Axial Compression Test and Bearing Capacity Design Method of Cold-Formed Steel with Unequal-Leg Lipped Angles

-

摘要:

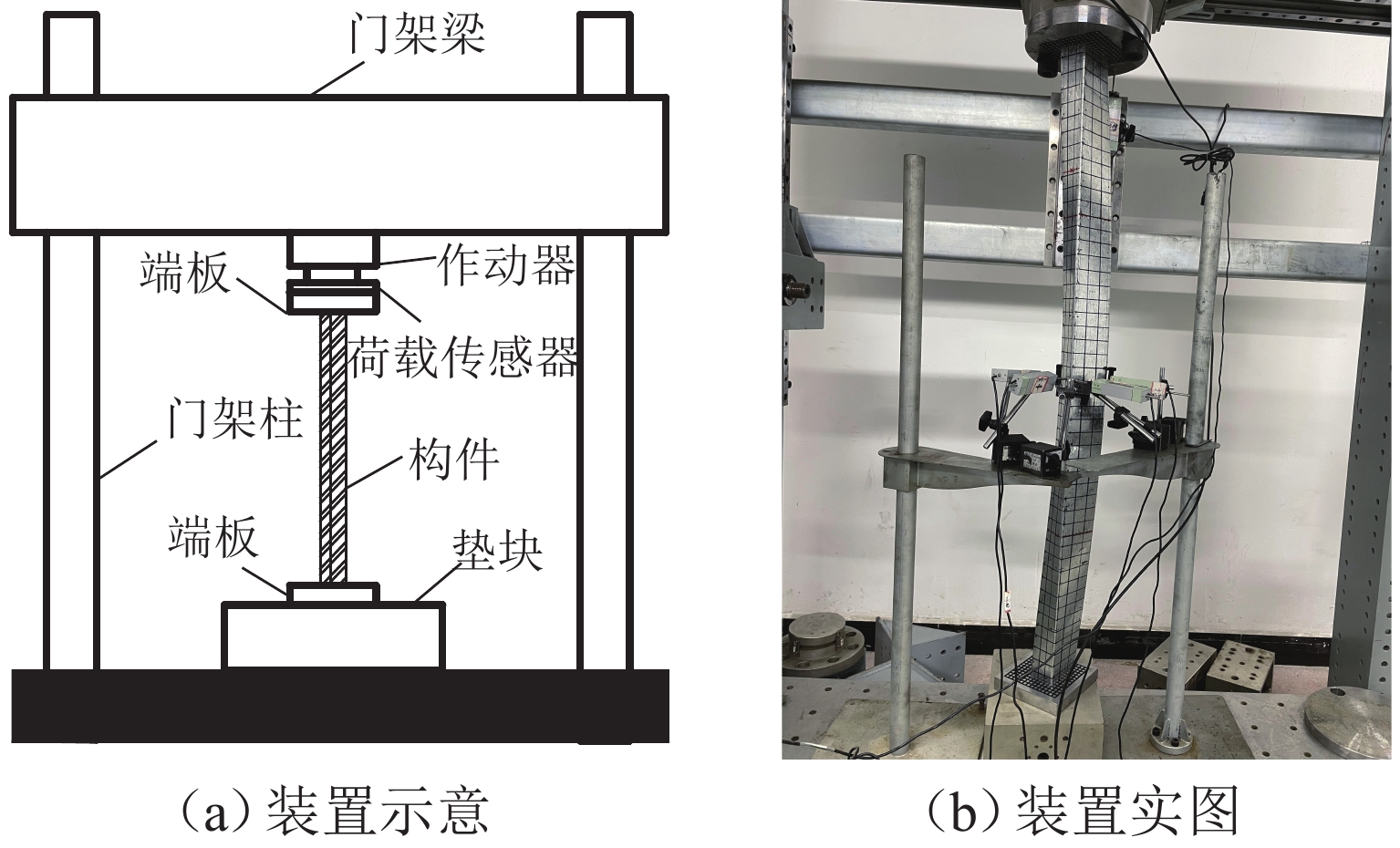

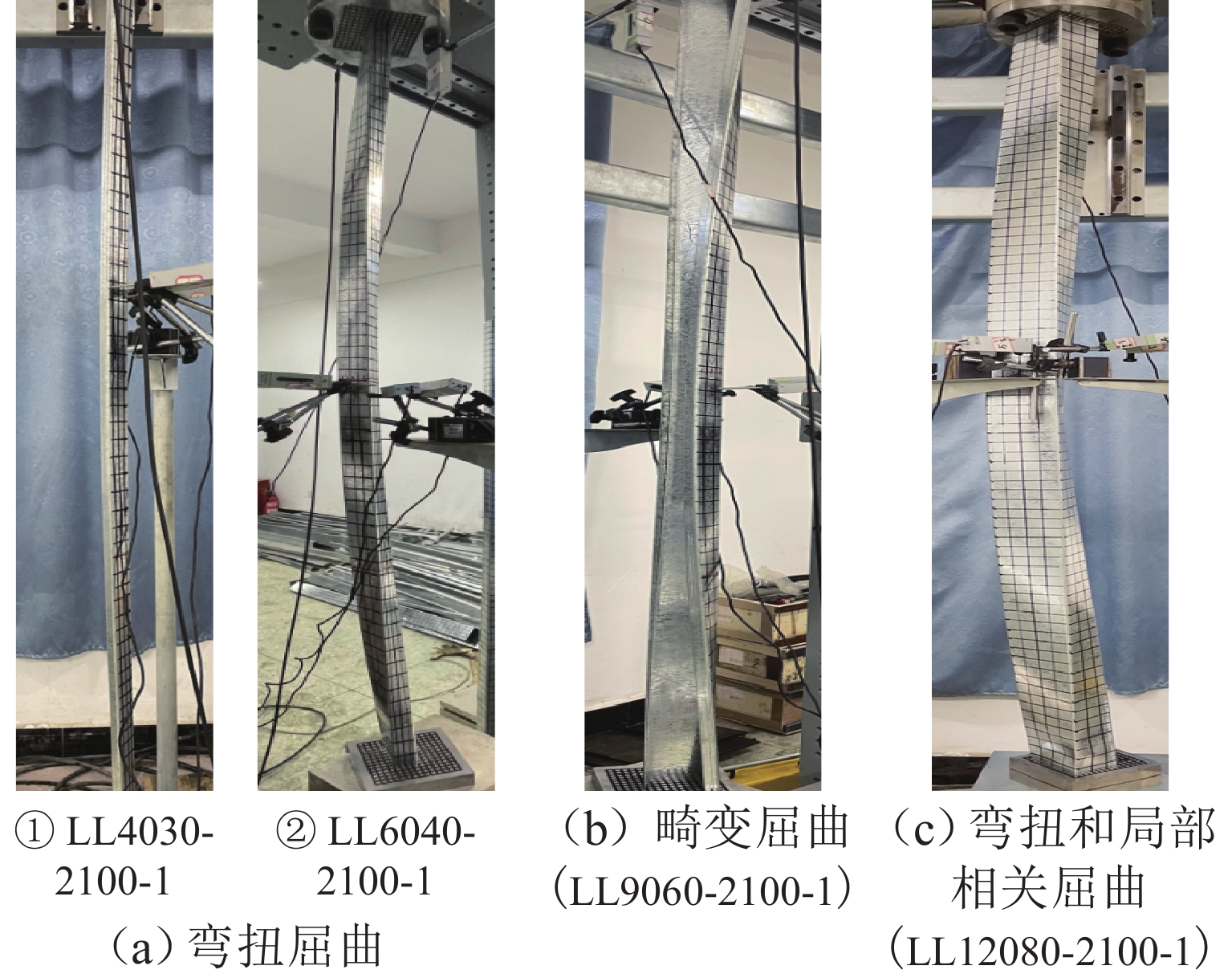

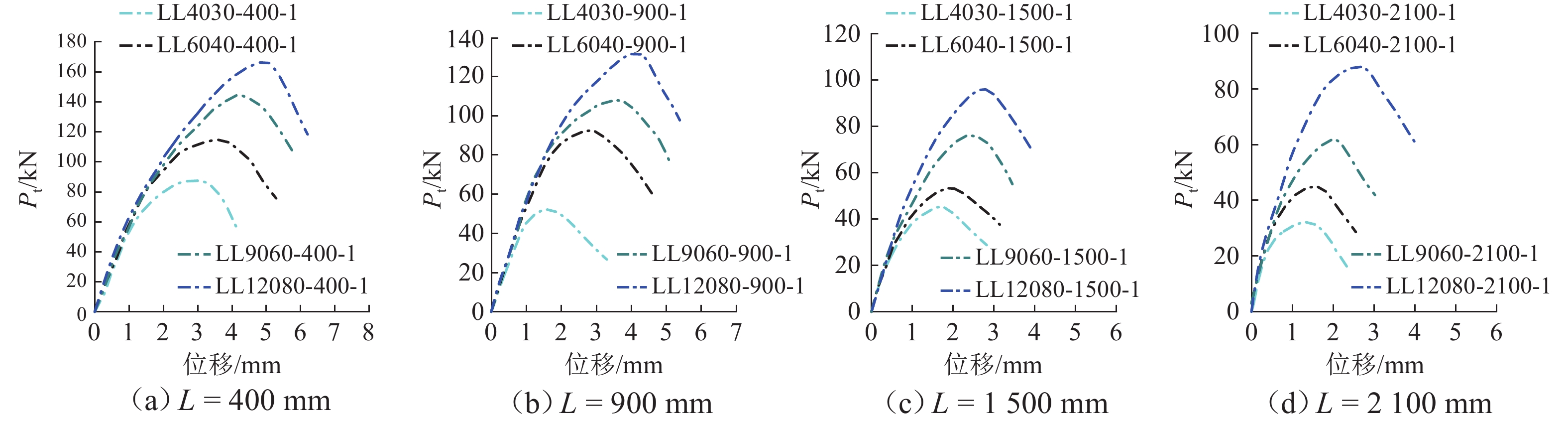

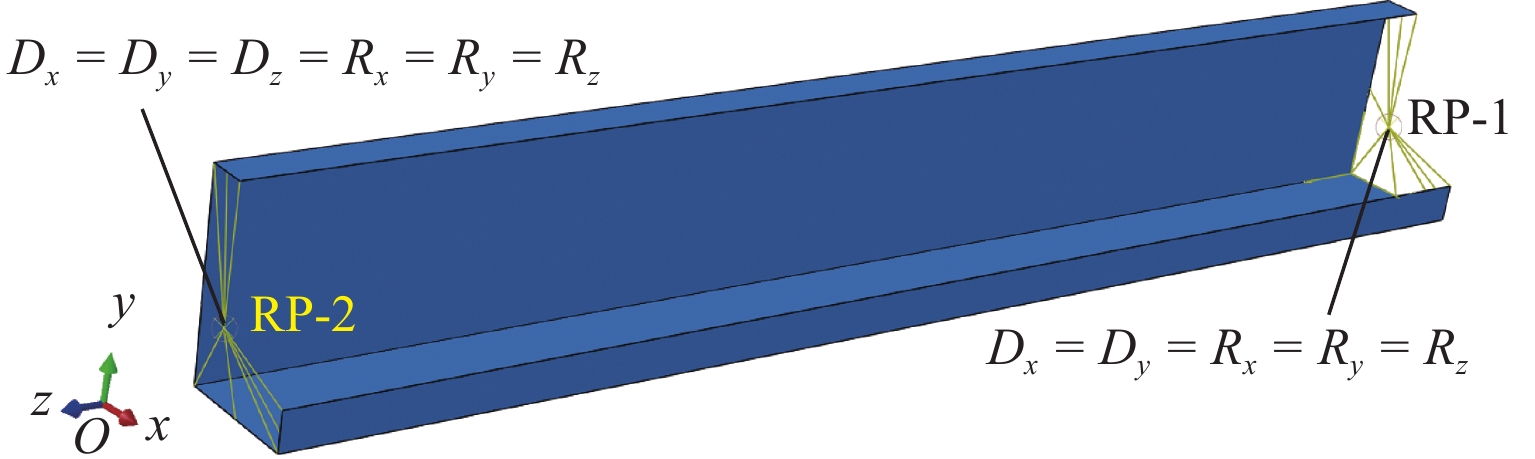

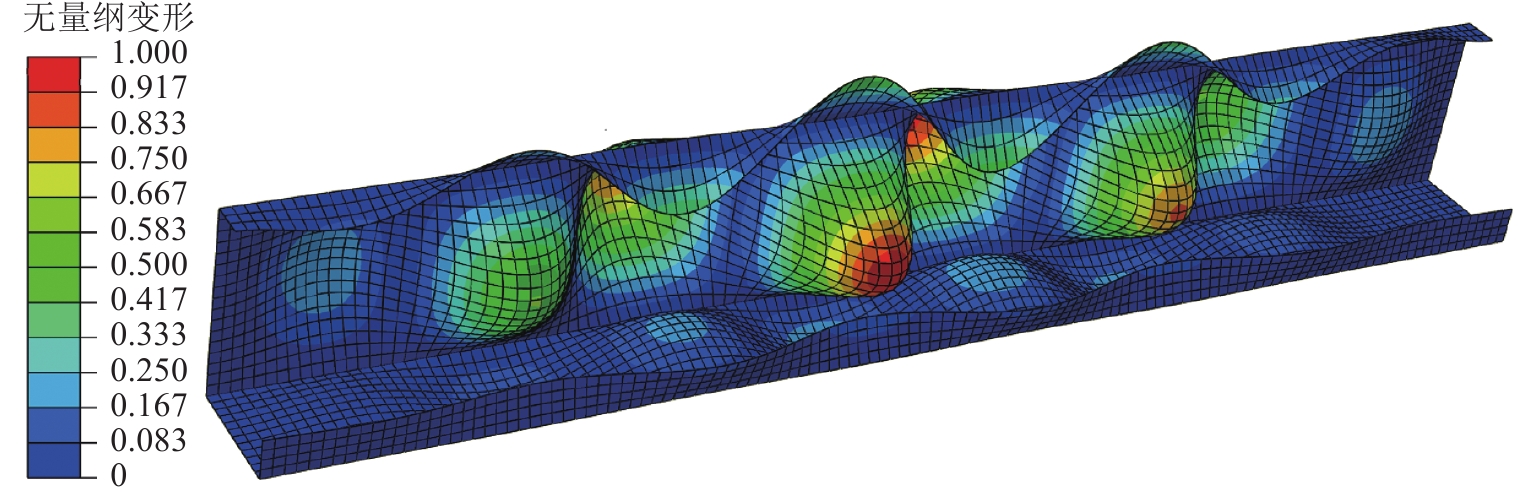

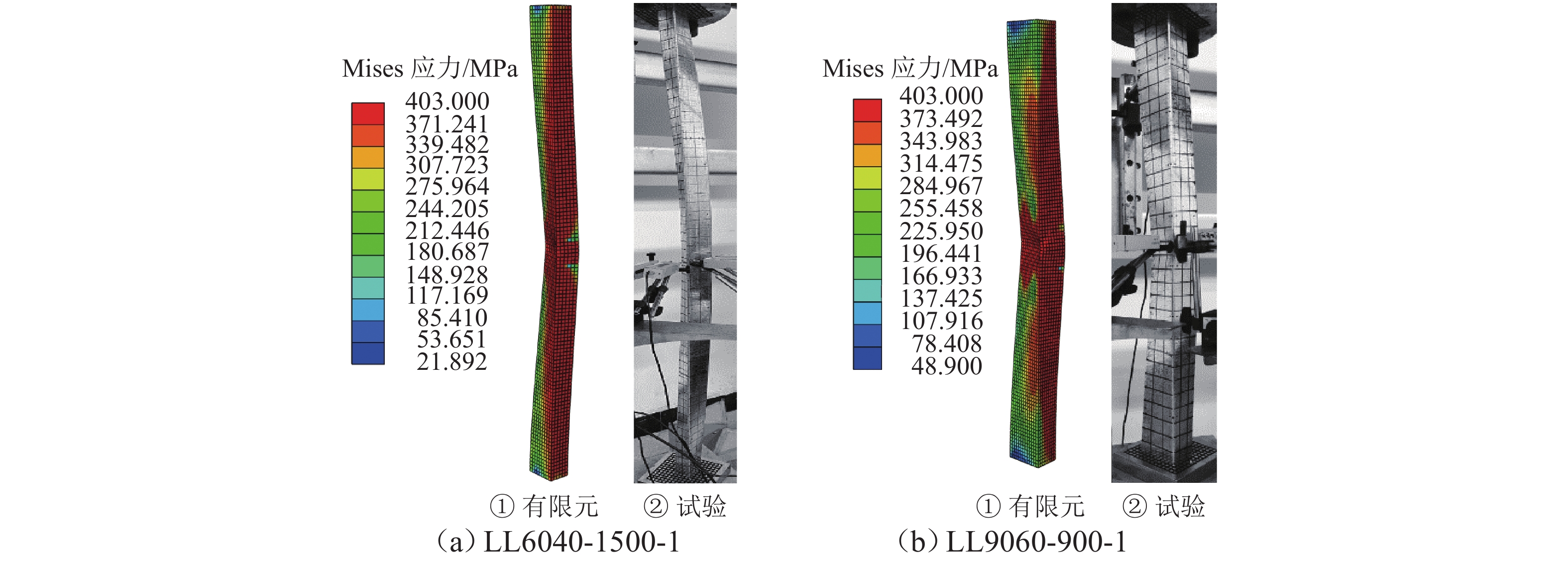

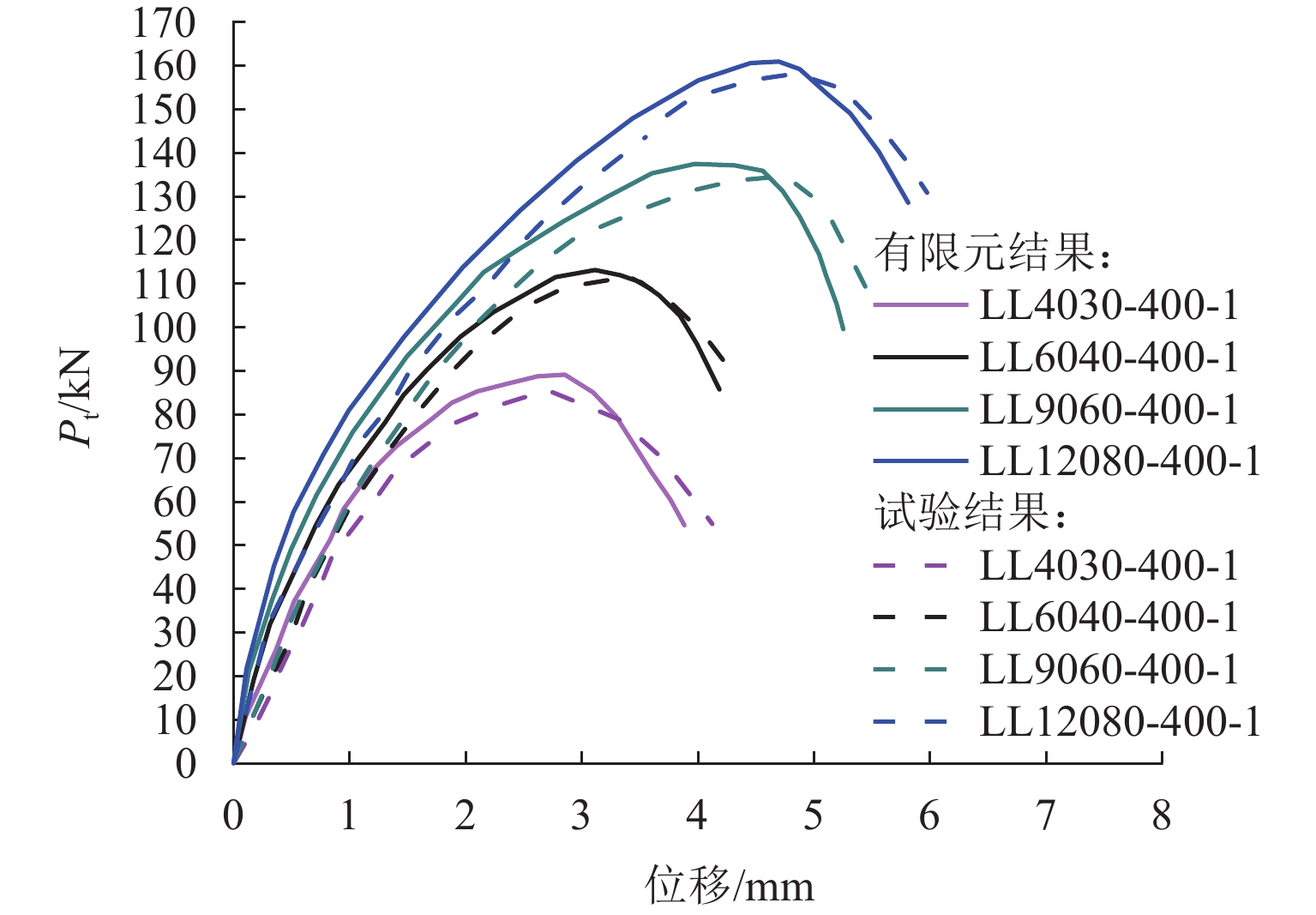

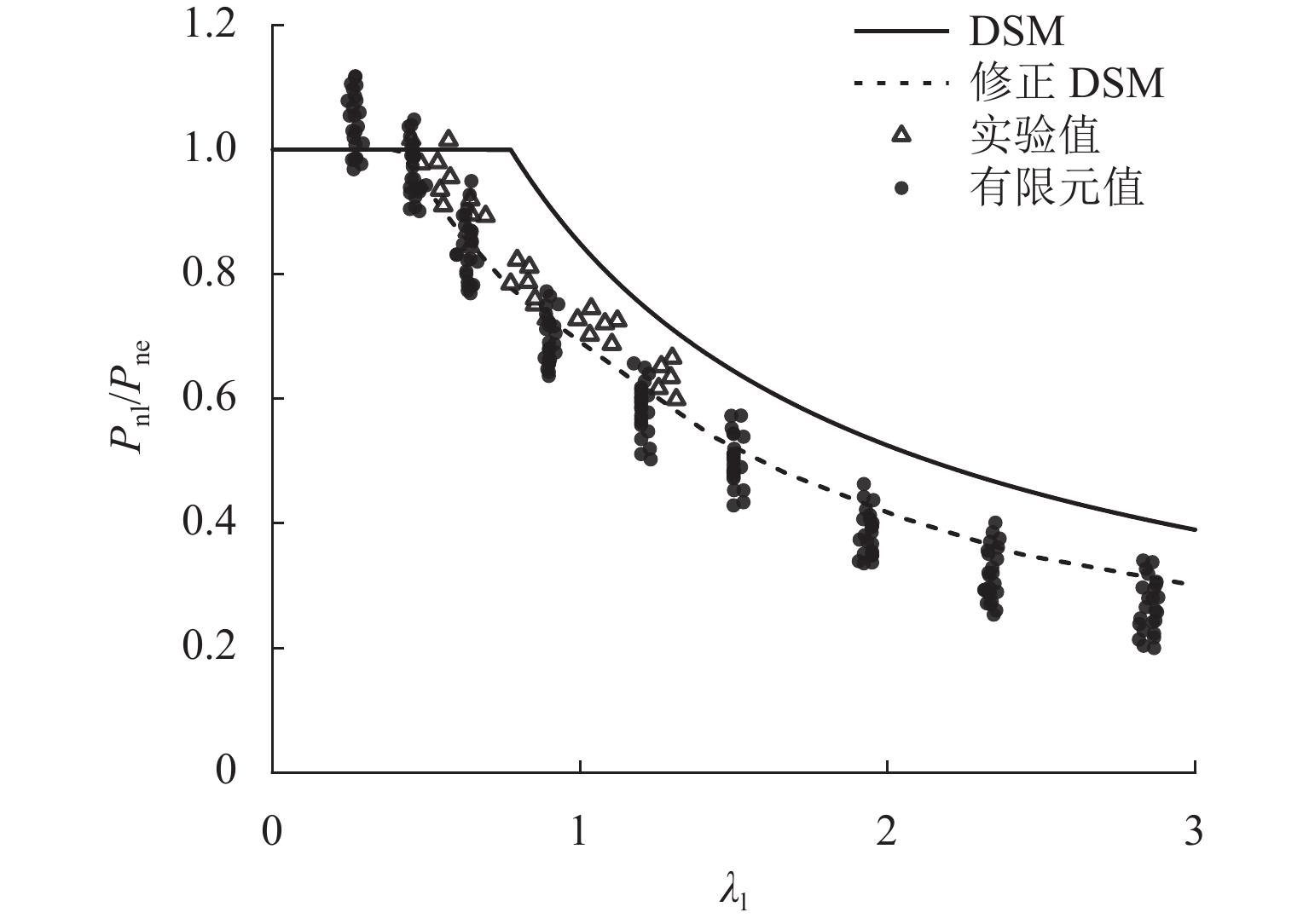

为研究轴心受压冷弯薄壁不等肢卷边角钢屈曲性能和承载力设计方法,采用试验和有限元程序分析其屈曲性能和极限承载力,并基于直接强度法提出承载力设计建议方法. 首先,开展32根不同截面、长细比和宽厚比的冷弯薄壁不等肢卷边角钢轴压试验;随后,采用ABAQUS有限元软件对冷弯薄壁不等肢卷边角钢在不同宽厚比、肢宽比、长细比等条件下的屈曲性能和承载力进行参数化分析;最后,基于试验和有限元分析结果提出轴心受压冷弯薄壁不等肢卷边角钢构件承载力计算的修正直接强度法公式. 结果表明:宽厚比较小,试件易发生弯扭屈曲,宽厚比较大,试件易发生局部屈曲(或弯扭)和局部相关屈曲;构件极限承载力随长细比增大而降低,随着宽厚比的增大,承载力增长趋势逐渐减缓;提出的修正直接强度法计算轴心受压冷弯薄壁不等肢卷边角钢构件承载力的可靠度指标均值均大于3.2,建议方法准确且安全可靠.

Abstract:To study the buckling performance and bearing capacity design method of the cold-formed thin-walled steel (CFTWS) with unequal-leg lipped angles under axial compression, the tests were conducted, and a finite element program was used to analyze the buckling performance and ultimate bearing capacity. Based on the direct strength method, the bearing capacity design method was presented. Firstly, the 32 CFTWS with unequal-leg lipped angles with different sections, slenderness ratios, and width-to-thickness ratios were tested under axial compression. Then, ABAQUS finite element software was used to perform parametric analysis on the buckling performance and bearing capacity of CFTWS with unequal-leg lipped angles with different width-to-thickness ratios, width ratios of legs, and slenderness ratios. Finally, the modified direct strength method for calculating the bearing capacity of CFTWS with unequal-leg lipped angles under axial compression was proposed based on the results of the test and finite element analysis. The results show that the specimens with a small width-to-thickness ratio are prone to flexural-torsional buckling, while the specimens with a large width-to-thickness ratio are prone to the local buckling or buckling related to flexural-torsional buckling and local buckling. The ultimate bearing capacity of the specimens decreases with the increase in the slenderness ratio, and the increase amplitude of the bearing capacity slows down with the increase in the width-to-thickness ratio. The reliability analysis shows that the reliability indexes of the bearing capacity of the CFTWS with unequal-leg lipped angles under axial compression calculated using the modified direct strength method are greater than 3.2, indicating that the proposed method is accurate and reliable.

-

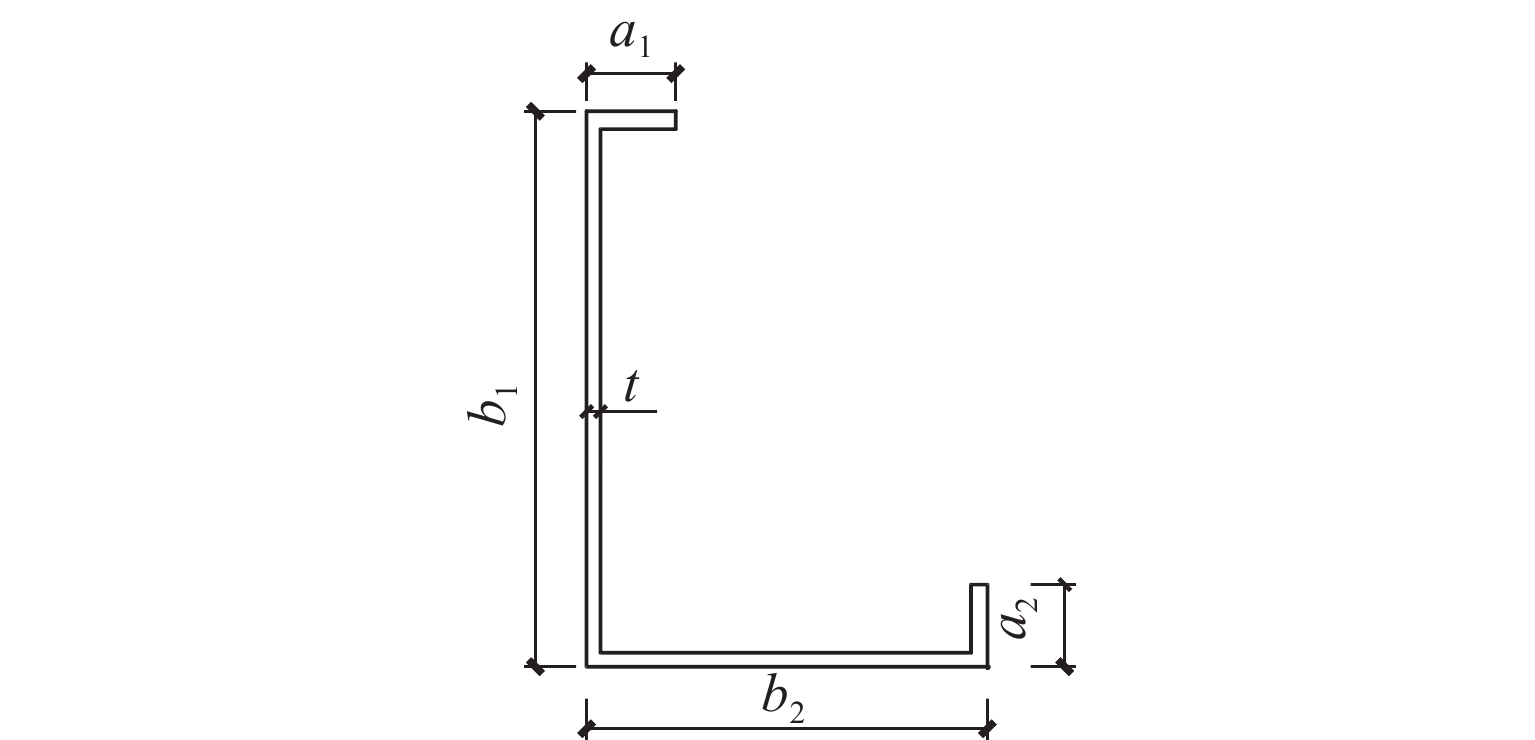

表 1 试件名义几何尺寸

Table 1. Nominal geometric dimension of specimens

试件编号 bl/mm b2/mm al/mm a2/mm t/mm b1/t b2/t LL4030 40 30 15 15 2 20 15 LL6040 60 40 20 20 2 30 20 LL9060 90 60 20 20 2 45 30 LL12080 120 80 24 24 2 60 40 表 2 试件实测几何尺寸

Table 2. Measured geometric dimensions of specimens

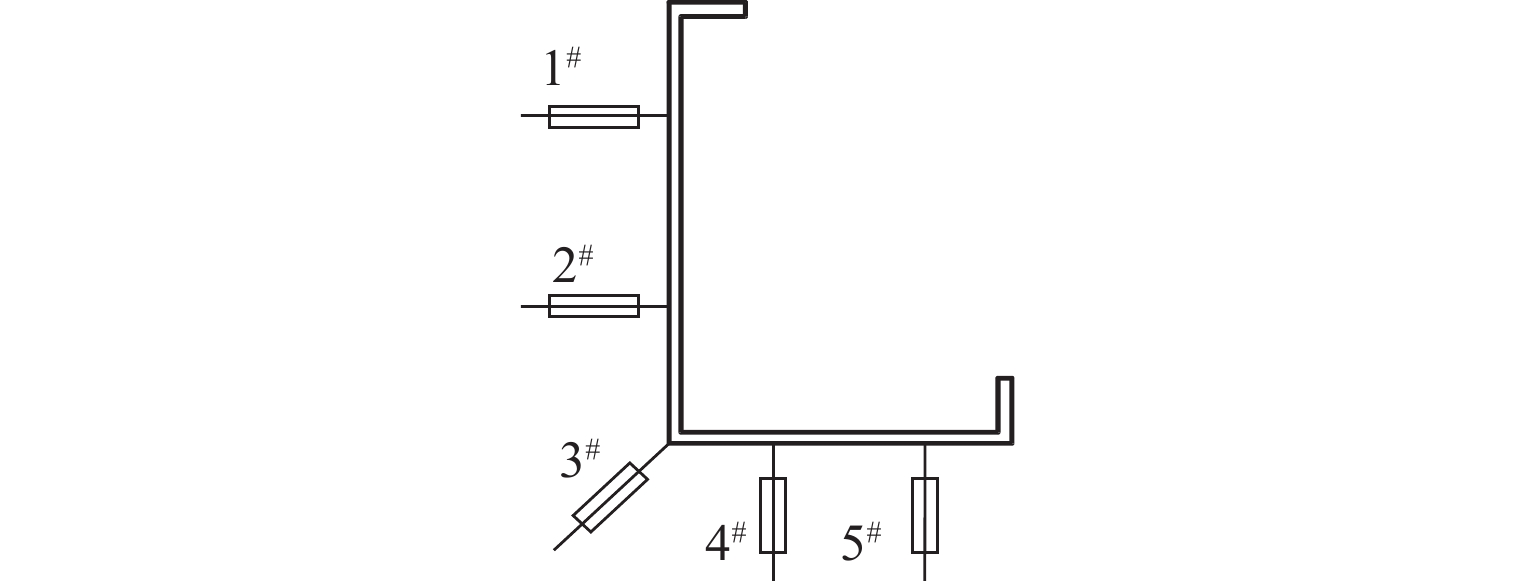

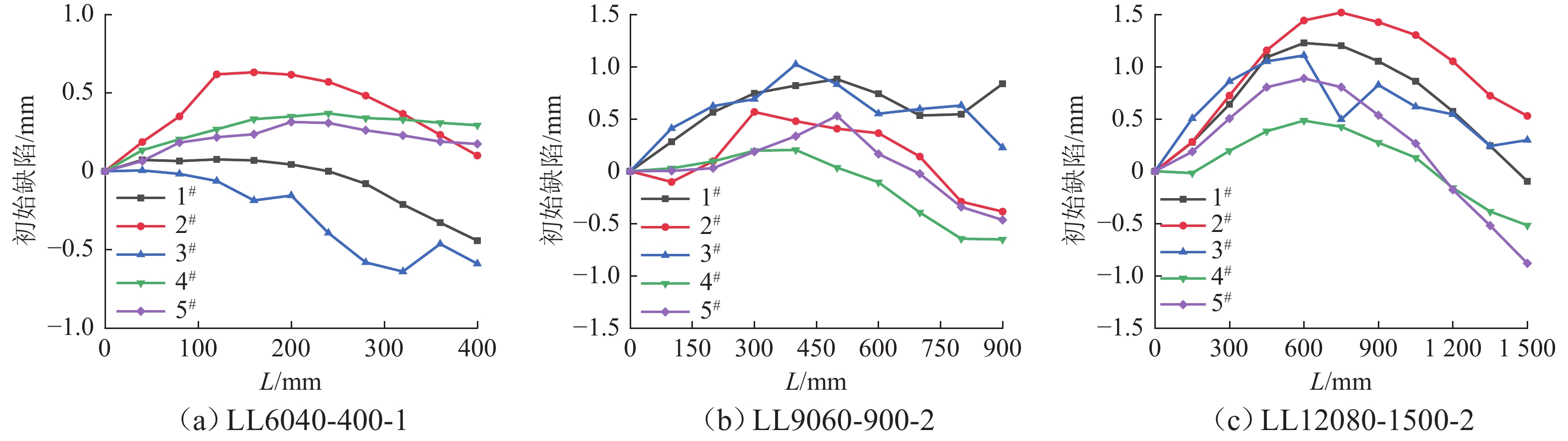

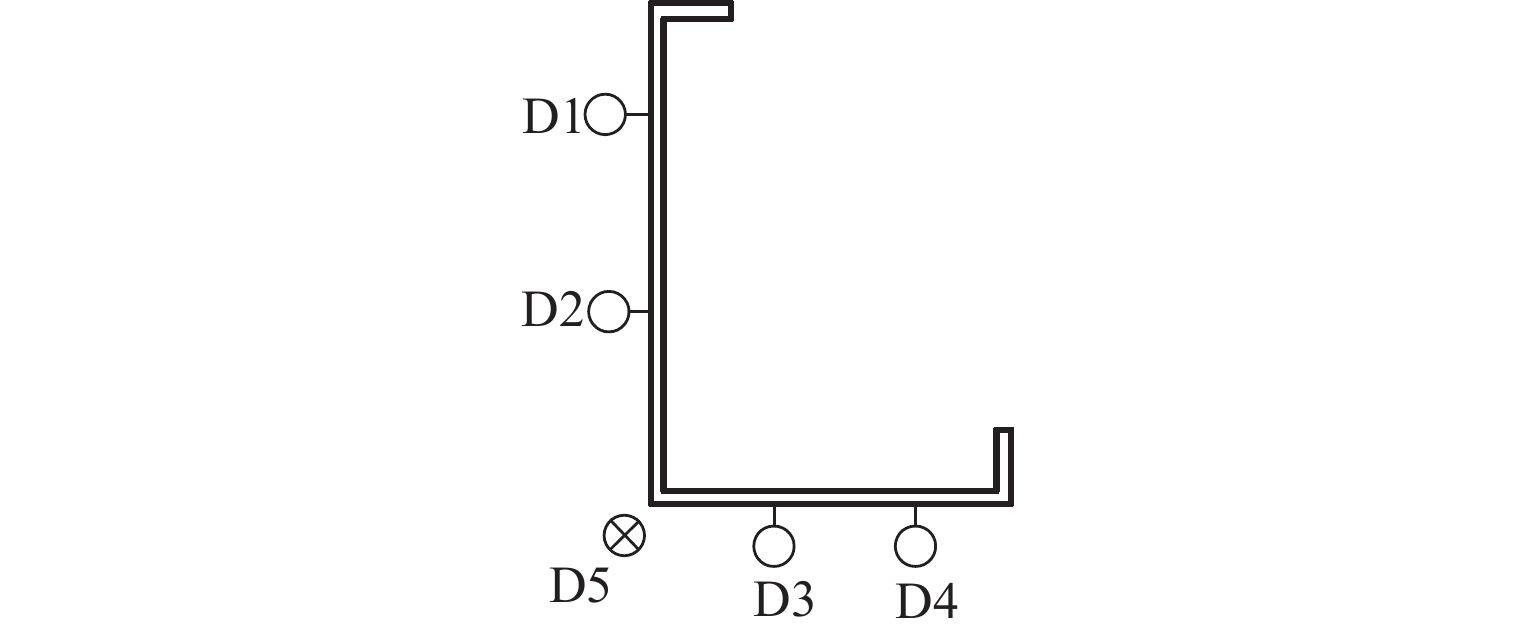

试件编号 bl/mm b2/mm al/mm a2/mm t/mm 长度 L/mm 长细比 λ LL4030-400-1 42.13 31.43 15.97 15.54 1.98 400.00 39.19 LL4030-400-2 41.51 31.45 15.56 16.34 1.98 399.27 39.88 LL4030-900-1 42.00 31.61 15.96 14.84 1.99 900.00 87.28 LL4030-900-2 42.25 31.05 15.14 15.79 2.00 900.00 89.45 LL4030-1500-1 41.98 31.48 15.99 15.28 1.97 1498.37 147.14 LL4030-1500-2 41.93 31.42 15.93 15.95 2.00 1499.33 146.65 LL4030-2100-1 42.07 31.32 15.60 15.96 1.98 2101.17 206.51 LL4030-2100-2 42.20 31.59 15.52 15.66 1.98 2101.27 206.93 LL6040-400-1 61.68 41.48 21.63 19.48 1.98 400.00 29.54 LL6040-400-2 61.35 41.52 21.17 21.00 1.97 399.00 29.40 LL6040-900-1 62.05 41.60 21.45 19.37 1.98 900.00 66.46 LL6040-900-2 62.16 41.63 21.54 19.61 2.09 900.00 68.25 LL6040-1500-1 62.10 41.64 21.06 20.48 1.99 1499.43 110.40 LL6040-1500-2 61.80 41.76 21.35 20.98 2.07 1499.27 111.54 LL6040-2100-1 62.24 41.37 21.32 19.86 1.91 2101.10 152.65 LL6040-2100-2 61.44 41.91 20.92 20.47 1.98 2100.00 154.12 LL9060-400-1 91.80 61.41 20.25 20.02 1.97 400.00 22.15 LL9060-400-2 91.92 61.31 20.12 20.50 1.97 399.50 22.16 LL9060-900-1 91.51 61.43 19.90 21.05 1.99 900.00 49.79 LL9060-900-2 91.90 61.89 20.67 20.19 2.00 900.00 49.39 LL9060-1500-1 91.50 62.59 20.51 20.88 2.00 1498.90 81.56 LL9060-1500-2 91.43 62.42 21.08 19.88 1.97 1499.10 81.69 LL9060-2100-1 92.07 61.52 20.99 19.69 1.98 2100.00 115.66 LL9060-2100-2 91.60 61.94 21.83 21.01 2.00 2101.03 113.94 LL12080-400-1 121.53 81.77 24.92 23.98 1.98 400.00 16.95 LL12080-400-2 121.30 81.82 24.19 24.22 1.98 399.27 17.00 LL12080-900-1 122.30 81.71 25.11 24.05 1.97 900.00 38.10 LL12080-900-2 121.87 81.95 23.68 24.90 1.97 900.00 38.23 LL12080-1500-1 121.97 82.20 24.71 24.17 2.00 1498.22 63.34 LL12080-1500-2 122.48 81.87 24.95 24.70 1.97 1499.13 63.33 LL12080-2100-1 122.79 81.89 23.76 24.03 1.98 2101.17 89.38 LL12080-2100-2 121.04 82.24 24.71 24.49 1.97 2100.14 88.61 表 3 试验和有限元分析角钢屈曲模式和承载力对比

Table 3. Comparisons of buckling modes and bearing capacities of steel angles between test and finite element analysis

试件编号 屈曲模式 ΔLmax/

mmΔGmax/

mmPt/kN PFE/kN PD/kN PMD/kN PY/kN Pt/PY Pt/ PFE Pt/ PD Pt/PMD 试验 有限元 一阶模态 LL4030-400-1 FT FT F 0.49 0.28 79.66 83.17 83.77 74.38 72.51 1.0986 0.9578 0.9509 1.0710 LL4030-400-2 FT FT F 0.41 0.34 79.38 82.66 83.67 73.51 73.41 1.0813 0.9603 0.9488 1.0799 LL4030-900-1 FT FT F 1.30 0.83 50.68 53.93 56.47 50.71 27.68 1.8312 0.9397 0.8974 0.9995 LL4030-900-2 FT FT F 1.54 0.77 52.72 54.70 56.90 50.97 27.97 1.8852 0.9638 0.9265 1.0342 LL4030-1500-1 FT FT F 1.30 0.38 40.70 40.93 40.36 42.15 23.01 1.7689 0.9944 1.0085 0.9655 LL4030-1500-2 FT FT F 1.14 0.17 40.98 41.52 41.89 43.75 23.88 1.7159 0.9869 0.9783 0.9366 LL4030-2100-1 FT FT F 1.84 0.08 30.52 31.19 24.48 25.57 13.96 2.1867 0.9786 1.2467 1.1936 LL4030-2100-2 FT FT F 1.10 0.09 29.26 31.35 24.50 25.59 13.97 2.0948 0.9335 1.2343 1.1434 LL6040-400-1 L L L 0.67 0.46 103.70 105.82 102.94 95.81 119.12 0.8706 0.9800 1.0074 1.0824 LL6040-400-2 L L L 0.75 0.31 102.46 105.26 105.33 96.41 121.73 0.8417 0.9734 0.9728 1.0628 LL6040-900-1 FT FT F 1.08 0.63 83.69 85.39 94.17 76.27 52.34 1.5989 0.9800 0.9886 1.0973 LL6040-900-2 FT FT F 1.17 0.74 83.62 84.70 98.45 80.28 54.25 1.5414 0.9872 0.9494 1.0416 LL6040-1500-1 FT FT F 1.15 0.60 59.96 61.98 74.21 61.37 42.31 1.4172 0.9673 0.9480 0.9769 LL6040-1500-2 FT FT F 1.42 0.43 60.82 63.31 78.23 64.30 44.60 1.3638 0.9607 0.9775 0.9459 LL6040-2100-1 FT FT F 1.17 0.24 48.66 50.69 41.59 43.44 23.71 2.0519 0.9600 1.1699 1.1201 LL6040-2100-2 FT FT F 1.42 1.08 49.94 50.96 42.99 44.90 24.51 2.0376 0.9800 1.1617 1.1122 LL9060-400-1 L L L 0.99 0.35 126.76 129.35 104.56 124.03 153.51 0.8257 0.9800 1.2123 1.0220 LL9060-400-2 L L L 0.57 0.57 125.71 129.60 106.03 124.39 155.32 0.8094 0.9700 1.1855 1.0106 LL9060-900-1 FT + L FT + L L 1.12 0.71 94.42 96.00 108.68 101.84 68.10 1.3865 0.9835 0.9688 0.9271 LL9060-900-2 FT + L FT + L L 1.02 0.92 95.60 97.20 107.99 102.07 67.07 1.4253 0.9835 0.9853 0.9366 LL9060-1500-1 FT + L FT + L L 0.79 0.71 77.34 80.36 90.86 94.90 51.80 1.4929 0.9625 0.9512 0.8149 LL9060-1500-2 FT + L FT + L L 0.88 0.83 77.04 78.87 85.54 89.34 48.77 1.5797 0.9768 0.9006 0.8623 LL9060-2100-1 D D F 1.22 0.90 59.95 61.37 48.74 50.90 27.79 2.1574 0.9768 1.2300 1.1776 LL9060-2100-2 D D F 1.08 0.77 61.51 63.42 54.77 57.20 31.22 1.9701 0.9700 1.2232 1.0754 LL12080-400-1 L L L 0.59 0.22 147.54 150.67 117.71 146.76 224.28 0.6578 0.9792 1.2535 1.0053 LL12080-400-2 L L L 0.58 0.14 146.78 150.41 117.29 146.49 223.06 0.6580 0.9759 1.2515 1.0020 LL12080-900-1 FT + L FT + L L 1.20 0.56 136.59 138.37 117.55 118.57 105.70 1.2923 0.9872 1.1620 1.1520 LL12080-900-2 FT + L FT + L L 1.52 1.11 131.36 138.86 118.35 118.60 106.10 1.2380 0.9460 1.1099 1.1075 LL12080-1500-1 FT + L FT + L L 1.20 1.56 97.14 98.99 116.57 104.35 81.31 1.1948 0.9813 0.8334 0.9309 LL12080-1500-2 FT + L FT + L L 1.52 1.11 98.56 98.19 116.67 102.58 83.41 1.1817 1.0038 0.8447 0.9608 LL12080-2100-1 FT + L FT + L L 1.44 1.42 85.43 85.91 73.43 76.89 41.97 2.0354 0.9948 1.2634 1.1110 LL12080-2100-2 FT + L FT + L L 1.45 1.54 85.82 86.48 76.31 80.96 44.19 1.9419 0.9926 1.2246 1.0600 均值 1.4760 0.9741 1.1246 1.0318 方差 0.2060 0.0002 0.0227 0.0077 变异系数 0.1395 0.0002 0.0201 0.0074 表 4 冷弯薄壁型不等肢卷边角钢轴压构件可靠指标

Table 4. Reliability indexes of CFTWS with unequal-leg lipped angles under axial compression

类型 ρ2 组合形式 ρ1=0.5 ρ1=1.0 ρ1=2.0 ρ1=3.0 可靠指标平均值 办公楼 0 1.3G + 1.5L1 4.518 4.467 4.442 4.403 4.457 0.5 1.3G + 0.9 × 1.5 (L1 + W) 4.306 4.298 4.253 4.198 4.264 1.0 1.3G + 0.9 × 1.5 (L1 + W) 4.178 4.161 4.102 4.087 4.132 2.0 1.3G + 0.9 × 1.5 (L1 + W) 4.096 4.011 3.918 3.824 3.962 3.0 1.3G + 0.9 × 1.5 (L1 + W) 3.954 3.898 3.837 3.763 3.863 4.0 1.3G + 0.9 × 1.5 (L1 + W) 3.781 3.675 3.621 3.601 3.670 住宅 0 1.3G + 1.5L2 4.924 4.869 4.841 4.799 4.858 0.5 1.3G + 0.9 × 1.5 (L2 + W) 4.693 4.684 4.635 4.575 4.647 1.0 1.3G + 0.9 × 1.5 (L2 + W) 4.554 4.535 4.471 4.454 4.503 2.0 1.3G + 0.9 × 1.5 (L2 + W) 4.464 4.372 4.270 4.168 4.318 3.0 1.3G + 0.9 × 1.5 (L2 + W) 4.309 4.248 4.182 4.101 4.210 4.0 1.3G + 0.9 × 1.5 (L2 + W) 4.121 4.005 3.947 3.925 3.999 注:ρ1 为活荷载标准值与风荷载标准值之和与恒荷载标准值的比值,ρ2 为风荷载标准值与活荷载标准值的比值. -

[1] 陈明,鲁卫波,武志远,等. 双肢冷弯C型钢蒙古包刚架的平面内稳定性[J]. 西南交通大学学报,2022,57(1):215-222.CHEN Ming, LU Weibo, WU Zhiyuan,et al. Investigation on in-plane stability of double-limb cold-formed C-shaped steel rigid frame of yurt[J]. Journal of Southwest Jiaotong University, 2022, 57(1):215-222. [2] ADLURI S M R, MADUGULA M K S. Flexural buckling of steel angles: experimental investigation[J]. Journal of Structural Engineering, 1996, 122(3): 309-317. doi: 10.1061/(ASCE)0733-9445(1996)122:3(309) [3] DINIS P B, CAMOTIM D, SILVESTRE N. On the mechanics of thin-walled angle column instability[J]. Thin-Walled Structures, 2012, 52: 80-89. doi: 10.1016/j.tws.2011.12.007 [4] American Iron and Steel Institute. North American specification for the design of cold-formed steel structural members: AISI S100-16[S]. Washington D. C.: American Ir-on and Steel Institute, 2016. [5] YOUNG B. Tests and design of fixed-ended cold-formed steel plain angle columns[J]. Journal of Structural Engineering, 2004, 130(12): 1931-1940. doi: 10.1061/(ASCE)0733-9445(2004)130:12(1931) [6] DE BARROS CHODRAUI G M, SHIFFERAW Y, MALITE M, et al, On the stability of cold-formed steel angles undercompression[J]. Rev Esc Minas, 2007, 60(2): 355-363. [7] SILVESTRE N, DINIS P B, CAMOTIM D. Developments on the design of cold-formed steel angles[J]. Journal of Structural Engineering, 2013, 139(5): 680-694. doi: 10.1061/(ASCE)ST.1943-541X.0000670 [8] ELLOBODY E, YOUNG B. Behavior of cold-formed steel plain angle columns[J]. Journal of Structural Engineering, 2005, 131(3): 457-466. doi: 10.1061/(ASCE)0733-9445(2005)131:3(457) [9] YOUNG B, ELLOBODY E. Buckling analysis of cold-formed steel lipped angle columns[J]. Journal of Structural Engineering, 2005, 131(10): 1570-1579. doi: 10.1061/(ASCE)0733-9445(2005)131:10(1570) [10] YOUNG B, CHEN J. Column tests of cold-formed steel non-symmetric lipped angle sections[J]. Journal of Constructional Steel Research, 2008, 64(7): 808-815. [11] SHIFFERAW Y, SCHAFER B W. Cold-formed steel lipped and plain angle columns with fixed ends[J]. Thin-Walled Structures, 2014, 80: 142-152. doi: 10.1016/j.tws.2014.03.001 [12] ZHANG L L, WANG F Y, LIANG Y T, et al. Press-braked S690 high strength steel equal-leg angle and plain channel section stub columns: testing, numerical simulation and design[J]. Engineering Structures, 2019, 201: 109764.1-109764.12. doi: 10.1016/j.engstruct.2019.109764 [13] 姚行友,胡成立,聂泽谕,等. 冷弯不等肢复杂卷边角钢轴压试验及承载力设计方法[J]. 建筑钢结构进展,2024,26(2): 34-44.YAO Xingyou1,HU Chengli,NIE Zeyu,et al. Experiment and design method of cold-formed thin-walled steel unequal-legged complex-lipped angles under axial Compressio[J]. Progress in Steel Building Structures, 2024, 26(9): 34-44. [14] 周宜松. 复杂卷边不等边角形截面冷弯薄壁型钢柱轴压稳定承载力研究[D]. 郑州:郑州大学,2020. [15] 徐步洲. 双卷边不等肢角钢冷弯薄壁型钢柱轴压稳定承载力研究[D]. 西安:西安建筑科技大学,2017. [16] 中华人民共和国建设部,中华人民共和国国家质量监督检验检疫总局. 冷弯薄壁型钢结构技术规范:GB 50018—2002[S]. 北京:中国计划出版社,2002. [17] 国家市场监督管理总局,国家标准化管理委员会. 金属材料拉伸试验第1部分:室温试验方法:GB/T 228.1—2021[S]. 北京:中国标准出版社,2021. [18] 姚行友,李元齐. 考虑畸变屈曲的冷弯薄壁型钢卷边槽形截面构件设计可靠度分析[J]. 建筑钢结构进展,2017,19(6): 65-74.YAO Xingyou, LI Yuanqi. Design Reliability Analysis of Cold-Formed Thin-Walled Steel Members with Lipped Channel Sections Considering Distortional Buckling[J]. Progress in Steel Building Structures, 2024, 19(6): 65-74. -

下载:

下载: