Influence of Temperature-Varying Characteristics on Operating Performance of Alpine Electric Multiple Units

-

摘要:

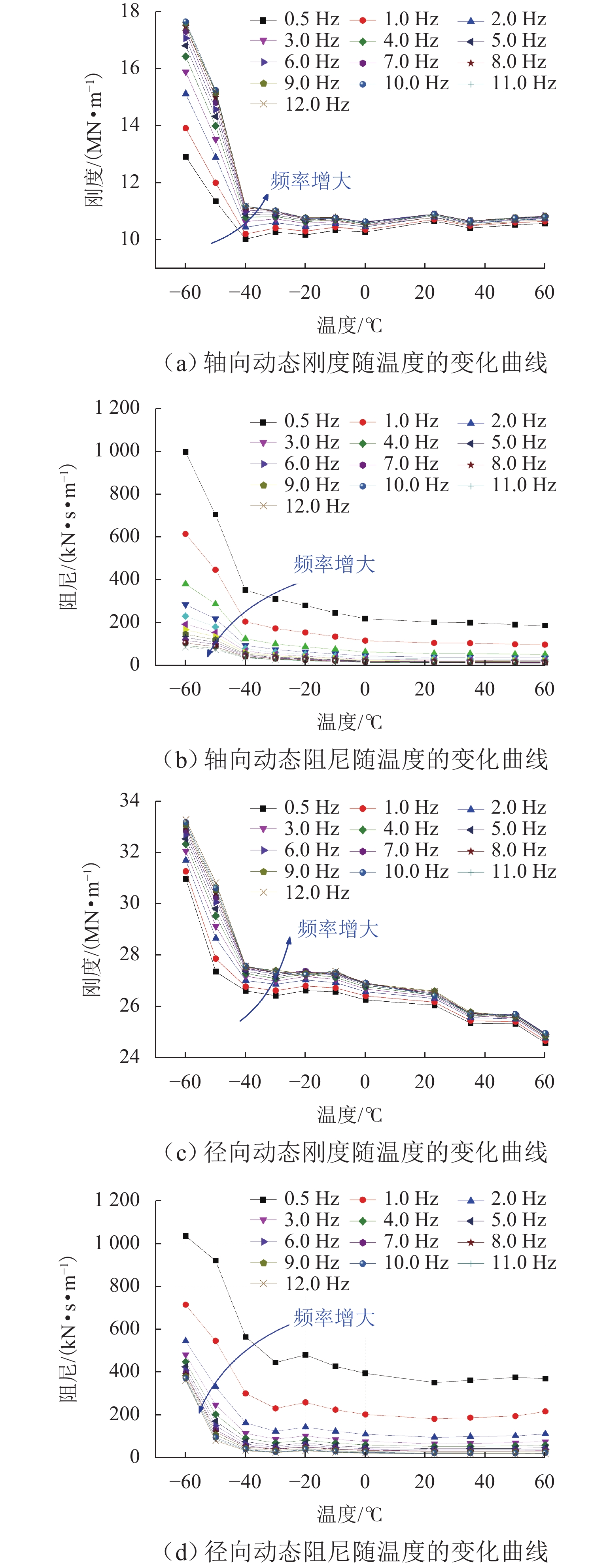

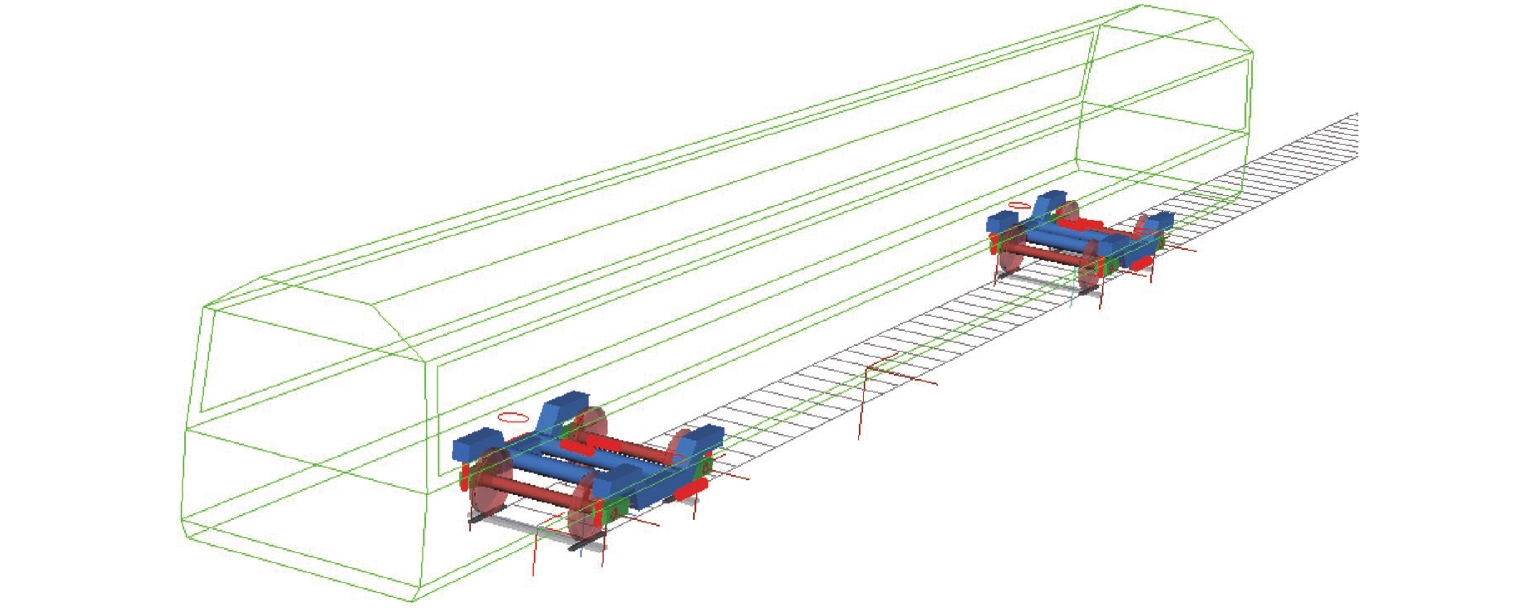

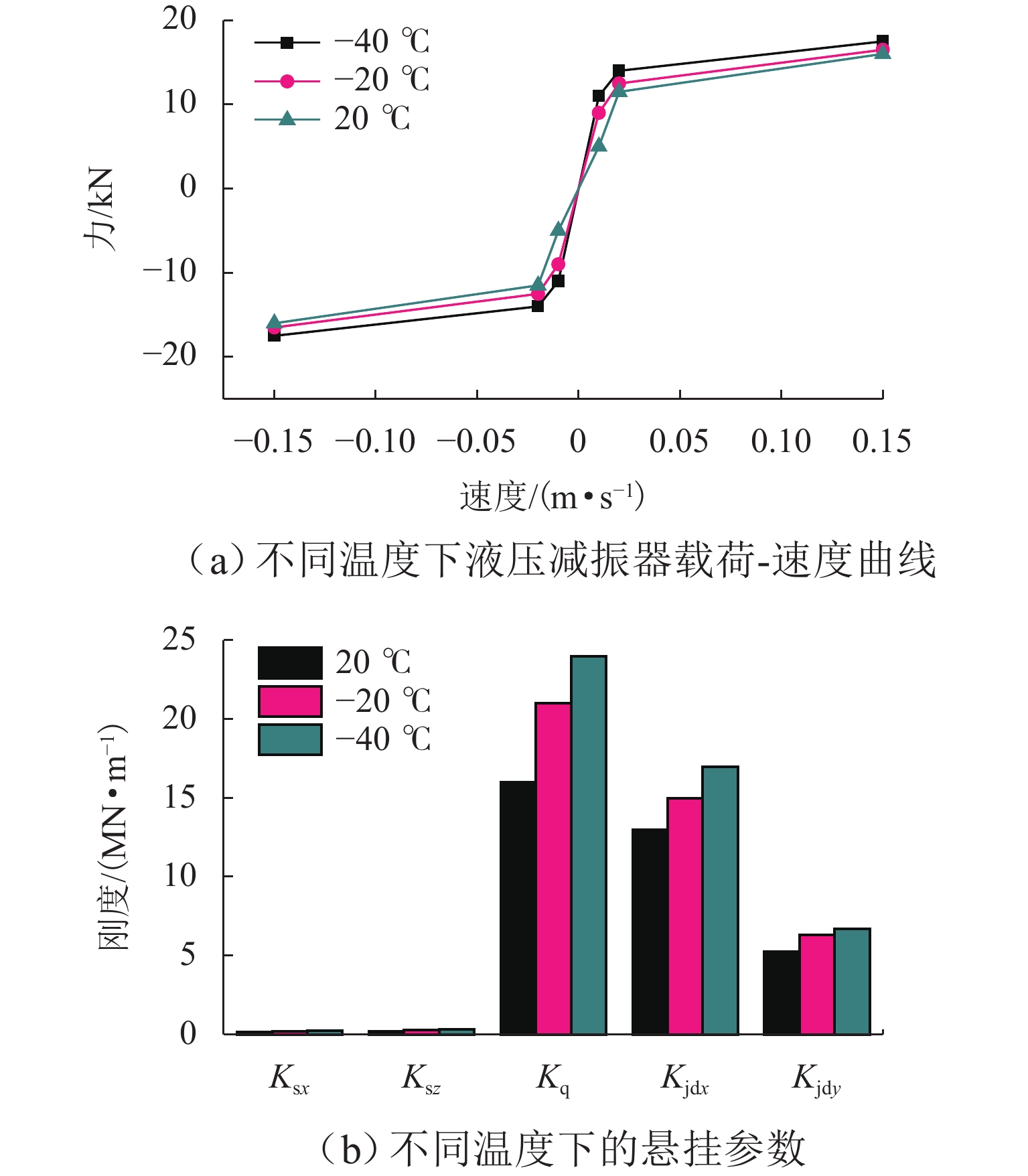

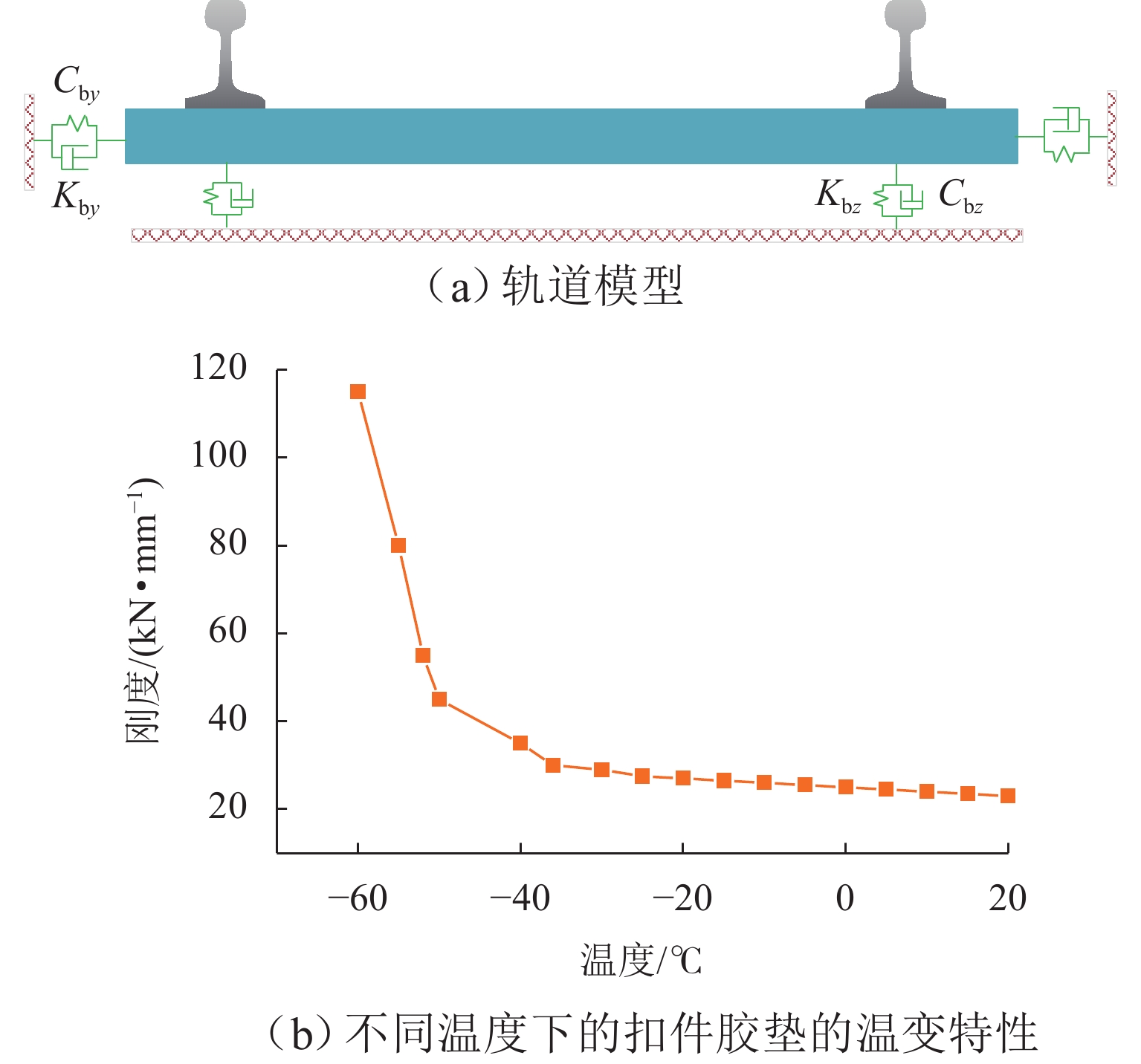

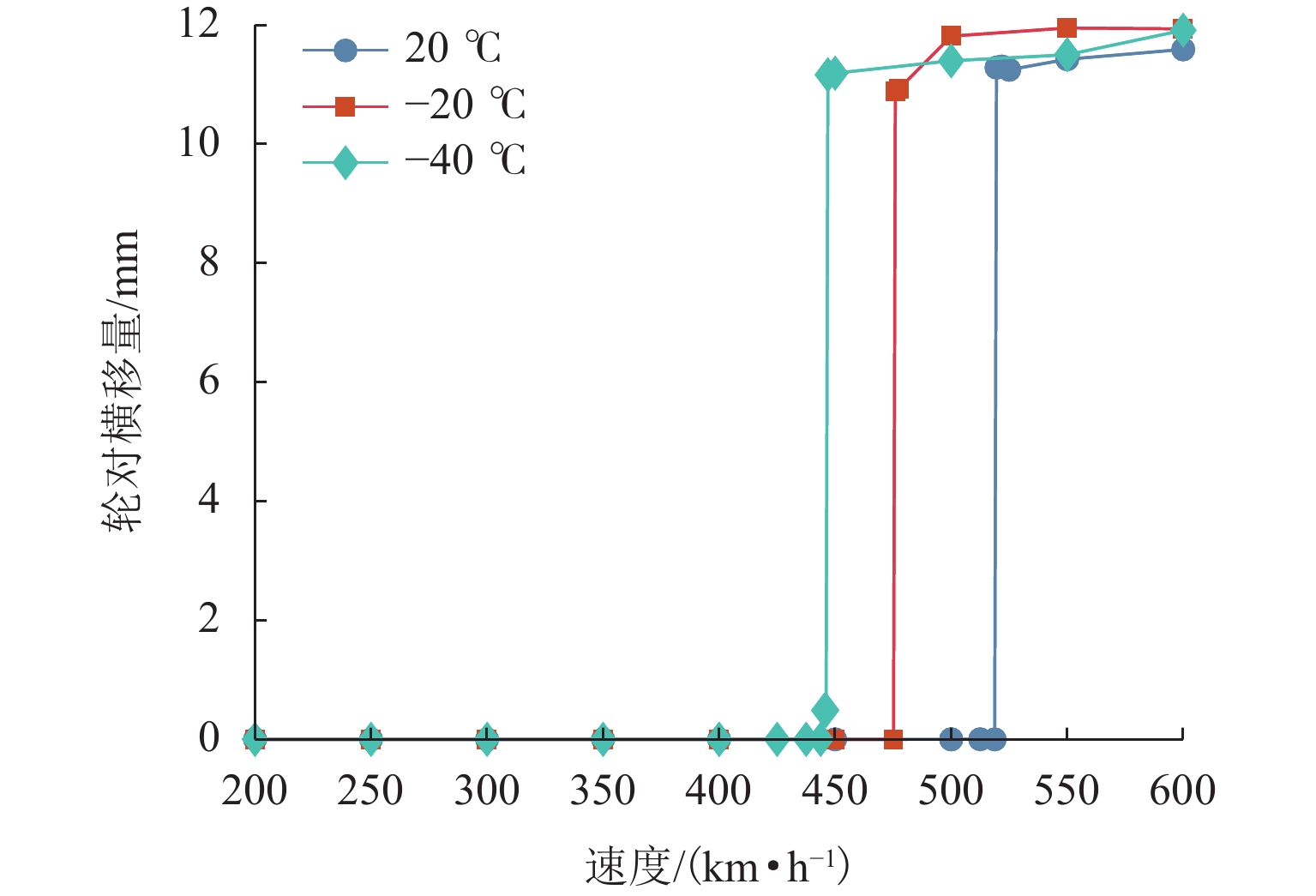

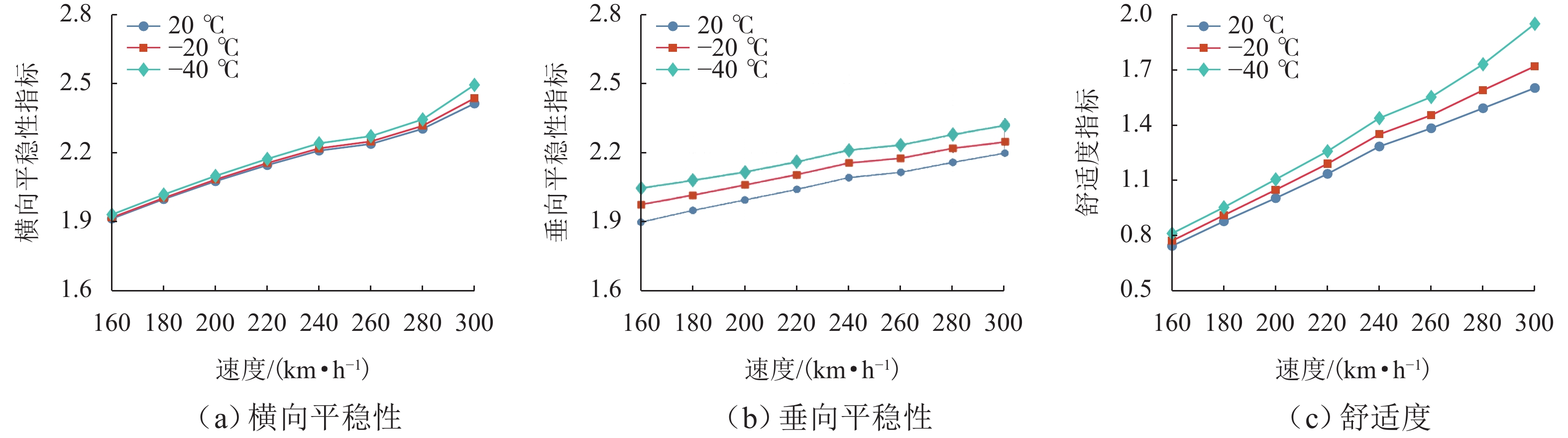

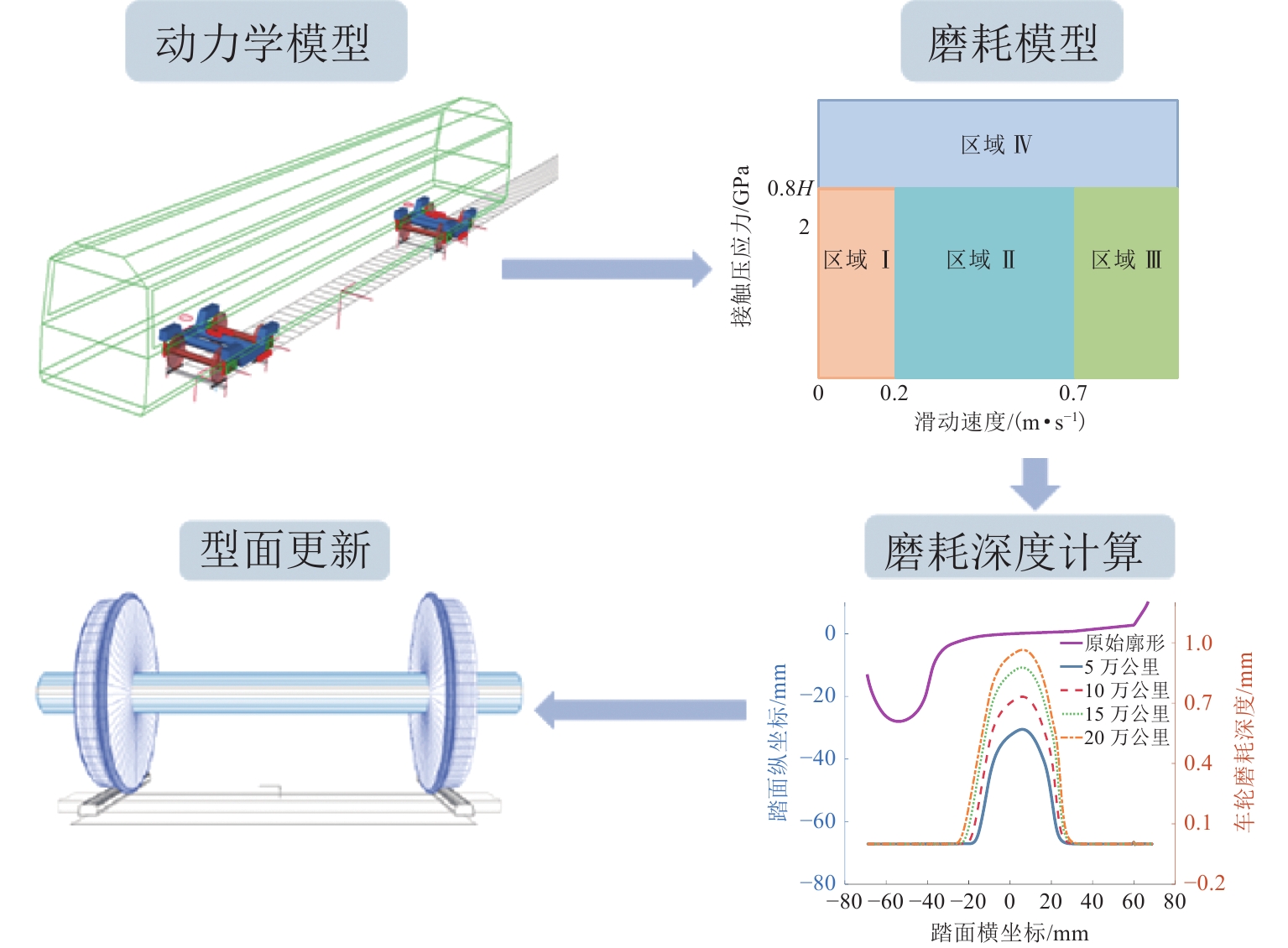

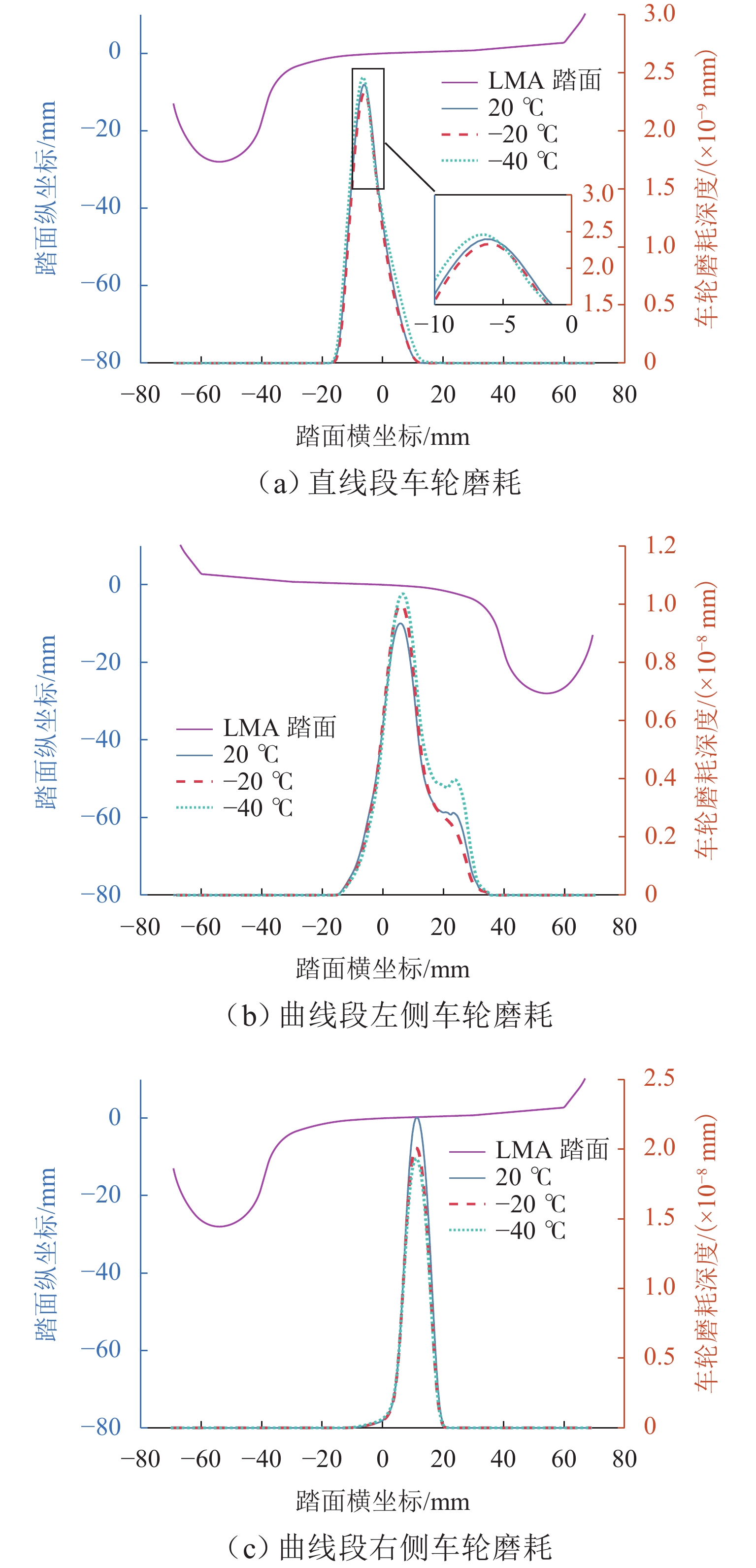

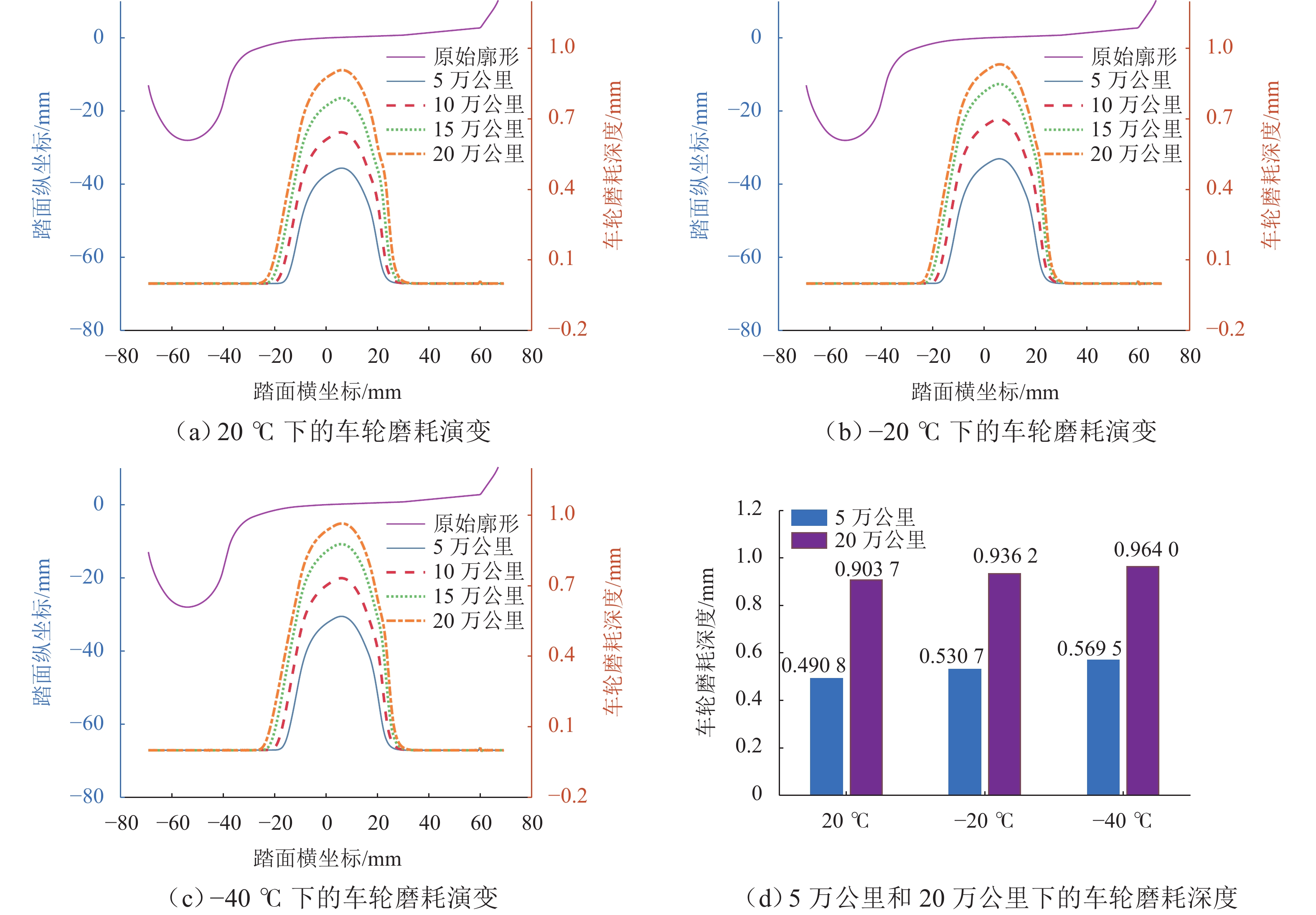

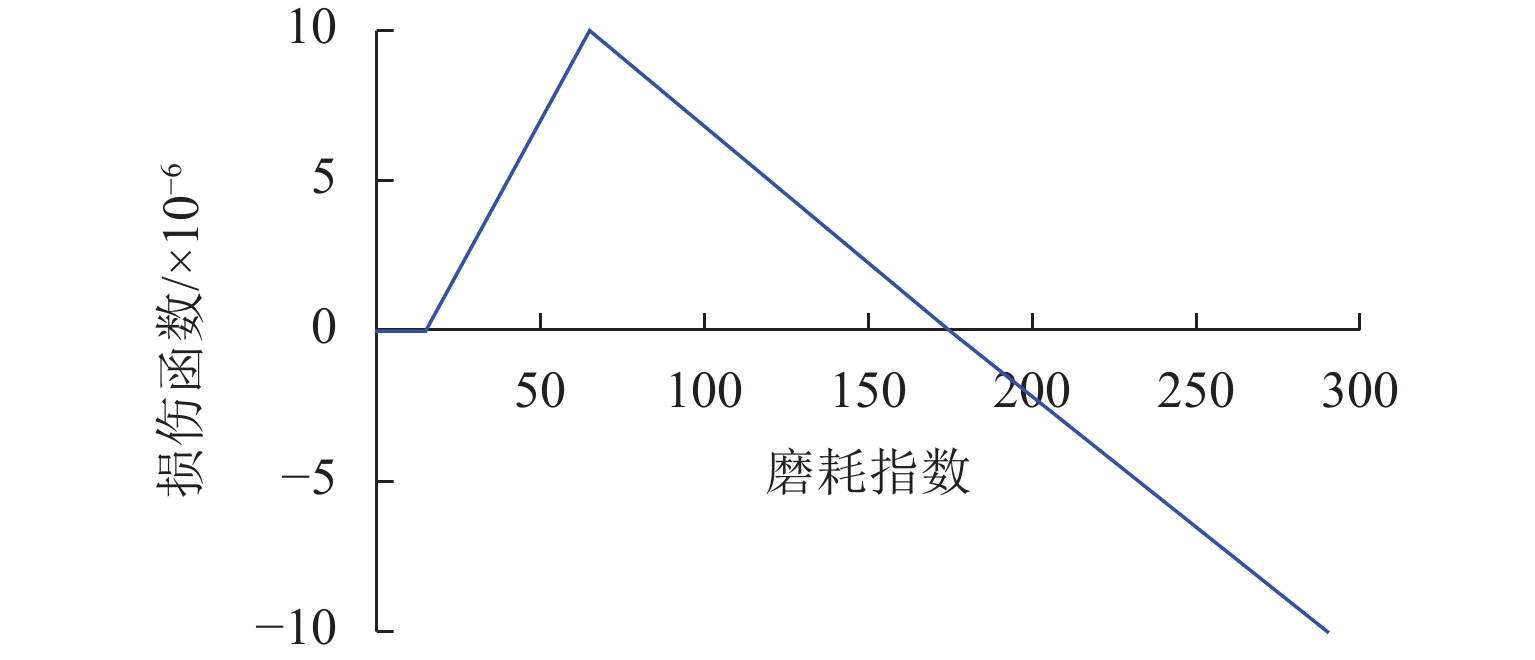

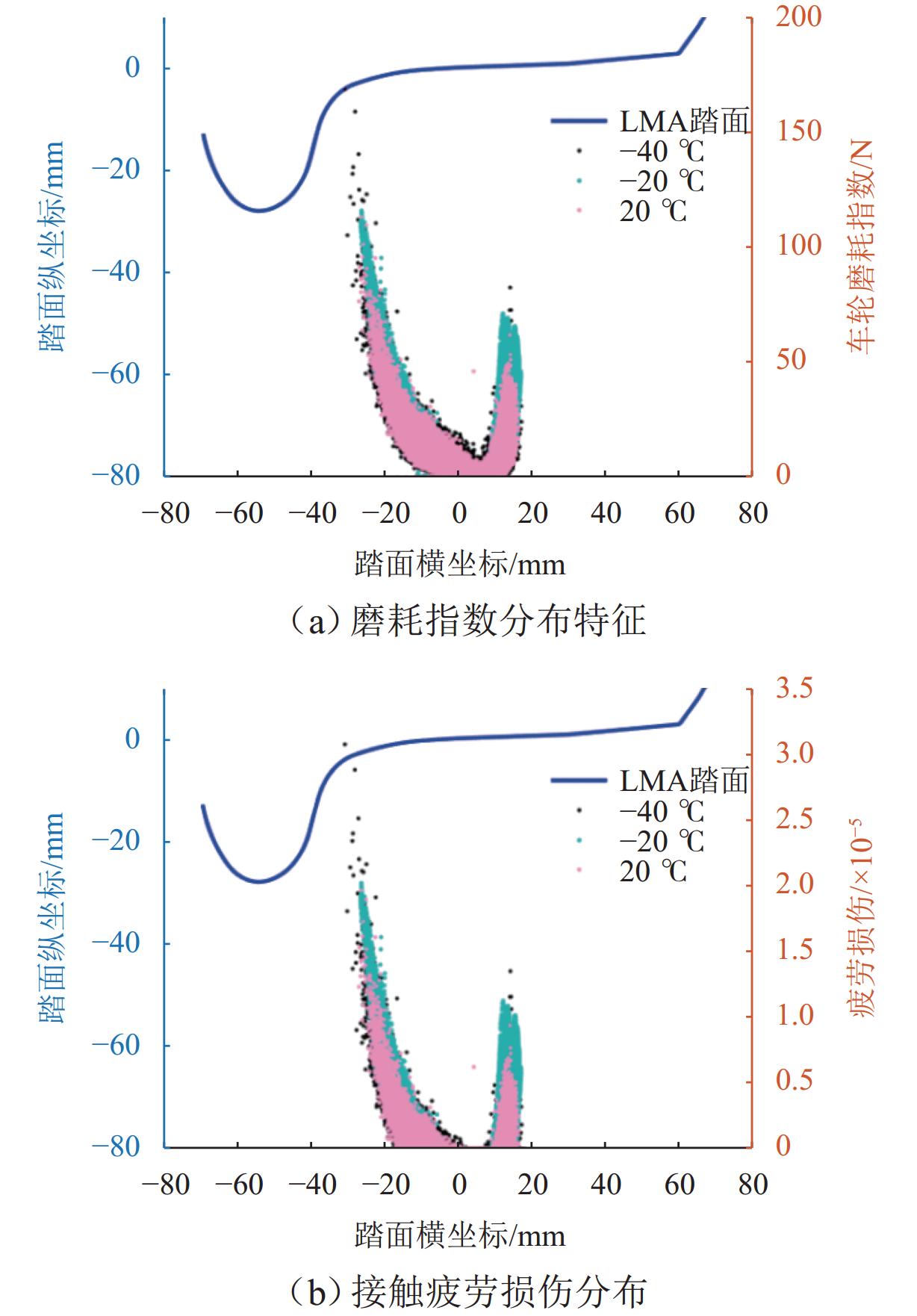

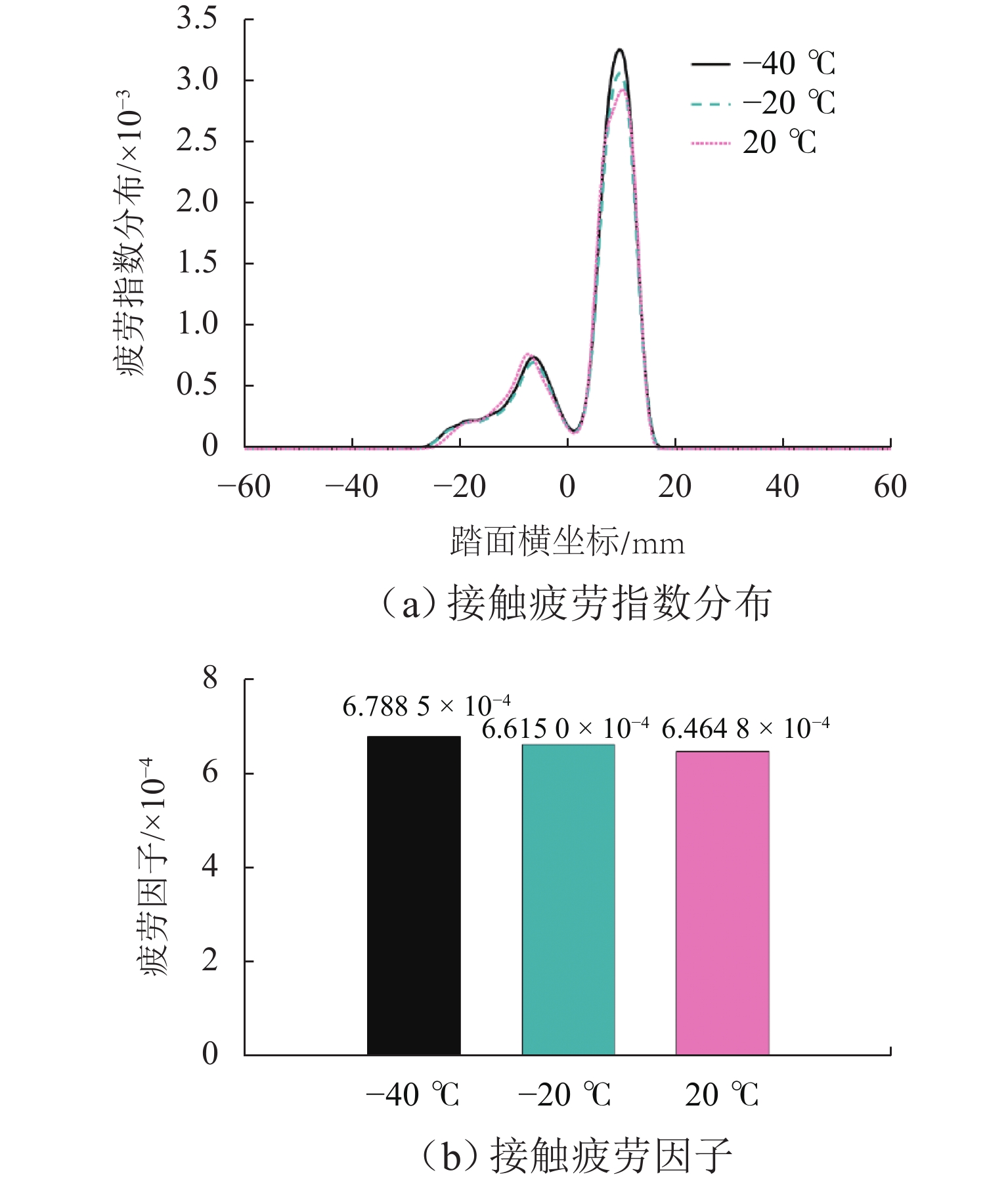

高寒动车组服役环境长期受温度的影响,车辆悬挂元件参数和轨下参数具有很强的季节变化特性,为了探究高寒动车组中橡胶元件温变特性对运行性能的影响,本文建立高寒动车组多体动力学模型,分析不同温度下的车辆动力学特性;利用Jendel磨耗模型探究不同温度下的车轮磨耗特性;基于疲劳预测模型提出车轮表面疲劳因子. 结果表明:温度变化会改变悬挂参数的刚度和阻尼值,随着温度降低,悬挂参数刚度增大;低温状态下,动车组动力学性能整体下降,随着温度降低车辆磨耗都会增大,当运行20万里程后,−40 ℃下车轮的磨耗深度最大,较20 ℃ 时增大6.2%;随着温度降低,表面接触疲劳指数也逐渐增大,温度分别为20、−20、−40 ℃时,车轮表面疲劳因子分别为

6.4648 ×10−4,6.6150 ×10−4,6.7885 ×10−4;温变特性对高寒动车组悬挂参数有较大影响,低温下整体动力学性能下降,磨耗增大,车轮表面疲劳增大.Abstract:The service environment of alpine electric multiple units (EMUs) is affected by temperature for a long time, and the vehicle suspension element parameters and under-rail parameters have strong seasonal variation characteristics. To investigate the influence of temperature-varying characteristics of rubber elements on the operating performance of alpine EMUs, a multi-body dynamics model of alpine EMUs was established to analyze the vehicle dynamics characteristics under different temperatures. Then, the wheel wear characteristics at different temperatures were analyzed by the Jendel wear model. Finally, the wheel surface fatigue index was proposed based on the fatigue prediction model. The results show that the temperature variation will change the stiffness and damping value of suspension parameters, and the stiffness of suspension parameters increases as the temperature decreases. The dynamic performance of the EMUs decreases at low temperatures. The wear of the vehicle increases as the temperature decreases. After 200 000 miles of operation, the largest depth of wheel wear is found at a temperature of −40 ℃, which is 6.2% greater than the depth of wheel wear at a temperature of 20 ℃. The surface contact fatigue index gradually increases as the temperature decreases, with wheel surface fatigue indexes being

6.4648 ×10−4,6.6150 ×10−4, and6.7885 ×10−4 at temperatures of 20 ℃, −20 ℃, and −40 ℃, respectively. Temperature-varying characteristics have a large effect on the suspension parameters of alpine EMUs, with dynamic performance deteriorating at low temperatures, wear intensifying, and wheel surface fatigue increasing. -

表 1 高速客运专线典型计算工况

Table 1. Typical calculation working conditions for high-speed passenger special lines

曲线半

径/m超高/

mm缓和曲线

长/m圆曲线

长/m运行速度/

(km•h−1)所占比例/

%直线 300 60 12000 80 220 480 300 1 9000 100 300 320 300 7 8000 120 340 250 300 8 7000 145 360 210 300 10 5500 165 360 210 300 7 5000 120 360 210 300 7 -

[1] 金学松,赵国堂,梁树林,等. 高速铁路轮轨磨损特征、机理、影响和对策:车轮踏面横向磨耗[J]. 机械工程学报,2018,54(4): 3-13. doi: 10.3901/JME.2018.04.003JIN Xuesong, ZHAO Guotang, LIANG Shulin, et al. Characteristics, mechanisms, influences and counter measures of high speed wheel/rail wear: transverse wear of wheel tread[J]. Journal of Mechanical Engineering, 2018, 54(4): 3-13. doi: 10.3901/JME.2018.04.003 [2] 谢清林,陶功权,王鹏,等. 高寒动车组车轮磨耗演变特性及其影响分析[J]. 工程力学,2019,36(10): 229-237.XIE Qinglin, TAO Gongquan, WANG Peng, et al. Wheel wear evolution characteristics of alpine high-speed emu and analysis of its influence[J]. Engineering Mechanics, 2019, 36(10): 229-237. [3] 徐腾养,池茂儒,田向阳,等. 抗蛇行减振器内部油液温度对其动态特性的影响[J]. 机车电传动,2016(6): 43-46.XU Tengyang, CHI Maoru, TIAN Xiangyang, et al. Infl uence of oil temperature of yaw damper on dynamic performance[J]. Electric Drive for Locomotives, 2016(6): 43-46. [4] 谭富星,石怀龙,王玮,等. 转向架橡胶件动态参数的高低温特性[J]. 交通运输工程学报,2019,19(4): 104-114.TAN Fuxing, SHI Huailong, WANG Wei, et al. High and low temperature characteristics of rubber component dynamic parameters of a bogie[J]. Journal of Traffic and Transportation Engineering, 2019, 19(4): 104-114. [5] 侯茂锐,胡晓依,郭涛,等. 高速动车组轴箱转臂节点性能对轮轨耦合振动的影响[J]. 交通运输工程学报,2021,21(6): 170-180.HOU Maorui, HU Xiaoyi, GUO Tao, et al. Effect of axle box rotary arm node performance on wheel-rail coupling vibration for high-speed EMUs[J]. Journal of Traffic and Transportation Engineering, 2021, 21(6): 170-180. [6] 侯茂锐,胡晓依,宗仁莉,等. 高速动车组转臂定位橡胶节点刚度对车辆动力学性能影响[J]. 中国铁道科学,2021,42(4): 120-128.HOU Maorui, HU Xiaoyi, ZONG Renli, et al. Influence of stiffness of arm positioning rubber node on vehicle dynamic performance of high-speed EMU[J]. China Railway Science, 2021, 42(4): 120-128. [7] 滕万秀,罗仁,石怀龙,等. 高寒动车组−40 ℃环境下动力学性能[J]. 机械工程学报,2019,55(4): 148-153. doi: 10.3901/JME.2019.04.148TENG Wanxiu, LUO Ren, SHI Huailong, et al. Dynamics behaviour of high-speed train at the low temperature of −40 ℃[J]. Journal of Mechanical Engineering, 2019, 55(4): 148-153. doi: 10.3901/JME.2019.04.148 [8] 罗仁,李然,胡俊波,等. 考虑随机参数的高速列车动力学分析[J]. 机械工程学报,2015,51(24): 90-96. doi: 10.3901/JME.2015.24.090LUO Ren, LI Ran, HU Junbo, et al. Dynamic analysis of high-speed train with stochastic parameters[J]. Journal of Mechanical Engineering, 2015, 51(24): 90-96. doi: 10.3901/JME.2015.24.090 [9] QI Y Y, DAI H Y. Influence of motor harmonic torque on wheel wear in high-speed trains[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2020, 234(1): 32-42. doi: 10.1177/0954409719830808 [10] 侯茂锐,陈秉智,成棣,等. 两种典型动车组车轮磨耗演变规律及其动力学影响研究[J]. 机械工程学报,2022,58(4): 191-201. doi: 10.3901/JME.2022.04.191HOU Maorui, CHEN Bingzhi, CHENG Di, et al. Two typical wheel wear evolution characteristics and its influence on dynamic performance of high-speed EMU[J]. Journal of Mechanical Engineering, 2022, 58(4): 191-201. doi: 10.3901/JME.2022.04.191 [11] SANG H T, ZENG J, QI Y Y, et al. Study on wheel wear mechanism of high-speed train in accelerating conditions[J]. Wear, 2023, 516/517: 204597.1-204597.1-5. [12] LI Y Y, REN Z S, ENBLOM R, et al. Wheel wear prediction on a high-speed train in China[J]. Vehicle System Dynamics, 2020, 58(12): 1839-1858. doi: 10.1080/00423114.2019.1650941 [13] 孙丽霞,李晓峰,胡晓依,等. 高速动车组车轮磨耗对轮轨接触关系及车辆动力学性能的影响[J]. 中国铁道科学,2020,41(6): 117-126.SUN Lixia, LI Xiaofeng, HU Xiaoyi, et al. Influence of wheel wear on wheel-rail contact relationship and vehicle dynamic performance of high-speed EMU[J]. China Railway Science, 2020, 41(6): 117-126. [14] 肖乾,周前哲,程玉琦,等. 高速列车车轮磨耗型面特征提取及参数化描述方法研究[J]. 机械工程学报,2023,59 (14) :245-253.XIAO Qian, ZHOU Qianzhe, CHENG Yuqi, et al. Study on extraction of wheel profile wear characteristics and curve parameterization description of high-speed train wheels[J]. Journal of Mechanical Engineering,2023,59 (14) :245-253. [15] YE Y G, HECHT M. Wear concentration index: an alternative to the target T-gamma in railway wheel profile optimization[C]//The IAVSD International Symposium on Dynamics of Vehicles on Roads and Tracks. Cham: Springer, 2022: 522-532. [16] 宋志坤,任海星,胡晓依,等. 动车组车轮多边形磨耗发展历程模拟及车轮粗糙度的影响[J]. 铁道学报,2021,43(6): 23-28.SONG Zhikun, REN Haixing, HU Xiaoyi, et al. Research on development process simulation and influencing factors of polygonal wear of high-speed train wheels[J]. Journal of the China Railway Society, 2021, 43(6): 23-28. [17] YE Y G, ZHU B, HUANG P, et al. OORNet: a deep learning model for on-board condition monitoring and fault diagnosis of out-of-round wheels of high-speed trains[J]. Measurement, 2022, 199: 111268.1-111268.60. [18] CUI X L, BAO P Y, LI T, et al. Research on the failure mechanism of elastic strip fracture in corrugated sections of metros[J]. Engineering Failure Analysis, 2023, 143: 106837.1-106837.12. [19] QI Y Y, DAI H Y, GAN F, et al. Optimization of rail profile design for high-speed lines based on Gaussian function correction method[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2023: 095440972311525.1-095440972311525.11. [20] 杨麒陆,王平. WJ-7型高速铁路扣件胶垫刚度温变性的测试与分析[J]. 中国铁路,2017(8): 58-63.YANG Qilu, WANG Ping. Tests and analysis of rubber pad stiffness of WJ-7 HSR fastening against temperature changes[J]. China Railway, 2017(8): 58-63. [21] 中华人民共和国国家市场监督管理总局,中国国家标准化管理委员会. 机车车辆动力学性能评定及试验鉴定规范:GB/T 5599—2019[S]. 北京:中国标准出版社,2019. [22] 石怀龙,罗仁,曾京. 国内外高速列车动力学评价标准综述[J]. 交通运输工程学报,2021,21(1): 36-58.SHI Huailong, LUO Ren, ZENG Jing. Review on domestic and foreign dynamics evaluation criteria of high-speed train[J]. Journal of Traffic and Transportation Engineering, 2021, 21(1): 36-58. [23] 黄彩虹,罗仁,曾京,等. 系统参数对高速列车车轮踏面凹陷磨耗的影响[J]. 交通运输工程学报,2016,16(3): 55-62.HUANG Caihong, LUO Ren, ZENG Jing, et al. Effect of system parameters on tread-hollow wear of high-speed train wheels[J]. Journal of Traffic and Transportation Engineering, 2016, 16(3): 55-62. [24] 祁亚运,戴焕云,干锋,等. 高速动车组车轮偏磨影响因素与限值研究[J]. 表面技术,2023,52(5): 51-60.QI Yayun, DAI Huanyun, GAN Feng, et al. Influencing factors and limits of asymmetrical wheel wear of high-speed EMUs[J]. Surface Technology, 2023, 52(5): 51-60. [25] JENDEL T. Prediction of wheel profile wear— comparisons with field measurements[J]. Wear, 2002, 253(1/2): 89-99. [26] TUNNA J, SINCLAIR J, PEREZ J. The development of a wheel wear and rolling contact fatigue model[J]. Engineering Materials Science, 2007, 9: 106951664.1-106951664.12. -

下载:

下载: