Effect of Measured Wheel-Rail Creep Curves on Rail Wear

-

摘要:

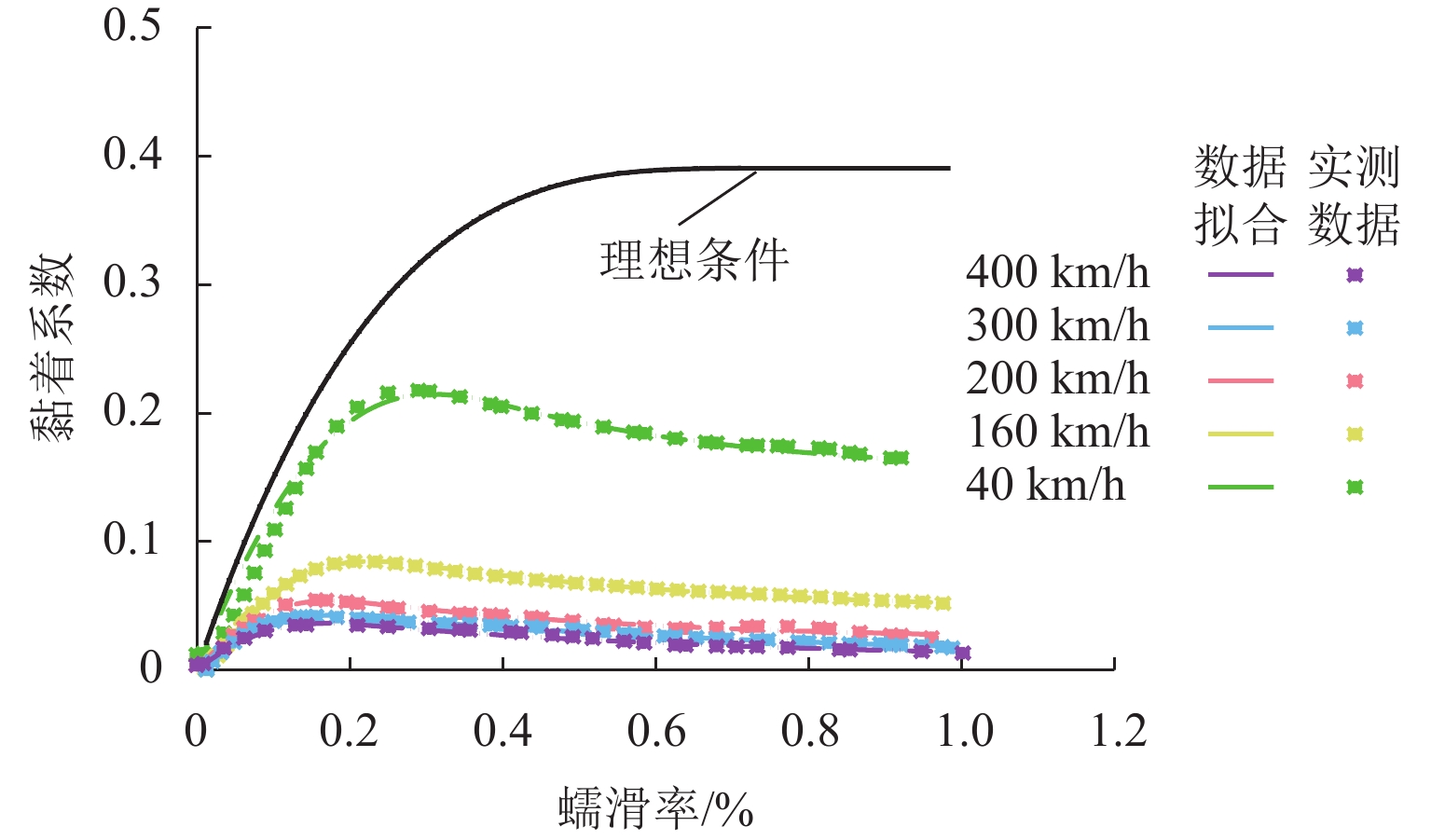

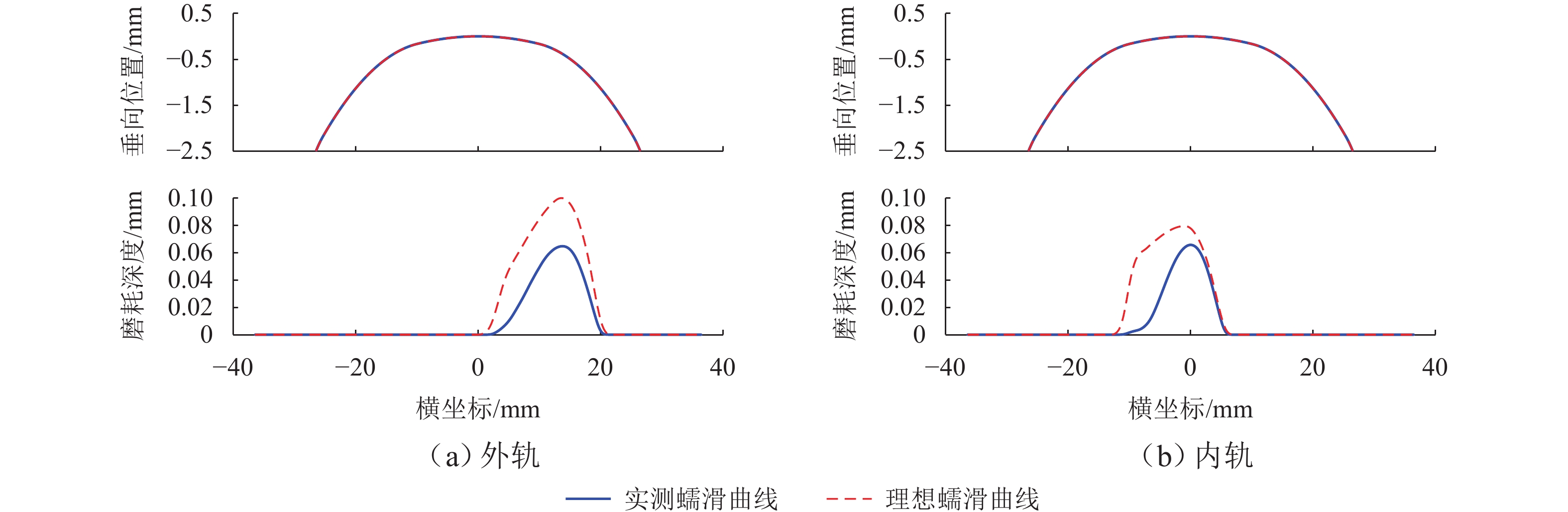

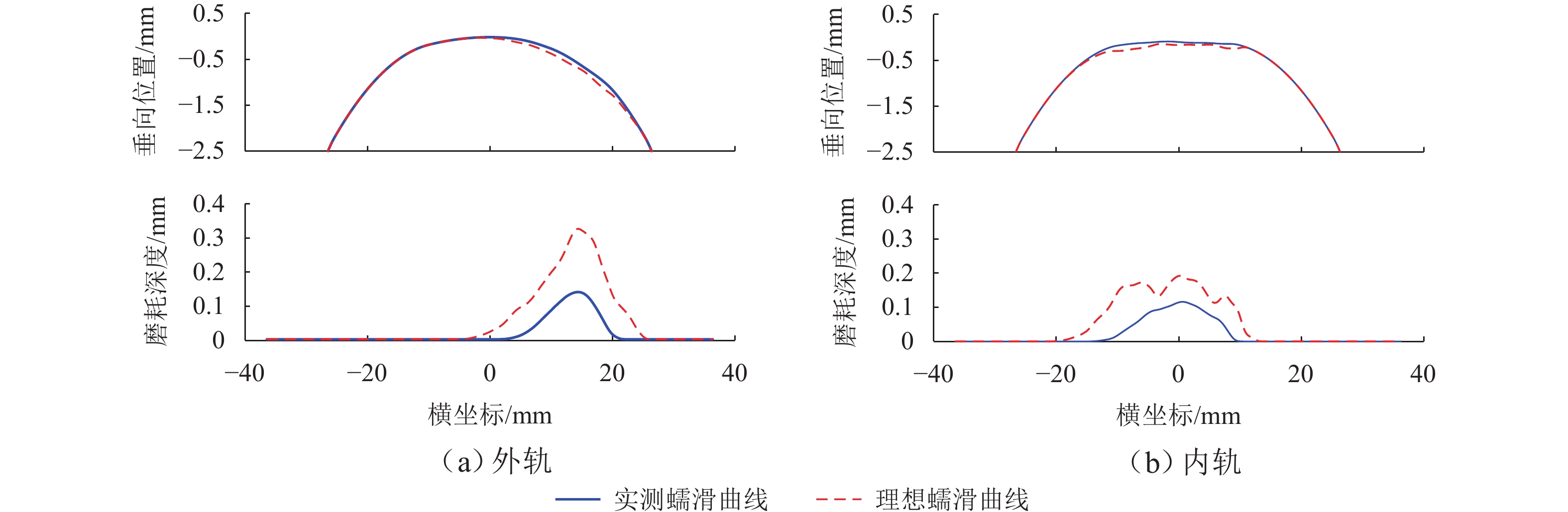

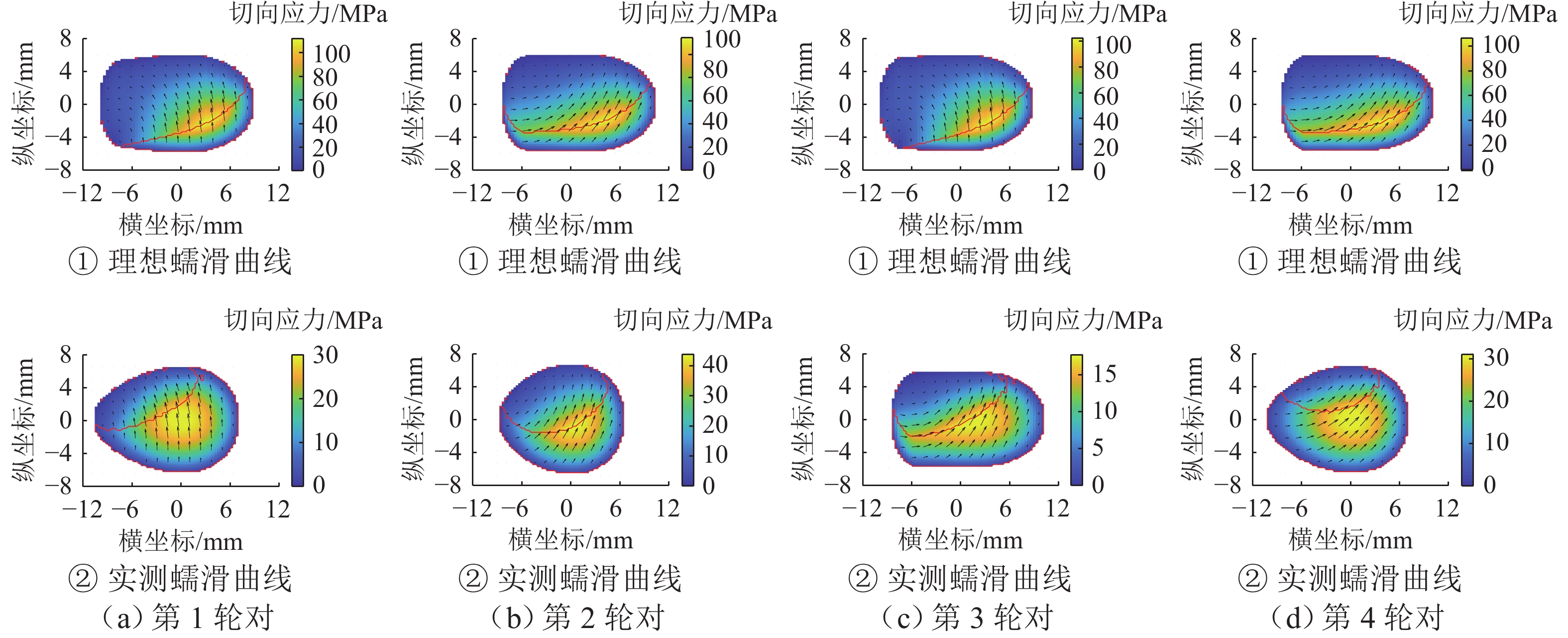

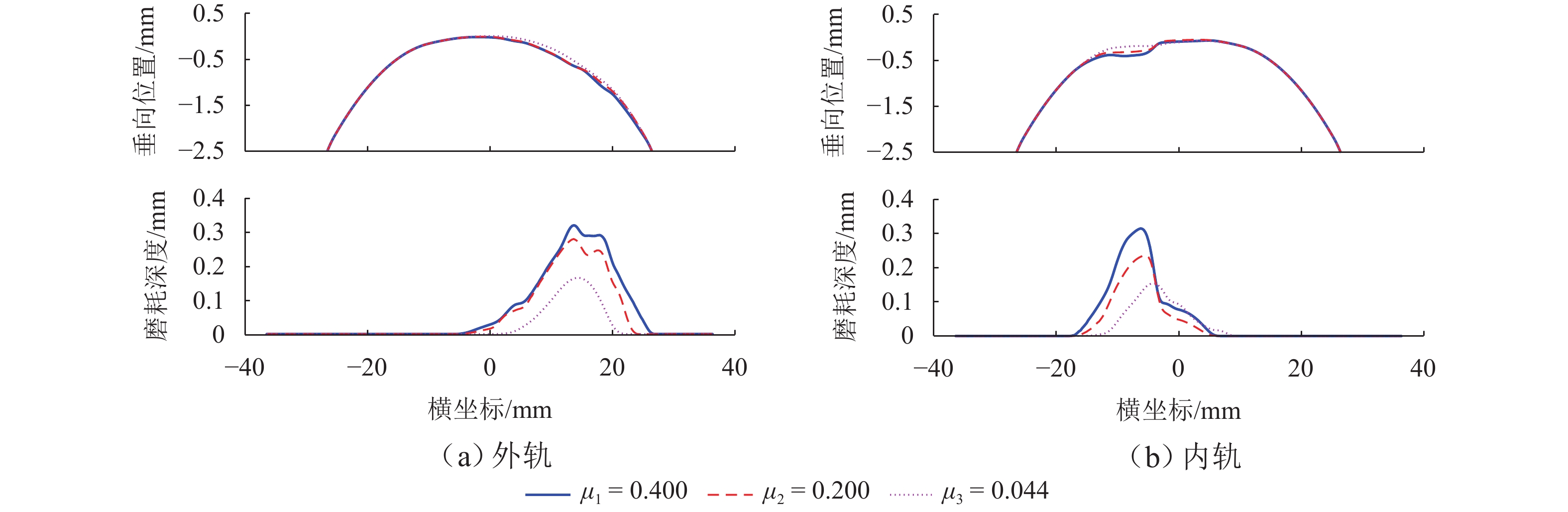

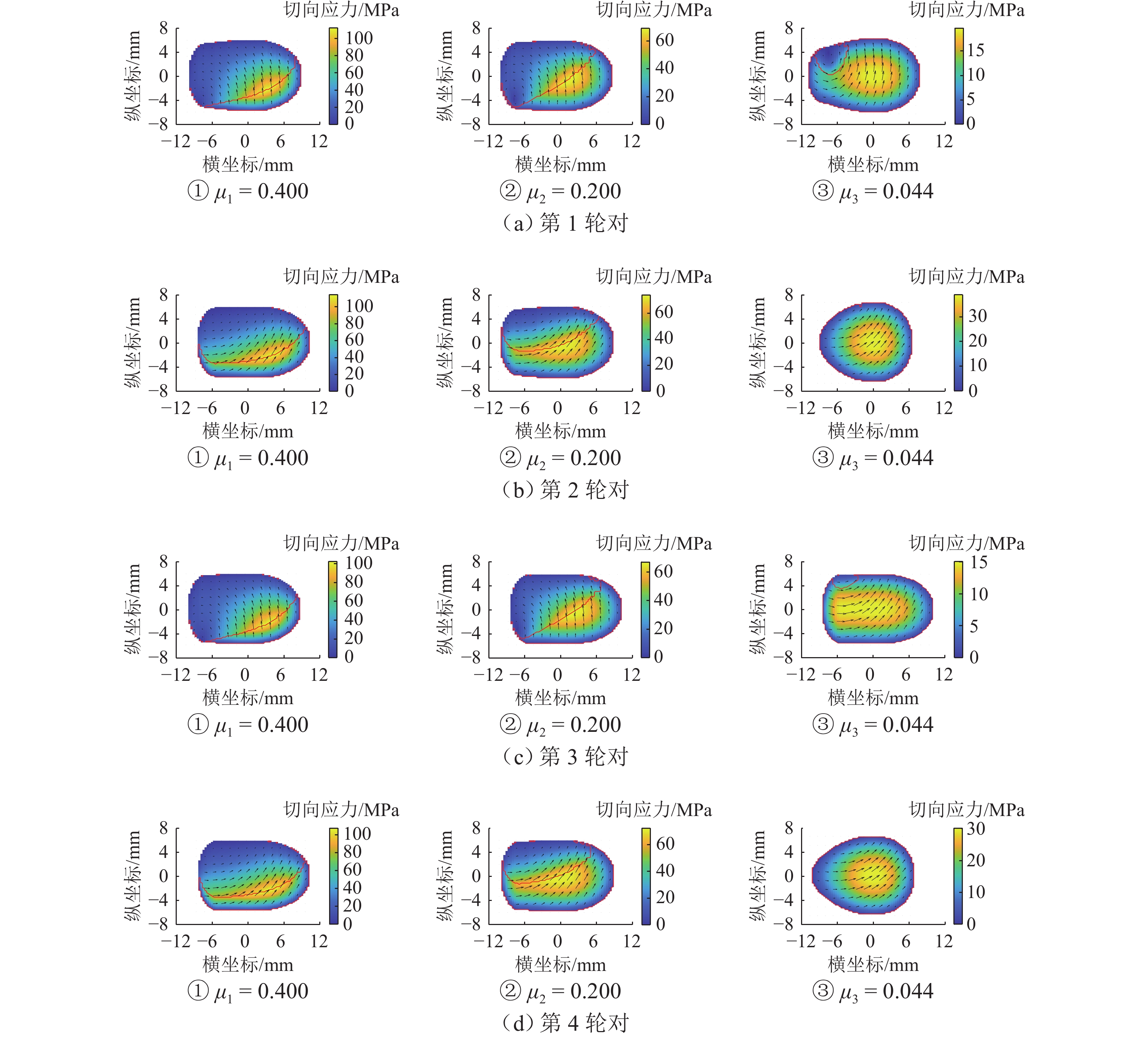

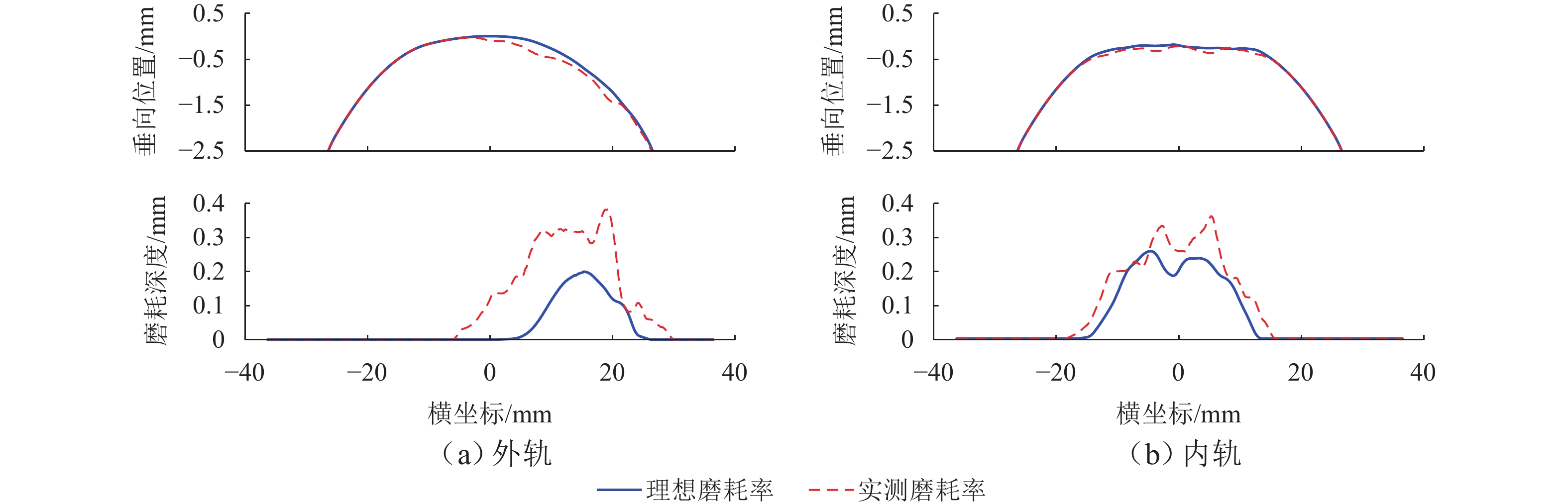

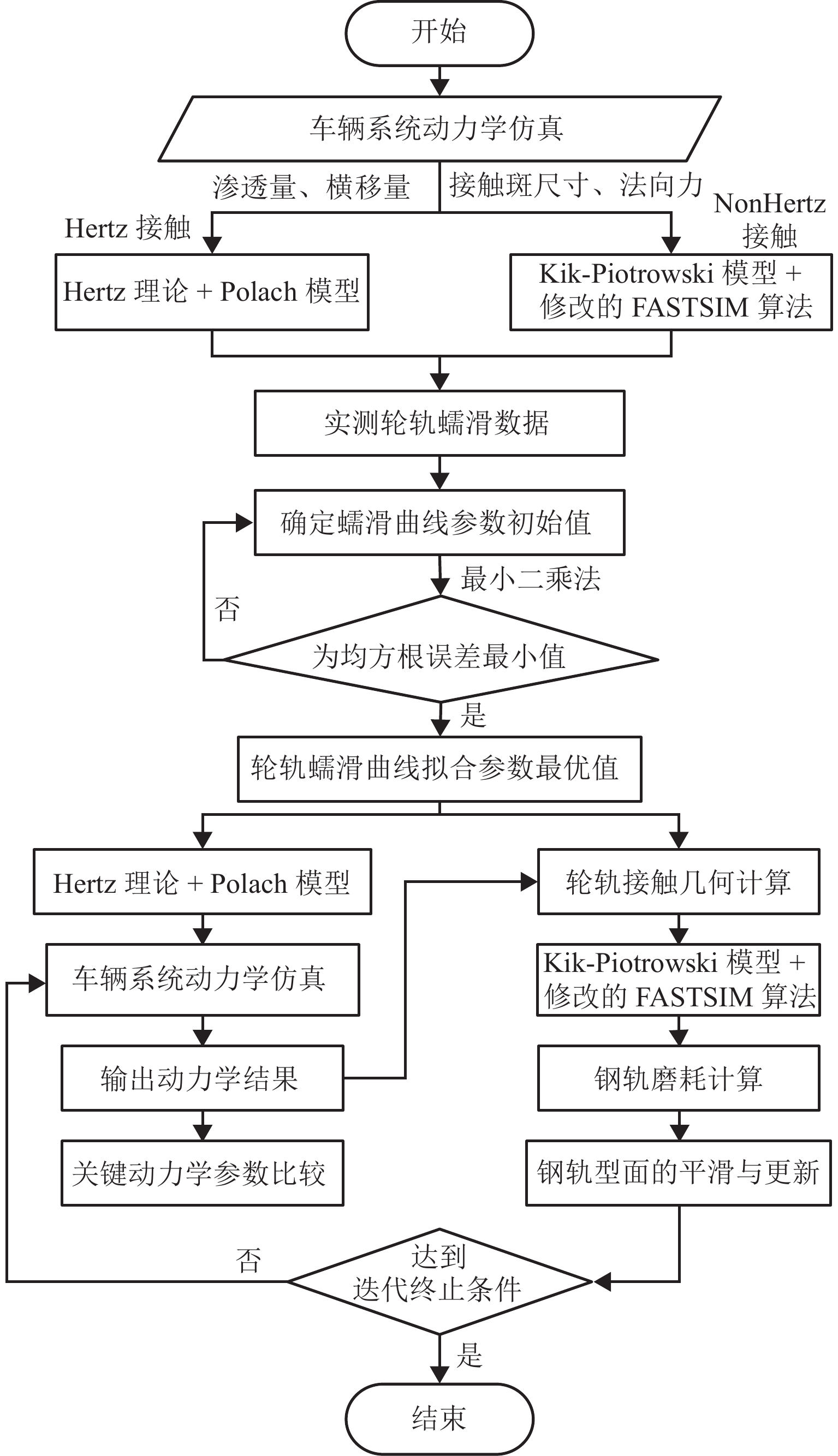

轮轨蠕滑曲线会影响轮轨动态相互作用,进而影响钢轨磨耗,为研究实测轮轨蠕滑曲线对钢轨磨耗的影响,首先,基于最小二乘法获得适用于Polach模型和修改FASTSIM算法的参数,模拟40~400 km/h行车速度范围内的实测蠕滑曲线;随后,在SIMPACK软件中建立车辆系统动力学模型,并通过Polach模型测得实测蠕滑曲线;最后,采用Kik-Piotrowski模型和修改的FASTSIM算法进行轮轨非赫兹滚动接触计算,并结合USFD磨耗模型预测钢轨磨耗,对比了理想与实测蠕滑曲线条件下钢轨磨耗的差异. 研究表明:理想蠕滑曲线条件下钢轨磨耗深度明显大于实测蠕滑曲线下的结果,随着车辆通过次数的增加,理想条件下钢轨磨耗分布范围更大,内外轨磨耗分布范围分别为实测蠕滑曲线的1.5倍和1.3倍;摩擦系数和磨耗率显著影响钢轨磨耗大小及磨耗分布情况,故在车辆动力学仿真和钢轨磨耗计算中有必要考虑实测轮轨蠕滑曲线;形成了确定实测蠕滑曲线参数的前处理程序,可服务于车辆动力学仿真和钢轨磨耗计算,可以有效指导现场进行钢轨打磨等养护维修工作.

Abstract:The wheel-rail creep curve influences dynamic wheel-rail interaction, which further affects rail wear. To study the effect of the measured wheel-rail creep curve on rail wear, parameters suitable for the Polach model and modified FASTSIM algorithm were obtained based on the least square method, and measured creep curves at the running speed of 40–400 km/h of the vehicle were simulated. After that, the vehicle system dynamics model was established in the SIMPACK, and measured creep curves were considered through the Polach model. Finally, the Kik-Piotrowski model and modified FASTSIM algorithm were used to calculate the non-Hertzian rolling contact, and rail wear was predicted by the USFD model. The discrepancies of rail wear under ideal and measured creep curves were compared. The research shows that the rail wear depth under the ideal creep curve is more obvious than that under the measured creep curve. As more vehicles pass the rail, the rail wear distribution range under ideal conditions is larger, and the distribution ranges of inner and outer rail are respectively 1.5 and 1.3 times those under the measured creep curve; the friction coefficient and wear rate significantly influence the magnitude and distribution range of rail wear, so it is necessary to consider the measured wheel-rail creep curve in vehicle dynamics simulation and rail wear calculation. A pre-processing program is developed to determine parameters of the measured creep curve, which can serve for vehicle dynamics simulation and rail wear calculation and effectively guide maintenance work such as rail grinding.

-

Key words:

- creep curve /

- numerical simulation /

- vehicle system dynamics model /

- rail wear /

- contact patch

-

表 1 修改的FASTSIM算法参数

Table 1. Modified FASTSIM algorithm parameters

速度 V/(km·h−1) k0 μ0 A B 40 0.85 0.340 0.46 27.00 160 0.47 0.120 0.38 5.15 200 0.39 0.075 0.31 4.40 300 0.32 0.056 0.16 1.90 400 0.27 0.050 0.16 1.70 表 2 Polach模型参数表

Table 2. Polach model parameters

V/(km·h−1) kA kS μ0 A B 40 0.80 0.44 0.74 0.23 40.0 160 0.50 0.14 0.32 0.16 7.8 200 0.47 0.13 0.19 0.14 7.6 300 0.37 0.11 0.13 0.12 4.0 400 0.24 0.10 0.10 0.08 2.5 -

[1] 王文健, 刘启跃. 轮轨黏着行为与增黏[M]. 北京: 科学出版社, 2017. [2] 安博洋,王平,徐义新,等. 基于POLACH方法的轮轨蠕滑曲线研究[J]. 机械工程学报,2018,54(4): 124-131. doi: 10.3901/JME.2018.04.124AN Boyang, WANG Ping, XU Yixin, et al. Study on wheel/rail creep curve based on POLACH’s method[J]. Journal of Mechanical Engineering, 2018, 54(4): 124-131. doi: 10.3901/JME.2018.04.124 [3] KALKER J J. A fast algorithm for the simplified theory of rolling contact[J]. Vehicle System Dynamics, 1982, 11(1): 1-13. doi: 10.1080/00423118208968684 [4] SHEN Z Y, HEDRICK J K, ELKINS J A. A comparison of alternative creep force models for rail vehicle dynamic analysis[J]. Vehicle System Dynamics, 1983, 12(1/2/3): 79-83. [5] POLACH O. A fast wheel-rail forces calculation computer code[J]. Vehicle System Dynamics, 1999, 33(S1): 728-739. doi: 10.1080/00423114.1999.12063125 [6] POLACH O. Creep forces in simulations of traction vehicles running on adhesion limit[J]. Wear, 2005, 258(7/8): 992-1000. [7] SPIRYAGIN M, POLACH O, COLE C. Creep force modelling for rail traction vehicles based on the Fastsim algorithm[J]. Vehicle System Dynamics, 2013, 51(11): 1765-1783. doi: 10.1080/00423114.2013.826370 [8] VOLLEBREGT E A H. Numerical modeling of measured railway creep versus creep-force curves with CONTACT[J]. Wear, 2014, 314(1/2): 87-95. [9] 王璞,高亮,蔡小培. 重载铁路钢轨磨耗演变过程的数值模拟[J]. 铁道学报,2014,36(10): 70-75. doi: 10.3969/j.issn.1001-8360.2014.10.012WANG Pu, GAO Liang, CAI Xiaopei. Numerical simulation of rail wear evolution of heavy-hual railways[J]. Journal of the China Railway Society, 2014, 36(10): 70-75. doi: 10.3969/j.issn.1001-8360.2014.10.012 [10] WANG P, GAO L. Numerical simulation of wheel wear evolution for heavy haul railway[J]. Journal of Central South University, 2015, 22(1): 196-207. doi: 10.1007/s11771-015-2510-1 [11] 姜涵文,高亮,安博伦,等. 基于神经网络的钢轨磨耗与通过总重关联关系的预测方法[J]. 铁道学报,2021,43(10): 75-83.JIANG Hanwen, GAO Liang, AN Bolun, et al. A neural network-based prediction approach of relationship between rail wear and gross traffic tonnage[J]. Journal of the China Railway Society, 2021, 43(10): 75-83. [12] 杨新文,刘小山,沈剑罡,等. 现代有轨电车线路轨底坡对槽型轨磨耗的影响[J]. 同济大学学报(自然科学版),2019,47(4): 528-534.YANG Xinwen, LIU Xiaoshan, SHEN Jiangang, et al. Effect of rail cant on groove-shaped rail wear in modern tram line[J]. Journal of Tongji University (Natural Science), 2019, 47(4): 528-534. [13] 李浩,孙加林,赵国堂. 动车所小半径曲线钢轨磨耗研究[J]. 中国铁道科学,2020,41(6): 39-51.LI Hao, SUN Jialin, ZHAO Guotang. Research on rail wear of small radius curve in EMU depot[J]. China Railway Science, 2020, 41(6): 39-51. [14] TAO G Q, DU X, ZHANG H J, et al. Development and validation of a model for predicting wheel wear in high-speed trains[J]. Journal of Zhejiang University: Science A, 2017, 18(8): 603-616. doi: 10.1631/jzus.A1600693 [15] TAO G Q, WEN Z F, GUAN Q H, et al. Locomotive wheel wear simulation in complex environment of wheel-rail interface[J]. Wear, 2019, 430/431: 214-221. doi: 10.1016/j.wear.2019.05.012 [16] TRAN M T, ANG K K, LUONG V H, et al. High-speed trains subject to abrupt braking[J]. Vehicle System Dynamics, 2016, 54(12): 1715-1735. doi: 10.1080/00423114.2016.1232837 [17] HERTZ H. Ueber die Berührung fester elastischer Körper[M]//JournaL Für Die Reine Und Angewandte Mathematik Band 92. [S.l.]: De Gruyter, 1882: 156-171. [18] PIOTROWSKI J, KIK W. A simplified model of wheel/rail contact mechanics for non-Hertzian problems and its application in rail vehicle dynamic simulations[J]. Vehicle System Dynamics, 2008, 46(1/2): 27-48. [19] 常崇义,陈波,蔡园武,等. 基于全尺寸试验台的水介质条件下高速轮轨黏着特性试验研究[J]. 中国铁道科学,2019,40(2): 25-32. doi: 10.3969/j.issn.1001-4632.2019.02.04CHANG Chongyi, CHEN Bo, CAI Yuanwu, et al. Experimental study on adhesion property of high speed wheel and rail in wet condition by full scale roller rig[J]. China Railway Science, 2019, 40(2): 25-32. doi: 10.3969/j.issn.1001-4632.2019.02.04 [20] BRAGHIN F, LEWIS R, DWYER-JOYCE R S, et al. A mathematical model to predict railway wheel profile evolution due to wear[J]. Wear, 2006, 261(11/12): 1253-1264. [21] WANG W J, LEWIS R, YANG B, et al. Wear and damage transitions of wheel and rail materials under various contact conditions[J]. Wear, 2016, 362/363: 146-152. doi: 10.1016/j.wear.2016.05.021 -

下载:

下载: