Design of Magnetorheological Damper Based on Magnetorheological Composite Materials

-

摘要:

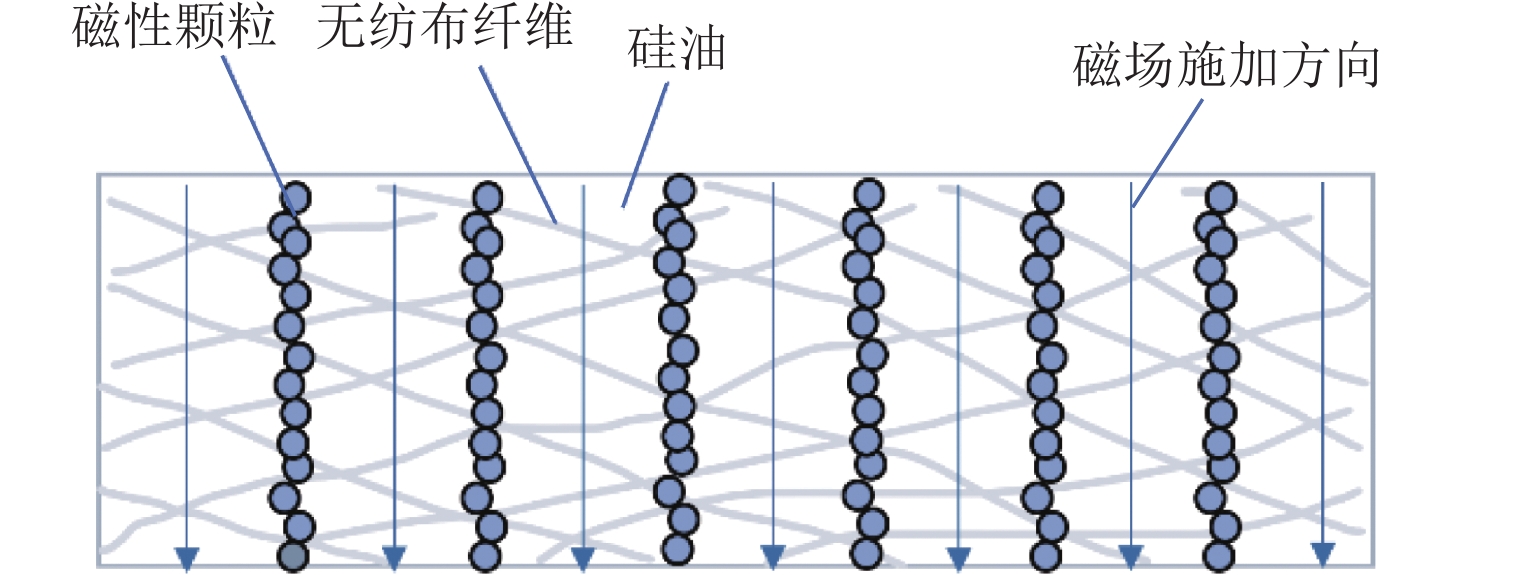

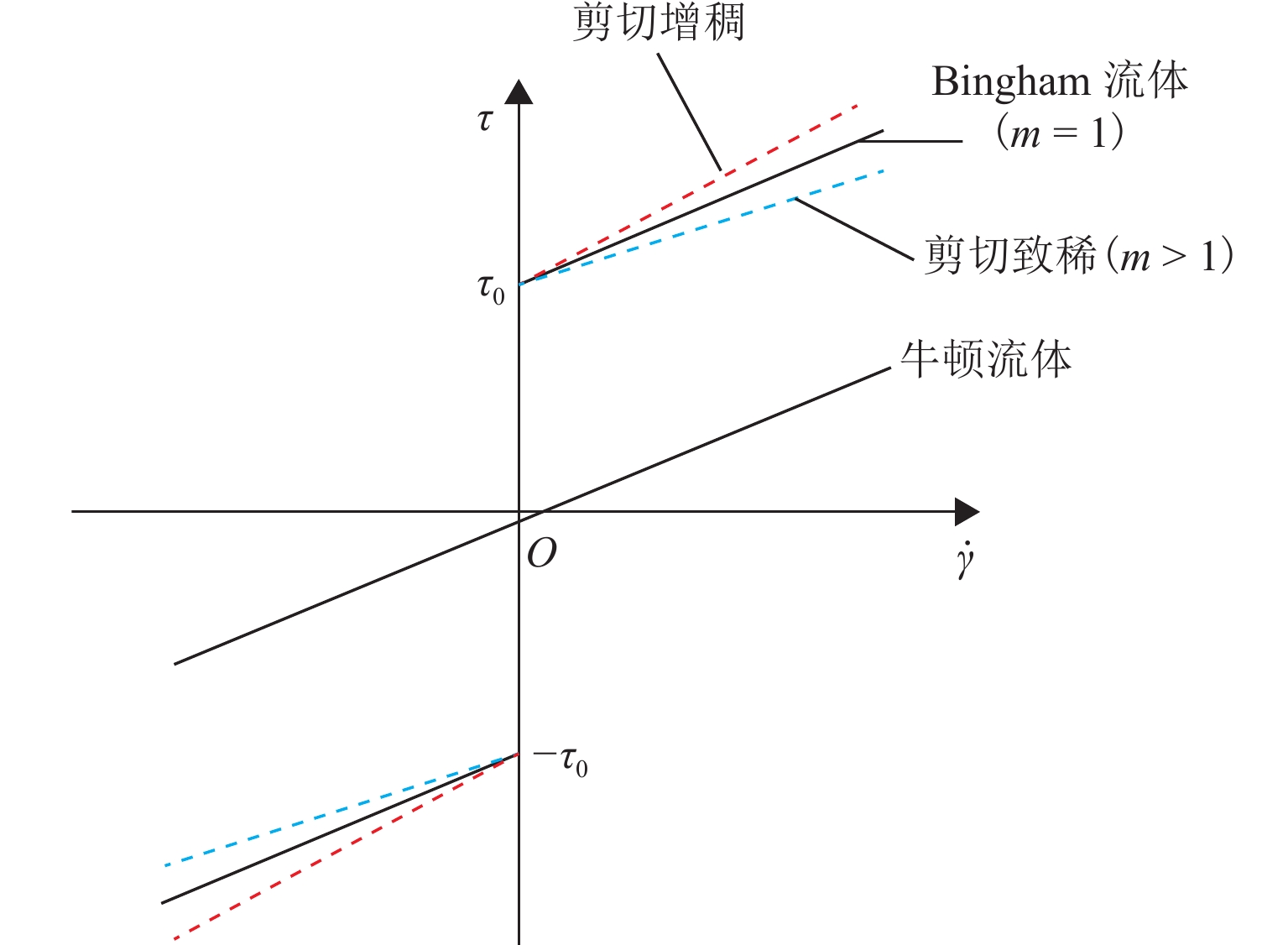

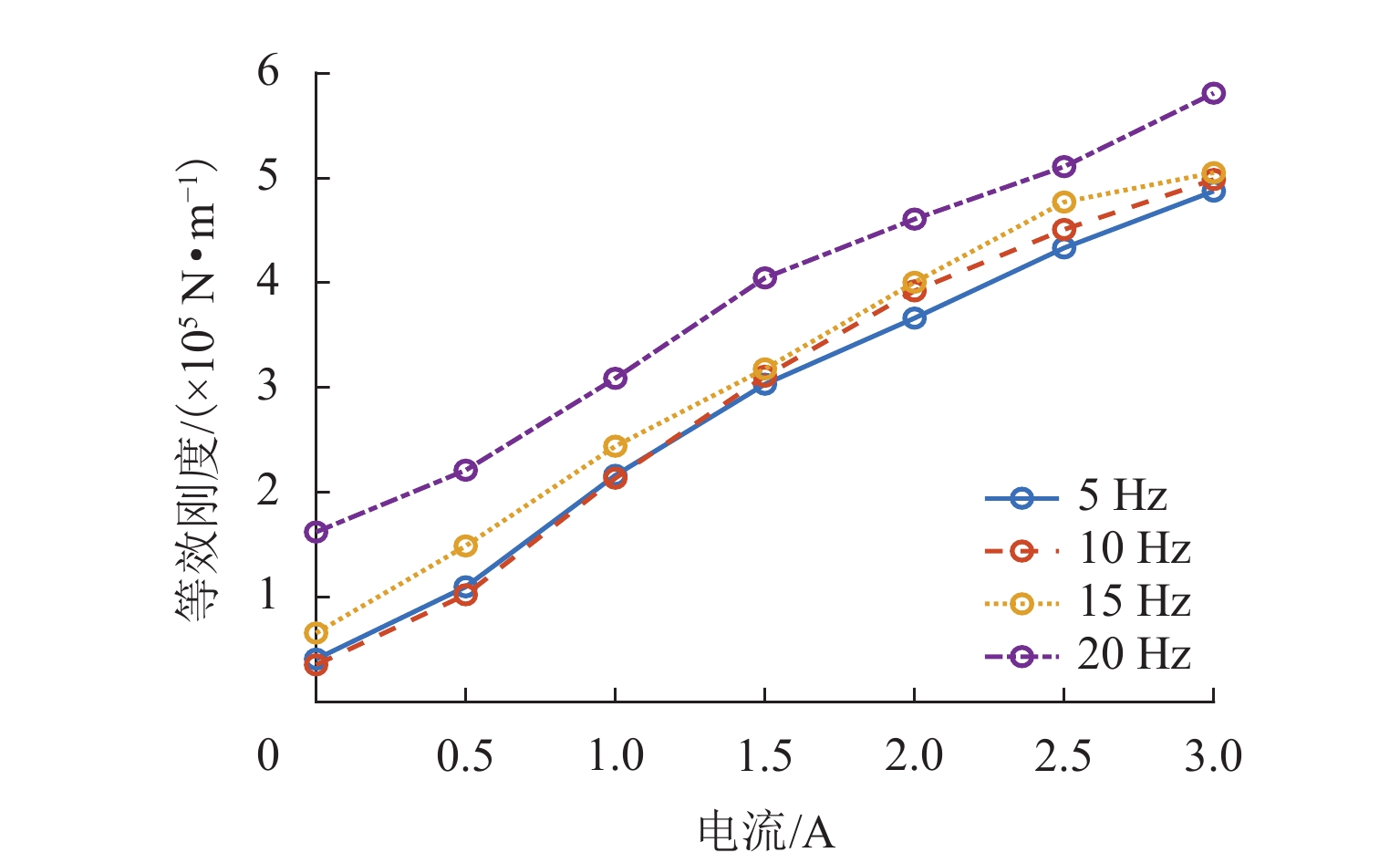

为解决传统磁流变阻尼器存在工作介质易沉降、密封要求较高,且中高频激励下阻尼器刚度快速增大,能耗衰减严重的问题,制备并测试了一种沉降稳定性能良好且密封要求低的磁流变复合材料,建立改进的Herschle-Bulkley模型用以表征复合材料的力学性能;基于该复合材料设计加工出一种剪切式磁流变阻尼器,并设计实验测试中、高频激励下阻尼器的性能响应规律. 研究结果表明:3 A电流激励下,当测试频率由5 Hz增大至20 Hz时,阻尼器动态刚度由4.87 × 105 N/m增加到6.29 × 105 N/m,且全频段阻尼器单周期耗能均在0.04 J左右,验证了所设计的磁流变阻尼器在中高频振动工况下的耗能能力.

Abstract:Traditional magnetorheological dampers involve sedimentary working media, high sealing requirements, rapidly increasing damper stiffness, and serious energy consumption attenuation under medium- and high-frequency excitation. In order to address these problems, a magnetorheological composite material with excellent settlement stability and low sealing requirements was prepared and tested, and an improved Herschle-Bulkley model was established to characterize the mechanical properties of the composite material. Furthermore, a shear magnetorheological damper was designed and manufactured based on the composite material, and the performance response law of the damper under medium- and high-frequency excitation was tested by designed experiments. The results show that the dynamic stiffness of the damper increases from 4.87 × 105 N/m to 6.29 × 105 N/m when the test frequency is increased from 5 Hz to 20 Hz under the current excitation of 3 A, and the single-cycle energy consumption of the damper under the full-band is about 0.04 J, which verified the energy consumption capacity of the designed magnetorheological damper under medium- and high-frequency vibrations.

-

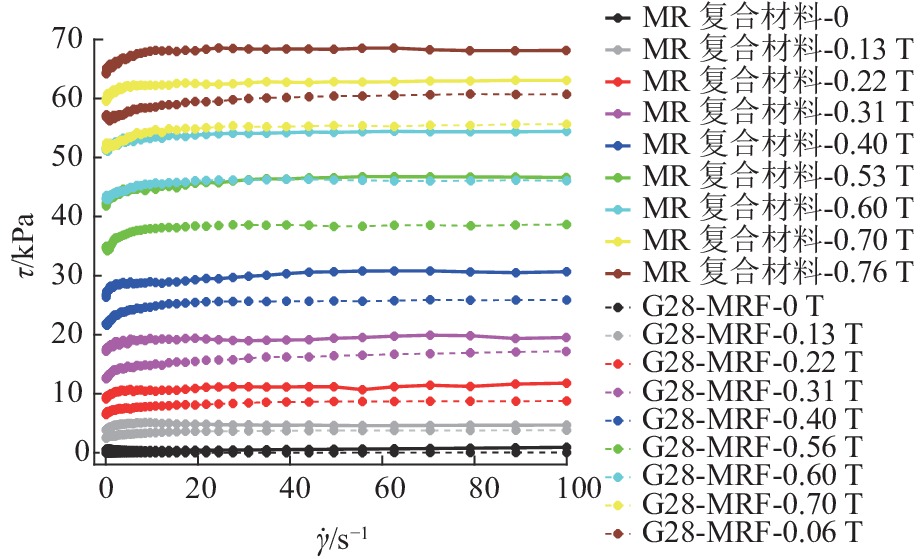

表 1 不同磁场下磁流变复合材料与磁流变液的平均剪切应力对比

Table 1. Comparison of average shear stress between magnetorheological composite materials and magnetorheological fluid under different magnetic fields

kPa 磁场强度/ T G28-MRF 磁流变复合材料 0 0.01 0.52 0.13 3.14 4.52 0.22 7.55 10.32 0.31 14.38 18.55 0.40 23.70 28.57 0.53 36.55 44.30 0.60 44.54 52.78 0.70 53.36 61.49 0.76 58.03 66.58 表 2 不同磁场强度下改进H-B模型各参数取值

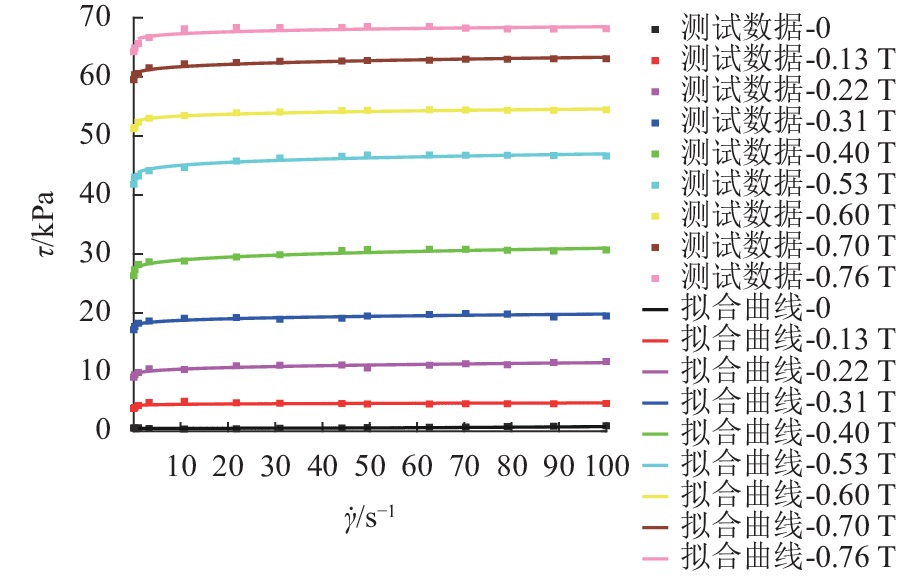

Table 2. Parameter values of improved H-B model under different magnetic field strengths

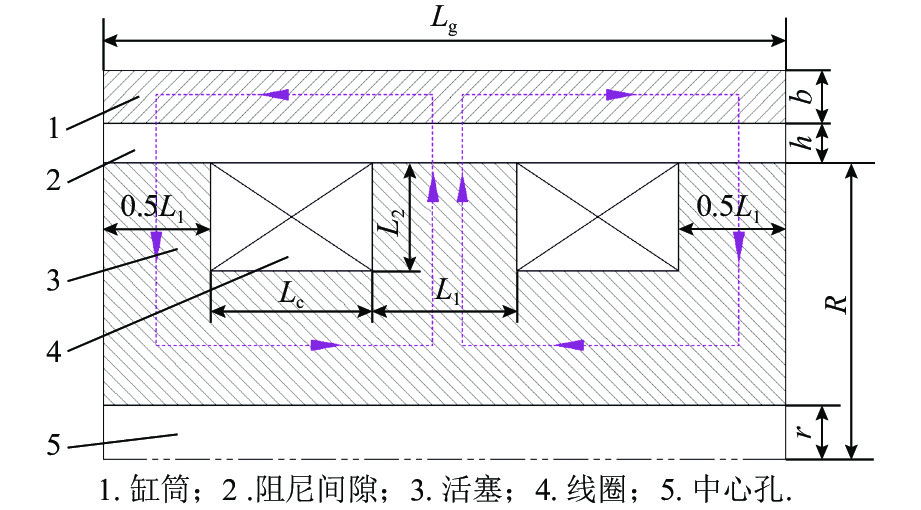

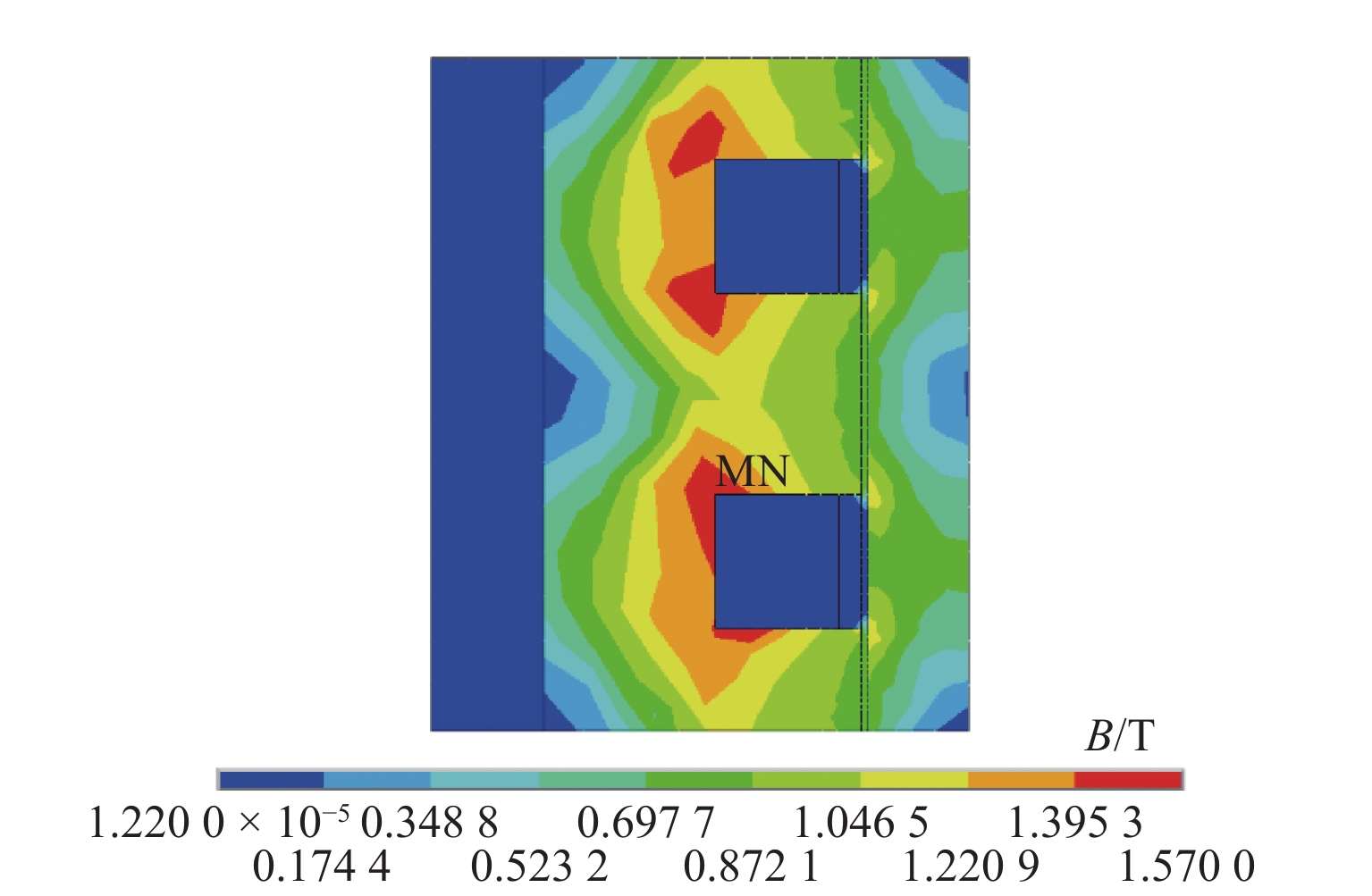

B/T K m C0 Cbase C1 0 0.03 0.5 323.30 0.01 0.31 0.13 533.00 7.9 1.55 0.89 1.44 0.22 761.30 3.9 1.41 0.78 0.66 0.31 954.30 4.5 1.39 0.56 0.90 0.40 1518.00 4.1 1.21 0.84 0.76 0.53 2016.00 4.9 1.21 1.17 0.92 0.60 1377.00 5.2 1.19 0.97 0.96 0.70 1264.00 4.2 1.15 0.71 0.81 0.76 2164.00 6.9 1.13 1.99 1.97 表 3 阻尼单元参数

Table 3. Damping element parameters

mm 参数 数值 参数 数值 h 0.3 6.0 30 r 5.0 b 4.5 9.0 R 19.2 6.5 表 4 阻尼器测试参数

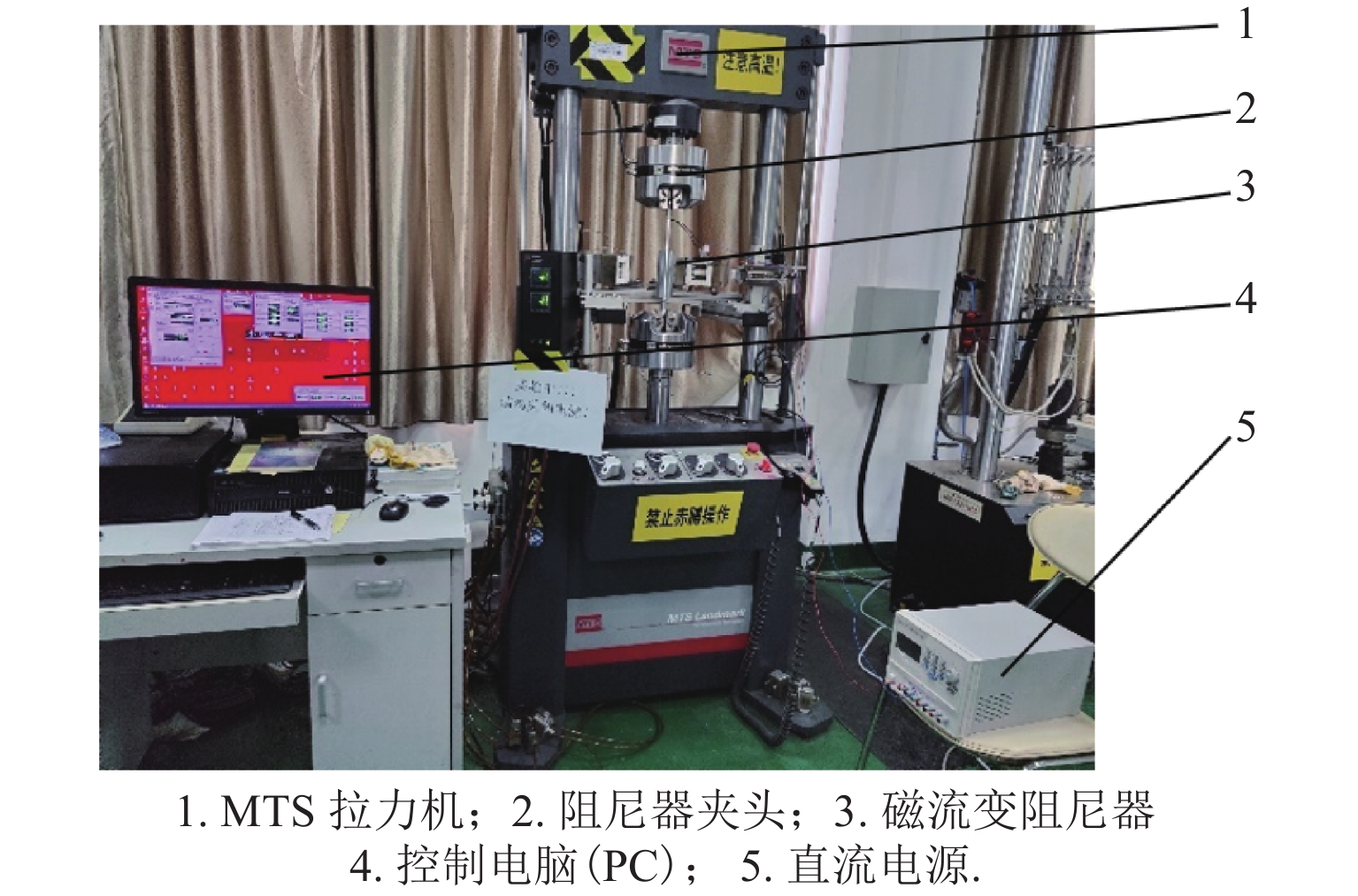

Table 4. Damper testing parameters

名称 测试

频率/Hz测试

振幅/mm测试

电流/A取值 5, 10, 15, 20 ±0.1 0, 0.5, 1.0, 1.5,

2.0, 2.5, 3.0 -

[1] 涂建维,朱倩莹,刘凡,等. 新型防泄漏磁流变阻尼器的密封构造与力学模型[J]. 土木工程学报,2018,51(增2): 92-97. doi: 10.15951/j.tmgcxb.2018.s2.014TU Jianwei, ZHU Qianying, LIU Fan, et al. New sealing device and mechanical model of leakproof MR damper[J]. China Civil Engineering Journal, 2018, 51(S2): 92-97. doi: 10.15951/j.tmgcxb.2018.s2.014 [2] 程海斌. 磁流变液的稳定性调控及其在重大工程中应用[D]. 武汉: 武汉理工大学, 2012. [3] 欧进萍,关新春. 磁流变耗能器及其性能[J]. 地震工程与工程振动,1998,18(3): 74-81. doi: 10.3969/j.issn.1000-1301.1998.03.010OU Jinping, GUAN Xinchun. Magnetorheological fluid dampers and their properties[J]. Earthquake Engineering and Engineering Vibration, 1998, 18(3): 74-81. doi: 10.3969/j.issn.1000-1301.1998.03.010 [4] GORDANINEJAD F, WANG X, HITCHCOCK G, et al. Modular high-force seismic magneto-rheological fluid damper[J]. Journal of Structural Engineering, 2010, 136(2): 135-143. doi: 10.1061/(ASCE)0733-9445(2010)136:2(135) [5] DAOMING W, WANG Y K, ZI B, et al. Development ofan active and passive finger rehabilitation robot using pneumatic muscle and magnetorheological damper[J]. Mechanism and Machine Theory, 2020, 147: 103762.1-103762.16. [6] LEE D Y, NAM Y J, YAMANE R, et al. Performance evaluation on vibration control of MR landing gear[J]. Journal of Physics Conference Series, 2009, 149(1): 012068.1-012068.6. [7] HIEMENZ G J, CHOI Y T, WERELEY N M. Semi-active control of vertical stroking helicopter crew seat for enhanced crashworthiness[J]. Journal of Aircraft, 2007, 44(3): 1031-1034. doi: 10.2514/1.26492 [8] 史文库,张曙光,陈志勇,等. 磁流变半主动座椅悬架建模及振动特性分析[J]. 西南交通大学学报,2023,58(2): 253-260.SHI Weiku, ZHANG Shuguang, CHEN Zhiyong, et al. modeling and vibration analysis of semi-active seat suspension with magnetorheological damper[J]. Journal of Southwest Jiaotong University, 2023, 58(2): 253-260. [9] 侯保林. 某火炮磁流变缓冲阻尼器的设计与分析[J]. 兵工学报,2006,27(4): 613-616. doi: 10.3321/j.issn:1000-1093.2006.04.008HOU Baolin. Design and analysis of a gun recoil magneto-rheological damper[J]. Acta Armamentarii, 2006, 27(4): 613-616. doi: 10.3321/j.issn:1000-1093.2006.04.008 [10] 焦小磊,马文来,赵阳,等. 中高频激励下微振动流体阻尼器解析模型[J]. 中国科学(技术科学),2017,47(12): 1273-1285. doi: 10.1360/N092017-00312JIAO Xiaolei, MA Wenlai, ZHAO Yang, et al. Analytical model of micro-vibration fluid damper under medium and high frequency excitation[J]. Scientia Sinica (Technologica), 2017, 47(12): 1273-1285. doi: 10.1360/N092017-00312 [11] 左曙光,毛钰,吴旭东,等. 磁流变减振器高频硬化特性建模及优化[J]. 振动与冲击,2016,35(10): 120-125,150. doi: 10.13465/j.cnki.jvs.2016.10.019ZUO Shuguang, MAO Yu, WU Xudong, et al. Modelling and optimization of high frequency hardening characteristics of magneto rheological damper[J]. Journal of Vibration and Shock, 2016, 35(10): 120-125,150. doi: 10.13465/j.cnki.jvs.2016.10.019 [12] 涂奉臣,陈照波,李华,等. 一种改进型磁流变阻尼器用于宽频隔振研究[J]. 振动工程学报,2007,20(5): 484-488. doi: 10.3969/j.issn.1004-4523.2007.05.010TU Fengchen, CHEN Zhaobo, LI Hua, et al. Research on improved magnetorheological damper for wide-band vibration control[J]. Journal of Vibration Engineering, 2007, 20(5): 484-488. doi: 10.3969/j.issn.1004-4523.2007.05.010 [13] 董小闵, 李坪洋, 席军. 一种适用于多领域、多工作模式的具有空间网状纤维基体的磁流变液复合材料及其制备方法: CN114141465A[P]. 2022-12-23. [14] YANG G Q. Large-scale magnetorheological fluid Damper for vibration mitigation modeling, testing and control[D]. South Bend: University of Notre Dame, 2001. [15] 邢志,吕建刚,李猛. 磁流变液特性分析及实验研究[J]. 磁性材料及器件,2005,36(3): 21-23. doi: 10.3969/j.issn.1001-3830.2005.03.007XING Zhi, LV Jiangang, LI Meng. Behavior analysis and experimental research on magnetorheological fluids[J]. Journal of Magnetic Materials and Devices, 2005, 36(3): 21-23. doi: 10.3969/j.issn.1001-3830.2005.03.007 [16] 周正木. 整星宽频隔振磁流变阻尼器设计理论及试验研究[D]. 重庆: 重庆大学, 2020. 期刊类型引用(1)

1. 於天澄. 基于改进遗传算法的磁流变阻尼器模型参数辨识方法. 电子设计工程. 2025(07): 192-196 .  百度学术

百度学术其他类型引用(3)

-

下载:

下载:

百度学术

百度学术