Flexural Performance of PP-ECC Beams Under Coupling of Freeze-Thaw Cycles and Bending Loads

-

摘要:

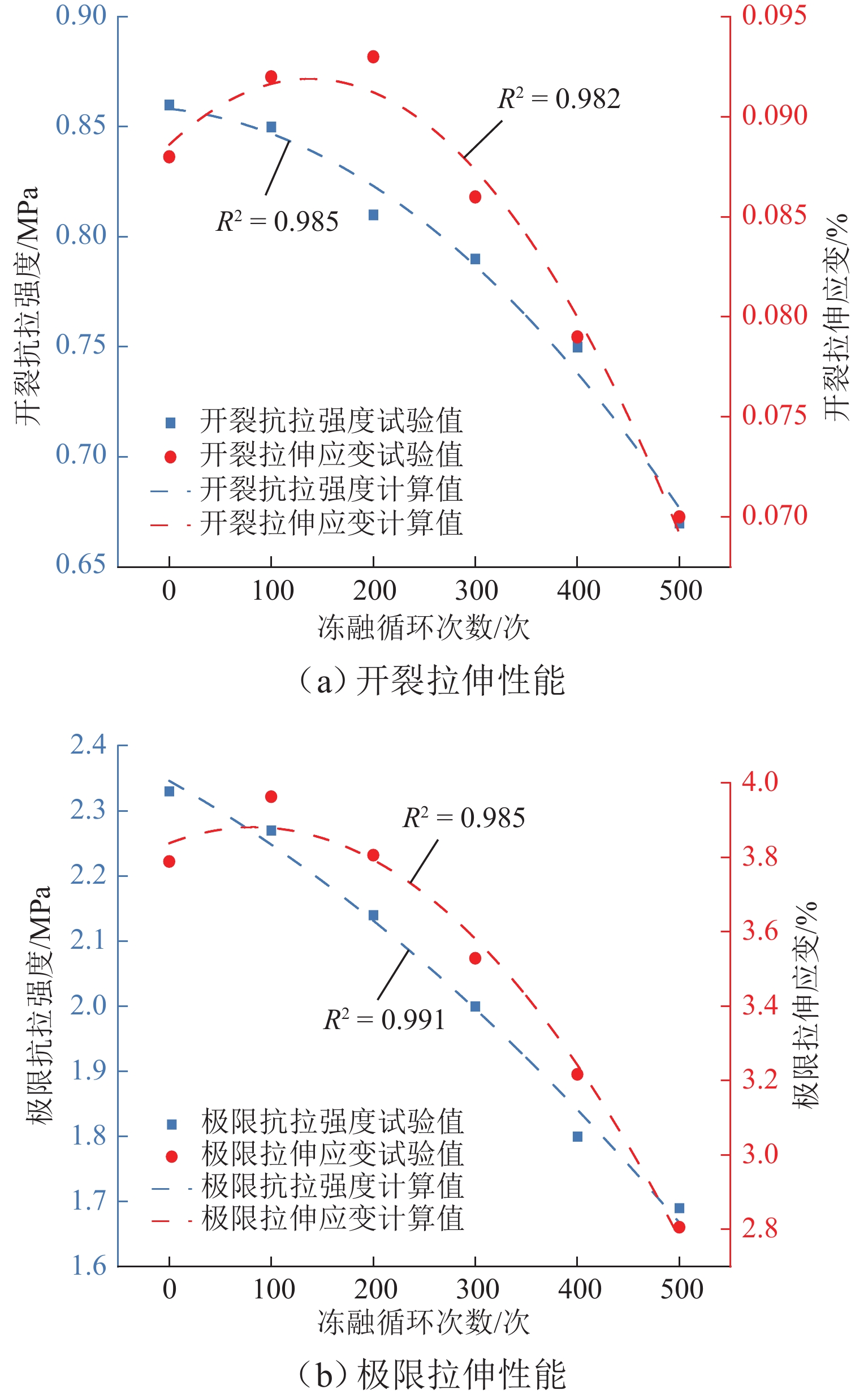

为探究冻融以及冻融-弯曲荷载耦合作用对聚丙烯纤维水泥基复合材料(PP-ECC)梁抗弯性能的影响,设置7种试验工况,采用三分点加载方式对PP-ECC梁抗弯性能进行研究,分析冻融及冻融-弯曲荷载耦合作用下PP-ECC梁的荷载-跨中挠度曲线、抗弯承载力及裂缝发展形态差异;基于计算假定和正常环境下PP-ECC梁抗弯承载力的计算模型,结合PP-ECC材料冻融劣化机理,推导出PP-ECC梁在冻融环境下抗弯承载力计算模型;在此基础上引入持荷损伤系数

γ ,建立冻融-弯曲荷载耦合作用下PP-ECC梁抗弯承载力计算模型. 研究结果表明:不同持荷比的PP-ECC梁极限抗弯承载力在冻融循环作用下出现不同程度降低,500次冻融循环后,持荷比为0、0.25、0.50的PP-ECC梁极限抗弯承载力分别降低了28.70%、27.09%、35.69%;受拉区PP-ECC材料开裂后不退出工作仍能协同受拉钢筋参与全截面受力;PP-ECC 梁在达到极限状态时,受拉区呈多条裂缝稳态发展模式,且随冻融损伤加剧,梁体最大裂缝宽度增大,裂缝数量减少;单一冻融以及冻融-弯曲荷载耦合作用下的PP-ECC梁仍满足平截面假定;基于平截面假定建立的冻融和冻融-弯曲荷载耦合作用下PP-ECC 梁的抗弯承载力计算模型吻合度分别在0.88~1.06和0.96~1.10.-

关键词:

- 冻融-弯曲荷载耦合作用 /

- 抗弯性能 /

- 聚丙烯纤维水泥基复合材料 /

- 抗弯承载力 /

- 多裂缝发展

Abstract:To investigate the effect of freeze-thaw cycles and coupling of freeze-thaw cycles and bending loads on the flexural performance of polypropylene fiber cement-based composite (PP-ECC) beams, seven experimental working conditions were set up. In addition, the three-point loading method was adopted to explore the flexural performance of PP-ECC beams. The differences in load-span deflection curves, flexural bearing capacity, and crack development patterns of PP-ECC beams under coupling of freeze-thaw cycles and bending loads were analyzed. Based on the calculation assumptions and the calculation model of the flexural bearing capacity of PP-ECC beams under normal environments, combined with the freeze-thaw deterioration mechanism of PP-ECC materials, the calculation model of flexural bearing capacity of PP-ECC beams under freeze-thaw environments was deduced. Furthermore, the load-bearing damage coefficient γ was introduced on this basis. The calculation model of the flexural bearing capacity of PP-ECC beams under the coupling of freeze-thaw cycles and bending loads was established. The research results show that the ultimate flexural bearing capacity of PP-ECC beams with different load-bearing ratios decreases to varying degrees under freeze-thaw cycles. After 500 freeze-thaw cycles, the ultimate flexural bearing capacity of PP-ECC beams with load-bearing ratios of 0, 0.25, and 0.5 decreases by 28.70%, 27.09%, and 35.69%, respectively. After cracking under tension, the PE-ECC material can still work with the rebar under tension and participate in the stress of the whole section. When the PP-ECC beam reaches the limit state, the zone under tension develops steadily with multiple cracks. With the aggravation of freeze-thaw damage, the width of the largest crack in the beam body increases, and the number of cracks decreases. The PP-ECC beam subjected to freeze-thaw cycles and coupling of freeze-thaw cycles and bending loads still satisfies the plane section assumption. The coincidence degree of the flexural bearing capacity calculation models of PP-ECC beams under freeze-thaw cycles and coupling of freeze-thaw cycles and bending loads established based on the plane section assumption is 0.88–1.06 and 0.96–1.10, respectively.

-

表 1 PP-ECC梁具体试验参数

Table 1. Specific test parameters of PP-ECC beam

试验梁

分组试件编号 冻融循环

次数/次弯曲

荷载/%抗弯性能

试验第Ⅰ组 E0-0 0 是 第Ⅱ组 E0-300 300 E0-500 500 第Ⅲ组 E0.25-300 300 25 E0.25-500 500 第Ⅳ组 E0.50-300 300 50 E0.50-500 500 表 2 钢筋性能指标

Table 2. Rebar performance indexes

型号 直径/

mm截面面

积/mm2屈服强

度/MPa极限强

度/MPa弹性模

量/GPaQ235 6 28.26 236 390 196 HRB400 6 28.26 406 576 197 HRB400 10 78.50 411 535 203 表 3 PP-ECC梁的配合比

Table 3. Mix proportion of PP-ECC beam

kg/m3 水泥 粉煤灰 PP纤维 水 820.0 442.0 18.2 504.8 表 4 PP-ECC梁四点弯曲试验结果

Table 4. Four-point bending test results of PP-ECC beam

试件编号 屈服荷载/kN 极限荷载/kN 极限抗弯承载力/(kN·m) 裂缝最大宽度/mm 最终裂缝数量/条 E0-0 33.95 33.97 5.10 0.90 36 E0-300 29.34 28.84 4.33 1.10 30 E0-500 24.82 24.22 3.63 1.34 25 E0.25-300 30.88 30.72 4.61 1.25 32 E0.25-500 24.64 25.02 3.75 1.42 29 E0.50-300 26.67 26.01 3.90 1.55 23 E0.50-500 21.21 21.87 3.28 1.80 18 表 5 PP-ECC材料本构参数

Table 5. Constitutive parameters of PP-ECC materials

PP-ECC 单轴拉伸本构参数 单轴受压本构参数 σtc/MPa εtc/% σtu/MPa εtu/% σcu/MPa εcu/% 0.86 0.088 2.33 3.789 31.65 0.38 表 6 抗弯承载力对比

Table 6. Comparison of flexural bearing capacity

冻融循环

次数/次抗弯承载力 计算值/

试验值计算值/

(kN·m)试验值/

(kN·m)0 4.50 5.10 0.88 300 4.18 4.33 0.97 500 3.88 3.63 1.06 表 7 抗弯承载力对比

Table 7. Comparison of flexural bearing capacity

冻融循环

次数/次持荷比 抗弯承载力 计算值/

试验值计算值/

(kN·m)试验值/

(kN·m)300 0 4.18 4.33 0.97 0.25 4.46 4.61 0.97 0.50 3.75 3.90 0.96 500 0 3.88 3.63 1.07 0.25 4.14 3.75 1.10 0.50 3.48 3.28 1.06 -

[1] CAMPIONE G, CANNELLA F, CAVALERI L. Shear and flexural strength prediction of corroded R. C. beams[J]. Construction and Building Materials, 2017, 149: 395-405. doi: 10.1016/j.conbuildmat.2017.05.125 [2] LI V C, LEUNG C K Y. Steady-state and multiple cracking of short random fiber composites[J]. Journal of Engineering Mechanics, 1992, 118(11): 2246-2264. doi: 10.1061/(ASCE)0733-9399(1992)118:11(2246) [3] LI V C, WU H C. Conditions for pseudo strain-hardening in fiber reinforced brittle matrix composites[J]. Applied Mechanics Reviews, 1992, 45(8): 390-398. doi: 10.1115/1.3119767 [4] YUAN F, PAN J L, DONG L T, et al. Mechanical behaviors of steel reinforced ECC or ECC/concrete composite beams under reversed cyclic loading[J]. Journal of Materials in Civil Engineering, 2014, 26(8): 04014047.1-04014047.8. [5] POURFALAH S. Behaviour of engineered cementitious composites and hybrid engineered cementitious composites at high temperatures[J]. Construction and Building Materials, 2018, 158: 921-937. doi: 10.1016/j.conbuildmat.2017.10.077 [6] JIN H S, LI F H, HU D H. Research on the flexural performance of reinforced engineered cementitious composite beams[J]. Structural Concrete, 2022, 23(4): 2198-2220. doi: 10.1002/suco.202100012 [7] 黄士元. 近代混凝土技术[M]. 西安: 陕西科学技术出版社, 1998. [8] SUN W, ZHANG Y M, YAN H D, et al. Damage and damage resistance of high strength concrete under the action of load and freeze-thaw cycles[J]. Cement and Concrete Research, 1999, 29(9): 1519-1523. doi: 10.1016/S0008-8846(99)00097-6 [9] KOSIOR-KAZBERUK M, BERKOWSKI P. Surface scaling resistance of concrete subjected to freeze-thaw cycles and sustained load[J]. Procedia Engineering, 2017, 172: 513-520. doi: 10.1016/j.proeng.2017.02.060 [10] SHEN Y, LIU J, ZHOU S Y, et al. Experimental investigation on the freeze-thaw durability of concrete under compressive load and with joints[J]. Construction and Building Materials, 2019, 229: 116893.1-116893.12. doi: 10.1016/j.conbuildmat.2019.116893 [11] WANG Y, WANG G, GUAN Z W, et al. The effect of freeze-thaw cycles on flexural behaviour of FRP-reinforced ECC beams[J]. Archives of Civil and Mechanical Engineering, 2021, 21(3): 1-24. [12] ZHANG Y X, BAI S, ZHANG Q B, et al. Failure behavior of strain hardening cementitious composites for shear strengthening RC member[J]. Construction and Building Materials, 2015, 78: 470-473. doi: 10.1016/j.conbuildmat.2015.01.037 [13] DING Y, YU K Q, YU J T, et al. Structural behaviors of ultra-high performance engineered cementitious composites (UHP-ECC) beams subjected to bending-experimental study[J]. Construction and Building Materials, 2018, 177: 102-115. doi: 10.1016/j.conbuildmat.2018.05.122 [14] YUN H D, KIM S W, LEE Y O, et al. Tensile behavior of synthetic fiber-reinforced strain-hardening cement-based composite (SHCC) after freezing and thawing exposure[J]. Cold Regions Science and Technology, 2011, 67(1/2): 49-57. [15] 靳贺松,李福海,何肖云峰,等. 聚丙烯纤维水泥基复合材料的抗冻性能研究[J]. 材料导报,2020,34(8): 8071-8076,8082. doi: 10.11896/cldb.18080117JIN Hesong, LI Fuhai, HE Xiaoyunfeng, et al. Research on frost resistance of polypropylene fiber cement-based composite material[J]. Materials Reports, 2020, 34(8): 8071-8076,8082. doi: 10.11896/cldb.18080117 [16] DUAN A, LI Z Y, ZHANG W C, et al. Flexural behaviour of reinforced concrete beams under freeze-thaw cycles and sustained load[J]. Structure and Infrastructure Engineering, 2017, 13(10): 1350-1358. doi: 10.1080/15732479.2016.1268172 [17] 李福海,胡丁涵,余泳江,等. PP-ECC梁抗弯性能试验研究[J]. 西南交通大学学报,2021,56(2): 272-281.LI Fuhai, HU Dinghan, YU Yongjiang, et al. Experimental study on flexural capacity of PP-ECC beam[J]. Journal of Southwest Jiaotong University, 2021, 56(2): 272-281. [18] 崔晶波. 荷载冻融耦合作用下再生粗骨料自密实混凝土梁的受弯力学性能试验研究[D]. 乌鲁木齐: 新疆大学, 2020. [19] IAN T. Research on seismic behavior of steel tube reinforeed conerete bridge columns[D]. Dalian: Dalian University of Technology, 2019. [20] LI F H, WEN T, LI J Y, et al. Ultrasonic-detected damage and bending behavior of reinforced PP-ECC beams after coupled action of freeze-thaw cycles and constant flexural load[J]. Case Studies in Construction Materials, 2022, 17: e01284.1-e01284.15. [21] 徐港,李运攀,潘琪,等. 盐冻环境下钢筋混凝土梁抗弯性能试验研究[J]. 土木建筑与环境工程,2014,36(3): 86-91.XU Gang, LI Yunpan, PAN Qi, et al. Experimental analysis on flexural performance of reinforced concrete beam in salt-frost environment[J]. Journal of Civil, Architectural & Environmental Engineering, 2014, 36(3): 86-91. [22] 刘泽军,李艳,温丛格. PVA-ECC劈裂抗拉强度与变形性能试验研究[J]. 建筑材料学报,2016,19(4): 746-751. doi: 10.3969/j.issn.1007-9629.2016.04.024LIU Zejun, LI Yan, WEN Congge. Experimental study on strength and deformation performance of PVA-ECC under splitting tension[J]. Journal of Building Materials, 2016, 19(4): 746-751. doi: 10.3969/j.issn.1007-9629.2016.04.024 -

下载:

下载: