Fracture Mechanism of Cologne-Egg Fastener Clips in Rail Corrugation Sections

-

摘要:

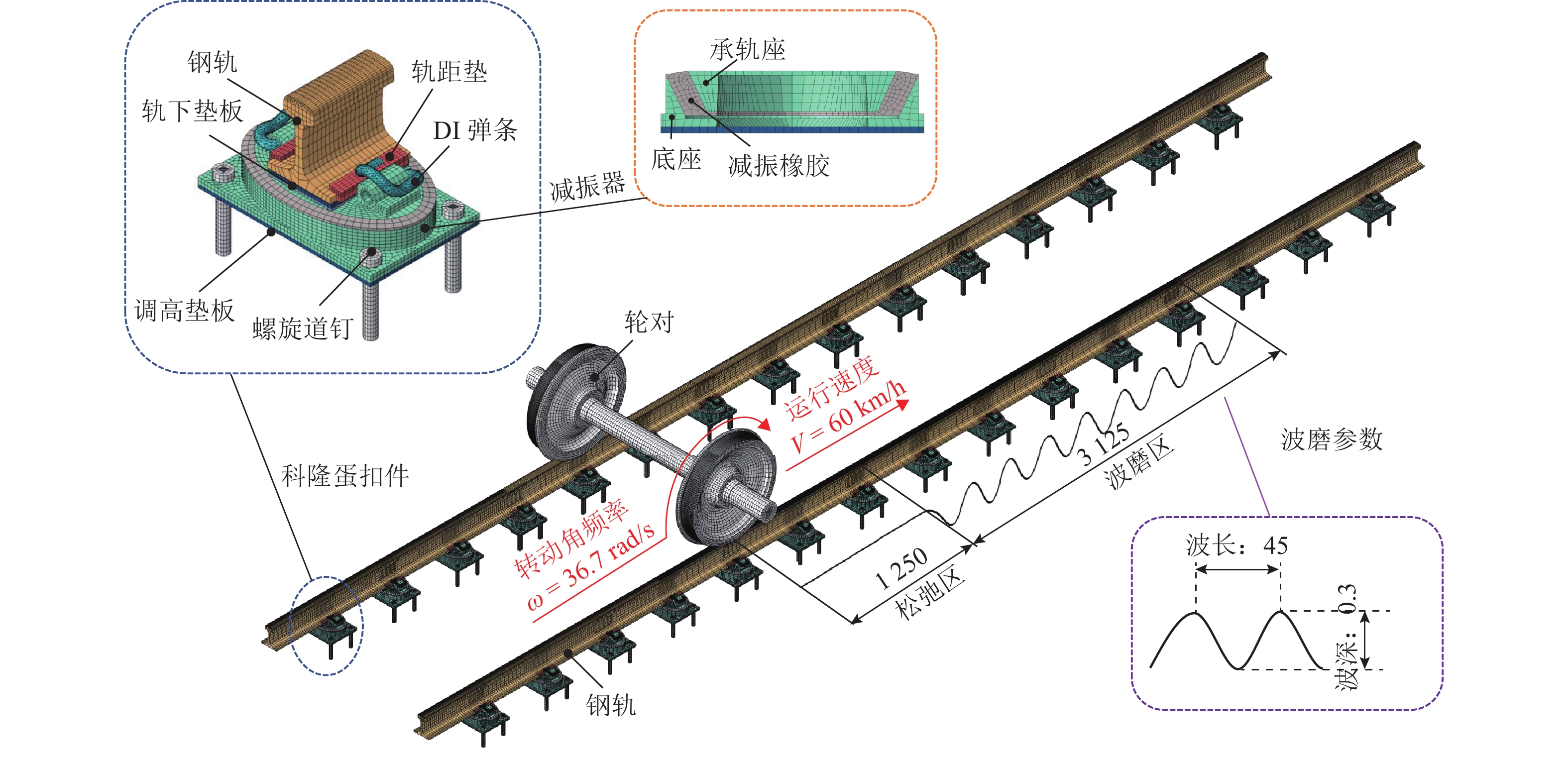

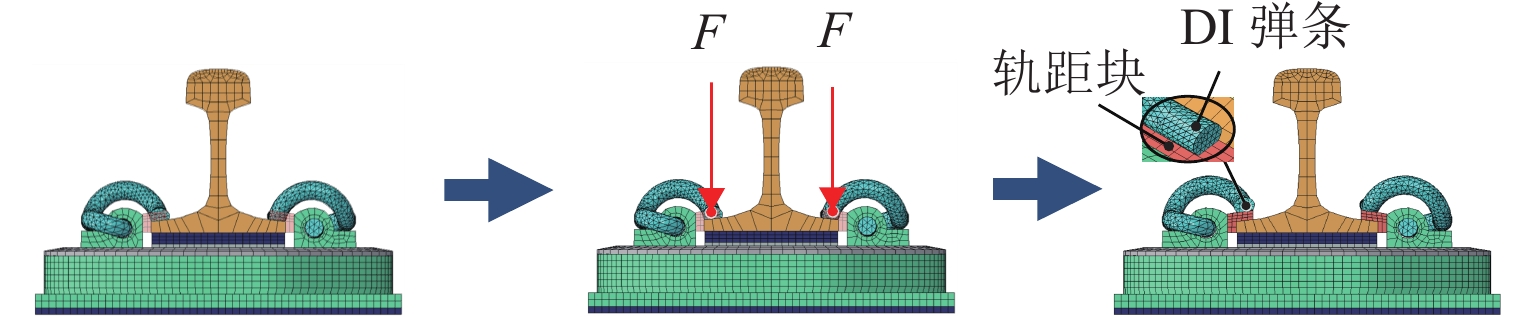

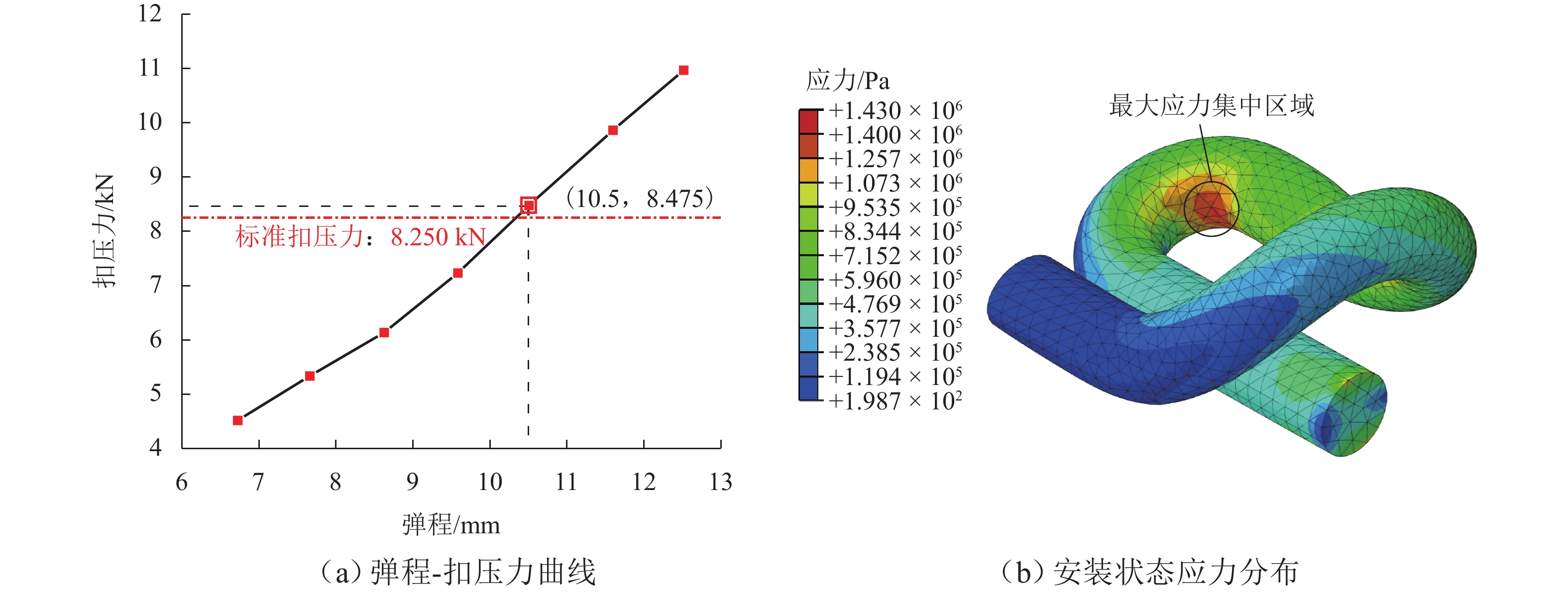

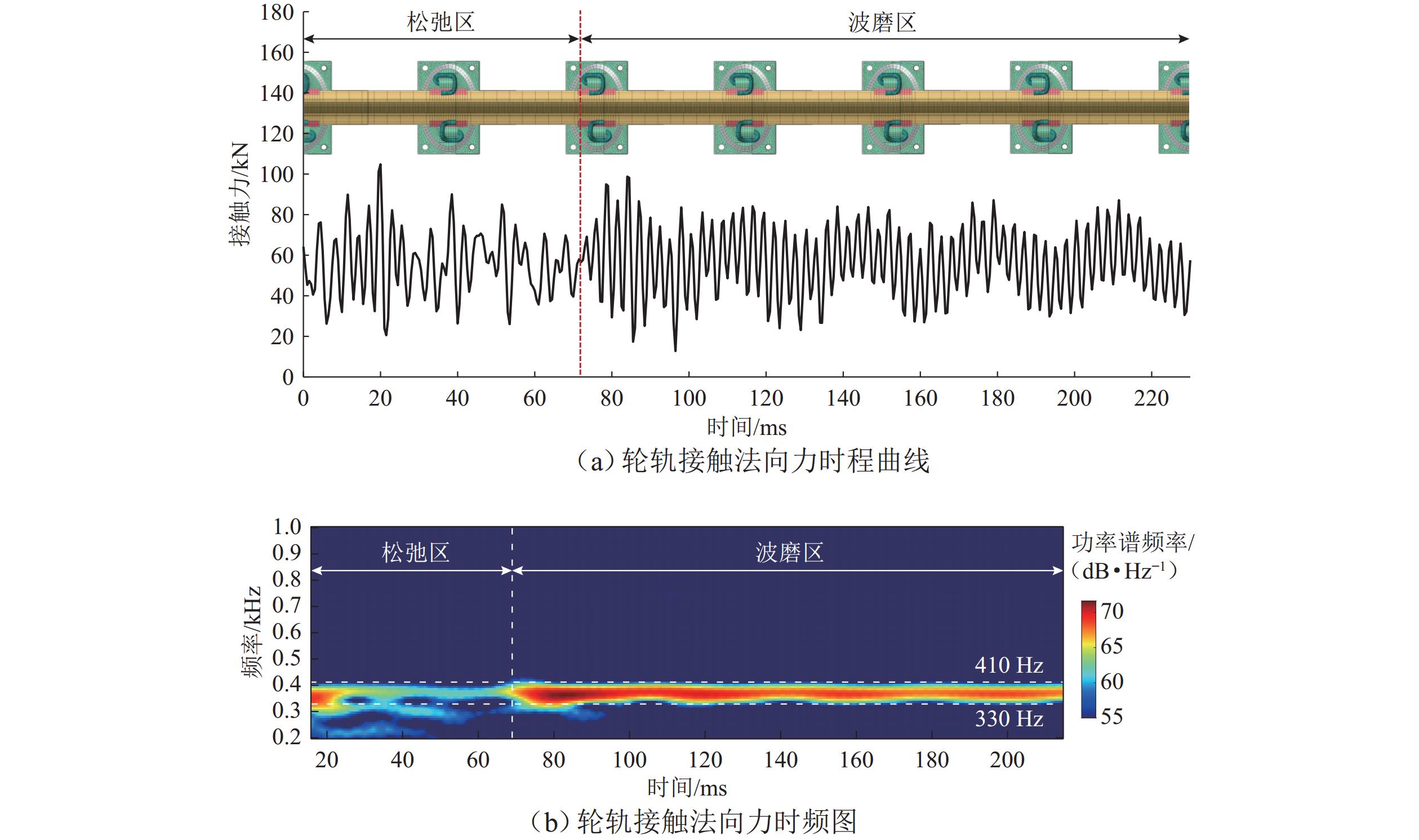

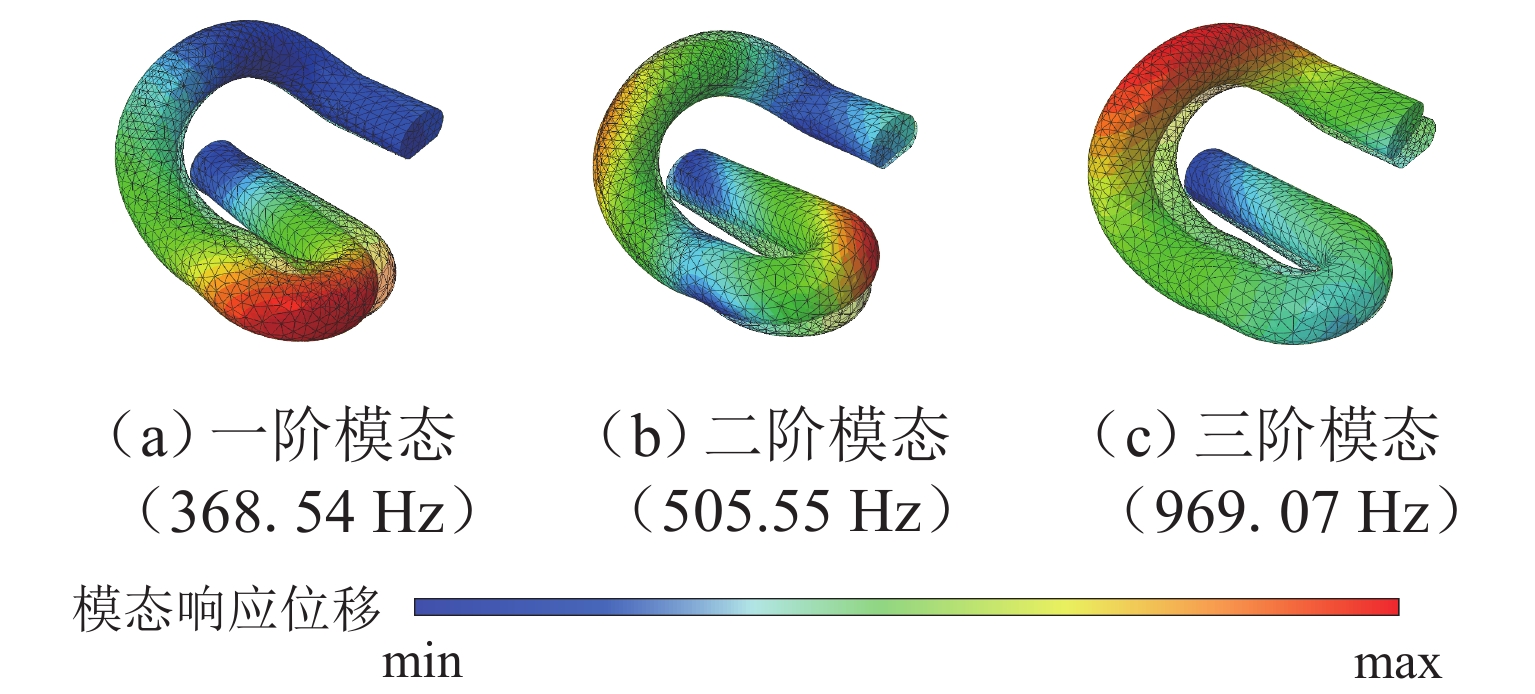

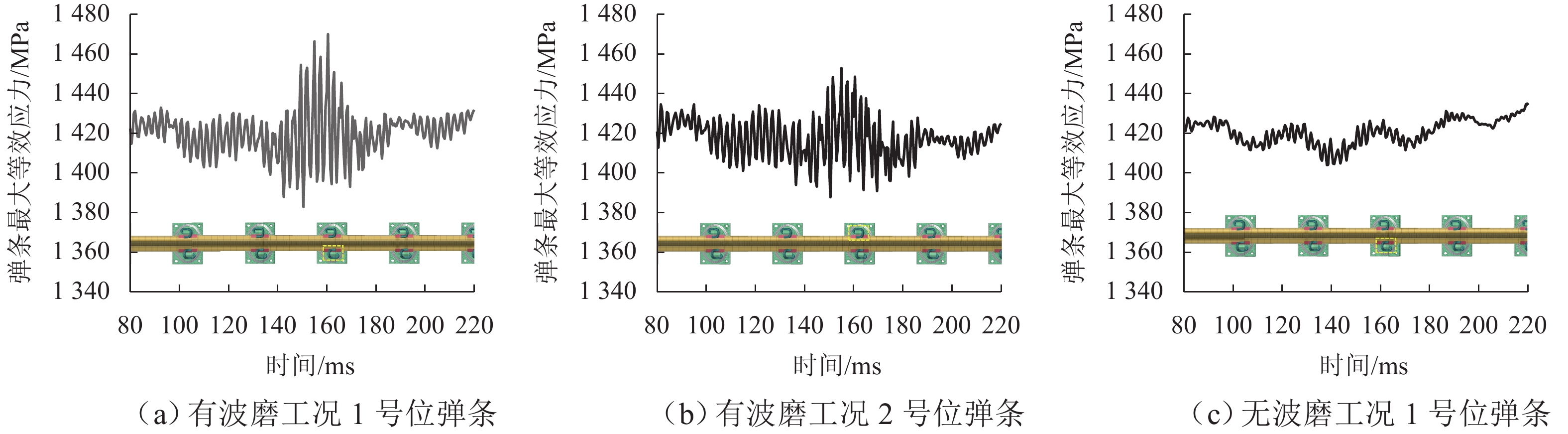

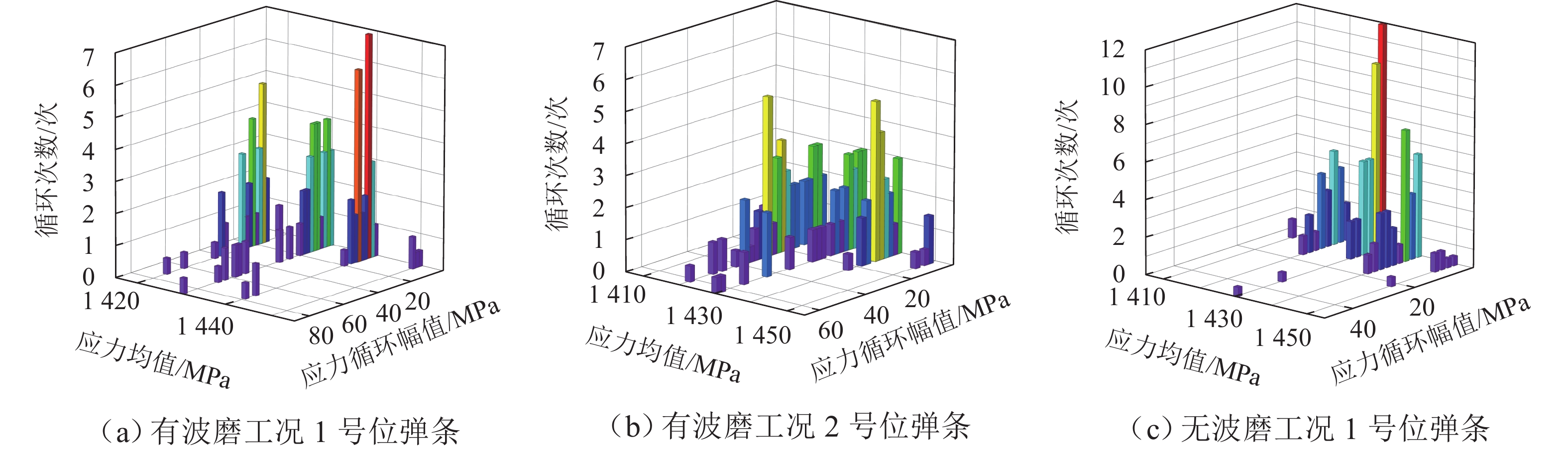

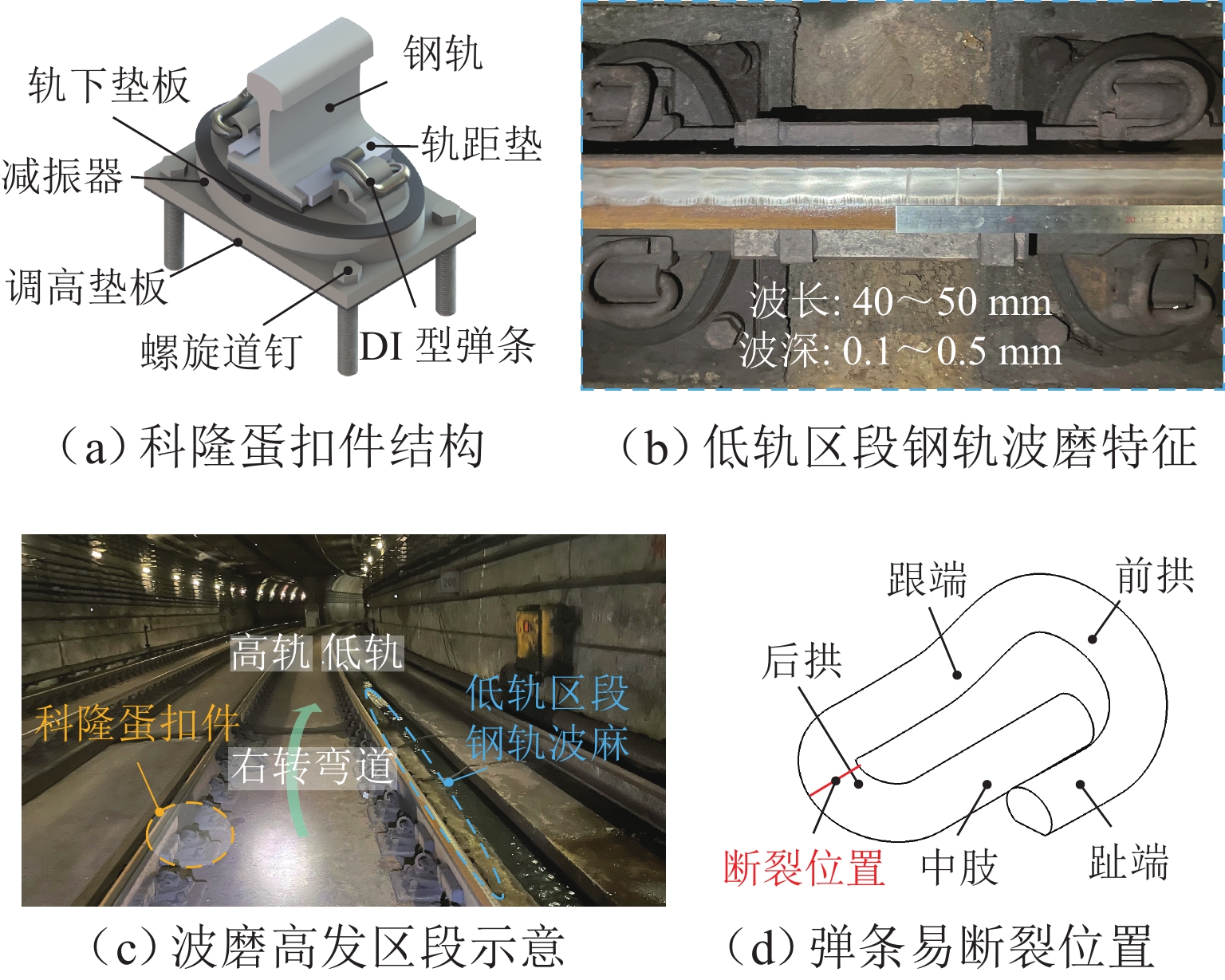

钢轨波磨作为地铁线路的典型钢轨损伤形式,其高发区段常伴随着扣件弹条断裂问题,严重影响列车的运营安全. 其中,科隆蛋扣件小半径区段是钢轨波磨的高发区段. 为探究科隆蛋扣件弹条的断裂机理,首先结合现场调研,构建包含完整科隆蛋扣件的轮对-钢轨-扣件系统有限元模型;然后,从共振响应的角度探究轮轨摩擦耦合振动激励下科隆蛋扣件弹条的共振响应;最后,从疲劳寿命角度,对比有无波磨区段科隆蛋扣件弹条的疲劳寿命情况,并以此量化不同弹条的疲劳损伤情况. 研究结果表明:在钢轨波磨高发区段,轮轨摩擦耦合振动主频与科隆蛋扣件弹条一阶约束模态一致,轮轨摩擦耦合振动引起的弹条共振是科隆蛋扣件断裂的主要原因;钢轨波磨加剧了轮轨摩擦耦合振动,使得科隆蛋扣件弹条寿命相较无波磨区段下降99.04%,仅为设计寿命的3.11%;此外,科隆蛋扣件小半径曲线区段低轨工作边一侧的弹条更容易发生疲劳失效,失效位置位于其弹条后拱端内侧.

Abstract:As typical rail damage of the railway, rail corrugation is often accompanied by the fastener clip fracture, which seriously affects the operation safety of the train. Moreover, the small-radius section of the Cologne-egg fastener experiences frequent rail corrugation. To explre the fracture mechanism of Cologne-egg fastener clips, firstly, the finite element model of the wheel set-rail-fastener system, including the complete Cologne-egg fastener model, was established baesd on the field investigation. Then, the resonant response of the Cologne-egg fastener clip was explored, considering the frictional coupling vibration of the wheel-rail system. Finally, the fatigue life of the Cologne-egg fastener clip was compared in the cases of with and without rail corrugation sections, and the fatigue damage of different clips was quantified. The results show that the dominant frequency of the frictional coupling vibration of the wheel-rail system is consistent with the first-mode constraint mode of the Cologne-egg fastener clip in the frequent rail corrugation sections, which indicates that the clip resonance induced by the frictional coupling vibration of the wheel-rail system is the main reason for the Cologne-egg fastener fracture. The frictional coupling vibration of the wheel-rail system is aggravated by the rail corrugation, which makes the clip life of the Cologne-egg fastener in the rail corrugation section decrease by 99.04% compared with that in the absence of rail corrugation section. The clip life is thus only 3.11% of the design clip life. Besides, the Cologne-egg fastener clip on the low gauge side is more prone to fatigue failure in the small-radius curved section, and the failure position is located on the inner side of the rear arch end of the clip.

-

表 1 轮对-钢轨-扣件系统有限元模型的材料属性[9,18-19]

Table 1. Material properties of finite element model of wheel set-rail-fastener system[9,18-19]

部件 弹性模量/Pa 泊松比 密度/

(kg•m−3)轮对 210.00×109 0.30 7800 钢轨 206.00×109 0.30 7800 DI 弹条 206.00×109 0.30 7800 轨距垫 6.20×109 0.35 1400 调高垫板 6.00×106 0.45 1190 承轨座/底座 170.00×109 0.30 7900 减振橡胶 5.58×106 0.49 1190 -

[1] 陈光雄,钱韦吉,莫继良,等. 轮轨摩擦自激振动引起小半径曲线钢轨波磨的瞬态动力学[J]. 机械工程学报,2014,50(9): 71-76. doi: 10.3901/JME.2014.09.071CHEN Guangxiong, QIAN Weiji, MO Jiliang, et al. A transient dynamics study on wear-type rail corrugation on a tight curve due to the friction-induced self-excited vibration of a wheelset-track system[J]. Journal of Mechanical Engineering, 2014, 50(9): 71-76. doi: 10.3901/JME.2014.09.071 [2] BAO P Y, CUI X L, DING H H, et al. Influences of friction self-excited vibration characteristics of various types of high-speed trains on rail corrugations in braking sections[J]. Engineering Failure Analysis, 2022, 134: 106087.1-106087.10. [3] 崔晓璐,唐传平,包鹏羽,等. 高速列车制动区段钢轨波磨抑制方法[J]. 西南交通大学学报,2023,58(3):656-664.CUI Xiaolu, TANG Chuanping, BAO Pengyu, et al. Rail corrugation suppression method on braking sections of high-speed trains[J]. Journal of Southwest Jiaotong University, 2023, 58(3):656-664. [4] 吴浩,韦凯,郭恭兵,等. 地铁扣件e型弹条受载特征分析[J]. 铁道科学与工程学报,2022,19(3): 665-673.WU Hao, WEI Kai, GUO Gongbing, et al. Analysis on loading characteristics of e-type clip of rail fastener[J]. Journal of Railway Science and Engineering, 2022, 19(3): 665-673. [5] 杨程亮,李承亮. Ⅲ型弹条断裂原因分析[J]. 铁道建筑,2019,59(4): 135-138. doi: 10.3969/j.issn.1003-1995.2019.04.30YANG Chengliang, LI Chengliang. Cause analysis of fracture of Ⅲ-type elastic rod[J]. Railway Engineering, 2019, 59(4): 135-138. doi: 10.3969/j.issn.1003-1995.2019.04.30 [6] HOLDER D E, CSENGE M V, QIAN Y, et al. Laboratory investigation of the Skl-style fastening system’s lateral load performance under heavy haul freight railroad loads[J]. Engineering Structures, 2017, 139: 71-80. doi: 10.1016/j.engstruct.2017.02.039 [7] LING L, LI W, SHANG H X, et al. Experimental and numerical investigation of the effect of rail corrugation on the behaviour of rail fastenings[J]. Vehicle System Dynamics, 2014, 52(9): 1211-1231. doi: 10.1080/00423114.2014.934844 [8] WANG P, LU J, ZHAO C Y, et al. Numerical investigation of the fatigue performance of elastic rail clips considering rail corrugation and dynamic axle load[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2021, 235(3): 339-352. doi: 10.1177/0954409720926016 [9] 潘兵,王安斌,高晓刚. 高速轮轨瞬态响应特性对弹条伤损的影响[J]. 噪声与振动控制,2020,40(2): 174-179. doi: 10.3969/j.issn.1006-1355.2020.02.031PAN Bing, WANG Anbin, GAO Xiaogang. Influences of the characteristics of high-speed wheel-rail transient responses on clip damage[J]. Noise and Vibration Control, 2020, 40(2): 174-179. doi: 10.3969/j.issn.1006-1355.2020.02.031 [10] 刘玉涛,段玉振,王豪,等. 高速铁路无砟轨道扣件弹条疲劳损伤统计分析[J]. 铁道标准设计,2021,65(2): 42-46,53.LIU Yutao, DUAN Yuzhen, WANG Hao, et al. Statistical analysis of fatigue damage of fasteners clips for ballastless track of high speed railway[J]. Railway Standard Design, 2021, 65(2): 42-46,53. [11] 辛涛,杨学敏,肖宏,等. 基于车轨耦合和扣件精细模型的弹条疲劳分析[J]. 中南大学学报(自然科学版),2016,47(12): 4269-4275.XIN Tao, YANG Xuemin, XIAO Hong, et al. Fatigue analysis of spring clip based on vehicle-track coupled model and detailed fastener model[J]. Journal of Central South University (Science and Technology), 2016, 47(12): 4269-4275. [12] 亓伟,刘玉涛,陈江,等. 客货混运线路扣件弹条疲劳特性准静态分析[J]. 机械工程学报,2018,54(12): 1-7. doi: 10.3901/JME.2018.12.001QI Wei, LIU Yutao, CHEN Jiang, et al. Quasi-static analysis of fatigue characteristic of rail fastening clip for railways with passenger and freight traffic[J]. Journal of Mechanical Engineering, 2018, 54(12): 1-7. doi: 10.3901/JME.2018.12.001 [13] HASAP A, NORAPHAIPHIPAKSA N, KANCHANOMAI C. Influence of malposition on the performance of elastic rail clip: toe load, stress, and friction[J]. Structures, 2020, 28: 2661-2670. doi: 10.1016/j.istruc.2020.10.073 [14] 刘艳,姜秀杰,李秋彤,等. W300-1型扣件弹条疲劳寿命的预测和评估[J]. 同济大学学报(自然科学版),2021,49(8): 1152-1161.LIU Yan, JIANG Xiujie, LI Qiutong, et al. Fatigue life prediction and evaluation of the W300-1 fastening clip[J]. Journal of Tongji University (Natural Science), 2021, 49(8): 1152-1161. [15] 陈明明,卢俊,余鸿,等. 地铁扣件DI弹条安装受力分析及工艺优化改进研究[J]. 铁道标准设计,2019,63(4): 52-57.CHEN Mingming, LU Jun, YU Hong, et al. Force analysis of installation state and optimization of type DI fastening clip in subway[J]. Railway Standard Design, 2019, 63(4): 52-57. [16] XU J, CUI X L, DING H H, et al. Optimization of vibration absorbers for the suppression of rail corrugation in the sharp curved section with Cologne-egg fasteners[J]. Vehicle System Dynamics, 2024, 62(2): 395-410. doi: 10.1080/00423114.2023.2170255 [17] CUI X L, CHEN G X, YANG H G, et al. Effect of the wheel/rail contact angle and the direction of the saturated creep force on rail corrugation[J]. Wear, 2015, 330/331: 554-562. doi: 10.1016/j.wear.2014.12.046 [18] 吴建忠. Ⅲ型轨道减振器扣件的设计与研究[D]. 北京: 北京交通大学,2009. [19] 宋子洋,卢俊,胡世斌,等. DT-Ⅲ型扣件系统弹条疲劳特性及优化研究[J]. 中南大学学报(自然科学版),2021,52(10): 3623-3635. doi: 10.11817/j.issn.1672-7207.2021.10.025SONG Ziyang, LU Jun, HU Shibin, et al. Study on fatigue characteristics and optimization of fastener clips of DT-Ⅲ fastener system[J]. Journal of Central South University (Science and Technology), 2021, 52(10): 3623-3635. doi: 10.11817/j.issn.1672-7207.2021.10.025 [20] 杨宏光,崔晓璐,陈光雄. 科隆蛋扣件与普通短轨枕过渡段钢轨波磨的瞬态动力学研究[J]. 润滑与密封,2016,41(11): 26-30,70. doi: 10.3969/j.issn.0254-0150.2016.11.006YANG Hongguang, CUI Xiaolu, CHEN Guangxiong. A transient dynamics study on rail corrugation in the transitional section from cologne-egg fasteners section to fix-dual short sleepers in a sharp curved track[J]. Lubrication Engineering, 2016, 41(11): 26-30,70. doi: 10.3969/j.issn.0254-0150.2016.11.006 [21] FERREÑO D, CASADO J A, CARRASCAL I A, et al. Experimental and finite element fatigue assessment of the spring clip of the SKL-1 railway fastening system[J]. Engineering Structures, 2019, 188: 553-563. doi: 10.1016/j.engstruct.2019.03.053 [22] 毕继红,陈花丽,任洪鹏. 基于雨流计数法的接触线疲劳寿命分析[J]. 铁道学报,2012,34(6): 34-39. doi: 10.3969/j.issn.1001-8360.2012.06.007BI Jihong, CHEN Huali, REN Hongpeng. Analysis on fatigue life of contact wire based on rain-flow counting method[J]. Journal of the China Railway Society, 2012, 34(6): 34-39. doi: 10.3969/j.issn.1001-8360.2012.06.007 [23] 郭骁. 地铁e型弹条扣件系统疲劳伤损机理研究[D]. 北京: 北京交通大学,2016. [24] 国家质量监督检验检疫总局,中国国家标准化管理委员会. 弹簧钢:GB/T 1222—2016[S]. 北京:中国标准出版社,2016. [25] XIAO H, GUO X, WANG H Y, et al. Fatigue damage analysis and life prediction of e-clip in railway fasteners based on ABAQUS and FE-SAFE[J]. Advances in Mechanical Engineering, 2018, 10(3): 168781401876724.1-168781401876724.12. [26] 崔晓璐. 地铁线路钢轨波磨现象发生机理研究[D]. 成都: 西南交通大学,2017. [27] 刘文光,陈国平. 含裂纹悬臂梁的振动与疲劳耦合分析[J]. 振动与冲击,2011,30(5): 140-144. doi: 10.3969/j.issn.1000-3835.2011.05.029LIU Wenguang, CHEN Guoping. Coupling analysis for vibration and fatigue of a cracked cantilever beam[J]. Journal of Vibration and Shock, 2011, 30(5): 140-144. doi: 10.3969/j.issn.1000-3835.2011.05.029 [28] 蔡力钢,马仕明,赵永胜,等. 多约束状态下重载机械式主轴有限元建模及模态分析[J]. 机械工程学报,2012,48(3): 165-173. doi: 10.3901/JME.2012.03.165CAI Ligang, MA Shiming, ZHAO Yongsheng, et al. Finite element modeling and modal analysis of heavy-duty mechanical spindle under multiple constraints[J]. Journal of Mechanical Engineering, 2012, 48(3): 165-173. doi: 10.3901/JME.2012.03.165 [29] DAMIR A, ELKHATIB A, NASSEF G. Prediction of fatigue life using modal analysis for grey and ductile cast iron[J]. International Journal of Fatigue, 2007, 29(3): 499-507. doi: 10.1016/j.ijfatigue.2006.05.004 [30] CUI X L, CHEN G X, YANG H J, et al. A case study of rail corrugation phenomenon based on the viewpoint of friction-induced oscillation of a wheelset-track system[J]. Journal of Vibroengineering, 2017, 19(6): 4516-4530. doi: 10.21595/jve.2017.17867 [31] SMUTNY J. Measurement and analysis of dynamic and acoustic parameters of rail fastening[J]. NDT & E International, 2004, 37(2): 119-129. [32] 肖宏,马春生,郭骁,等. e型扣件弹条断裂原因频谱分析[J]. 同济大学学报(自然科学版),2017,45(7): 1000-1008.XIAO Hong, MA Chunsheng, GUO Xiao, et al. Fractures of e-type fastening clip by spectral analysis method[J]. Journal of Tongji University (Natural Science), 2017, 45(7): 1000-1008. -

下载:

下载: