Direct Current Ampacity of 35 kV Alternating Current Cross-Linked Polyethylene Cables Under Various Direct Current Topologies and Laying Environments

-

摘要:

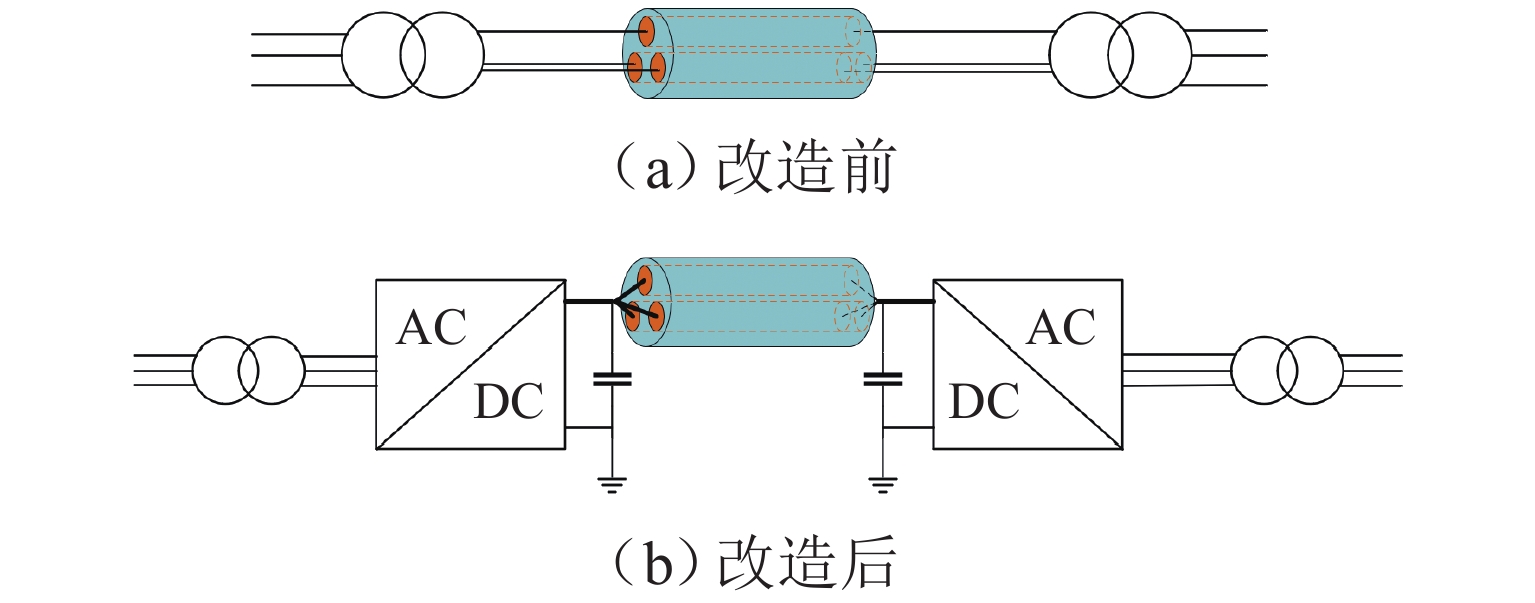

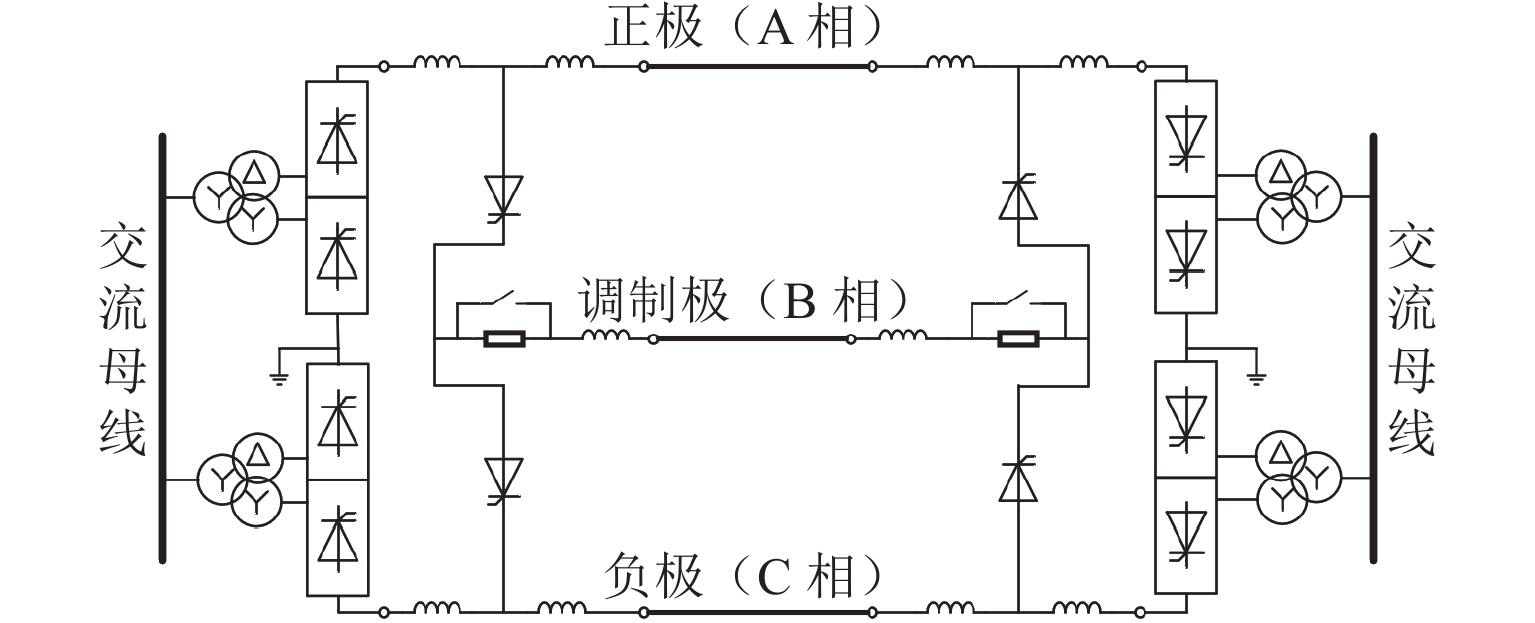

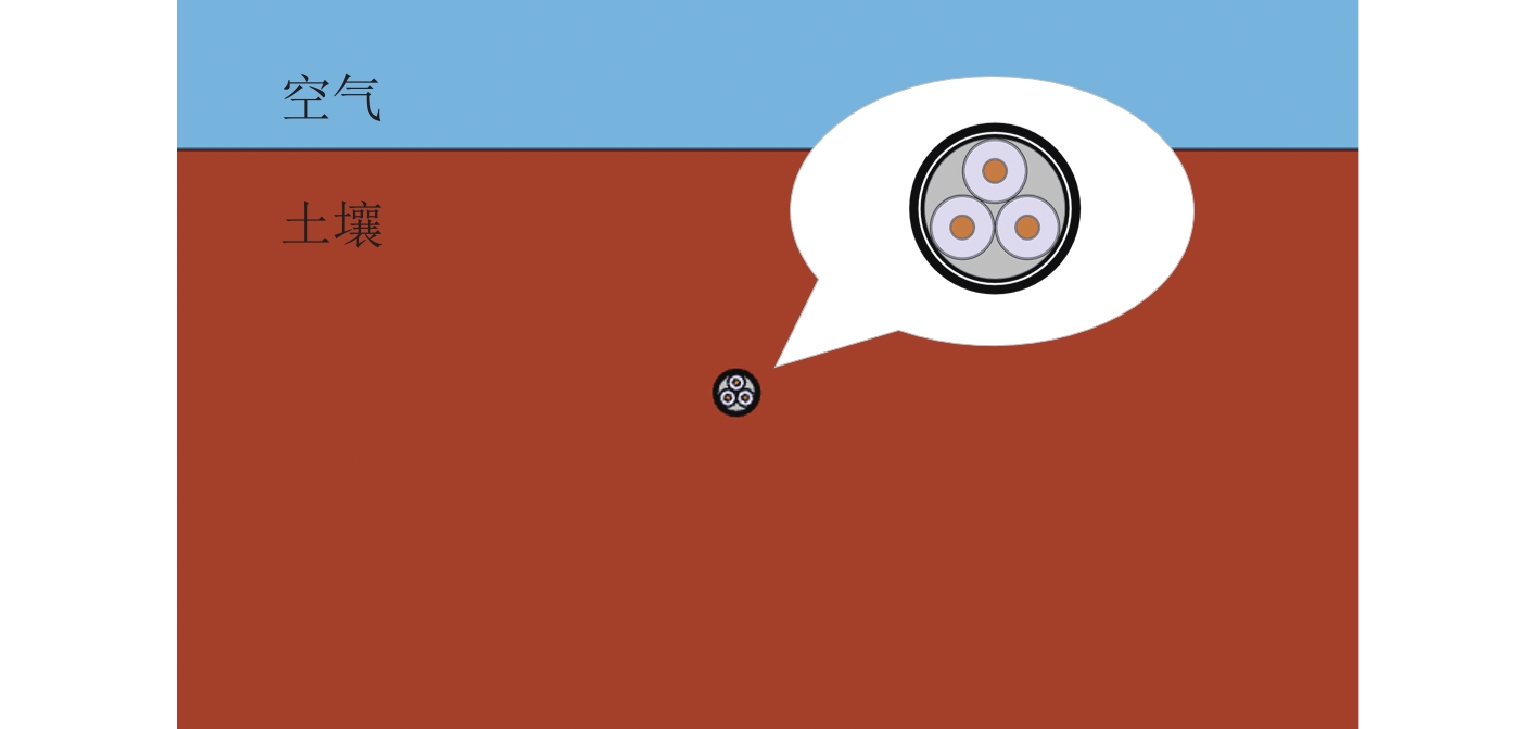

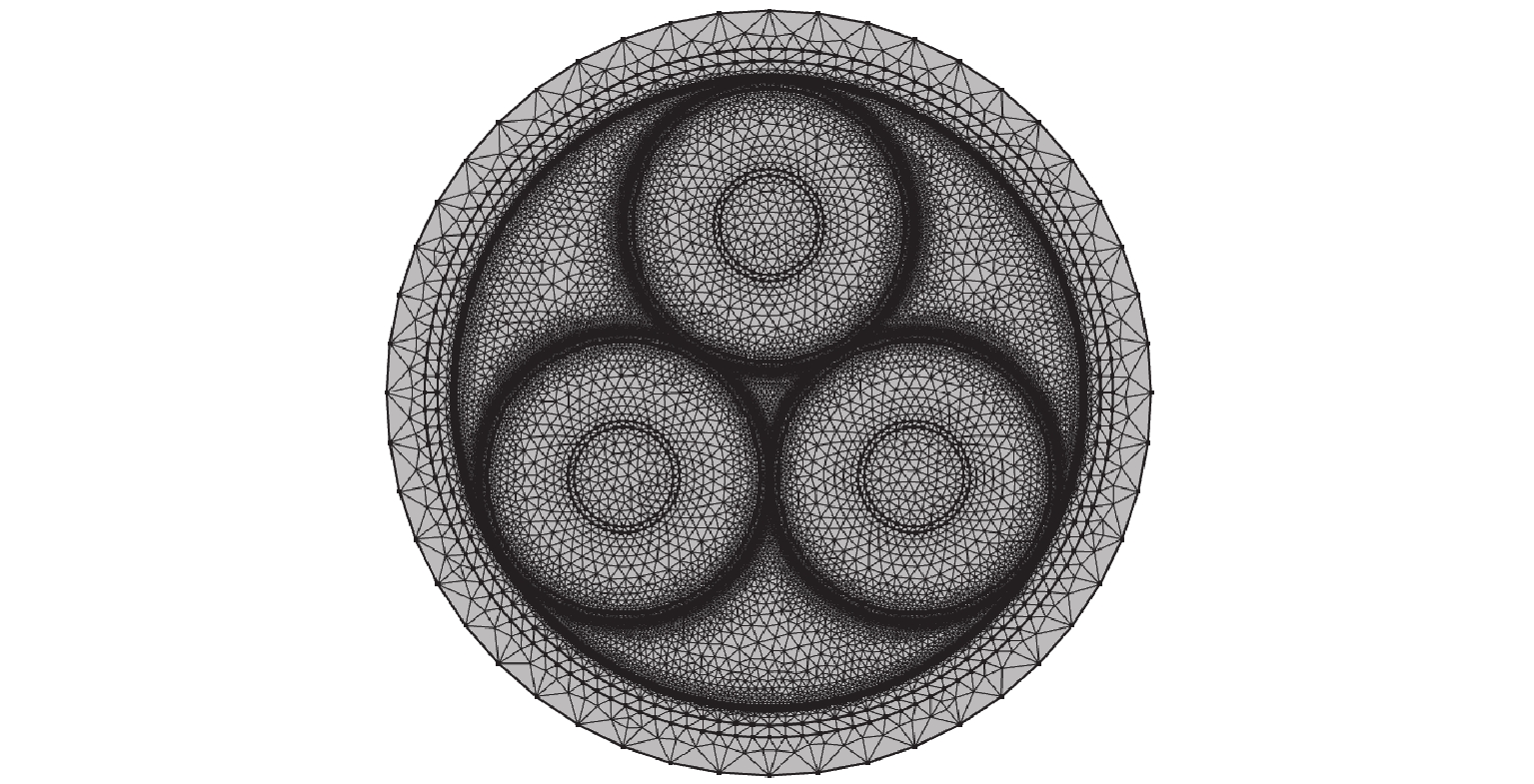

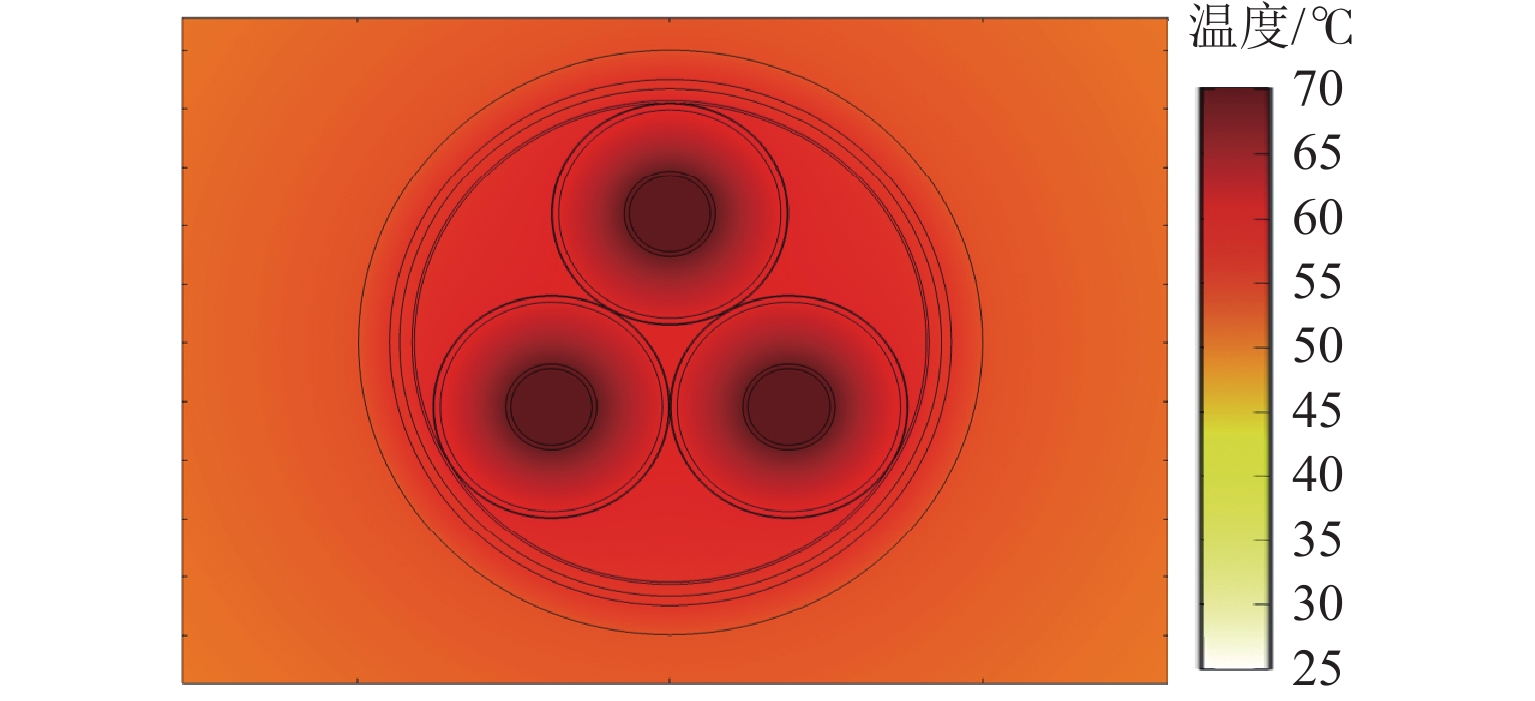

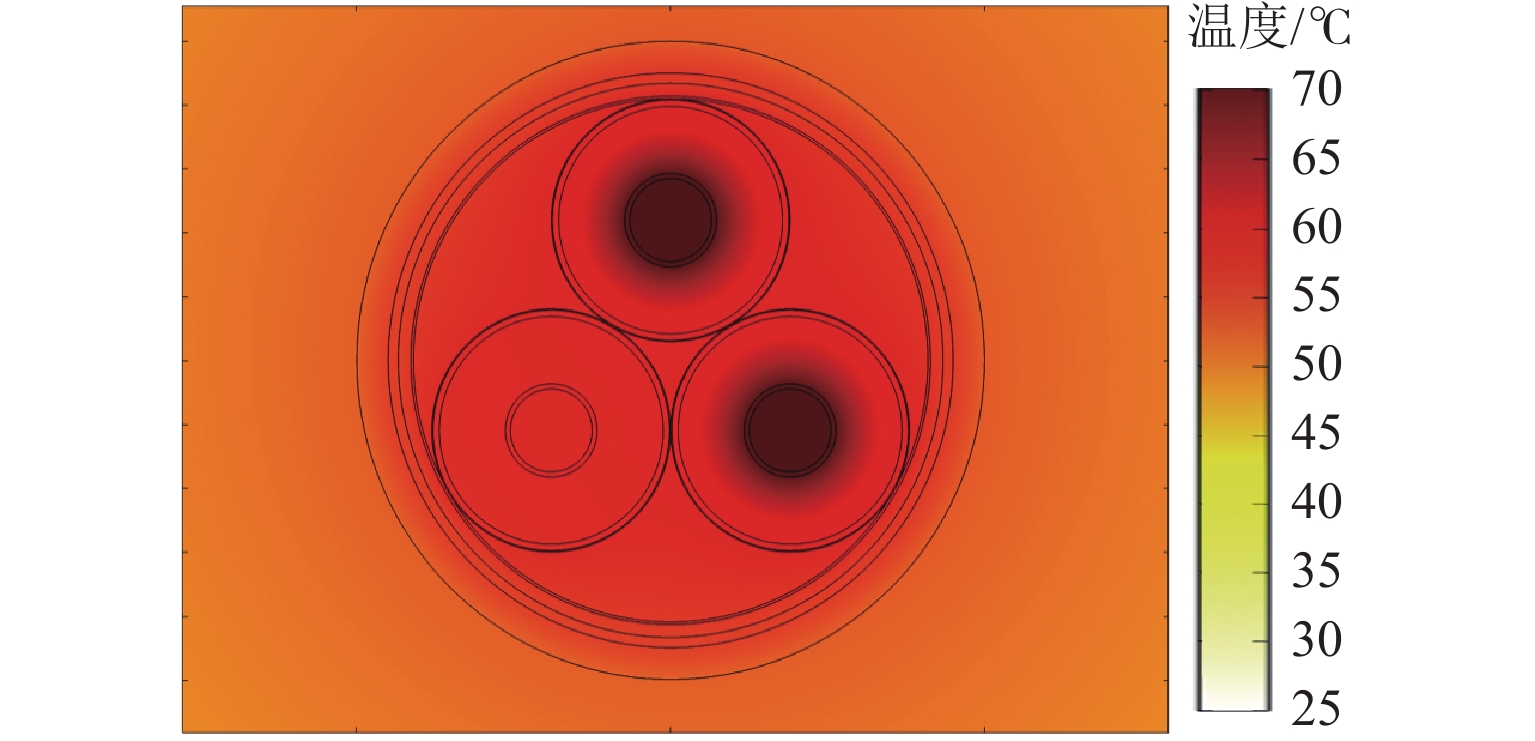

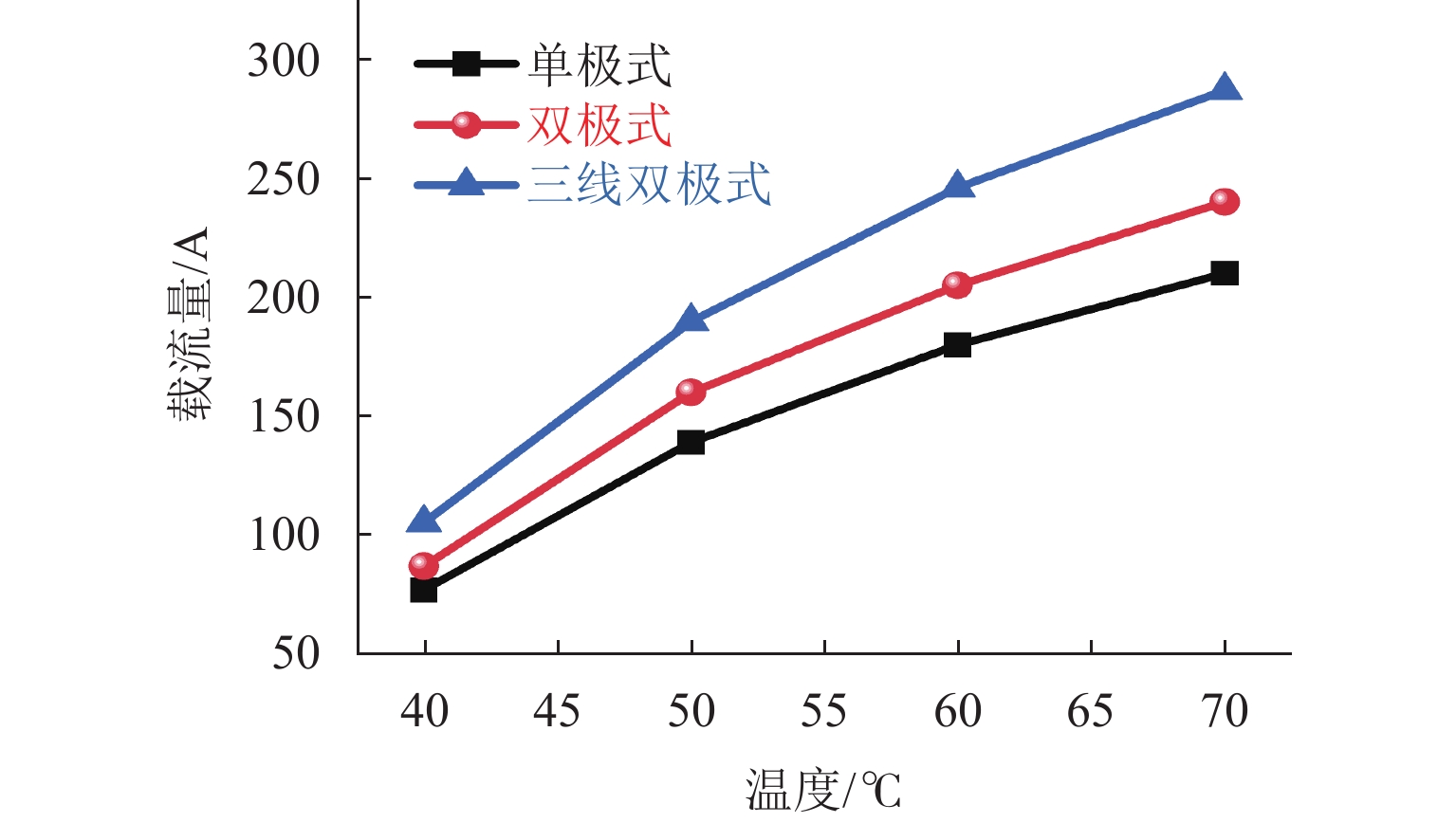

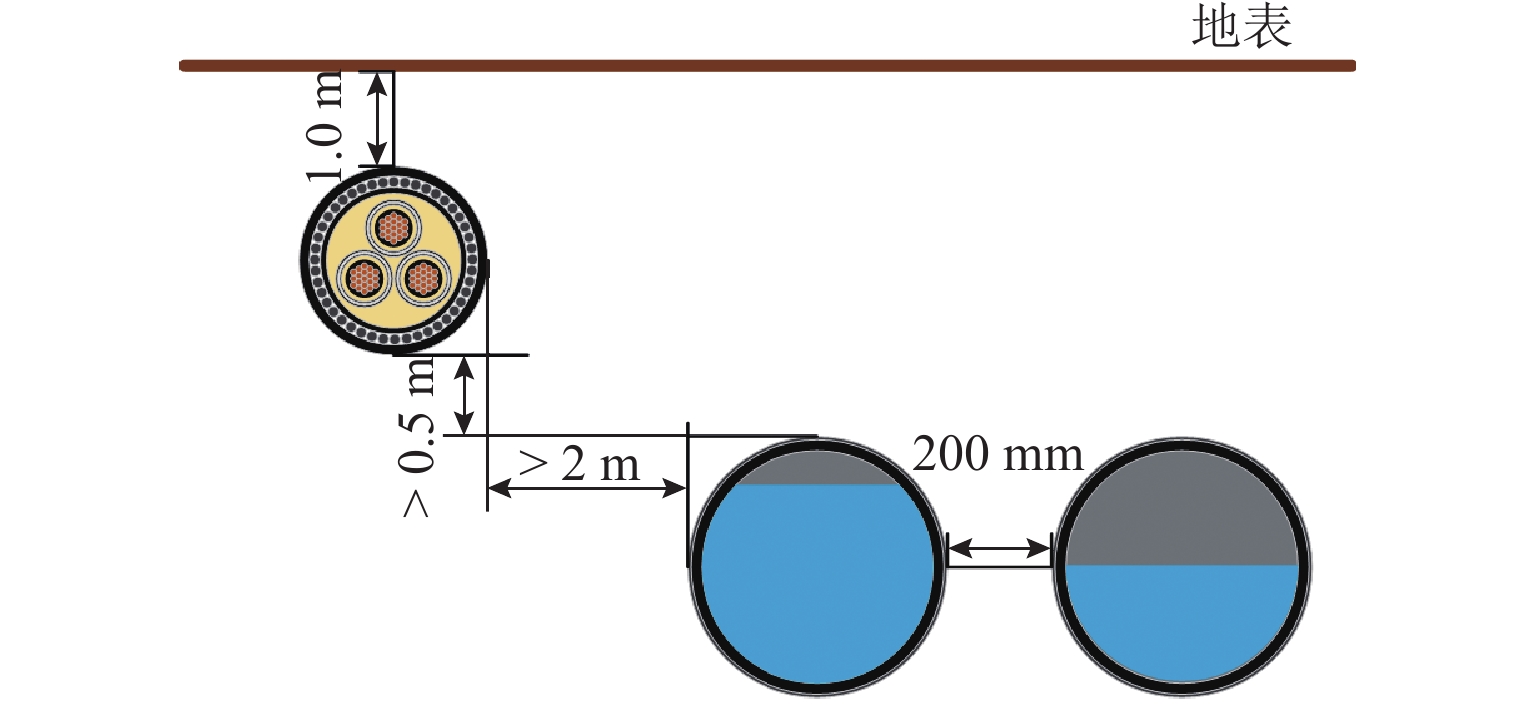

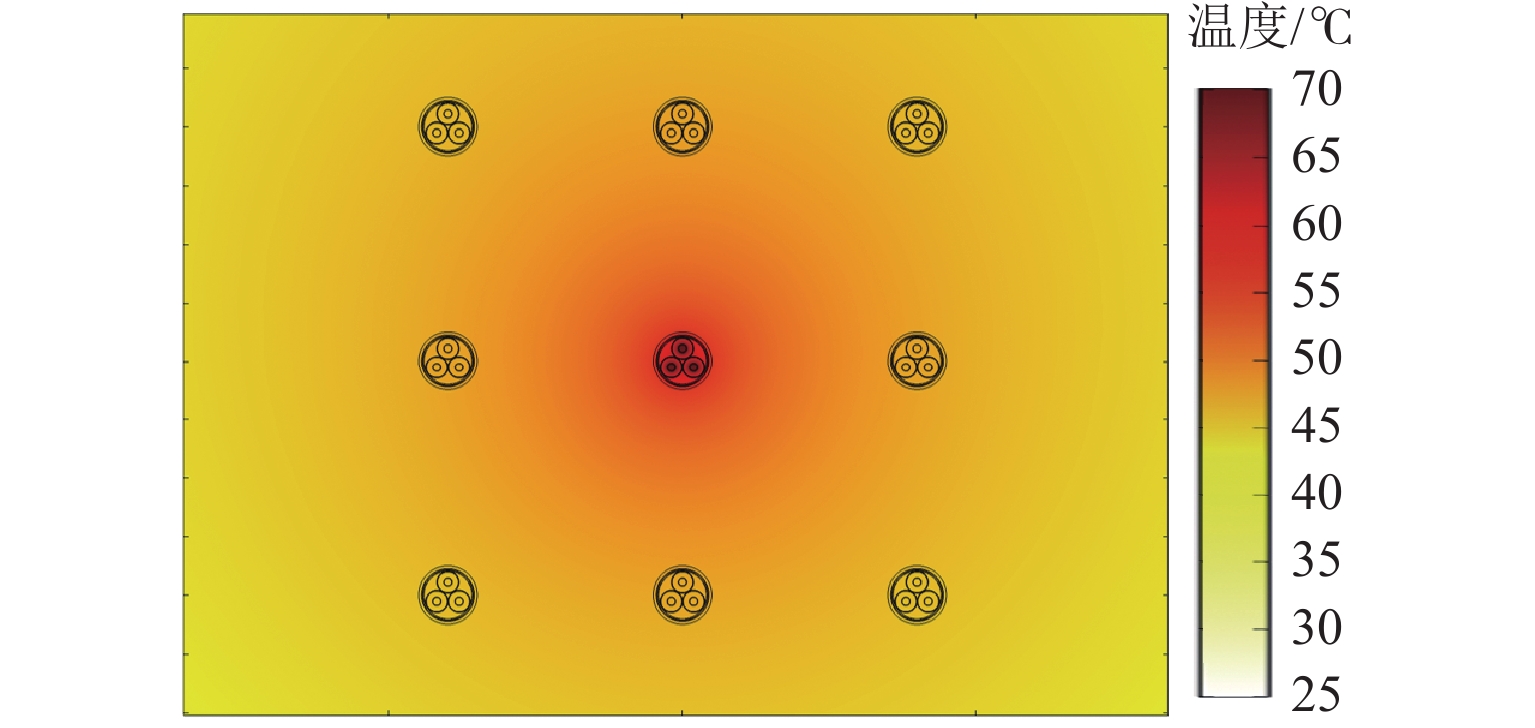

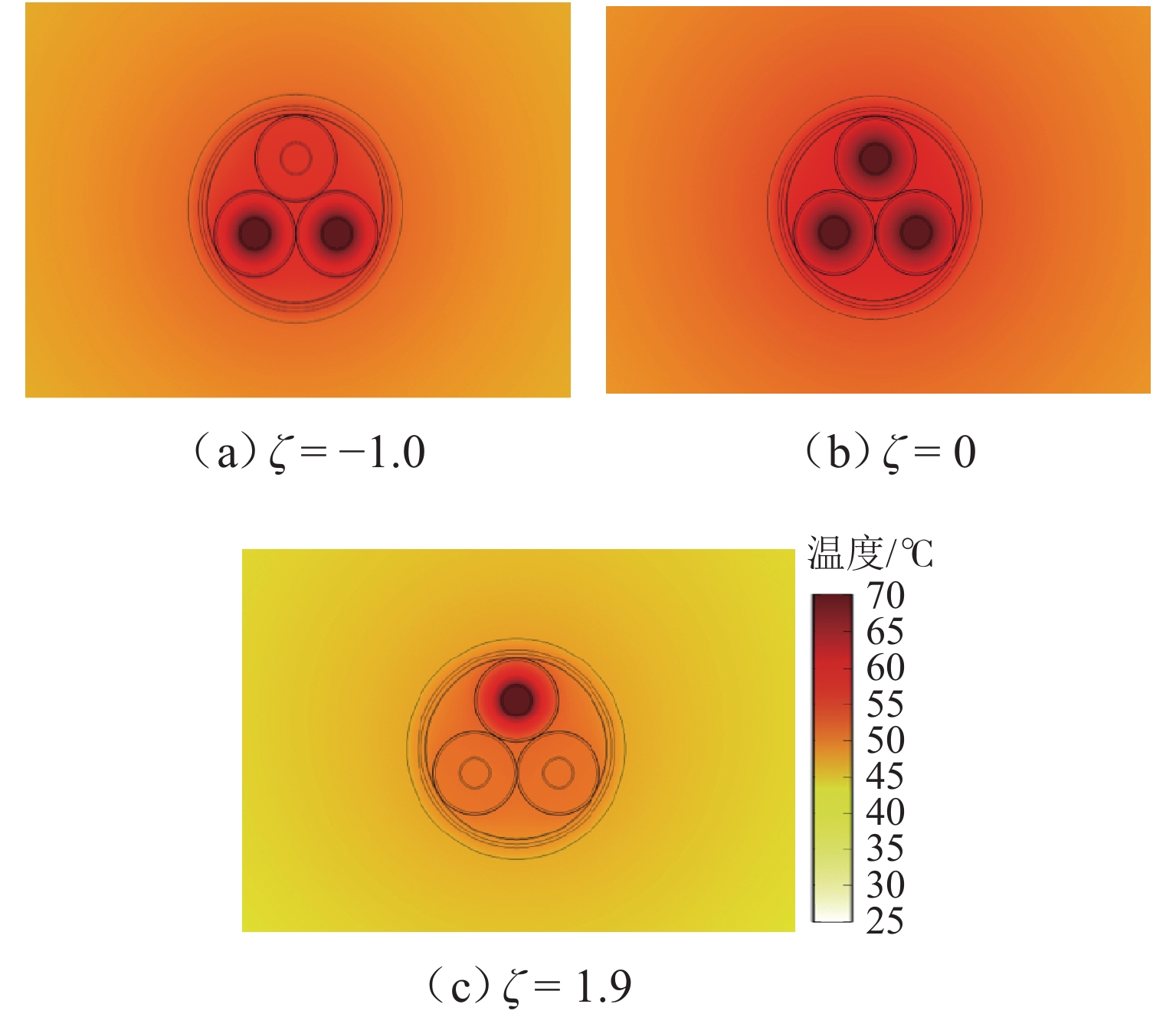

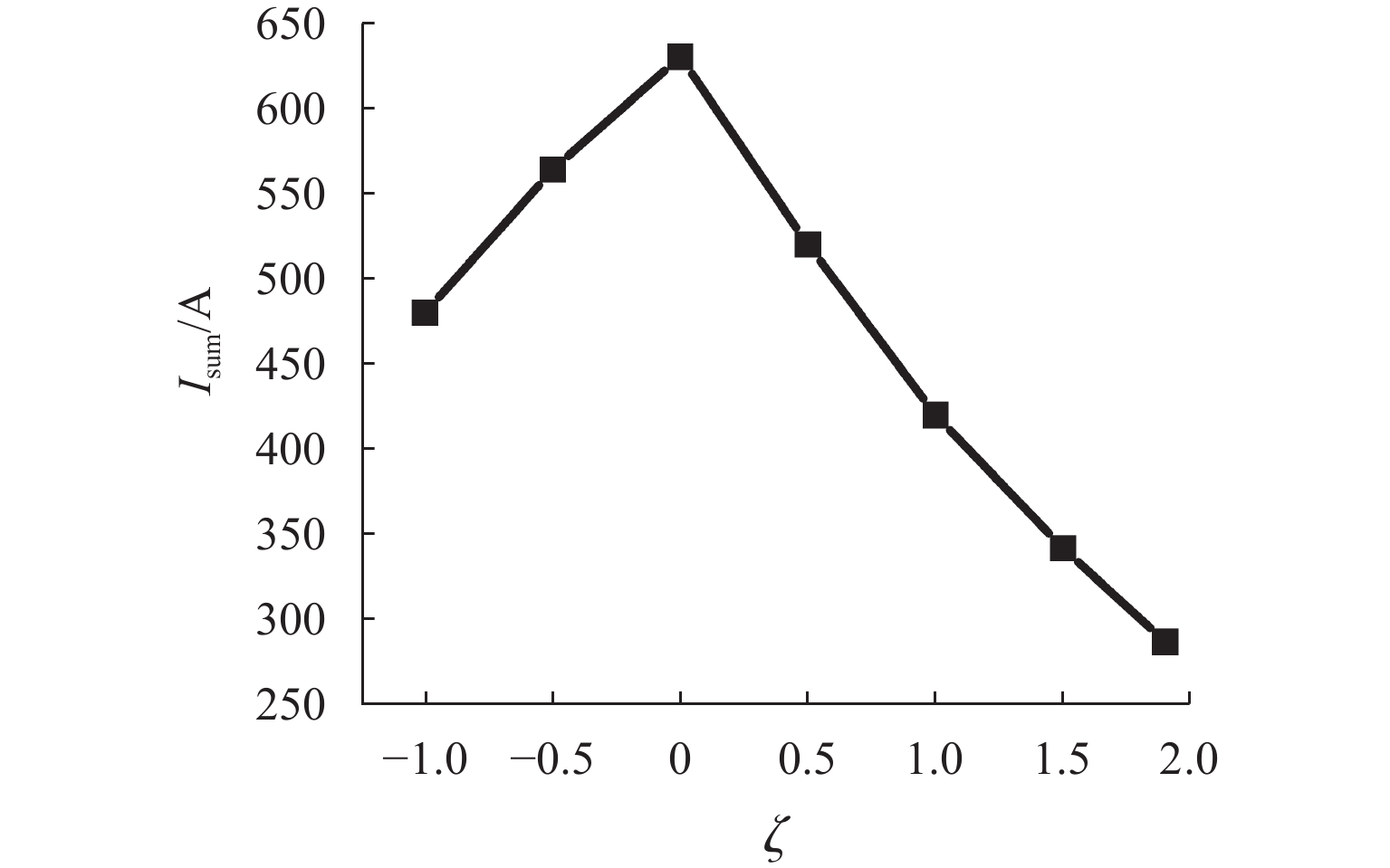

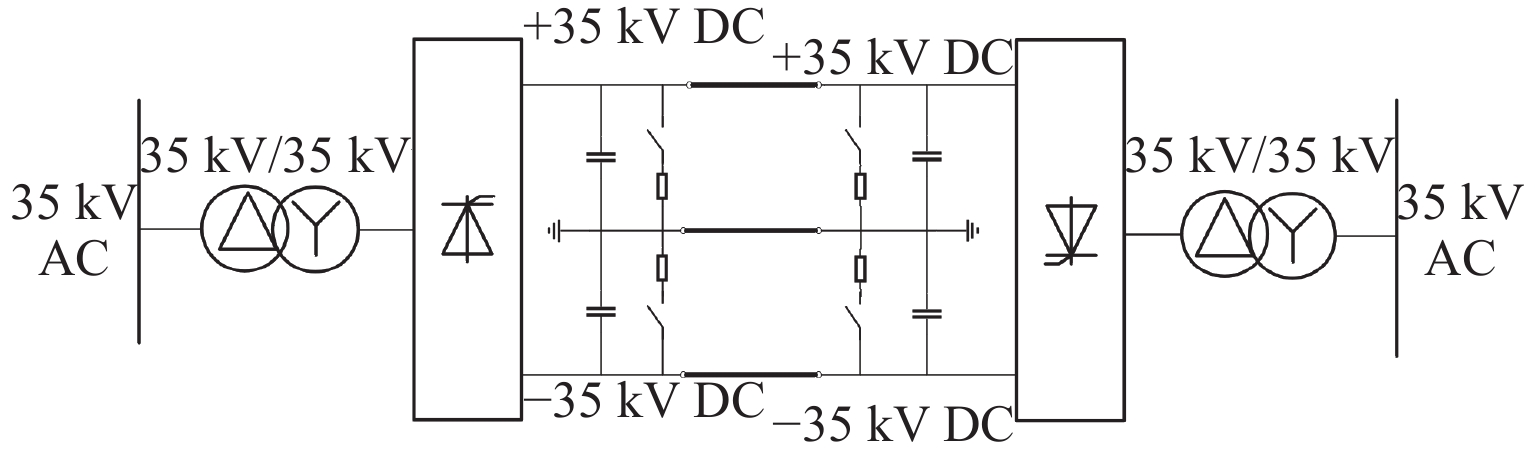

交流电缆改为直流运行对于新能源发电并网以及提高供电容量有着重要意义. 以35 kV交流交联聚乙烯(cross-linked polyethylene,XLPE)电缆为研究对象,采用有限元方法对三线双极式、单极式和双极式3种直流拓扑结构下的三芯交流电缆进行温度场仿真;同时考虑配电网中常见的影响因素,如靠近热水管道、电缆集群敷设、电流不平衡等,研究其对交流电缆改为直流运行下的电缆载流量的影响. 研究发现:在相同工作温度下,35 kV交流XLPE电缆在单极式直流拓扑结构下运行时的载流量最小,在三线双极式直流拓扑下运行时的载流量最大;当交流电缆与城市供水管道水平间距为2.0 m,垂直间距为0.5 m时,在上述3种直流拓扑下运行时的载流量下降了约3.0%;在电缆集群敷设时,加载非同步峰值能使载流量最大提升90 A;电缆载流量随电流不平衡度先增大后减小,在不平衡度为0时,电缆载流量达到最大. 研究结果为35 kV交流XLPE电缆的直流改造提供了参考依据.

Abstract:Converting alternating current (AC) cables into direct current (DC) operation is of great significance to achieve new energy generation connected to the grid and increase power supply capacity. A 35 kV AC cross-linked polyethylene (XLPE) cable was taken as the research object, and temperature field simulation of the three-core AC cable was carried out through the finite element method under three kinds of DC topologies: three-wire bipole, monopole, and bipole. At the same time, common influencing factors in the distribution network were considered, such as distance from hot water pipes, cable cluster laying, and current imbalance, so as to explore the influence of these factors on the ampacity of the cable when the AC cable was changed to the DC operation. The results show that under the same operating temperature, the 35 kV AC XLPE cable has the smallest ampacity when operating under the monopolar DC topology and the largest ampacity under the three-wire bipolar DC topology. When the horizontal distance between AC cable and urban water supply pipes is 2.0 m, and the vertical distance is 0.5 m, the ampacity of cables operating under the above kinds of DC topologies is reduced by about 3.0%. The maximum ampacity can be increased by 90 A as the asynchronous peak value is loaded when the cable cluster is laid. The cable ampacity increases first and then decreases with increasing current imbalance, and it reaches the maximum value when the current imbalance is 0. The research results can provide some reference for converting 35 kV AC XLPE cables into DC operation.

-

Key words:

- XLPE cables /

- DC topologies /

- laying environment /

- DC ampacity

-

表 1 电缆材料与尺寸参数

Table 1. Cable materials and size parameters

结构名称 材料 厚度/mm 直径/mm 导体 铜 13.0 导体屏蔽层 半导体混合物 0.8 14.6 XLPE 屏蔽层 XLPE 10.5 35.6 绝缘屏蔽层 半导体混合物 1.0 37.6 铜屏蔽层 铜 0.2 38.0 包带 聚丙烯 0.4 83.2 内护套 聚氯乙烯 2.0 87.2 铠装层 钢 1.6 90.4 外护套 聚氯乙烯 5.0 100.4 表 2 电缆材料的物理参数

Table 2. Physical parameters of cable materials

材料 密度/

(kg·m−3)比热容/

(J·(kg·K)−1)热导率/

(W·(m·K)−1)铜 8900 380 385.00 XLPE 1200 1000 0.29 聚氯乙烯 1380 1000 0.16 半导电材料 1200 1100 0.28 填充材料 550 1900 0.25 钢 7850 450 45.00 表 3 热水管道的材料和结构参数

Table 3. Hot water pipe materials and structural parameters

结构名称 材料 厚度/mm 半径/mm 工作区 水 516 保温层 硬质聚氨酯 65 581 外护管 高密度聚乙烯 15 596 螺旋焊缝钢管 钢 14 610 -

[1] 郑欢,江道灼,杜翼. 交流配电网与直流配电网的经济性比较[J]. 电网技术,2013,37(12): 3368-3374.ZHENG Huan, JIANG Daozhuo, DU Yi. Economic comparison of AC and DC distribution system[J]. Power System Technology, 2013, 37(12): 3368-3374. [2] ALASSI A, BAÑALES S, ELLABBAN O, et al. HVDC transmission: technology review, market trends and future outlook[J]. Renewable and Sustainable Energy Reviews, 2019, 112: 530-554. doi: 10.1016/j.rser.2019.04.062 [3] WANG M, AN T, ERGUN H K, et al. Review and outlook of HVDC grids as backbone of transmission system[J]. CSEE Journal of Power and Energy Systems, 2021, 7(4): 797-810. [4] 徐政,许烽. 输电线路交改直的关键技术研究[J]. 高电压技术,2016,42(1): 1-10.XU Zheng, XU Feng. Research on key technologies of AC-to-DC transmission lines conversion[J]. High Voltage Engineering, 2016, 42(1): 1-10. [5] YU J, SMITH K, URIZARBARRENA M, et al. Initial designs for the ANGLE DC project; converting existing AC cable and overhead line into DC operation[C]//13th IET International Conference on AC and DC Power Transmission (ACDC 2017). Manchester: IET, 2017: 1-6. [6] 刘英,曹晓珑,何子兰,等. 现役交流XLPE电缆配电线路改为直流运行的技术方案及实例分析[J]. 中国电机工程学报,2016,36(1): 96-103.LIU Ying, CAO Xiaolong, HE Zilan, et al. Technical scheme and case study of the uprating renovation of existing XLPE cables from AC distribution system to DC operation[J]. Proceedings of the CSEE, 2016, 36(1): 96-103. [7] LIU Y, CAO X L, FU M L. The upgrading renovation of an existing XLPE cable circuit by conversion of AC line to DC operation[J]. IEEE Transactions on Power Delivery, 2017, 32(3): 1321-1328. doi: 10.1109/TPWRD.2015.2496178 [8] 郑雁翎. 电缆线路的电缆群载流量优化数值计算模型研究[J]. 高电压技术,2015,41(11): 3760-3765.ZHENG Yanling. Research on optimal numerical caculation model of cable groups ampacity in cable route[J]. High Voltage Engineering, 2015, 41(11): 3760-3765. [9] 郑雁翎,许志亮,张冠军,等. 采用MATLAB仿真的变电站高压进线温度场和载流量数值计算[J]. 高电压技术,2012,38(3): 566-572.ZHENG Yanling, XU Zhiliang, ZHANG Guanjun, et al. Numerical calculation of temperature field and ampacity of high-voltage lines using MATLAB[J]. High Voltage Engineering, 2012, 38(3): 566-572. [10] 王启隆,王国海,陈向荣,等. 10 kV交流XLPE电缆改为直流运行的热电耦合仿真[J]. 西南交通大学学报,2022,57(1): 46-54. doi: 10.3969/j.issn.0258-2724.20200111WANG Qilong, WANG Guohai, CHEN Xiangrong, et al. Thermo-electric coupling simulation for 10 kV AC XLPE cable in DC operation[J]. Journal of Southwest Jiaotong University, 2022, 57(1): 46-54. doi: 10.3969/j.issn.0258-2724.20200111 [11] 刘士利,李宁,蔡国伟,等. 66kV交流交联聚乙烯电缆线路改为直流运行的直流载流量[J]. 高电压技术,2017,43(5): 1664-1669.LIU Shili, LI Ning, CAI Guowei, et al. DC ampacity of 66 kV AC XLPE cable line transformed into DC operation[J]. High Voltage Engineering, 2017, 43(5): 1664-1669. [12] LI J X, YANG F, FANG Z K, et al. Assessment on capacity expansion of AC XLPE cable under DC operation with the constraint of temperature and electric field intensity[J]. IET Generation, Transmission & Distribution, 2022, 16(13): 2612-2622. [13] 许烽,徐政. 一种适用于交流线路改造成直流的扩展式双极直流输电结构[J]. 中国电机工程学报,2014,34(33): 5827-5835.XU Feng, XU Zheng. An extended bipole HVDC structure with three wires for conversion of AC lines to HVDC[J]. Proceedings of the CSEE, 2014, 34(33): 5827-5835. [14] LIU Y, ZHANG S D, CAO X L, et al. Simulation of electric field distribution in the XLPE insulation of a 320 kV DC cable under steady and time-varying states[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2018, 25(3): 954-964. doi: 10.1109/TDEI.2018.006973 [15] 陈铮铮,赵健康,欧阳本红,等. 直流电缆料工作温度和击穿特性的纳米改性研究[J]. 高电压技术,2015,41(4): 1214-1227.CHEN Zhengzheng, ZHAO Jiankang, OUYANG Benhong, et al. Study on the nanoparticle-modification of working temperature and breakdown characteristics for insulating materials in DC cables[J]. High Voltage Engineering, 2015, 41(4): 1214-1227. [16] 杨黎明,朱智恩,杨荣凯,等. 柔性直流电缆绝缘料及电缆结构设计[J]. 电力系统自动化,2013,37(15): 117-124. doi: 10.7500/AEPS20130607005YANG Liming, ZHU Zhien, YANG Rongkai, et al. Insulation material and structure design of HVDC flexible cables[J]. Automation of Electric Power Systems, 2013, 37(15): 117-124. doi: 10.7500/AEPS20130607005 [17] Internation Electrotechnical Commission. Electric cables—calculation of the current rating—part 1-3: current rating equations (100% load factor) and calculation of losses—current sharing between parallel single-core cables and calculation of circulating current losses: IEC 60287-1-3[S]. Geneva: IEC National Committees, 2014. [18] 中华人民共和国住房和城乡建设部. 城镇供热直埋热水管道技术规程:CJJ/T 81—2013 [S]. 北京:中国建筑工业出版社,2013. [19] 陈向荣,王启隆,于竞哲,等. 10 kV交流XLPE电缆在不同直流拓扑结构和敷设方式下的直流载流量仿真研究[J]. 高电压技术,2021,47(11): 4044-4054.CHEN Xiangrong, WANG Qilong, YU Jingzhe, et al. Simulation research on DC ampacity of 10 kV AC XLPE cable under different DC operation topologies and laying modes[J]. High Voltage Engineering, 2021, 47(11): 4044-4054. [20] 曾嵘,赵宇明,赵彪,等. 直流配用电关键技术研究与应用展望[J]. 中国电机工程学报,2018,38(23): 6790-6801.ZENG Rong, ZHAO Yuming, ZHAO Biao, et al. A prospective look on research and application of DC power distribution technology[J]. Proceedings of the CSEE, 2018, 38(23): 6790-6801. [21] 阮羚,赵艾萱,邓丹,等. 三芯电缆不平衡电流对温度分布的影响[J]. 高电压技术,2018,44(8): 2704-2709.RUAN Ling, ZHAO Aixuan, DENG Dan, et al. Influence of unbalanced current in 3-core power cable on temperature distribution[J]. High Voltage Engineering, 2018, 44(8): 2704-2709. -

下载:

下载: