Damage Failure of Two Alloy Seal Rings Paired with Impregnated Graphite

-

摘要:

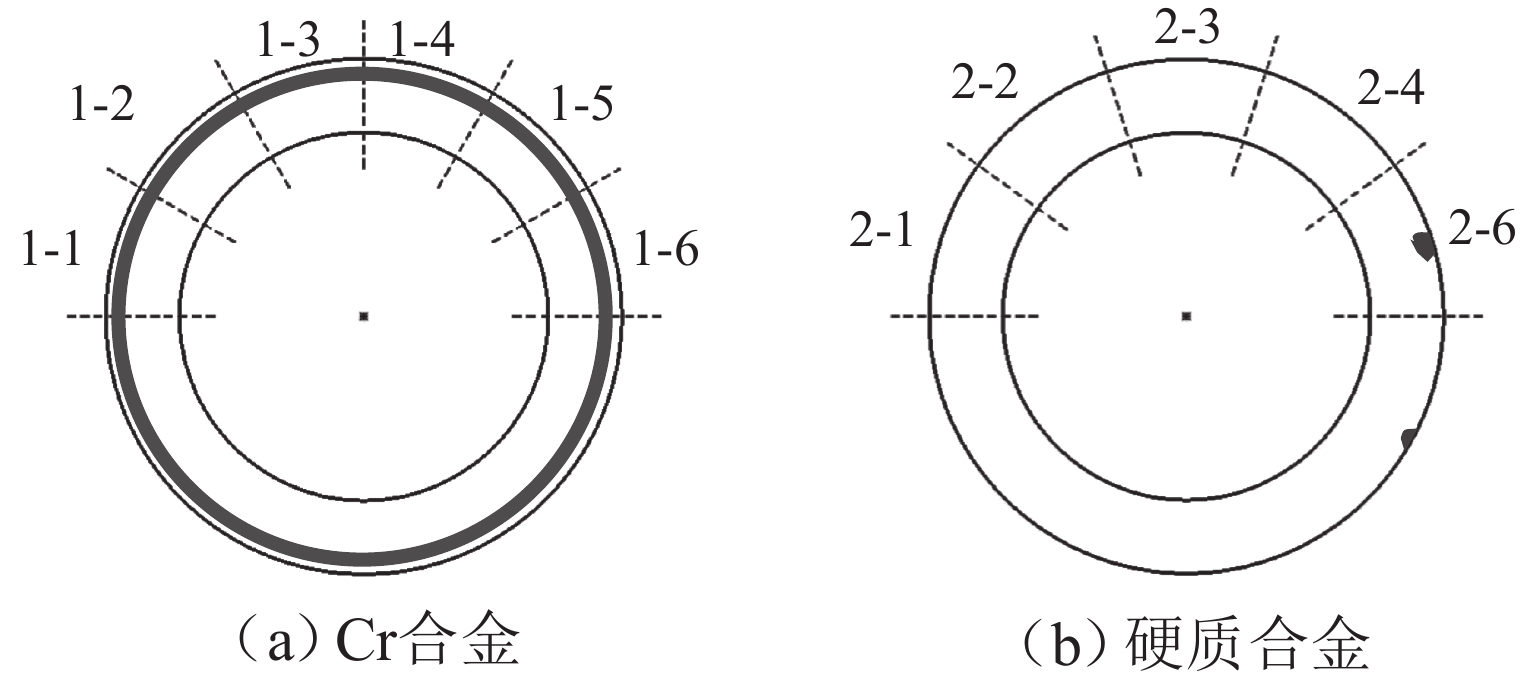

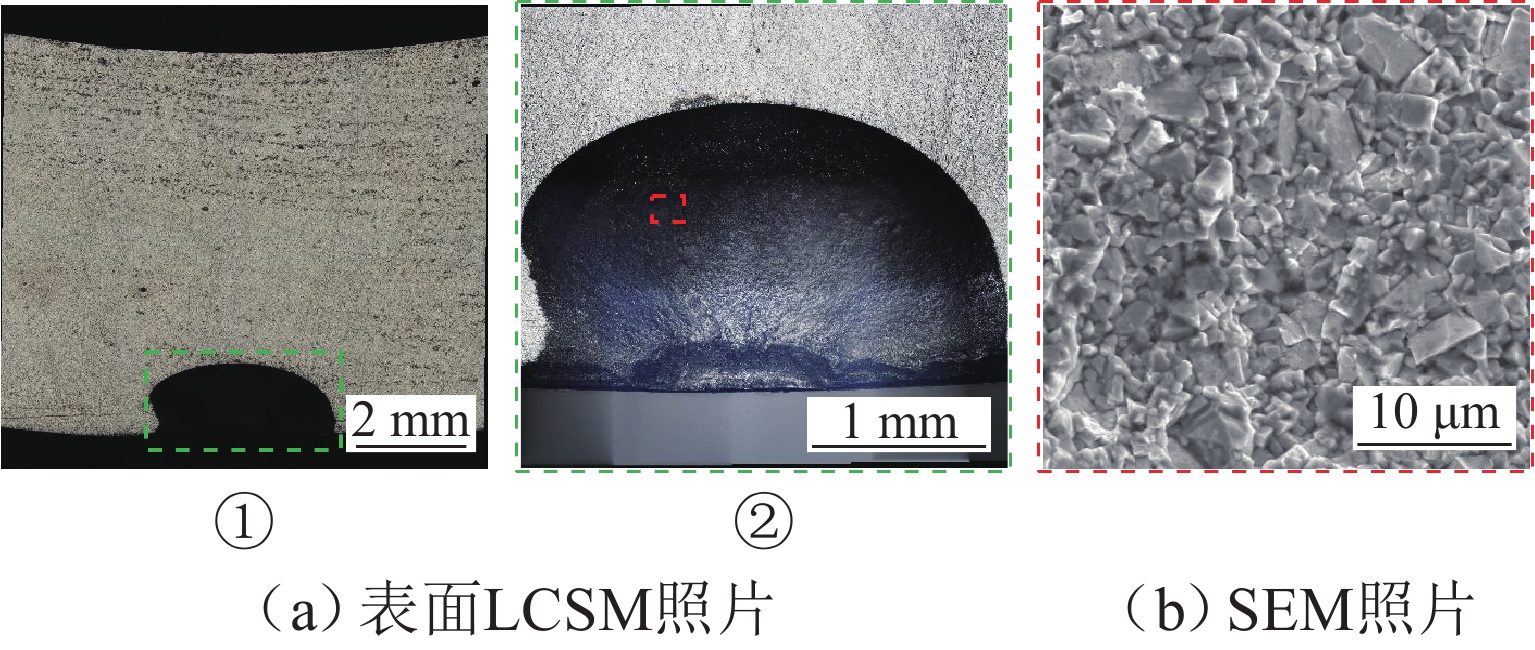

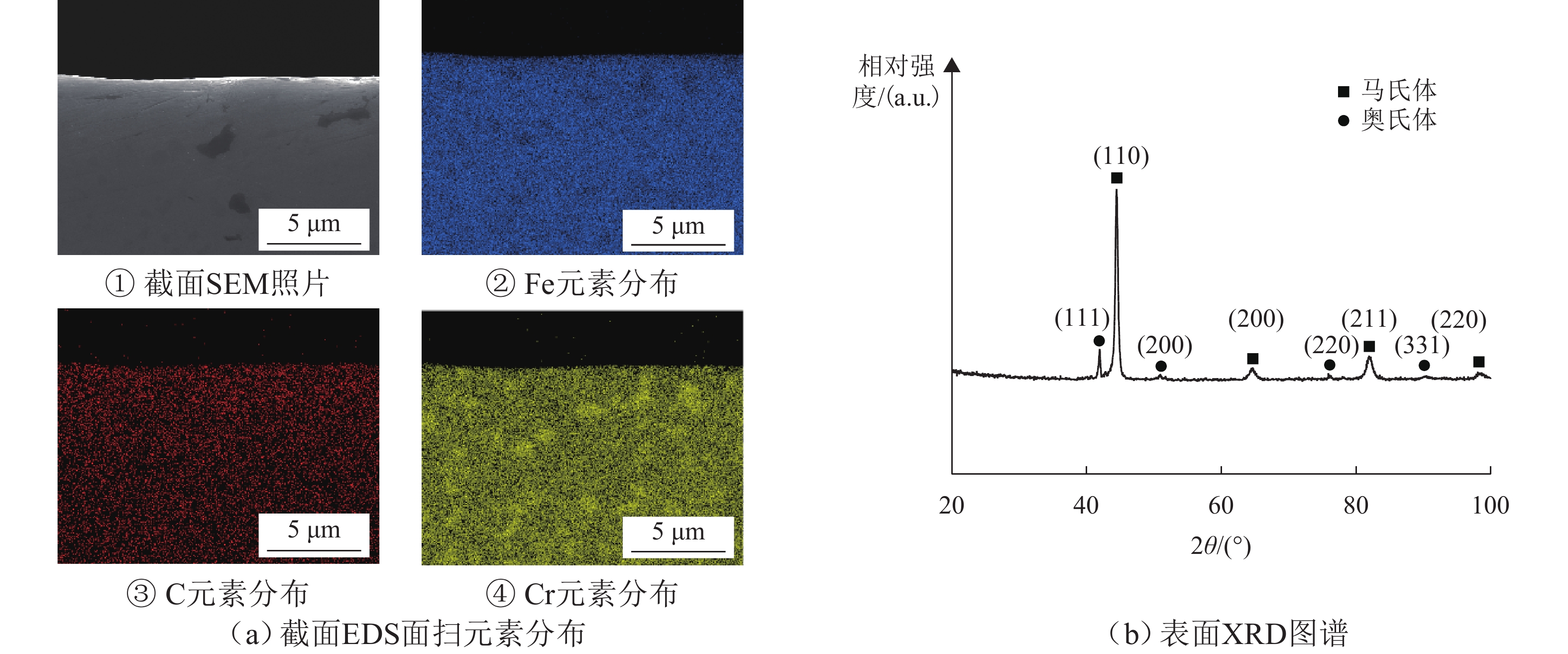

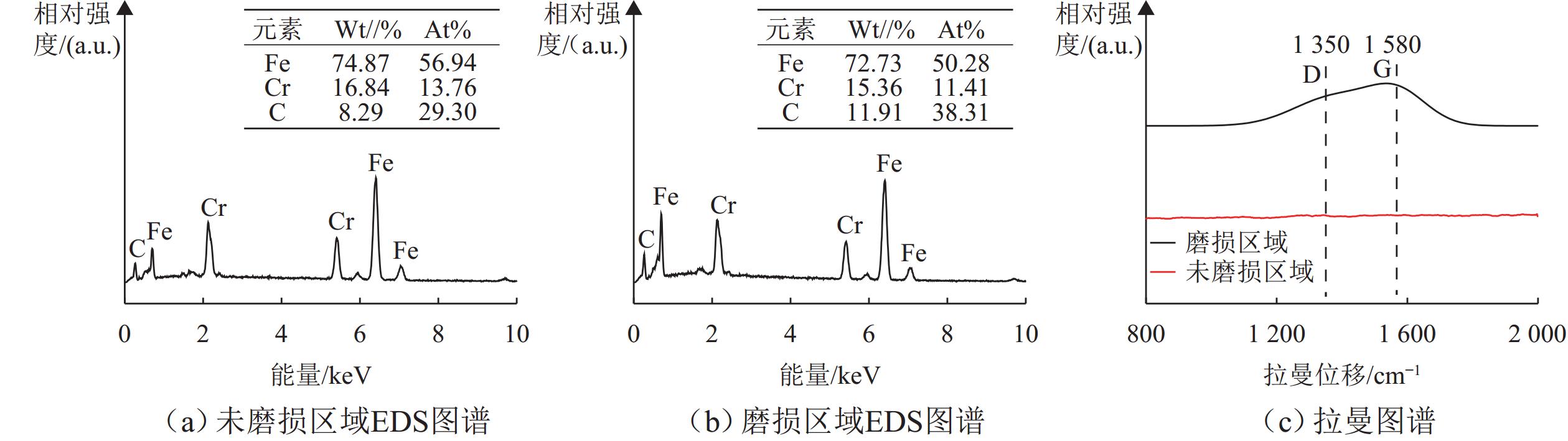

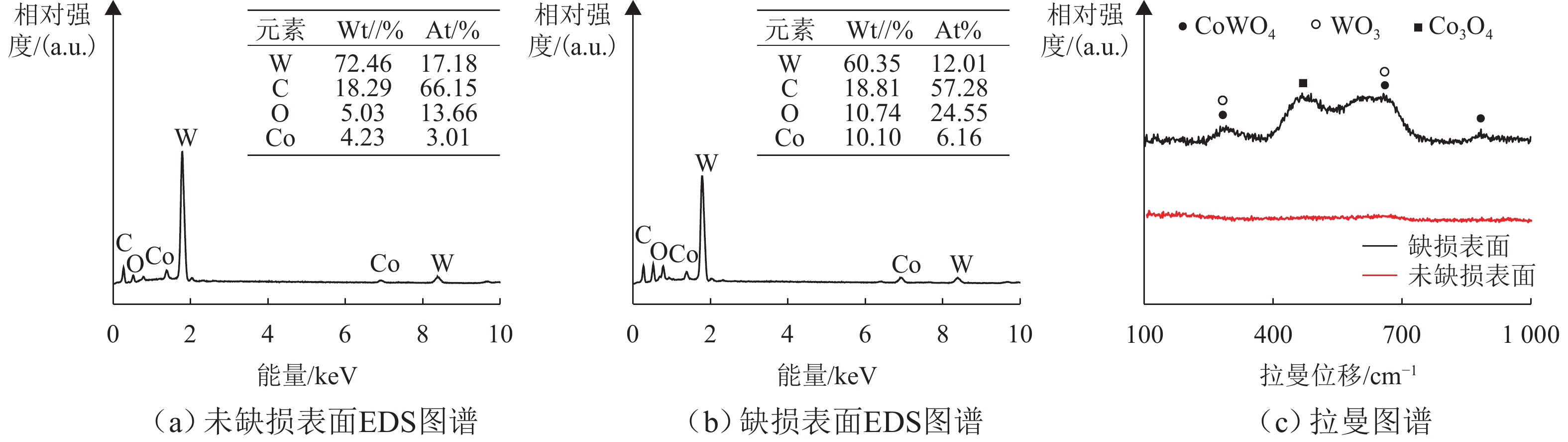

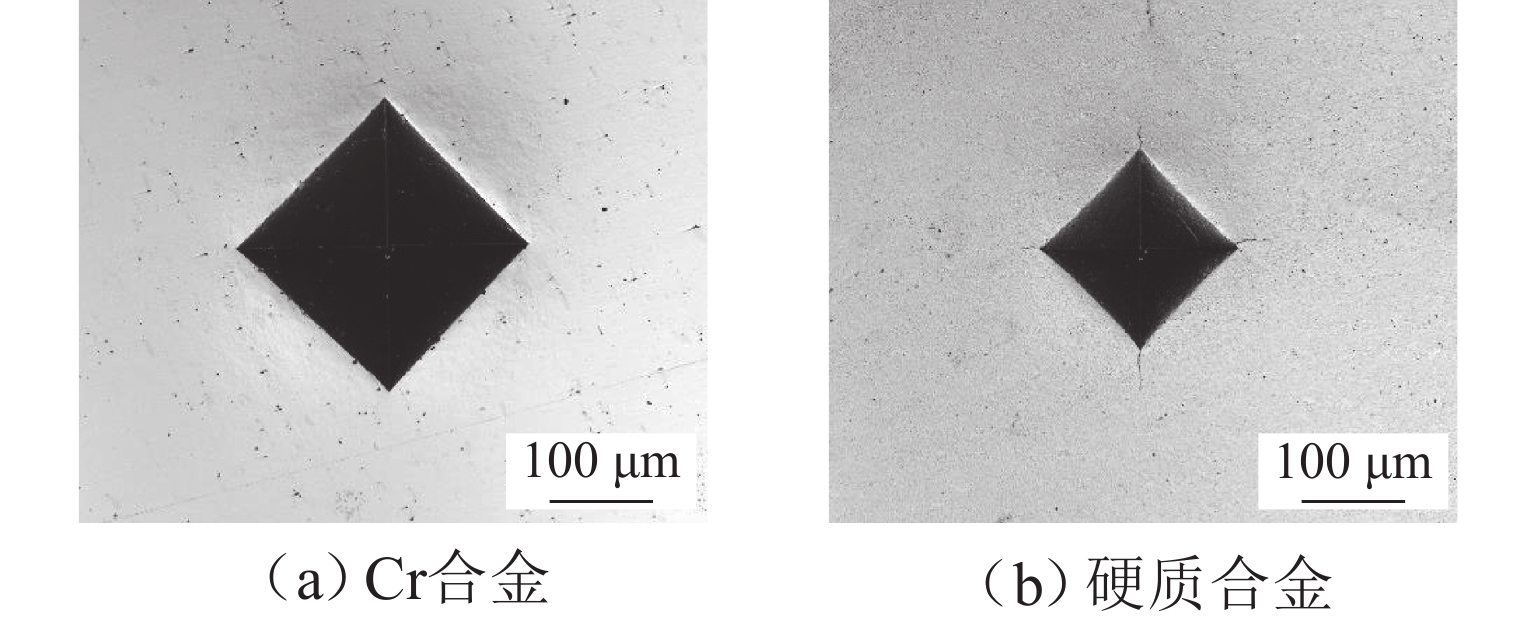

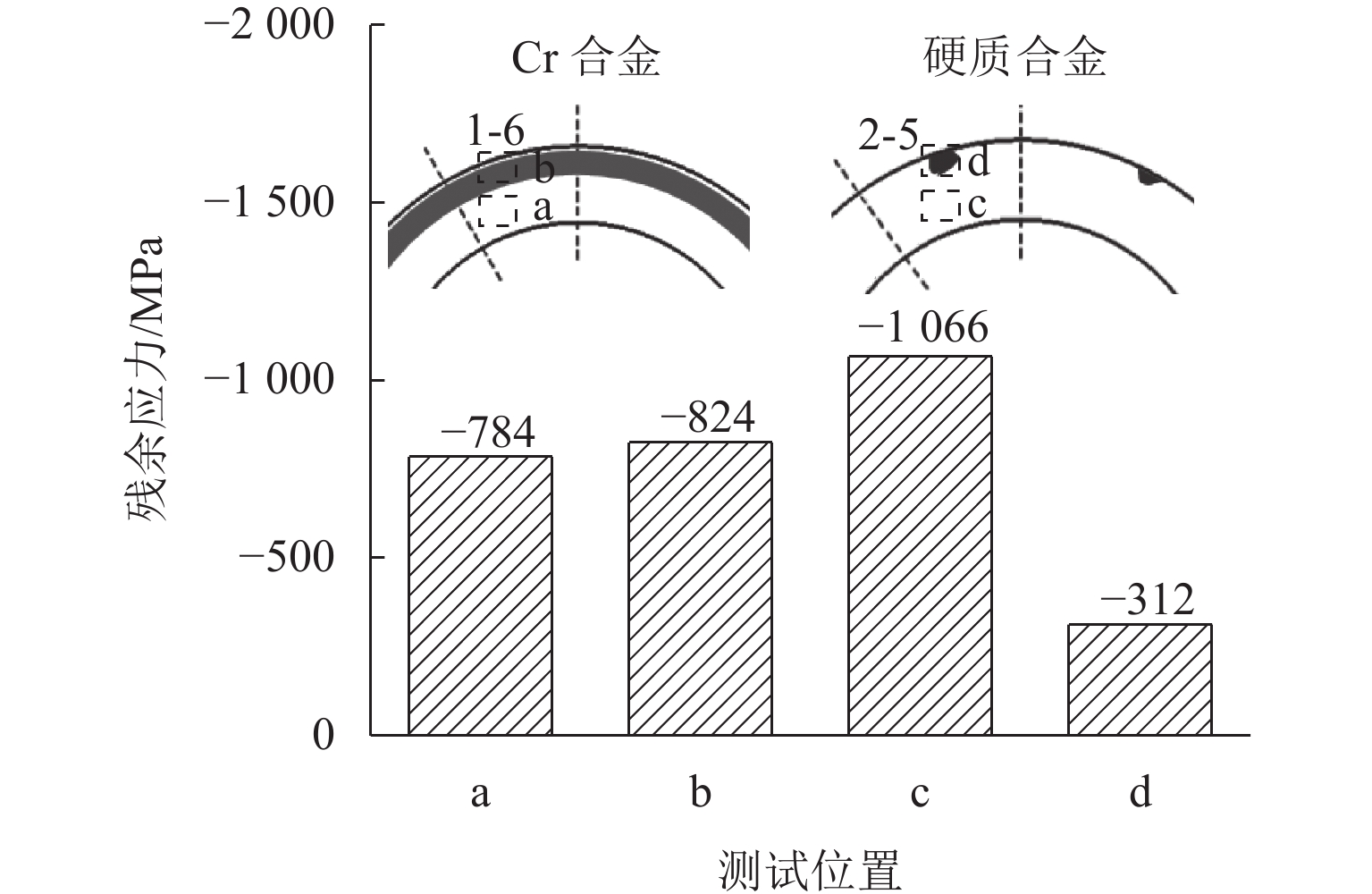

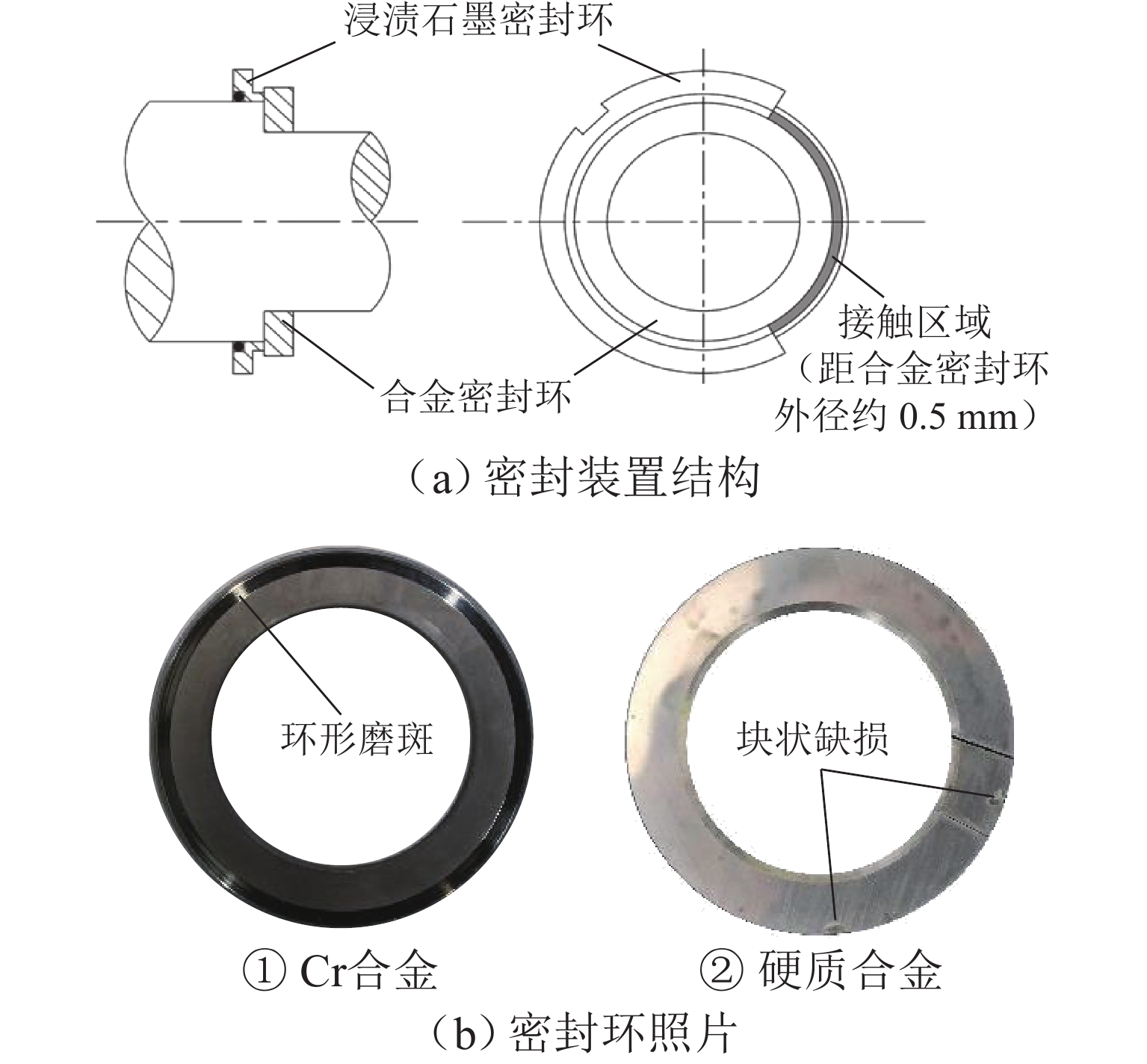

某石油化工泵分别采用Cr合金密封环和YG-6硬质合金密封环,在300~400 ℃与浸渍石墨密封环配副,发现Cr合金密封环长期服役仍能保持良好的密封性能,而硬质合金密封环运行一段时间后发生气体泄漏. 为探究2种合金密封环服役性能差异的缘由,对失效密封环进行表面形貌、化学成分与力学性能表征,分析失效机制. 研究结果表明:Cr合金密封环材质为含Cr的马氏体钢,未作表面强化处理,表面硬度和弹性模量分别为(629.8±14.2) HV30和(244.7±17.4) GPa,与浸渍石墨配副接触区出现以轻微犁削效应为主的环形磨斑,磨损表面粗糙度显著降低;硬质合金密封环表面硬度和弹性模量分别为(

1 475.3 ±60.1) HV30和(815.3±57.2) GPa,密封环表面残余应力高,存在氧化腐蚀诱导的材料脆化,配副接触区无明显磨损,但出现氧化开裂导致的块状缺损;Cr合金密封环表面的低刚度和高粗糙度导致其配副接触区发生磨粒磨损,但磨损表面存在打磨抛光行为,与浸渍石墨配副仍能保持良好的密封性能,而YG-6硬质合金密封环表面高残余应力和高温服役环境诱导的材料氧化脆化,导致配副接触区发生开裂破坏,密封失效.Abstract:Cr alloy seal ring and YG-6 cemented carbide seal ring were used to pair with impregnated graphite seal ring in a petrochemical pump at 300–400 ℃, respectively. It was found that the Cr alloy seal ring maintained good sealing performance for a long-term service, while gas leakage occurred to the cemented carbide seal ring after a short time of service. To explore the reasons for the difference in service performance of two kinds of alloy seal rings, the surface morphologies, chemical compositions, and mechanical properties of the failed seal rings were characterized, and their failure mechanisms were analyzed. The results show that the Cr alloy seal ring is made from martensitic Cr-containing steel without surface strengthening treatment, and the surface hardness and elastic modulus are (629.8±14.2) HV30 and (244.7±17.4) GPa, respectively. On its contact area with impregnated graphite, an annular wear scar characterized by a slight ploughing effect is observed, and the surface roughness of the wear significantly decreases. The surface hardness and elastic modulus of the cemented carbide seal ring are (1475.3±60.1) HV30 and (815.3±57.2) GPa, respectively. There exists high residual stress and material embrittlement induced by oxidative corrosion in the seal ring surface. No obvious wear occurs on the contact area with impregnated graphite, but blocky defects caused by oxidation cracking appear. Due to low stiffness and high surface roughness, the Cr alloy seal ring suffers from abrasive wear on its surface with impregnated graphite, but the wear surface has grinding and polishing behaviors, maintaining its good sealing performance when paired with impregnated graphite. For the YG-6 cemented carbide seal ring, defects by cracking occur in the contact area with impregnated graphite under the action of the high surface residual stress and the material oxidation and embrittlement induced by high temperatures, resulting in sealing failure.

-

Key words:

- seal rings /

- Cr alloy /

- cemented carbide /

- failure analysis /

- abrasive wear /

- oxidation embrittlement

-

-

[1] 国家质量监督检验检疫总局,中国国家标准化管理委员会. 机械密封名词术语:GB/T 5894—2015[S]. 北京: 中国标准出版社,2016. [2] 李香,李鲲. 机械密封行业现状及 “十四五” 发展思路[J]. 液压气动与密封,2021,41(2): 9-12.LI Xiang, LI Kun. Development status of mechanical seal industry and development ideas of “the 14th five year plan”[J]. Hydraulics Pneumatics & Seals, 2021, 41(2): 9-12. [3] 丁雪兴,王竞墨,王世鹏,等. 机械密封影响因素分析及展望[J]. 石油化工高等学校学报,2021,34(6): 89-96. doi: 10.3969/j.issn.1006⁃396X.2021.06.014DING Xuexing, WANG Jingmo, WANG Shipeng, et al. Analysis and prospect of influencing factors of mechanical seal[J]. Journal of Petrochemical Universities, 2021, 34(6): 89-96. doi: 10.3969/j.issn.1006⁃396X.2021.06.014 [4] 卞伟. 核电站主泵机械密封失效分析[J]. 失效分析与预防,2021,16(2): 134-138. doi: 10.3969/j.issn.1673-6214.2021.02.010BIAN Wei. Failure analysis of mechanical seal of main pump in nuclear power plant[J]. Failure Analysis and Prevention, 2021, 16(2): 134-138. doi: 10.3969/j.issn.1673-6214.2021.02.010 [5] JIN J, PENG X D, JIANG J B, et al. Frictional characteristics of impregnated graphite with different graphitization degree versus chromium stainless steel under varying PV values[J]. Tribology International, 2020, 146: 106063.1-106063.9. [6] ZHAO X Y, LIU Y, WEN Q F, et al. Frictional performance of silicon carbide under different lubrication conditions[J]. Friction, 2014, 2(1): 58-63. doi: 10.1007/s40544-014-0039-1 [7] 王建磊,张琛,王晓虎,等. N2O4环境下液体火箭发动机涡轮泵机械密封浸渍石墨的磨损机理研究[J]. 机械工程学报,2019,55(7): 119-127. doi: 10.3901/JME.2019.07.119WANG Jianlei, ZHANG Chen, WANG Xiaohu, et al. Wear mechanism of liquid rocket engine turbopump mechanical seal graphite surface in the N2O4 environment[J]. Journal of Mechanical Engineering, 2019, 55(7): 119-127. doi: 10.3901/JME.2019.07.119 [8] SKOWROŃSKA J, KOSUCKI A, STAWIŃSKI Ł. Overview of materials used for the basic elements of hydraulic actuators and sealing systems and their surfaces modification methods[J]. Materials, 2021, 14(6): 1422.1-1422.24. [9] ENGQVIST H, BOTTON G A, EDERYD S, et al. Wear phenomena on WC-based face seal rings[J]. International Journal of Refractory Metals and Hard Materials, 2000, 18(1): 39-46. doi: 10.1016/S0263-4368(00)00011-1 [10] SHIHAB T A, SHLAPAK L S, NAMER N S, et al. Increasing of durability of mechanical seals of oil and gas centrifugal pumps using tungsten-free cermet with Cu-Ni-Mn binder[J]. Journal of Physics: Conference Series, 2021, 1741(1): 012031.1-012031.13. [11] 王旭东,汪彩芬,朱彩强,等. 三种机械密封材料的摩擦磨损性能研究[J]. 材料导报,2017,31(增1): 463-466.WANG Xudong, WANG Caifen, ZHU Caiqiang, et al. Study on friction and wear properties of three kinds of mechanical seal materials[J]. Materials Reports, 2017, 31(S1): 463-466. [12] LIU Y, ZHAO X Y, WEN Q F, et al. On frictional performance of sintering materials used by mechanical seals in water[J]. Industrial Lubrication and Tribology, 2014, 66(1): 23-30. doi: 10.1108/ILT-10-2011-0075 [13] ZHAO J Y, LI Y J, LIU Y, et al. Friction and wear performances of impregnated graphite in ring-on-ring tribological test[J]. Tribology International, 2022, 174: 107715.1-107715.8. [14] LIANG H Q, YAO X M, ZHANG H, et al. Friction and wear behavior of pressureless liquid phase sintered SiC ceramic[J]. Materials & Design, 2015, 65: 370-376. [15] BONNY K, DE BAETS P, PEREZ Y, et al. Friction and wear characteristics of WC–Co cemented carbides in dry reciprocating sliding contact[J]. Wear, 2010, 268(11/12): 1504-1517. [16] SCHUBERT W D, NEUMEISTER H, KINGER G, et al. Hardness to toughness relationship of fine-grained WC–Co hardmetals[J]. International Journal of Refractory Metals and Hard Materials, 1998, 16(2): 133-142. doi: 10.1016/S0263-4368(98)00028-6 [17] 刘萍,翟峻,刘王平,等. 合金成分和涂层对WC–Co硬质合金疲劳性能的影响[J]. 硬质合金,2022,39(2): 75-84. doi: 10.3969/j.issn.1003-7292.2022.02.001LIU Ping, ZHAI Jun, LIU Wangping, et al. Effects of alloy composition and coating on fatigue properties of WC–Co cemented carbide[J]. Cemented Carbide, 2022, 39(2): 75-84. doi: 10.3969/j.issn.1003-7292.2022.02.001 [18] 廖承志,杨屹,杨刚,等. 脉冲磁场对YG6硬质合金力学性能及耐磨性的影响[J]. 热加工工艺,2020,49(12): 57-61.LIAO Chengzhi, YANG Yi, YANG Gang, et al. Effects of pulsed magnetic field on mechanical properties and wear resistance of YG6 cemented carbides[J]. Hot Working Technology, 2020, 49(12): 57-61. [19] REN X Y, PENG Z J, PENG Y, et al. Effect of SiC nano-whisker addition on WC–Ni based cemented carbides fabricated by hot-press sintering[J]. International Journal of Refractory Metals and Hard Materials, 2013, 36: 294-299. doi: 10.1016/j.ijrmhm.2012.10.009 [20] 彭光健,张泰华. 表面残余应力的仪器化压入检测方法研究进展[J]. 力学学报,2022,54(8): 2287-2303. doi: 10.6052/0459-1879-22-222PENG Guangjian, ZHANG Taihua. Progress in instrumented indentation methods for determination of surface residual stress[J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(8): 2287-2303. doi: 10.6052/0459-1879-22-222 [21] ZHAO J, LI Q Z, LI S X, et al. Influence of a carbon-based tribofilm induced by the friction temperature on the tribological properties of impregnated graphite sliding against a cemented carbide[J]. Friction, 2021, 9(4): 686-696. doi: 10.1007/s40544-019-0358-3 [22] HE Z, LIAN P F, SONG Y, et al. Improving molten fluoride salt and Xe135 barrier property of nuclear graphite by phenolic resin impregnation process[J]. Journal of Nuclear Materials, 2018, 499: 79-87. doi: 10.1016/j.jnucmat.2017.11.019 [23] ZHANG G L, LIU Y, GUO F, et al. Friction characteristics of impregnated and non-impregnated graphite against cemented carbide under water lubrication[J]. Journal of Materials Science & Technology, 2017, 33(10): 1203-1209. [24] 彭旭东,何良杰,江锦波,等. 浸酚醛树脂石墨/SiC密封材料摩擦学特性研究[J]. 中国机械工程,2021,32(11): 1283-1292. doi: 10.3969/j.issn.1004-132X.2021.11.003PENG Xudong, HE Liangjie, JIANG Jinbo, et al. Study on tribological properties of phenolic resin impregnated graphite/SiC ceramic sealing materials[J]. China Mechanical Engineering, 2021, 32(11): 1283-1292. doi: 10.3969/j.issn.1004-132X.2021.11.003 [25] 黄道远,易丹青,刘会群,等. 硬质合金强度随温度的变化及失效机理的研究[J]. 材料热处理学报,2007,28(5): 105-108. doi: 10.3969/j.issn.1009-6264.2007.05.024HUANG Daoyuan, YI Danqing, LIU Huiqun, et al. Effect of temperature on bending strength and failure mechanism of cemented carbide[J]. Transactions of Materials and Heat Treatment, 2007, 28(5): 105-108. doi: 10.3969/j.issn.1009-6264.2007.05.024 [26] CHEN L Y, YI D Q, WANG B, et al. Mechanism of the early stages of oxidation of WC–Co cemented carbides[J]. Corrosion Science, 2016, 103: 75-87. doi: 10.1016/j.corsci.2015.11.007 [27] WANG Q, LI L X, YANG G B, et al. Influence of heat treatment on the microstructure and performance of high-velocity oxy-fuel sprayed WC–12Co coatings[J]. Surface and Coatings Technology, 2012, 206(19/20): 4000-4010. [28] 陈国桓,李克永. 碳化硅——机械密封环的最佳材料[J]. 化工设备设计,1983(4): 50-54. -

下载:

下载: