Bending Properties of Polypropylene Fiber-Sulfoaluminate Cement-Based Repair Material Using Grey Relation Theory

-

摘要:

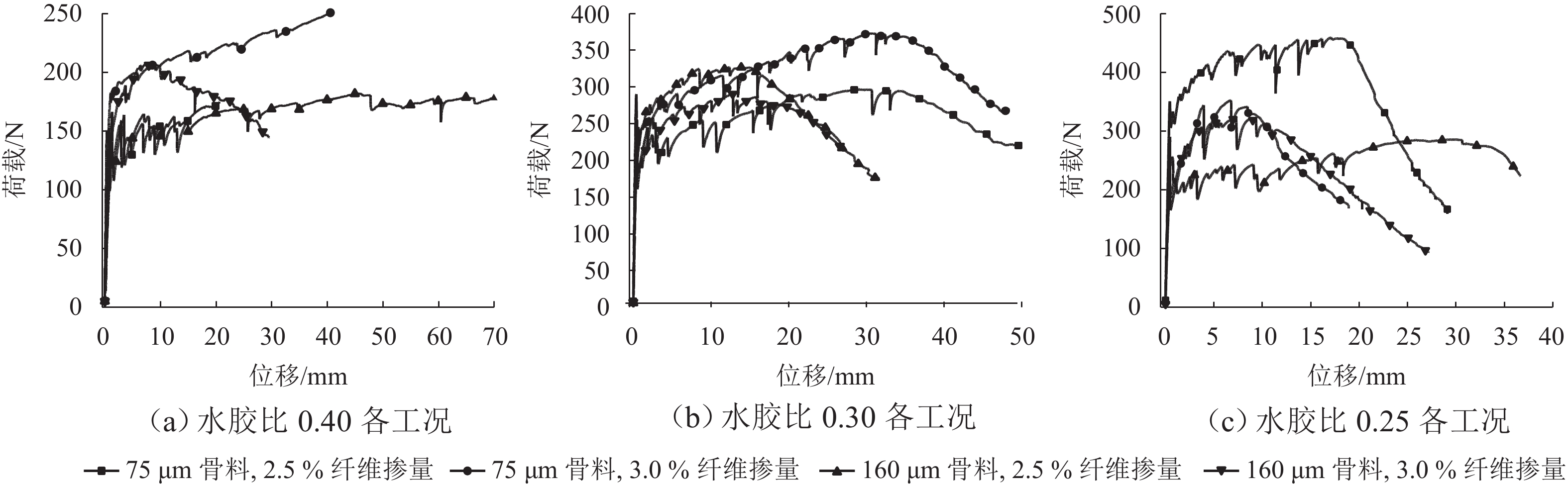

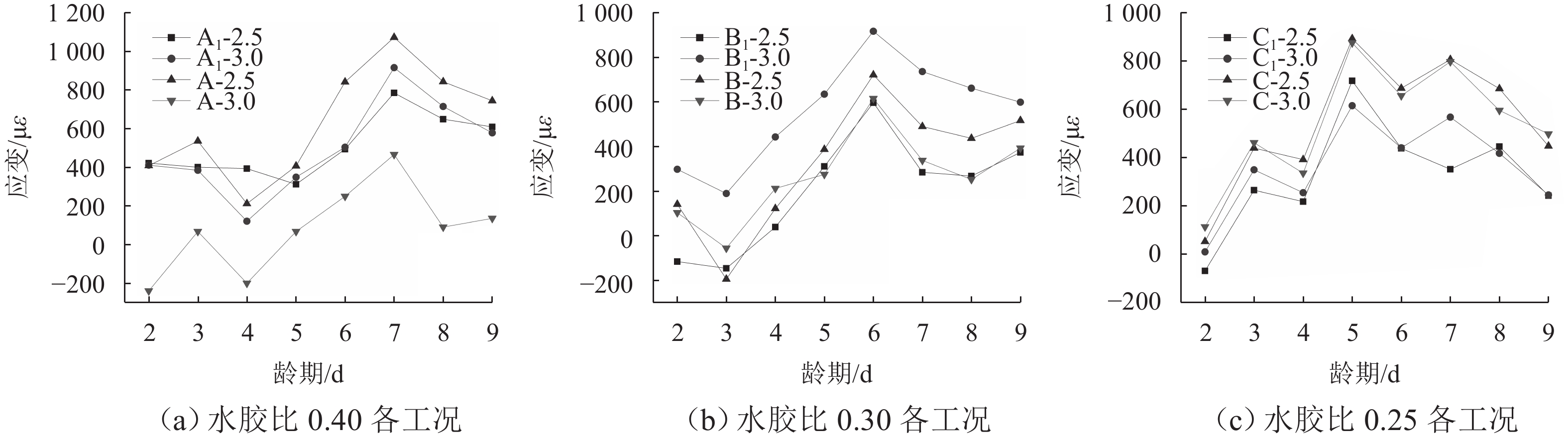

为提高水泥基增强复合材料(ECC)经济效益并控制修复周期,以较低成本的聚丙烯纤维和快硬早强硫铝酸盐水泥为关键组材,设计聚丙烯纤维硫铝酸盐水泥基(PP-SACC)修复材料,并探究水胶比、纤维掺量及骨料粒径对修复材料弯曲性能的影响规律,联用灰色关联模型对PP-SACC各工况进行综合评价. 研究结果表明:纤维掺量是影响强度、韧性及裂缝特性最重要的因素,纤维掺量对初裂强度、韧性指标及平均裂缝宽度的影响因子分别为 −0.68、0.79和 −0.98;骨料粒径对裂缝特性同样有明显的影响,石英砂尺寸对平均裂缝宽度的影响因子为 −0.86;水胶比对强度和韧性也有着显著的影响,合理的水胶比更有利于充分发挥纤维的桥连效应;PP-SACC修复材料在具备优异韧性的同时具有挠曲硬化特性.

-

关键词:

- PP纤维-硫铝酸盐水泥基修复材料 /

- 弯曲延性 /

- 挠曲硬化 /

- 改进灰色关联分析

Abstract:To improve the economic benefits of engineered cementitious composite (ECC) and control the repair cycle, the polypropylene fiber-sulfoaluminate cement-based (PP-SACC) repair materials were designed with polypropylene fiber featuring low cost and sulfoaluminate cement featuring fast hardening and early strength employed as the key components. The influence of water-binder ratio, fiber content, and aggregate size on the bending properties of the repair materials was explored. In addition, the grey relation model was used to comprehensively evaluate PP-SACC under all working conditions. The results indicate that the fiber content is the most important factor that affects the strength, toughness, and crack characteristics. The influence factors of fiber content on initial crack strength, toughness index, and average crack width are −0.68, 0.79, and −0.98, respectively. The aggregate size can significantly affect the crack characteristics. The influence factor of quartz sand size on the average crack width is −0.86. The water-binder ratio also greatly affects the strength and toughness, and a reasonable water-binder ratio is beneficial to leverage the bridging effect of the fiber. The PP-SACC repair material has excellent toughness and flexural hardening properties.

-

表 1 快硬硫铝酸盐水泥的化学成分组成

Table 1. Chemical compositions of fast-hardening sulfoaluminate cement

% 成分 质量分数 成分 质量分数 CaO 47.4 SO3 12.3 Al2O3 23.5 MgO 4.4 SiO2 10.1 Fe2O3 2.3 表 2 微珠化学成分组成

Table 2. Chemical compositions of cenosphere

% 成分 质量分数 成分 质量分数 SiO2 56.6 Fe2O3 5.3 CaO 4.8 Na2O 1.4 MgO 1.3 K2O 3.3 Al2O3 26.5 SO3 0.8 表 3 PP纤维物性参数

Table 3. Physical properties of PP fibers

参数 断裂强度/MPa 当量直径/μm 纤维长度/mm 初始弹性模量/GPa 断裂伸长率/% 取值 630 25.46 12 7.1 25.2 表 4 PP-SACC各工况基本配合比

Table 4. Mix proportions of PP-SACC under all working conditions

试件编号 水胶比 骨料粒径/μm 纤维掺量/% 修复材料流动度/mm 基体流动度/mm A1-2.5 0.40 75 2.5 216 173 A1-3.0 0.40 75 3.0 196 A-2.5 0.40 160 2.5 211 230 A-3.0 0.40 160 3.0 183 B1-2.5 0.30 75 2.5 181 119 B1-3.0 0.30 75 3.0 165 B-2.5 0.30 160 2.5 173 123 B-3.0 0.30 160 3.0 137 C1-2.5 0.25 75 2.5 162 104 C1-3.0 0.25 75 3.0 150 C-2.5 0.25 160 2.5 171 118 C-3.0 0.25 160 3.0 155 表 5 各工况初裂强度值

Table 5. Initial crack strengths under all working conditions

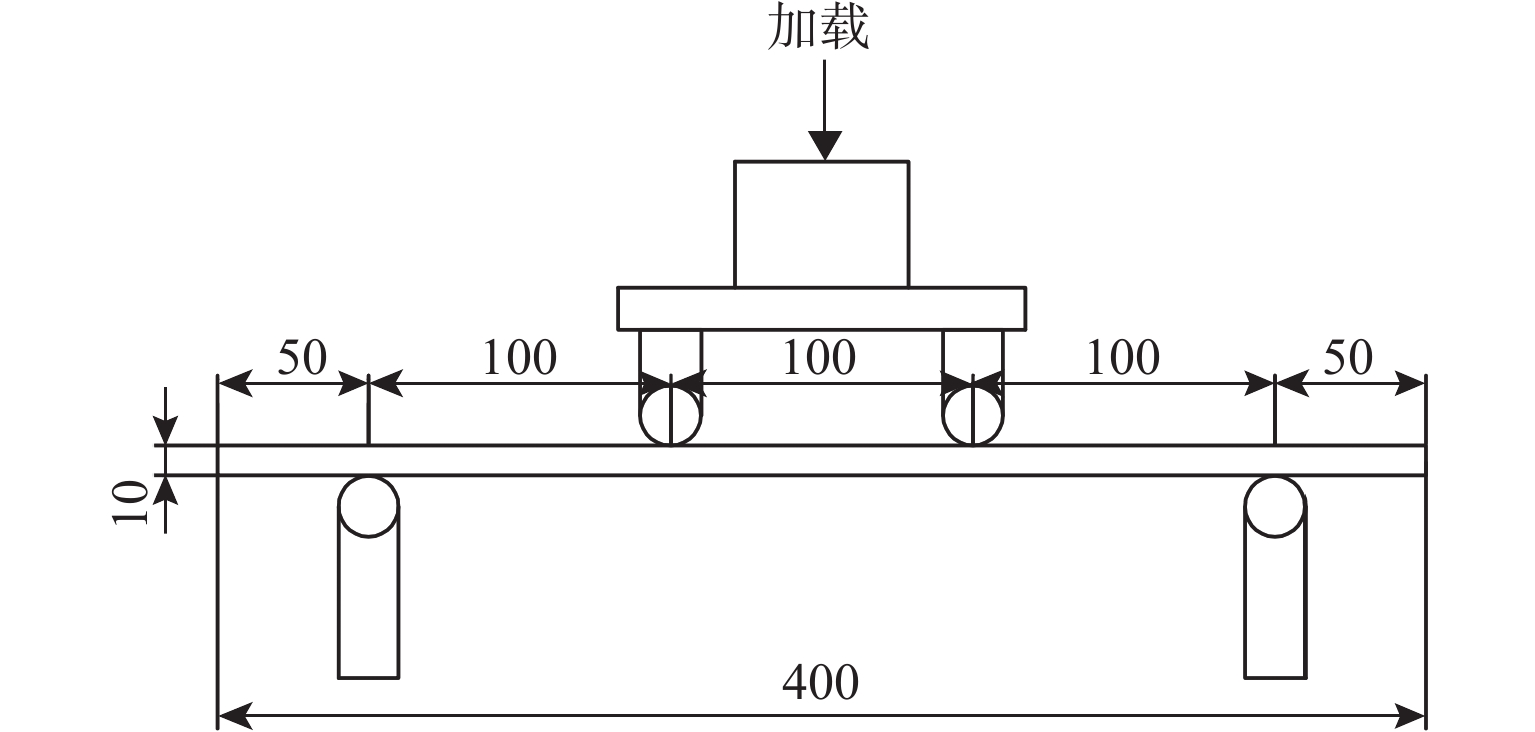

MPa 编号 初裂强度 编号 初裂强度 A1-2.5 4.56 B-2.5 8.74 A1-3.0 5.06 B-3.0 6.31 A-2.5 4.59 C1-2.5 8.44 A-3.0 4.32 C1-3.0 8.32 B1-2.5 6.79 C-2.5 8.44 B1-3.0 5.73 C-3.0 8.14 表 6 各工况四点弯曲开裂行为

Table 6. Cracking behavior of four-point bending under all working conditions

编号 平均裂缝

宽度/mm根数/根 编号 平均裂缝

宽度/mm根数/根 A1-2.5 0.240 6.33 B-2.5 0.230 6.00 A1-3.0 0.140 14.67 B-3.0 0.210 5.33 A-2.5 0.190 5.67 C1-2.5 0.190 7.33 A-3.0 0.470 1.67 C1-3.0 0.490 3.00 B1-2.5 0.290 4.67 C-2.5 0.230 8.33 B1-3.0 0.190 11.67 C-3.0 0.250 3.67 表 7 各工况弯曲韧性指标

Table 7. Toughness indexes under all working conditions

编号 I5 I10 I20 I40 A1-2.5 3.82 7.49 17.14 33.13 A1-3.0 4.11 8.15 16.91 35.8 A-2.5 4.43 8.99 18.99 39.88 A-3.0 4.32 8.56 18.31 38.17 B1-2.5 3.74 7.14 15.79 32.92 B1-3.0 4.33 8.77 18.65 40.29 B-2.5 3.80 7.59 15.84 33.96 B-3.0 4.22 8.49 17.76 38.40 C1-2.5 4.12 8.23 17.30 39.11 C1-3.0 3.58 7.14 17.05 36.97 C-2.5 3.91 7.46 16.49 32.81 C-3.0 3.72 7.55 17.92 29.69 表 8 反应弯曲性能指标关联度

Table 8. Correlation of bending property indexes

影响因子 I40 平均裂缝宽度 初裂强度值 水胶比 0.7321 0.6531 − 0.8558 骨料粒径 − 0.2364 − 0.8583 − 0.2188 纤维掺量 0.7947 − 0.9843 − 0.6774 表 9 PP-SACC各工况性能测试结果汇总

Table 9. Test results of PP-SACC under all working conditions

组号 I40 平均裂缝

宽度/mm初裂强度

值/MPaA1-2.5 33.13 0.237 4.56 A1-3.0 35.80 0.137 5.06 A-2.5 39.88 0.194 4.59 A-3.0 38.17 0.475 4.32 B1-2.5 32.92 0.292 6.79 B1-3.0 40.29 0.193 5.73 B-2.5 33.96 0.233 8.74 B-3.0 38.40 0.206 6.31 C1-2.5 39.11 0.193 8.44 C1-3.0 36.97 0.491 8.32 C-2.5 32.81 0.231 8.44 C-3.0 29.69 0.250 8.14 -

[1] 李梦杰. 聚合物混凝土在路面破损快速维修的试验研究[D]. 郑州: 郑州大学,2021. [2] 龙方来. 聚合物改性水泥混凝土路面薄层快速修补材料配比研究[D]. 郑州: 郑州大学,2016. [3] 王亮,杜国庆,高华,等. 渗透类防水防腐涂覆体系在桥梁修复中的应用[J]. 中国建筑防水,2020(12): 36-39.WANG Liang, DU Guoqing, GAO Hua, et al. Application of capillary waterproofing and anti-corrosive coating system in bridge repairing[J]. China Building Waterproofing, 2020(12): 36-39. [4] 钟世云,袁华. 聚合物在混凝土中的应用[M]. 北京:化学工业出版社,2003:8 [5] CHEN K Y, WU D Z, YI M, et al. Mechanical and durability properties of metakaolin blended with slag geopolymer mortars used for pavement repair[J]. Construction and Building Materials, 2021, 281(2): 122566.1-122566.26. [6] SADRMOMTAZI A, KHOSHKBIJARI R K. Bonding durability of polymer-modified concrete repair overlays under freeze–thaw conditions[J]. Magazine of Concrete Research, 2017, 69(24): 1268-1275. doi: 10.1680/jmacr.17.00014 [7] SIDDIKA A, HAJIMOHAMMADI A, MAMUN M A A, et al. Waste glass in cement and geopolymer concretes: a review on durability and challenges[J]. Polymers, 2021, 13(13): 2071.1-2071.26. [8] 陈全胜,侯圣均,江传彬,等. PVA纤维水泥基复合材料抗冲蚀磨损性能试验研究[J]. 西南交通大学学报,2023,58(1): 150-158.CHEN Quansheng, HOU Shengjun, JIANG Chuanbin, et al. Experimental study on hydro-abrasion performance of polyvinyl alcohol fiber cementitious composites[J]. Journal of Southwest Jiaotong University, 2023, 58(1): 150-158. [9] AFROUGHSABET V, BIOLZI L, OZBAKKALOGLU T. High-performance fiber-reinforced concrete: a review[J]. Journal of Materials Science, 2016, 51(14): 6517-6551. doi: 10.1007/s10853-016-9917-4 [10] CAO Q, LI H, LIN Z B. Effect of active confinement on compressive behavior of GFRP-confined expansive concrete under axial cyclic loading[J]. ACI Structural Journal, 2020, 117(1): 207-216. [11] BELAIDI A S E, BENABED B, SOUALHI H. Physical and mechanical properties of concrete repair materials in dry and hot-dry environment[J]. Journal of Adhesion Science and Technology, 2015, 29(6): 543-554. doi: 10.1080/01694243.2014.998001 [12] SOUPIONIS G, GEORGIOU P, ZOUMPOULAKIS L. Polymer composite materials fiber-reinforced for the reinforcement/repair of concrete structures[J]. Polymers, 2020, 12(9): 2058.1-2058.14. [13] XU S L, WANG N, ZHANG X F. Flexural behavior of plain concrete beams strengthened with ultra high toughness cementitious composites layer[J]. Materials and Structures, 2012, 45(6): 851-859. doi: 10.1617/s11527-011-9803-0 [14] 徐世烺,王楠,尹世平. 超高韧性水泥基复合材料加固钢筋混凝土梁弯曲控裂试验研究[J]. 建筑结构学报,2011,32(9): 115-122.XU Shilang, WANG Nan, YIN Shiping. Experimental study on flexural characteristics of RC beams strengthened with post-poured ultra high toughness cementitious composites[J]. Journal of Building Structures, 2011, 32(9): 115-122. [15] 徐世烺,王楠. 后浇UHTCC加固既有混凝土复合梁的弯曲控裂性能[J]. 中国公路学报,2011,24(3): 36-43. doi: 10.3969/j.issn.1001-7372.2011.03.006XU Shilang, WANG Nan. Flexural crack control performance of existing concrete composite beam reinforced by post-poured UHTCC[J]. China Journal of Highway and Transport, 2011, 24(3): 36-43. doi: 10.3969/j.issn.1001-7372.2011.03.006 [16] WU C, LI V C. Thermal-mechanical behaviors of CFRP-ECC hybrid under elevated temperatures[J]. Composites Part B: Engineering, 2017, 110: 255-266. doi: 10.1016/j.compositesb.2016.11.037 [17] 冯虎,刘光辉,毕永涛,等. 微细钢纤维快硬高强硫铝酸盐水泥砂浆与钢筋黏结性能研究[J]. 施工技术,2019,48(2): 121-125.FENG Hu, LIU Guanghui, BI Yongtao, et al. Bond properties between micro-steel-fiber reinforced fast hardening high strength sulphoaluminate cement mortar and steel bar[J]. Construction Technology, 2019, 48(2): 121-125. [18] 田俊. 超高韧性水泥基复合材料加固混凝土结构的界面力学性能与耐久性能研究[D]. 南京:东南大学,2017. [19] 张成龙,刘漪,张明. PP/PVA纤维增强硫铝酸盐水泥基快速修补材料试验研究[J]. 硅酸盐通报,2021,40(7): 2174-2183.ZHANG Chenglong, LIU Yi, ZHANG Ming. PP/PVA fiber reinforced sulphoaluminate cement-based rapid repair material[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(7): 2174-2183. [20] 李文强. 纤维水泥基修补材料在桥墩冲刷破坏中的应用研究[D]. 成都: 西南交通大学,2018. [21] 何欢,杨荣俊,文俊强,等. PVA纤维增强快硬硫铝酸盐水泥基ECC材料性能的研究[J]. 硅酸盐通报,2019,38(5): 1484-1490,1496.HE Huan, YANG Rongjun, WEN Junqiang, et al. Study on the rapid hardening sulphoaluminate-based engineered cementitious composites reinforced with PVA fiber[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(5): 1484-1490,1496. [22] 中华人民共和国国家质量监督检验检疫总局,中国国家标准化管理委员会. 水泥胶砂流动度测定方法:GB/T 2419—2005[S]. 北京: 中国标准出版社,2005. [23] 国家市场监督管理总局,国家标准化管理委员会. 水泥胶砂强度检验方法(ISO法): GB/T 17671—2021[S]. 北京: 中国标准出版社,2021. [24] 蔡向荣. 超高韧性水泥基复合材料基本力学性能和应变硬化过程理论分析[D]. 大连:大连理工大学,2010. [25] 中国工程建设标准化协会. 纤维混凝土试验方法标准:CECS 13—2009[S]. 北京:中国计划出版社,2010. [26] CONG L, LI V, CHRISTOPHER K Y L. Flaw characterization and correlation with cracking strength in Engineered Cementitious Composites (ECC)[J]. Cement & Concrete Research, 2018, 107: 64-74. [27] 邓聚龙. 灰色控制系统[J]. 华中工学院学报,1982(3): 9-18. [28] QI Z F, HUANG Z Y, LI H, et al. Study of flexural response in strain hardening cementitious composites based on proposed parametric model[J]. Materials, 2018, 12(1): 113.1-113.14. [29] 李京坤,程进章,郭辉娟,等. 基于灰色关联度的超临界流体换热系数影响因素研究[J]. 湖北电力,2022,46(1): 58-64.LI Jingkun, CHENG Jinzhang, GUO Huijuan, et al. Study on influencing factors of supercritical fluid heat transfer coefficient based on grey correlation degree[J]. Hubei Electric Power, 2022, 46(1): 58-64. [30] 阴悦. 复合材料目视损伤检验影响因素的灰色关联分析[D]. 南京: 南京航空航天大学,2017. [31] 王建明. 多目标模糊识别优化决策理论与应用研究[D]. 大连: 大连理工大学,2004. [32] 周小川. 模糊层次分析法和灰色关联度在铁路方案决策中的应用[D]. 成都: 西南交通大学,2011. [33] 中华人民共和国住房和城乡建设部. 建筑砂浆基本性能试验方法标准:JGJ/T 70—2009[S]. 北京: 中国建筑工业出版社,2009. -

下载:

下载: