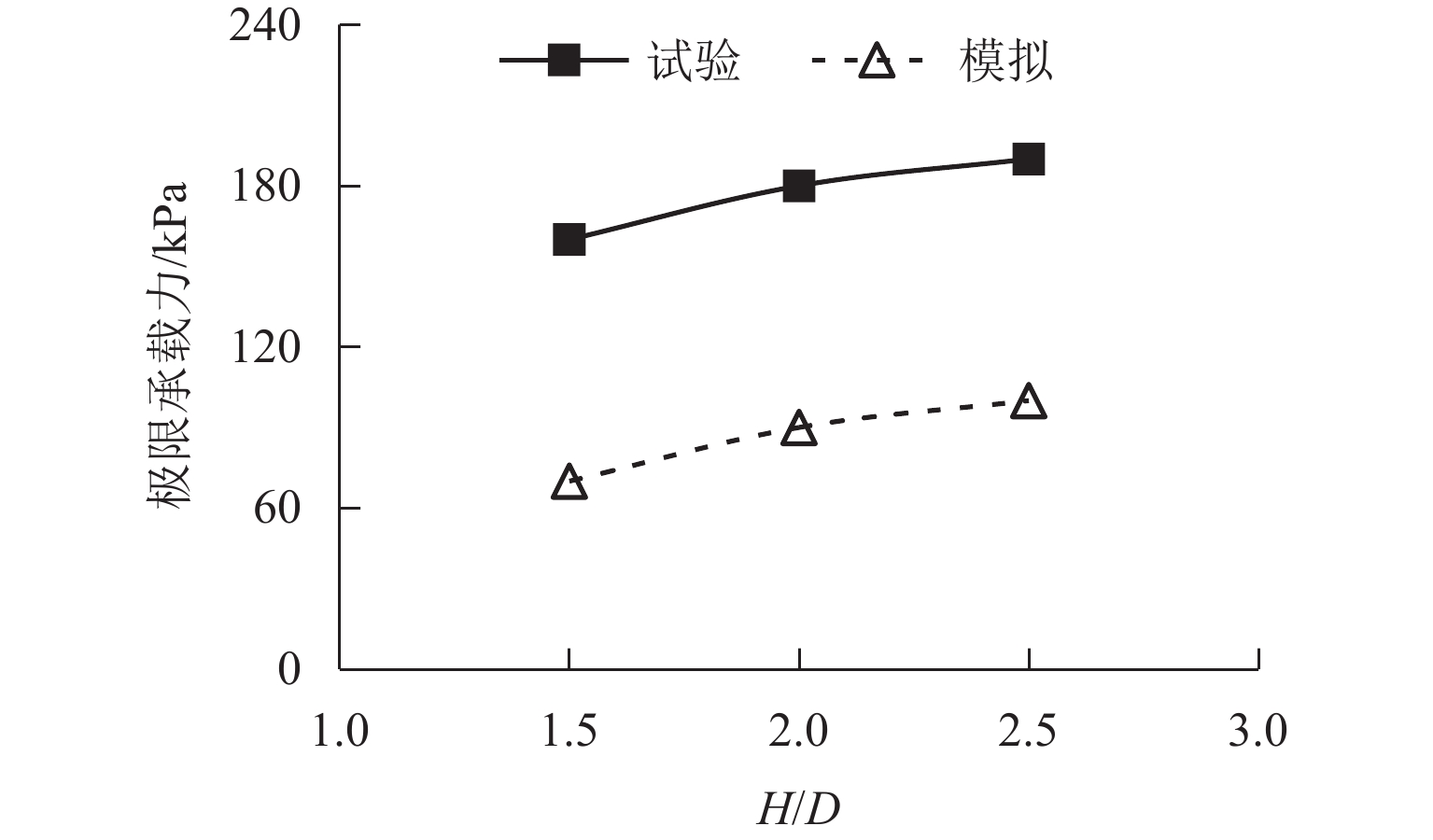

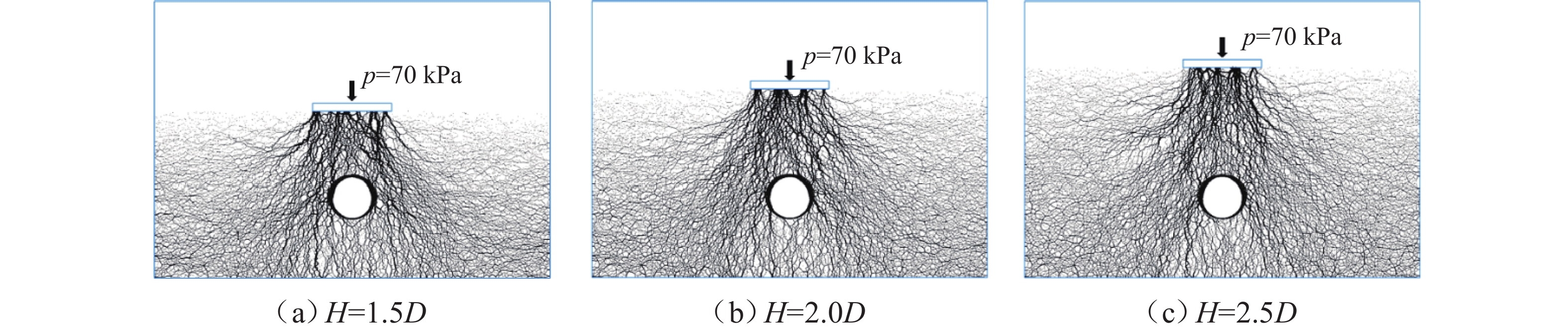

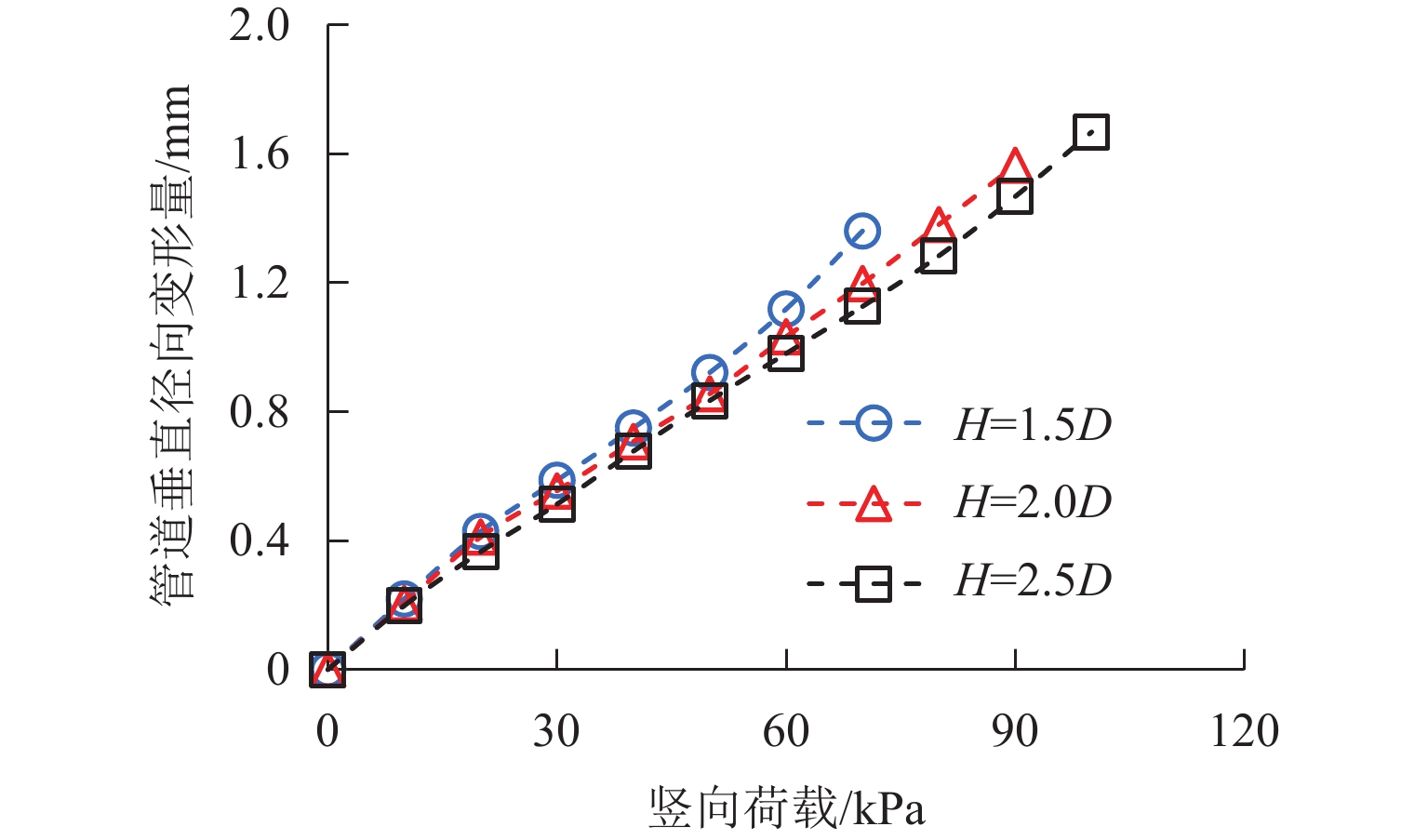

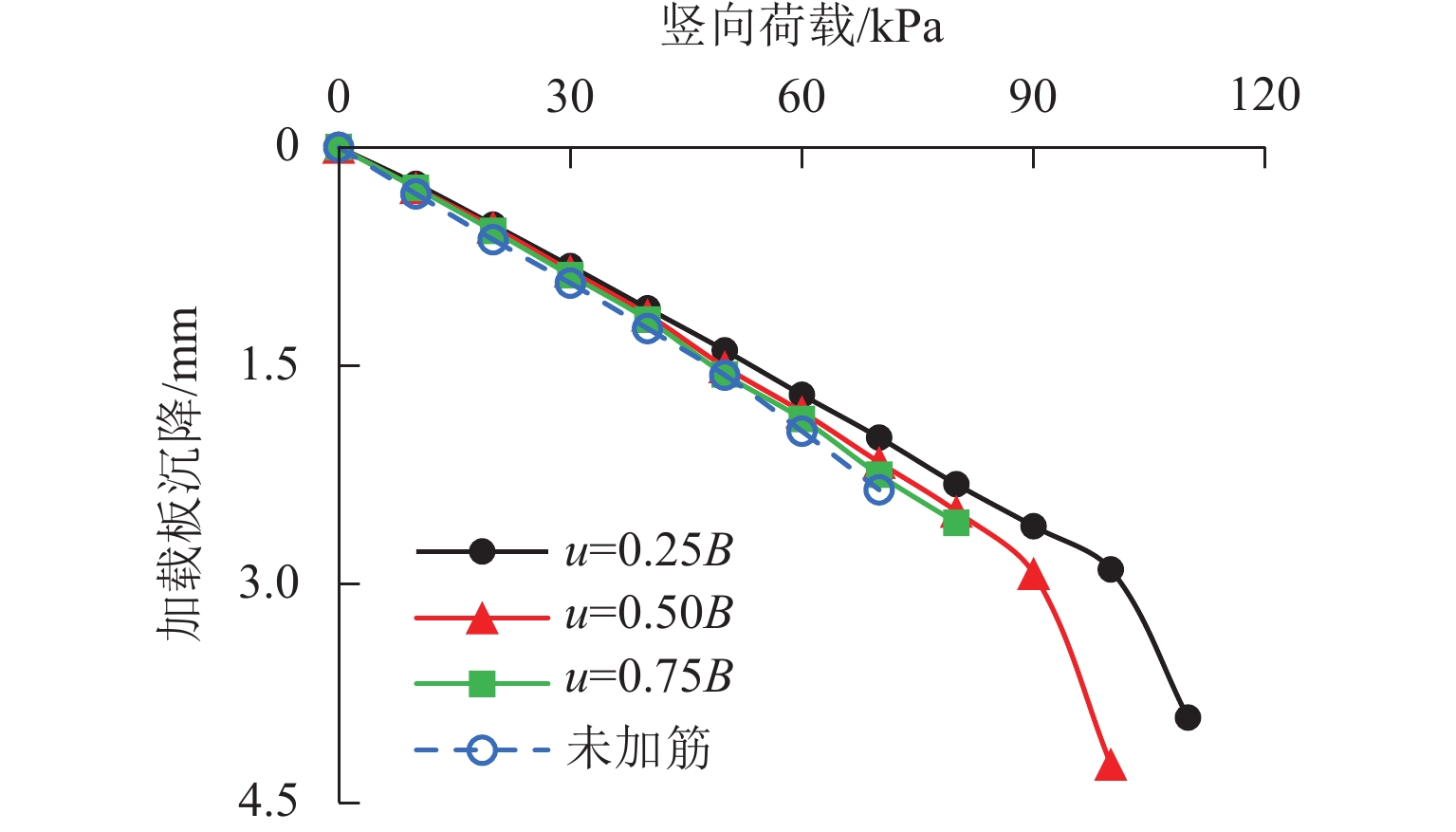

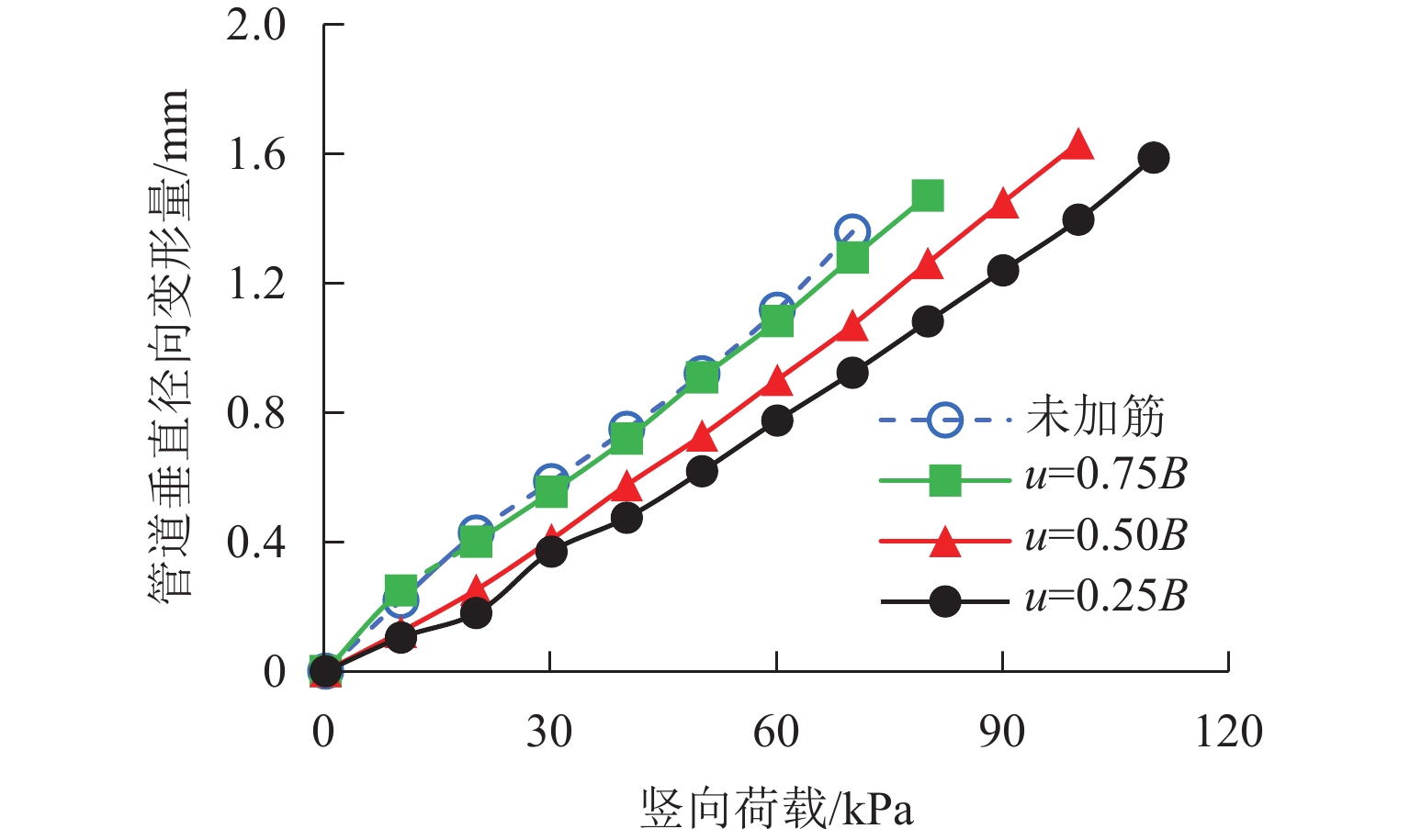

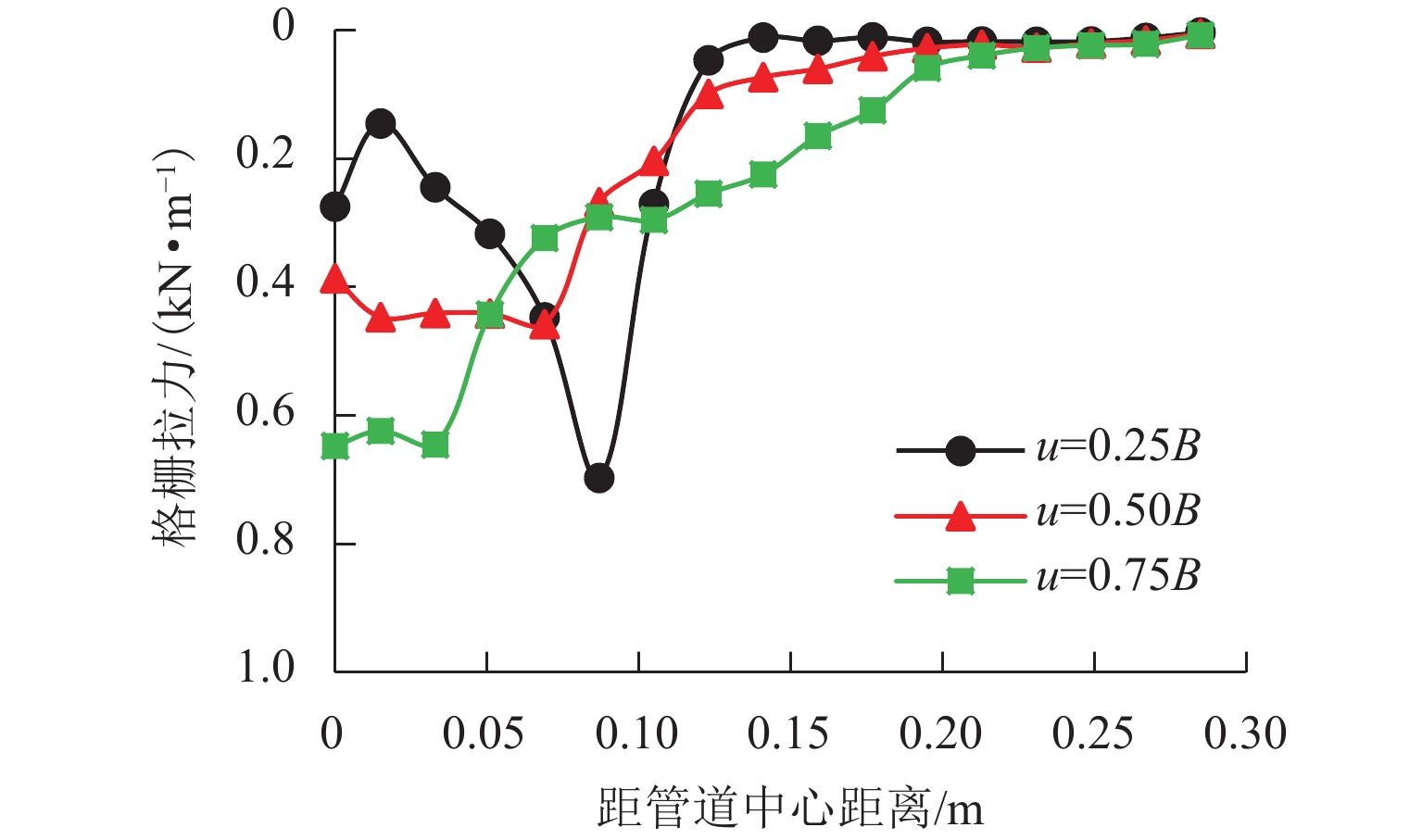

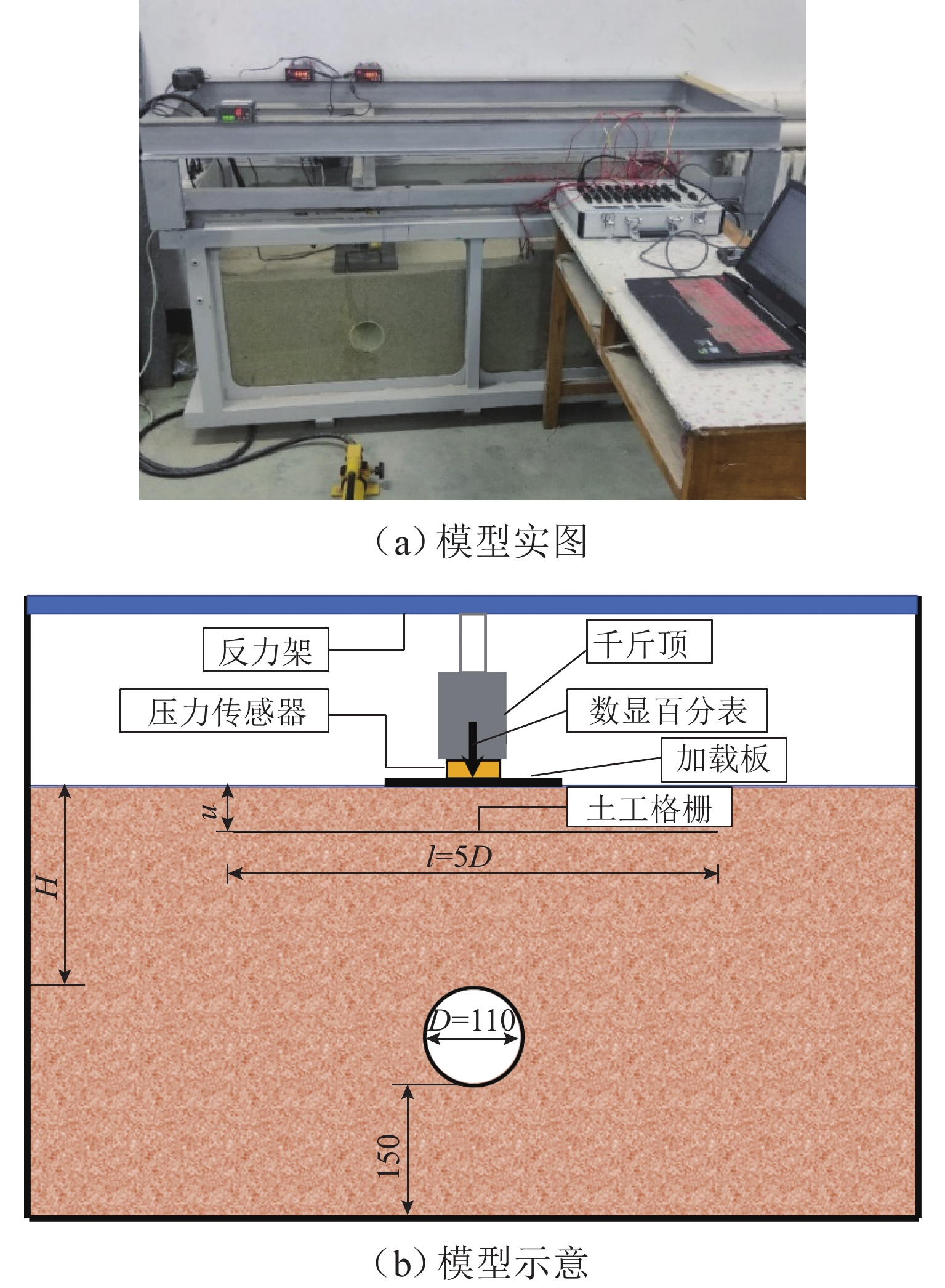

为深入研究竖向荷载作用下土工格栅加筋埋地管道的防护效果,基于室内模型试验,建立离散元仿真分析模型,从细观层面探究竖向荷载作用下土工格栅加筋埋地管道与周围土体系统的力学响应与变形行为,揭示不同管道埋深与不同筋材埋深条件下,加载板荷载-沉降关系曲线、模型内部颗粒间接触力、颗粒位移与管道垂直径向变形等发展演化规律. 研究结果表明:当管道埋深

H 较浅时(H =1.5D ,D 为管道模型外径),其极限承载力小于管道埋深较大的工况,虽然相同荷载作用下加载板沉降较小,但管道垂直径向变形较大;对管道上方进行土工格栅加筋后,模型系统承载力显著提高,管道垂直径向变形减小;土工格栅埋深越浅,加筋效果越显著,当土工格栅埋深从0.75B 减小至0.25B 时,极限承载力提高约57.2%,管道径向变形减小约27.9%. 本研究从细观层面揭示了管道、土体与土工格栅之间的相互作用机理,实现土工格栅加筋防护埋地管道力学与变形行为的可视化.Abstract:In order to deeply study the protective effect of geogrid-reinforced buried pipelines under vertical load, indoor model tests were carried out, and a discrete element simulation analysis model was established. The mechanical response and deformation behavior of geogrid-reinforced buried pipelines and surrounding soil systems under vertical load were explored from the mesoscopic level, and the development and evolution laws of the load-settlement curve of loading plate, contact force between particles inside the model, particle displacement, and vertical radial deformation of pipelines were revealed under different buried depths of pipelines and reinforcements. The results show that when the buried depth of the pipeline

H is shallow (H = 1.5D ,D is the outer diameter of the pipeline model), the ultimate bearing capacity is smaller than that of the pipeline with a large buried depth. Although the settlement of the loading plate is smaller under the same load, the vertical radial deformation of the pipeline is large. After the geogrid above the pipeline is reinforced, the ultimate bearing capacity of the model system is significantly increased, and the vertical radial deformation of the pipeline is reduced. A shallower buried depth of the geogrid indicates a more obvious reinforcement effect. When the buried depth of the geogridu is reduced from 0.75B to 0.25B , the ultimate bearing capacity is increased by about 57.2%, and the radial deformation of the pipeline is reduced by about 27.9%. In this study, the interaction mechanism among pipelines, soil, and geogrid is revealed from the mesoscopic level, and the mechanical and deformation behavior of geogrid-reinforced protected buried pipelines were visualized.-

Key words:

- buried pipelines /

- geogrid /

- mechanical behavior /

- deformation characteristics /

- discrete element /

- mesoscopic study

-

表 1 离散元模型参数取值

Table 1. Parameter used in discrete element model

名称 接触模型 孔隙率 ρ1/

(kg·m−3)颗粒

直径/mm摩擦系数 有效模量/MPa 刚度比 E1/MPa 平行黏结刚度比 黏结激活间隙 S1/

(MPa·m−1)S2/

(MPa·m−1)砂土 线性 0.151 2650 1.5~6.0 4.00 20 1 管道 平行黏结 1500 3.2 0.25 8 2 1900.0 2 10−5 400.0 400.0 土工格栅 平行黏结 905 3.0 0.30 8 1 64.5 1 10−5 24.5 24.5 表 2 离散元数值模拟方案

Table 2. Numerical simulation scheme of discrete element

名称 H l u 未加筋 1.5D/2.0D/2.5D 土工格栅加筋 1.5D 5.0D 0.25B/0.50B/0.75B -

[1] 李玉芹,郭恩栋,于天洋,等. 基于VB6.0的供水管网震害预测方法和软件[J]. 自然灾害学报,2020,29(1): 72-78.LI Yuqin, GUO Endong, YU Tianyang, et al. Earthquake damage prediction method and software for water supply pipeline network based on VB6.0[J]. Journal of Natural Disasters, 2020, 29(1): 72-78. [2] 周恩全,宗之鑫,王琼,等. 橡胶-粉土轻质混合土中管道动力响应特性[J]. 岩土力学,2020,41(4): 1388-1395.ZHOU Enquan, ZONG Zhixin, WANG Qiong, et al. Dynamic characteristics of pipe buried in rubber-silt lightweight mixtures[J]. Rock and Soil Mechanics, 2020, 41(4): 1388-1395. [3] 张虎,邵磊,余成,等. 冲击荷载对埋地管道影响的试验与数值模拟研究[J]. 地震工程与工程振动,2022,42(3): 243-252.ZHANG Hu, SHAO Lei, YU Cheng, et al. Experimental and numerical simulation study of impact loading on buried pipeline[J]. Earthquake Engineering and Engineering, 2022, 42(3): 243-252. [4] 钟紫蓝,韩春堂,李锦强,等. 浅埋管道水平横向作用下砂土极限承载力研究[J]. 岩土力学,2022,43(增2): 95-103.ZHONG Zilan, HAN Chuntang, LI Jinqiang, et al. Ultimate bearing capacity of sand under lateral horizontal movement of shallowly buried pipelines[J]. Rock and Soil Mechanics, 2022, 43(S2): 95-103. [5] 肖成志,王嘉勇,杨爱克. 静载作用下埋地管道数值模拟及其力学性能分析[J]. 防灾减灾工程学报,2018,38(1): 22-29,167.XIAO Chengzhi, WANG Jiayong, YANG Aike. Numerical simulation and mechanical performance analysis of buried pipes subjected to static load[J]. Journal of Disaster Prevention and Mitigation Engineering, 2018, 38(1): 22-29,167. [6] 罗滔,陈鹏,邱焕峰,等. 土工格栅与填料相互作用研究进展[J]. 武汉大学学报(工学版),2020,53(增1): 111-115.LUO Tao, CHEN Peng, QIU Huanfeng, et al. A review on the interaction between geogrid and backfill[J]. Engineering Journal of Wuhan University, 2020, 53(S1): 111-115. [7] MOGHADDAS TAFRESHI S N, KHALAJ O. Laboratory tests of small-diameter HDPE pipes buried in reinforced sand under repeated-load[J]. Geotextiles and Geomembranes, 2008, 26(2): 145-163. doi: 10.1016/j.geotexmem.2007.06.002 [8] 肖成志,王嘉勇,杨亚欣,等. 土工格栅防护埋地HDPE管道的变形与力学性能[J]. 西南交通大学学报,2017,52(1): 38-44,68. doi: 10.3969/j.issn.0258-2724.2017.01.006XIAO Chengzhi, WANG Jiayong, YANG Yaxin, et al. Deformation and mechanical performance of buried HDPE pipes reinforced by geogrids[J]. Journal of Southwest Jiaotong University, 2017, 52(1): 38-44,68. doi: 10.3969/j.issn.0258-2724.2017.01.006 [9] 刘宽,肖成志,王子寒. 格栅防护埋地管道的承载特性及设计参数分析[J]. 深圳大学学报(理工版),2019,36(1): 52-60. doi: 10.3724/SP.J.1249.2019.01052LIU Kuan, XIAO Chengzhi, WANG Zihan. Performance of bearing capacity and analysis of design parameters of buried pipelines with geogrid protection[J]. Journal of Shenzhen University (Science and Engineering), 2019, 36(1): 52-60. doi: 10.3724/SP.J.1249.2019.01052 [10] 肖成志,何晨曦,王嘉勇. 循环荷载作用下格栅防护柔性埋地管道的性能分析[J]. 岩土工程学报,2018,40(10): 1852-1861. doi: 10.11779/CJGE201810012XIAO Chengzhi, HE Chenxi, WANG Jiayong. Performance of flexible buried pipes reinforced by geogrids under cyclic loading[J]. Chinese Journal of Geotechnical Engineering, 2018, 40(10): 1852-1861. doi: 10.11779/CJGE201810012 [11] 王卫华,李夕兵. 离散元法及其在岩土工程中的应用综述[J]. 岩土工程技术,2005,19(4): 177-181. doi: 10.3969/j.issn.1007-2993.2005.04.005WANG Weihua, LI Xibing. A review on fundamentals of distinct element method and its applications in geotechnical engineering[J]. Geotechnical Engineering Technique, 2005, 19(4): 177-181. doi: 10.3969/j.issn.1007-2993.2005.04.005 [12] 崔晓艳,庄妍,张希栋,等. 循环荷载下桩承式路堤中土拱效应动力折减系数离散元研究[J]. 湖南大学学报(自然科学版),2022,49(9): 164-172.CUI Xiaoyan, ZHUANG Yan, ZHANG Xidong, et al. Discrete element analysis on dynamic reduction coefficient of soil arching effect in pile supported embankment under cyclic load[J]. Journal of Hunan University (Natural Sciences), 2022, 49(9): 164-172. [13] WANG Z J, RUIKEN A, JACOBS F, et al. A new suggestion for determining 2D porosities in DEM studies[J]. Geomechanics and Engineering, 2014, 7(6): 665-678. doi: 10.12989/gae.2014.7.6.665 [14] WANG Z J, JACOBS F, ZIEGLER M. Experimental and DEM investigation of geogrid–soil interaction under pullout loads[J]. Geotextiles and Geomembranes, 2016, 44(3): 230-246. doi: 10.1016/j.geotexmem.2015.11.001 [15] 胡雄玉,晏启祥,何川,等. 土压平衡盾构掘进对散粒体地层扰动和开挖面破坏特性研究[J]. 岩石力学与工程学报,2016,35(8): 1618-1627.HU Xiongyu, YAN Qixiang, HE Chuan, et al. Study on the disturbance and excavation face failure feature of granular mixtures stratum due to EPB shield tunneling[J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(8): 1618-1627. [16] 刘勇,朱俊樸,闫斌. 基于离散元理论的粗粒土三轴试验细观模拟[J]. 铁道科学与工程学报,2014,11(4): 58-62. doi: 10.3969/j.issn.1672-7029.2014.04.010LIU Yong, ZHU Junpu, YAN Bin. Meso-mechanical simulation study on triaxial test of coarse-grained soil based on DEM[J]. Journal of Railway Science and Engineering, 2014, 11(4): 58-62. doi: 10.3969/j.issn.1672-7029.2014.04.010 [17] 肖成志,杨亚欣,杨爱克,等. 静载作用下土工格栅加筋防护埋地管道力学性能实验研究[J]. 岩石力学与工程学报,2015,34(9): 1928-1937.XIAO Chengzhi, YANG Yaxin, YANG Aike, et al. Mechanical performance of buried pipes protected by geogrids under static load[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(9): 1928-1937. -

下载:

下载: