Seismic Testing and Calculation Method of Assembled Bridge Piers with Hybrid Connection of Engineered Cementitious Composites and Assembled Mortise-Tenon Joints

-

摘要:

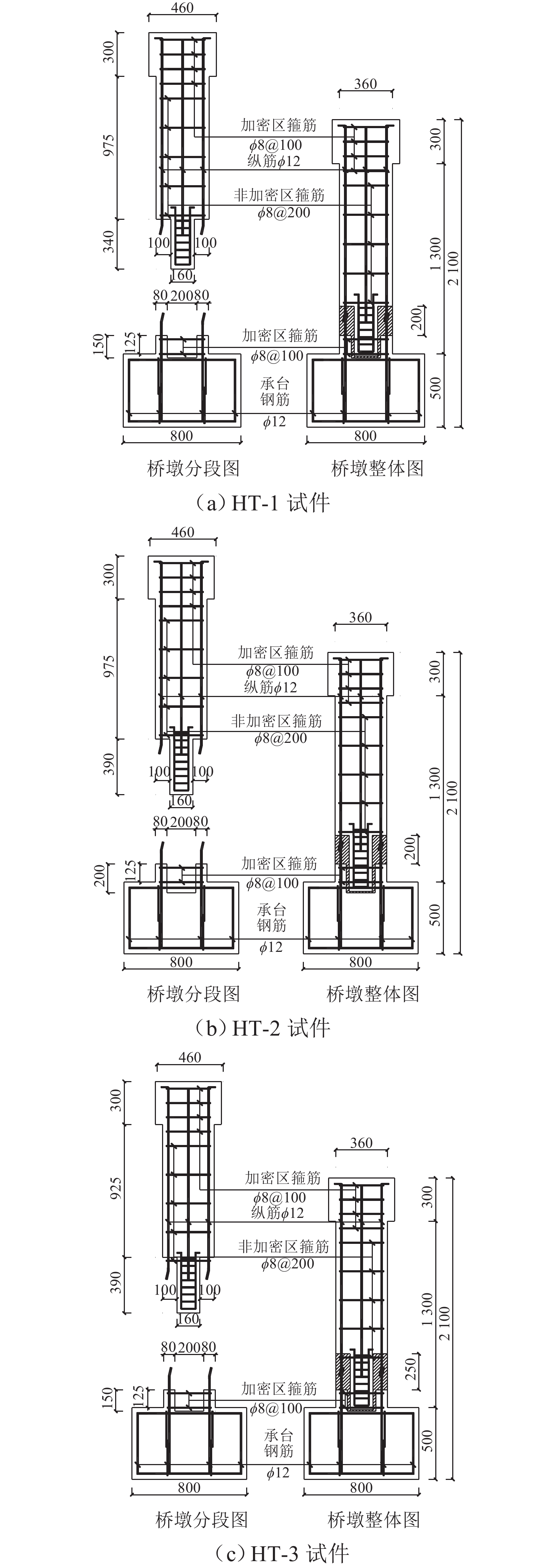

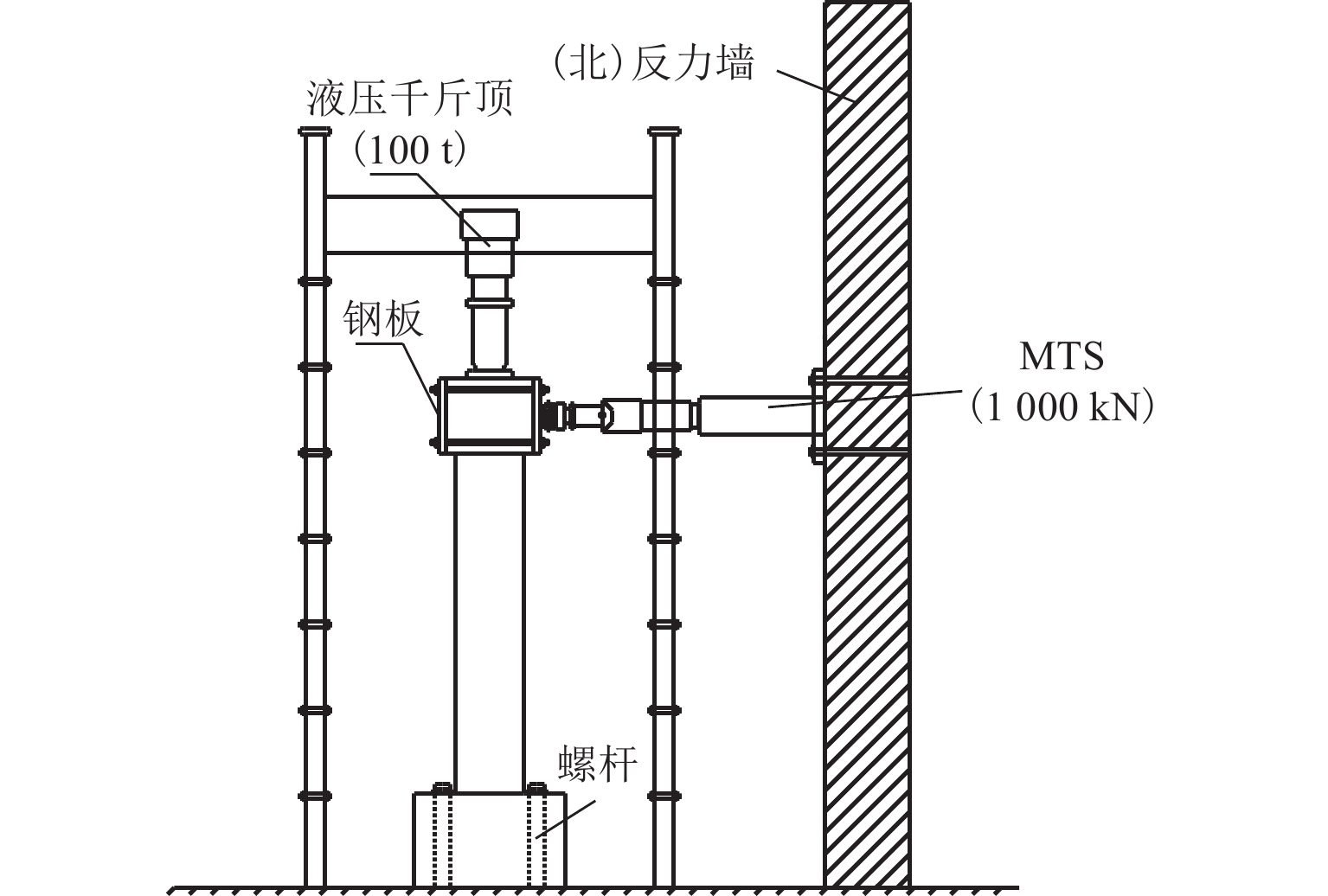

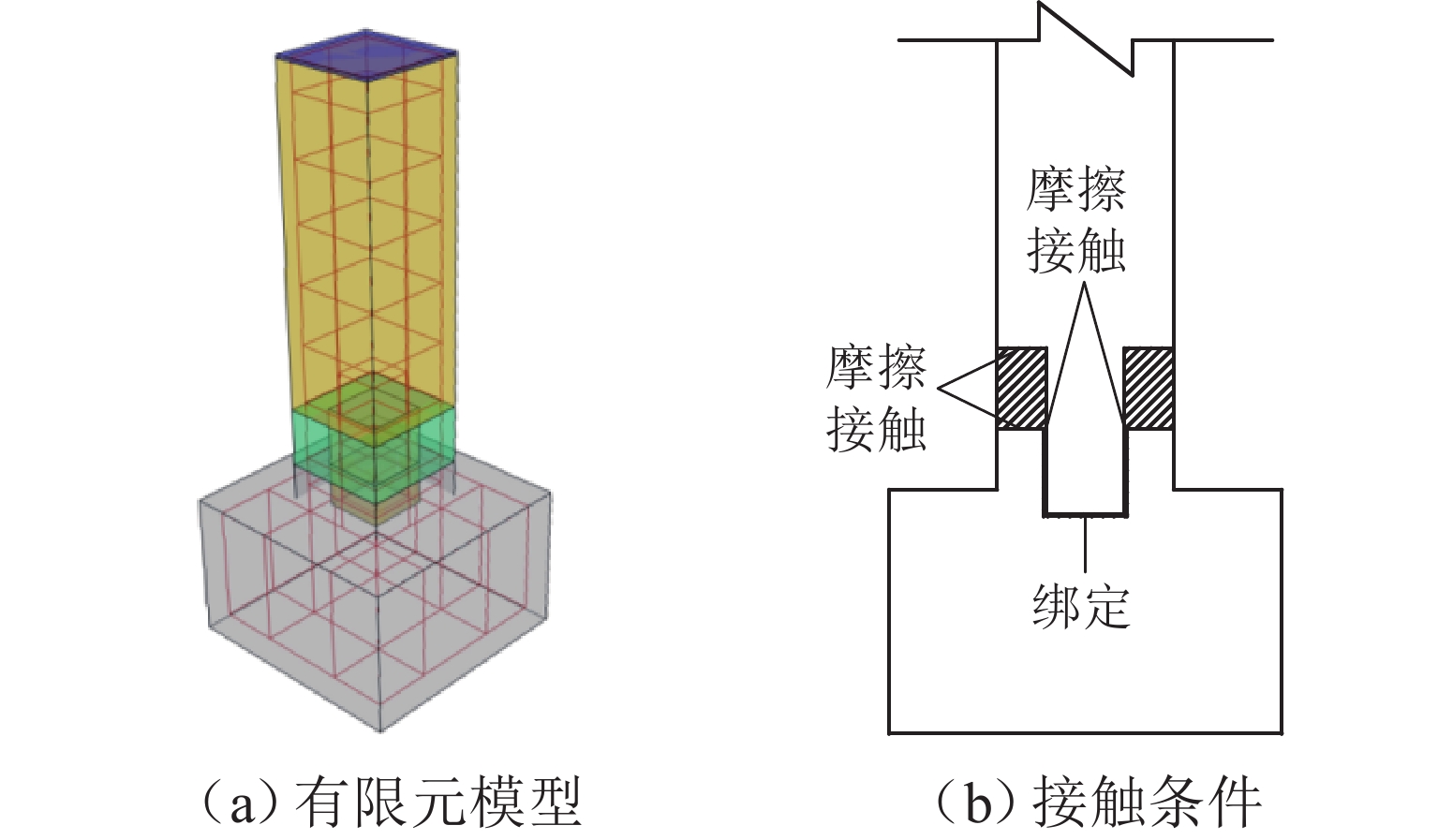

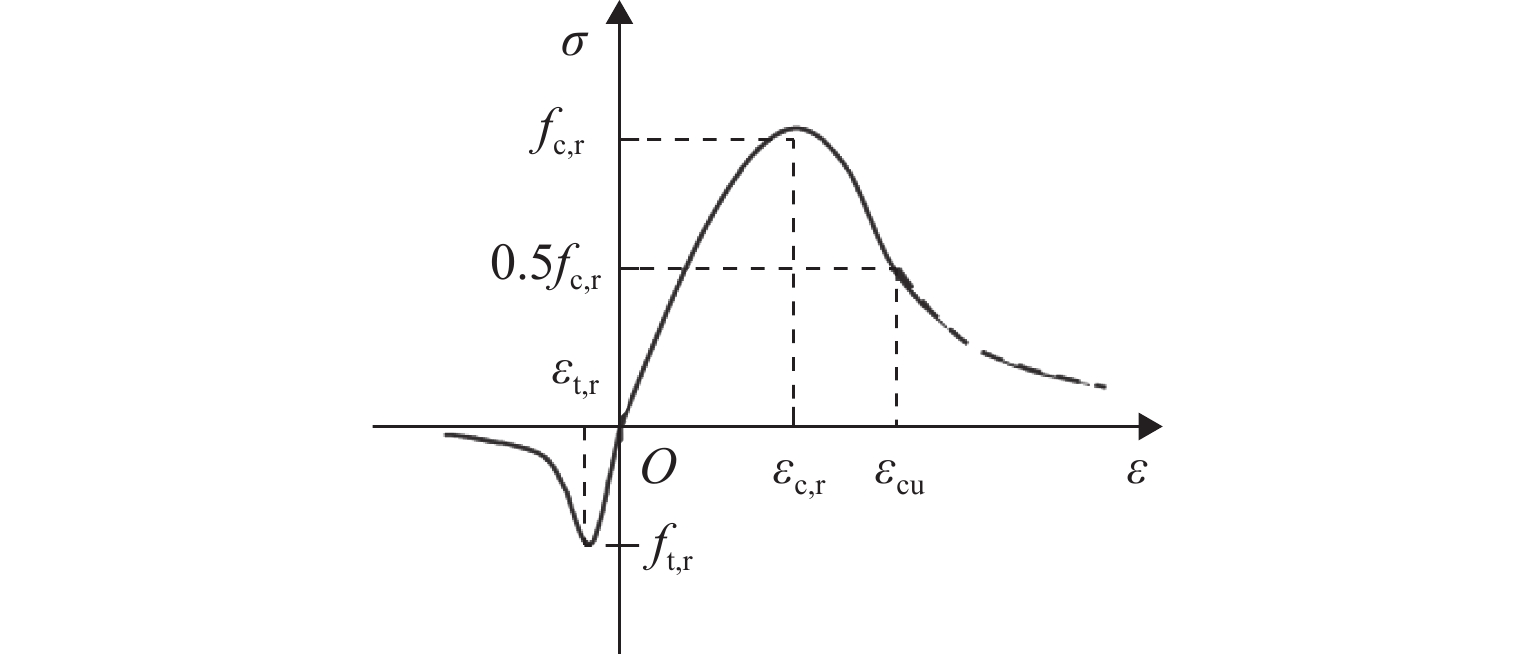

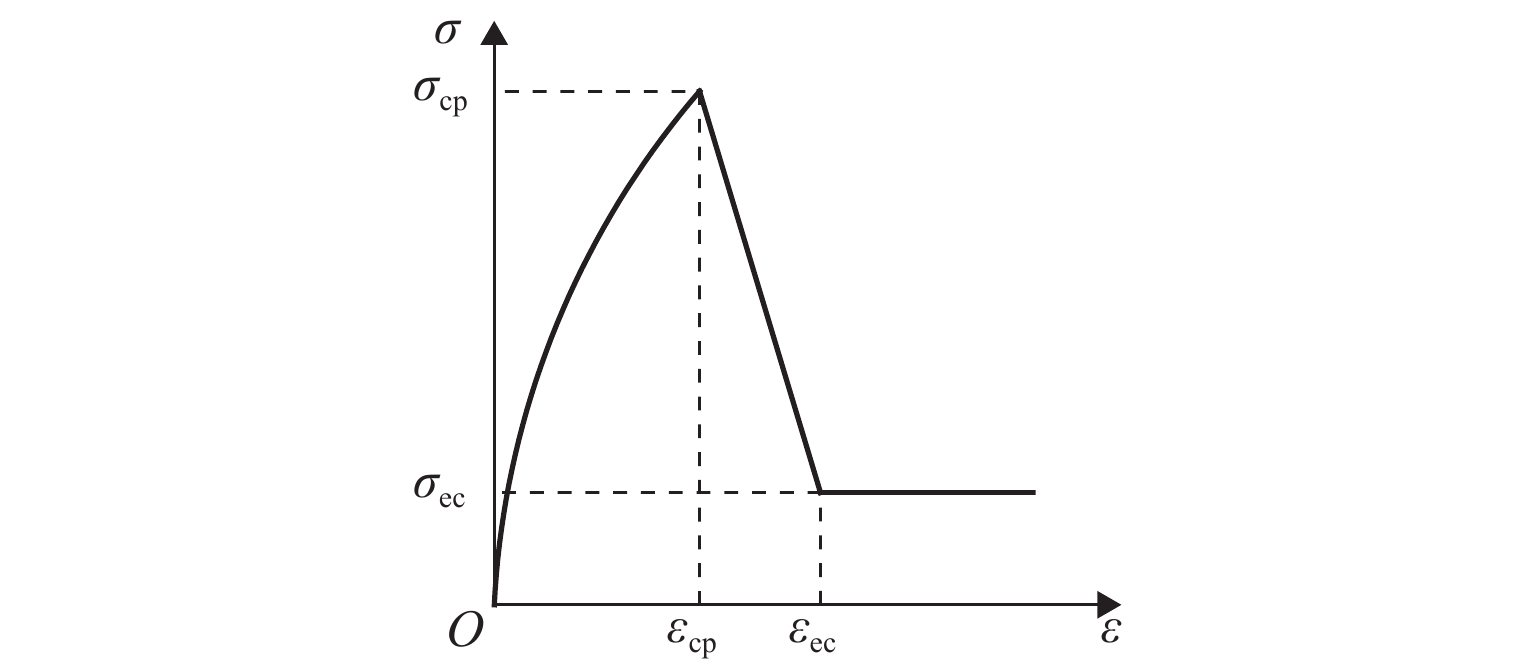

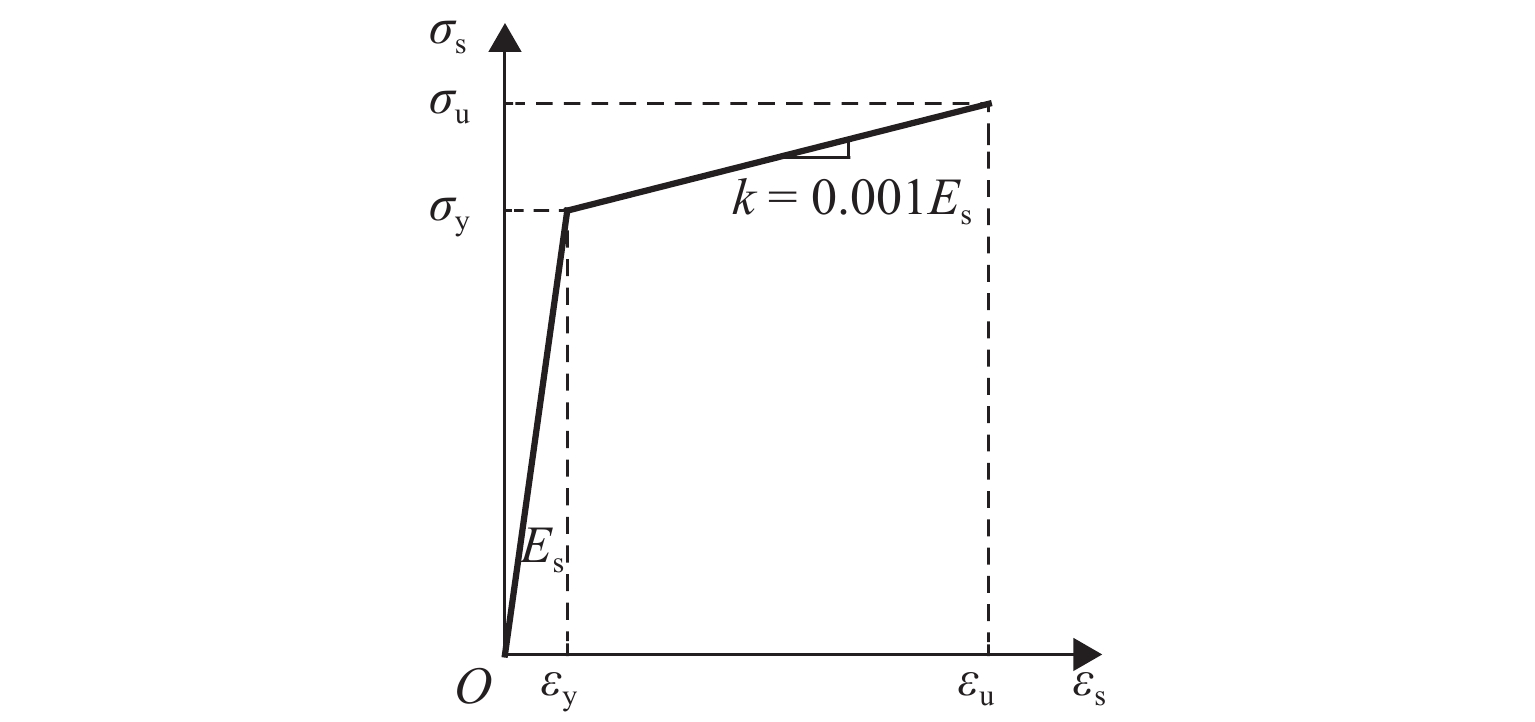

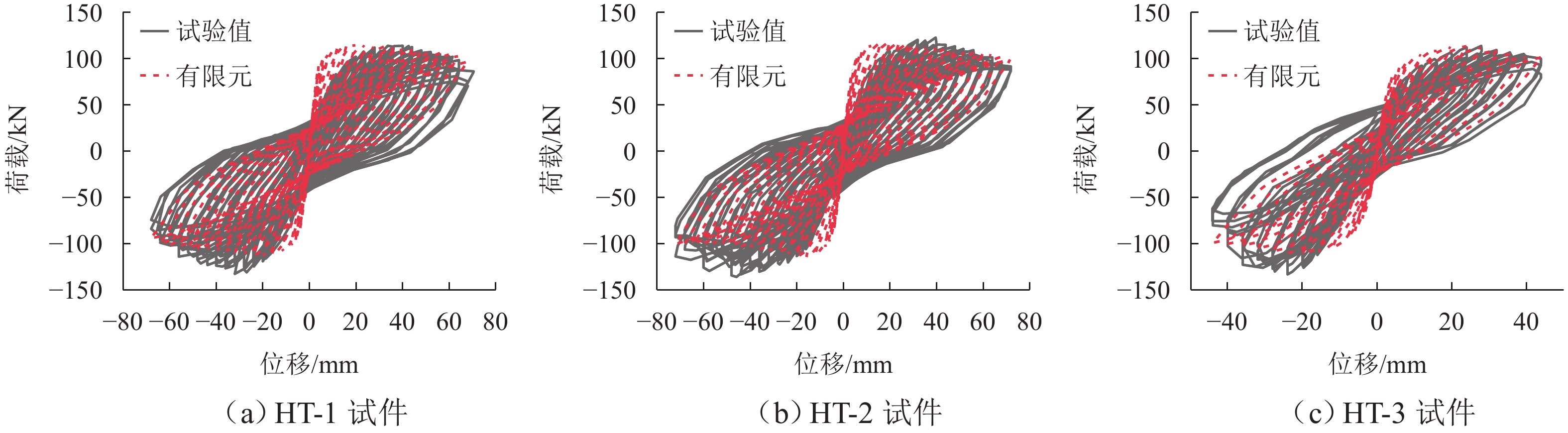

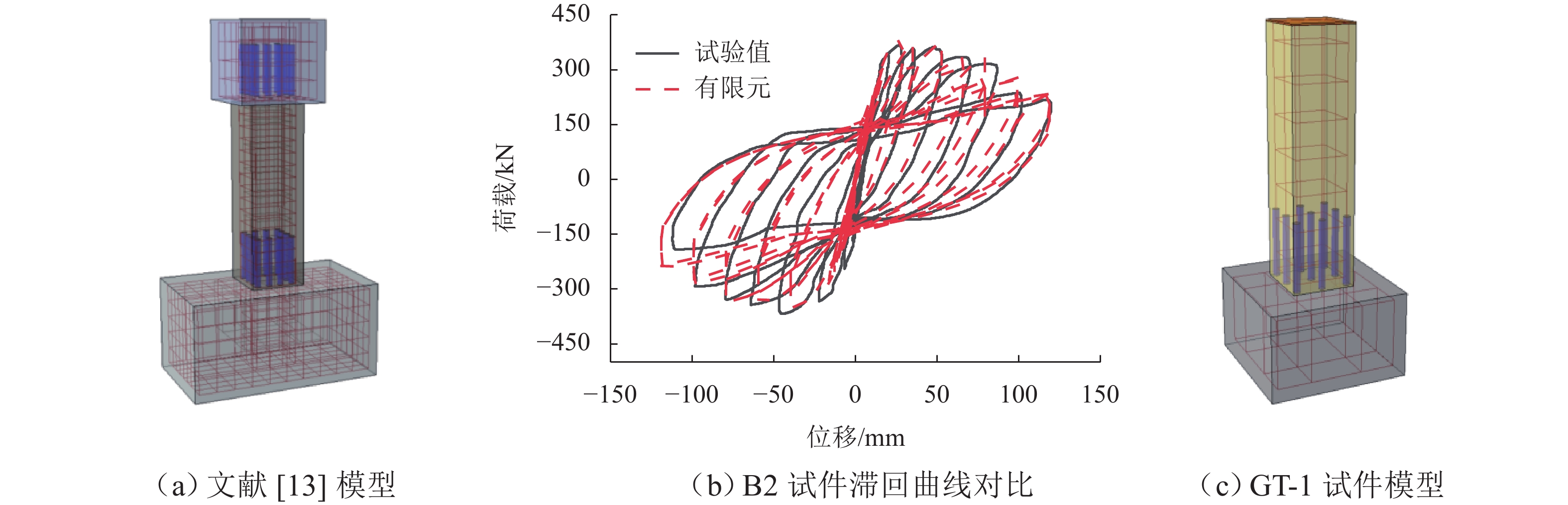

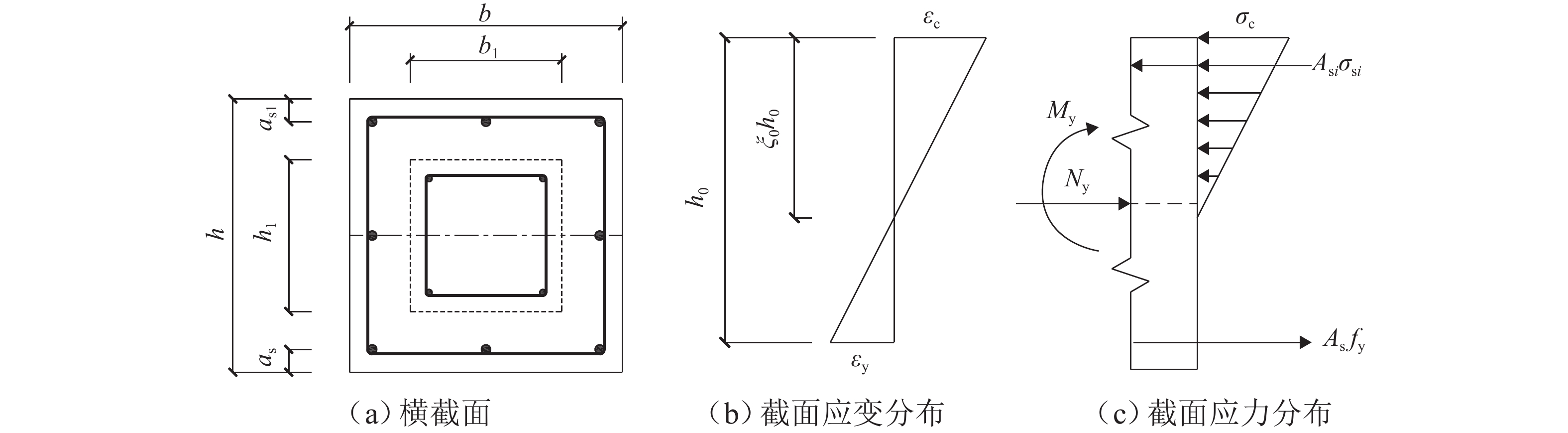

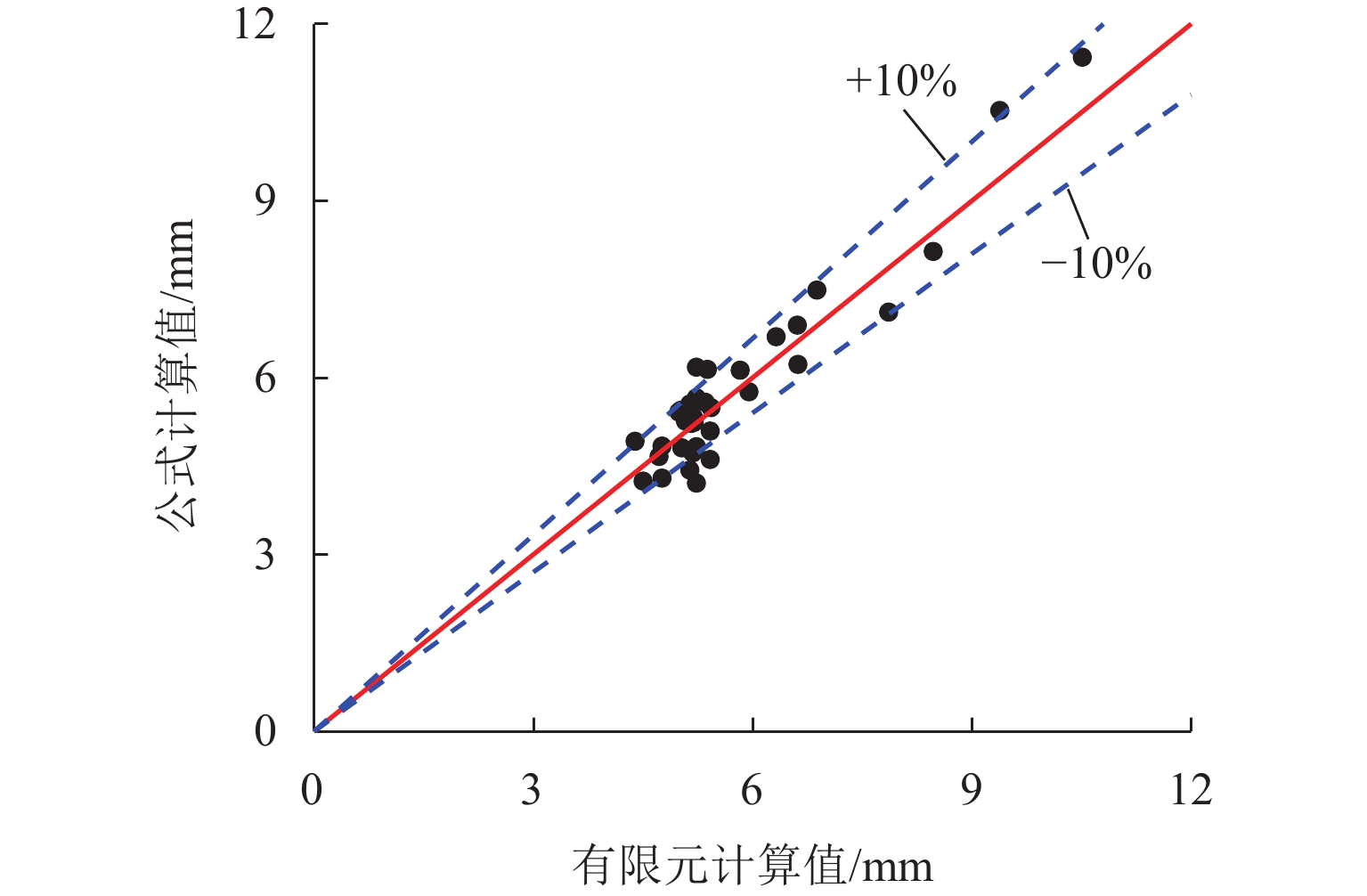

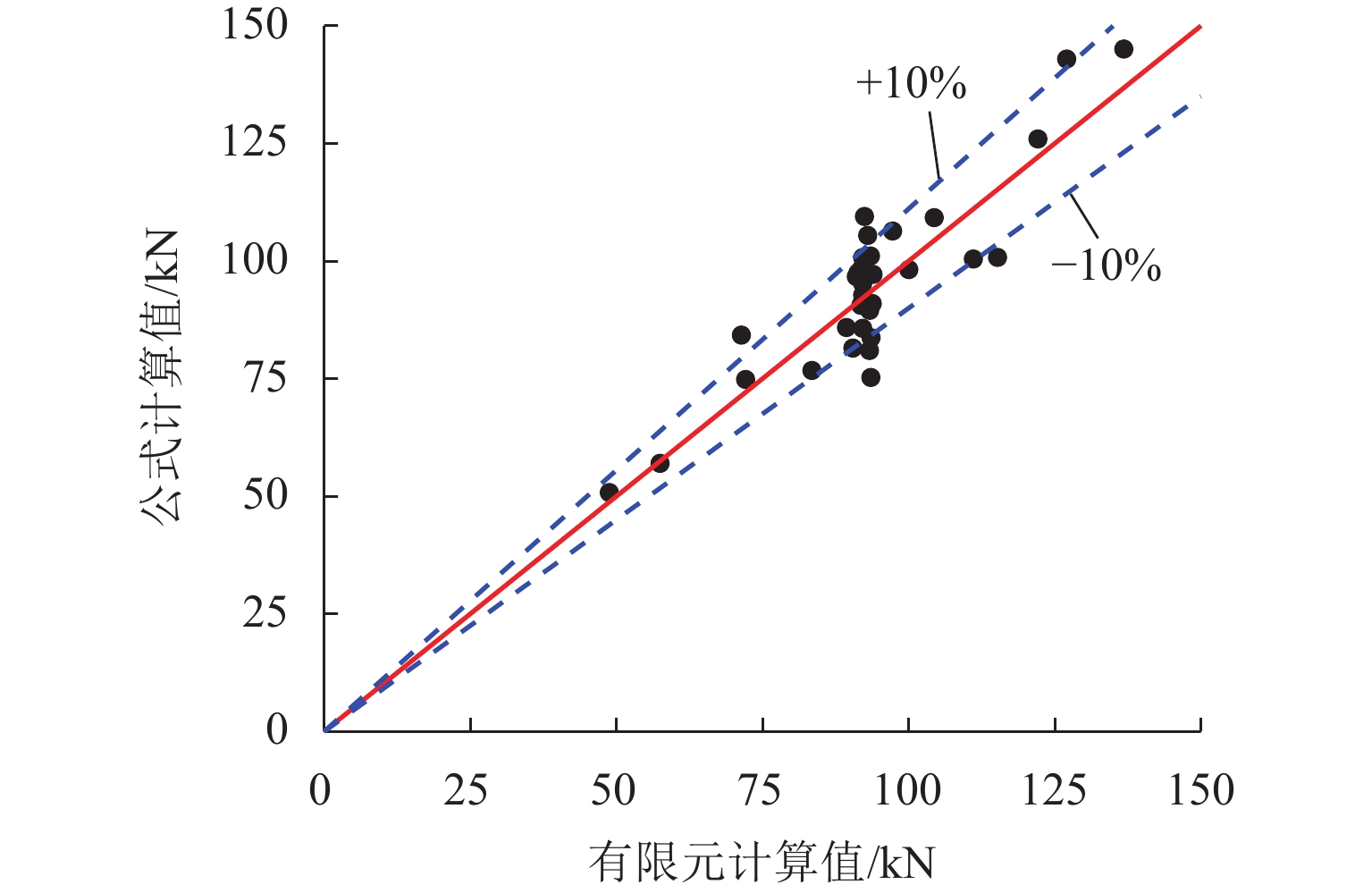

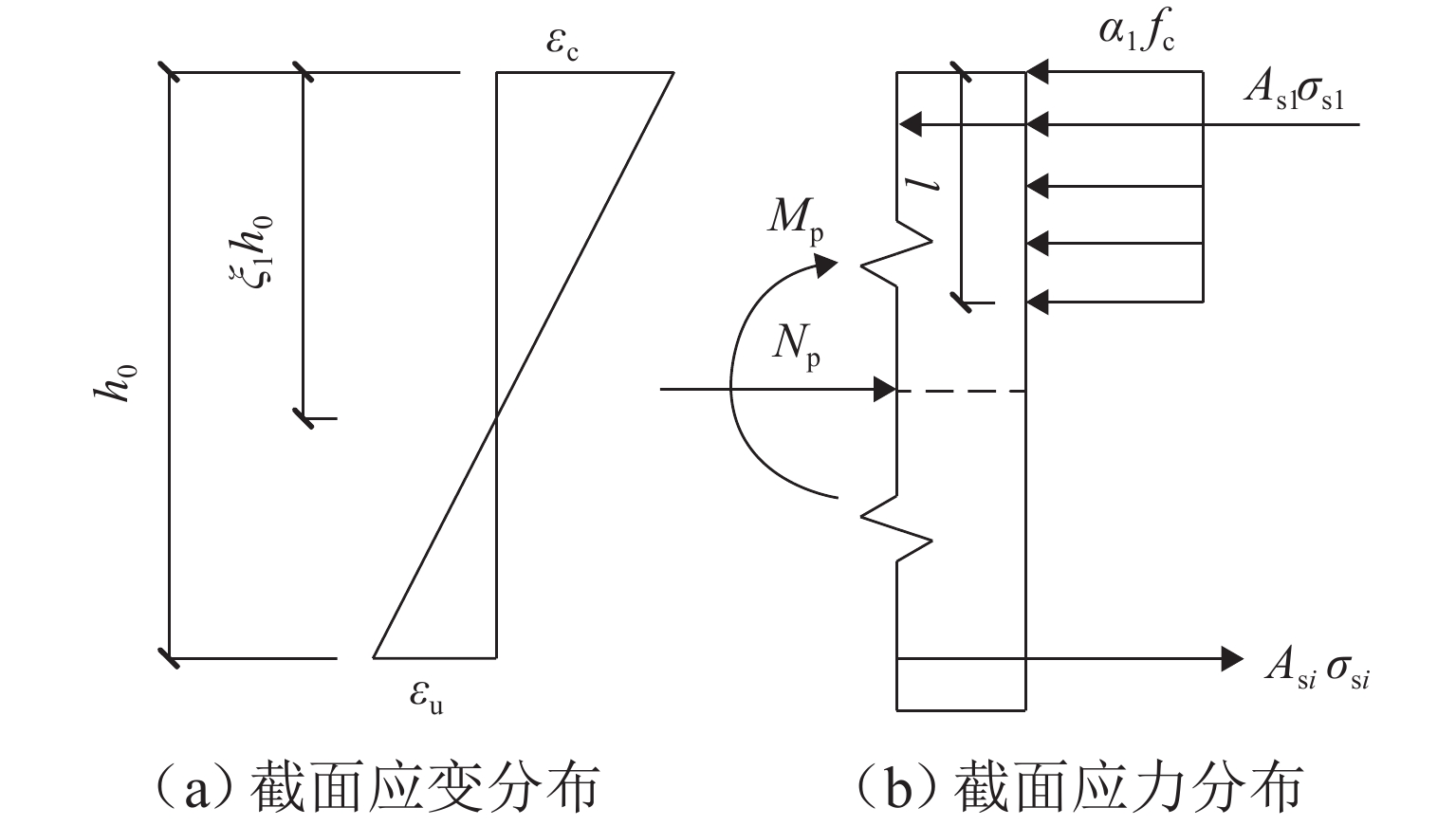

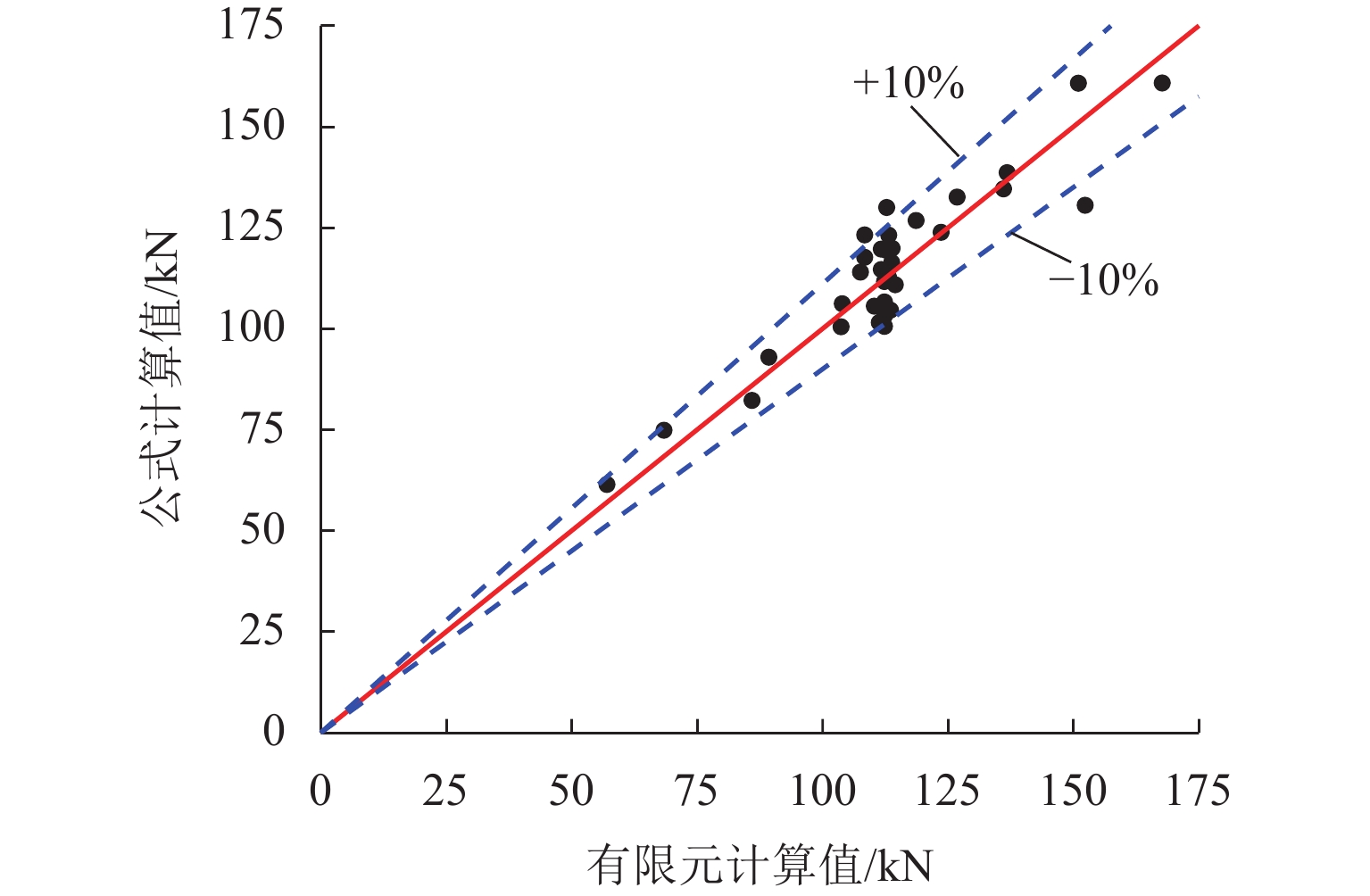

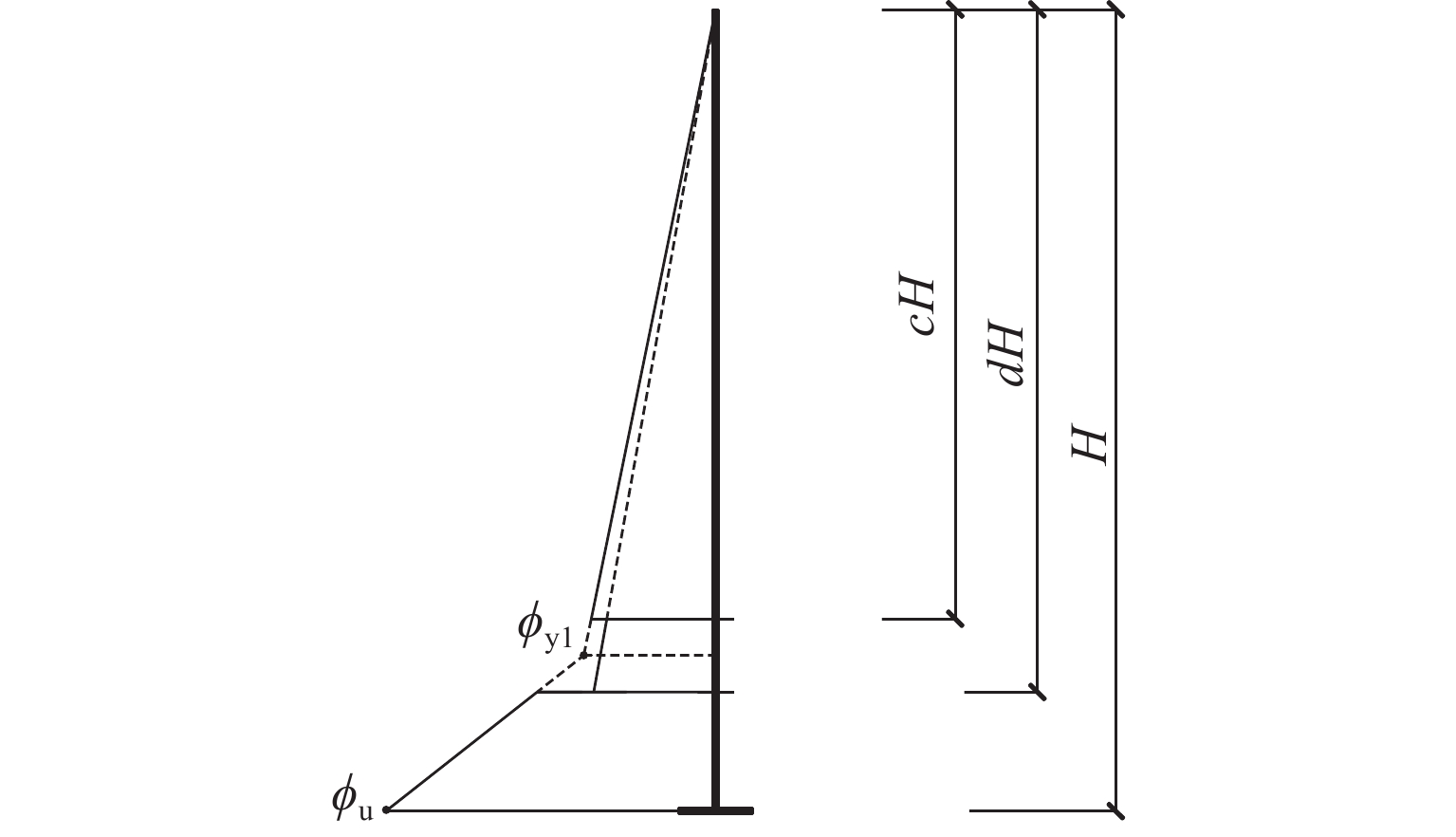

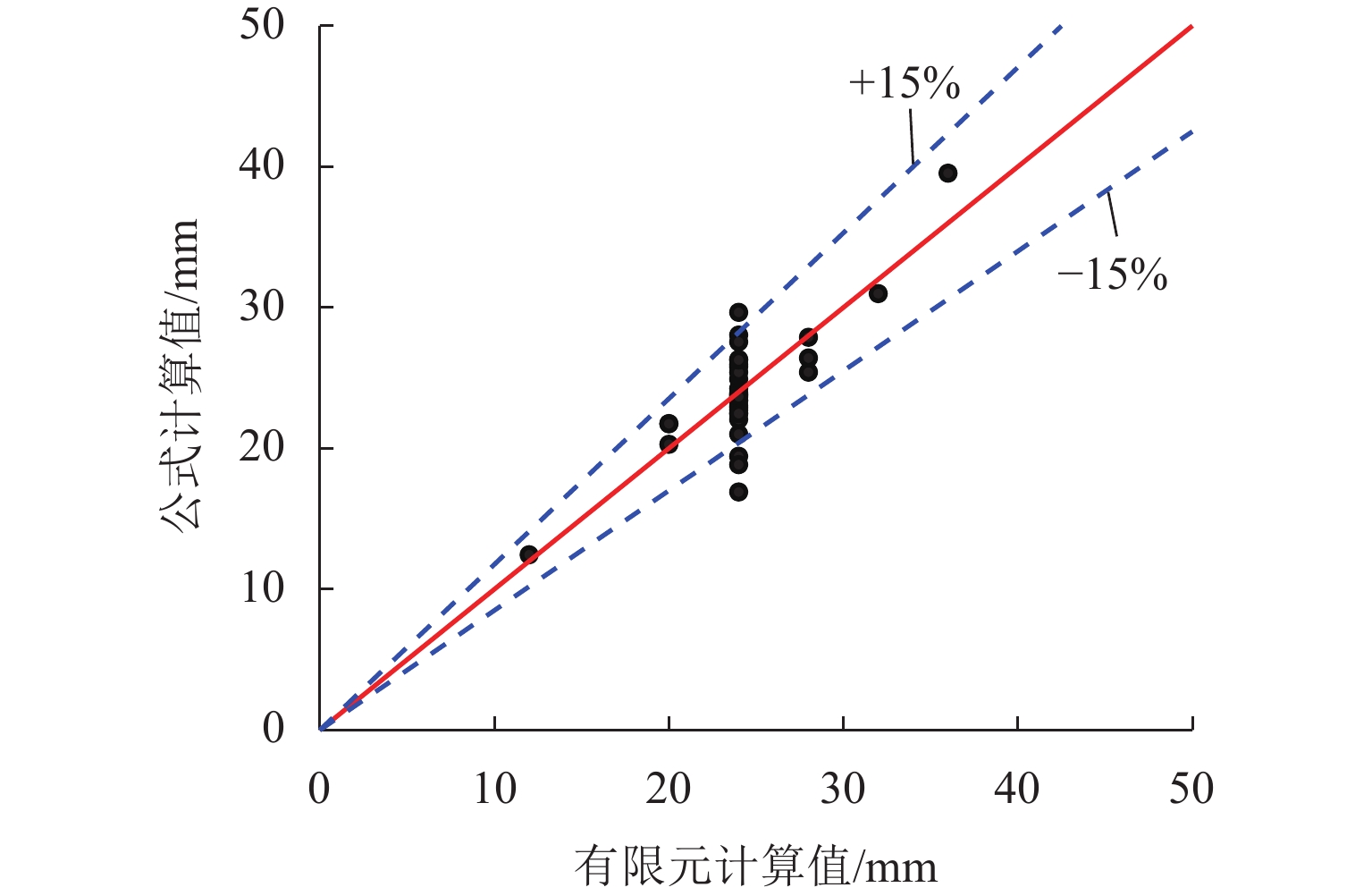

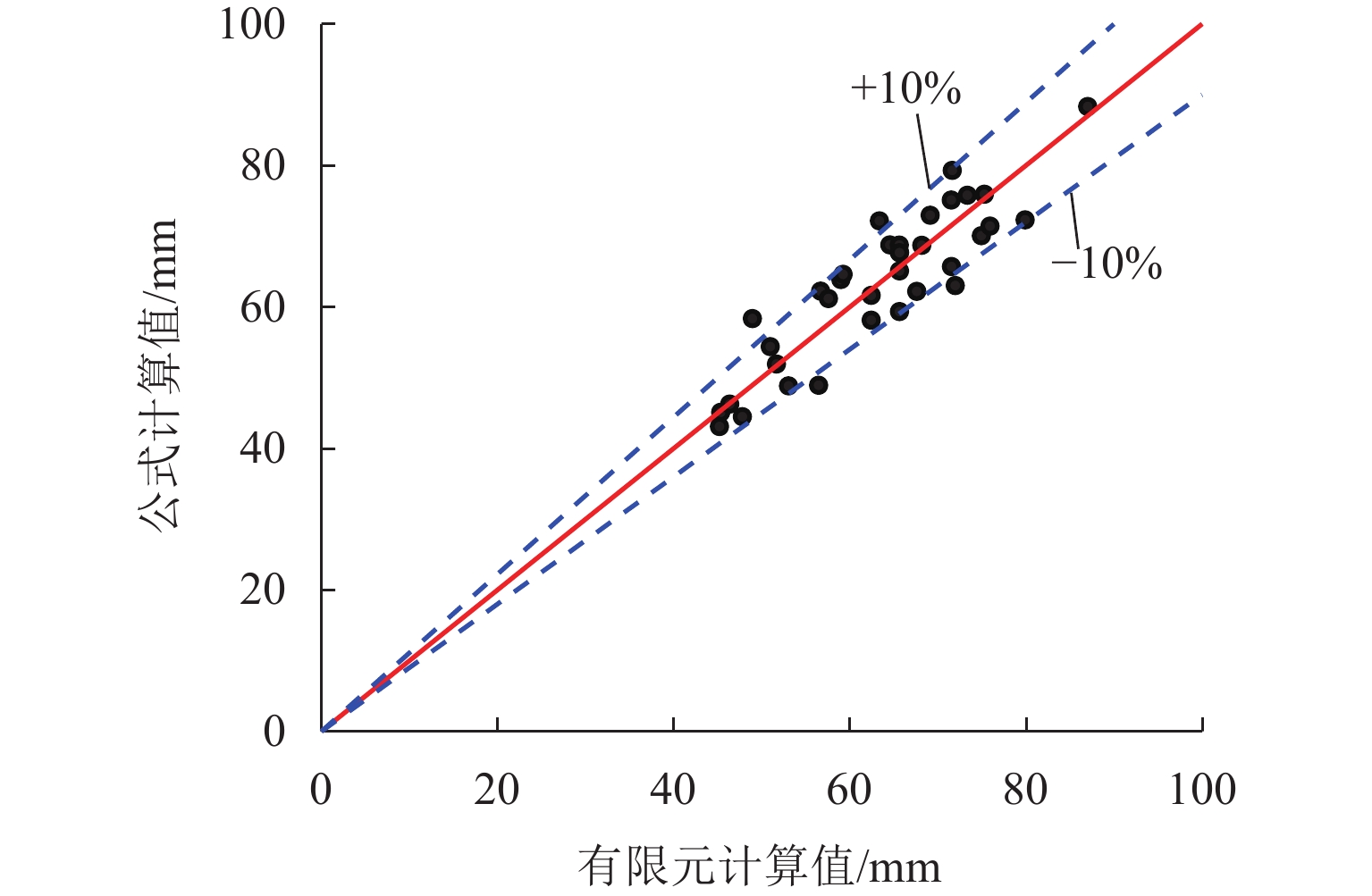

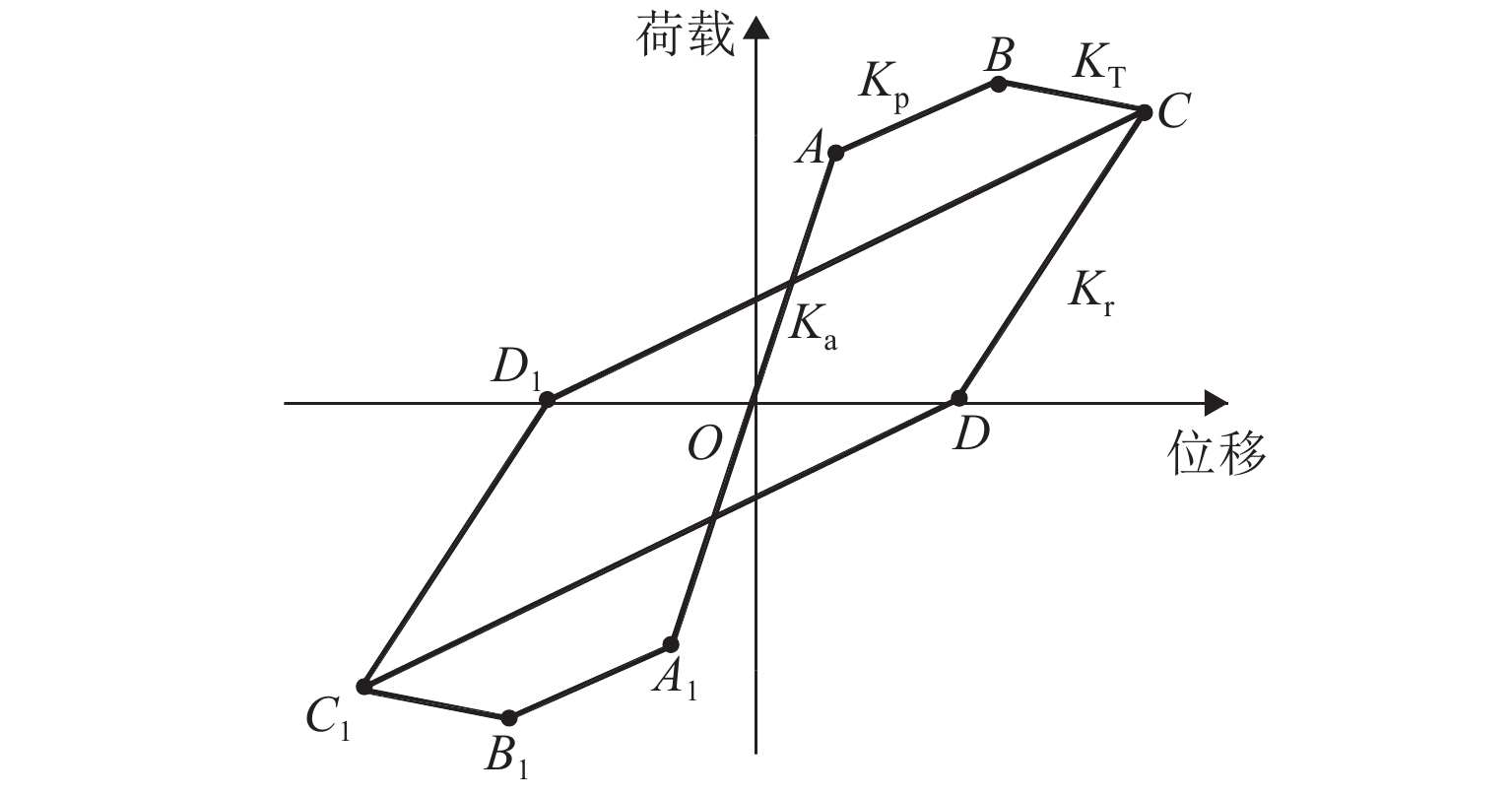

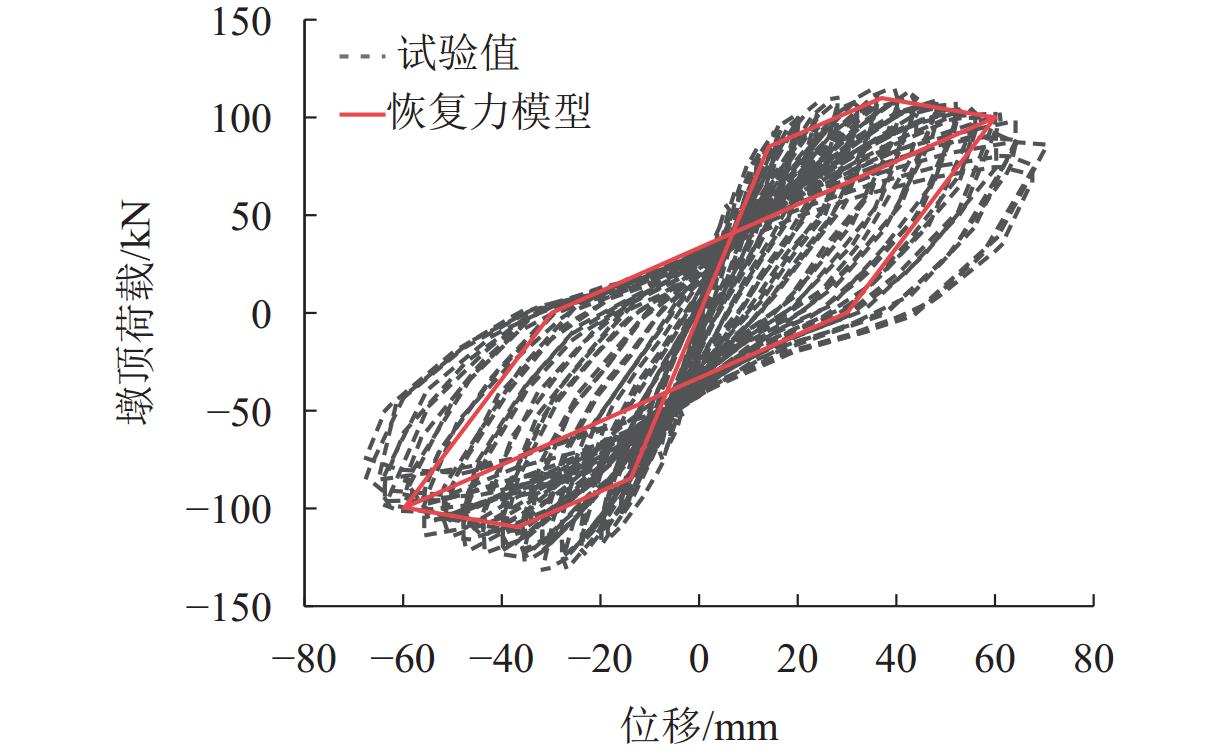

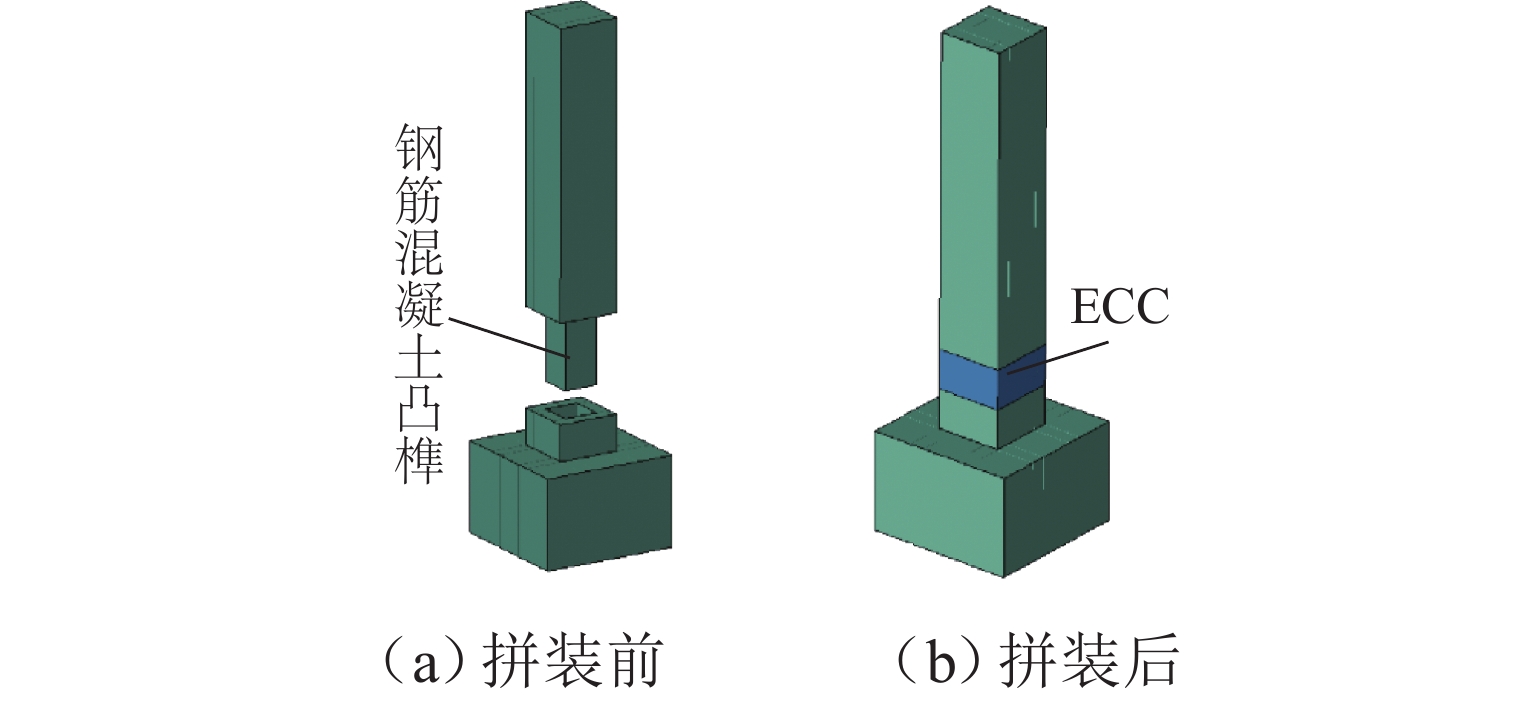

为提高装配式桥墩的受力性能和耐久性,提出采用现浇纤维增强水泥基复合材料(ECC)和预制榫卯混合连接的装配式桥墩,开展不同设计参数(凹槽深度和现浇ECC层厚度)的桥墩拟静力试验,建立经试验验证的ABAQUS有限元模型;同时进行拓展参数分析,在此基础上进行理论推导,提出混合连接装配式RC (reinforced concrete)桥墩的骨架曲线特征值计算方法和恢复力模型. 结果表明:3根桥墩试件破坏模式均为压弯破坏,各试件的ECC现浇段均未发生破坏;凹槽深度、现浇ECC段高度的变化对桥墩的延性系数、极限位移的影响较为显著;理论分析计算结果与有限元分析结果吻合良好,除峰值位移外,各公式计算值与有限元计算值之比均在0.85~1.14,计算结果可靠;混合连接装配式桥墩恢复力模型计算的滞回曲线与试验曲线吻合较好,可用于桥墩弹塑性计算.

-

关键词:

- 桥梁工程 /

- 榫卯连接 /

- 抗震性能 /

- 纤维增强水泥基复合材料 /

- 恢复力模型

Abstract:In order to improve the force performance and durability of assembled bridge piers, it was proposed to adopt the assembled bridge piers with hybrid connection of cast-in-place fiber-reinforced engineered cementitious composites (ECC) and assembled mortise and tenon joints and carry out the pseudo-static tests of the bridge piers with different design parameters (depth of the groove and thickness of the cast-in-place ECC layer), so as to establish the experimentally-validated ABAQUS finite-element model. In addition, extended parametric analysis was carried out, and theoretical derivation was conducted on the basis of the finite element parametric analysis. The calculation method of the eigenvalue of the skeleton curve and the restoring force model of the hybrid-connected assembled RC bridge pier were proposed. The results show that the damage mode of the three bridge pier specimens is compression bending damage, and the cast-in-place ECC section of each specimen is not damaged; the changes in the depth of the groove and the height of the cast-in-place ECC section have significant effects on the ductility coefficient and ultimate displacement of the bridge piers. The results of the theoretical analysis coincide with the results of the finite element analysis. The ratio of the calculated values of the formulas to the values of the finite element analysis ranges from 0.85 to 1.14, except for peak displacement, and the results are reliable; the hysteresis curve calculated by the hybrid-connected assembled bridge pier restoring force model matches well with the test curve, which can be used for the elastic-plastic calculation of bridge piers.

-

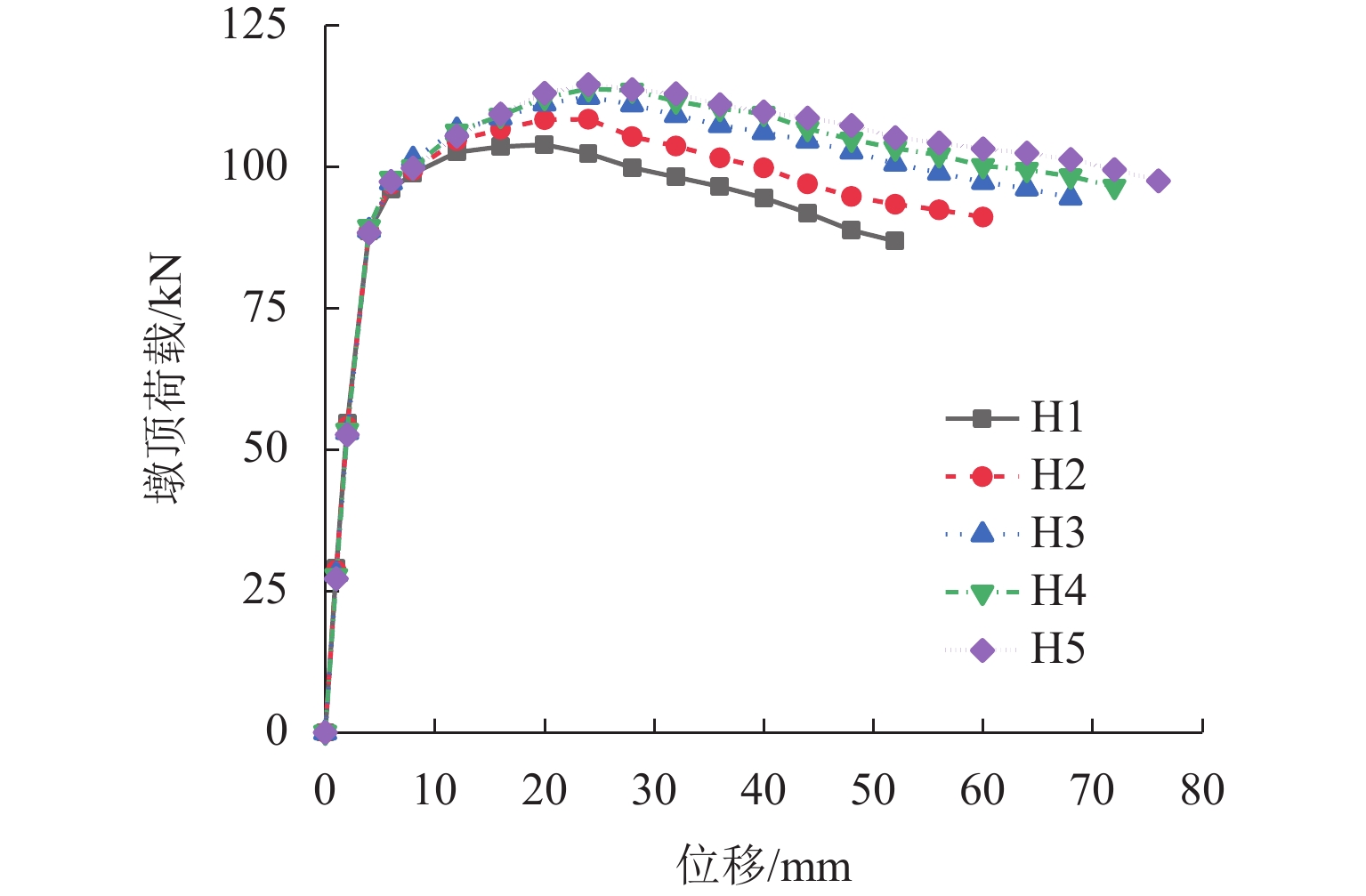

表 1 不同ECC段高度的特征值

Table 1. Eigenvalues of different ECC section heights

编号 ECC 厚度/

mmPy/kN Δy/mm Pmax/kN Δmax/

mmΔu/mm µu H1 100 90.5 4.5 103.9 20 48.9 10.9 H2 150 91.8 4.8 108.4 24 56.7 11.9 H3 200 92.1 5.2 112.4 24 65.6 12.6 H4 250 93.8 5.4 113.8 24 71.5 13.4 H5 300 93.5 5.4 114.5 24 75.3 13.9 表 2 不同凹槽深度的特征值

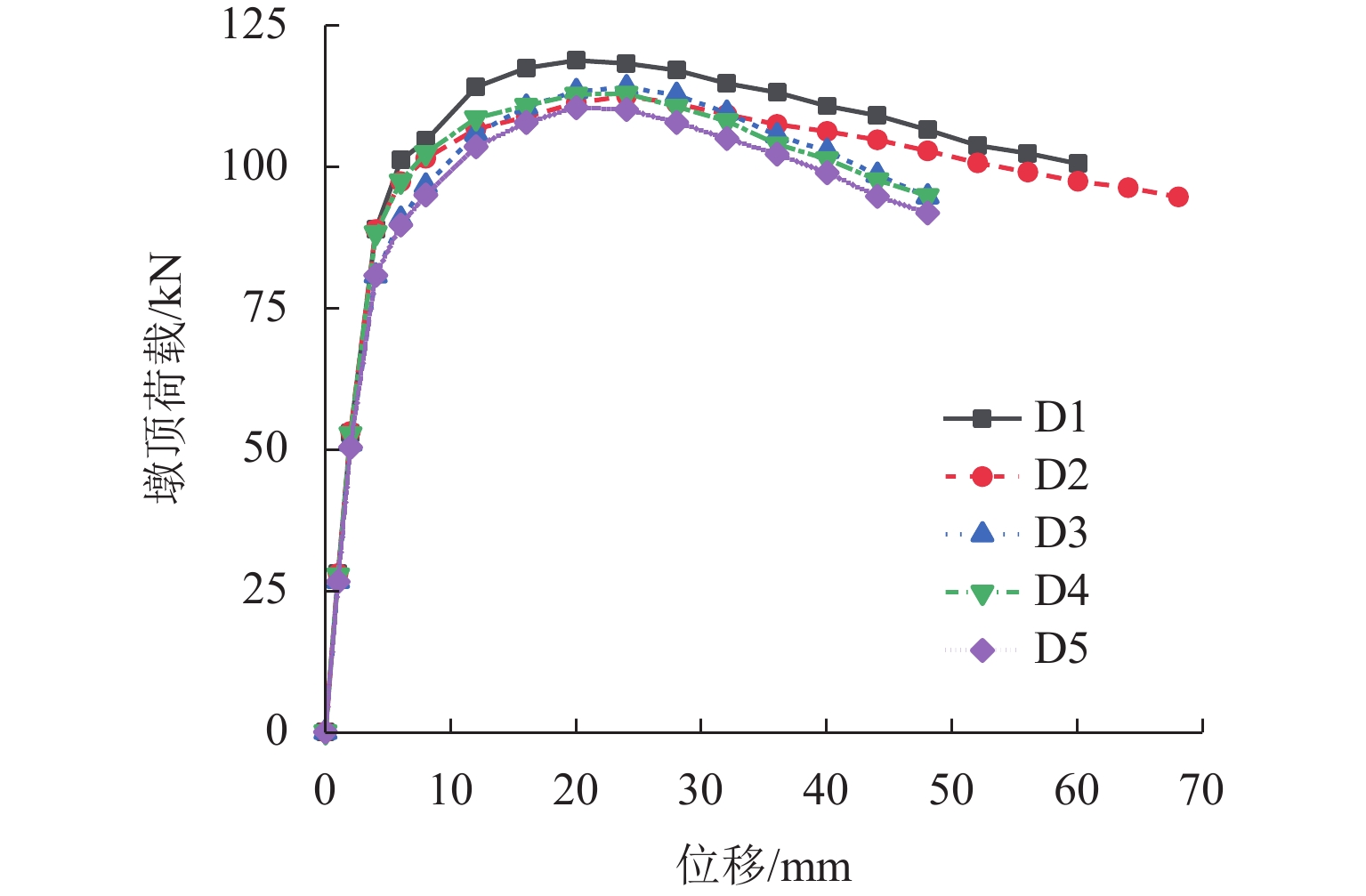

Table 2. Eigenvalues of different depths of groove

编号 凹槽深度/

mmPy/kN Δy/mm Pmax/kN Δmax/mm Δu/mm µu D1 100 97.3 5.4 118.7 20 59.0 11.0 D2 150 92.1 5.2 112.4 24 65.6 12.6 D3 200 92.4 6.6 113.9 24 47.8 7.2 D4 250 93.0 6.3 112.8 24 46.4 7.3 D5 300 89.4 6.0 110.3 24 45.2 7.6 表 3 不同轴压比的特征值

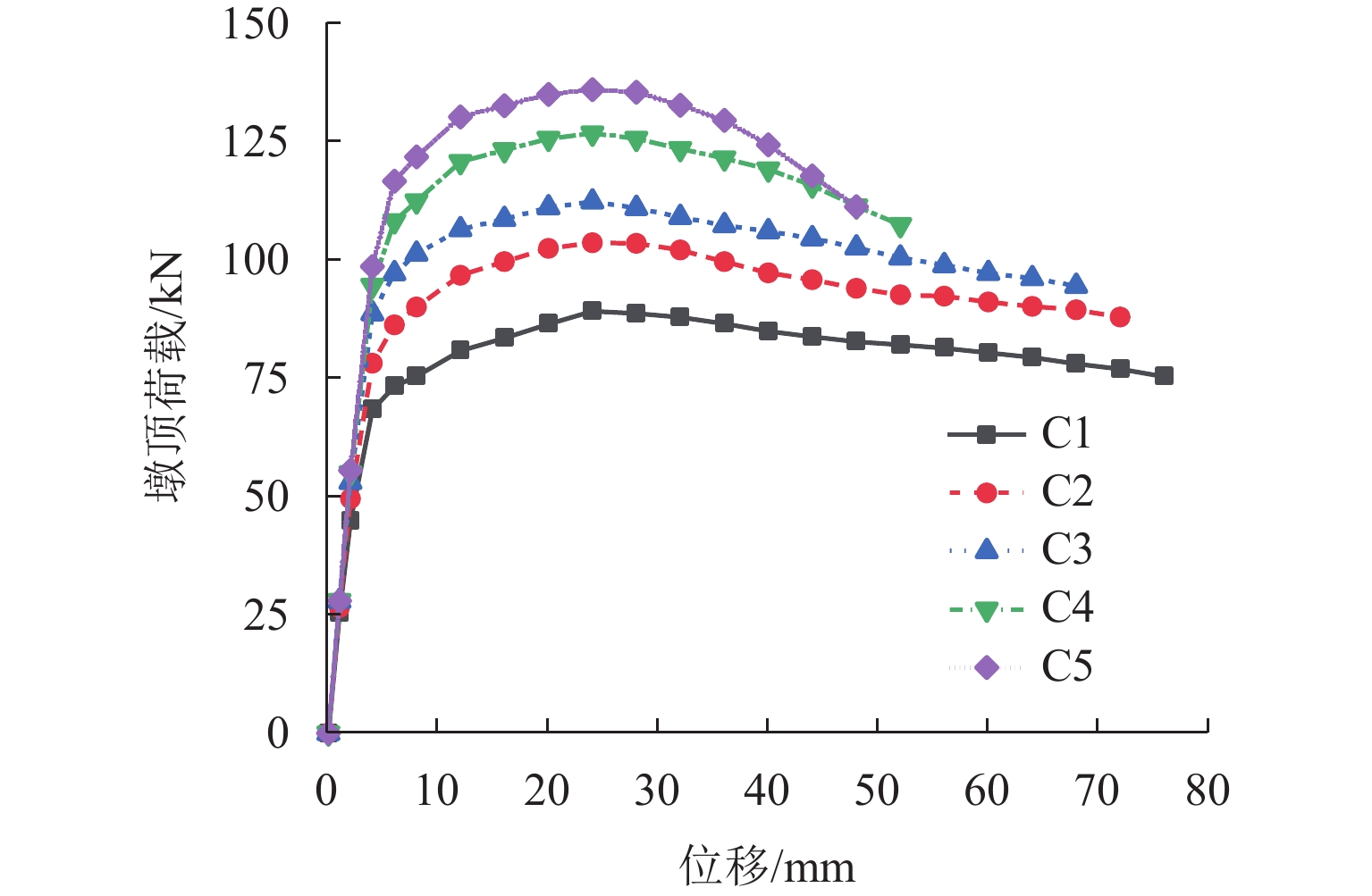

Table 3. Eigenvalues of different axial compression ratios

编号 轴压比 Py/kN Δy/mm Pmax/kN Δmax/mm Δu/mm µu C1 0.10 71.4 5.2 89.3 24 74.9 14.5 C2 0.15 83.5 5.2 103.7 24 71.6 13.8 C3 0.20 92.1 5.2 112.4 24 65.6 12.6 C4 0.25 104.4 5.4 126.8 24 51.7 9.5 C5 0.30 115.2 5.8 136.1 24 45.3 7.8 -

[1] 黄云青,赵建锋. 不同连接方式对预制拼装桥墩抗震性能的影响[J]. 青岛理工大学学报,2019,40(6): 38-43. doi: 10.3969/j.issn.1673-4602.2019.06.006HUANG Yunqing, ZHAO Jianfeng. Influence of different connection modes on seismic performance of precast segmental assembly bridge pier[J]. Journal of Qingdao University of Technology, 2019, 40(6): 38-43. doi: 10.3969/j.issn.1673-4602.2019.06.006 [2] 魏红一,肖纬,王志强,等. 采用套筒连接的预制桥墩抗震性能试验研究[J]. 同济大学学报(自然科学版),2016,44(7): 1010-1016.WEI Hongyi, XIAO Wei, WANG Zhiqiang, et al. Experimental study on seismic performance of precast bridge pier with grouted splice sleeve[J]. Journal of Tongji University (Natural Science), 2016, 44(7): 1010-1016. [3] 王景全,王震,高玉峰,等. 预制桥墩体系抗震性能研究进展:新材料、新理念、新应用[J]. 工程力学,2019,36(3): 1-23.WANG Jingquan, WANG Zhen, GAO Yufeng, et al. Review on aseismic behavior of precast piers: new material, new concept, and new application[J]. Engineering mechanics, 2019, 36(3): 1-23. [4] 林上顺,林永捷,夏樟华,等. 不同拼接构造的装配式圆柱墩偏压性能试验[J]. 工业建筑,2022,52(4): 91-97.LIN Shangshun, LIN Yongjie, XIA Zhanghua, et al. Experimental research on mechanical properties of prefabricated cylindrical piers with different splicing structures under eccentric compression[J]. Industrial Construction, 2022, 52(4): 91-97. [5] 欧智菁,谢铭勤,秦志清,等. 带钢管剪力键的装配式混凝土桥墩抗震性能[J]. 西南交通大学学报,2021,56(6): 1169-1175,1191.OU Zhijing, XIE Mingqin, QIN Zhiqing, et al. Seismic performance test and FEM analysis of assembled concrete pier with sleeve and steel tube shear connector[J]. Journal of Southwest Jiaotong University, 2021, 56(6): 1169-1175,1191. [6] 张志刚,张仁毅,张沛,等. 可自修复的高延性混凝土(ECC)在机场道面的适用性分析[J]. 重庆大学学报,2021,44(1): 97-105. doi: 10.11835/j.issn.1000-582X.2021.01.011ZHANG Zhigang, ZHANG Renyi, ZHANG Pei, et al. Feasibility study of engineered cementitious composites (ECC) with self-healing capacity for airfield pavement[J]. Journal of Chongqing University, 2021, 44(1): 97-105. doi: 10.11835/j.issn.1000-582X.2021.01.011 [7] 李庆华,徐世烺. 超高韧性水泥基复合材料基本性能和结构应用研究进展[J]. 工程力学,2009,26(增2): 23-67.LI Qinghua, XU Shilang. Performance and application of ultra high toughness cementitious composite: a review[J]. Engineering Mechanics, 2009, 26(S2): 23-67. [8] 林上顺,林永捷,夏樟华,等. U HPC和预制榫卯混合连接装配式RC桥墩拟静力试验[J]. 桥梁建设,2023,53(1): 16-23.LIN Shangshun, LIN Yongjie, XIA Zhanghua, et al. Quasi-static test of prefabricated segmental RC pier with hybrid UHPC and prefabricated mortise-tenon connections[J]. Bridge Construction, 2023, 53(1): 16-23. [9] 包龙生,王贺鑫,汤维维,等. 采用榫卯剪力键的预应力装配式双柱桥墩拟静力分析[J]. 沈阳建筑大学学报(自然科学版),2018,34(4): 692-702.BAO Longsheng, WANG Hexin, TANG Weiwei, et al. Pseudo static analysis of assembly type double column pier based on ABAQUS[J]. Journal of Shenyang Jianzhu University (Natural Science), 2018, 34(4): 692-702. [10] 中华人民共和国住房与城乡建设部. 混凝土结构设计规范:GB 50010—2010[S] . 北京:中国建筑工业出版社,2010. [11] 曹明. ABAQUS损伤塑性模型损伤因子计算方法研究[J]. 交通标准化,2012(2): 51-54.CAO Ming. Research on damage plastic calculation method of ABAQUS concrete damaged plasticity model[J]. Traffic Standardization, 2012(2): 51-54 [12] 杜亮. ECC材料基本力学性能研究[D]. 苏州:苏州科技大学,2019. [13] 刘阳. 灌浆套筒连接装配式桥墩节点力学性能研究[D]. 广州:华南理工大学,2020. [14] 苏浩. 钢筋增强ECC-钢管混凝土叠合柱抗震性能研究[D]. 南京:东南大学,2018. [15] SEZEN H, SETZLER E. Reinforcement slip in reinforced concrete columns[J]. ACI Structural Journal, 2008, 105(3): 280-289. [16] 李义柱. 600 MPa级钢筋混凝土柱受力性能试验与理论研究[D]. 南京:东南大学,2019. [17] 郭子雄,吕西林. 高轴压比框架柱恢复力模型试验研究[J]. 土木工程学报,2004,37(5): 32-38. doi: 10.3321/j.issn:1000-131X.2004.05.005GUO Zixiong, LU Xilin. Experimental study on the hysteretic model of RC columns with high axial comprfssire ratio[J]. China Civil Engineering Journal, 2004, 37(5): 32-38. doi: 10.3321/j.issn:1000-131X.2004.05.005 -

下载:

下载: