Adhesion Adaptability of Dual-Source-Powered Electric Multiple Unit on Qinghai−Xizang Line

-

摘要:

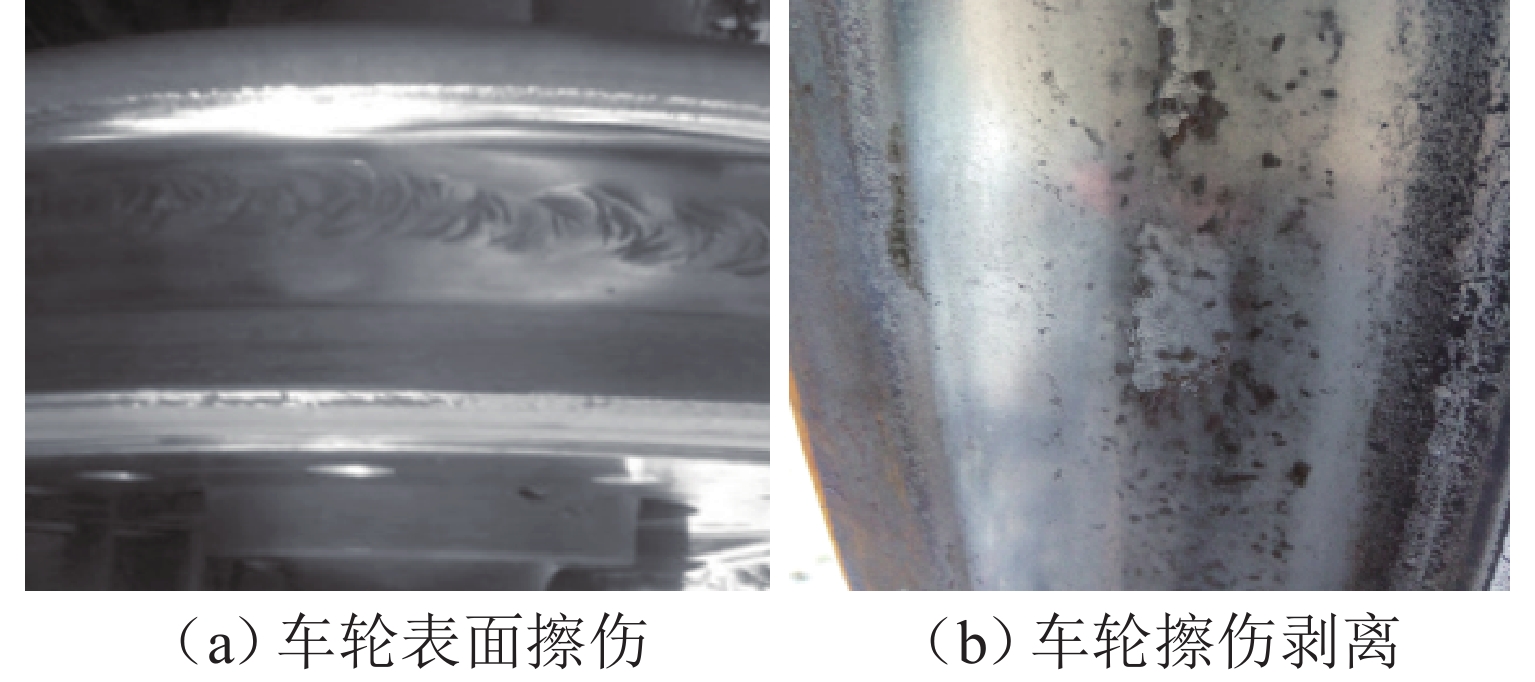

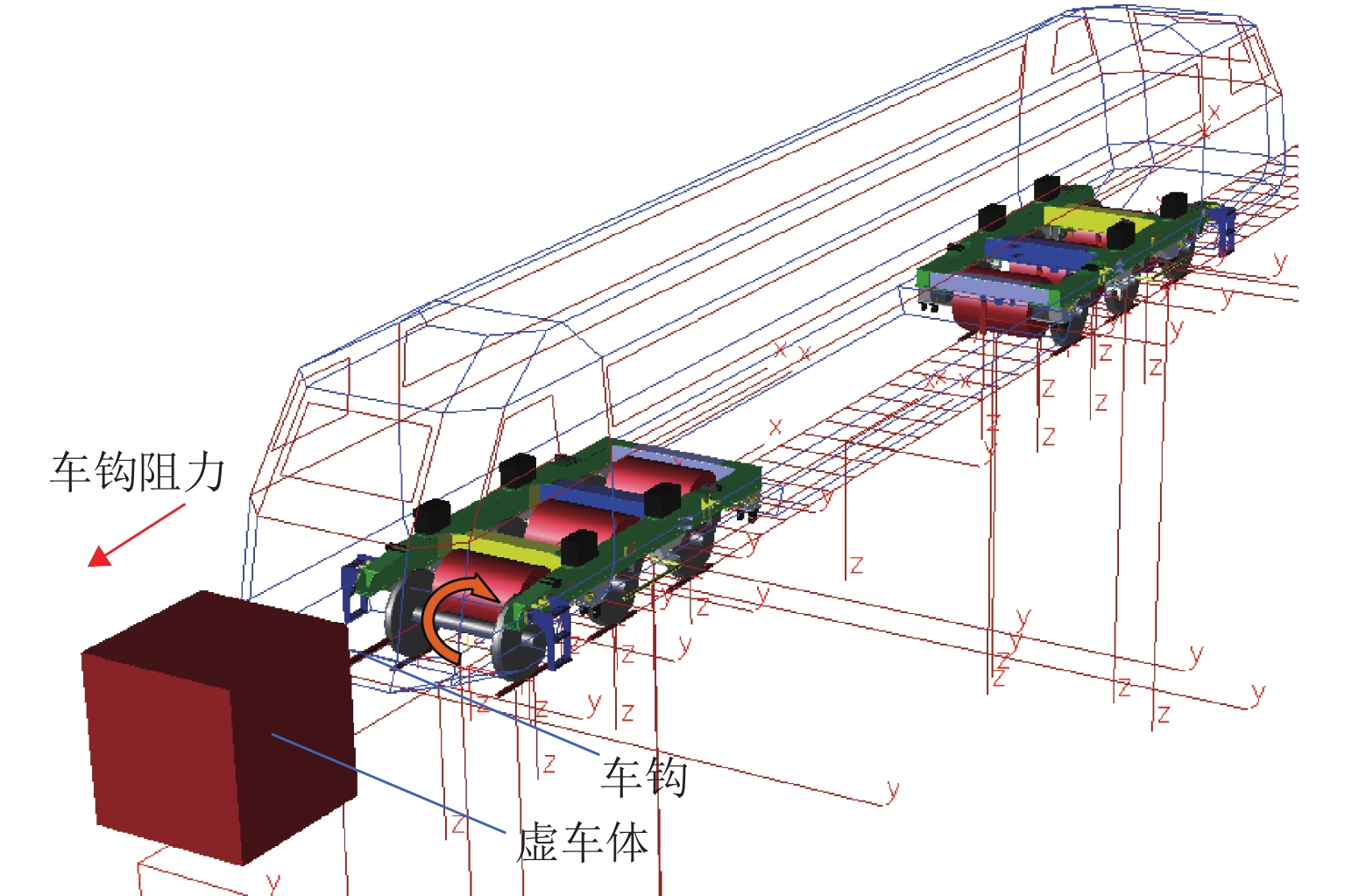

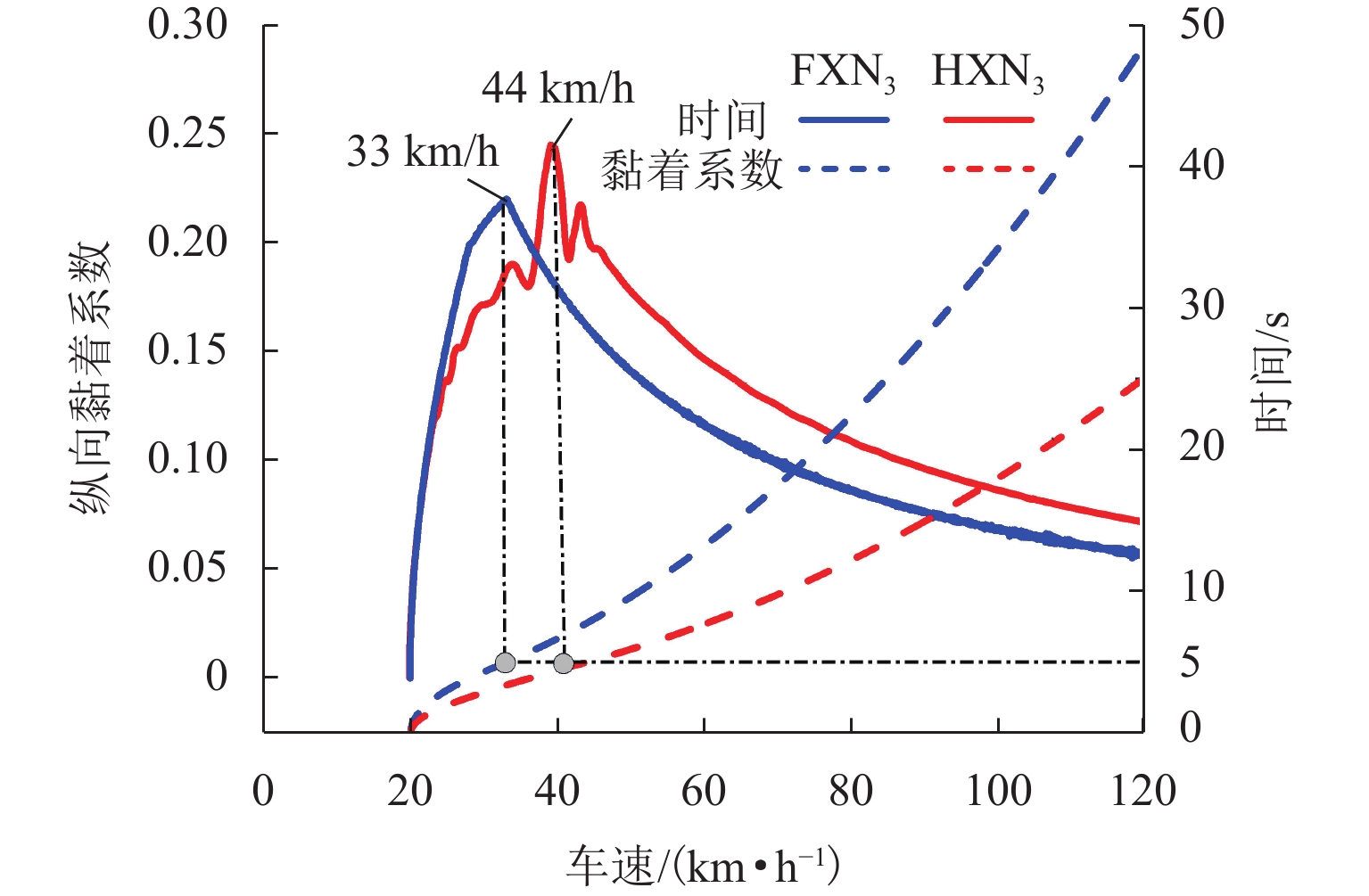

为了分析运行效率更高的双源动车组在青藏线(格尔木—拉萨段)运行的可行性,建立机车动力学模型并进行了验证;采用动力学方法研究了双源动车组机车(动车)和青藏线成熟运营的HXN3内燃机车在直线段、曲线段和坡道上的牵引黏着系数、牵引力、蠕滑率与速度之间的关系;通过对比2个机车的动力学响应,验证牵引工况下双源动车组的黏着特性. 通过分析可以发现:1) 机车的牵引黏着系数与机车的牵引力成正比,当车速在40~120 km/h时,双源动车组机车的黏着系数由0.19降低至0.09,黏着富裕度则由59.0%提高至85.7%;2) 在直线段和坡道情况下,双源动车组的黏着富裕度均大于HXN3机车,对适应恶劣外界环境引起的轮轨黏着下降能力更强,对高原环境的适应性更优;3) 曲线段,忽略结构引起的黏降差异,

R 300 m曲线时,双源动车组和HXN3型机车的黏降幅度分别为6.3%和6.8%,R 800 m曲线时,HXN3型机车曲线黏降幅度为3.0%,而双源动车组低于限值,可以保证有足够的黏着.Abstract:In order to analyze the feasibility of a dual-source-powered electric multiple unit (EMU) with enhanced operational efficiency on the Qinghai–Xizang Line (Golmud–Lhasa section), the dynamics model of EMU was established and verified. A dynamic method was adopted to study the relationship among the traction adhesion coefficients, traction force, creepage, and speed for the dual-source-powered EMU and the HXN3 internal combustion locomotive operating on the straight sections, curved sections, and ramps of the Qinghai–Xizang Line. The adhesion characteristics of dual-source-powered EMU under traction conditions were validated by comparing the dynamic responses of the two locomotives. The analysis finds that: 1) The traction adhesion coefficients of the locomotives are proportional to their traction force. Moreover, within the speed range of 40–120 km/h, the adhesion coefficient of the dual-source-powered EMU decreases from 0.19 to 0.09, while the adhesion affluence increases from 59.0% to 85.7%. 2) The adhesion affluence of the dual-source-powered EMU is superior to that of the HXN3 locomotive in both straight sections and ramps, thereby enhancing its ability to cope with low wheel-rail adhesion conditions in harsh external environments and exhibiting better adaptability in plateau environments. 3) In the curved section, by ignoring the structure-induced adhesion reduction difference, the adhesion reduction amplitudes of the dual-source-powered EMU and HXN3 locomotive are 6.3% and 6.8%, respectively, at

R 300 m curve. At theR 800 m curve, the HXN3 locomotive demonstrates an adhesion reduction amplitude of 3.0%, while the adhesion reduction amplitude of the dual-source-powered EMU is below the threshold value, ensuring sufficient adhesion.-

Key words:

- plateau railway /

- dual-source-powered /

- internal combustion locomotive /

- dynamic /

- traction adhesion

-

表 1 HXN3和FXN3机车主要技术参数

Table 1. Main technical parameters of HXN3 and FXN3 locomotives

序号 参数 HXN3 FXN3 1 轨距/mm 1435 1435 2 持续速度/(km·h−1) 23 28 3 定距/m 13.900 16.435 4 轴距/m 1.755/1.925 1.950/2.050 5 最大运用速度/(km·h−1) 120 160 6 柴油机装车功率/kW 3700 3500 7 起动牵引力/kN 620 245 8 持续牵引力/kN 598 200 9 牵引杆高度/m 0.725 0.685 10 牵引杆长度/m 1.238 1.350 表 2 HXN3和FXN3机车动力学参数(部分)

Table 2. Main dynamic parameters of HXN3 and FXN3 locomotives (part)

序号 参数 HXN3 FXN3 1 一系纵向刚度/(MN·m−1) 30.00 28.59 2 一系横向刚度/(MN·m−1) 0.800 3.588 3 一系垂向刚度/(MN·m−1) 0.838 2.320 4 二系纵向刚度(橡胶堆或

钢簧)/(MN·m−1)0.300 0.192 5 二系横向刚度/(MN·m−1) 0.200 0.192 6 二系垂向刚度/(MN·m−1) 7.700 0 0.5185 7 抗蛇形减振器/(kN·s·m−1) 16.5@0.01 14.2@0.01 8 二系横向减振器/(kN·s·m−1) 4.5@0.10 2.8@0.05 9 轴重/t 25 23 -

[1] 罗秀云,蒲云,陈尚云. 青藏铁路格拉段运输安全监控信息系统[J]. 西南交通大学学报,2005,40(5): 680-683.LUO Xiuyun, PU Yun, CHEN Shangyun. Transportation safety monitor information system for gulmud-lasa line in Qinghai—Tibet railway[J]. Journal of Southwest Jiaotong University, 2005, 40(5): 680-683. [2] 魏玉光,杨浩,韩学雷. 青藏铁路弹性运输能力理论[J]. 北京交通大学学报,2006,30(3): 15-18,33.WEI Yuguang, YANG Hao, HAN Xuelei. Elasticity transportation capacity theory of Qinghai—Tibet railway[J]. Journal of Beijing Jiaotong University, 2006, 30(3): 15-18,33. [3] 钱铭,张大勇,廖洪涛. 复兴号高原双源动力集中动车组关键技术[J]. 中国铁路,2022(6): 1-9.QIAN Ming, ZHANG Dayong, LIAO Hongtao. Key technologies of Fuxing Plateau dual-source power centralized EMU[J]. China Railway, 2022(6): 1-9. [4] 黄问盈,杨宁清,黄民. 青藏高原铁路机车轮周功率的探讨[J]. 中国铁道科学,2001,22(4): 8-15.HUANG Wenying, YANG Ningqing, HUANG Min. Study on locomotive output power at wheel rim for Qinghai—Tibet Plateau railway[J]. China Railway Science, 2001, 22(4): 8-15. [5] 王晨,罗世辉,樊慧,等. 高原机车悬挂方案对车辆振动特性的影响[J]. 振动 测试与诊断,2018,38(3): 583-589.WANG Chen, LUO Shihui, FAN Hui, et al. Influence of plateau locomotive suspension structure on vehicle vibration characteristics[J]. Journal of Vibration, Measurement & Diagnosis, 2018, 38(3): 583-589. [6] 伍赛特. 青藏铁路机车车辆选型及技术特点研究[J]. 现代制造技术与装备,2020(3): 13-14,17.WU Saite. Research on selection and technical characteristics of locomotive and rolling stock of Qinghai Tibet railway[J]. Modern Manufacturing Technology and Equipment, 2020(3): 13-14,17. [7] 申瑞源. 我国机车车辆技术的发展与展望[J]. 铁道学报,2019,41(1): 36-42.SHEN Ruiyuan. Development and prospect of rolling stock technology in China[J]. Journal of the China Railway Society, 2019, 41(1): 36-42. [8] 王佥. FXN3型客运内燃机车车体设计与分析[D]. 大连:大连理工大学,2019. [9] 赵鑫,温泽峰,王衡禹,等. 中国轨道交通轮轨滚动接触疲劳研究进展[J]. 交通运输工程学报,2021,21(1): 1-35.ZHAO Xin, WEN Zefeng, WANG Hengyu, et al. Research progress on wheel/rail rolling contact fatigue of rail transit in China[J]. Journal of Traffic and Transportation Engineering, 2021, 21(1): 1-35. [10] IMAI K, OHISHI K, SANO T, et al. Planning torque distribution control of rolling stock for fine anti-slip/skid re-adhesion control[J]. IEEJ Transactions on Industry Applications, 2010, 130(7): 890-901. doi: 10.1541/ieejias.130.890 [11] JOHNSON K L. The effect of a tangential contact force upon the rolling motion of an elastic sphere on a plane[J]. Journal of Applied Mechanics, 1958, 25(3): 339-346. doi: 10.1115/1.4011823 [12] BHASKAR A, JOHNSON K L, WOOD G D, et al. Wheel-rail dynamics with closely conformal contact Part 1: dynamic modelling and stability analysis[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 1997, 211(1): 11-26. doi: 10.1243/0954409971530860 [13] DOI H, MIYAMOTO T, NISHIYAMA Y, et al. A new experimental device to investigate creep forces between wheel and rail[J]. Wear, 2011, 271(1/2): 40-46. [14] ZHU Y, OLOFSSON U. An adhesion model for wheel-rail contact at the micro level using measured 3D surfaces[J]. Wear, 2014, 314(1/2): 162-170. [15] SPIRYAGIN M, LEE K S, YOO H H. Control system for maximum use of adhesive forces of a railway vehicle in a tractive mode[J]. Mechanical Systems and Signal Processing, 2008, 22(3): 709-720. doi: 10.1016/j.ymssp.2007.09.018 [16] TELLISKIVI T. Simulation of wear in a rolling–sliding contact by a semi-Winkler model and the Archard’s wear law[J]. Wear, 2004, 256(7/8): 817-831. [17] 陈光雄. 钢轨波磨预测模型验证工况的研究[J]. 西南交通大学学报,2022,57(5): 1017-1023,1054.CHEN Guangxiong. Study on validation conditions of rail corrugation prediction models[J]. Journal of Southwest Jiaotong University, 2022, 57(5): 1017-1023,1054. [18] 毕鑫,罗世辉,马卫华. 牵引力对机车车轮轮轨黏着性能的影响分析[J]. 铁道学报,2014,36(2): 18-24.BI Xin, LUO Shihui, MA Weihua. Analysis on influence of traction force on locomotive wheel-rail adhesion performance[J]. Journal of the China Railway Society, 2014, 36(2): 18-24. [19] POLACH O. Creep forces in simulations of traction vehicles running on adhesion limit[J]. Wear, 2005, 258(7/8): 992-1000. [20] TOMBERGER C, DIETMAIER P, SEXTRO W, et al. Friction in wheel–rail contact: a model comprising interfacial fluids, surface roughness and temperature[J]. Wear, 2011, 271(1/2): 2-12. [21] 曲天威,罗世辉,马卫华. 33 t轴重内燃机车方案及机车曲线黏着问题研究[J]. 铁道学报,2020,42(9): 39-48.QU Tianwei, LUO Shihui, MA Weihua. Study on diesel locomotive concepts with 33 t axle load and its curving adhesion problem[J]. Journal of the China Railway Society, 2020, 42(9): 39-48. [22] YAMASHITA M, SOEDA T. Development of re-adhesion control method considering axle-weight transfer of electric locomotive[J]. Quarterly Report of RTRI, 2011, 52(1): 7-12. doi: 10.2219/rtriqr.52.7 [23] 黄问盈. 铁道轮轨黏着系数[J]. 铁道机车车辆,2010,30(5): 17-25,33.HUANG Wenying. Railway wheel-rail adhesion coefficient[J]. Railway Locomotive & Car, 2010, 30(5): 17-25,33. [24] 王文健,刘启跃. 轮轨黏着行为与增黏[M]. 北京:科学出版社,2017. [25] 薛应花,丁军君,王利军,等. 面向川藏铁路的机车车辆运行基本阻力研究[J]. 机车电传动,2021(3): 67-72.XUE Yinghua, DING Junjun, WANG Lijun, et al. Research on the basic resistance of locomotives and rolling stocks in Sichuan—Tibet railway[J]. Electric Drive for Locomotives, 2021(3): 67-72. [26] 廖子平. HXN3高原型内燃机车轮对轮缘裂纹研究[J]. 技术与市场,2020,27(11): 14-17,20.LIAO Ziping. Study on wheel flange crack of HXN3 high prototype internal combustion engine wheel set[J]. Technology and Market, 2020, 27(11): 14-17,20. [27] 何华武,刘增杰,刁晓明,等. 既有线提速200 km/h平纵断面技术标准研究与验证[J]. 铁道学报,2007,29(2): 64-70.HE Huawu, LIU Zengjie, DIAO Xiaoming, et al. Study and validation of the technical standard for the plane and profile sections of existing lines with 200 km/h speed-raising[J]. Journal of the China Railway Society, 2007, 29(2): 64-70. -

下载:

下载: