Effect of Fly Ash and Silica Fume Contents on Mechanical Properties of Alkali-Activated Slag-Based Concrete

-

摘要:

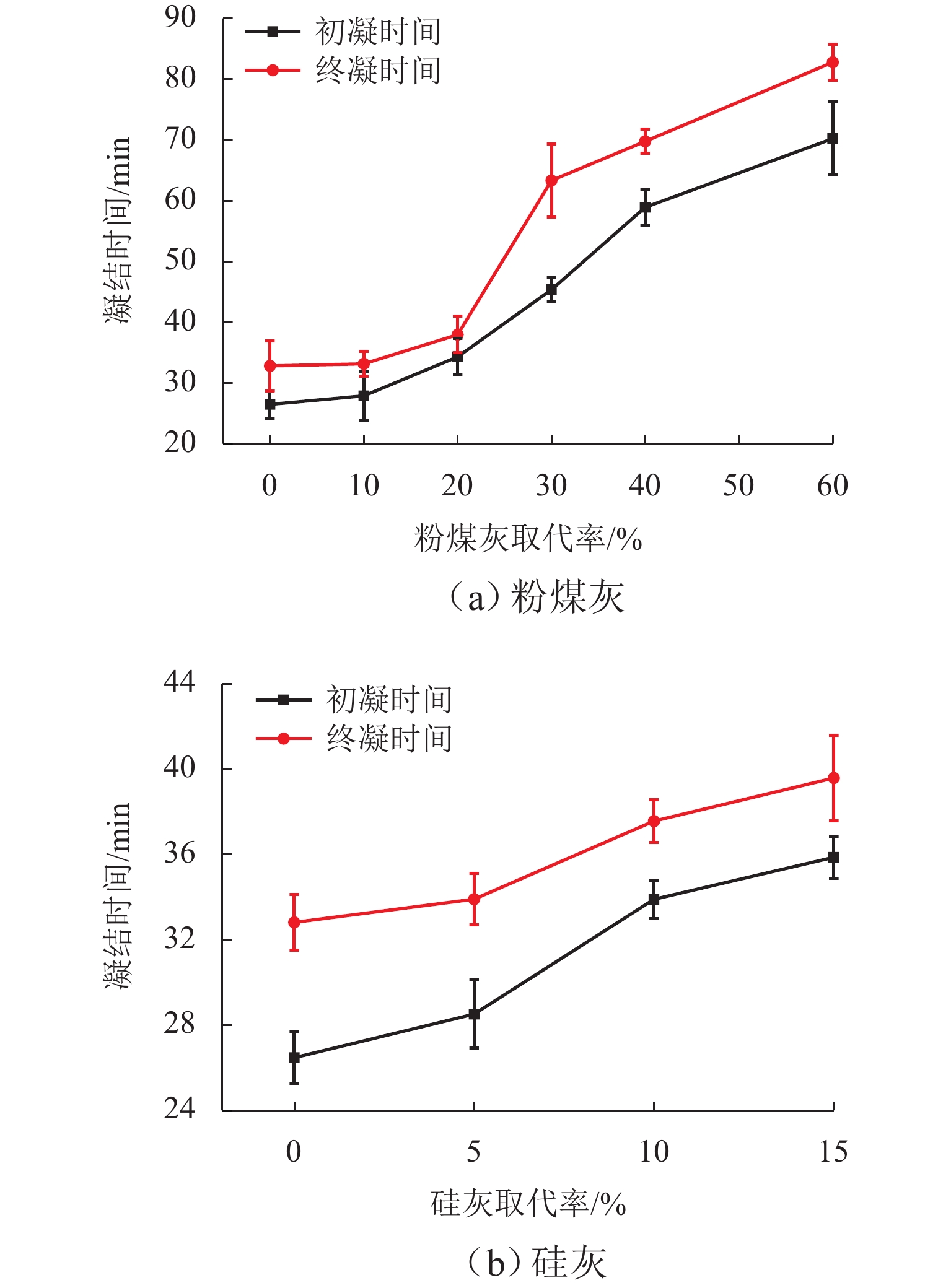

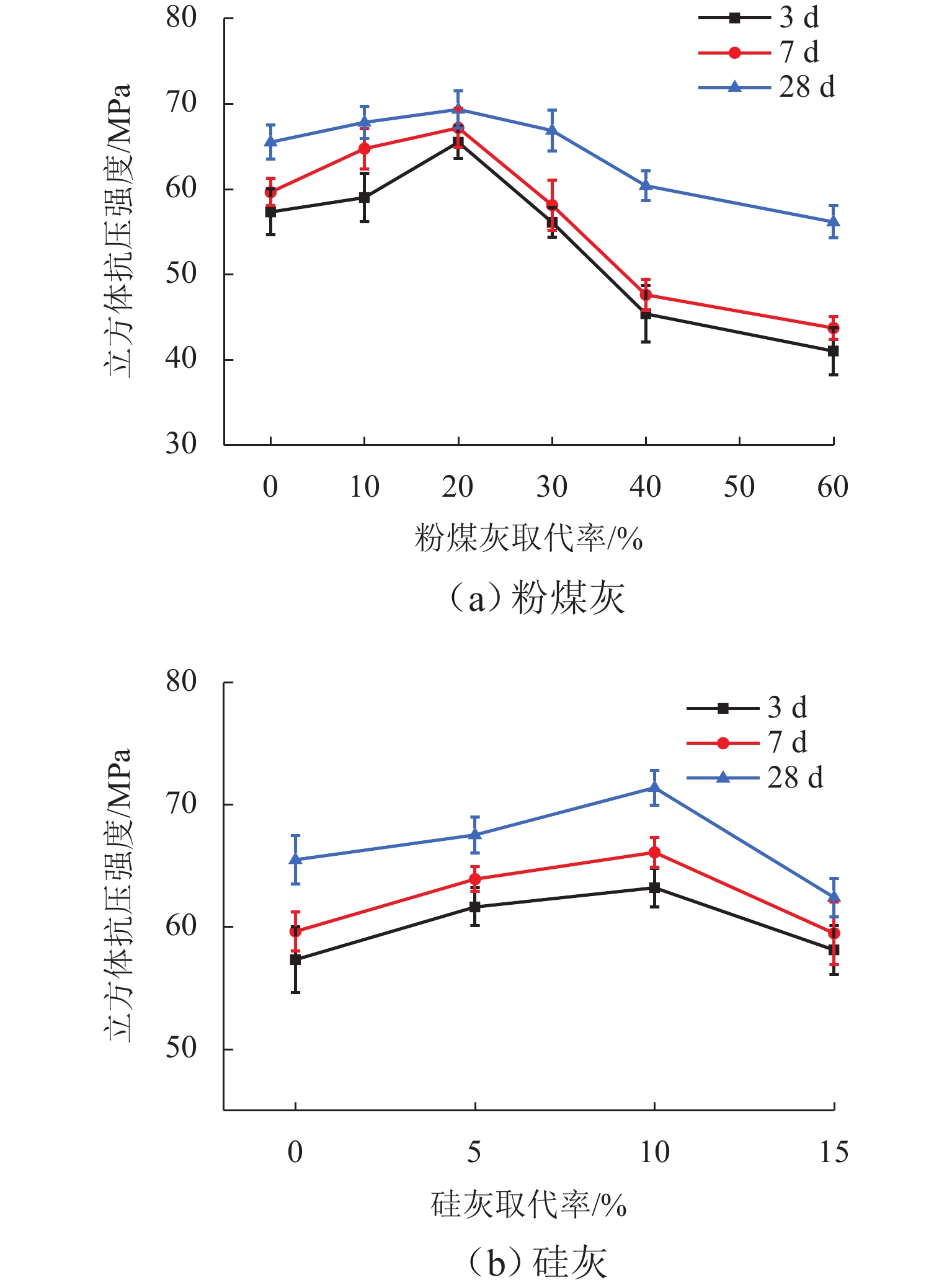

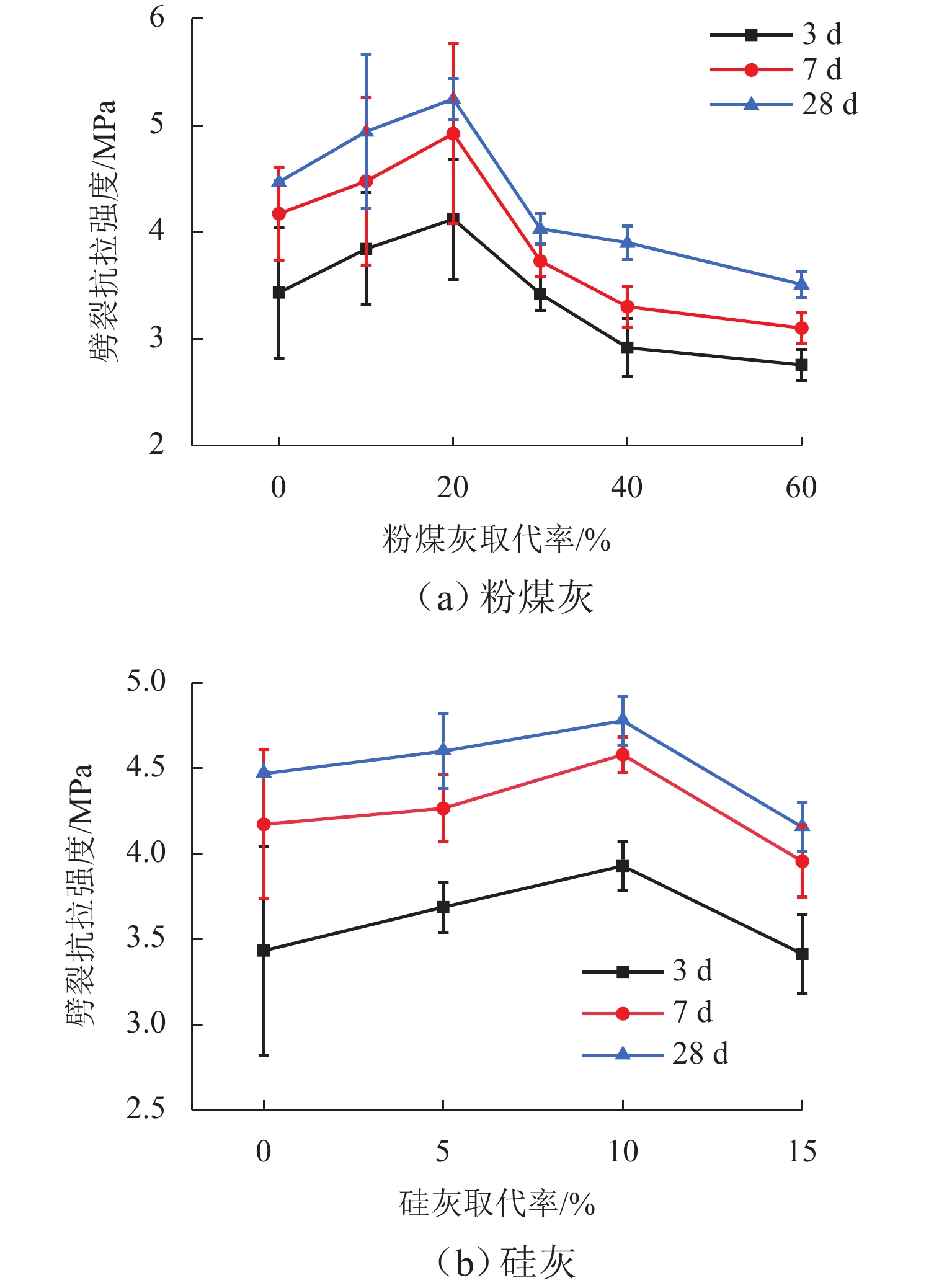

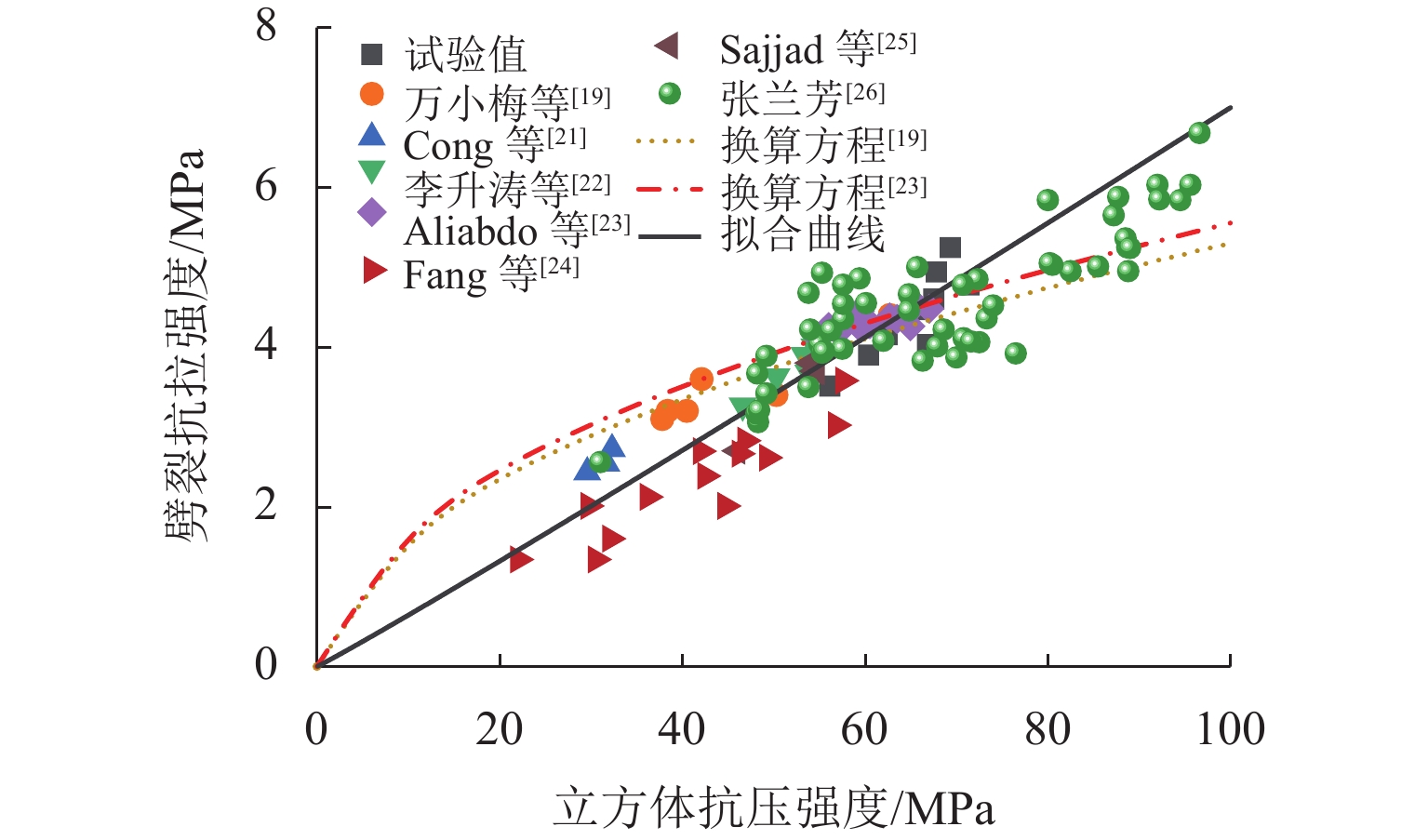

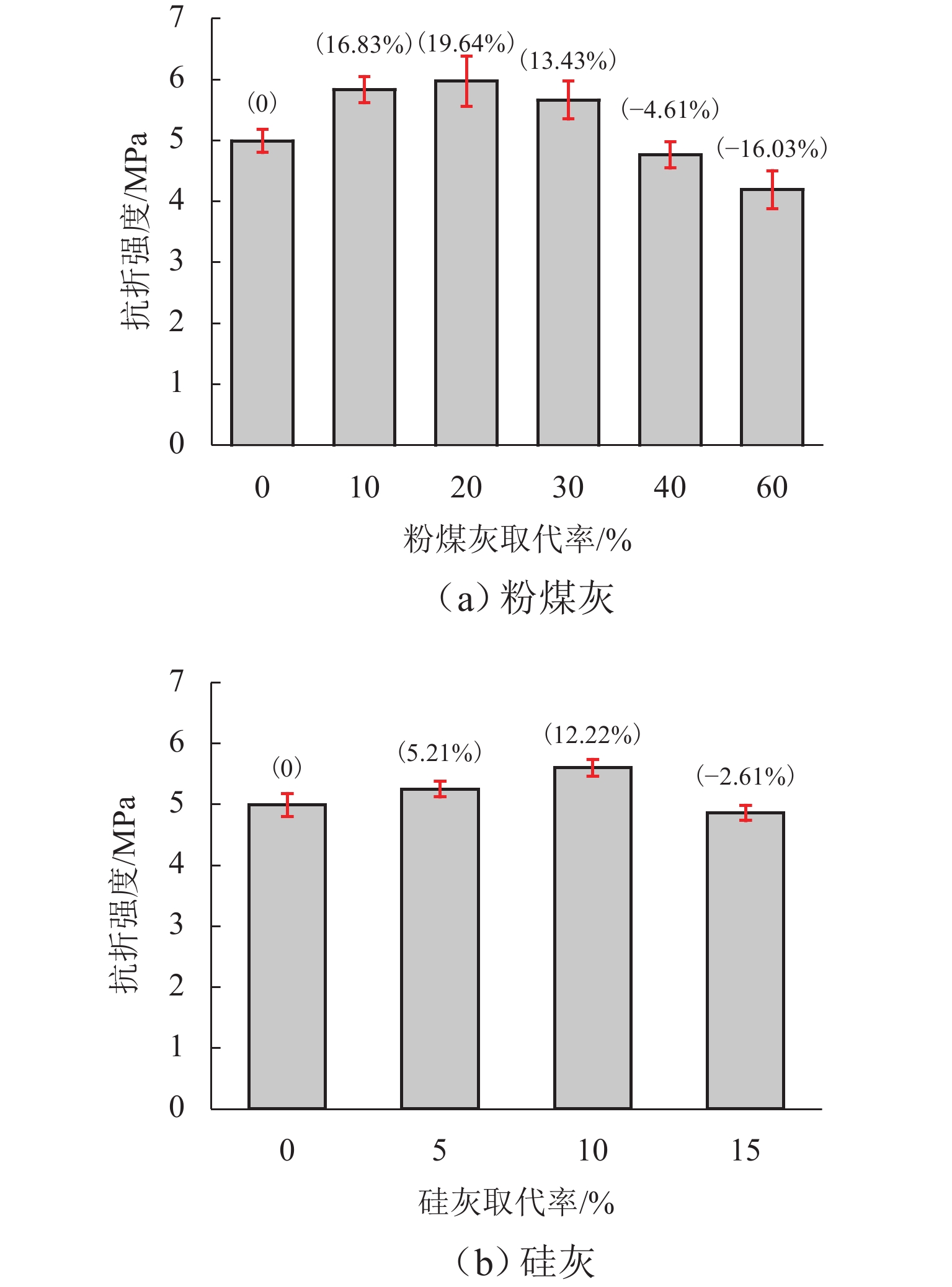

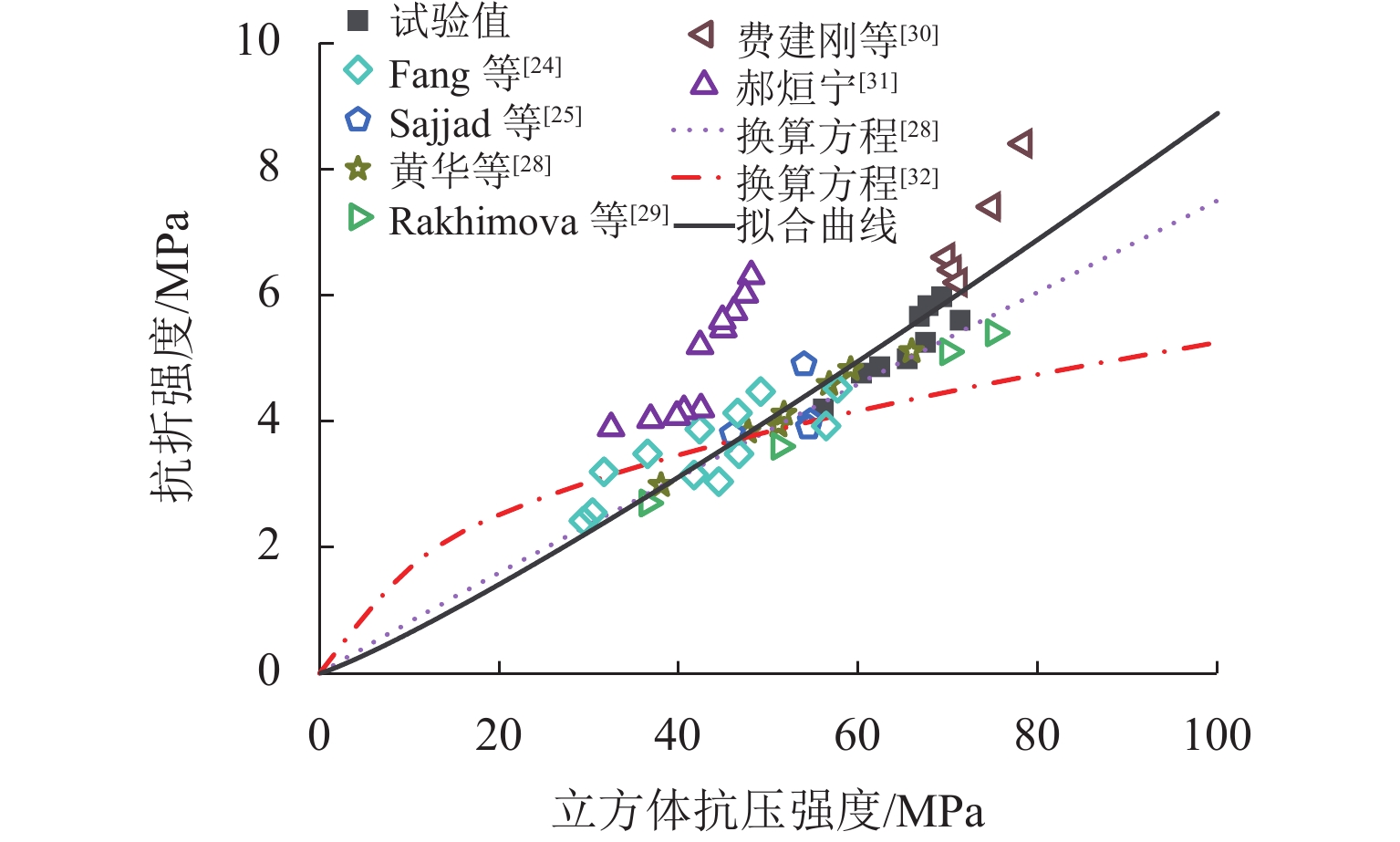

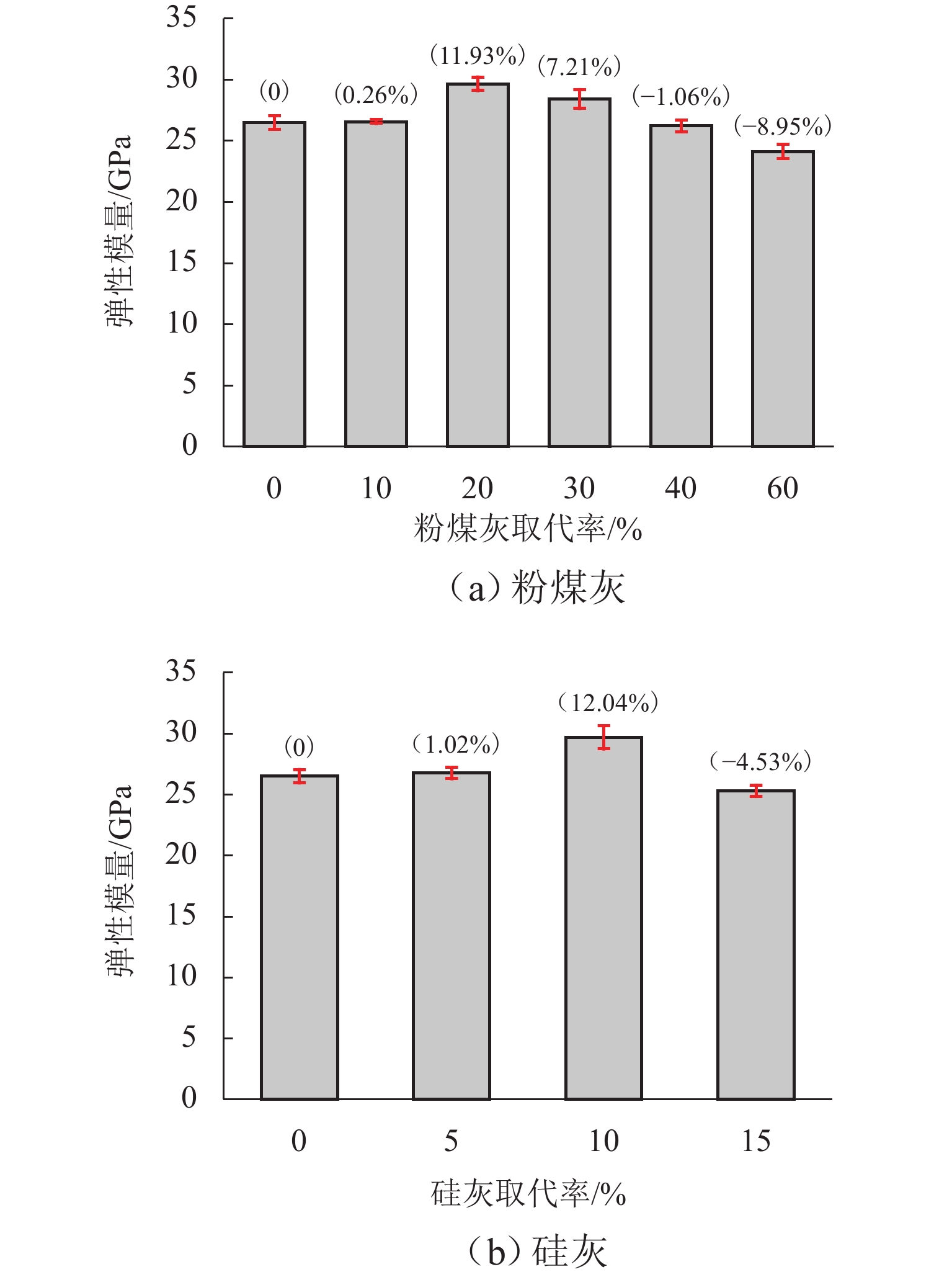

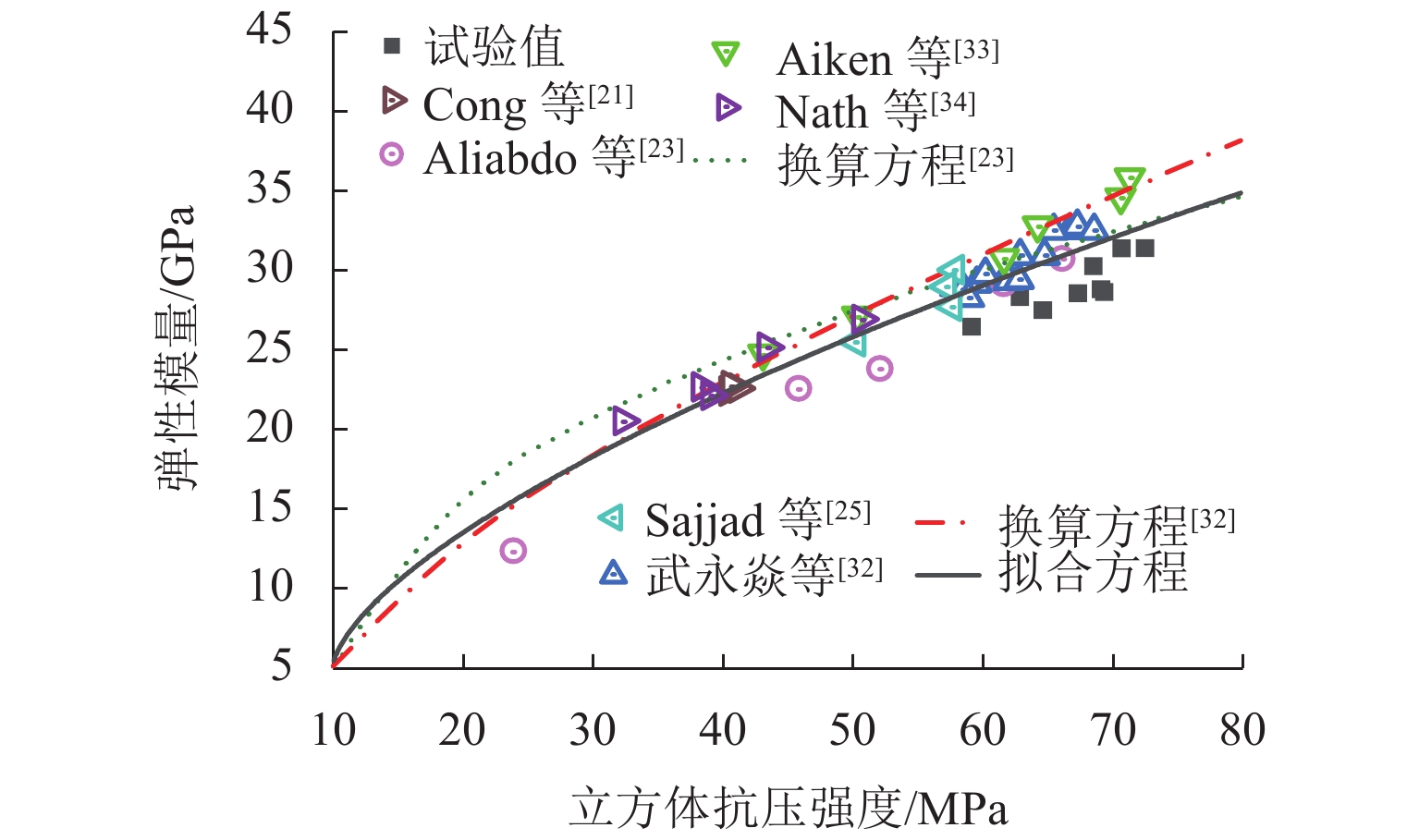

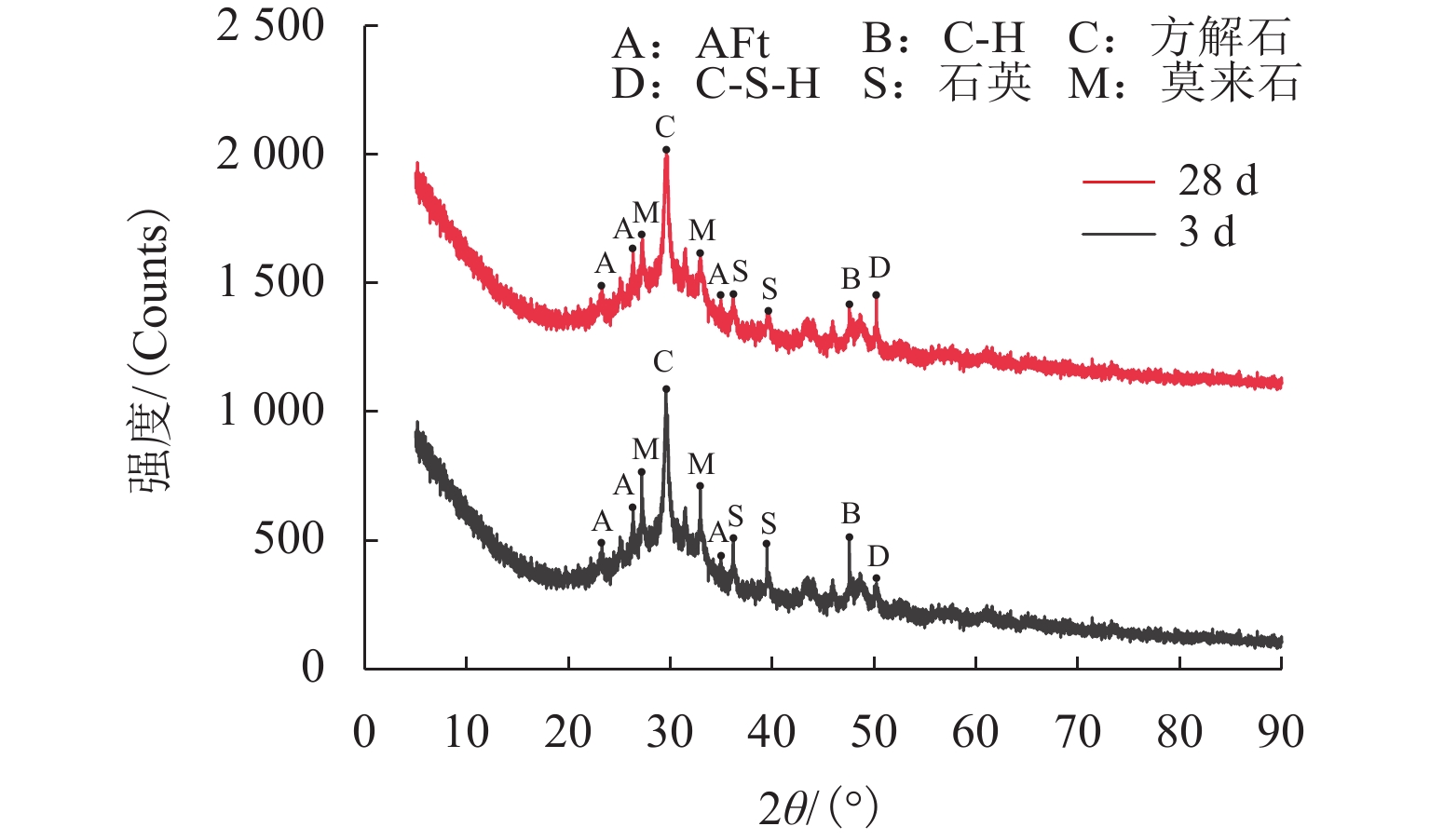

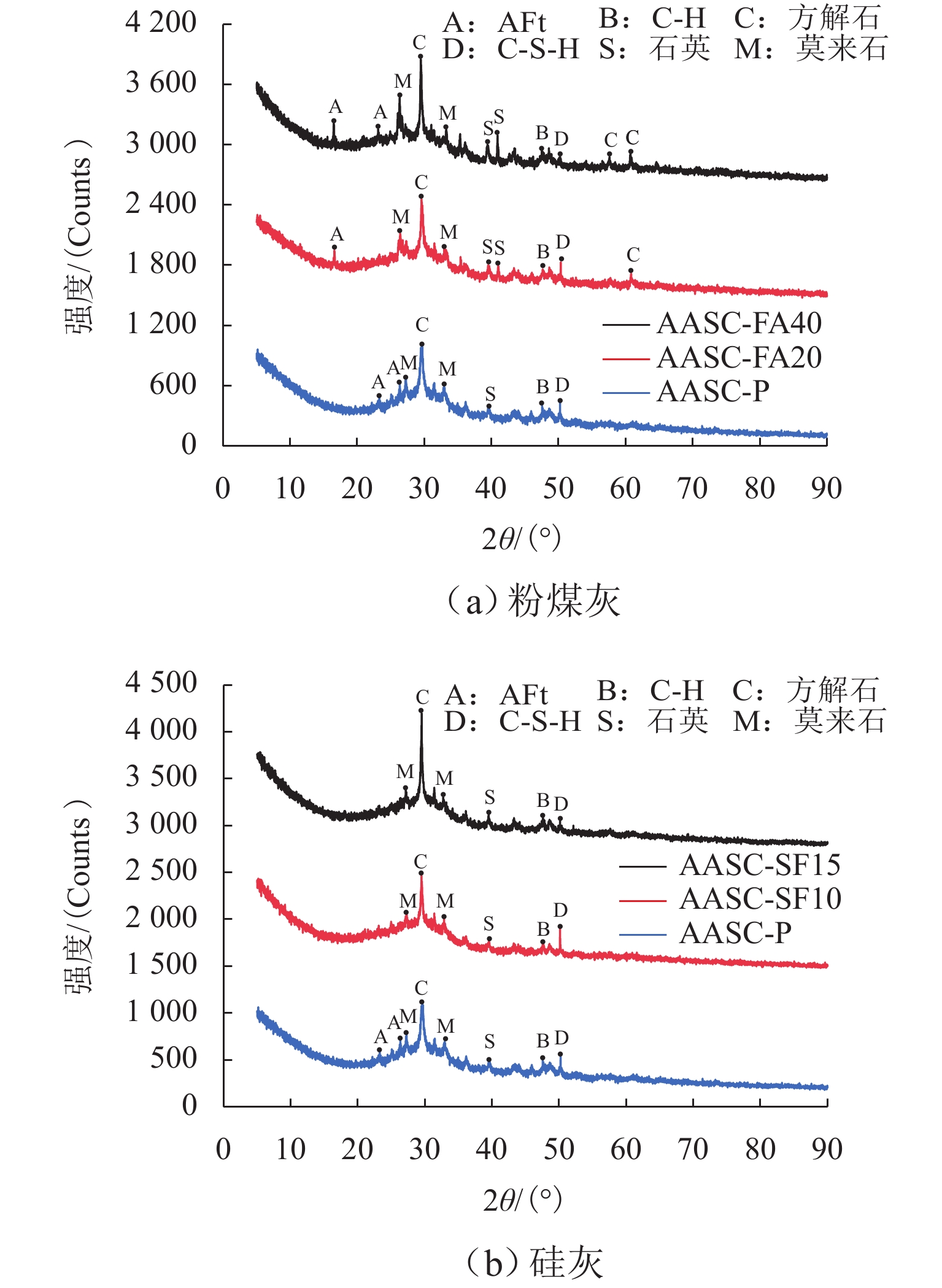

为研究粉煤灰和硅灰取代率对碱矿渣混凝土(AASC)性能的影响,通过凝结时间和基本力学性能试验,探究AASC凝结时间、立方体抗压强度、立方体劈拉强度、抗折强度和弹性模量的变化规律,基于试验结果,采用回归分析的方法,建立立方体劈裂抗拉强度、抗折强度以及弹性模量与立方体抗压强度的转换关系方程,并结合AASC的微观形貌和物相组成,揭示粉煤灰和硅灰对AASC性能的影响机理. 结果表明:粉煤灰和硅灰的取代可延长AASC的凝结时间;AASC力学性能指标随粉煤灰和硅灰取代率的增大而呈现出先增强后减弱的趋势,粉煤灰和硅灰最优取代率分别为20%和10%;提出的AASC立方体劈拉强度、抗折强度以及弹性模量的经验公式拟合精度高;粉煤灰(取代率≤20%)和硅灰(取代率≤10%)的取代促进了AASC的水化反应,使微观形貌更为密实.

Abstract:In order to study the effect of fly ash and silica fume contents on the properties of alkali-activated slag-based concrete (AASC), the changes in setting time, cubic compressive strength, cubic splitting tensile strength, flexural strength, and elastic modulus of AASC were investigated by conducting tests on setting time and basic mechanical properties. Based on the test results, a regression analysis method was used to establish the conversion relationship equation of cubic splitting tensile strength, flexural strength, and elastic modulus with cubic compressive strength, and the effect of fly ash and silica fume on the properties of AASC was revealed according to the microstructure and phase composition. The results show that the fly ash and silica fume can prolong the setting time of AASC; the mechanical property indicators of AASC tend to strengthen and then weaken with the increase in the contents of fly ash and silica fume, and the optimal contents of fly ash and silica fume are 20% and 10%, respectively. The proposed empirical formulae for cubic splitting tensile strength, flexural strength, and elastic modulus of AASC have a high fitting precision. The appropriate contents of fly ash (silica fume≤20%) and silica fume (silica fume≤10%) can promote the hydration reaction of AASC and the denser microstructures.

-

Key words:

- alkali-activated slag-based concrete /

- fly ash /

- silica fume /

- mechanical property /

- microstructures

-

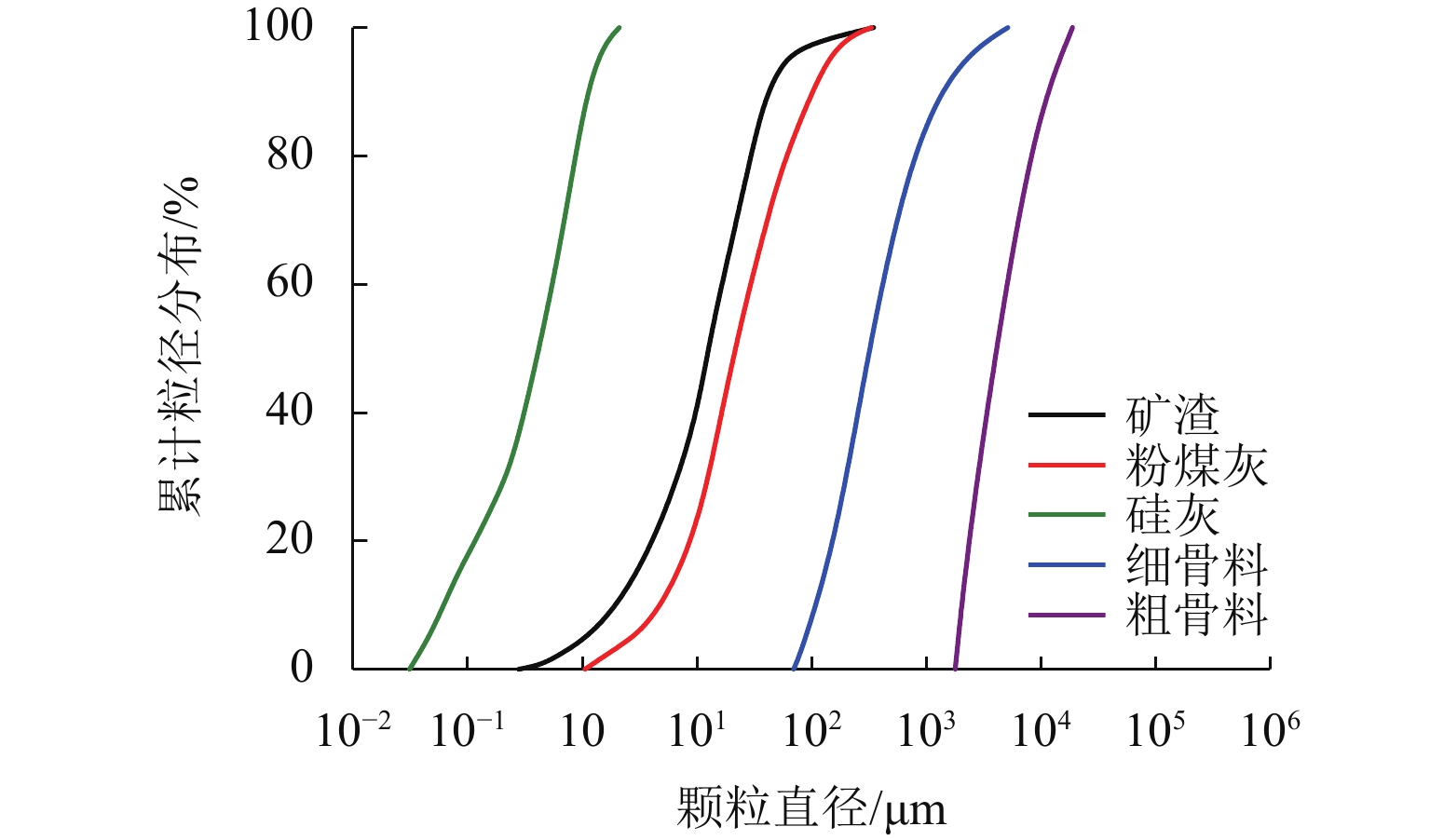

表 1 胶凝材料的主要化学成分

Table 1. Main chemical compositions of cementitious materials

% 胶凝材料 CaO SiO2 Al2O3 MgO SO3 K2O Na2O MnO Fe2O3 TiO2 矿渣 36.82 26.75 19.66 11.10 2.65 0.29 0.84 0.37 0.32 0.94 粉煤灰 5.60 45.10 24.20 2.10 0.85 0.85 硅灰 0.12 96.65 0.31 0.11 0.97 0.07 表 2 胶凝材料的主要物理性能

Table 2. Main physical properties of cementitious materials

胶凝材料 密度/

(g·cm−3)比表面积/

(m2·kg−4)需水量

比/%流动度

比/%矿渣 2.80 455 105 95 粉煤灰 2.20 330 95 120 硅灰 2.17 19000 120 表 3 AASC配合比设计

Table 3. Mix proportion design of AASC

kg/m3 试件编号 矿渣 粉煤灰 硅灰 细骨料 粗骨料 水玻璃 NaOH 水 减水剂 AASC-P 417.00 0 0 724.00 1085.00 161.80 3.60 84.00 3.30 AASC-FA10 375.30 41.70 0 AASC-FA20 333.60 83.40 0 AASC-FA30 291.90 125.10 0 AASC-FA40 250.20 166.80 0 AASC-FA60 166.80 250.20 0 AASC-SF5 396.20 0 20.85 AASC-SF10 375.30 0 41.70 AASC-SF15 354.50 0 62.55 -

[1] DING Y, DAI J G, SHI C J. Mechanical properties of alkali-activated concrete: a state-of-the-art review[J]. Construction and Building Materials, 2016, 127: 68-79. doi: 10.1016/j.conbuildmat.2016.09.121 [2] MOHAMED O A. A review of durability and strength characteristics of alkali-activated slag concrete[J]. Materials, 2019, 12(8): 1198.1-1198.19. [3] 顾亚敏,方永浩. 碱矿渣水泥的收缩与开裂特性及其减缩与增韧[J]. 硅酸盐学报,2012,40(1): 76-84.GU Yamin, FANG Yonghao. Shrinkage, cracking, shrinkage-reducing and toughening of alkali-activated slag cement—a short review[J]. Journal of the Chinese Ceramic Society, 2012, 40(1): 76-84. [4] GAO X, YU Q L, BROUWERS H J H. Assessing the porosity and shrinkage of alkali activated slag-fly ash composites designed applying a packing model[J]. Construction and Building Materials, 2016, 119: 175-184. doi: 10.1016/j.conbuildmat.2016.05.026 [5] RAMEZANIANPOUR A A, MOEINI M A. Mechanical and durability properties of alkali activated slag coating mortars containing nanosilica and silica fume[J]. Construction and Building Materials, 2018, 163: 611-621. doi: 10.1016/j.conbuildmat.2017.12.062 [6] SUN B B, SUN Y B, YE G, et al. A mix design methodology of slag and fly ash-based alkali-activated paste[J]. Cement and Concrete Composites, 2022, 126: 104368.1-104368.15. [7] SUN Y B, LIU Z Y, GHORBANI S, et al. Fresh and hardened properties of alkali-activated slag concrete: the effect of fly ash as a supplementary precursor[J]. Journal of Cleaner Production, 2022, 370: 133362.1-133362.12. [8] ROSTAMI M, BEHFARNIA K. The effect of silica fume on durability of alkali activated slag concrete[J]. Construction and Building Materials, 2017, 134: 262-268. doi: 10.1016/j.conbuildmat.2016.12.072 [9] 中华人民共和国住房和城乡建设部. 普通混凝土配合比设计规程:JGJ 55—2011[S]. 北京:中国建筑工业出版社,2011. [10] LI N, SHI C J, ZHANG Z H, et al. A mixture proportioning method for the development of performance-based alkali-activated slag-based concrete[J]. Cement and Concrete Composites, 2018, 93: 163-174. doi: 10.1016/j.cemconcomp.2018.07.009 [11] BONDAR D, NANUKUTTAN S, PROVIS J L, et al. Efficient mix design of alkali activated slag concretes based on packing fraction of ingredients and paste thickness[J]. Journal of Cleaner Production, 2019, 218: 438-449.BONDAR D,NANUKUTTAN S,PROVIS J L,et al. Efficient mix design of alkali activated slag concretes based on packing fraction of ingredients and paste thickness[J]. Journal of Cleaner Production,2019,218:438-449. [12] 中华人民共和国住房和城乡建设部,国家市场监督管理总局. 混凝土物理力学性能试验方法标准:GB/T 50081—2019[S]. 北京:中国建筑工业出版社,2019. [13] 中华人民共和国住房和城乡建设部. 普通混凝土拌合物性能试验方法标准:GB/T 50080—2016[S]. 北京:中国建筑工业出版社,2017. [14] 刘翼玮,张祖华,史才军,等. 硅灰对高强地聚物胶凝材料性能的影响[J]. 硅酸盐学报,2020,48(11): 1689-1699.LIU Yiwei, ZHANG Zuhua, SHI Caijun, et al. Influence of silica fume on performance of high-strength geopolymer[J]. Journal of the Chinese Ceramic Society, 2020, 48(11): 1689-1699. [15] DONG M H, ELCHALAKANI M, KARRECH A. Development of high strength one-part geopolymer mortar using sodium metasilicate[J]. Construction and Building Materials, 2020, 236: 117611.1-117611.13. [16] LIU G, FLOREA M V A, BROUWERS H J H. Characterization and performance of high volume recycled waste glass and ground granulated blast furnace slag or fly ash blended mortars[J]. Journal of Cleaner Production, 2019, 235: 461-472. doi: 10.1016/j.jclepro.2019.06.334 [17] KUMAR S, KUMAR R, MEHROTRA S P. Influence of granulated blast furnace slag on the reaction, structure and properties of fly ash based geopolymer[J]. Journal of Materials Science, 2010, 45(3): 607-615. doi: 10.1007/s10853-009-3934-5 [18] 张雄,张恒,张晓乐,等. 硅灰调控混凝土力学性能的关键界面参数研究[J]. 建筑材料学报,2019,22(4): 626-631. doi: 10.3969/j.issn.1007-9629.2019.04.018ZHANG Xiong, ZHANG Heng, ZHANG Xiaole, et al. Key interface parameters for the control of silica fume on mechanical properties of concrete[J]. Journal of Building Materials, 2019, 22(4): 626-631. doi: 10.3969/j.issn.1007-9629.2019.04.018 [19] 万小梅,张宇,赵铁军,等. 碱激发矿渣混凝土的力学性能[J]. 材料导报,2018,32(12): 2091-2095. doi: 10.11896/j.issn.1005-023X.2018.12.028WAN Xiaomei, ZHANG Yu, ZHAO Tiejun, et al. Mechanical properties of alkali-activated slag concrete[J]. Materials Reports, 2018, 32(12): 2091-2095. doi: 10.11896/j.issn.1005-023X.2018.12.028 [20] LEE N K, LEE H K. Setting and mechanical properties of alkali-activated fly ash/slag concrete manufactured at room temperature[J]. Construction and Building Materials, 2013, 47: 1201-1209. doi: 10.1016/j.conbuildmat.2013.05.107 [21] CONG X Y, ZHOU W, ELCHALAKANI M. Experimental study on the engineering properties of alkali-activated GGBFS/FA concrete and constitutive models for performance prediction[J]. Construction and Building Materials, 2020, 240: 117977.1-117977.22. [22] 李升涛,陈徐东,张伟,等. 基于长江下游超细疏浚砂的碱激发矿渣混凝土力学性能[J]. 复合材料学报,2022,39(1): 335-343.LI Shengtao, CHEN Xudong, ZHANG Wei, et al. Mechanical properties of alkali activated slag concrete with ultra fine dredged sand from Yangtze River[J]. Acta Materiae Compositae Sinica, 2022, 39(1): 335-343. [23] ALIABDO A A, ABD ELMOATY A E M, EMAM M A. Factors affecting the mechanical properties of alkali activated ground granulated blast furnace slag concrete[J]. Construction and Building Materials, 2019, 197: 339-355. doi: 10.1016/j.conbuildmat.2018.11.086 [24] FANG G H, HO W K, TU W L, et al. Workability and mechanical properties of alkali-activated fly ash-slag concrete cured at ambient temperature[J]. Construction and Building Materials, 2018, 172: 476-487. doi: 10.1016/j.conbuildmat.2018.04.008 [25] SAJJAD U, SHEIKH M N, HADI M N S. Incorporation of graphene in slag-fly ash-based alkali-activated concrete[J]. Construction and Building Materials, 2022, 322: 126417.1-126417.12. [26] 张兰芳. 碱激发复合渣体(AAW)混凝土的性能研究[D]. 重庆:重庆大学,2006. [27] BERNAL S A, DE GUTIÉRREZ R M, PROVIS J L. Engineering and durability properties of concretes based on alkali-activated granulated blast furnace slag/metakaolin blends[J]. Construction and Building Materials, 2012, 33: 99-108. doi: 10.1016/j.conbuildmat.2012.01.017 [28] 黄华,郭梦雪,张伟,等. 粉煤灰-矿渣基地聚物混凝土力学性能与微观结构[J]. 哈尔滨工业大学学报,2022,54(3): 74-84. doi: 10.11918/202104058HUANG Hua, GUO Mengxue, ZHANG Wei, et al. Mechanical property and microstructure of geopolymer concrete based on fly ash and slag[J]. Journal of Harbin Institute of Technology, 2022, 54(3): 74-84. doi: 10.11918/202104058 [29] RAKHIMOVA N R, RAKHIMOV R Z. Hydrated Portland cement as an admixture to alkali-activated slag cement[J]. Advances in Cement Research, 2015, 27(2): 107-117. [30] 费建刚,袁晓辉,申晓伟,等. 碱矿渣混凝土基本力学性能试验研究[J]. 信阳师范学院学报(自然科学版),2017,30(3): 484-488. doi: 10.3969/j.issn.1003-0972.2017.03.029FEI Jiangang, YUAN Xiaohui, SHEN Xiaowei, et al. Experimental study on basic mechanical properties of alkali-activated slag concrete[J]. Journal of Xinyang Normal University (Natural Science Edition), 2017, 30(3): 484-488. doi: 10.3969/j.issn.1003-0972.2017.03.029 [31] 郝烜宁. 碱-矿渣混凝土缓凝技术研究[D]. 哈尔滨:哈尔滨工业大学,2021. [32] 武永焱,明鑫,范小春. 无机聚合物海砂混凝土基本力学性能试验研究[J]. 武汉理工大学学报,2019,41(5): 71-78.WU Yongyan, MING Xin, FAN Xiaochun. Experimental study on basic mechanical properties of inorganic polymer sea sand concrete[J]. Journal of Wuhan University of Technology, 2019, 41(5): 71-78. [33] AIKEN T A, KWASNY J, SHA W, et al. Mechanical and durability properties of alkali-activated fly ash concrete with increasing slag content[J]. Construction and Building Materials, 2021, 301: 124330.1-124330.17. [34] NATH P, SARKER P K. Flexural strength and elastic modulus of ambient-cured blended low-calcium fly ash geopolymer concrete[J]. Construction and Building Materials, 2017, 130: 22-31. doi: 10.1016/j.conbuildmat.2016.11.034 [35] GAO X, YU Q L, BROUWERS H J H. Reaction kinetics, gel character and strength of ambient temperature cured alkali activated slag-fly ash blends[J]. Construction and Building Materials, 2015, 80: 105-115. doi: 10.1016/j.conbuildmat.2015.01.065 [36] 李亚杰,方坤河. 建筑材料[M]. 6版. 北京: 中国水利水电出版社,2009:97. [37] DUAN P, YAN C J, ZHOU W. Compressive strength and microstructure of fly ash based geopolymer blended with silica fume under thermal cycle[J]. Cement and Concrete Composites, 2017, 78: 108-119. doi: 10.1016/j.cemconcomp.2017.01.009 [38] 黄燕,胡翔,史才军,等. 混凝土中水泥浆体与骨料界面过渡区的形成和改进综述[J]. 材料导报,2023,37(1): 102-113.HUANG Yan, HU Xiang, SHI Caijun, et al. Review on the formation and improvement of interfacial transition zone between cement paste and aggregate in concrete[J]. Materials Reports, 2023, 37(1): 102-113. [39] NEDELJKOVIĆ M, LI Z M, YE G. Setting, strength, and autogenous shrinkage of alkali-activated fly ash and slag pastes: effect of slag content[J]. Materials, 2018, 11(11): 2121.1-2121.20. doi: 10.3390/ma11112121 [40] 姚力豪,王彦平,陈昶旭,等. 硅灰对粉煤灰-矿渣基地聚物性能的影响[J]. 新型建筑材料,2022,49(5): 48-52. doi: 10.3969/j.issn.1001-702X.2022.05.012YAO Lihao, WANG Yanping, CHEN Changxu, et al. Effect of silica fume on properties of fly ash-slag based geopolymer[J]. New Building Materials, 2022, 49(5): 48-52. doi: 10.3969/j.issn.1001-702X.2022.05.012 -

下载:

下载: