Experimental Study on Seismic Performance of Mortise-Tenon Joints in Traditional Residential Wood Structures in South China Mountainous Regions

-

摘要:

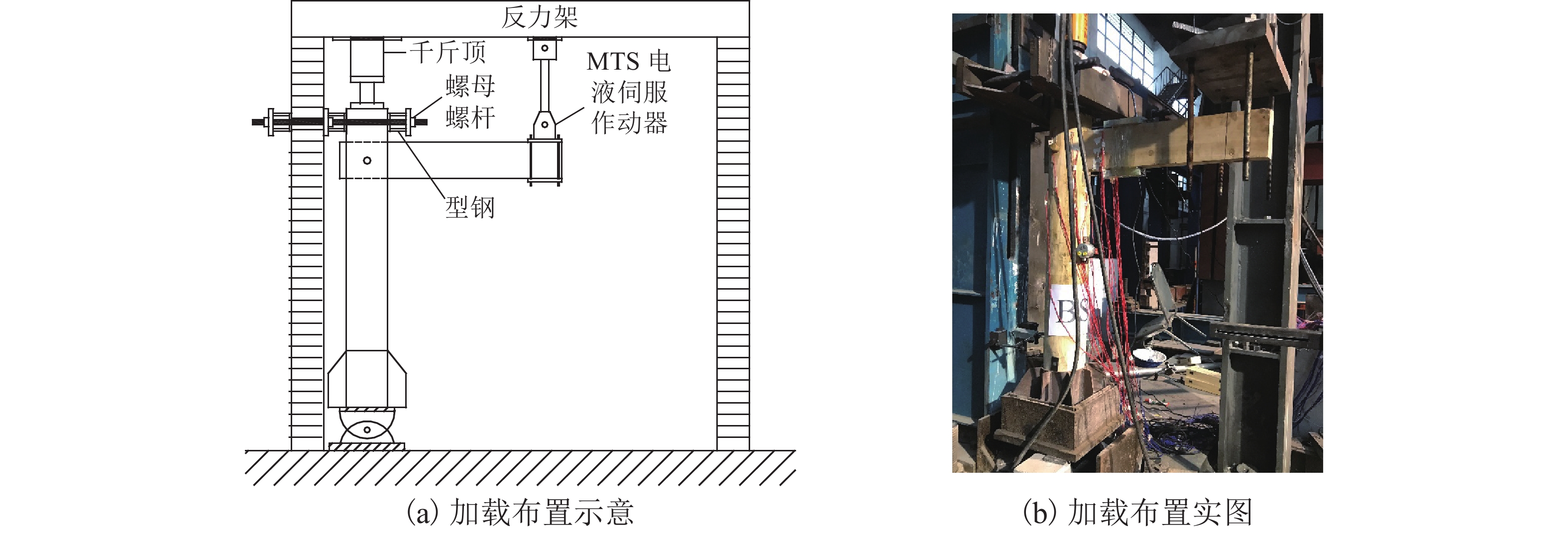

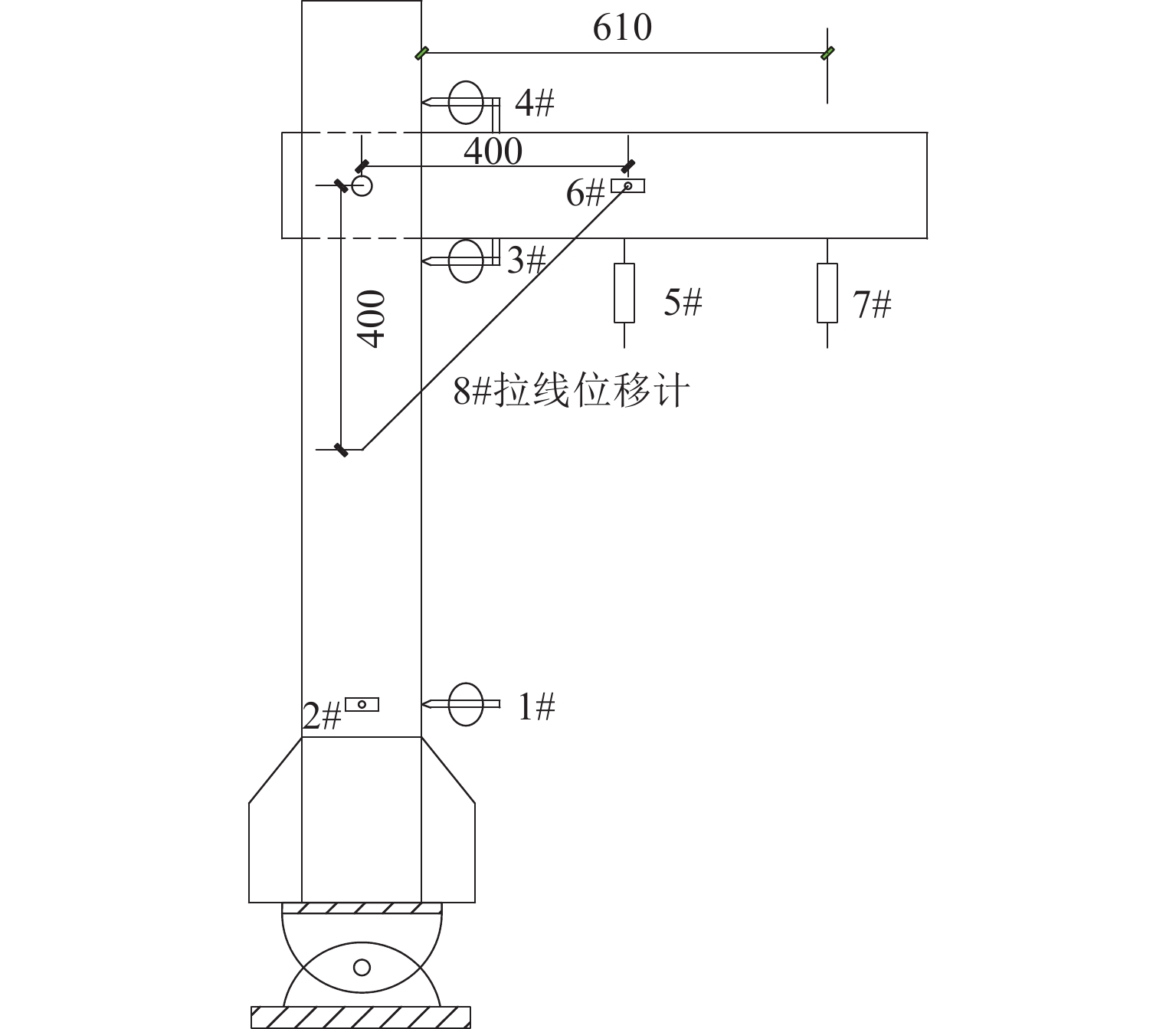

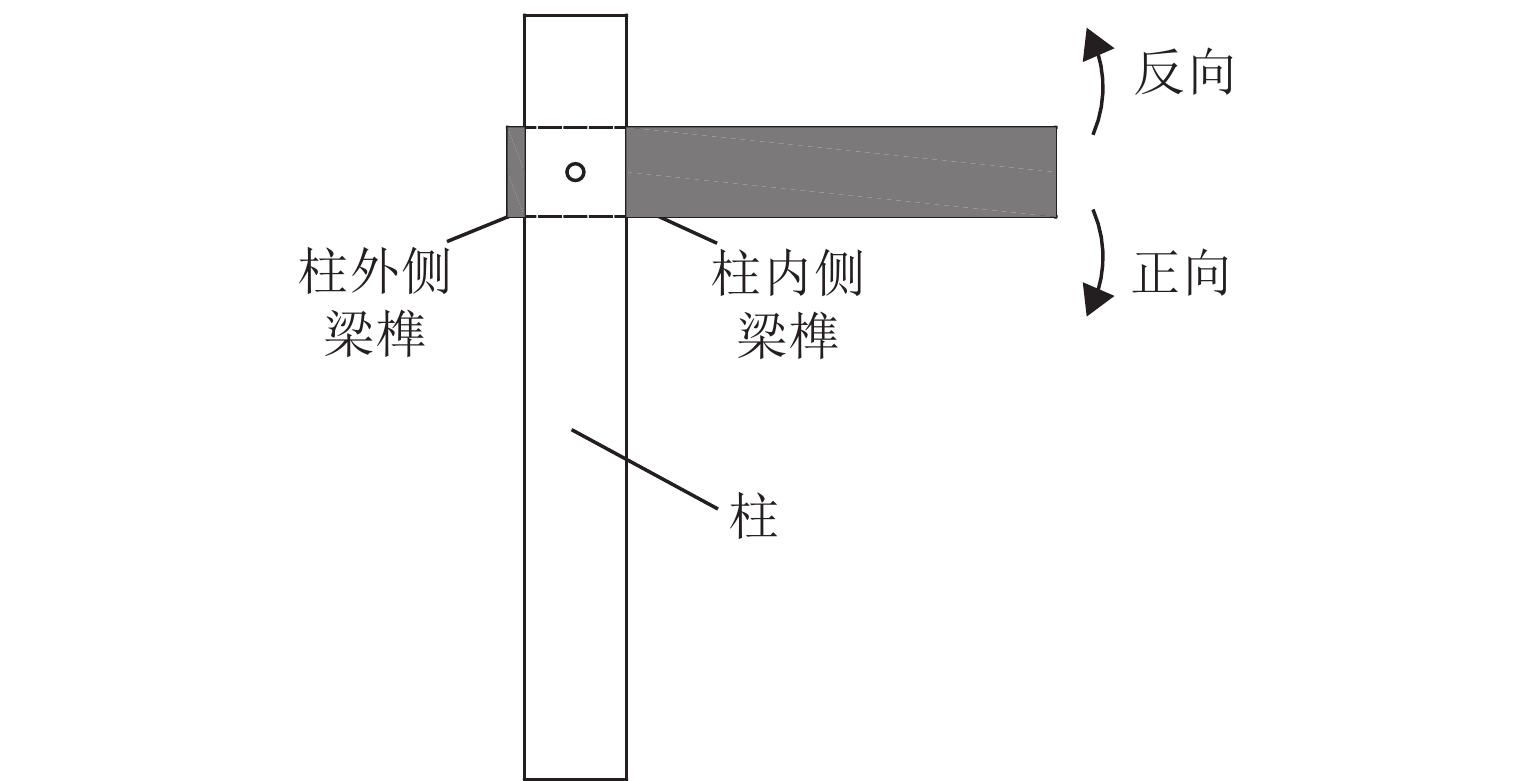

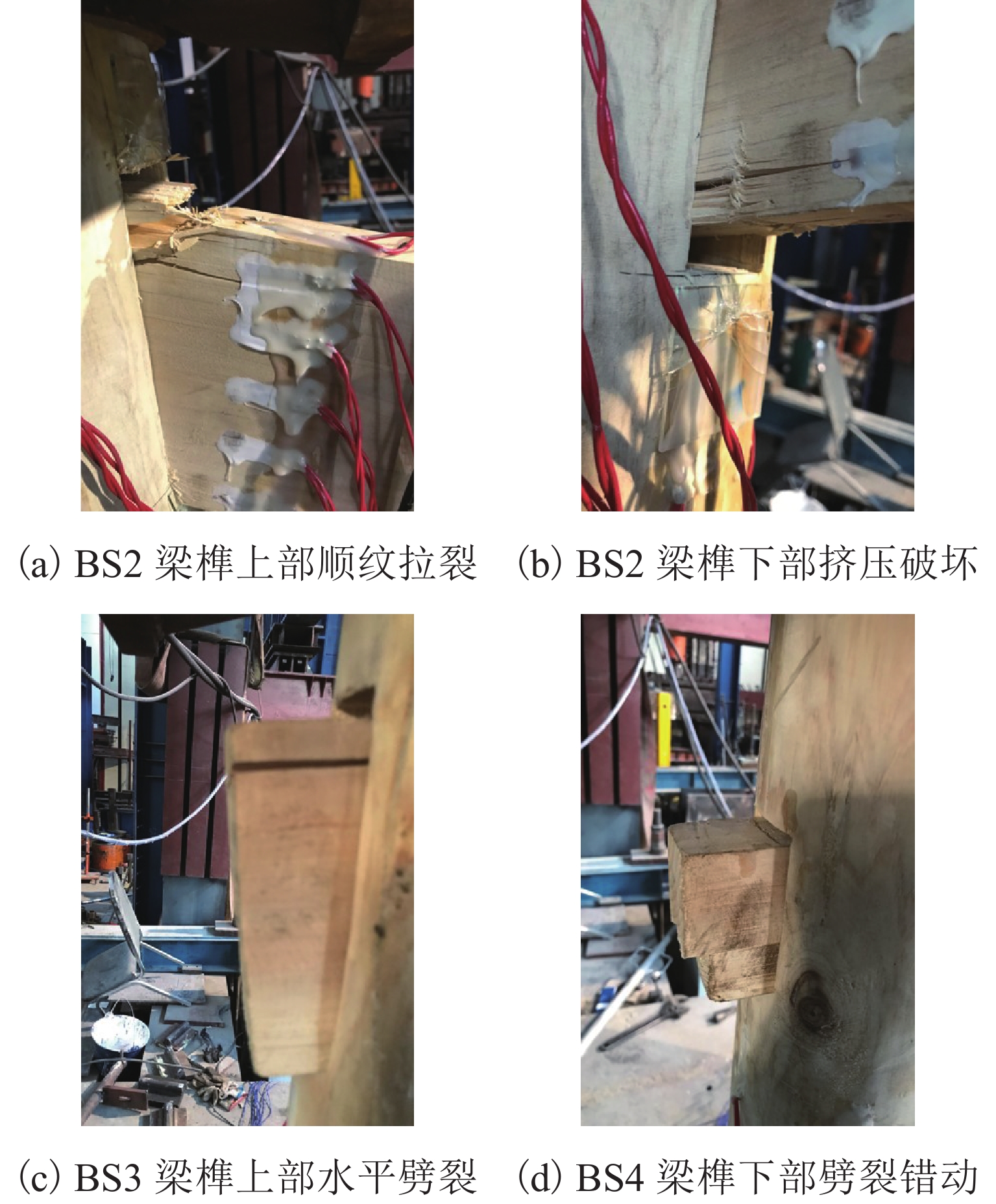

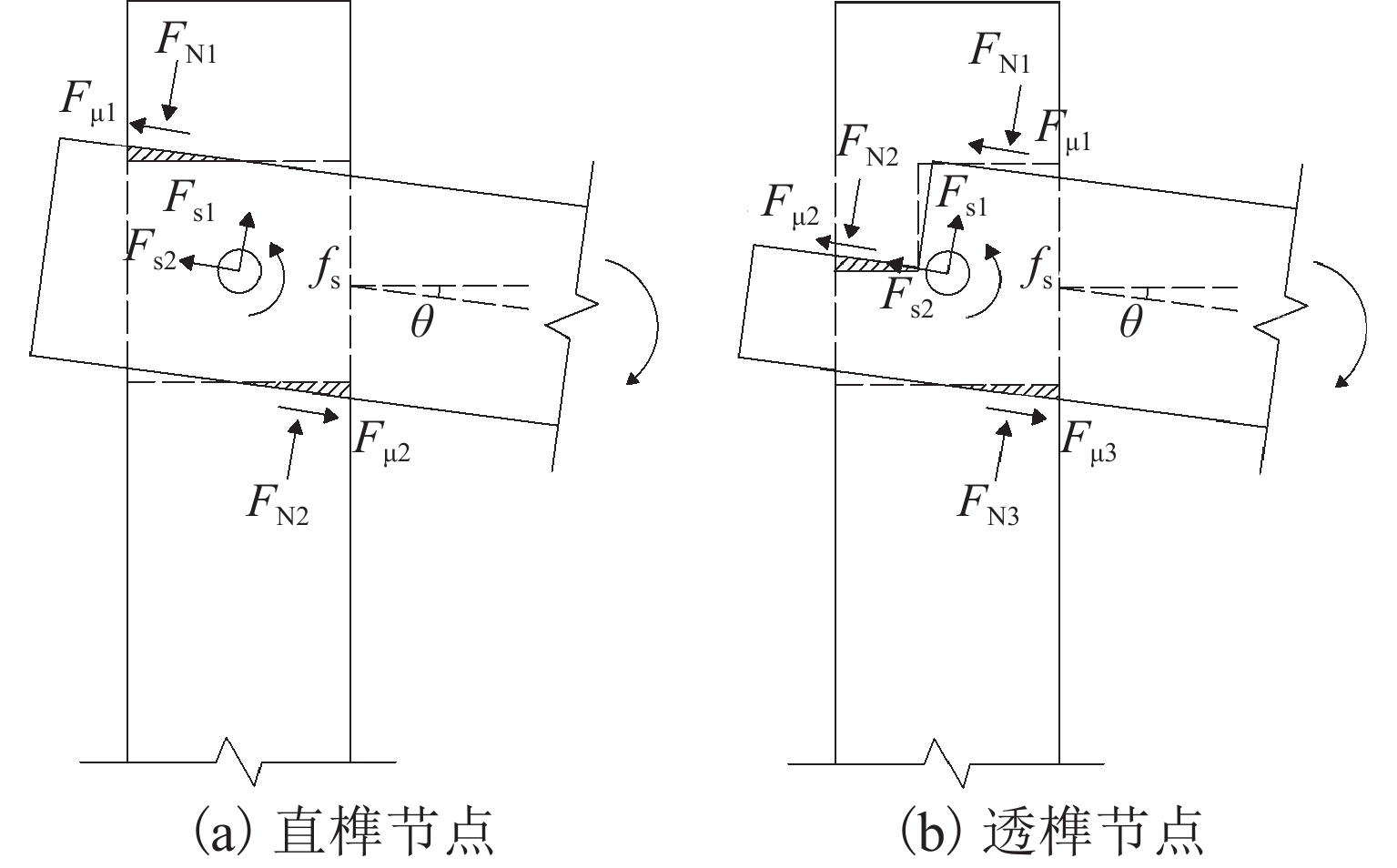

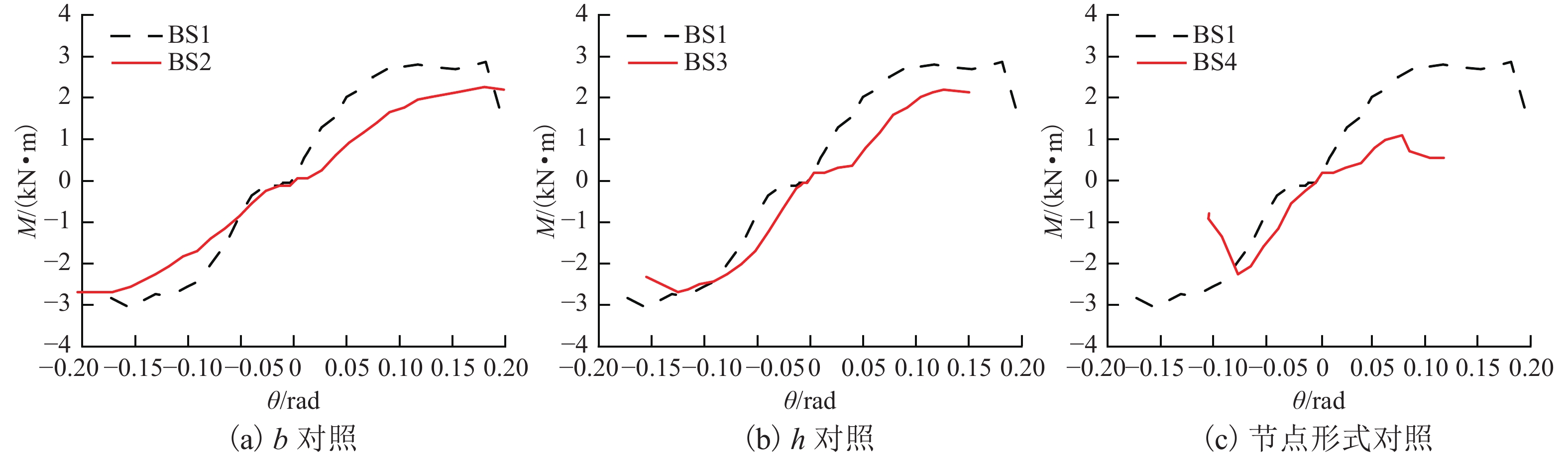

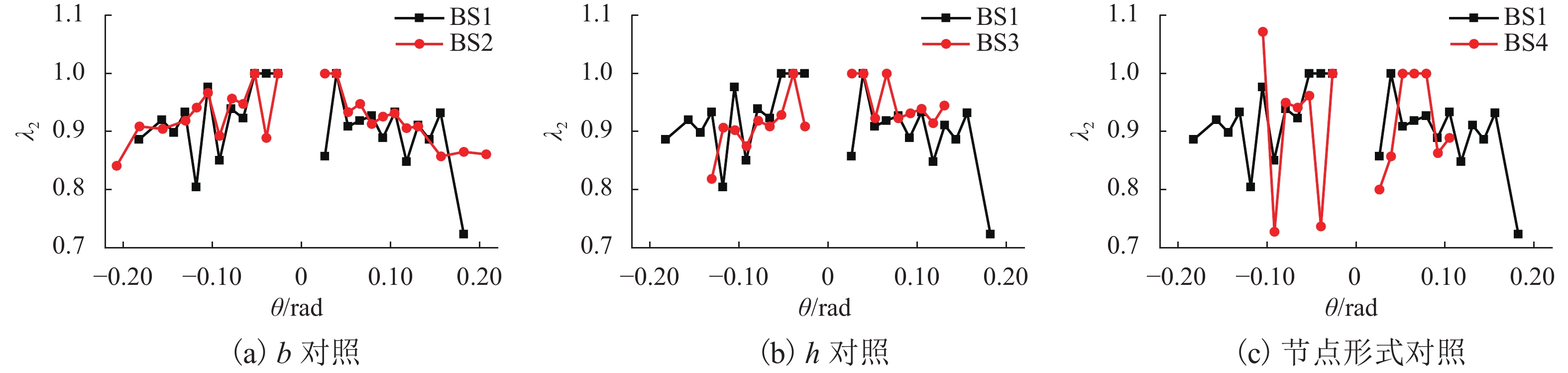

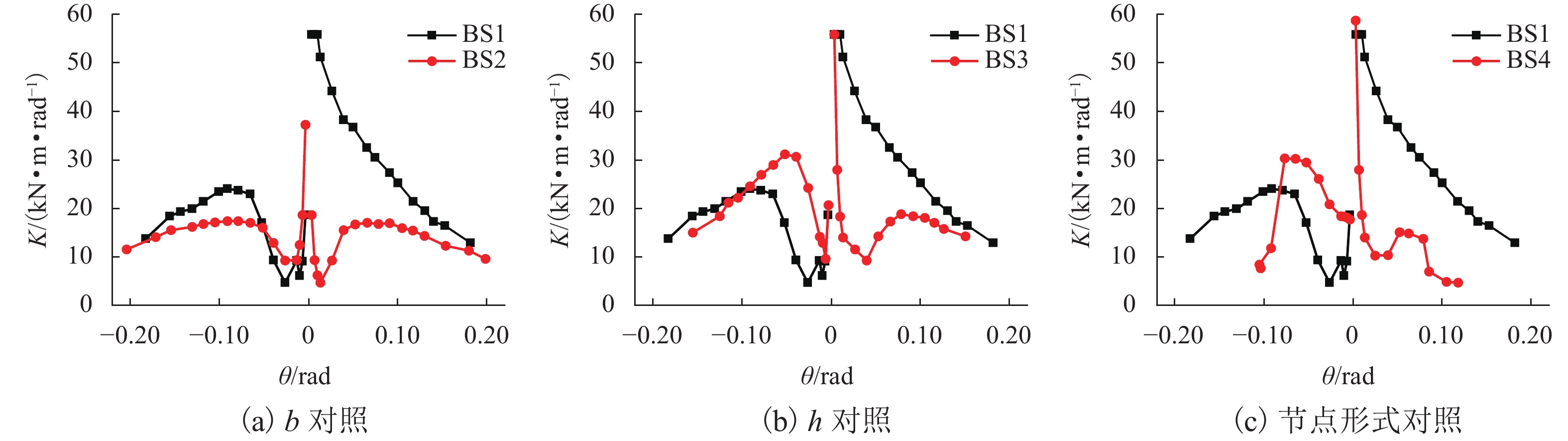

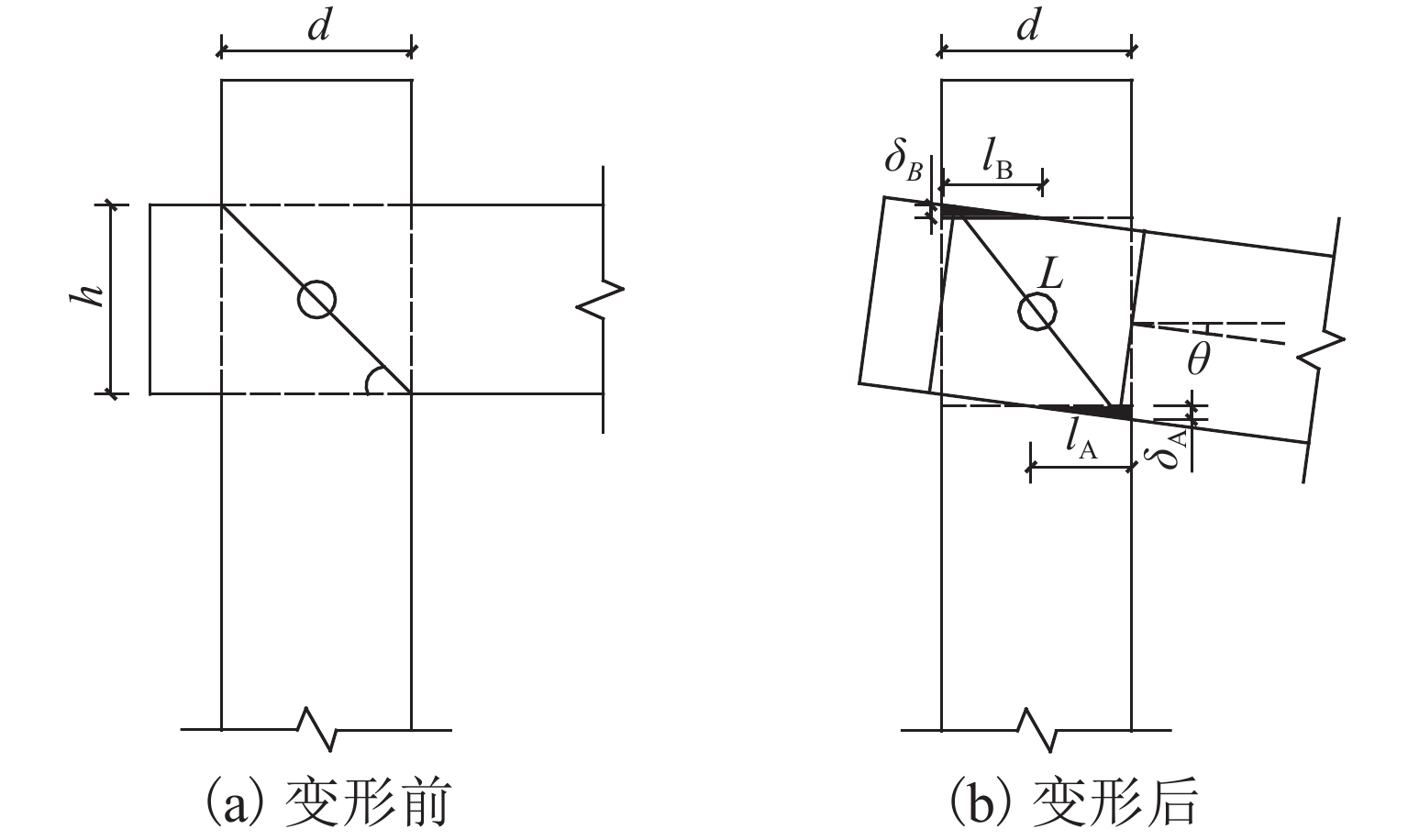

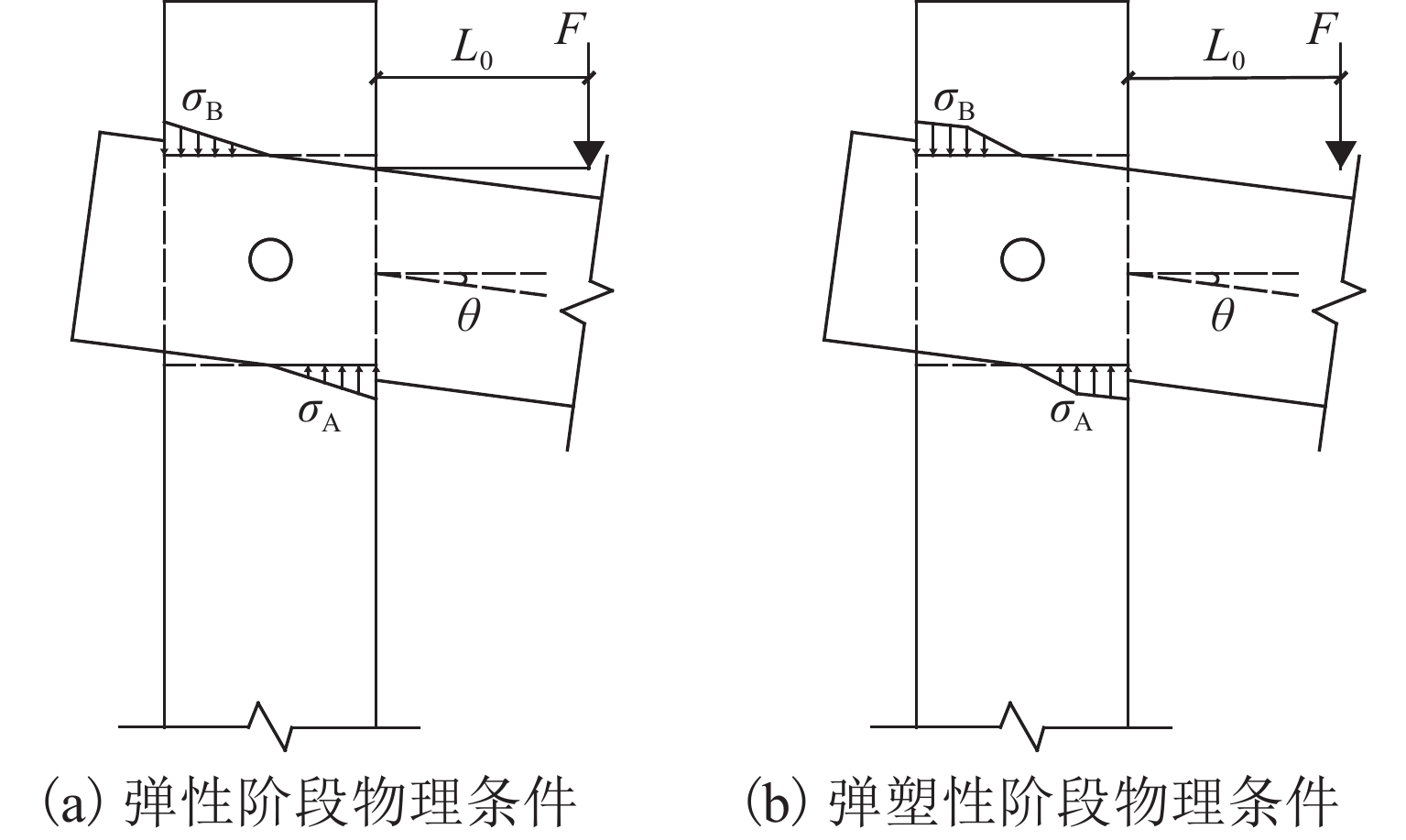

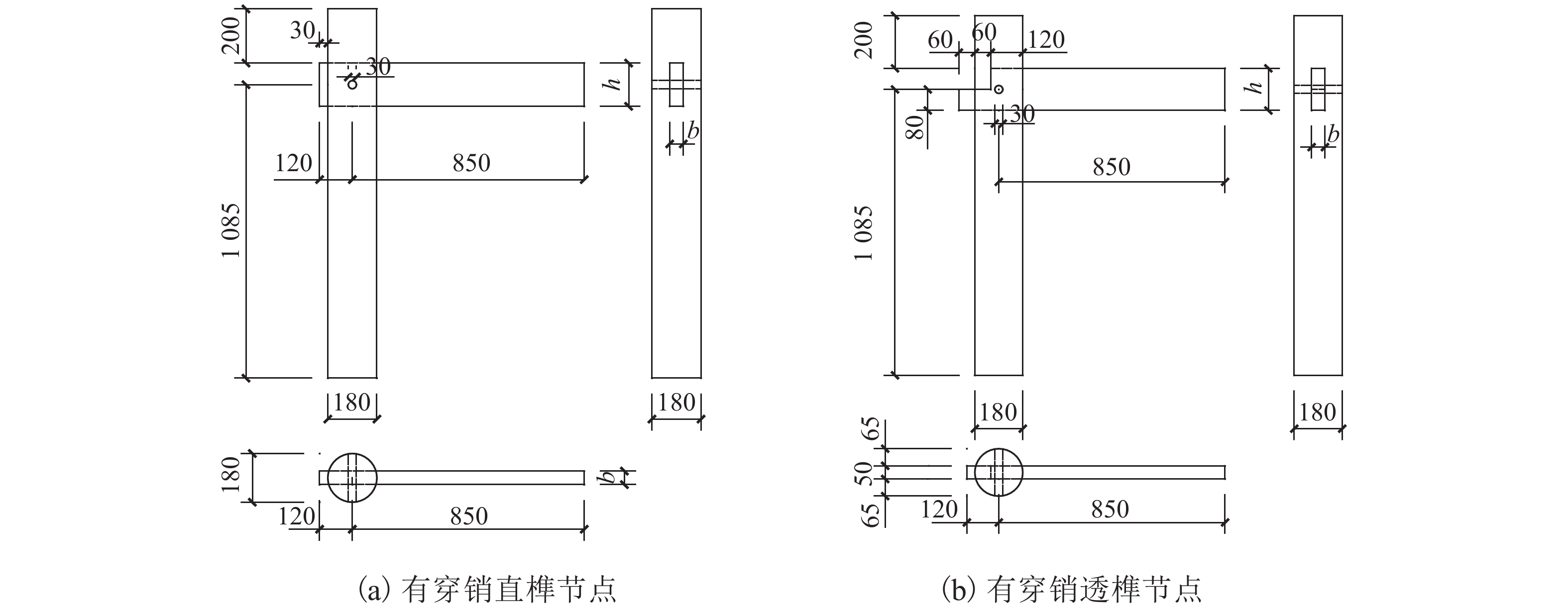

为研究截面参数和节点形式对有穿销直榫节点抗震性能的影响,首先,以梁高、梁宽为研究参数,并与有穿销透榫节点作对比,共设计制作了4个足尺节点试件;然后,通过低周往复加载试验,研究不同参数下节点的破坏形态、滞回曲线、骨架曲线、延性、强度和刚度退化及耗能能力等性能;最后,推导有穿销直榫节点的弯矩-转角理论公式,并与试验结果进行对比. 研究结果表明:试件的主要破坏形态为柱内侧梁榫受拉边缘的顺纹拉裂破坏,伴随有柱内侧梁榫受压边缘的挤压变形和柱外侧梁榫的水平劈裂;节点的弯矩-转角滞回曲线呈捏缩效应明显的反Z形;在试验设计参数范围内,有穿销直榫节点的转动刚度和抗弯承载力随着梁截面高度和宽度的增大而增大,但是强度退化系数和等效黏滞阻尼系数的变化不明显;相比于有穿销透榫节点,有穿销直榫节点的正向抗弯承载力大62%,反向抗弯承载力大26%,且承载力下降更平缓,表明有穿销直榫节点具有更好的抗震性能;有穿销直榫节点理论公式所得结果与试验结果误差在9%内.

Abstract:In order to explore the influence of section parameters and joint forms on the seismic performance of the straight-tenon joints with a bolt pin, four full-scale joint specimens were designed and fabricated, with beam height and beam width as the research parameters. In addition, they were compared with the through-tenon joint with a bolt pin. Then, through low-cycle reciprocating loading tests, the failure modes, hysteresis loops, skeleton curves, ductility, strength degradation, stiffness degradation, and energy dissipation capacity of the joints with different parameters were studied. Finally, the theoretical formula of bending moment versus angle of the straight-tenon joints with a bolt pin was derived and compared with the experimental results. The study results show that the primary failure modes of the specimens are the tension failure along the tension edge of the beam tenon inside of the column, accompanied by the extrusion deformation of the compression edge of the beam tenon inside of the column and the horizontal splitting of the beam tenon outside of the column. The hysteretic loop of bending moment versus angle of the joints shows an anti-Z shape with an obvious pinching effect. Within the range of experimental design parameters, with the increase in beam section height and beam section width, the rotational stiffness and flexural bearing capacity of the straight-tenon joints with a bolt pin increase, but the changes of strength degradation coefficient and equivalent viscous damping coefficient are not obvious. Compared with the through-tenon joint with a bolt pin, the flexural bearing capacity of the straight-tenon joint with a bolt pin is 62% larger in the downward loading direction and is 26% larger in the upward loading direction, and the bearing capacity decreases more slowly in the post-peak stage. It reflects that the straight-tenon joint with a bolt pin has better seismic performance than the through-tenon joint with a bolt pin. The error between the test and the theoretical formula of the straight-tenon joints with a bolt pin is within 9%.

-

表 1 试件参数

Table 1. Parameters of specimens

试件编号 梁截面高度

/mm梁截面宽度

/mm构造形式 BS1 160 50 直榫 BS2 160 40 直榫 BS3 130 50 直榫 BS4 160 50 透榫 表 2 杉木木材力学性能

Table 2. Mechanical properties of Chinese fir

指标 试件个数/个 平均值/MPa 平均含水率/% fLt 12 75.27 11.7 fLc 12 31.13 11.3 fRc 12 4.33 12.4 fTc 12 4.00 12.1 fLm 12 68.12 12.2 ELt 12 11583 11.7 ELc 12 11431 11.9 ERc 12 1074 12.2 ETc 12 637 12.0 ELm 10 8687 12.2 表 3 加载方案

Table 3. Loading scheme

控制位移/mm 每级增量/mm 循环次数/次 ≤8 2 1 16~80 8 3 >80 16 3 表 4 理论极限承载力与试验结果对比

Table 4. Comparison of theoretical maximum capacity and test results

加载方向 试件编号 试验结果/ (kN·m) 计算结果/ (kN·m) 差异/% 正向 BS1 2.867 2.978 3.87 BS2 2.257 2.565 13.64 BS3 2.196 2.352 7.10 平均 8.20 反向 BS1 −3.050 −2.978 2.36 BS2 −2.684 −2.565 4.43 BS3 −2.684 −2.352 12.37 平均 6.39 -

[1] 丁磊,王志骞,俞茂宏. 西安鼓楼木结构的动力特性及地震反应分析[J]. 西安交通大学学报,2003,37(9): 986-988. doi: 10.3321/j.issn:0253-987X.2003.09.027DING Lei, WANG Zhiqian, YU Maohong. Dynamic characteristics and earthquake responses of Xi’an drum-tower[J]. Journal of Xi’an Jiaotong University, 2003, 37(9): 986-988. doi: 10.3321/j.issn:0253-987X.2003.09.027 [2] 潘毅,张启,王晓玥,等. 古建筑木结构燕尾榫节点力学模型研究[J]. 建筑结构学报,2021,42(8): 151-159.PAN Yi, ZHANG Qi, WANG Xiaoyue, et al. Research on mechanical model of dovetail joint for Chinese ancient timber structures[J]. Journal of Building Structures, 2021, 42(8): 151-159. [3] 杨庆山. 古建筑木结构的承载及抗震机理[J]. 土木与环境工程学报(中英文),2022,44(2): 1-9.YANG Qingshan. Load-bearing and aseismic mechanism of traditional wooden structures[J]. Journal of Civil and Environmental Engineering, 2022, 44(2): 1-9. [4] 陈庆军,彭章锋,蔡健,等. 广府古建筑木结构箍头榫节点抗震性能研究[J]. 建筑结构学报,2019,40(10): 168-179.CHEN Qingjun, PENG Zhangfeng, CAI Jian, et al. Seismic behavior of hoop head tenon-mortise joint in ancient wood structures in Guangfu[J]. Journal of Building Structures, 2019, 40(10): 168-179. [5] 淳庆,潘建伍,董运宏. 江南地区传统木构建筑透榫节点受力性能研究[J]. 西南交通大学学报,2016,51(5): 862-869. doi: 10.3969/j.issn.0258-2724.2016.05.007CHUN Qing, PAN Jianwu, DONG Yunhong. Mechanical properties of Tou mortise-tenon joints of the traditional timber buildings in the South Yangtze River regions[J]. Journal of Southwest Jiaotong University, 2016, 51(5): 862-869. doi: 10.3969/j.issn.0258-2724.2016.05.007 [6] ZHANG B Z, XIE Q F, LI S Y, et al. Effects of gaps on the rotational performance of traditional straight mortise-tenon joints[J]. Engineering Structures, 2022, 260: 114231.1-114231.19. doi: 10.1016/j.engstruct.2022.114231 [7] 谢启芳,郑培君,崔雅珍,等. 古建筑木结构直榫节点抗震性能试验研究[J]. 地震工程与工程振动,2015,35(3): 232-241. doi: 10.13197/j.eeev.2015.03.232.xieqf.029XIE Qifang, ZHENG Peijun, CUI Yazhen, et al. Experimental study on seismic behavior of straight mortise-tenon joints of ancient timber buildings[J]. Earthquake Engineering and Engineering Dynamics, 2015, 35(3): 232-241. doi: 10.13197/j.eeev.2015.03.232.xieqf.029 [8] 陈春超,邱洪兴. 直榫节点受弯性能研究[J]. 建筑结构学报,2016,37(增1): 292-298. doi: 10.14006/j.jzjgxb.2016.S1.041CHEN Chunchao, QIU Hongxing. Study on flexural behavior of straight mortise-tenon joints[J]. Journal of Building Structures, 2016, 37(S1): 292-298. doi: 10.14006/j.jzjgxb.2016.S1.041 [9] 陈春超,邱洪兴. 透榫节点的受弯性能[J]. 东南大学学报(自然科学版),2016,46(2): 326-334. doi: 10.3969/j.issn.1001-0505.2016.02.016CHEN Chunchao, QIU Hongxing. Flexural behavior of penetrated mortise-tenon joints[J]. Journal of Southeast University (Natural Science Edition), 2016, 46(2): 326-334. doi: 10.3969/j.issn.1001-0505.2016.02.016 [10] 潘毅,王超,唐丽娜,等. 古建筑木结构直榫节点力学模型的研究[J]. 工程力学,2015,32(2): 82-89.PAN Yi, WANG Chao, TANG Lina, et al. Study on mechanical model of straight-tenon joints in ancient timber structures[J]. Engineering Mechanics, 2015, 32(2): 82-89. [11] 潘毅,安仁兵,王晓玥,等. 古建筑木结构透榫节点力学模型研究[J]. 土木工程学报,2020,53(4): 61-70,82. doi: 10.15951/j.tmgcxb.2020.04.007PAN Yi, AN Renbing, WANG Xiaoyue, et al. Study on mechanical model of through-tenon joints in ancient timber structures[J]. China Civil Engineering Journal, 2020, 53(4): 61-70,82. doi: 10.15951/j.tmgcxb.2020.04.007 [12] 王展光,刘人源,石昂,等. 单向加载下明销直榫节点力学性能研究[J]. 建筑结构,2021,51(21): 136-141. doi: 10.19701/j.jzjg.2021.21.025WANG Zhanguang, LIU Renyuan, SHI Ang, et al. Research on mechanical performance of straight mortise-tenon joints with exposed dowels under uniaxial loading[J]. Building Structure, 2021, 51(21): 136-141. doi: 10.19701/j.jzjg.2021.21.025 [13] 王展光,石昂,邵建华,等. 明销透榫节点抗弯性能研究[J]. 建筑结构,2021,51(18): 118-124.WANG Zhanguang, SHI Ang, SHAO Jianhua, et al. Research on flexural behavior of tenon joint with penetrating pin[J]. Building Structure, 2021, 51(18): 118-124. [14] 国家技术监督局. 木材物理力学性质试验方法: GB 1927—1943-91[S]. 北京: 中国建筑工业出版社, 1991. [15] 高永林,陶忠,叶燎原,等. 传统木结构典型榫卯节点基于摩擦机理特性的低周反复加载试验研究[J]. 建筑结构学报,2015,36(10): 139-145.GAO Yonglin, TAO Zhong, YE Liaoyuan, et al. Low-cycle reversed loading tests study on typical mortise-tenon joints of traditional timber building based on friction mechanism[J]. Journal of Building Structures, 2015, 36(10): 139-145. [16] 中华人民共和国住房和城乡建设部. 建筑抗震试验规程: JGJ/T 101—2015[S]. 北京: 中国建筑工业出版社, 2015. [17] 沈在康. 混凝土结构试验方法新标准应用讲评[M]. 北京: 中国建筑工业出版社, 1994. [18] 贺俊筱,王娟,杨庆山,等. 木楔加固对松动透榫节点抗震性能的影响[J]. 土木与环境工程学报(中英文),2022,44(2): 91-97.HE Junxiao, WANG Juan, YANG Qingshan, et al. Effects of wedge strengthening on seismic performance of loose penetrated mortise-tenon joint[J]. Journal of Civil and Environmental Engineering, 2022, 44(2): 91-97. [19] 金昱成,苏何先,潘文,等. 木结构榫卯节点抗震性能及加固对比试验研究[J]. 土木与环境工程学报(中英文),2022,44(2): 138-147.JIN Yucheng, SU Hexian, PAN Wen, et al. Experimental research on seismic performance and reinforcement comparison of mortise-tenon joints in timber structures[J]. Journal of Civil and Environmental Engineering, 2022, 44(2): 138-147. -

下载:

下载: