Modeling and Analysis of High-Speed Maglev Electromagnets Based on Nonlinear Materials

-

摘要:

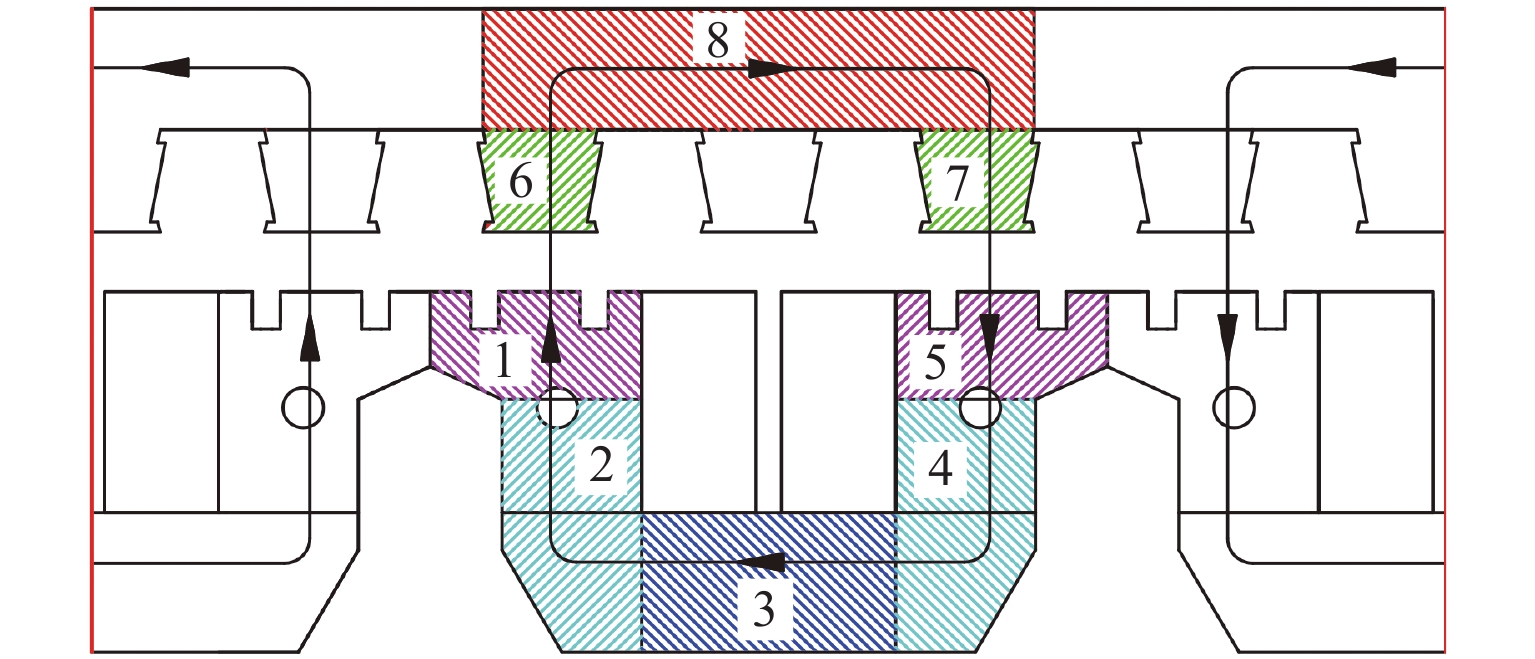

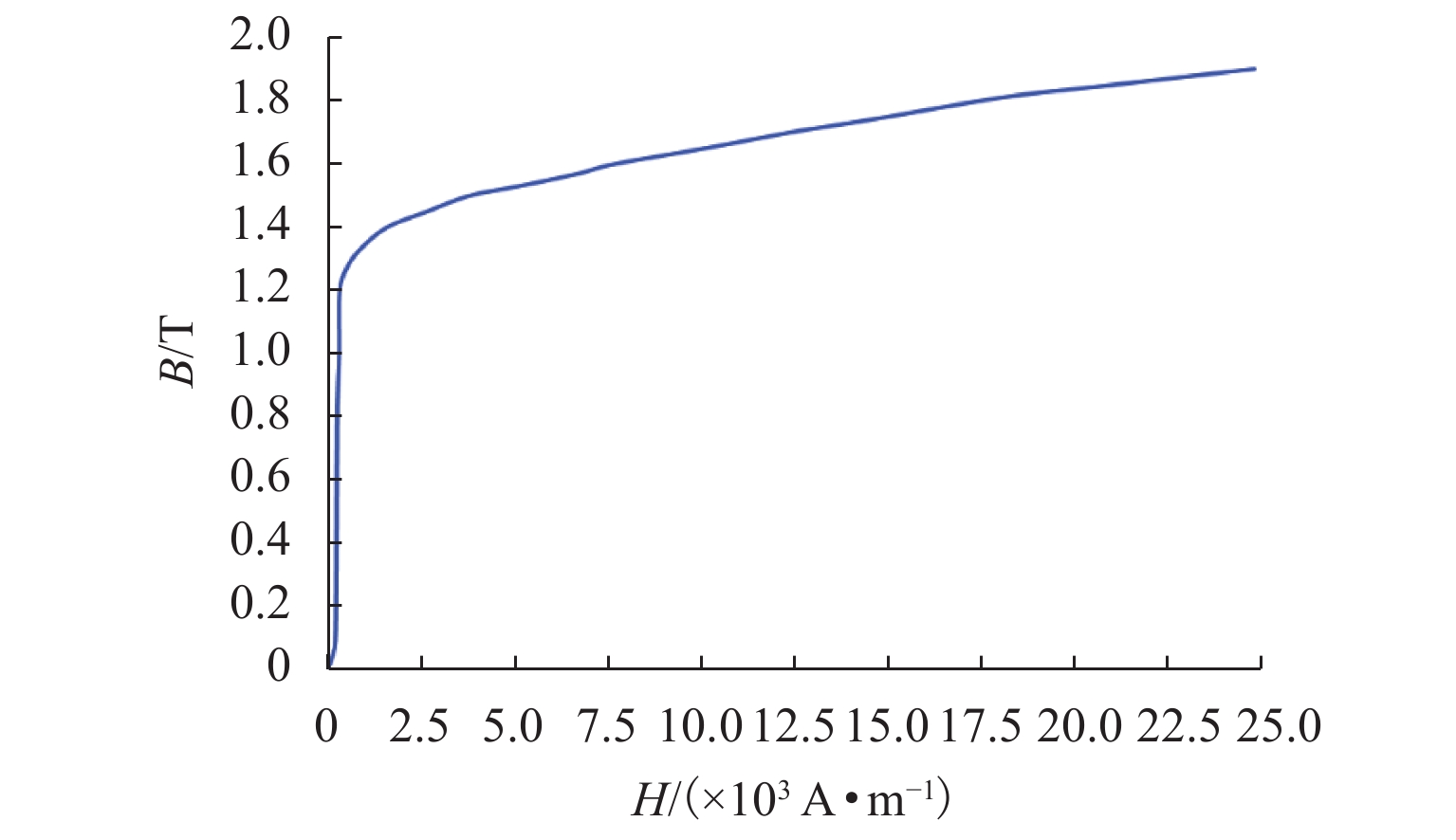

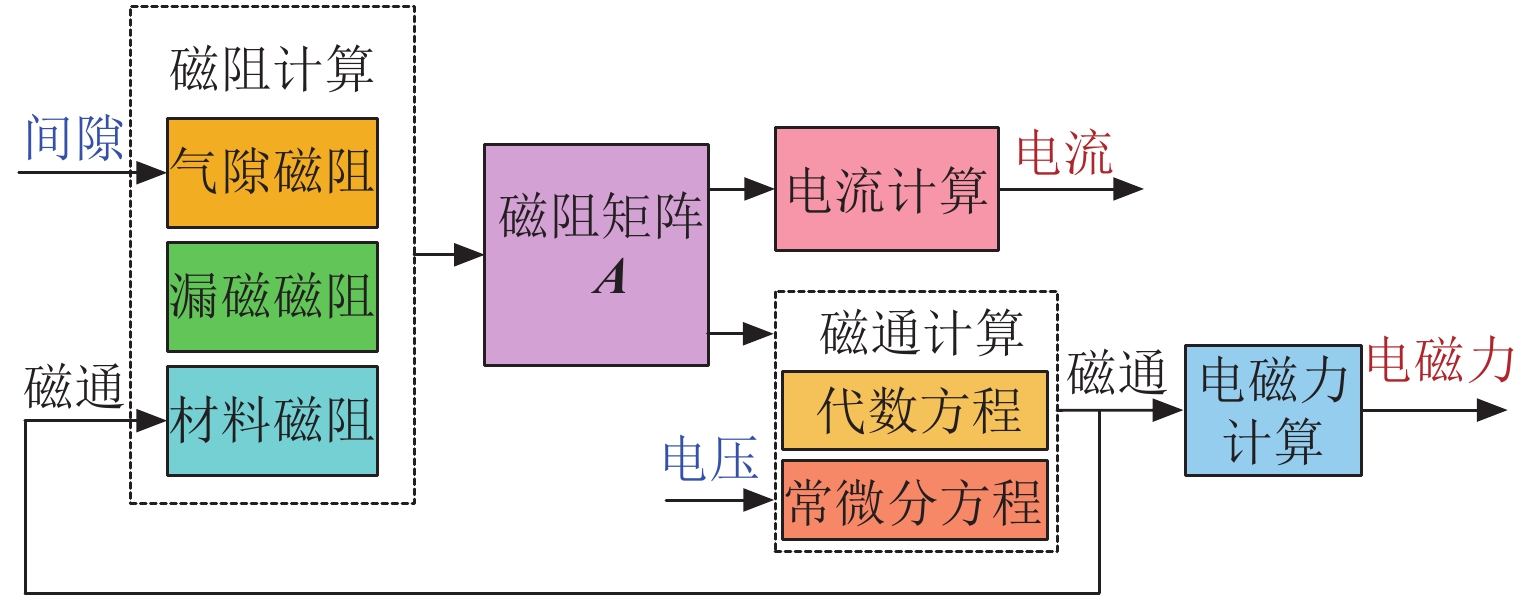

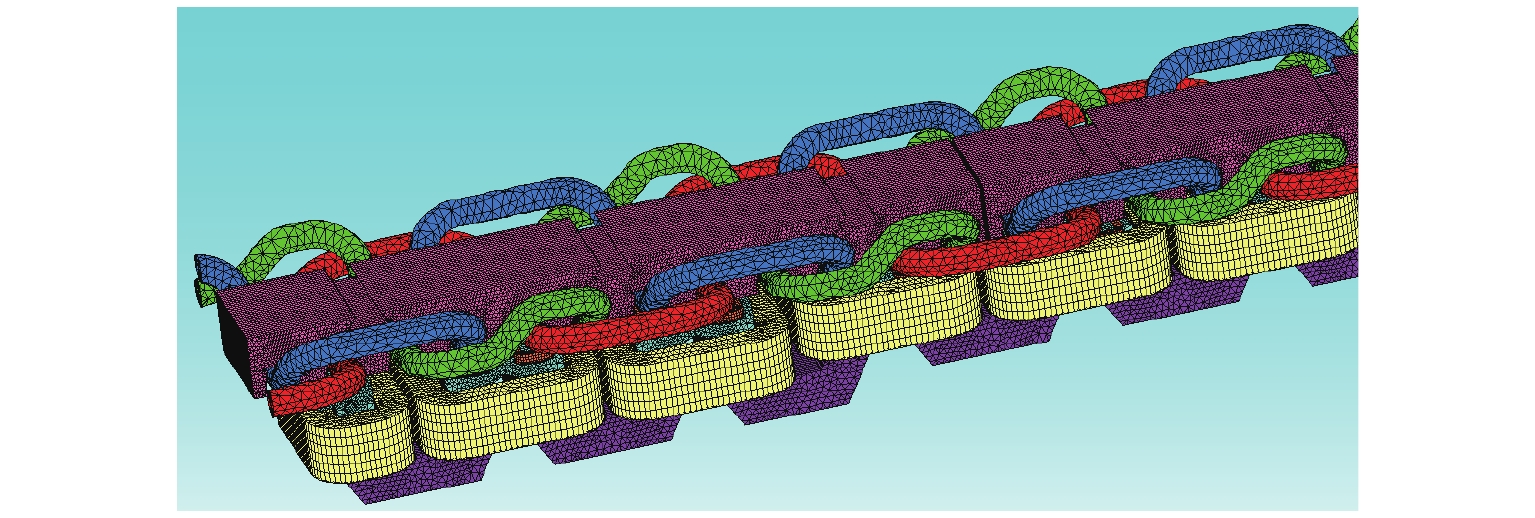

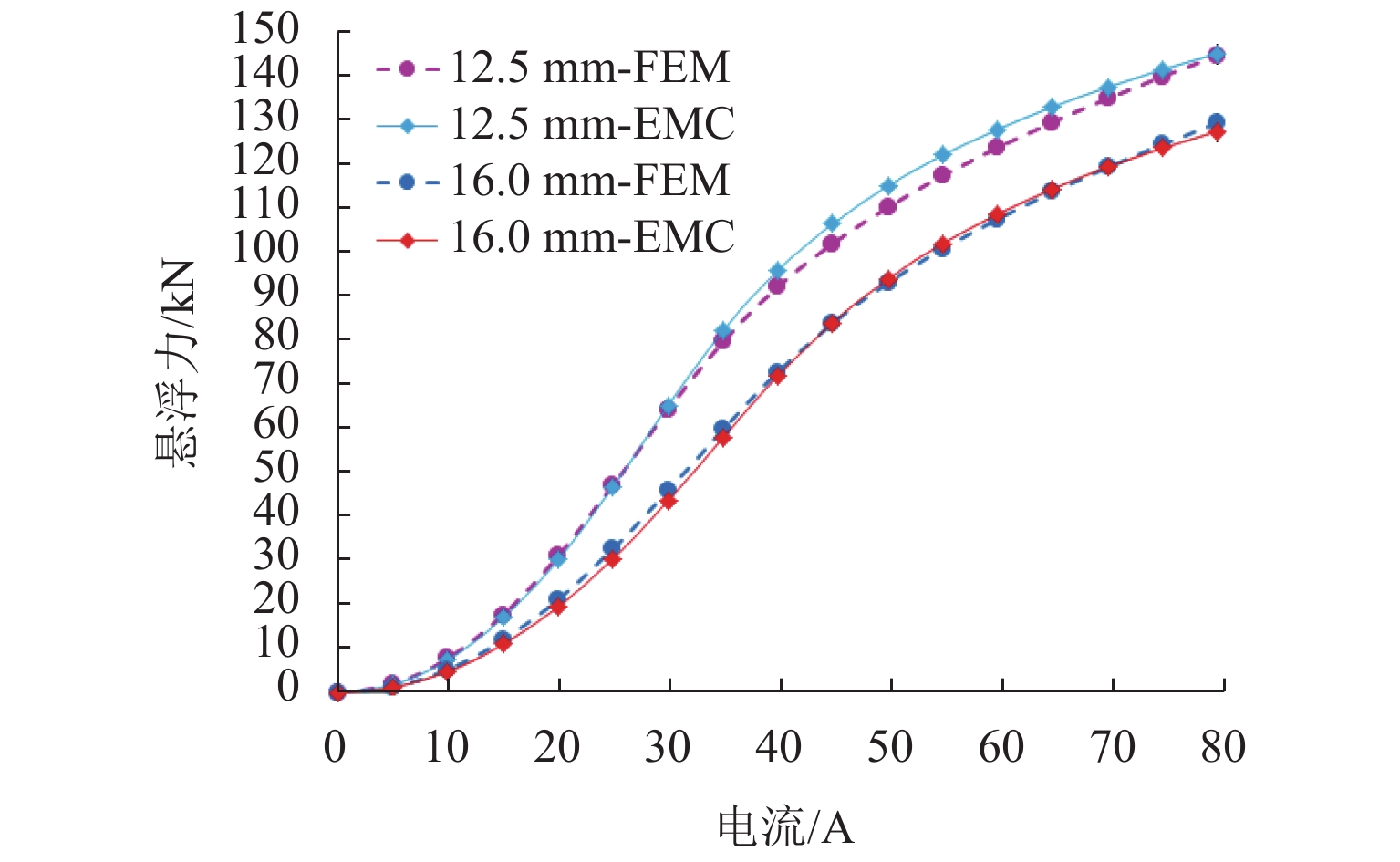

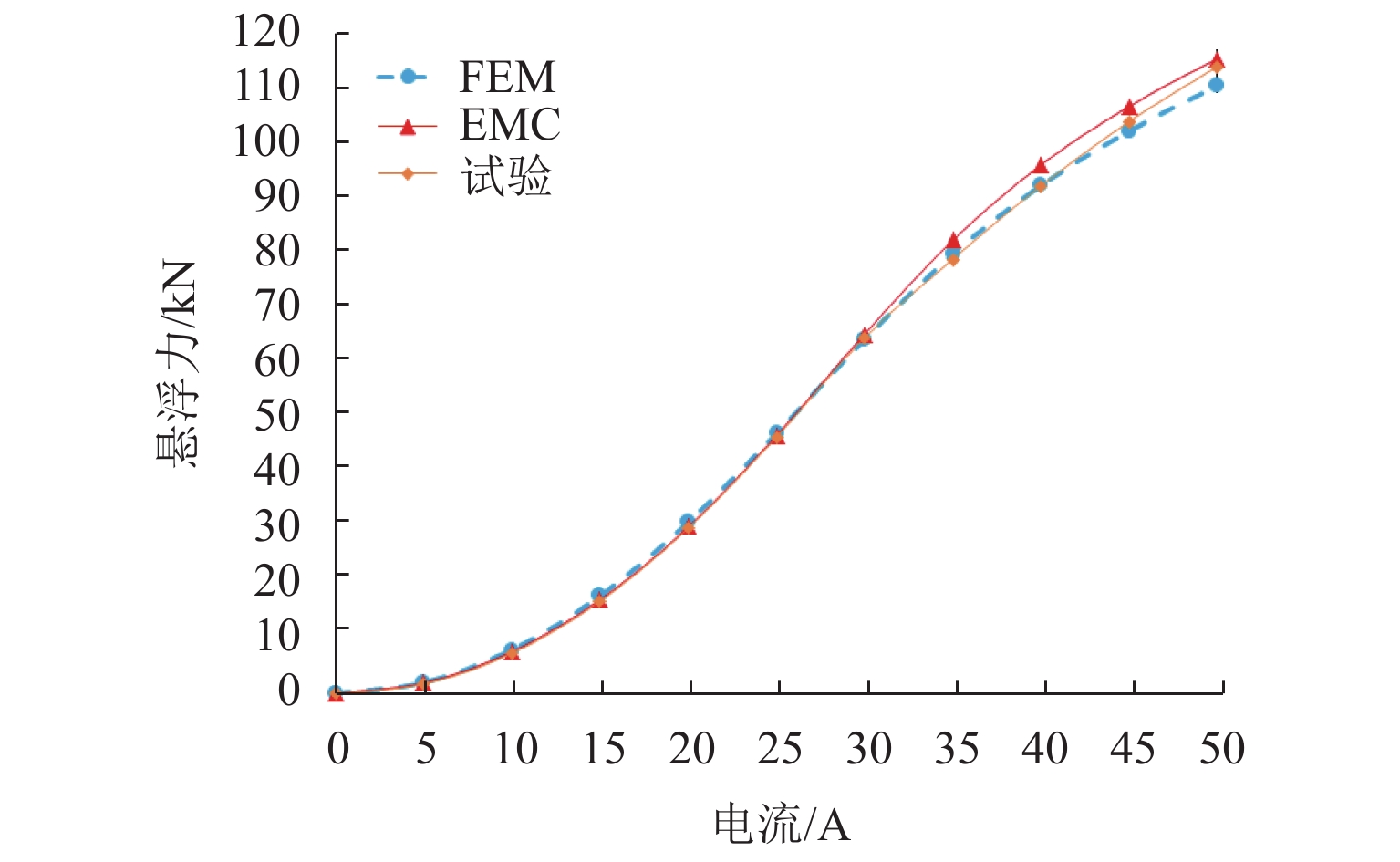

为更加精确、快速地分析高速磁浮悬浮电磁铁的电磁力特性,实现与控制、动力学模型的良好匹配,提出一种基于非线性材料的高速磁浮悬浮电磁铁电磁力建模方法. 首先,在搭建电磁铁等效磁路(equivalent magnetic circuit, EMC)模型时,考虑了导磁材料自身的非线性,导磁材料的磁阻计算以内部磁通为基础,推导以电压及间隙为输入,电流及电磁力为输出的电磁铁解析模型,计算电磁力-间隙-电流特性,并与传统EMC模型进行对比分析;其次,搭建电磁铁有限元(finite element method, FEM)模型,对非线性EMC模型的结果进行验证;最后,采用地面试验台对悬浮电磁铁进行电磁力测试,验证EMC及FEM模型的准确性. 研究结果表明:与传统电磁力模型相比,本文EMC模型计算的电磁力在大电流区间会出现饱和现象,更接近实际情况,适用范围更广;磁间隙12.5 mm,电流50 A工况下,EMC与FME计算的电磁力偏差仅为4.5%,且与试验结果具有非常高的一致性;高精度的非线性电磁力模型为悬浮系统动态特性联合分析及参数优化奠定了基础.

Abstract:In order to analyze the electromagnetic force characteristics of high-speed maglev electromagnets more accurately and efficiently and achieve good matching with control and dynamics models, a modeling method of electromagnetic force of high-speed maglev electromagnets based on nonlinear materials was proposed. Firstly, when the equivalent magnetic circuit (EMC) model of the electromagnet was built, the nonlinearity of the magnetic material was considered, and its reluctance was calculated based on the internal magnetic flux. The analytical model of the electromagnet was derived, with voltage and gap as input and current and electromagnetic force as output. The characteristics of the electromagnetic force, gap, and current were calculated and compared with traditional EMC models. Secondly, a finite element method (FEM) model of the electromagnet was built to validate the results of the nonlinear EMC model. Finally, the electromagnetic force of the maglev electromagnet was tested on a ground test bench, verifying the accuracy of the EMC and FEM models. The research results indicate that compared with that calculated by the traditional electromagnetic force model, the electromagnetic force calculated by the EMC model in this paper will experience saturation in the high current range, which is closer to the actual situation and has a wider application range. Under the magnetic gap of 12.5 mm and current of 50 A, the electromagnetic force deviation between EMC and FME is only 4.5%, and it is highly consistent with the test results. Therefore, the high-precision nonlinear electromagnetic force model lays the foundation for joint analysis of dynamic characteristics and parameter optimization of levitation systems.

-

表 1 悬浮电磁铁及长定子参数

Table 1. Parameters of maglev electromagnet and long stator

项点 取值 项点 取值 定子极距/mm 258.0 铁芯厚度/mm 170.0 电磁铁极距/mm 266.5 磁极匝数 300 定子齿宽度/mm 43.0 额定磁间隙/mm 12.5 定子槽宽度/mm 43.0 恒定相对磁导率 7 000 -

[1] LIU Q, LI H, WANG W, et al. Analysis and experiment of 5-DOF decoupled spherical vernier-gimballing magnetically suspended flywheel (VGMSFW)[J]. IEEE Access, 2020, 8: 111707-111717. doi: 10.1109/ACCESS.2020.3001144 [2] 韩邦成,彭松,贺赞,等. 磁悬浮控制力矩陀螺高速电机绕组涡流损耗计算及热分析[J]. 光学精密工程,2020,28(1): 130-140. doi: 10.3788/OPE.20202801.0130HAN Bangcheng, PENG Song, HE Zan, et al. Eddy current loss calculation and thermal analysis of high-speed motor winding in magnetically suspended control moment gyroscope[J]. Optics and Precision Engineering, 2020, 28(1): 130-140. doi: 10.3788/OPE.20202801.0130 [3] ZHAI L X, SUN J J, MA X, et al. Thermal-structure coupling analysis and multi-objective optimization of motor rotor in MSPMSM[J]. Chinese Journal of Aeronautics, 2019, 32(7): 1733-1747. doi: 10.1016/j.cja.2018.09.008 [4] 邓自刚,刘宗鑫,李海涛,等. 磁悬浮列车发展现状与展望[J]. 西南交通大学学报,2022,57(3): 455-474,530.DENG Zigang, LIU Zongxin, LI Haitao, et al. Development status and prospect of maglev train[J]. Journal of Southwest Jiaotong University, 2022, 57(3): 455-474,530. [5] 熊嘉阳,邓自刚. 高速磁悬浮轨道交通研究进展[J]. 交通运输工程学报,2021,21(1): 177-198. doi: 10.19818/j.cnki.1671-1637.2021.01.008XIONG Jiayang, DENG Zigang. Research progress of high-speed maglev rail transit[J]. Journal of Traffic and Transportation Engineering, 2021, 21(1): 177-198. doi: 10.19818/j.cnki.1671-1637.2021.01.008 [6] 马光同,杨文姣,王志涛,等. 超导磁浮交通研究进展[J]. 华南理工大学学报(自然科学版),2019,47(7): 68-74,82.MA Guangtong, YANG Wenjiao, WANG Zhitao, et al. Research development of superconducting maglev transportation[J]. Journal of South China University of Technology (Natural Science Edition), 2019, 47(7): 68-74,82. [7] 翟明达,龙志强,李晓龙,等. 考虑涡流效应的端部悬浮系统建模与控制器优化设计[J]. 同济大学学报(自然科学版),2021,49(12): 1652-1659. doi: 10.11908/j.issn.0253-374x.21207ZHAI Mingda, LONG Zhiqiang, LI Xiaolong, et al. Modeling of front magnetic levitation system and optimization design of controller considering eddy current effect[J]. Journal of Tongji University (Natural Science), 2021, 49(12): 1652-1659. doi: 10.11908/j.issn.0253-374x.21207 [8] WANG Z Q, HUANG C C, LI X L, et al. Levitation control of PEMS high speed maglev train considering the coupling effects within a joint structure[C]//2018 Chinese Control and Decision Conference (CCDC). Shenyang: IEEE, 2018: 1138-1143. [9] 张宝安,虞大联,李海涛,等. 高速磁浮悬浮架柔性特征对曲线通过性能的影响[J]. 西南交通大学学报,2022,57(3): 475-482.ZHANG Baoan, YU Dalian, LI Haitao, et al. Influence of flexibility characteristics of levitation chassis on curve negotiationperformance of high-speed maglev vehicle[J]. Journal of Southwest Jiaotong University, 2022, 57(3): 475-482. [10] HAN W T, SUN J J, LIU X K, et al. A novel hybrid suspension electromagnet for middle-low speed maglev train[J]. Journal of Magnetics, 2017, 22(3): 463-471. doi: 10.4283/JMAG.2017.22.3.463 [11] 禹春敏,邓智泉,梅磊,等. 基于精确磁路的新型混合型轴向-径向磁悬浮轴承研究[J]. 电工技术学报,2021,36(6): 1219-1228. doi: 10.19595/j.cnki.1000-6753.tces.200029YU Chunmin, DENG Zhiquan, MEI Lei, et al. Re- search on a new hybrid axial-radial magnetic bearing based on precise magnetic circuit[J]. Transactions of China Electrotechnical Society, 2021, 36(6): 1219-1228. doi: 10.19595/j.cnki.1000-6753.tces.200029 [12] SUN J J, JU Z Y, HAN W T, et al. A novel integrated 4-DOF radial hybrid magnetic bearing for MSCMG[J]. Journal of Magnetism and Magnetic Materials, 2017, 421: 86-97. doi: 10.1016/j.jmmm.2016.07.070 [13] DING S S, SUN J J, HAN W T, et al. Modeling and analysis of a novel guidance magnet for high-speed maglev train[J]. IEEE Access, 2019, 7: 133324-133334. doi: 10.1109/ACCESS.2019.2940728 [14] POLINDER H, SLOOTWEG J G, HOEIJMAKERS M J, et al. Modelling of a linear PM machine including magnetic saturation and end effects: maximum force to current ratio[C]//IEEE International Electric Machines and Drives Conference, 2003. Madison: IEEE, 2003: 805-811. -

下载:

下载: