Shear Bearing Capacity of Ultra-High Performance Concrete Keyed Joints Based on Shear-Compression Strength Criterion

-

摘要:

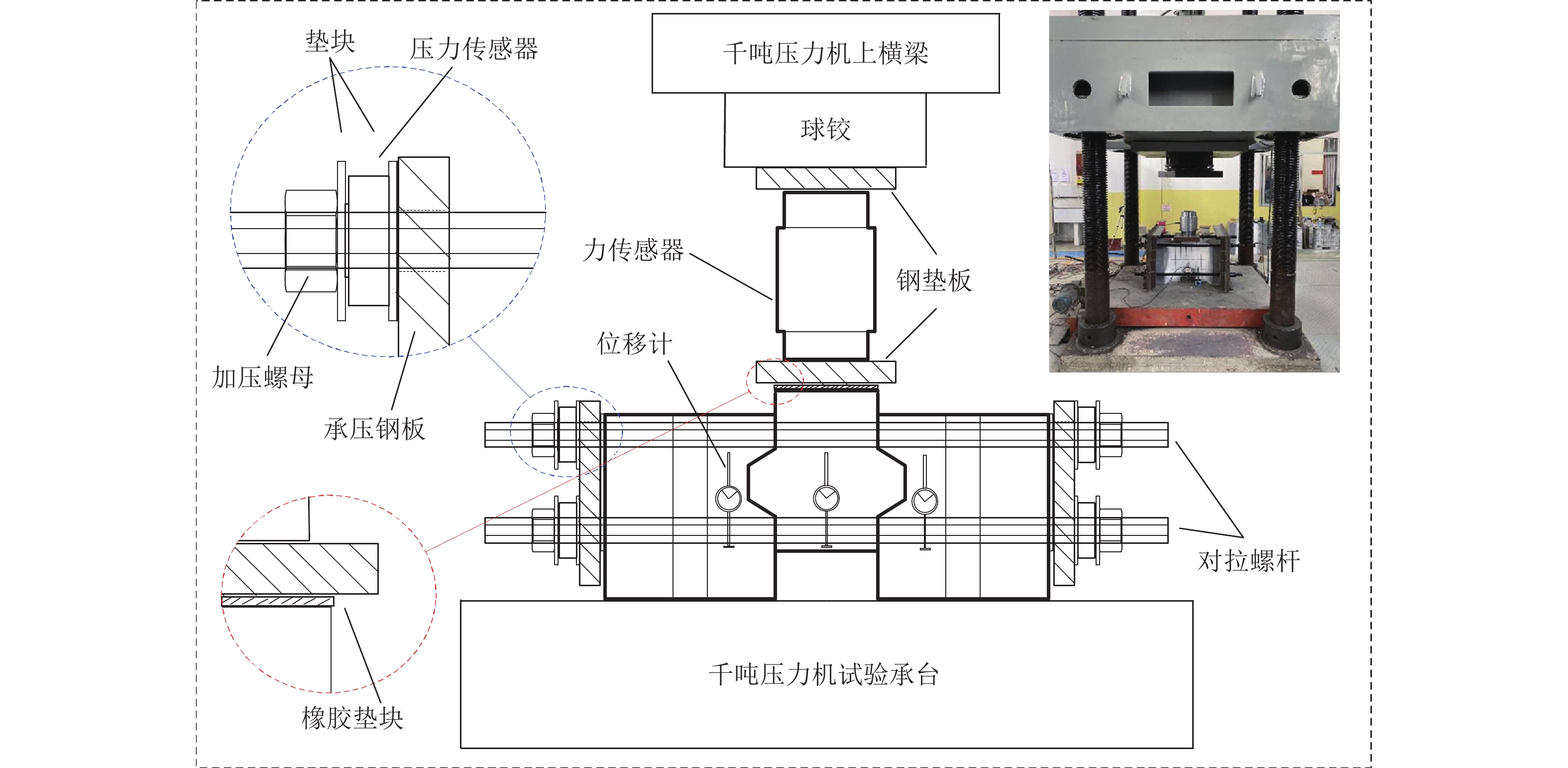

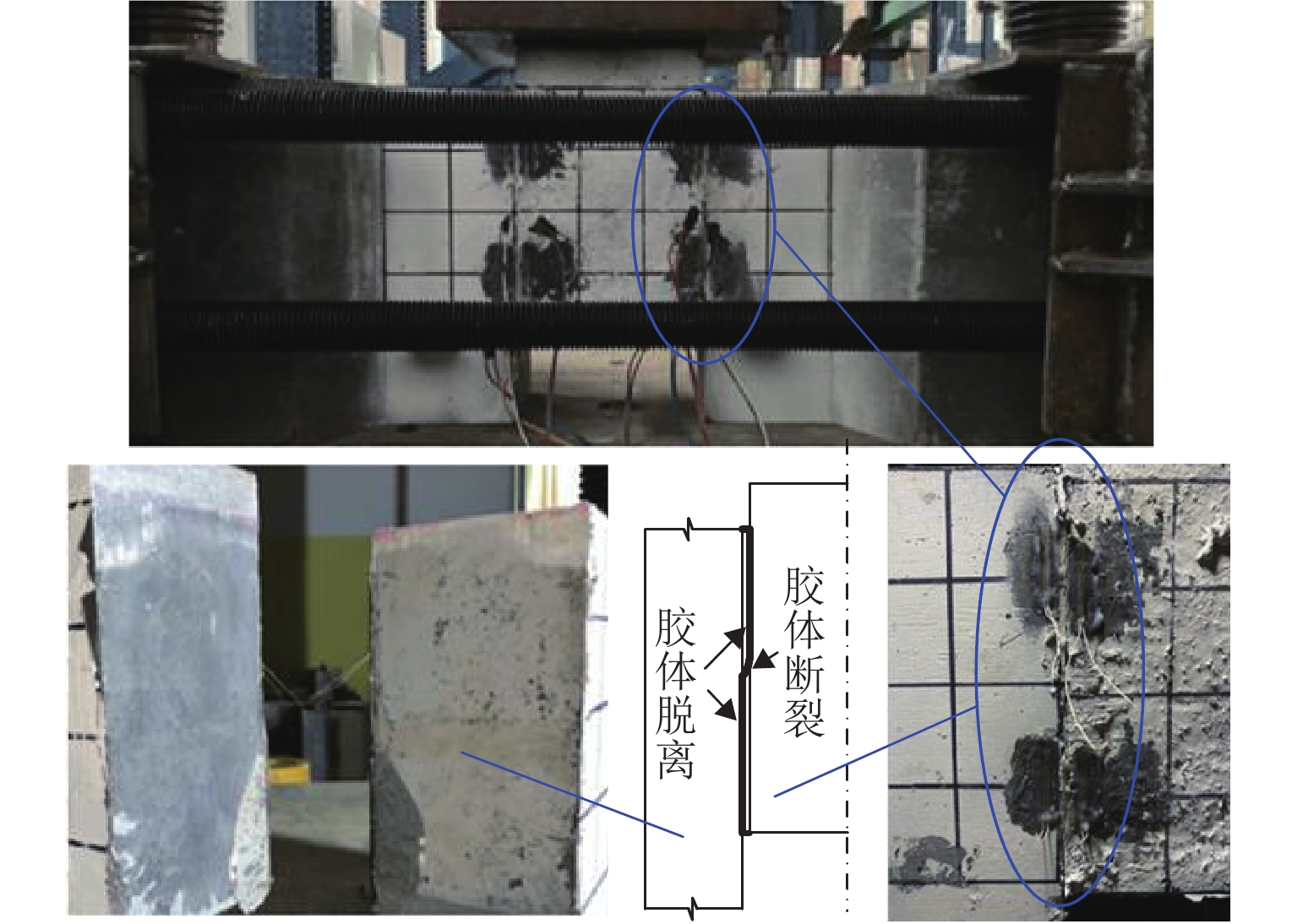

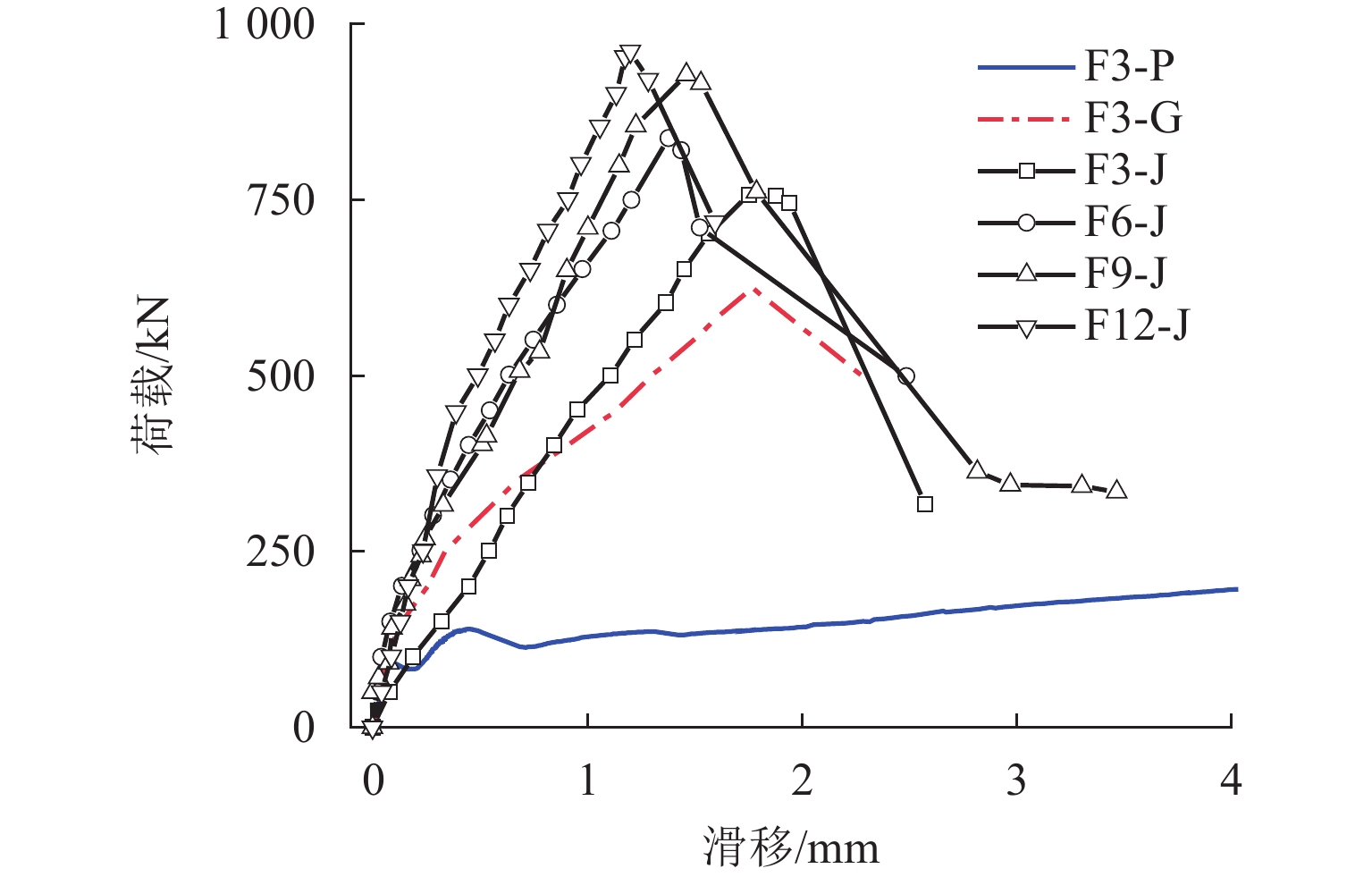

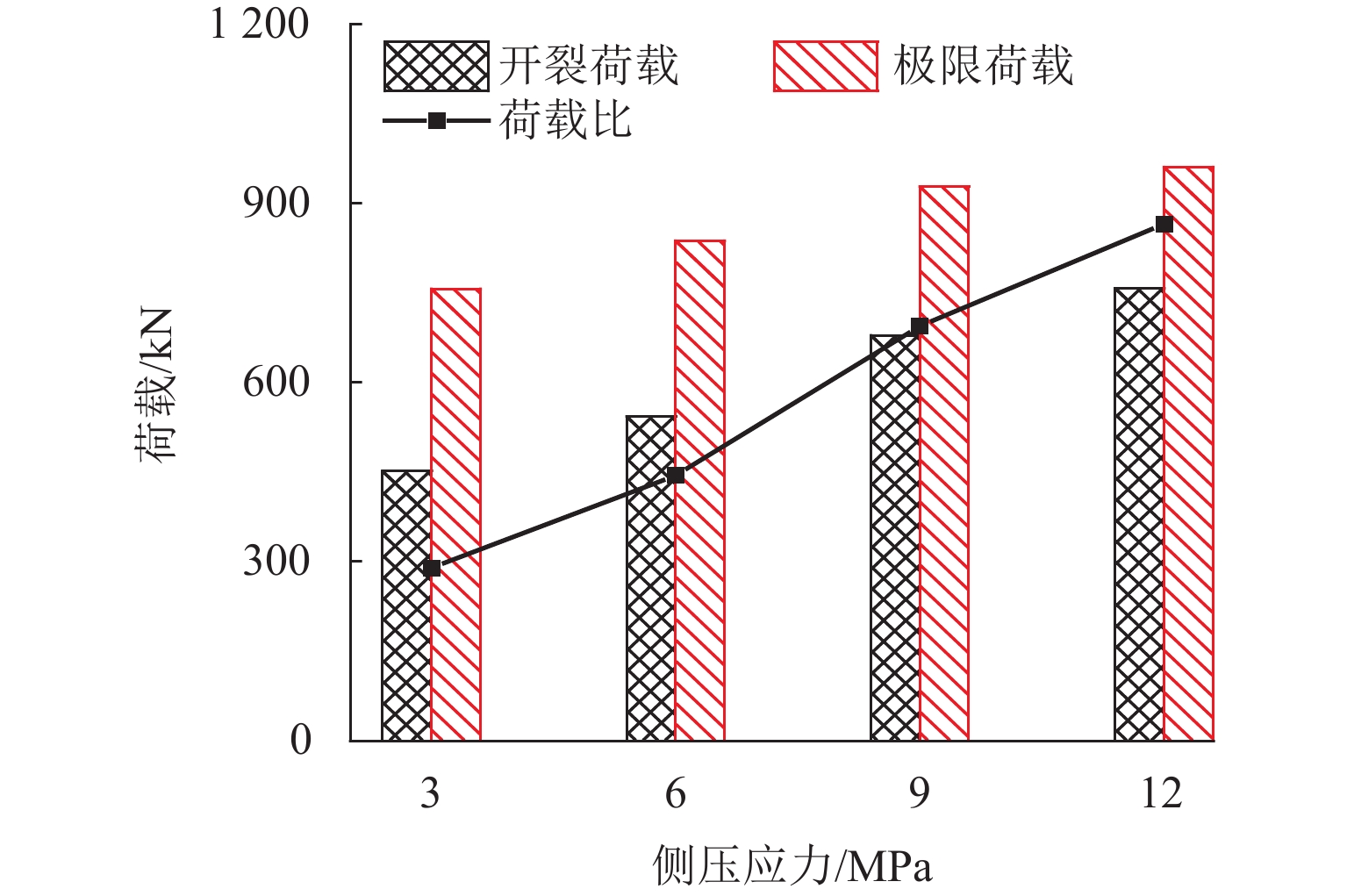

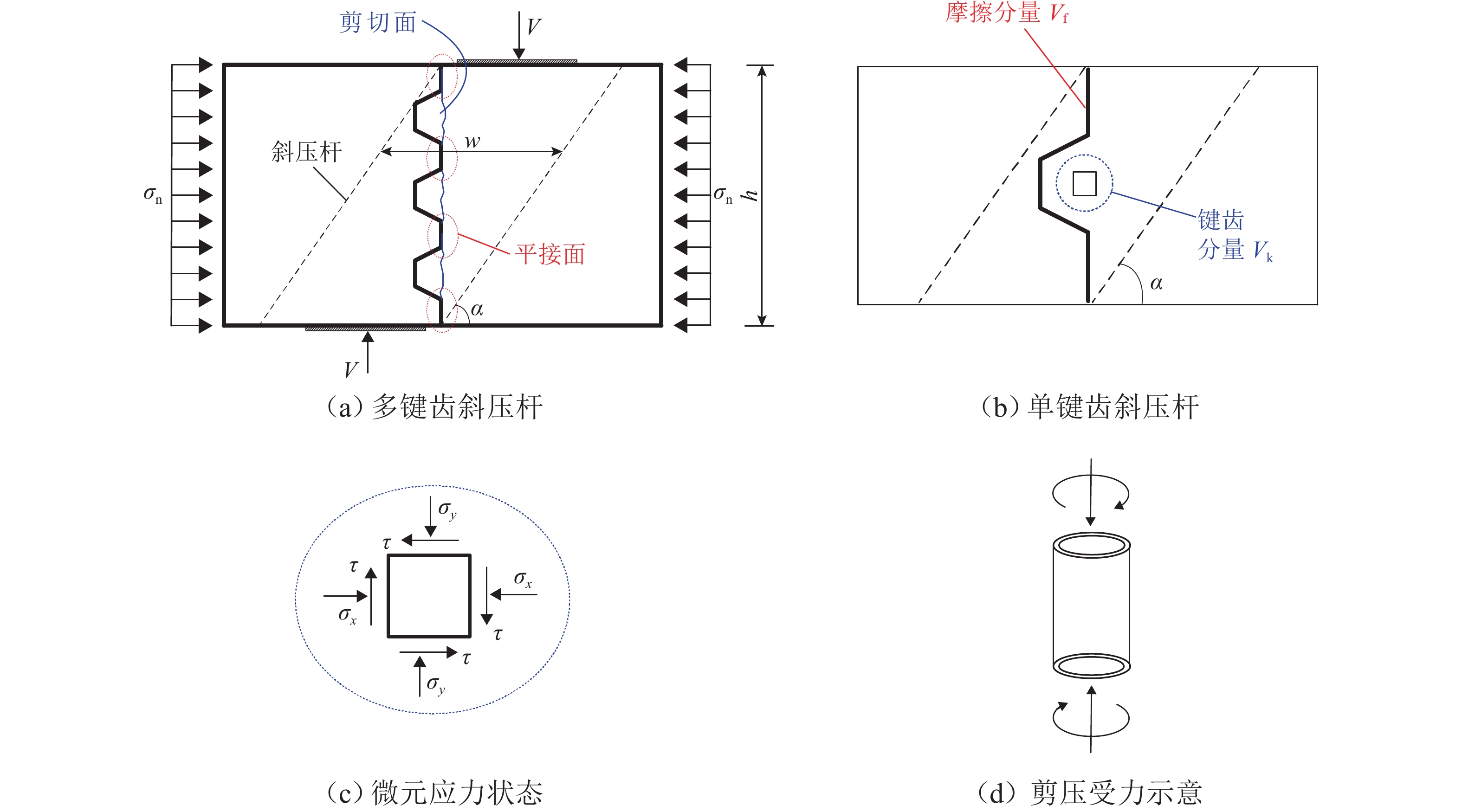

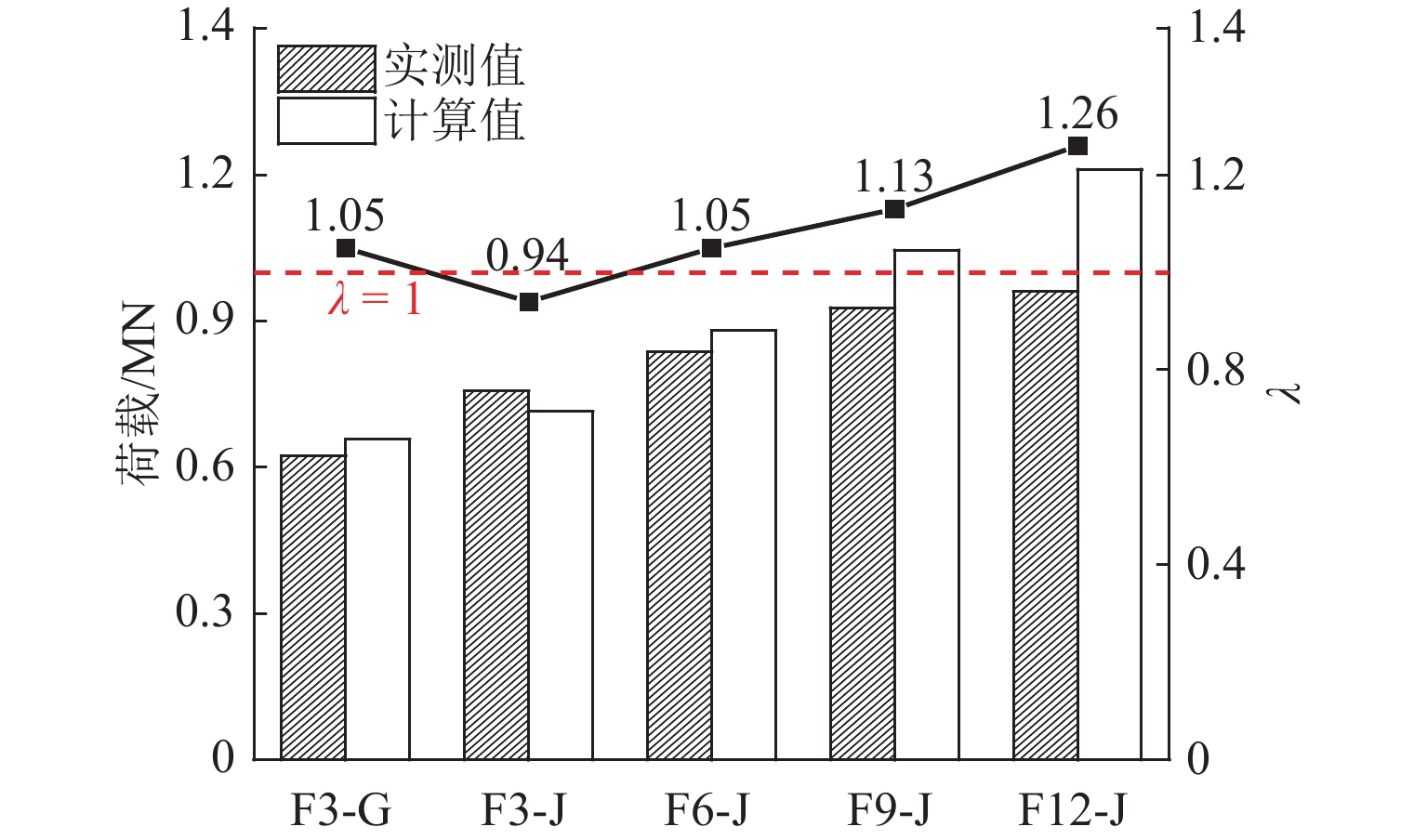

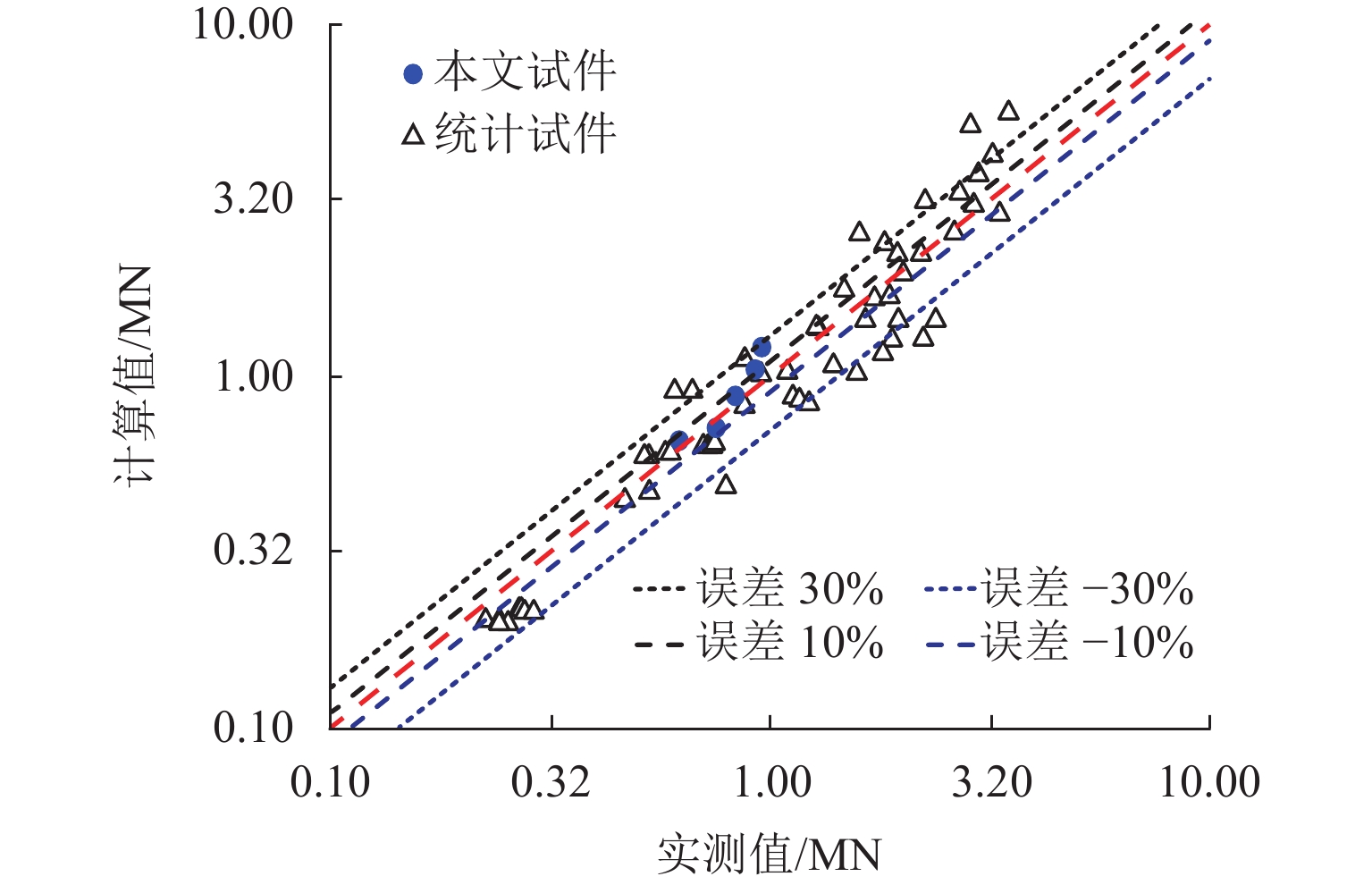

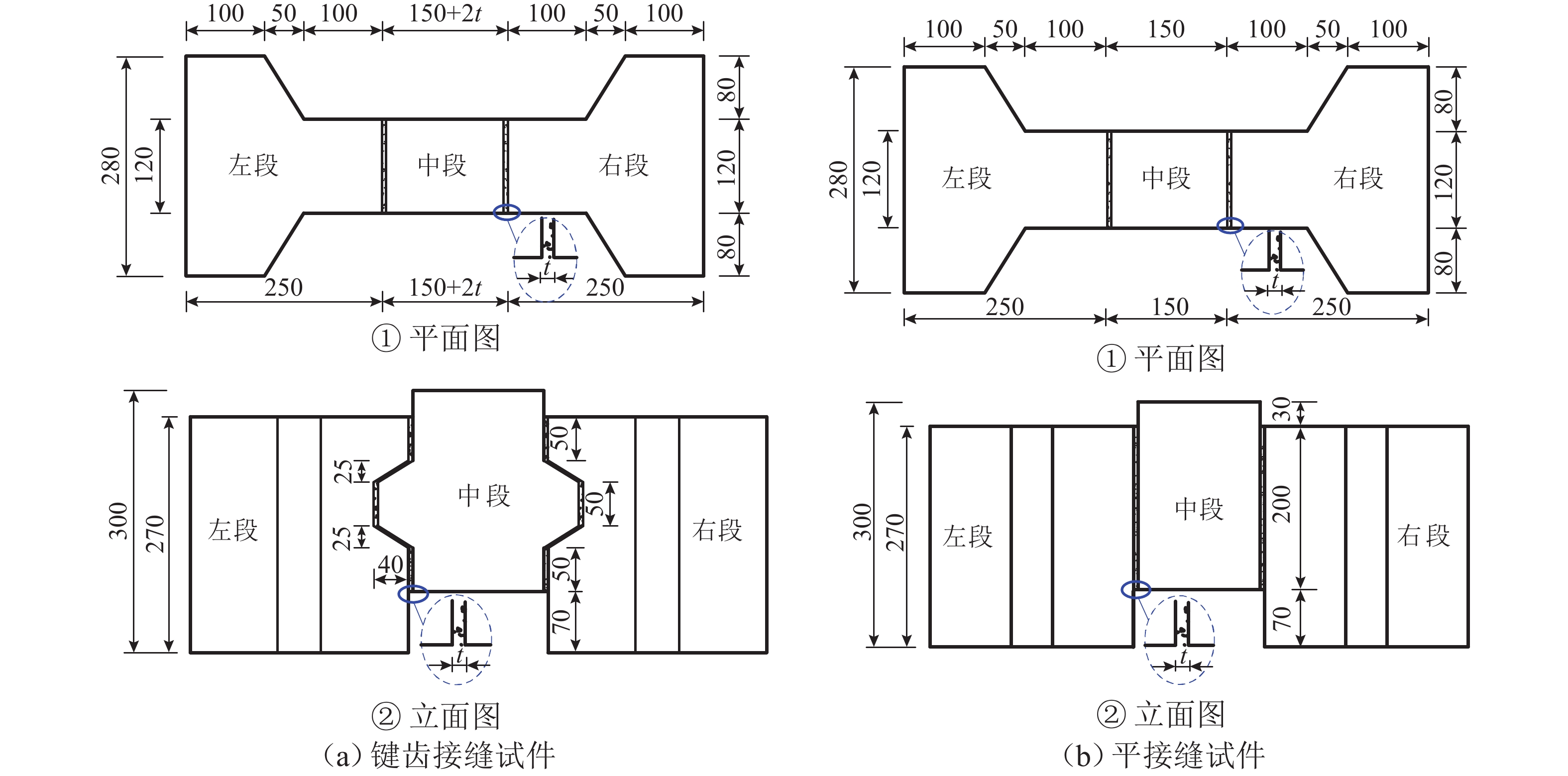

为探明超高性能混凝土(UHPC)键齿接缝的抗剪承载力及其计算方法,以接缝类型、侧压应力为参数开展5个UHPC键齿接缝和1个UHPC平接缝的足尺模型试验,研究UHPC接缝试件的破坏模式和抗剪承载力变化规律;基于混凝土剪压强度准则,采用八面体应力公式推导UHPC键齿接缝的抗剪承载力计算公式,并与试验结果进行对比验证;通过收集62个UHPC键齿接缝的已有试验数据,对本文所提的计算公式进行精度分析. 研究结果表明:UHPC键齿接缝因键齿根部出现竖向贯通主裂缝而破坏,具有明显的脆性特征;在相同侧压应力下,胶接缝试件的极限荷载比干接缝大21.3%,当侧压应力由3 MPa增大至12 MPa时,胶接缝试件的极限荷载增大了26.9%;本文计算公式可较准确地预测UHPC键齿接缝的抗剪承载力,且离散性较低,计算结果总体偏保守,其中本文5个键齿接缝试件的平均绝对误差为11%,62个已有试件的平均绝对误差为21%.

Abstract:To find out the shear bearing capacity and its calculation method of ultra-high performance concrete (UHPC) keyed joints, a full-scale model test of five UHPC keyed joints and a UHPC flat joint were carried out with the joint type and lateral compressive stress as parameters. The failure mode and the variation of shear bearing capacity of the specimens with UHPC joint were studied. Then, based on the shear-compression strength criterion of concrete, the octahedral stress formula was used to derive the formula for calculating the shear bearing capacity of UHPC keyed joints, which was then validated by the test results. Finally, the experimental data of 62 UHPC keyed joints were collected and used to verify the accuracy of the developed formula. The results show that the UHPC keyed joint is damaged by vertical major cracks developed at the root of the keys and has obvious brittle characteristics. The ultimate load of the specimen with an epoxied joint is greater than that with a dry joint by 21.3% under the same lateral compressive stress. When the lateral compressive stress increases from 3 MPa to 12 MPa, the ultimate load of the specimen with an epoxied joint increases by 26.9%. The developed formula can accurately predict the shear bearing capacity of UHPC keyed joints with low dispersion and conservative results in general. The average absolute errors of the specimen with five keyed joints are 11%, and those of 62 existing specimens are 21%.

-

表 1 试件参数

Table 1. Specimen parameters

试件

编号接缝

类型设计侧压

应力/MPa实际侧压

应力/MPa预估承

载力/kNF3-P 平接缝 3 3.13 86.40 F3-G 干接缝 3 3.05 263.17 F3-J 胶接缝 3 2.99 526.40 F6-J 胶接缝 6 6.05 589.53 F9-J 胶接缝 9 9.01 646.66 F12-J 胶接缝 12 12.04 698.57 表 2 试件抗剪承载力对比

Table 2. Comparison of shear bearing capacity of specimens

试件编号 Vt/kN Vc/kN λ $ \overline \lambda $ Sλ λcov F3-G 623.7 657.1 1.05 1.09 0.11 0.10 F3-J 756.3 714.7 0.94 F6-J 836.8 880.3 1.05 F9-J 927.6 1045.9 1.13 F12-J 960.1 1211.5 1.26 表 3 参数分析结果

Table 3. Analysis results of influencing parameters

影响参数 试件数量/个 $ \overline \lambda $ Sλ λcov 键齿数量 单键齿 35 0.92 0.20 0.25 多键齿 27 1.08 0.21 0.25 接缝形式 干接缝 38 0.96 0.18 0.22 胶接缝 24 1.03 0.25 0.31 约束应力比 ≤1% 9 0.93 0.15 0.16 (1%,2%] 13 0.89 0.24 0.27 (2%,5%] 16 0.87 0.17 0.20 (5%,10%] 15 1.09 0.19 0.21 >10% 10 1.22 0.29 0.25 -

[1] 《中国公路学报》编辑部. 中国桥梁工程学术研究综述•2021[J]. 中国公路学报,2021,34(2): 1-97. doi: 10.3969/j.issn.1001-7372.2021.02.002Editorial Department of China Journal of Highway and Transport. Review on China’s bridge engineering research: 2021[J]. China Journal of Highway and Transport, 2021, 34(2): 1-97. doi: 10.3969/j.issn.1001-7372.2021.02.002 [2] 欧智菁,陈伟隆,曹磊. UHPC 预制管混凝土组合柱抗震性能[J]. 西南交通大学学报,2025,60(1):63-71.OU ZHIjing, CHEN Weilong, CAO Lei. Seismic performance investigation of UHPC precast concrete composite columns [J]. Journal of Southwest Jiaotong University,2025,60(1):63-71. [3] 邓宗才,王天宇. 高强钢丝布增强UHPC 约束混凝土柱轴压性能[J]. 西南交通大学学报,2025,60(1):72-83.DENG Zongcai, WANG Tianyu. Axial compression behavior of concrete columns confined by ultra-high performance concrete reinforced with high-strength steel wire cloth [J]. Journal of Southwest Jiaotong University,2025,60(1):72-83. [4] BUYUKOZTURK O, BAKHOUM M M, BEATTIE S M. Shear behavior of joints in precast concrete segmental bridges[J]. Journal of Structural Engineering, 1990, 116(12): 3380-3401. doi: 10.1061/(ASCE)0733-9445(1990)116:12(3380) [5] TURMO J, RAMOS G, APARICIO A C. Shear strength of dry joints of concrete panels with and without steel fibres. Application to precast segmental bridges[J]. Engineering Structures, 2006, 28(1): 23-33. doi: 10.1016/j.engstruct.2005.07.001 [6] ROBERTS C L, BREEN J, KREGER M. Measurement based revisions for segmental bridge design and construction criteria. final report[R]. Austin: University of Texas, 1993. [7] GOPAL B A, HEJAZI F, HAFEZOLGHORANI M, et al. Shear strength of dry and epoxy joints for ultra-high-performance fiber-reinforced concrete[J]. ACI Structural Journal, 2020, 117(1): 279-288. [8] 孙雪帅. 预制拼装桥梁节段间接缝抗剪性能试验研究[D]. 南京:东南大学,2015. [9] 刘桐旭. 节段预制拼装UHPC梁接缝抗剪性能试验与理论研究[D]. 南京:东南大学,2017. [10] JIANG H B, HUANG C W, FENG J H, et al. Direct shear behavior of castellated dry RPC joints in precast concrete segmental bridges[J]. Structures, 2021, 33: 4579-4595. doi: 10.1016/j.istruc.2021.07.013 [11] 王景全,胡玉庆,刘桐旭,等. 超高性能混凝土大键齿干接缝受剪性能与承载力计算方法[J]. 建筑结构学报,2021,42(10): 177-185.WANG Jingquan, HU Yuqing, LIU Tongxu, et al. Shear performance and bearing capacity calculation method for UHPC dry joints with large-keys[J]. Journal of Building Structures, 2021, 42(10): 177-185. [12] 潘仁胜,何伟伟,程灵霄,等. UHPC大键齿干接缝直剪性能及尺寸参数分析[J]. 湖南大学学报(自然科学版),2021,48(7): 129-137.PAN Rensheng, HE Weiwei, CHENG Lingxiao, et al. Direct shear behavior and dimensional parameter analysis of UHPC dry joint with big shear key[J]. Journal of Hunan University (Natural Sciences), 2021, 48(7): 129-137. [13] 闫泽宇. 节段预制拼装UHPC接缝抗剪性能研究[D]. 长沙:湖南大学,2019. [14] 郑凡,江建,李有志. 节段预制UHPC桥梁接缝抗剪性能试验研究[J]. 公路工程,2022,47(6): 1-9,41. doi: 10.12361/2661-3522-04-06-93072ZHENG Fan, JIANG Jian, LI Youzhi. Experimental study on the shear behavior of joints in precast segmental UHPC bridges[J]. Highway Engineering, 2022, 47(6): 1-9,41. doi: 10.12361/2661-3522-04-06-93072 [15] 中华人民共和国住房和城乡建设部,国家市场监督管理总局. 混凝土物理力学性能试验方法标准:GB/T 50081—2019[S]. 北京:中国建筑工业出版社,2019. [16] 蒋大骅. 国外混凝土强度理论述评[J]. 同济大学学报,1978,6(1): 145-156.TaHua Chiang. A brief review on the failure criterion for concrete[J]. Journal of Tongji University, 1978, 6(1): 145-156. [17] 蒋大骅. 钢筋混凝土梁抗剪强度的一个新解[J]. 土木工程学报,1984,17(3): 23-34.JIANG Dahua. A new solution for shear strength of reinforced concrete beams[J]. China Civil Engineering Journal, 1984, 17(3): 23-34. [18] KIM Y J, CHIN W J, JEON S J. Interface shear strength at joints of ultra-high performance concrete structures[J]. International Journal of Concrete Structures and Materials, 2018, 12(6): 767-780. doi: 10.1186/s40069-018-0298-8 [19] AASHTO. Guide specifications for design and construction of segmental concrete bridges: 2003 interim revisions [S]. Washington D. C.: AASHTO, 2003. [20] ACI Committee. Building code requirements for reinforced concrete:ACI 318-08 [S]. Farmington Hills: [s.n.], 2008. -

下载:

下载: