Multi-Objective Optimization for Flywheel Motors Based on Parameter Priority Division

-

摘要:

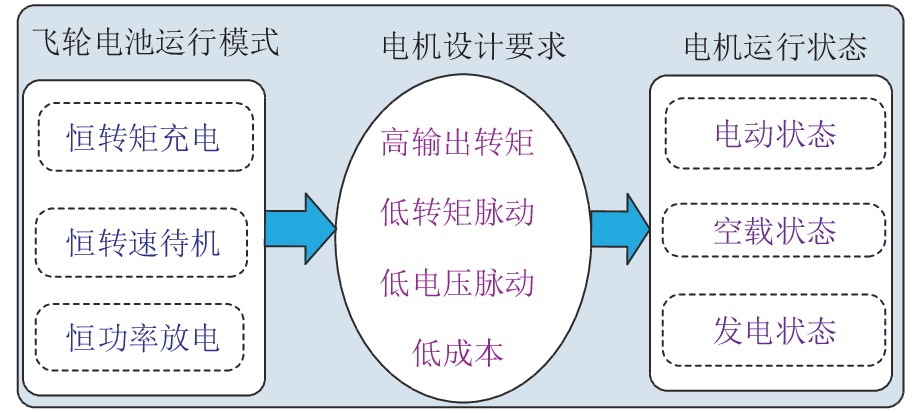

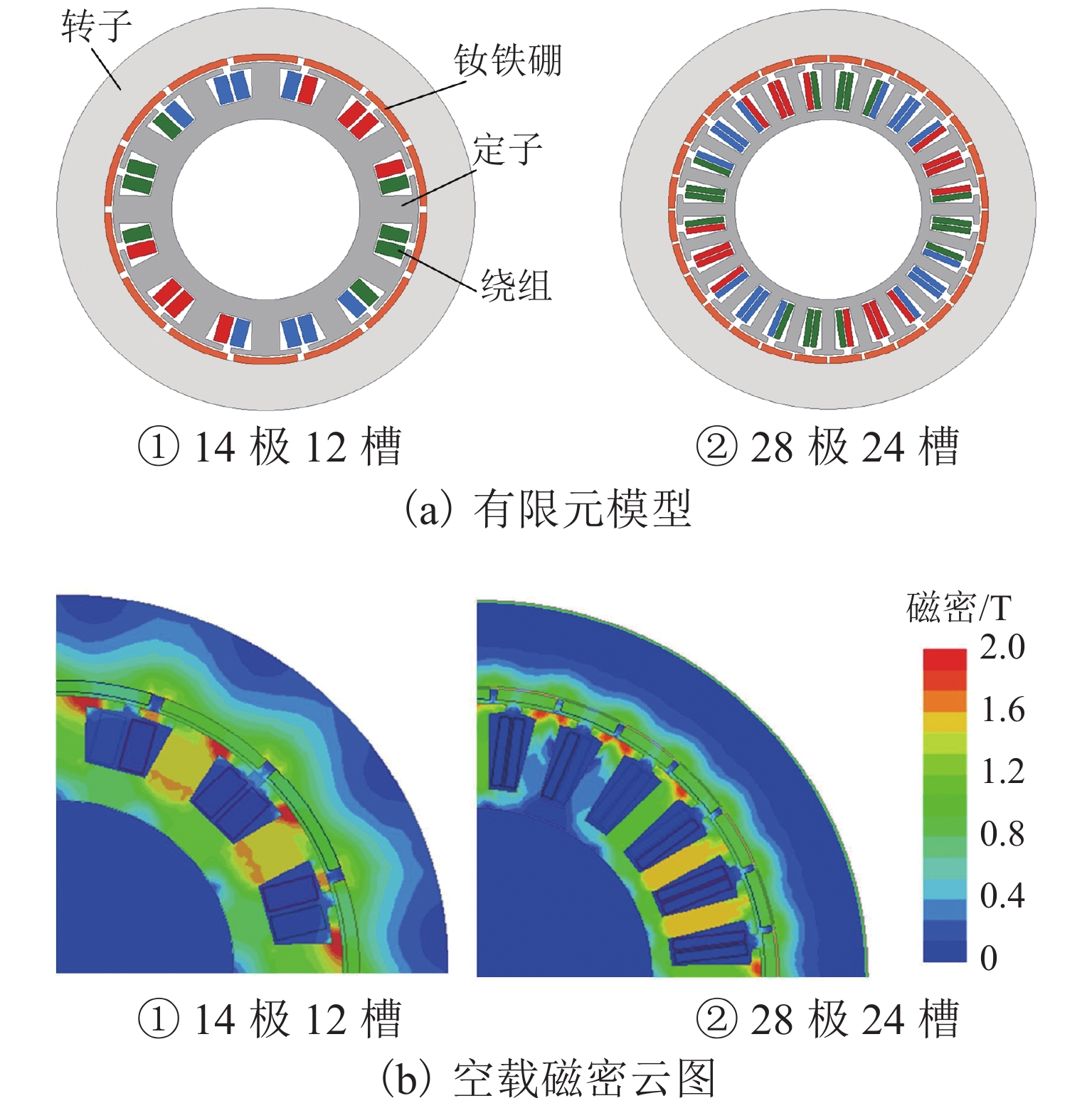

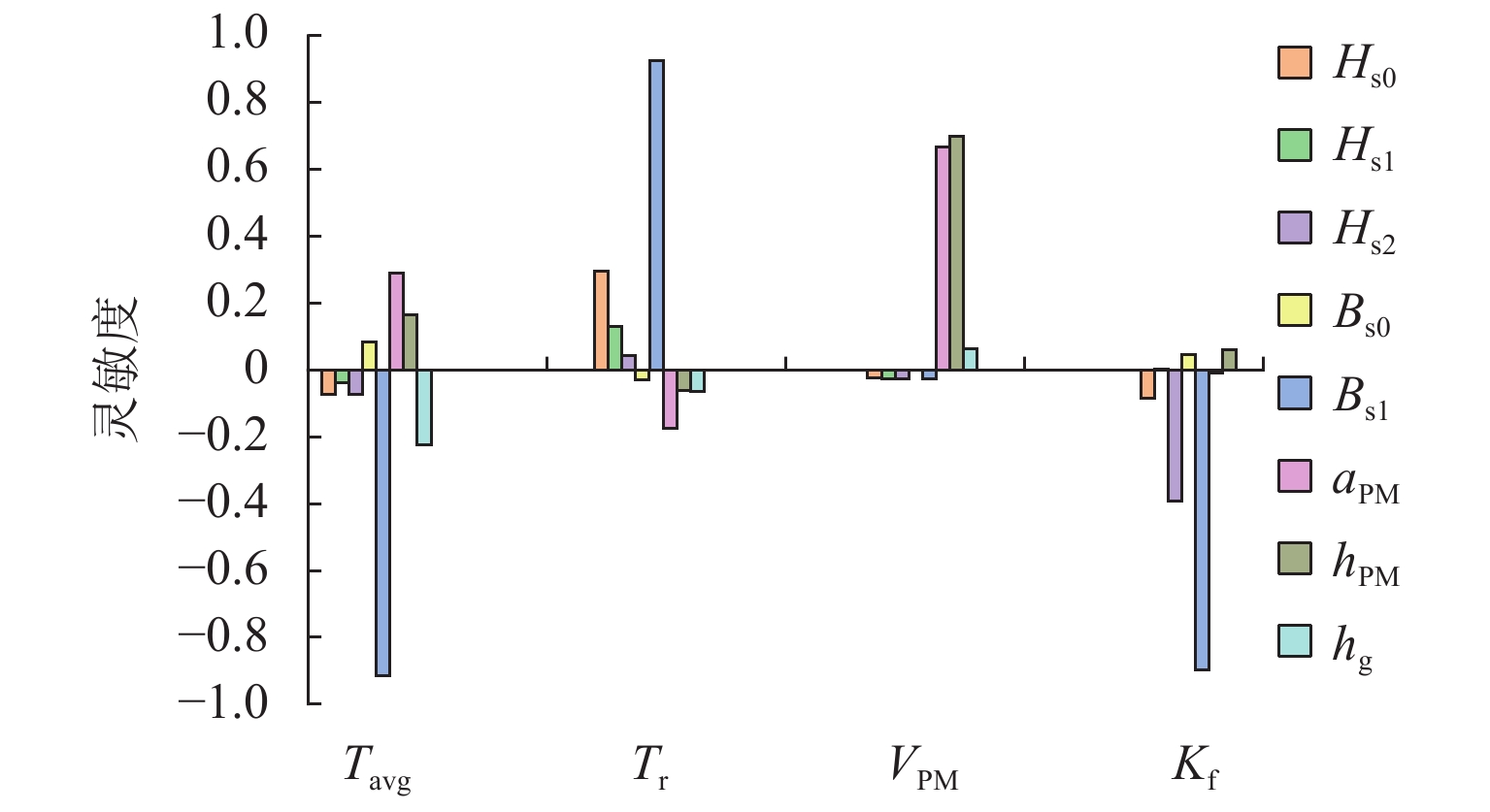

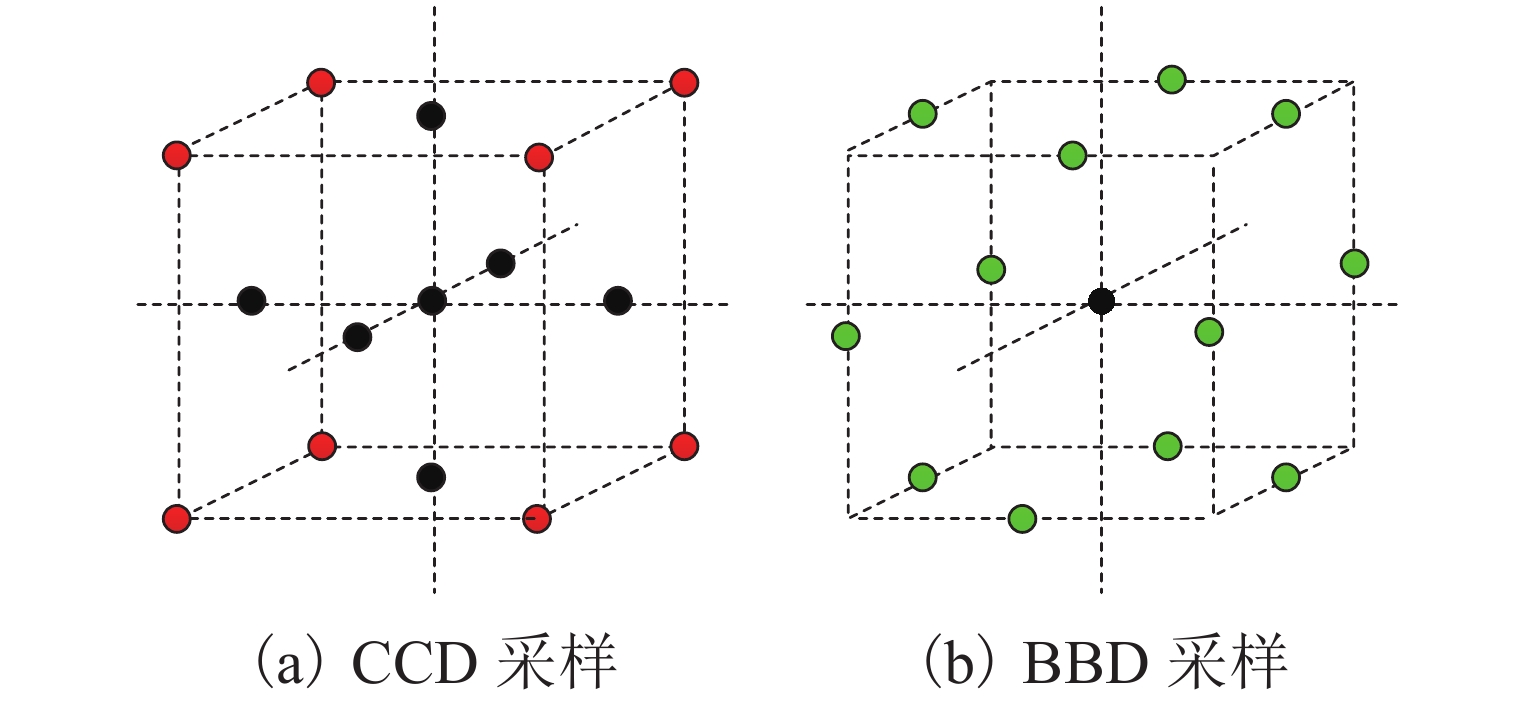

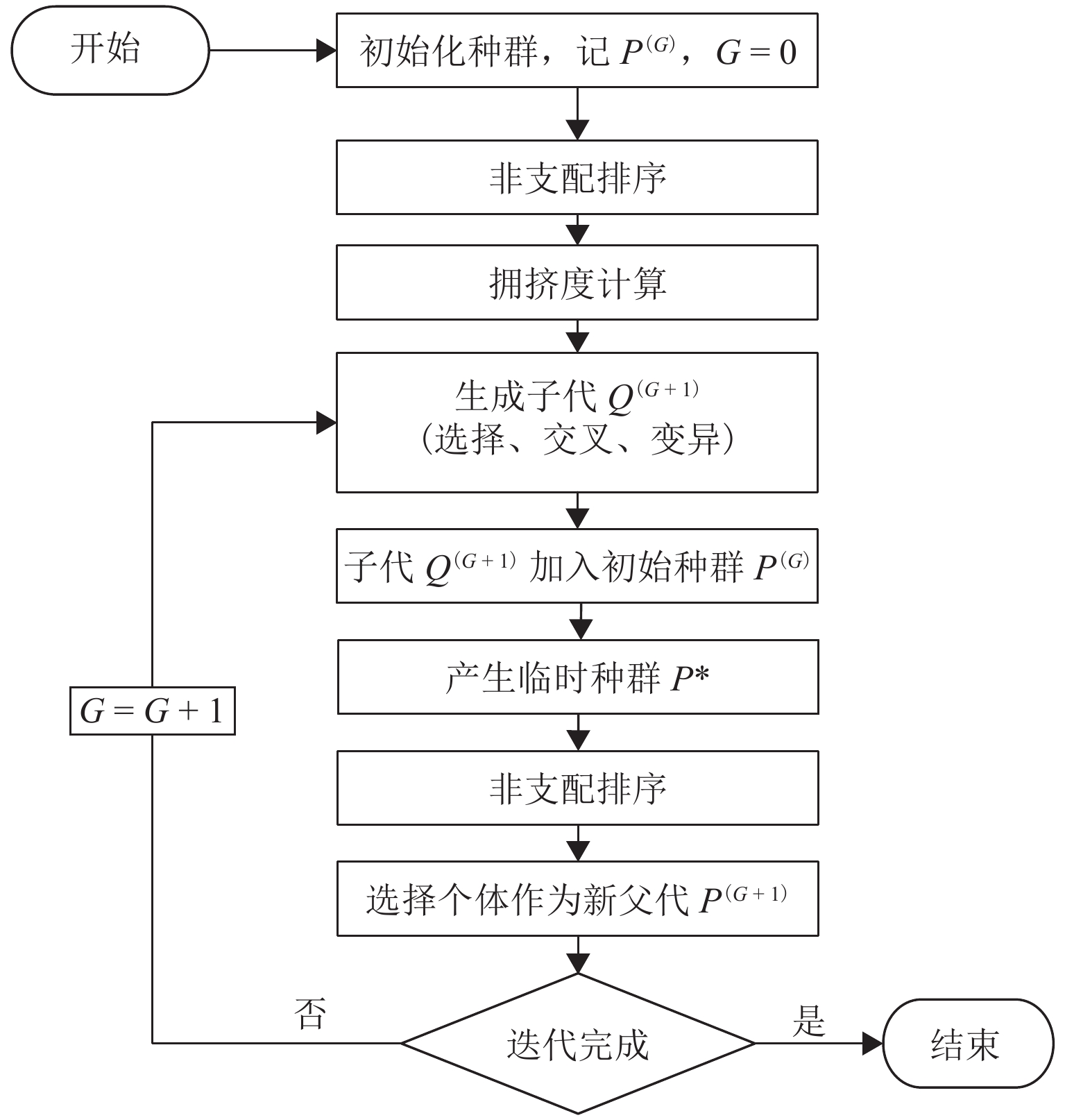

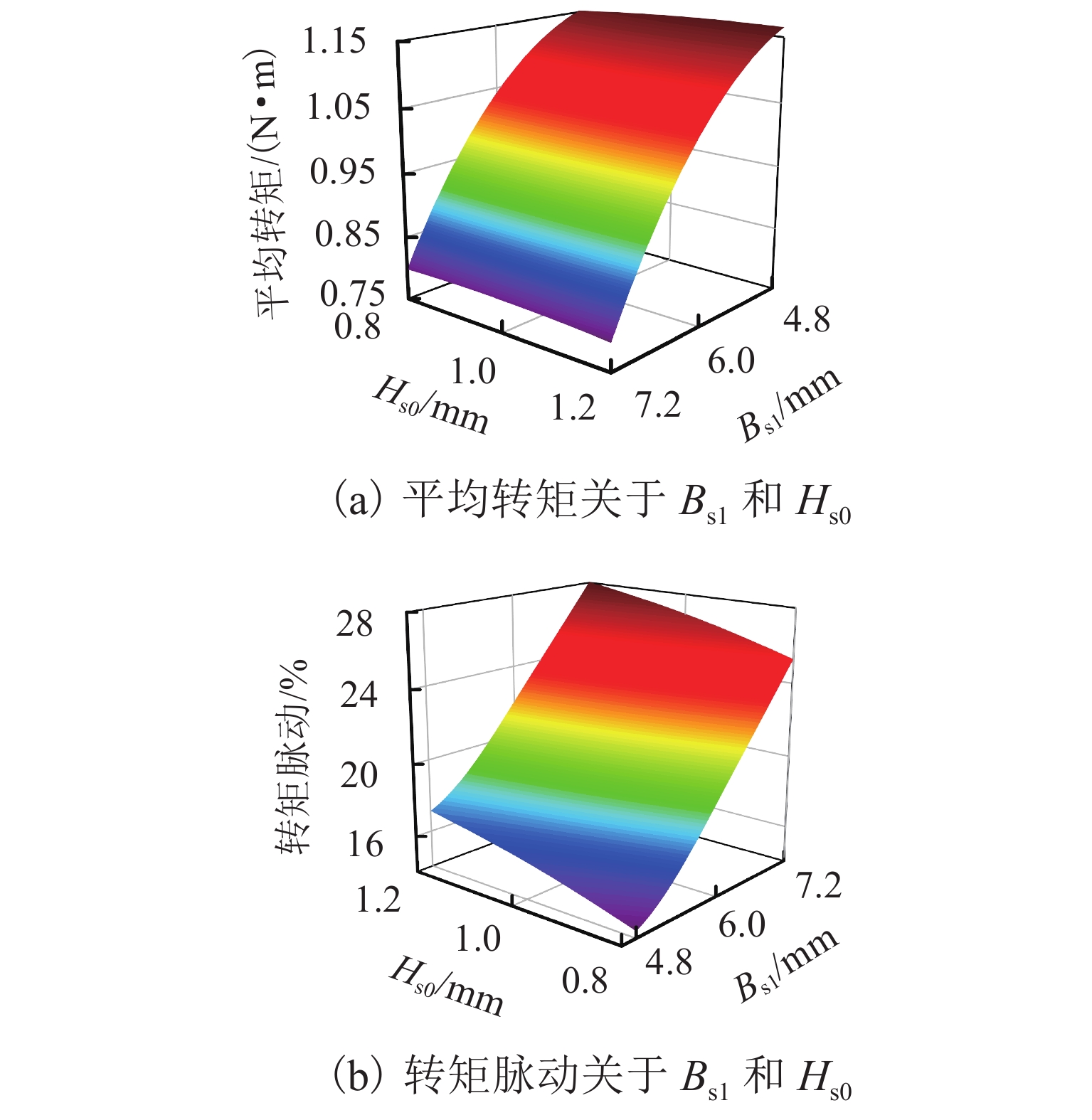

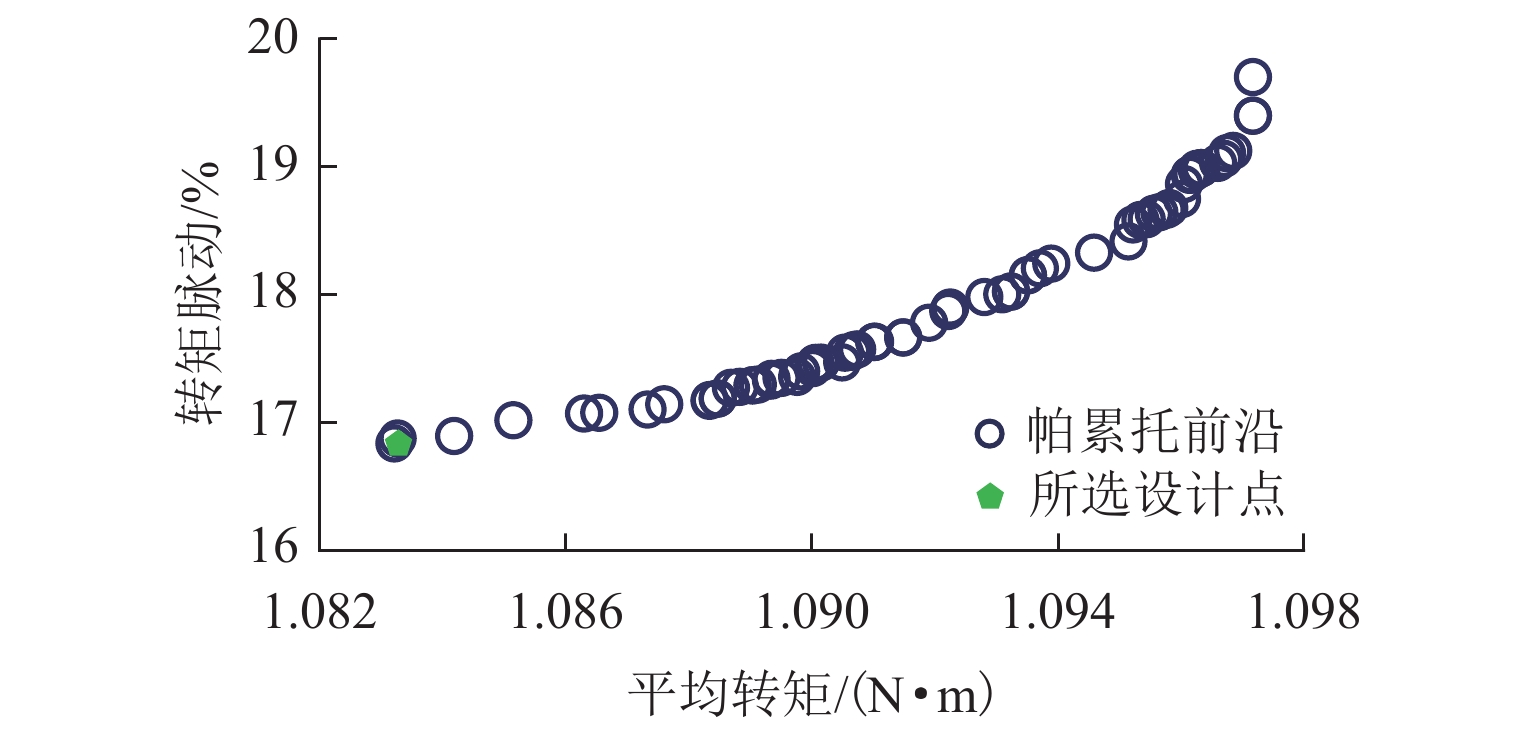

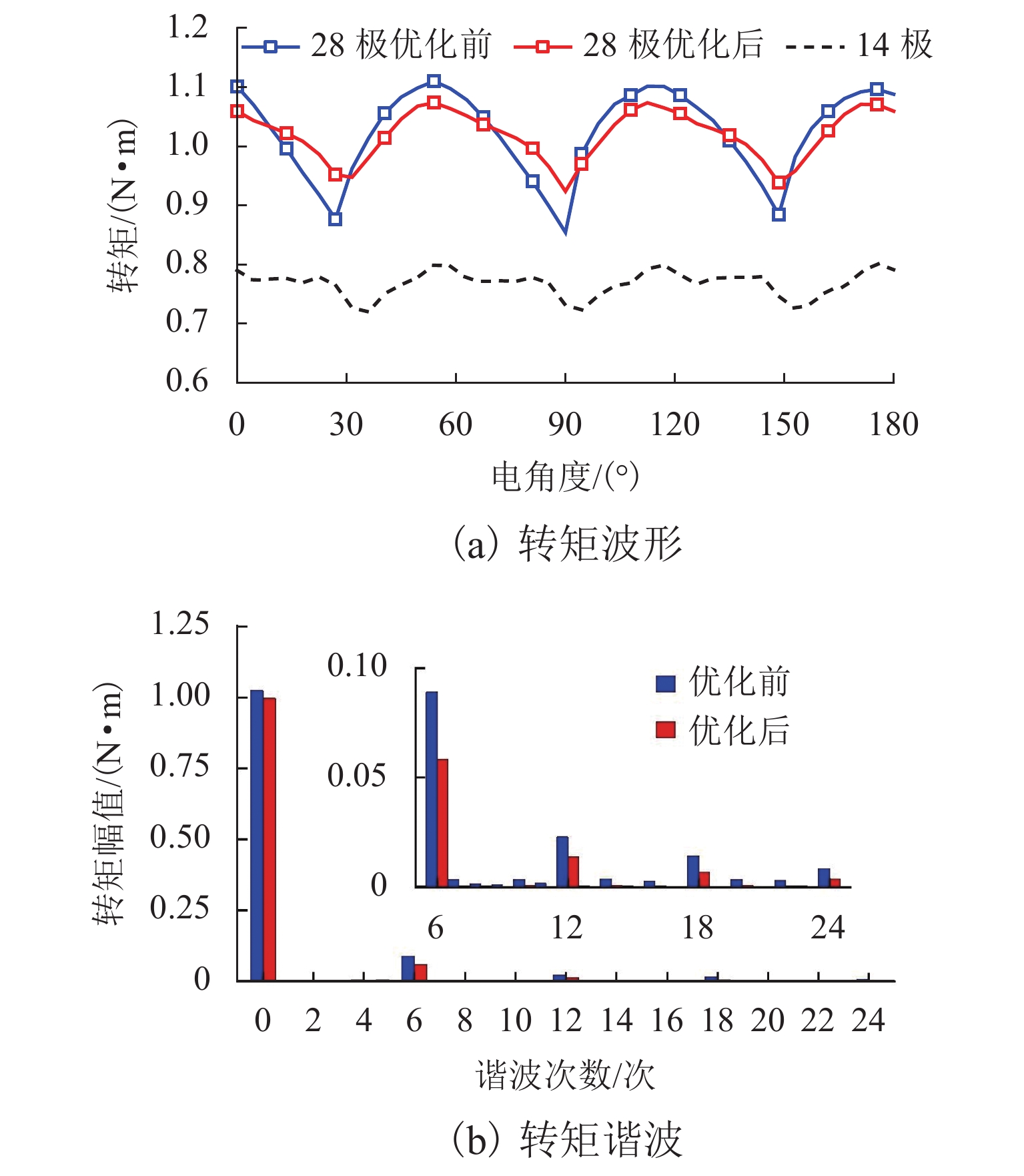

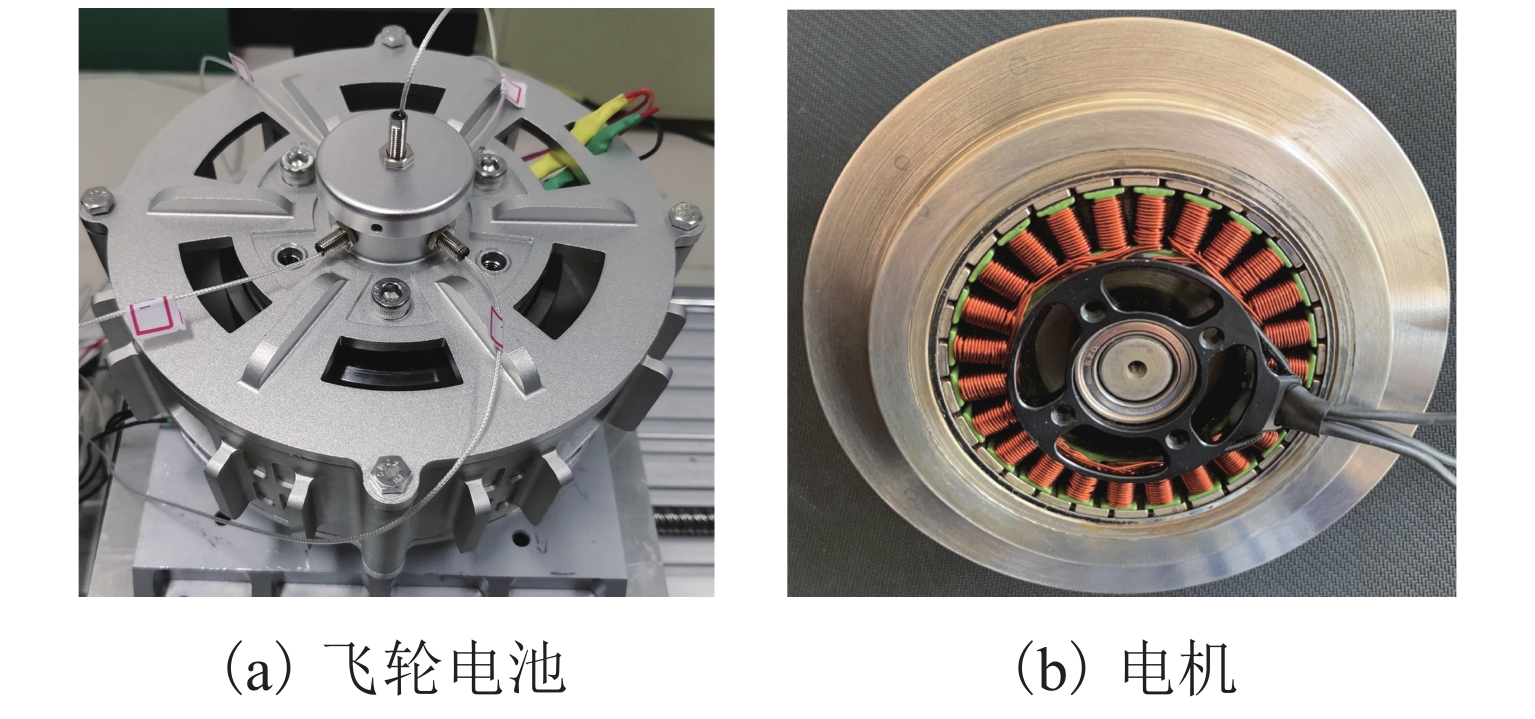

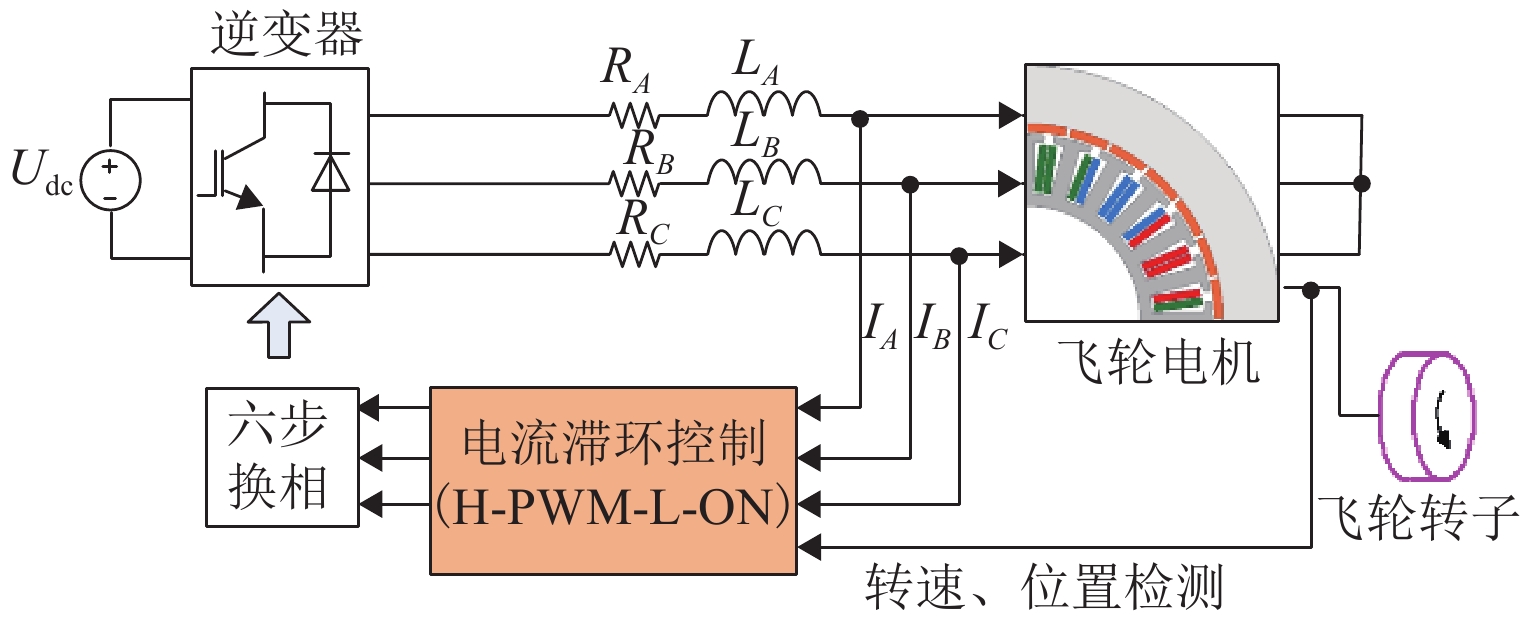

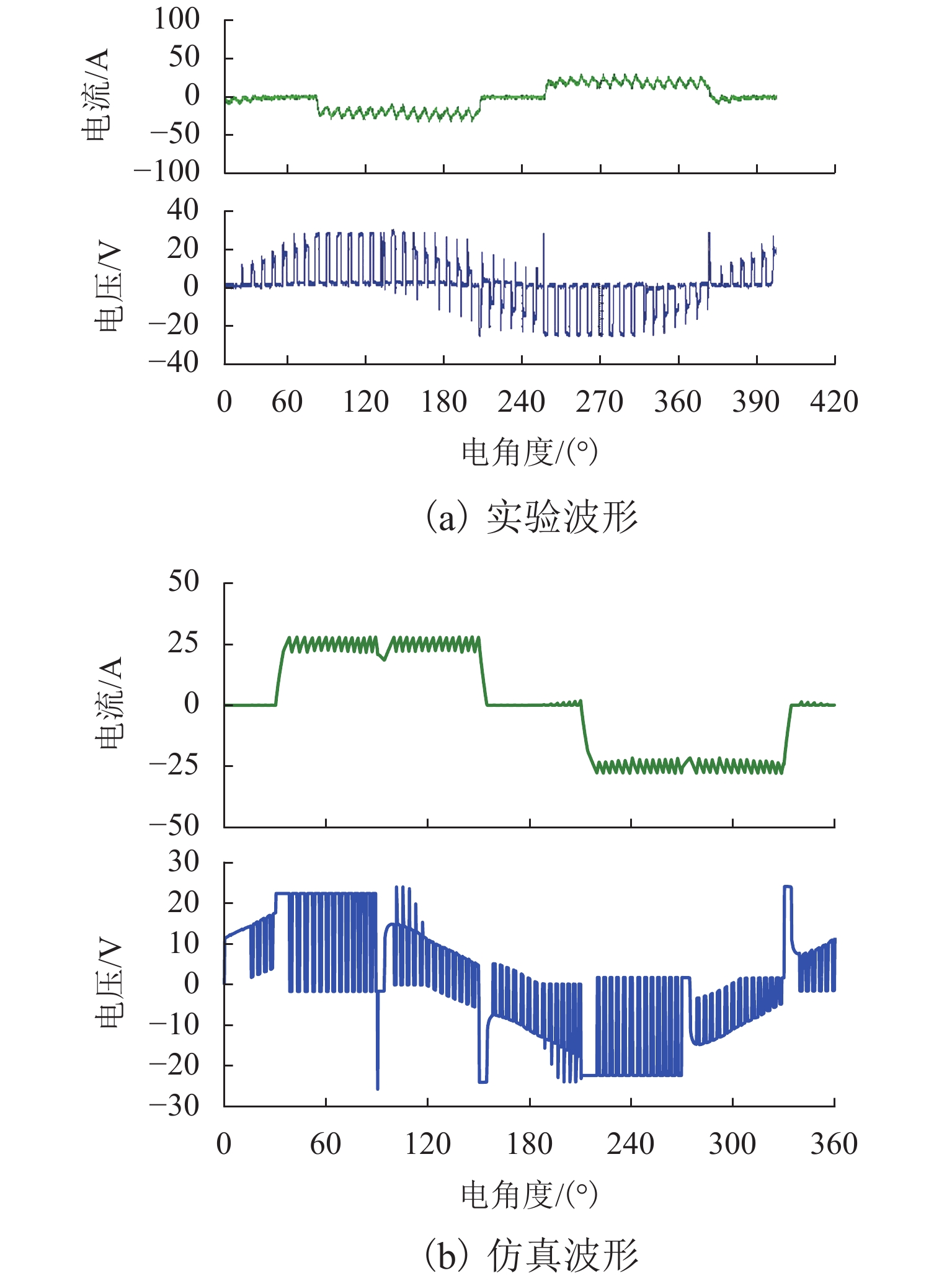

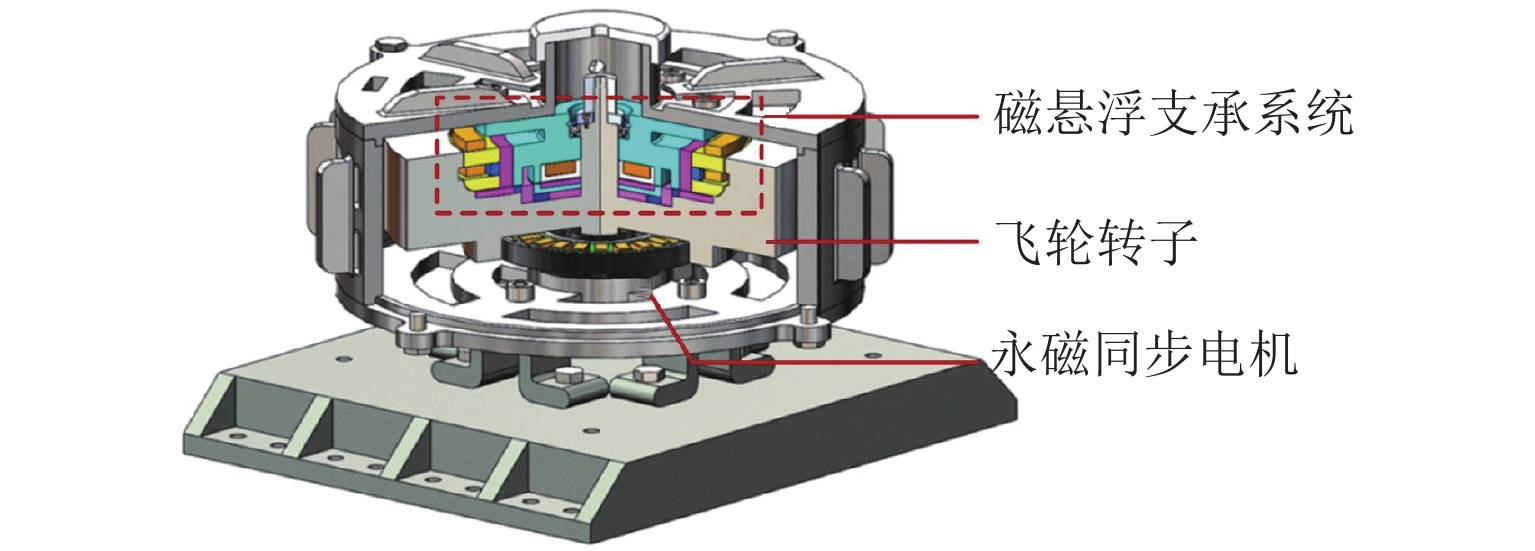

为改善电机转矩性能,同时降低永磁材料成本,首先,根据飞轮电池的运行模式,提出飞轮电机的设计要求,并选取输出转矩、转矩脉动和永磁体用量为设计目标;在此基础上,采用等效磁路法和有限元法计算电机的主要尺寸和性能,同时确定合适的槽极配合以及初始结构参数;其次,使用相关系数法分析该电机各结构参数与优化目标之间的相关性,并合理划分转子尺寸和定子尺寸的优先级;最后,采用有限元代理模型和多目标优化算法(非支配排序遗传算法Ⅱ,NSGA-Ⅱ)相结合的方法对设计参数进行逐级寻优,并通过场路联合仿真和样机实验进行验证. 研究结果表明:采用参数优先级划分的方式可以减少优化过程中数据点的采样,缩短了整个过程中有限元分析的时间;优化后,电机反电势梯形化程度更高,转矩脉动减小了40%,永磁体用量降低了8%.

Abstract:This paper aims to improve the torque performance of a flywheel motor and reduce its permanent magnet cost. Firstly, according to the operating mode of the flywheel battery, the design requirements of the flywheel motor were proposed, and the output torque, torque ripple, and consumption of permanent magnets were selected as the design objectives. On this basis, the equivalent magnetic circuit method and finite element method were used to calculate the main size and performance of the motor, and the appropriate number of slots and poles and initial structural parameters were determined. Secondly, the correlation coefficient method was utilized to analyze the correlation between the structural parameters of the motor and the optimization objectives, and the priority of rotor sizes and stator sizes was divided reasonably. Finally, the finite element surrogate model and the multi-objective optimization algorithm, namely the non-dominated sorting genetic algorithm Ⅱ (NSGA-Ⅱ) were used to optimize the design parameters step by step, and the correctness of optimization results was verified by the field-circuit co-simulation method and prototype experiment. The results show that the proposed method of parameter priority division can reduce the sampling of data points in the optimization process and shorten the time of finite element analysis in the whole process. After optimization, the back electromotive force of the motor is more trapezoidal. The torque ripple is reduced by 40%, and the consumption of permanent magnets is reduced by 8%.

-

表 1 SPMSM主要尺寸参数

Table 1. Main size parameters of SPMSM

参数 电机 12 极 14 槽 24 极 28 槽 转速/(r·min−1) 4000 驱动方式 无刷直流 有效轴长/mm 8 转子外径/mm 100 定子外径/mm 73 定子内径/mm 40 气隙长度/mm 0.5 永磁体用量/kg 0.02 导体线径/mm 0.6 (8 股并绕) 电流密度/(A·mm−2) 8 槽满率/% 75 槽总面积/mm2 912 1248 每相串联匝数/匝 36 48 反电势平均值/V 6.52 8.70 输出转矩/(N·m) 0.78 1.03 表 2 电机设计变量初始值和优化范围

Table 2. Initial value and optimal ranges of motor design variables

mm 设计变量 初值 范围 Hs0 1.0 [0.8,1.2] Hs1 0.5 [0.4,0.6] Hs2 10 [8,12] Bs0 2.0 [1.6,2.4] Bs1 6.0 [4.8,7.2] aPM 0.90 [0.64,0.96] hPM 1.6 [1.2,1.8] hg 0.5 [0.2,0.8] 表 3 参数优先级

Table 3. Priority of parameters

优先级 目标 参数变量 优先级 1 Tavg, Tr Hs0,Hs1,Hs2,Bs1 优先级 2 Tavg,Tr,VPM aPM,hPM,hg 表 4 NSGA-Ⅱ算法的参数设定值

Table 4. Parameter setting values of NSGA-II algorithm

参数 设定值 初始种群/个 100 迭代数目/个 80 交叉概率/% 90 变异概率/% 5 最大迭代次数/次 20 最大允许帕累托百分比/% 70 表 5 优先级1优化结果

Table 5. Optimization results in in priority 1

设计变量 初始点 优化结果 Hs0/mm 1.0 0.8 Hs1/mm 0.5 0.4 Hs2/mm 10.0 11.9 Bs1/mm 6.00 5.58 Tavg /(N·m) 1.04 1.08 Tr/% 20.9 16.1 Kf/% 76 75 表 6 优先级2优化结果

Table 6. Optimization results in priority 2

设计变量 优先级 1 结果 优先级 2 优化结果 aPM /mm 0.9 0.8 hPM/mm 1.60 1.25 hg/mm 0.5 0.6 Tavg/(N·m) 1.08 1.02 Tr/% 16.1 14.7 VPM /mm3 2430 2234 -

[1] 张维煜,张林东,于焰均. 磁悬浮支承-飞轮系统稳定运行关键技术综述[J]. 西南交通大学学报,2022,57(3): 627-639.ZHANG Weiyu, ZHANG Lindong, YU Yanjun. Review on key technologies of stable operation for magnetic suspension support-flywheel system[J]. Journal of Southwest Jiaotong University, 2022, 57(3): 627-639. [2] 邓自刚,刘宗鑫,李海涛,等. 磁悬浮列车发展现状与展望[J]. 西南交通大学学报,2022,57(3): 455-474,530.DENG Zigang, LIU Zongxin, LI Haitao, et al. Development status and prospect of maglev train[J]. Journal of Southwest Jiaotong University, 2022, 57(3): 455-474,530. [3] LIU K, YIN M, HUA W, et al. Design and optimization of an external rotor ironless BLDCM used in a flywheel energy storage system[J]. IEEE Transactions on Magnetics, 2018, 54(11): 1-5. [4] LIU Z Q, WANG K, LI F. Design and analysis of permanent magnet homopolar machine for flywheel energy storage system[J]. IEEE Transactions on Magnetics, 2019, 55(7): 8105706.1-8105706.6. [5] 汤平华,漆亚梅,黄国辉,等. 定子无铁心飞轮电机绕组涡流损耗分析[J]. 电工技术学报,2010,25(3): 27-32.TANG Pinghua, QI Yamei, HUANG Guohui, et al. Eddy Current loss analysis of ironless flywheel electric machine’s winding[J]. Transactions of China Electrotechnical Society, 2010, 25(3): 27-32. [6] 付兴贺,江政龙,吕鸿飞,等. 电励磁同步电机无刷励磁与转矩密度提升技术发展综述[J]. 电工技术学报,2022,37(7): 1689-1702.FU Xinghe, JIANG Zhenglong, LÜ Hongfei, et al. Review of the blushless excitation and torque density improvement in wound field synchronous motors[J]. Transactions of China Electrotechnical Society, 2022, 37(7): 1689-1702. [7] LIU G H, ZENG Y, ZHAO W X, et al. Permanent magnet shape using analytical feedback function for torque improvement[J]. IEEE Transactions on Industrial Electronics, 2018, 65(6): 4619-4630. doi: 10.1109/TIE.2017.2772142 [8] 胡鹏飞,王东,靳栓宝,等. 弓形磁极永磁电机谐波削极技术的优化研究[J]. 中国电机工程学报,2020,40(18): 5987-5997.HU Pengfei, WANG Dong, JIN Shuanbao, et al. Research on the optimization of harmonic pole shaping technologies for arcuate pole permanent magnet motors[J]. Proceedings of the CSEE, 2020, 40(18): 5987-5997. [9] 赵品志,杨贵杰,李勇. 三次谐波注入式五相永磁同步电机转矩密度优化[J]. 中国电机工程学报,2010,30(33): 71-77.ZHAO Pinzhi, YANG Guijie, LI Yong. Torque density optimization for five-phase PMSM with third harmonic injection[J]. Proceedings of the CSEE, 2010, 30(33): 71-77. [10] 殷明,王森,陶侃凯,等. 双圈磁钢飞轮电机的设计及优化[J]. 飞控与探测,2020,3(2): 75-80.YIN Ming, WANG Sen, TAO Kankai, et al. Design and optimization of a double-circle permanent magnet motor used in reaction flywheel system[J]. Flight Control & Detection, 2020, 3(2): 75-80. [11] KIM K H, PARK H I, JANG S M, et al. Comparison of characteristics of double-sided permanent-magnet synchronous motor/generator according to magnetization patterns for flywheel energy storage system using an analytical method[J]. IEEE Transactions on Magnetics, 2015, 51(3): 1-4. [12] 罗成,张昆仑,王滢. 永磁电磁混合Halbach阵列电动悬浮的稳定性控制[J]. 西南交通大学学报,2022,57(3): 574-581.LUO Cheng, ZHANG Kunlun, WANG Ying. Stability control of electrodynamic suspension with permanent magnet and electromagnet hybrid Halbach array[J]. Journal of Southwest Jiaotong University, 2022, 57(3): 574-581. [13] ZHU X Y, WU W Q, QUAN L, et al. Design and multi-objective stratified optimization of a less-rare-earth hybrid permanent magnets motor with high torque density and low cost[J]. IEEE Transactions on Energy Conversion, 2019, 34(3): 1178-1189. doi: 10.1109/TEC.2018.2886316 [14] XU G H, ZHAO W X, LIU G H, et al. Torque performance improvement of consequent-pole PM motors with hybrid rotor configuration[J]. IEEE Transactions on Transportation Electrification, 2021, 7(3): 1561-1572. doi: 10.1109/TTE.2020.3041194 [15] 张邦富,程明,王飒飒,等. 基于改进型代理模型优化算法的磁通切换永磁直线电机优化设计[J]. 电工技术学报,2020,35(5): 1013-1021.ZHANG Bangfu, CHENG Ming, WANG Sasa, et al. Optimal design of flux-switching permanent magnet linear machine based on improved surrogate-based optimization algorithm[J]. Transactions of China Electrotechnical Society, 2020, 35(5): 1013-1021. [16] XU L, ZHAO W X, LIU G H, et al. Design optimization of a spoke-type permanent-magnet vernier machine for torque density and power factor improvement[J]. IEEE Transactions on Vehicular Technology, 2019, 68(4): 3446-3456. doi: 10.1109/TVT.2019.2902729 [17] 刘国海,王艳阳,陈前. 非对称V型内置式永磁同步电机的多目标优化设计[J]. 电工技术学报,2018,33(增2): 385-393.LIU Guohai, WANG Yanyang, CHEN Qian. Multi-objective optimization of an asymmetric V-shaped interior permanent magnet synchronous motor[J]. Transactions of China Electrotechnical Society, 2018, 33(S2): 385-393. [18] 赵玫,于帅,邹海林,等. 聚磁式横向磁通永磁直线电机的多目标优化[J]. 电工技术学报,2021,36(17): 3730-3740.ZHAO Mei, YU Shuai, ZOU Hailin, et al. Multi-objective optimization of transverse flux permanent magnet linear machine with the concentrated flux mover[J]. Transactions of China Electrotechnical Society, 2021, 36(17): 3730-3740. [19] 张河山,邓兆祥,妥吉英,等. 基于改进人工蜂群算法的轮毂电机多目标优化[J]. 西南交通大学学报,2019,54(4): 671-678.ZHANG Heshan, DENG Zhaoxiang, TUO Jiying, et al. Multi-objective optimum design for in-wheel motor based on improved artificial bee colony algorithm[J]. Journal of Southwest Jiaotong University, 2019, 54(4): 671-678. [20] 陈云云,朱孝勇,全力,等. 基于参数敏感度的双凸极永磁型双定子电机的优化设计和性能分析[J]. 电工技术学报,2017,32(8): 160-168. doi: 10.19595/j.cnki.1000-6753.tces.2017.08.019CHEN Yunyun, ZHU Xiaoyong, QUAN Li, et al. Parameter sensitivity optimization design and performance analysis of double-salient permanent-magnet double-stator machine[J]. Transactions of China Electrotechnical Society, 2017, 32(8): 160-168. doi: 10.19595/j.cnki.1000-6753.tces.2017.08.019 [21] LEI G, LIU C C, ZHU J G, et al. Techniques for multilevel design optimization of permanent magnet motors[J]. IEEE Transactions on Energy Conversion, 2015, 30(4): 1574-1584. doi: 10.1109/TEC.2015.2444434 [22] ZHAO W X, YAO T, XU L, et al. Multi-objective optimization design of a modular linear permanent-magnet vernier machine by combined approximation models and differential evolution[J]. IEEE Transactions on Industrial Electronics, 2021, 68(6): 4634-4645. doi: 10.1109/TIE.2020.2988233 [23] 李培强,李慧,李欣然. 基于灵敏度与相关性的综合负荷模型参数优化辨识策略[J]. 电工技术学报,2016,31(16): 181-188.LI Peiqiang, LI Hui, LI Xinran. Optimized identification strategy for composite load model parameters based on sensitivity and correlation analysis[J]. Transactions of China Electrotechnical Society, 2016, 31(16): 181-188. [24] SUN X D, SHI Z, LEI G, et al. Multi-objective design optimization of an IPMSM based on multilevel strategy[J]. IEEE Transactions on Industrial Electronics, 2021, 68(1): 139-148. doi: 10.1109/TIE.2020.2965463 [25] CROUX C, DEHON C. Influence functions of the Spearman and Kendall correlation measures[J]. Statistical Methods & Applications, 2010, 19(4): 497-515. [26] 黄允凯,周涛. 基于等效磁路法的轴向永磁电机效率优化设计[J]. 电工技术学报,2015,30(2): 73-79.HUANG Yunkai, ZHOU Tao. Efficiency optimization design of axial flux permanent magnet machines using magnetic equivalent circuit[J]. Transactions of China Electrotechnical Society, 2015, 30(2): 73-79. [27] 周扬,周瑾,张越,等. 基于RBF近似模型的磁悬浮轴承结构优化设计[J]. 西南交通大学学报,2022,57(3): 682-692.ZHOU Yang, ZHOU Jin, ZHANG Yue, et al. Optimum structural design of active magnetic bearing based on RBF approximation model[J]. Journal of Southwest Jiaotong University, 2022, 57(3): 682-692. [28] LIU G H, WANG Y Y, CHEN Q, et al. Multiobjective deterministic and robust optimization design of a new spoke-type permanent magnet machine for the improvement of torque performance[J]. IEEE Transactions on Industrial Electronics, 2020, 67(12): 10202-10212. doi: 10.1109/TIE.2019.2962472 [29] LI Y W, ZHU C S, WU L J, et al. Multi-objective optimal design of high-speed surface-mounted permanent magnet synchronous motor for magnetically levitated flywheel energy storage system[J]. IEEE Transactions on Magnetics, 2019, 55(7): 8202708.1-8202708.8. -

下载:

下载: