Review on Intelligent Image Recognition of Apparent Diseases of Stay Cable

-

摘要:

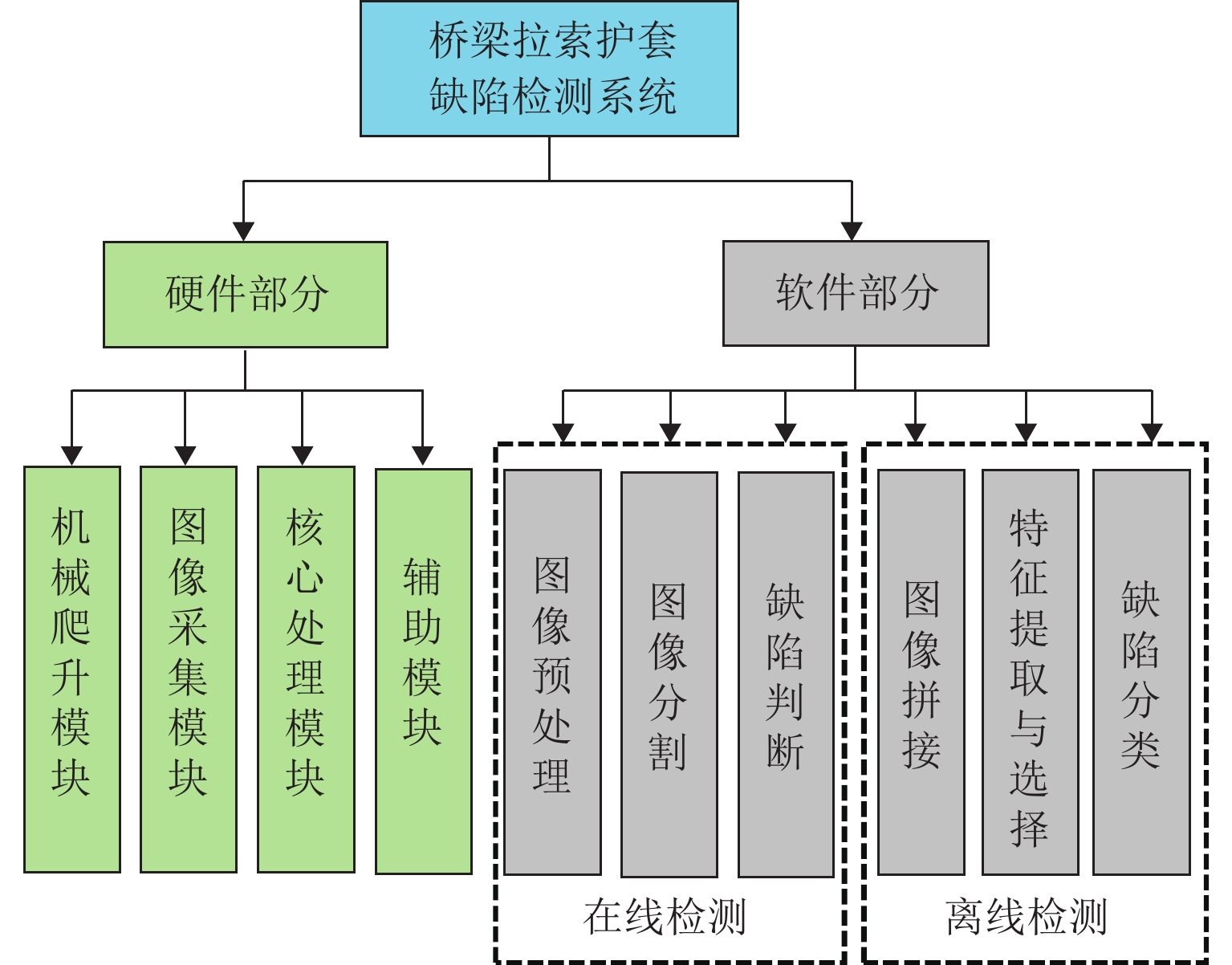

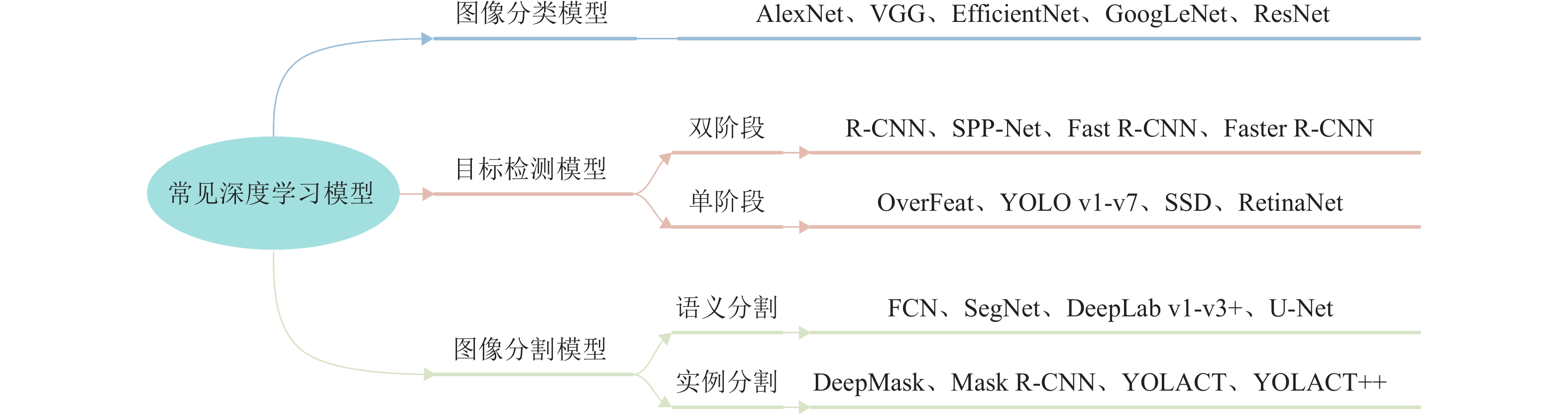

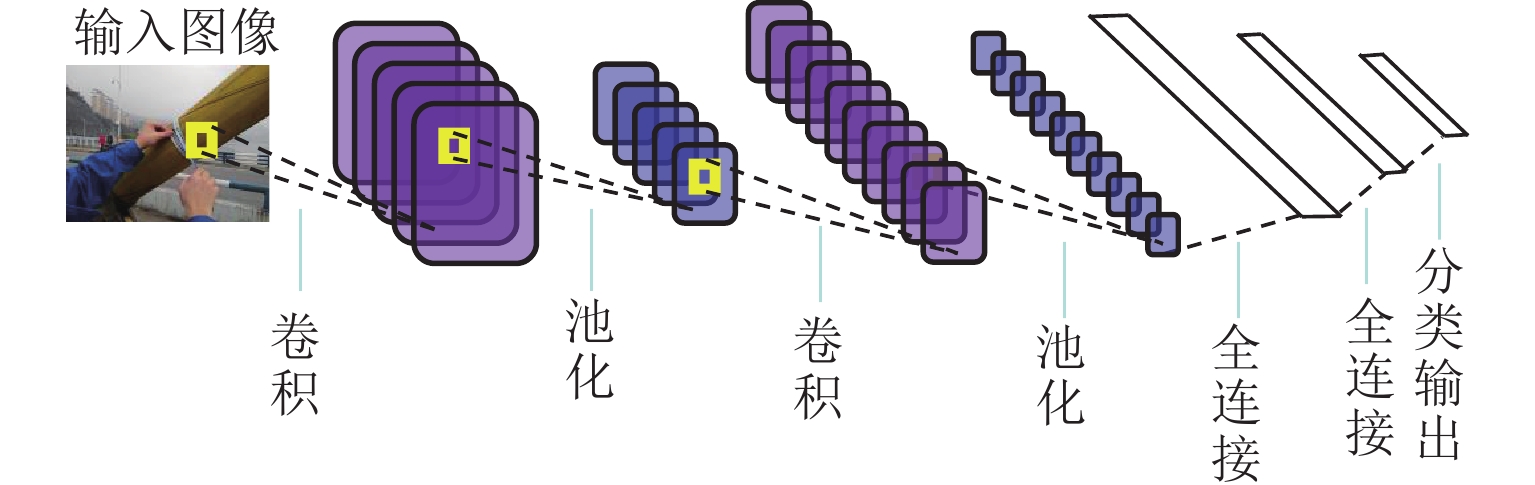

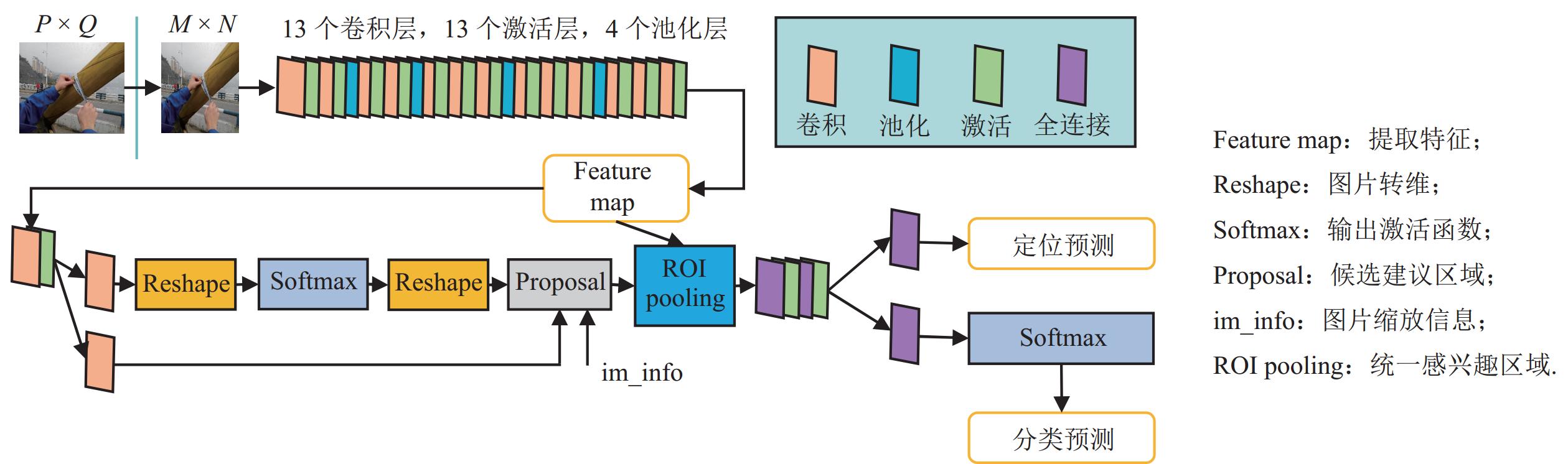

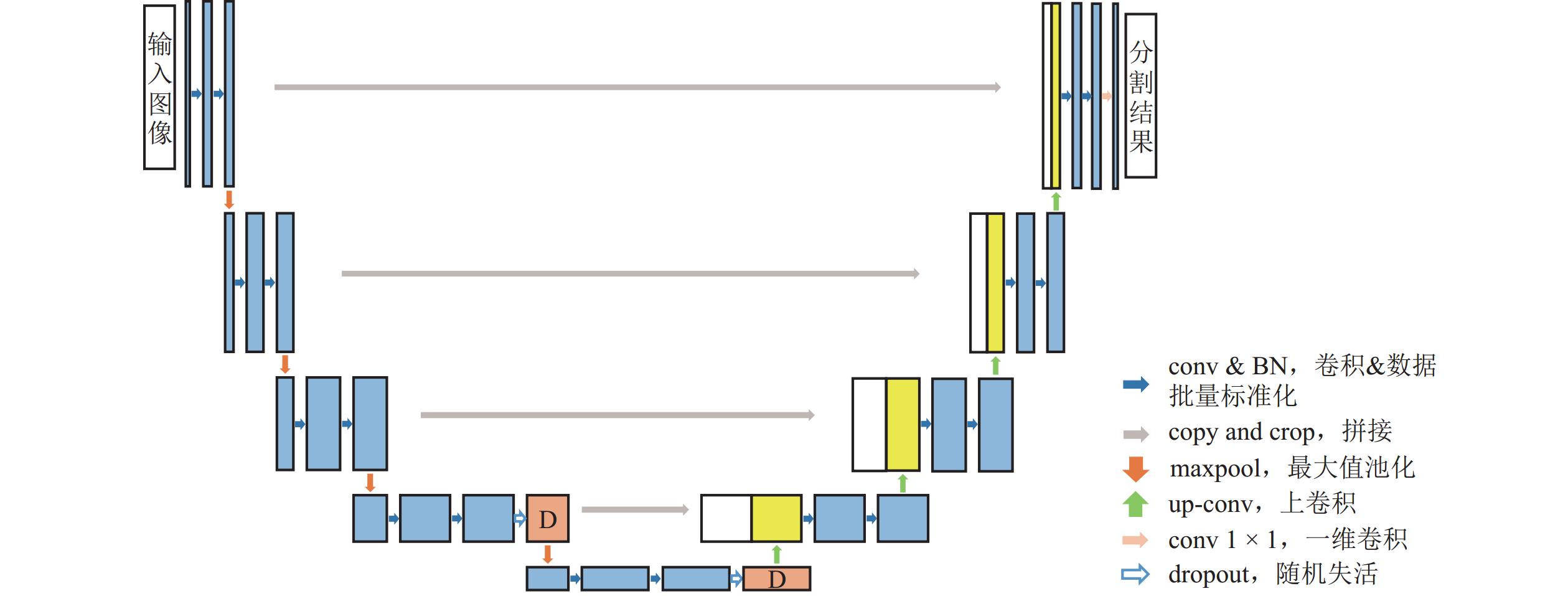

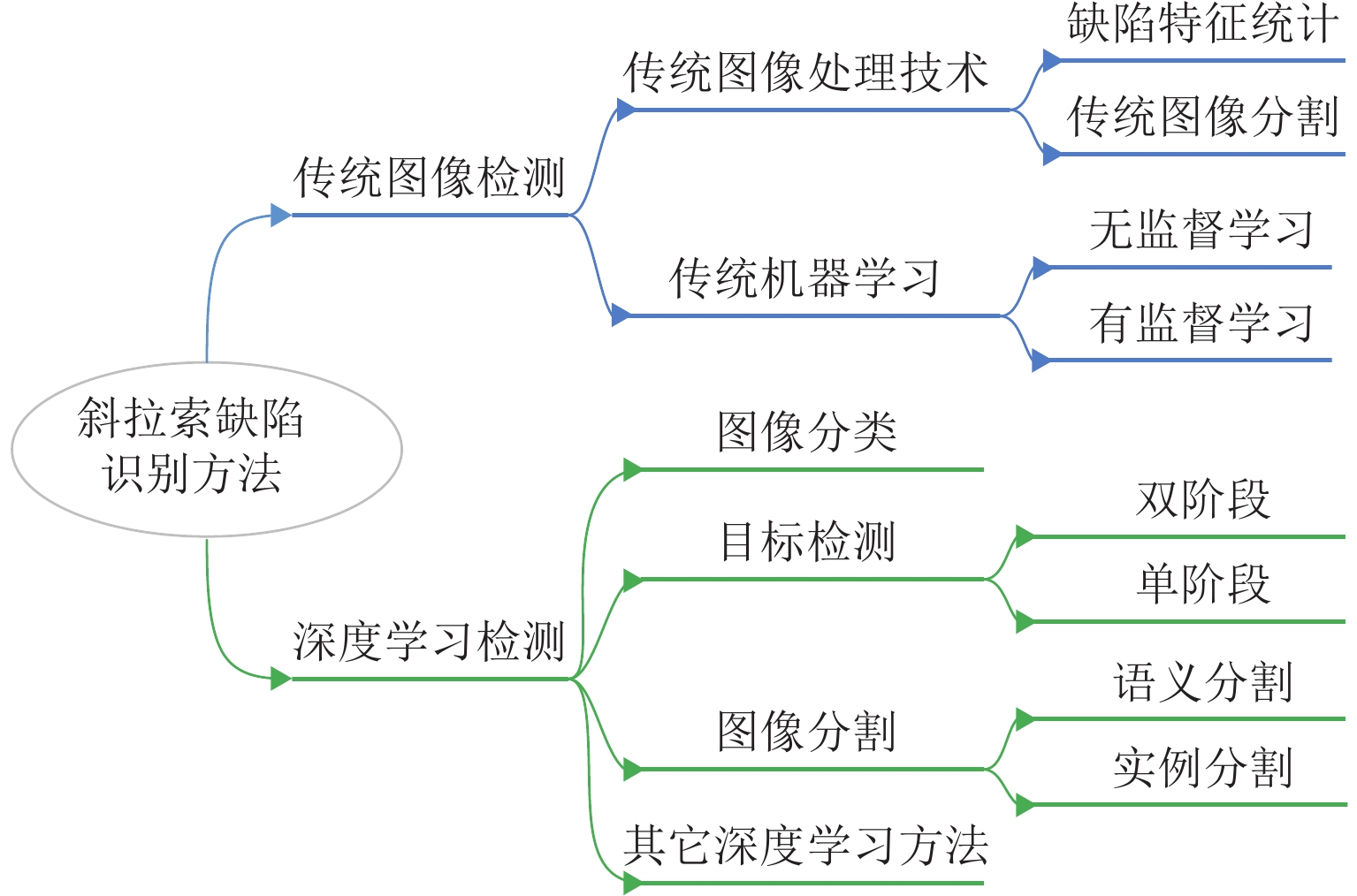

斜拉索是斜拉桥的主要承重构件之一,其外层护套病害容易渗透影响索内钢丝健康,采用视频图像法智能识别出拉索表观病害意义重大. 从传统图像检测和深度学习两方面系统地综述了基于图像识别的斜拉索表观损伤识别方法,以及各个方法的基本原理和应用效果,对目前的检测实例进行深入分析;介绍一些前沿深度学习方法,为拉索表观检测提供参考;归纳各类方法的主要特点,对目前检测中存在的问题进行了探讨和展望. 以深度学习模型为主的图像识别方法具有较好的识别准确率和算法鲁棒性、较强的学习能力和适应性,综合图像缺陷识别效果最优,但仍存在检测精度和速度难平衡、图像数据需求大和标注成本高等难点. 为此,可以采取提高图像质量、构建更多半监督和无监督相关的深度学习模型、提升检测模型学习能力等手段改善检测方法.

Abstract:The stay cable is one of the main load-bearing elements of cable-stayed bridges, and the disease of its outer sheath is easy to penetrate inside the cable and affect the health of the steel wire. Therefore, it is significant to use the video image method to intelligently identify the apparent disease of the cable. Based on image recognition, the methods of apparent disease recognition for stay cable were systematically reviewed from two aspects: traditional image detection and deep learning. The basic principles and application effects of each method were introduced, and the current detection examples were analyzed. Some cutting-edge deep learning methods were introduced to provide a reference for the apparent detection of cables. The main features of various methods were summarized, and the problems existing in the current detection were discussed and prospected. The deep learning model-based image recognition method had better recognition accuracy and algorithm robustness, stronger learning ability and adaptability, and optimal comprehensive image defect recognition effect, but there were still difficulties such as the difficult balance between detection accuracy and speed, large image data demand, and high labeling cost. To this end, detection methods could be improved by improving image quality, constructing more semi-supervised and unsupervised deep learning models, and enhancing the learning ability of detection models.

-

Key words:

- stay cable /

- apparent disease /

- image recognition /

- deep learning

-

表 1 基于传统方法的图像病害识别对比

Table 1. Comparison of image disease recognition based on traditional methods

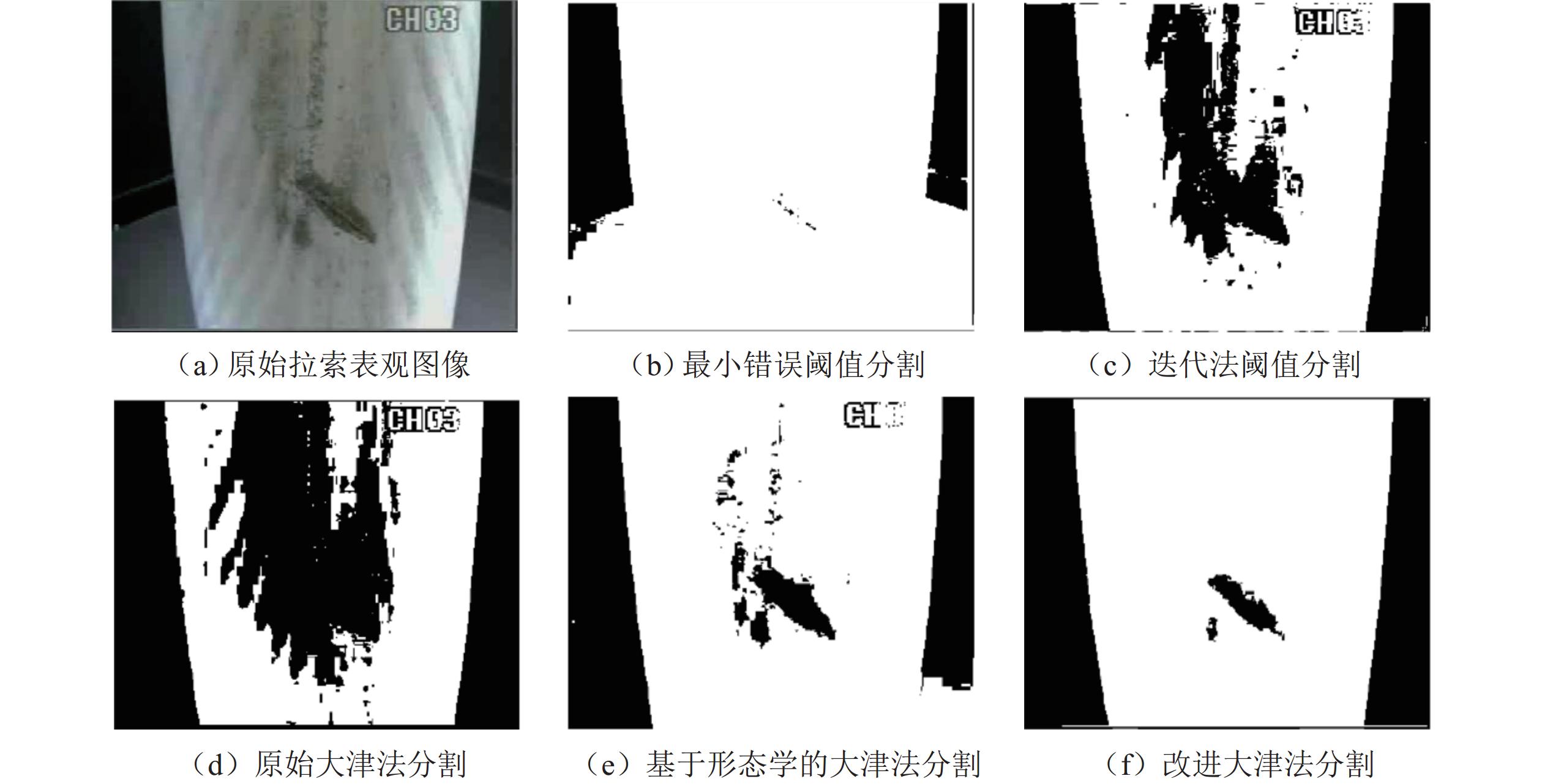

文献 方法类别 具体方法 贡献 局限性 应用场景 缺陷特征 [18] 缺陷特征统计 去噪、增强、分割、特征统计识别 方法简单有效 存在误判、检测样本少、步骤较多、实时性差 斜拉索表观检测 开裂类缺陷 [19] 缺陷特征统计 特征统计、模式识别 从灰度和纹理 2 个角度划分缺陷,提高检测效率;设计缺陷面积获取算法 噪声影响大、分类简单、面积有一定误判、实时性不足 斜拉索表观检测 粗糙和光滑

2 类缺陷[22] 传统图像分割 有效区域提取、阈值图像差分 有效解决光照不均匀,针对断丝、变形和磨损等缺陷效果较好 检测效果不够全面,鲁棒性不足 斜拉索表观检测 [24] 传统图像分割 Sobel 边缘检测 有效改善检测速度 微观缺陷难检测(孔洞、裂缝) 斜拉索表观检测 损伤面积大于10−4 m2 [27] 传统图像分割 边缘检测、伪缺陷去除算法、区域生长 区域生长提高检测精度 表皮杂质较多的情况下误差较大 斜拉索表观检测 像素灰度特征类似的缺陷 [28] 传统图像分割 图像裁剪、区域生长 有效提高检测速度 应用场景较单一 钢板波纹检测 [30] 无监督学习 图像增强、PCA 无需人为标注缺陷样本 存在误报率,需要人工检查核验 斜拉索表观检测 划伤类缺陷 [33] 无监督学习 密度峰值聚类、谱多流形聚类 实现表面相互干扰的不同缺陷分离,改善多种缺陷自适应检测 没有明显密度分布的大面积生锈情况难检测,鲁棒性差 直线导轨表面检测 复杂缺陷相互干扰 [36] 有监督学习 粒子群优化、SVM 有效识别多种类型缺陷 人工提取大量特征,实时性难度大 斜拉索表观检测 开裂、表面腐蚀和凹坑类缺陷 [40] 有监督学习 基于改进粒子群优化的缺陷分割、随机森林 引入多种评价指标进行评价,提高鲁棒性 皮革本身纹理易误判为缺陷、多阶段检测时间复杂度较高 皮革表观检测 纹理类特征明显的缺陷 表 2 基于深度学习的图像病害识别对比

Table 2. Comparison of image disease recognition based on deep learning

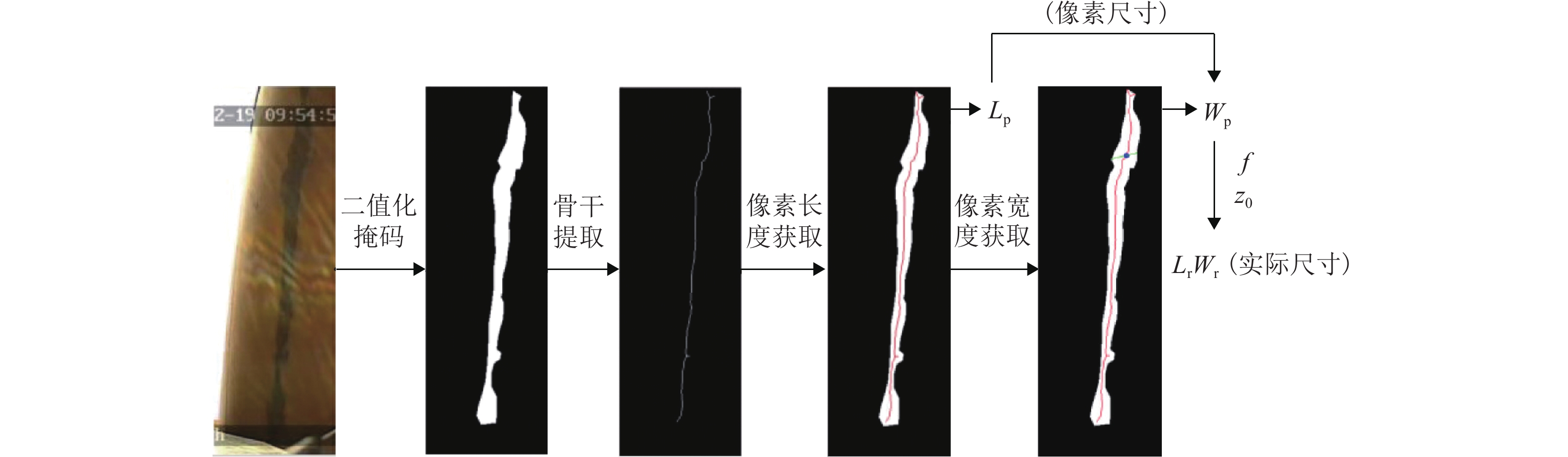

文献 研究领域 具体方法 贡献 局限性 应用场景 缺陷特征 [45] 图像分类 分类神经网络、集成学习 多模型融合有效提升鲁棒性和准确率 需大量标注样本、多方法集成实时性难实现 斜拉索表观检测 深度学习算法通过自主学习图像的有利特征,大多数方法能识别复杂情况下的多类缺陷 [47] 图像分类 迁移学习、GoogLeNet 迁移学习解决小样本问题 针对大面积下的微观缺陷难分类 塑料垫片缺陷检测 [48] 图形分类 改进 Alexnet 卷积网络 利用传统图像处理技术完成缺陷目标自动标注 算法抗干扰能力有待提升 隧道裂缝识别 [50] 目标检测 Faster R-CNN 检测精度极高 速度仍有待改善 斜拉索表观检测 [56] 目标检测 YOLOv3、TensorRT 优化推理 检测速度极快,完全满足实时性 检测精度受影响,有误差 斜拉索表观检测 [58] 目标检测 改进的 YOLOv4 保证速度的基础上提升检测精度 针对尺寸类检测需求不足 内燃机缸套表面缺陷检测 [62] 图像分割 语义分割 获取缺陷目标边界 影响速度,且同一类多个缺陷未分离 钢轨表面检测 [67] 图像分割 Cascade Mask R-CNN、图像骨架提取算法 准确度较高且获取单个目标准确边界,获得单个缺陷尺寸 速度难以实时检测,尺寸估计存在误差 斜拉索表观检测 [69] 图像分割 YOLACT 实例分割 有效分割出划痕类低语义缺陷、满足检测速度实时性 标注工作过于繁重 金属螺丝表面缺陷检测 [70] 其他深度学习 半监督生成对抗网络 节省标注成本、具有较好鲁棒性和灵活性 有一定误差 钢表面缺陷检测 [72] 其他深度学习 自特征重构与提炼模型、无监督学习 仅少数无缺陷样本训练,精确度较高 所检测缺陷类型单一,应用领域扩展性不高 纺织品表面缺陷检测 [74] 其他深度学习 三维重建和仿真、图像风格迁移 节省图像成本,提高模型适应性 应用场景存在局限 污水管内部表观检测 表 3 各类方法优缺点总结

Table 3. Advantages and disadvantages of various methods

方法类别 优点 缺点 适用场景 备注 传统图像处理技术 算法严格、不需要人工标注数据、无需大量样本 利用特征较少、需人工分析提取特征、算法鲁棒性和适用性差、检测效果单一 适用于外界环境干扰小和缺陷特征明显的任务,可设计简单快速的检测算法 各类算法在检测速度上均存在参差不齐的现象,综合检测效果以深度学习表现最优 传统机器学习 利用更多的图像特征、同种注重算法、分类效果更丰富、小样本也可、无监督无需标注数据 需人工统计特征、识别效果较单一、算法适用性有限、泛化能力不强 抗干扰能力有限、面对不同检测任务需分析对比多个算法后选择合适的模型 深度学习 不需要人工统计特征、算法鲁棒性和适应性较强、检测效果丰富(分类、定位、分割)、功能强大(缺陷图像生成、半监督减少人工标注等) 检测速度和精度难平衡、一些效果好的检测模型离不开大量标注数据的训练、硬件配置要求高且训练周期长、可解释性低 深度学习具有较强的学习能力和泛化能力,适合大多数检测任务 表 4 斜拉索表观病害识别效果

Table 4. Recognition effect of apparent disease of stay cable

文献 采用方法 检测效果 不足之处 [18] 纹理特征统计 完全识别病害图像且正常图像识别率为89.23%,简单有效 存在误判、图像质量要求高 [19] 灰度特征统计、模式识别 不同缺陷的检测准确率均高于 90% 且缺陷面积误差低于 20%. 易受噪声影响、分类简单、难以区分附着物与真实缺陷、缺陷深度难检测 [21] 形态学、阈值分割 病害图像漏检率 0%,正常图像漏检率 22.22%,有效实现缺陷形状表征 正常图像误判率较高,分类效果简单 [22] 大津法 阈值分割 图像缺陷识别精确度达到 90%以上 检测效果单一 [29] Sobel 边缘检测、阈值分割 检测出面积大于 10−4 m2 的斜拉索缺陷,且检测速度为 0.025 m/s 适用性较低,微小缺陷难识别 [24] 基于 Sobel 的边缘检测算法 有效地检测出面积大于 10−4 m2 的缺陷,检测效率达 0.05 m/s 微小缺陷难检测 [25] 基于 Scharr 的边缘检测算法 检测结果达到 96.6% 的准确率和 0.6% 的漏检率 存在对易错检的磨损干扰等图像的误判,造成准确率低的问题 [30] PCA 有效检测出病害的大小和位置 需大量高质量训练图像,不能适应复杂检测环境 [36] 改进 SVM 有效识别纵向开裂、横向开裂、表面腐蚀和凹坑4 种缺陷,分类准确率高达 96.25% 存在缺陷不能完整识别现象、缺陷类别识别不全 [37] 阈值分割、PCA、SVM 实时性较好,满足拉索缺陷检测需求 采用模拟样本、可信度不足且样本数量不足 [45] 集成学习、图像分类 实现缺陷图像精准分类,准确率高达 97.83% 集成 3 个分类网络、推理速度较低造成检测效率不高 [50] Faster R-CNN 该模型检测准确率超过 99%,检测速度相较与传统检测技术提高 300% 训练图像单一、不能达到实时检测 [55] 改进 YOLOv3 mAP 指标为 93.7%,FPS 指标达 17 帧/s,满足实时检测要求 检测精度低于双阶段检测模型 [56] YOLOv3、TensorRT 检测准确率超过 80% 且检测一张图像仅需 0.012 s 高速的检测速度造成检测精度下降 [57] YOLOv5 能够准确识别斜拉索表观病害,解决人工检测中高成本与风险、低效率、低精度等问题 精度有待提高 [66] Mask R-CNN 一定程度上解决识别精度低、效率低等问题 实时性仍旧不足 [67] 改进 Cascade Mask R-CNN 通过实验对比,评估中获得了最佳 IoU 为 0.743,F1 得分 85.1%,准确度高达 99.6%,总平均像素长度误差为 6.1%,总平均像素宽度误差为 7.3% FPS 仅为 7.8 帧/s,较低 -

[1] 《中国公路学报》编辑部. 中国桥梁工程学术研究综述•2021[J]. 中国公路学报,2021,34(2): 1-97. doi: 10.3969/j.issn.1001-7372.2021.02.002Editorial Department of China Journal of Highway and Transport. Review on China’s bridge engineering research: 2021[J]. China Journal of Highway and Transport, 2021, 34(2): 1-97. doi: 10.3969/j.issn.1001-7372.2021.02.002 [2] 苑仁安,张明金,郑清刚,等. 超大跨斜拉桥横桥向恒载非对称力学行为[J]. 西南交通大学学报,2023,58(3): 527-534. doi: 10.3969/j.issn.0258-2724.20210279YUAN Renan, ZHANG Mingjin, ZHENG Qinggang, et al. Mechanical characteristics of super-long-span cable-stayed bridge with transverse asymmetrical load[J]. Journal of Southwest Jiaotong University, 2023, 58(3): 527-534. doi: 10.3969/j.issn.0258-2724.20210279 [3] LIU S W, SUN Y H, JIANG X Y, et al. A review of wire rope detection methods, sensors and signal processing techniques[J]. Journal of Nondestructive Evaluation, 2020, 39: 1-18. doi: 10.1007/s10921-019-0643-0 [4] 钱骥,孙利民,蒋永. 桥梁拉索损伤声发射监测研究进展[J]. 应用声学,2016,35(4): 369-376.QIAN Ji, SUN Limin, JIANG Yong. Advances in acoustic emission technique to cables health monitoring[J]. Journal of Applied Acoustics, 2016, 35(4): 369-376. [5] 中华人民共和国交通运输部. 在用公路桥梁现场检测技术规程:JTG/T 5214—2022[S]. 北京:人民交通出版社,2022. [6] 刘倩倩,徐程,韩勇涛,等. 一种用于斜拉桥拉索套管的喷涂装置:CN211051767U[P]. 2020-07-21. [7] WANG Z P, HE B, ZHOU Y M, et al. Design and implementation of a cable inspection robot for cable-stayed bridges[J]. Robotica, 2021: 1-17. [8] LI J, YIN C Y, SHI Y D, et al. Circumferentially rotatable inspection robot with elastic suspensions for bridge cables[J]. Industrial Robot: the International Journal of Robotics Research and Application, 2022, 49(5): 981-993. doi: 10.1108/IR-11-2021-0261 [9] 马晔,邹露鹏,张理轻. 无人机加载光学摄像及红外成像系统对海上特大桥塔索质量检测的运用技术[J]. 公路交通科技,2018,35(8): 89-93,105.MA Ye, ZOU Lupeng, ZHANG Liqing. Application technology of UAV equipped with optical camera and digital infrared imagery in inspecting quality of pylon and stay cable of sea-crossing bridge[J]. Journal of Highway and Transportation Research and Development, 2018, 35(8): 89-93,105. [10] 杨传礼,张修庆. 基于机器视觉和深度学习的材料缺陷检测应用综述[J]. 材料导报,2022,36(16): 226-234.YANG Chuanli, ZHANG Xiuqing. Survey of applications of material defect detection based on machine vision and deep learning[J]. Materials Reports, 2022, 36(16): 226-234. [11] 赵朗月,吴一全. 基于机器视觉的表面缺陷检测方法研究进展[J]. 仪器仪表学报,2022,43(1): 198-219.ZHAO Langyue, WU Yiquan. Research progress of surface defect detection methods based on machine vision[J]. Chinese Journal of Scientific Instrument, 2022, 43(1): 198-219. [12] 黄梦涛,连一鑫. 基于改进Canny算子的锂电池极片表面缺陷检测[J]. 仪器仪表学报,2021,42(10): 199-209.HUANG Mengtao, LIAN Yixin. Lithium battery electrode plate surface defect detection based on improved Canny operator[J]. Chinese Journal of Scientific Instrument, 2021, 42(10): 199-209. [13] DHIVYA, M, RENUKA D M. Detection of structural defects in fabric parts using a novel edge detection method[J]. The Computer Journal, 2019, 62(7): 1036-1043. doi: 10.1093/comjnl/bxy121 [14] WANG S, LIU X Q, YANG T F, et al. Panoramic crack detection for steel beam based on structured random forests[J]. IEEE Access, 2018, 6: 16432-16444. doi: 10.1109/ACCESS.2018.2812141 [15] SINGH, S A, DESAI K A. Automated surface defect detection framework using machine vision and convolutional neural networks[J]. Journal of Intelligent Manufacturing, 2023, 34(4): 1995-2011. doi: 10.1007/s10845-021-01878-w [16] 郭继昌,岳惠惠,张怡,等. 图像增强对显著性目标检测的影响研究[J]. 中国图象图形学报,2022,27(7): 2129-2147. doi: 10.11834/j.issn.1006-8961.2022.7.zgtxtxxb-a202207005GUO Jichang, YUE Huihui, ZHANG Yi, et al. The analysis of image enhancement on salient object detection[J]. Journal of Image and Graphics, 2022, 27(7): 2129-2147. doi: 10.11834/j.issn.1006-8961.2022.7.zgtxtxxb-a202207005 [17] 王田,邹子龙,乔美娜. 基于图像特征分析的物体轮廓提取[J]. 北京航空航天大学学报,2016,42(8): 1762-1768.WANG Tian, ZOU Zilong, QIAO Meina. Object contour extraction based on image feature analysis[J]. Journal of Beijing University of Aeronautics and Astronautics, 2016, 42(8): 1762-1768. [18] 刘朝涛,杜子学,武维,等. 基于图像处理的桥梁缆索检测系统研制[J]. 重庆交通大学学报(自然科学版),2014,33(2): 5-9.LIU Chaotao, DU Zixue, WU Wei, et al. Development of cable inspection system based on image processing[J]. Journal of Chongqing Jiaotong University (Natural Science), 2014, 33(2): 5-9. [19] 蔡步文. 基于图像处理的斜拉桥缆索表面缺陷检测的研究[D]. 重庆:重庆大学,2010. [20] 王建林,潘建平. 一种桥梁拉索表面缺陷图像的背景分割方法研究[J]. 测绘工程,2018,27(7): 24-29.WANG Jianlin, PAN Jianping. A method of background segmentation for surface defect of bridge cables[J]. Engineering of Surveying and Mapping, 2018, 27(7): 24-29. [21] 阳振宇. 基于MATLAB的桥梁拉索表面缺陷视频检测[D]. 重庆:重庆交通大学,2019. [22] CHEN J N, WANG H, TU C L, et al. Surface defect detection of cable based on threshold image difference[C]//2021 IEEE Far East NDT New Technology & Application Forum (FENDT). Kunming: IEEE, 2022: 185-190. [23] 高潮,任可,郭永彩,等. 基于DSP和图像识别的拉索表面缺陷检测技术[J]. 重庆大学学报(自然科学版),2007,30(9): 36-38.GAO Chao, REN Ke, GUO Yongcai, et al. Detecting technology of cabel surface defect based on DSP and image recognition[J]. Journal of Chongqing University (Natural Science Edition), 2007, 30(9): 36-38. [24] 李新科,高潮,郭永彩,等. 桥梁拉索表面缺陷的分布式机器视觉检测[J]. 光学技术,2013,39(5): 424-428.LI Xinke, GAO Chao, GUO Yongcai, et al. The inspection method based on distributed machine vision for surface defects of bridge cables[J]. Optical Technique, 2013, 39(5): 424-428. [25] 刘淑敏. 基于机器视觉的桥梁裂纹检测算法研究[D]. 重庆:重庆大学,2019. [26] LIU X M, TIAN H, WANG Y, et al. Research on image segmentation algorithm and performance of power insulator based on adaptive region growing[J]. Journal of Electrical Engineering & Technology, 2022, 17(6): 3601-3612. [27] 蔡步文,周忆,申超. 斜拉桥缆索表面缺陷提取方法研究[J]. 微计算机信息,2010,26(32): 188-190.CAI Buwen, ZHOU Yi, SHEN Chao. Crack detection algorithm design for cable’s protective layer surface on cable-stayed bridge[J]. Microcomputer Information, 2010, 26(32): 188-190. [28] LI L Y, HAO P F. Steel plate corrugation defect intelligent detection method based on picture cropping and region growing algorithm[C]//2019 14th IEEE Conference on Industrial Electronics and Applications (ICIEA). Xi’an: IEEE, 2019: 587-590. [29] ZOU G F, LI T T, LI G Y, et al. A visual detection method of tile surface defects based on spatial-frequency domain image enhancement and region growing[C]//2019 Chinese Automation Congress (CAC). Hangzhou: IEEE, 2020: 1631-1636. [30] HO H N, KIM K D, PARK Y S, et al. An efficient image-based damage detection for cable surface in cable-stayed bridges[J]. NDT & E International, 2013, 58: 18-23. [31] 周兆逸,张亚南,王肖锋,等. 基于改正二维主成分分析的焊缝表面缺陷检测[J]. 焊接学报,2021,42(11): 70-76,101.ZHOU Zhaoyi, ZHANG Yanan, WANG Xiaofeng, et al. Weld surface defect detection based on improved twodimensional principal component analysis[J]. Transactions of the China Welding Institution, 2021, 42(11): 70-76,101. [32] 王欣,高炜欣,王征,等. 基于并行计算的PCA在缺陷检测中的应用[J]. 计算机工程与设计,2016,37(10): 2810-2815,2850.WANG Xin, GAO Weixin, WANG Zheng, et al. Application of PCA in defect detection based on parallel computing[J]. Computer Engineering and Design, 2016, 37(10): 2810-2815,2850. [33] ZHOU Y H, MA Z X, SHI X W, et al. An adaptive clustering method detecting the surface defects on linear guide rails[J]. International Journal of Computer Integrated Manufacturing, 2019, 32(8): 798-808. doi: 10.1080/0951192X.2019.1636409 [34] LI X G, ZHU J A, SHI H R, et al. Surface defect detection of seals based on K-means clustering algorithm and particle swarm optimization[J]. Scientific Programming, 2021(1): 3965247.1-3965247.12. [35] YANG H, CHEN Y F, SONG K Y, et al. Multiscale feature-clustering-based fully convolutional autoencoder for fast accurate visual inspection of texture surface defects[J]. IEEE Transactions on Automation Science and Engineering, 2019, 16(3): 1450-1467. doi: 10.1109/TASE.2018.2886031 [36] LI X K, GUO Y C, LI Y M. Particle swarm optimization-based SVM for classification of cable surface defects of the cable-stayed bridges[J]. IEEE Access, 2019, 8: 44485-44492. [37] 李鑫. 桥梁拉索护套表面缺陷视觉检测及智能识别研究[D]. 长沙:湖南大学,2019. [38] ZHANG K B, YAN Y D, LI P F, et al. Fabric defect detection using salience metric for color dissimilarity and positional aggregation[J]. IEEE Access, 2018, 6: 49170-49181. doi: 10.1109/ACCESS.2018.2868059 [39] CHANG Z Y, CAO J, ZHANG Y Z. A novel image segmentation approach for wood plate surface defect classification through convex optimization[J]. Journal of Forestry Research, 2018, 29(6): 1789-1795. doi: 10.1007/s11676-017-0572-7 [40] JAWAHAR M, CHANDRA BABU N K, VANI K, et al. Vision based inspection system for leather surface defect detection using fast convergence particle swarm optimization ensemble classifier approach[J]. Multimedia Tools and Applications, 2021, 80(3): 4203-4235. doi: 10.1007/s11042-020-09727-3 [41] 夏毅敏,李清友,邓朝辉,等. 基于轻量级模型的隧道岩性快速识别方法[J]. 西南交通大学学报,2021,56(2): 420-427.XIA Yimin, LI Qingyou, DENG Chaohui, et al. Rapid identification method for lithology of tunnel based on lightweight model[J]. Journal of Southwest Jiaotong University, 2021, 56(2): 420-427. [42] 范新南,汪杰,史朋飞,等. 基于头脑风暴优化的PCNN路面裂缝分割算法[J]. 西南交通大学学报,2021,56(3): 572-578.FAN Xinnan, WANG Jie, SHI Pengfei, et al. Pavement crack segmentation algorithm based on pulse coupled neural network with brainstorming optimization[J]. Journal of Southwest Jiaotong University, 2021, 56(3): 572-578. [43] THAKUR M, PILLAI S K. A review on various methods for classification of massive noisy image[C]//2019 International Conference on Intelligent Sustainable Systems (ICISS). Palladam: IEEE, 2019: 525-528. [44] HE K M, ZHANG X Y, REN S Q, et al. Deep residual learning for image recognition[C]//2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR). Las Vegas: IEEE, 2016: 770-778. [45] 董斌. 斜拉桥拉索外套表观病害与索力时变识别方法研究[D]. 南京:东南大学,2020. [46] JIANG X Z, WANG X F, CHEN D F. Research on defect detection of castings based on deep residual network[C]//2018 11th International Congress on Image and Signal Processing, BioMedical Engineering and Informatics (CISP-BMEI). Beijing: IEEE, 2019: 1-6. [47] CHEN X Y, WANG D Y, SHAO J J, et al. Plastic gasket defect detection based on transfer learning[J]. Scientific Programming, 2021(1): 5990020.1-5990020.11. [48] 王耀东,朱力强,余祖俊,等. 基于样本自动标注的隧道裂缝病害智能识别研究[J]. 西南交通大学学报,2023,58(5):1-8.WANG Yaodong, ZHU Liqiang, YU Zhujun, et al. Research of tunnel cracks recognition based on automatic sample labeling[J]. Journal of Southwest Jiaotong University,2023,58(5):1-8. [49] REN S Q, HE K M, GIRSHICK R, et al. Faster R-CNN: towards real-time object detection with region proposal networks[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2017, 39(6): 1137-1149. doi: 10.1109/TPAMI.2016.2577031 [50] 余朝阳. 斜拉索检测机器人的智能表观检测研究[J]. 公路交通技术,2020,36(2): 86-92.YU Chaoyang. Research on intelligent apperance algorithm of stay cable detection robot[J]. Technology of Highway and Transport, 2020, 36(2): 86-92. [51] 晏班夫,徐观亚,栾健,等. 基于Faster R-CNN与形态法的路面病害识别[J]. 中国公路学报,2021,34(9): 181-193. doi: 10.3969/j.issn.1001-7372.2021.09.015YAN Banfu, XU Guanya, LUAN Jian, et al. Pavement distress detection based on faster R-CNN and morphological operations[J]. China Journal of Highway and Transport, 2021, 34(9): 181-193. doi: 10.3969/j.issn.1001-7372.2021.09.015 [52] 李东洁,李若昊. 基于改进Faster RCNN的马克杯缺陷检测方法[J]. 激光与光电子学进展,2020,57(4): 353-360.LI Dongjie, LI Ruohao. Mug defect detection method based on improved faster RCNN[J]. Laser & Optoelectronics Progress, 2020, 57(4): 353-360. [53] LI L, JIANG Z J, LI Y N. Surface defect detection algorithm of aluminum based on improved faster RCNN[C]//2021 IEEE 9th International Conference on Information, Communication and Networks (ICICN). Xi’an: IEEE, 2022: 527-531. [54] REDMON J, DIVVALA S, GIRSHICK R, et al. You only look once: unified, real-time object detection[C]//2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR). Las Vegas: IEEE, 2016: 779-788. [55] 李运堂,谢梦鸣,王鹏峰,等. 基于改进YOLOV3算法的斜拉桥拉索表面缺陷检测方法[J]. 传感技术学报,2021,34(11): 1509-1517. doi: 10.3969/j.issn.1004-1699.2021.11.014LI Yuntang, XIE Mengming, WANG Pengfeng, et al. Defects inspection method for cable surface of cable-stayed bridge based on improved YOLOV3 algorithm[J]. Chinese Journal of Sensors and Actuators, 2021, 34(11): 1509-1517. doi: 10.3969/j.issn.1004-1699.2021.11.014 [56] 张可惠. 桥梁斜拉索表观缺陷视觉检测系统研究[D]. 长沙:湖南大学,2021. [57] 周朗明,万智,胡帅花,等. 一种斜拉桥缆索表面多类型病害智能检测和识别方法:CN113313107A[P]. 2021-08-27. [58] LI J Y, SU Z F, GENG J H, et al. Real-time detection of steel strip surface defects based on improved YOLO detection network[J]. IFAC-PapersOnLine, 2018, 51(21): 76-81. doi: 10.1016/j.ifacol.2018.09.412 [59] CHEN Y B, FU Q S, WANG G T. Surface defect detection of nonburr cylinder liner based on improved YOLOv4[J]. Mobile Information Systems, 2021, 2021: 1-13. [60] RONNEBERGER O, FISCHER P, BROX T. U-net: convolutional networks for biomedical image segmentation[C]//International Conference on Medical Image Computing and Computer-Assisted Intervention. Cham: Springer, 2015: 234-241. [61] QIAN K. Automated detection of steel defects via machine learning based on real-time semantic segmentation[C]//Proceedings of the 3rd International Conference on Video and Image Processing. Shanghai: ACM, 2019: 42-46. [62] 李忠海,白秋阳,王富明,等. 基于语义分割的钢轨表面缺陷实时检测系统[J]. 计算机工程与应用,2021,57(12): 248-256. doi: 10.3778/j.issn.1002-8331.2004-0101LI Zhonghai, BAI Qiuyang, WANG Fuming, et al. Real-time detection system of rail surface defects based on semantic segmentation[J]. Computer Engineering and Applications, 2021, 57(12): 248-256. doi: 10.3778/j.issn.1002-8331.2004-0101 [63] LIANG Z C, ZHANG H, LIU L, et al. Defect detection of rail surface with deep convolutional neural networks[C]//2018 13th World Congress on Intelligent Control and Automation (WCICA). Changsha: IEEE, 2019: 1317-1322. [64] TANG C W, FENG X X, WEN H T, et al. Semantic segmentation network for surface defect detection of automobile wheel hub fusing high-resolution feature and multi-scale feature[J]. Applied Sciences, 2021, 11(22): 10508.1-10508.20. doi: 10.3390/app112210508 [65] HE K M, GKIOXARI G, DOLLÁR P, et al. Mask R-CNN[C]//2017 IEEE International Conference on Computer Vision (ICCV). Venice: IEEE, 2017: 2980-2988. [66] 王兴松,李杰,田梦倩. 基于深度学习的桥梁拉索表面缺陷实时识别系统及方法:CN112101138A[P]. 2020-12-18. [67] HOU S T, DONG B, WANG H C, et al. Inspection of surface defects on stay cables using a robot and transfer learning[J]. Automation in Construction, 2020, 119: 103382.1-103382.14. doi: 10.1016/j.autcon.2020.103382 [68] 余加勇,李锋,薛现凯,等. 基于无人机及Mask R-CNN的桥梁结构裂缝智能识别[J]. 中国公路学报,2021,34(12): 80-90. doi: 10.3969/j.issn.1001-7372.2021.12.007YU Jiayong, LI Feng, XUE Xiankai, et al. Intelligent identification of bridge structural cracks based on unmanned aerial vehicle and mask R-CNN[J]. China Journal of Highway and Transport, 2021, 34(12): 80-90. doi: 10.3969/j.issn.1001-7372.2021.12.007 [69] CHEN W Y, TSAO Y R, LAI J Y, et al. Real-time instance segmentation of metal screw defects based on deep learning approach[J]. Measurement Science Review, 2022, 22(3): 107-111. doi: 10.2478/msr-2022-0014 [70] ZHANG G W, PAN Y, ZHANG L M. Semi-supervised learning with GAN for automatic defect detection from images[J]. Automation in Construction, 2021, 128: 103764.1-103764.14. doi: 10.1016/j.autcon.2021.103764 [71] ZHAO Z X, LI B, DONG R, et al. A surface defect detection method based on positive samples[C]//Pacific Rim International Conference on Artificial Intelligence. Cham: Springer, 2018: 473-481. [72] PENG Z R, GONG X Y, WEI B G, et al. Automatic unsupervised fabric defect detection based on self-feature comparison[J]. Electronics, 2021, 10(21): 2652.1-2652.12. doi: 10.3390/electronics10212652 [73] MATUSZCZYK, D, TSCHORN N, WEICHERT F. Deep learning based synthetic image generation for defect detection in additive manufacturing industrial environments[C]//2022 7th International Conference on Mechanical Engineering and Robotics Research (ICMERR). Krakow: IEEE, 2022: 209-218. [74] YUN J P, SHIN W C, KOO G, et al. Automated defect inspection system for metal surfaces based on deep learning and data augmentation[J]. Journal of Manufacturing Systems, 2020, 55: 317-324. doi: 10.1016/j.jmsy.2020.03.009 -

下载:

下载: