Analysis of Split Grouting Mechanism Considering Coupling Effect of Slurry and Soil Stress

-

摘要:

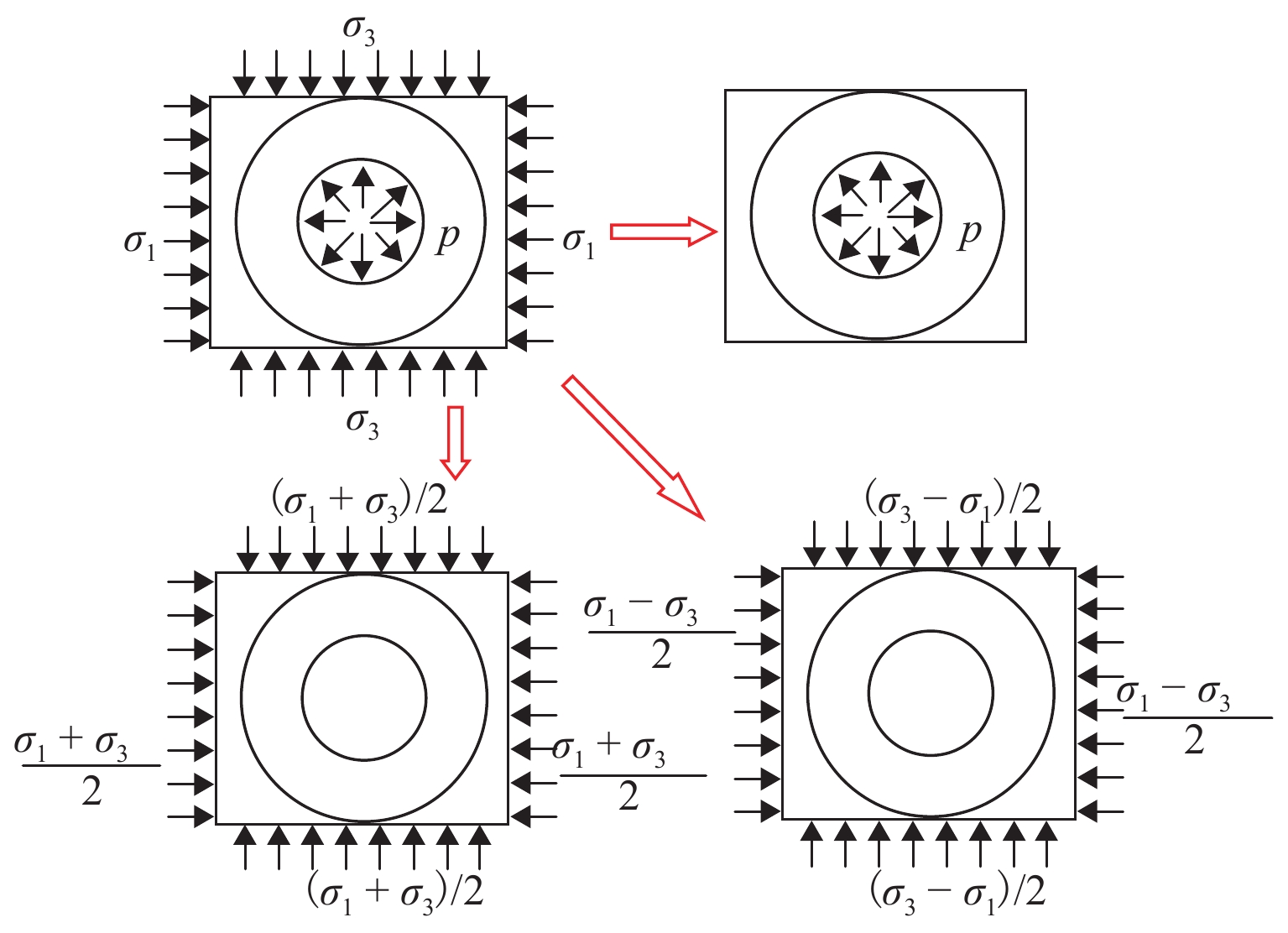

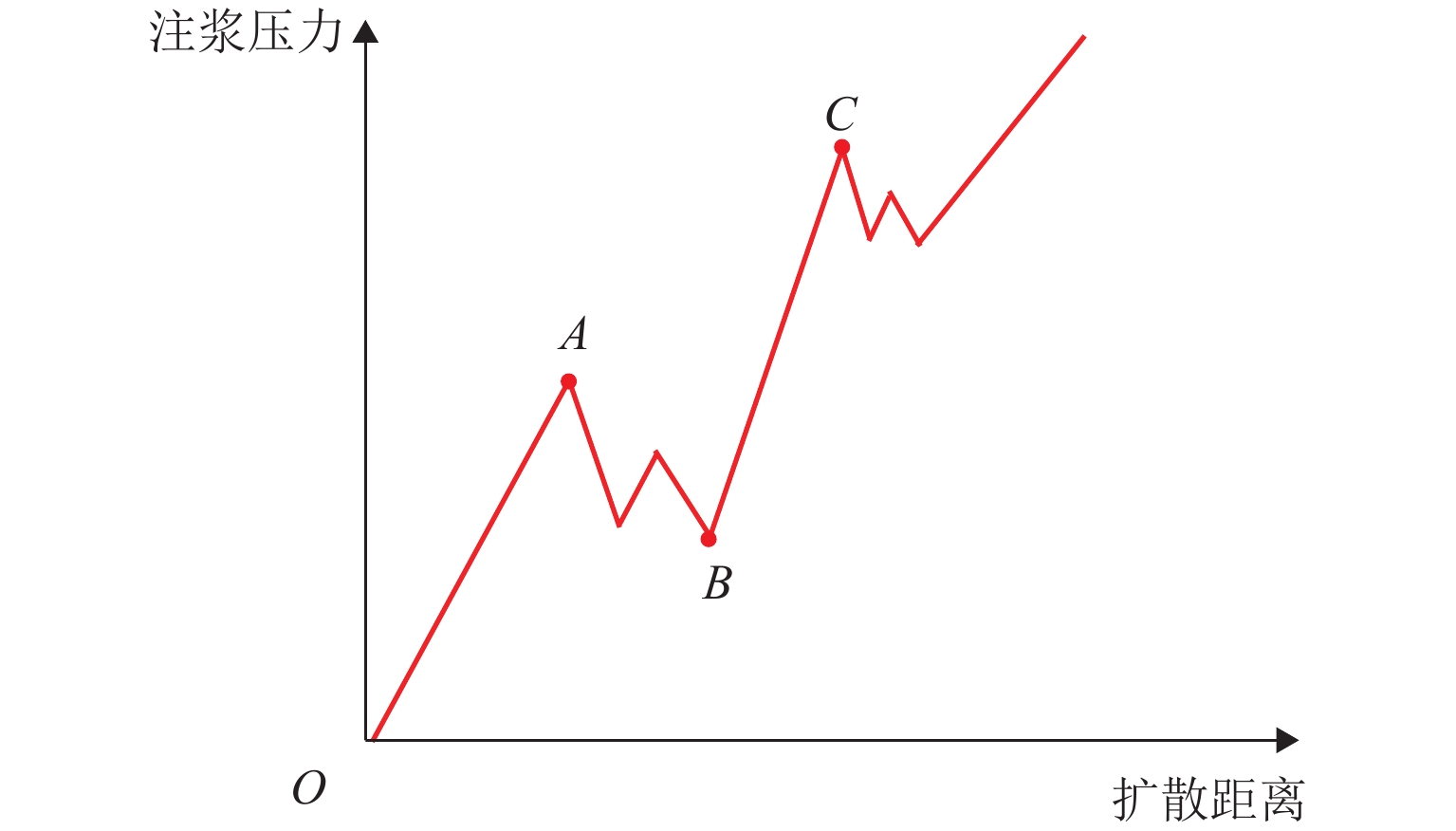

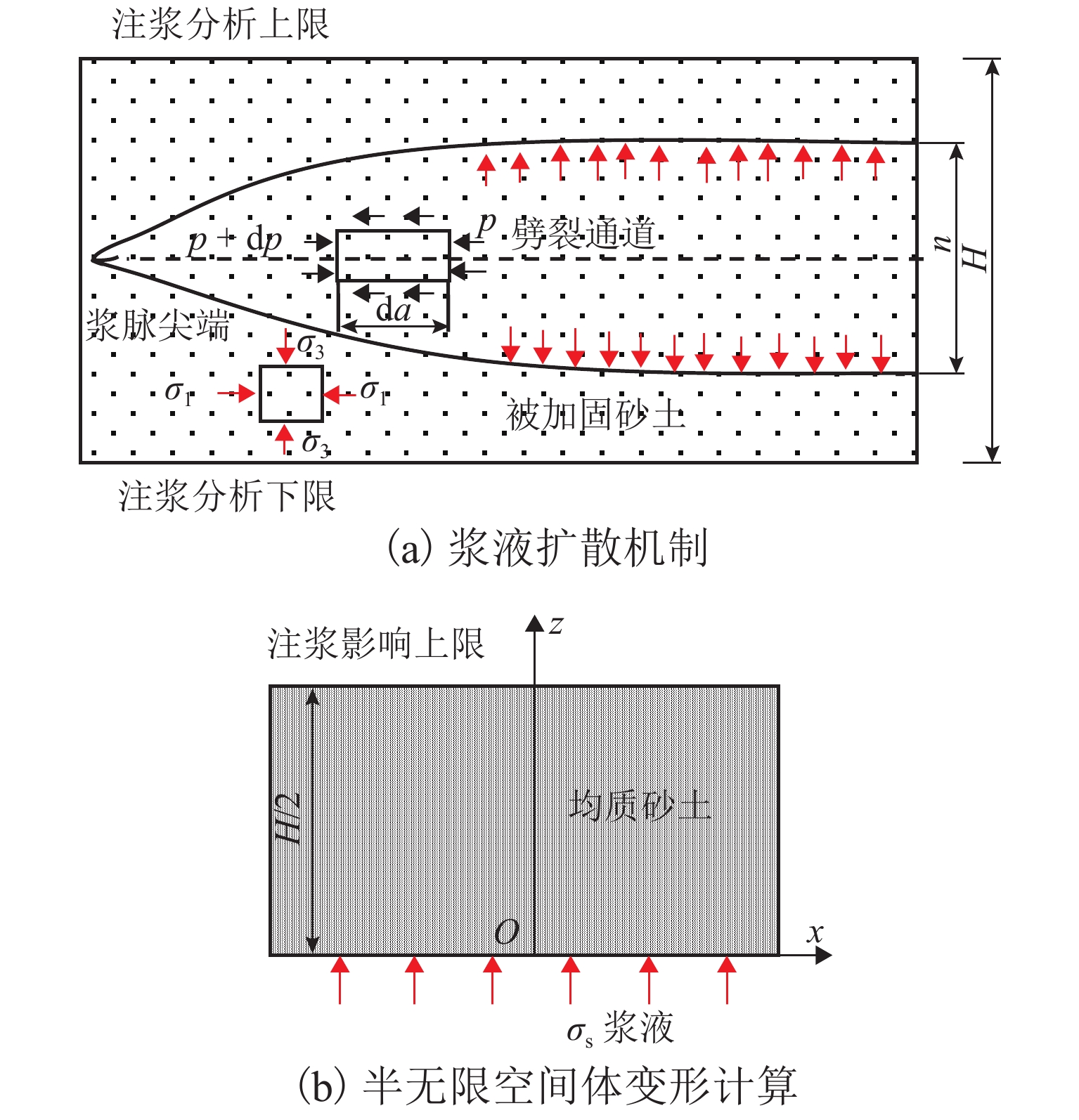

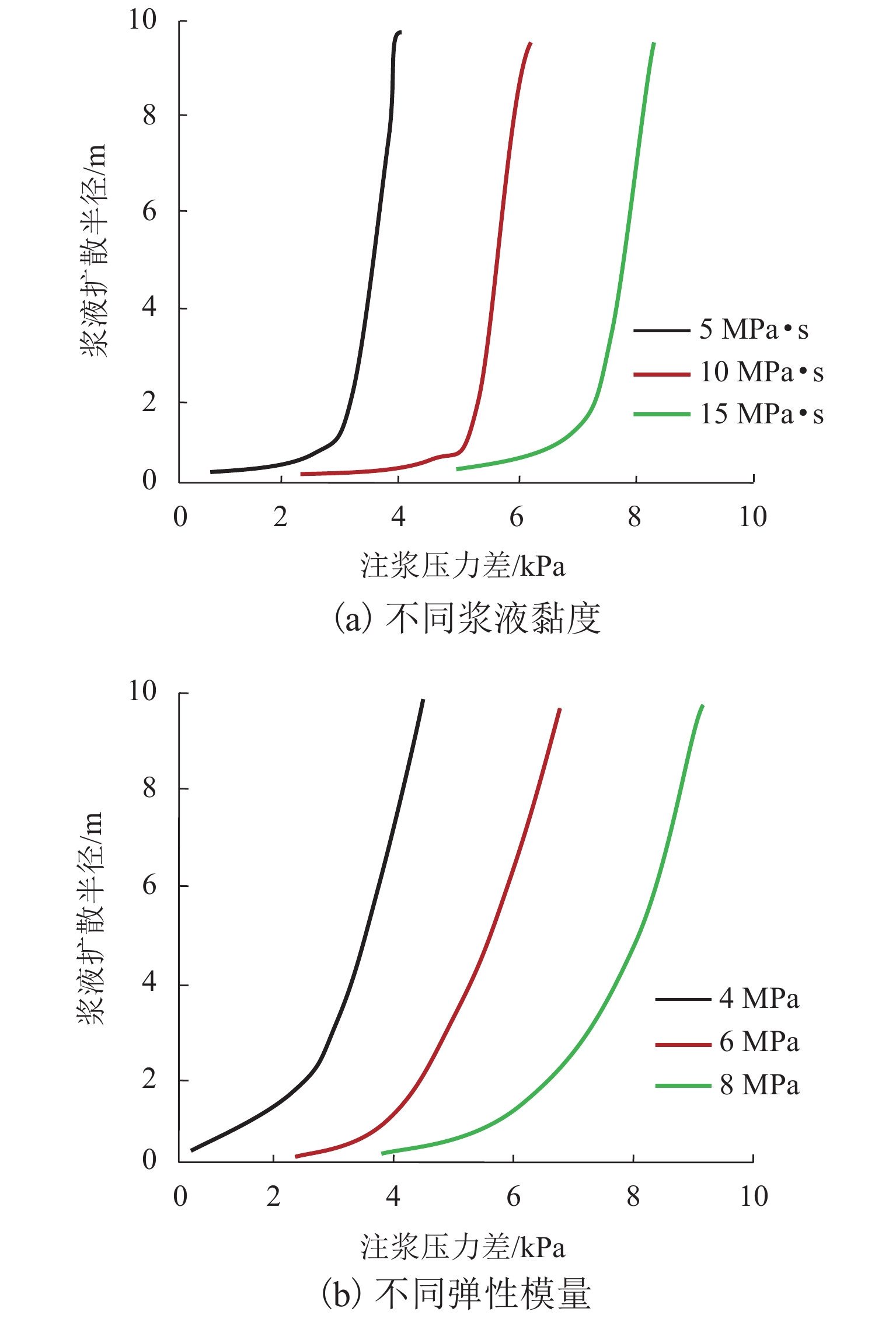

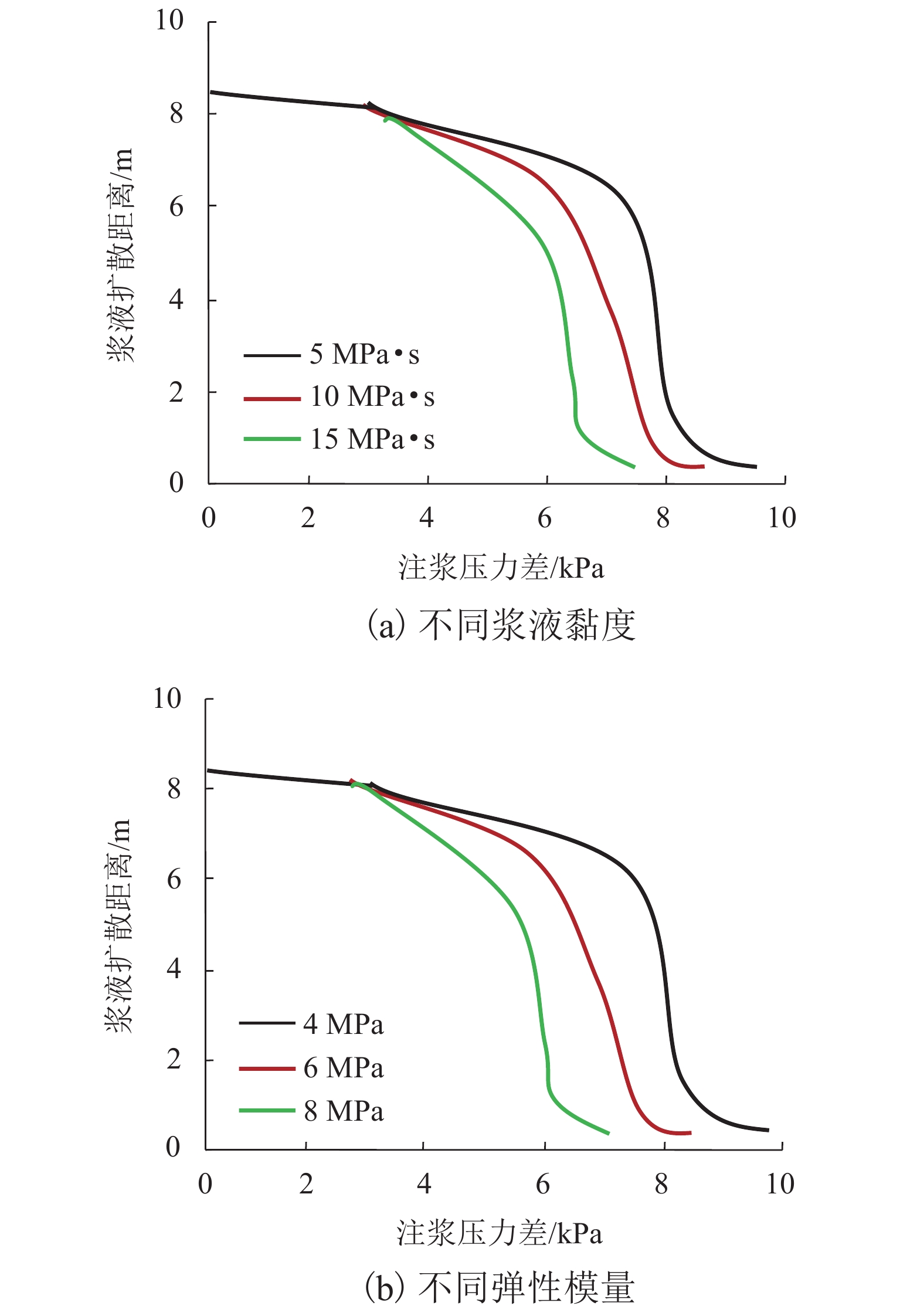

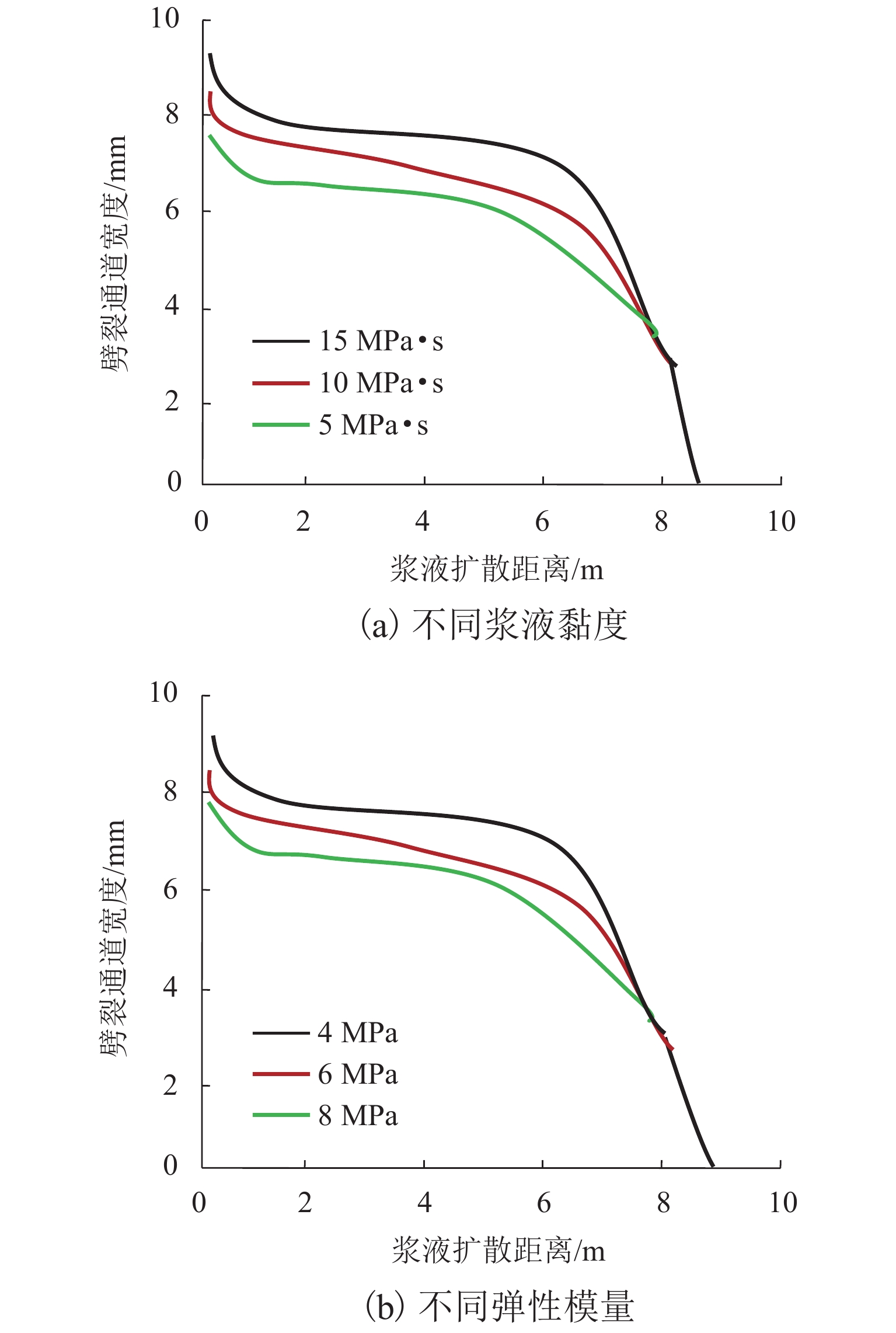

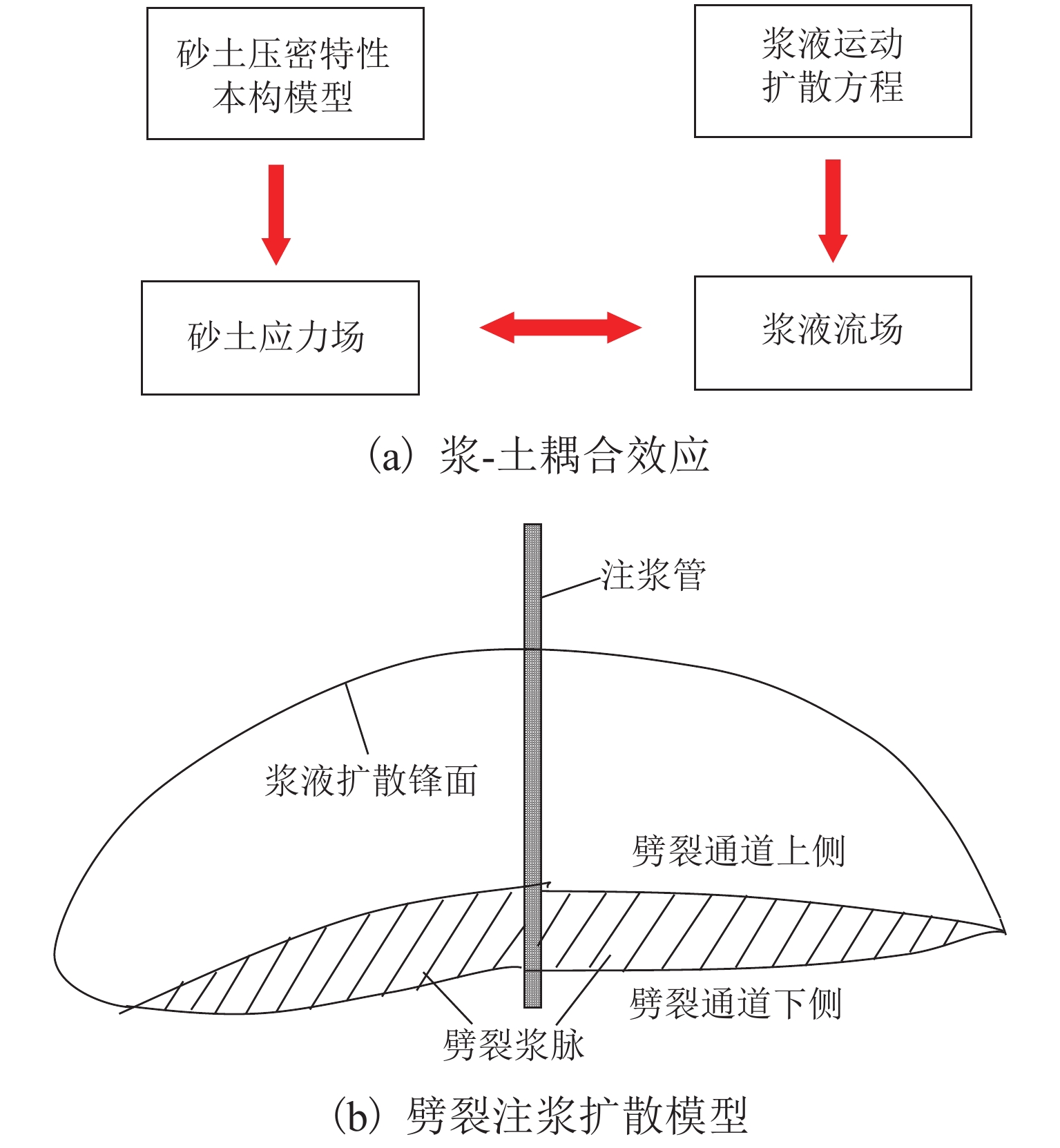

浆土应力耦合作用对劈裂注浆浆液扩散规律具有显著影响,砂土劈裂注浆设计应充分考虑这种影响作用. 将劈裂注浆视作平面无限域的圆形扩张过程,基于牛顿型本构方程分析了浆液流场变化特征,并将劈裂通道下侧砂层视作半无限空间弹性体,采用弹性力学推导了均布荷载下劈裂通道宽度、浆液压力的分布方程. 通过设置不同的浆液黏度、砂土弹性模量参数,深刻揭示了耦合效应下砂土劈裂注浆基本机理. 结合郑州地铁某在建工程进行了对比验证. 研究结果表明:浆液压力在孔口及远端处急速衰减,而在中间区段呈稳定变化趋势,劈裂通道宽度基本由浆液压力决定,其分布趋势与浆液压力分布趋势相同;浆液黏度、砂土弹性模量是影响劈裂扩散半径的重要因素,黏度和模量均与扩散半径正相关,黏度与劈裂宽度正相关,模量则与劈裂宽度负相关;本文理论计算值与现场开挖实际值偏差12%~15%,基本符合预期要求.

Abstract:The coupling effect of slurry and soil stress has a significant influence on the slurry diffusion law of split grouting, which should be fully considered in the design phase of split grouting. The split grouting is regarded as a circular expansion process in an infinite plane domain. Based on the Newtonian constitutive equation, variation characteristics of the slurry flow field are analyzed. The sand layer under the splitting channel is regarded as a semi-infinite elastic body. The distribution equations of the splitting channel width and the slurry pressure under the uniform load are derived by elastic mechanics. By setting different slurry viscosity and sand elastic modulus parameters, the basic mechanism of split grouting in sandy soil under coupling effect is revealed. The results show that the slurry pressure decreases rapidly at the orifice and the far end, but changes slowly in the middle section. The width of the splitting channel is basically determined by the slurry pressure, and has a distribution trend the same as that of the slurry pressure. The viscosity of slurry and the elastic modulus of sand are important factors affecting the splitting diffusion radius , and both are positively related to the diffusion radius. The slurry viscosity is positively related to the splitting width, while the modulus is negatively related to the splitting width. Finally, a comparison was made through a project under construction, and it was found that the deviation between the theoretical calculation value and the actual excavation value was 12%−15%, which basically met the expected requirements.

-

表 1 郑州地铁区间隧道砂土力学参数

Table 1. Mechanical parameters of sandy soil in Zhengzhou Metro Tunnel

参数 天然密度/(g·cm−3) 干密度/(g·cm−3) 弹性模量/MPa 泊松比 含水率/% 含泥量/% 注浆影响范围/m 取值 2.01 1.68 5.94 0.38 23.3 11.8 10 -

[1] DONGSOON P, JEHEON O. Permeation grouting for remediation of dam cores[J]. Engineering Geology, 2018, 233: 63-75. doi: 10.1016/j.enggeo.2017.12.011 [2] 张庆松,王洪波,刘人太,等. 考虑浆液扩散路径的多孔介质渗透注浆机理研究[J]. 岩土工程学报,2018,40(5): 918-924. doi: 10.11779/CJGE201805017ZHANG Qingsong, WANG Hongbo, LIU Rentai, et al. Infiltration grouting mechanism of porous media considering diffusion paths of grout[J]. Chinese Journal of Geotechnical Engineering, 2018, 40(5): 918-924. doi: 10.11779/CJGE201805017 [3] RASOULI R, HAYASHI K, ZEN K. Controlled permeation grouting method for mitigation of liquefaction[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2016, 142(11): 1-11. [4] 刘人太,郑卓,李术才,等. 地下工程裂隙型涌水超前注浆治理方法[J]. 西南交通大学学报,2019,54(1): 48-54.LIU Rentai, ZHENG Zhuo, LI Shucai, et al. Pre-excavation grouting to prevent water inflow of jointed rock in underground construction[J]. Journal of Southwest Jiaotong University, 2019, 54(1): 48-54. [5] 李召峰,李术才,刘人太,等. 富水破碎岩体注浆加固实验与机制研究[J]. 岩石力学与工程学报,2017,36(1): 198-207. doi: 10.13722/j.cnki.jrme.2016.0119LI Zhaofeng, LI Shucai, LIU Rentai, et al. Grouting reinforcement experiment for water-rich broken rock mass[J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(1): 198-207. doi: 10.13722/j.cnki.jrme.2016.0119 [6] 张庆松,张连震,张霄,等. 基于浆液黏度时空变化的水平裂隙岩体注浆扩散机制[J]. 岩石力学与工程学报,2015,34(6): 1198-1210. doi: 10.13722/j.cnki.jrme.2014.0958ZHANG Qingsong, ZHANG Lianzhen, ZHANG Xiao, et al. Grouting diffusion in a horizontal crack considering temporal and spatial variation of viscosity[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(6): 1198-1210. doi: 10.13722/j.cnki.jrme.2014.0958 [7] 叶飞,秦楠,梁兴,等. 基于驱替效应的盾构壁后注浆微观模型分析[J]. 西南交通大学学报,2022,57(2): 339-345. doi: 10.3969/j.issn.0258-2724.20200344YE Fei, QIN Nan, LIANG Xing, et al. Microscopic model analysis of shield tunnel backfill grouting based on displacement effect[J]. Journal of Southwest Jiaotong University, 2022, 57(2): 339-345. doi: 10.3969/j.issn.0258-2724.20200344 [8] 张连震,李志鹏,张庆松,等. 基于土体非线性压密效应的劈裂注浆机制分析[J]. 岩石力学与工程学报,2016,35(7): 1483-1493. doi: 10.13722/j.cnki.jrme.2015.0565ZHANG Lianzhen, LI Zhipeng, ZHANG Qingsong, et al. Split grouting mechanism based on nonlinear characteristics of compression process of soil[J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(7): 1483-1493. doi: 10.13722/j.cnki.jrme.2015.0565 [9] 张庆松,张连震,刘人太,等. 基于“浆-土”界面应力耦合效应的劈裂注浆理论研究[J]. 岩土工程学报,2016,38(2): 323-330.ZHANG Qingsong, ZHANG Lianzhen, LIU Rentai, et al. Split grouting theory based on slurry-soil coupling effects[J]. Chinese Journal of Geotechnical Engineering, 2016, 38(2): 323-330. [10] 秦鹏飞. 不良地质体注浆细观力学模拟研究[J]. 煤炭学报,2020,45(7): 2646-2654. doi: 10.13225/j.cnki.jccs.2019.0634QIN Pengfei. Study on meso-mechanical simulation of grouting in bad geo-body[J]. Journal of China Coal Society, 2020, 45(7): 2646-2654. doi: 10.13225/j.cnki.jccs.2019.0634 [11] 申时钊,涂小兵,雷进生,等. 不同渗透系数的非均质黏土劈裂注浆数值模拟[J]. 水利水运工程学报,2022(5): 102-112.SHEN Shizhao, TU Xiaobing, LEI Jinsheng, et al. Numerical simulation of split grouting of heterogeneous clay with different permeability coefficient[J]. Hydro-Science and Engineering, 2022(5): 102-112. [12] 刘海明,卢昊正,南敢,等. 基于黏度时变性的Herschel-Bulkley流体劈裂注浆扩散特性研究[J]. 自然灾害学报,2022,31(3): 213-221.LIU Haiming, LU Haozheng, NAN Gan, et al. Research on diffusion characteristics of Herschel-Bulkley fluid fracture grouting based on time variation of viscosity[J]. Journal of Natural Disasters, 2022, 31(3): 213-221. [13] 周茗如,张建斌,卢国文,等. 扩孔理论在非饱和黄土劈裂注浆中的应用[J]. 建筑结构学报,2018,39(增1): 368-378. doi: 10.14006/j.jzjgxb.2018.S1.048ZHOU Mingru, ZHANG Jianbin, LU Guowen, et al. Application of expansion hole theory in fracture grouting of unsaturated loess[J]. Journal of Building Structures, 2018, 39(S1): 368-378. doi: 10.14006/j.jzjgxb.2018.S1.048 [14] 蔡德国,叶飞,曹凯,等. 砂性地层盾构隧道壁后注浆浆液扩散室内试验[J]. 中国公路学报,2018,31(10): 274-283.CAI Deguo, YE Fei, CAO Kai, et al. Test of grout diffusion of shield tunnel backfill grouting in sandy strata[J]. China Journal of Highway and Transport, 2018, 31(10): 274-283. [15] WANG S Y, CHAN D H, LAM K C, et al. A new laboratory apparatus for studying dynamic compaction grouting into granular soils[J]. Soils and Foundations, 2013, 53(3): 462-468. doi: 10.1016/j.sandf.2013.04.007 [16] 付艳斌,陈湘生,吕桂阳,等. 基于小孔扩张弹塑性理论的注浆起始劈裂压力研究[J]. 中国公路学报,2020,33(12): 154-163. doi: 10.3969/j.issn.1001-7372.2020.12.012FU Yanbin, CHEN Xiangsheng, LYU Guiyang, et al. Study on initial fracture pressure of grouting based on the elastic-plastic theory of cavity expansion[J]. China Journal of Highway and Transport, 2020, 33(12): 154-163. doi: 10.3969/j.issn.1001-7372.2020.12.012 [17] 徐芝纶. 弹性力学(上册)[M]. 4版. 北京: 高等教育出版社, 2006. [18] 姚茂宏,谢长岭,程少振,等. 双孔劈裂条件下地应力及孔间应力的耦合分析[J]. 北京交通大学学报,2021,45(3): 61-68. doi: 10.11860/j.issn.1673-0291.20200140YAO Maohong, XIE Changling, CHENG Shaozhen, et al. Coupling analysis of in-situ stress and inter hole stress under double-hole splitting[J]. Journal of Beijing Jiaotong University, 2021, 45(3): 61-68. doi: 10.11860/j.issn.1673-0291.20200140 [19] PANTAZOPOULOS I A, MARKOU I N, CHRISTODOULOU D N, et al. Development of microfine cement grouts by pulverizing ordinary cements[J]. Cement and Concrete Composites, 2012, 34(5): 593-603. doi: 10.1016/j.cemconcomp.2012.01.009 [20] KANG S P, KWON S J. Effects of red mud and Alkali-activated slag cement on efflorescence in cement mortar[J]. Construction and Building Materials, 2017, 133: 459-467. [21] PEPPER R A, COUPERTHWAITE S J, MILLAR G J. Comprehensive examination of acid leaching behaviour of mineral phases from red mud: recovery of Fe, Al, Ti, and Si[J]. Minerals Engineering, 2016, 99: 8-18. doi: 10.1016/j.mineng.2016.09.012 [22] 张淼,邹金锋,陈嘉祺,等. 非对称荷载作用下土体劈裂注浆压力分析[J]. 岩土力学,2013,34(8): 2255-2263.ZHANG Miao, ZOU Jinfeng, CHEN Jiaqi, et al. Analysis of soil fracturing grouting pressure under asymmetric loads[J]. Rock and Soil Mechanics, 2013, 34(8): 2255-2263. [23] 邹金锋,童无欺,罗恒,等. 基于Hoek-Brown强度准则的裂隙岩体劈裂注浆力学机理[J]. 中南大学学报(自然科学版),2013,44(7): 2889-2896.ZOU Jinfeng, TONG Wuqi, LUO Heng, et al. Mechanism of fracture grouting for fractured rock based on Hoek-Brown failure criterion[J]. Journal of Central South University (Science and Technology), 2013, 44(7): 2889-2896. [24] 黄明利,管晓明,吕奇峰. 基于弹性力学的诱导劈裂注浆机制分析[J]. 岩土力学,2013,34(7): 2059-2064.HUANG Mingli, GUAN Xiaoming, LÜ Qifeng. Mechanism analysis of induced fracture grouting based on elasticity[J]. Rock and Soil Mechanics, 2013, 34(7): 2059-2064. [25] 张连震,张庆松,刘人太,等. 基于浆液-岩体耦合效应的微裂隙岩体注浆理论研究[J]. 岩土工程学报,2018,40(11): 2003-2011.ZHANG Lianzhen, ZHANG Qingsong, LIU Rentai, et al. Grouting mechanism in fractured rock considering slurry-rock stress coupling effects[J]. Chinese Journal of Geotechnical Engineering, 2018, 40(11): 2003-2011. [26] 邹金锋,李亮,杨小礼. 劈裂注浆扩散半径及压力衰减分析[J]. 水利学报,2006,37(3): 314-319. doi: 10.3321/j.issn:0559-9350.2006.03.010ZOU Jinfeng, LI Liang, YANG Xiaoli. Penetration radius and pressure attenuation law in fracturing grouting[J]. Journal of Hydraulic Engineering, 2006, 37(3): 314-319. doi: 10.3321/j.issn:0559-9350.2006.03.010 [27] 张忠苗,邹健. 桩底劈裂注浆扩散半径和注浆压力研究[J]. 岩土工程学报,2008,30(2): 181-184.ZHANG Zhongmiao, ZOU Jian. Penetration radius and grouting pressure in fracture grouting[J]. Chinese Journal of Geotechnical Engineering, 2008, 30(2): 181-184. [28] ZHOU H, LIU H L, ZHA Y H, et al. Influence of stress anisotropy on the cylindrical cavity expansion in undrained elastic-perfectly plastic soil[J]. Science China Technological Sciences, 2018, 61(3): 370-380. doi: 10.1007/s11431-017-9127-7 -

下载:

下载: