Characteristics and Calculation Method of Impact Load in Rockburst Tunnel

-

摘要:

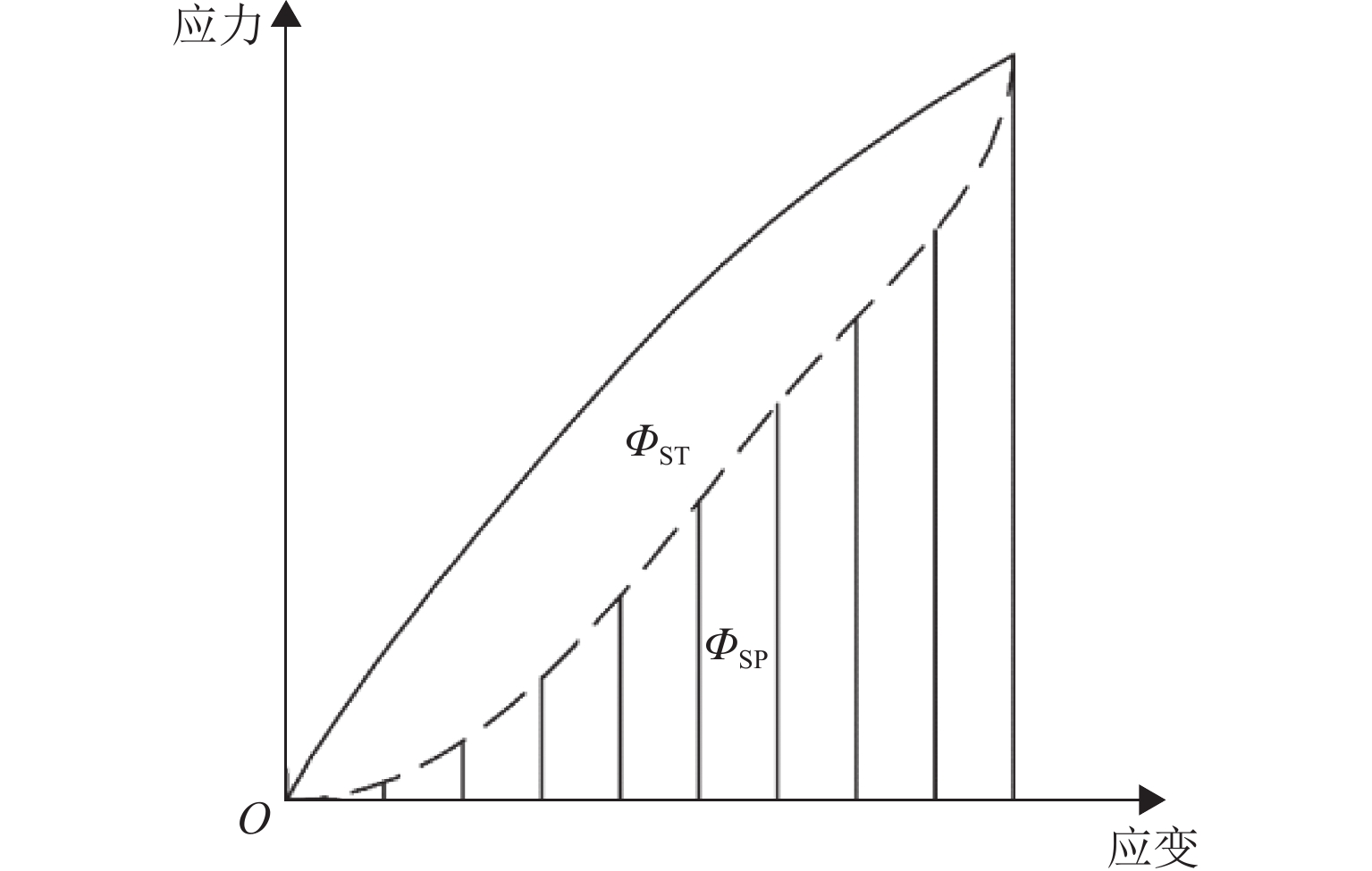

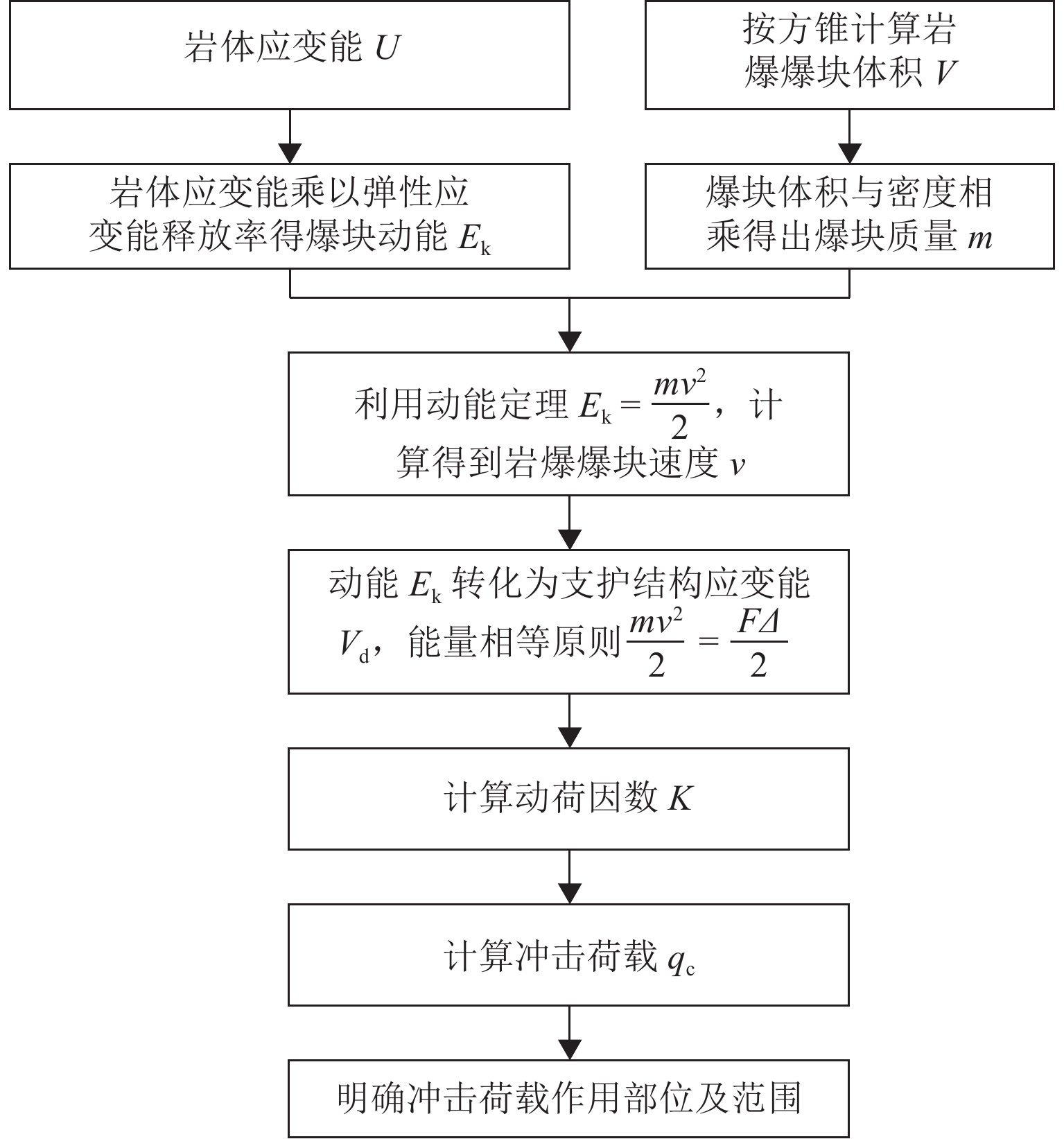

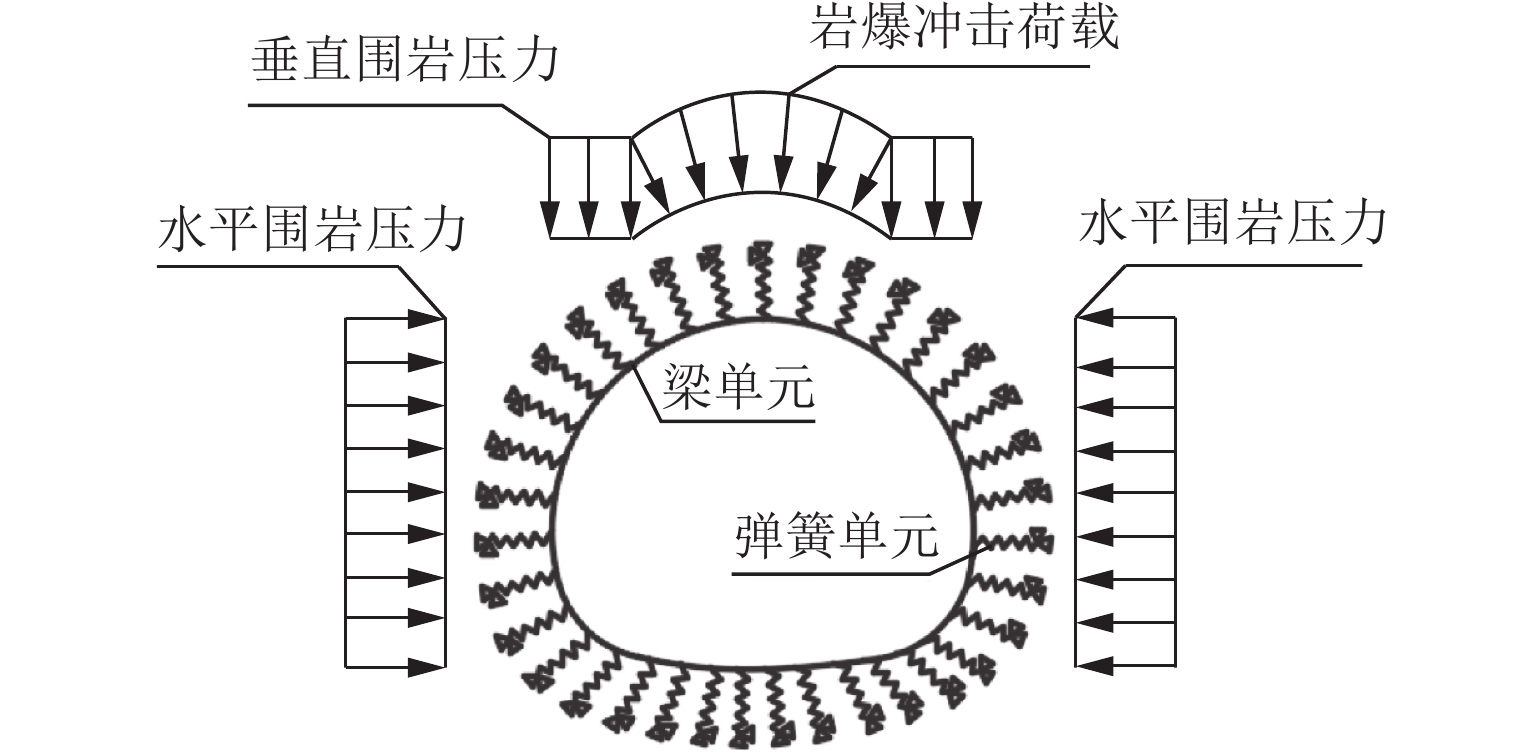

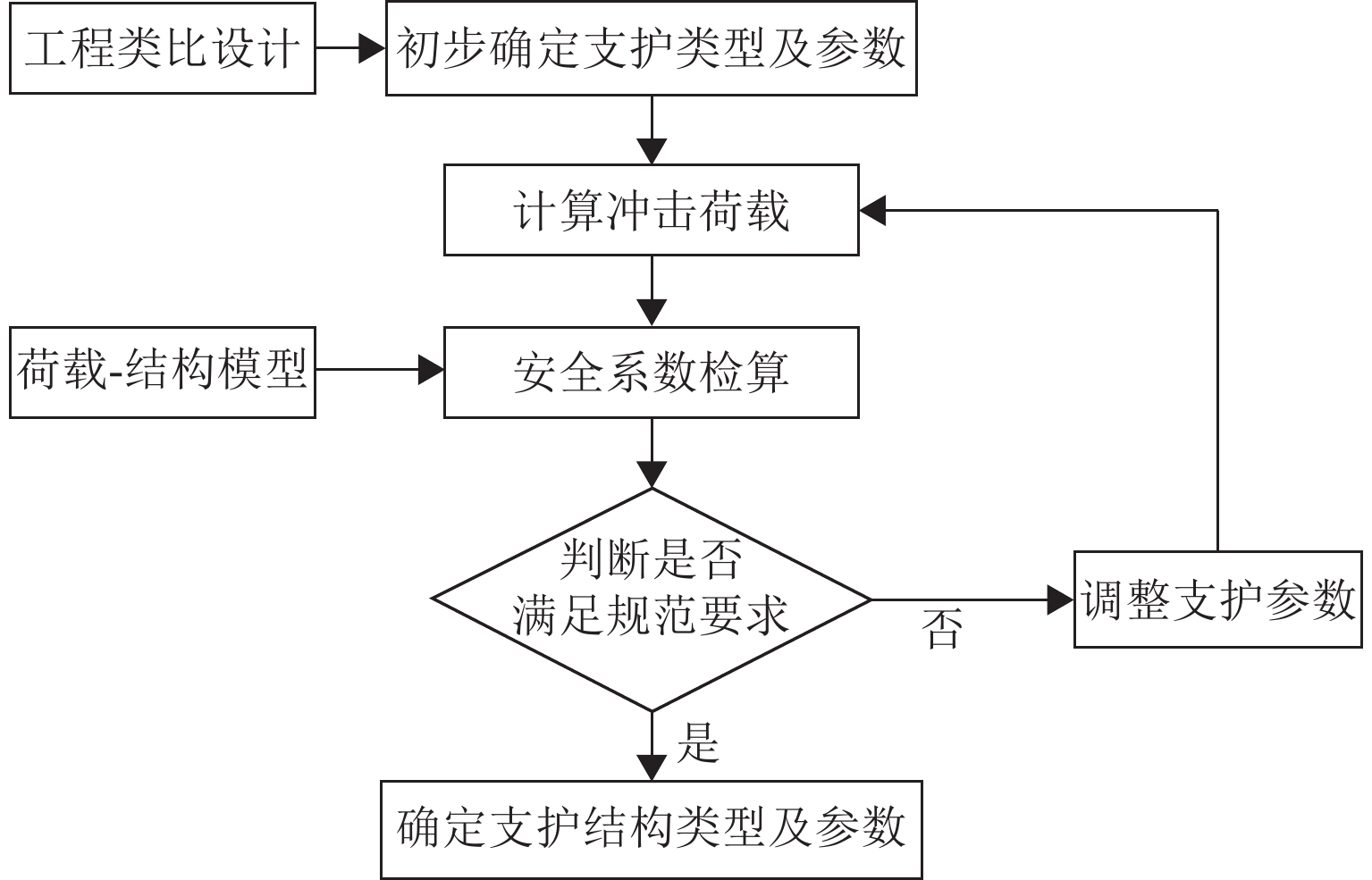

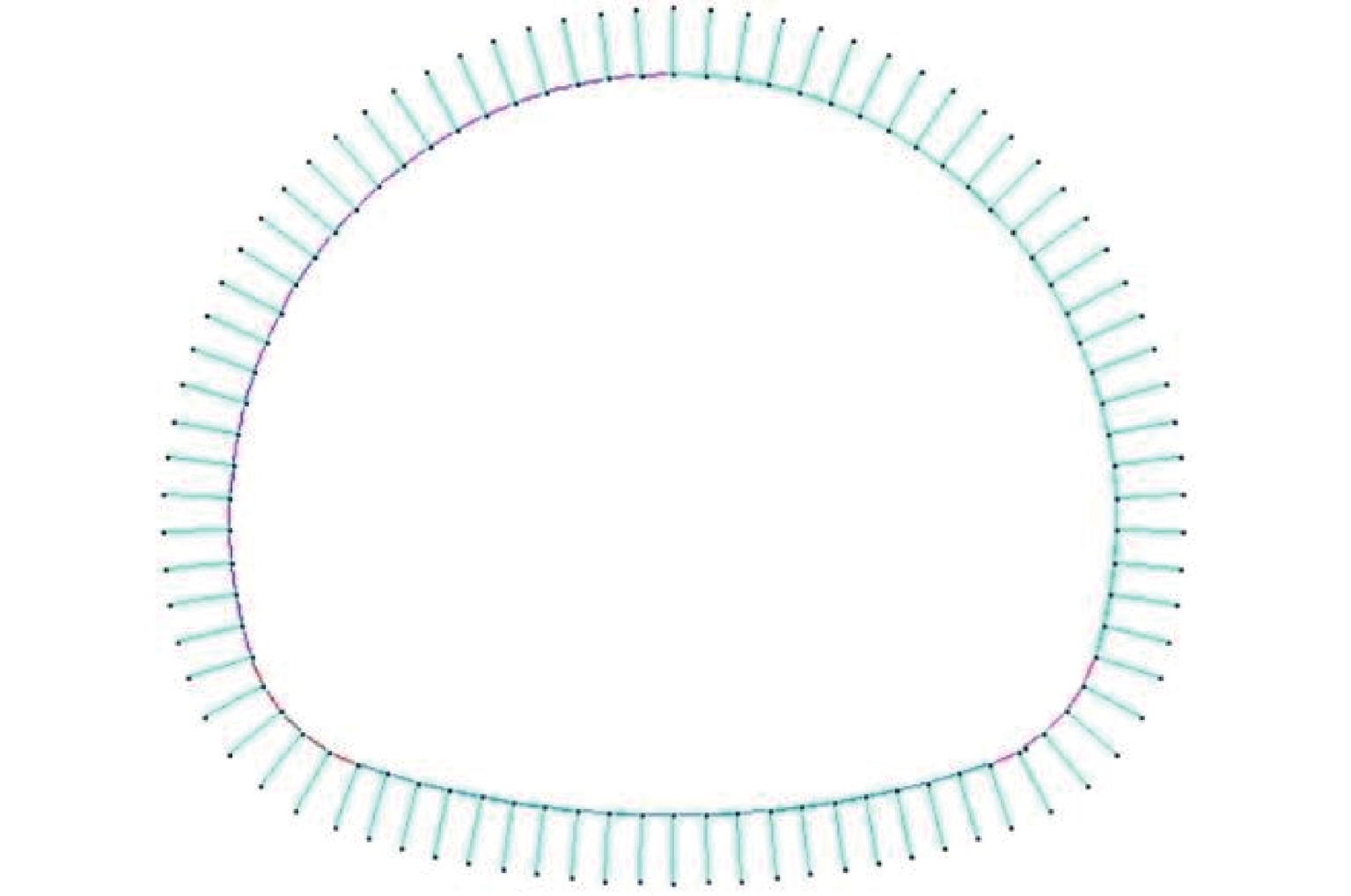

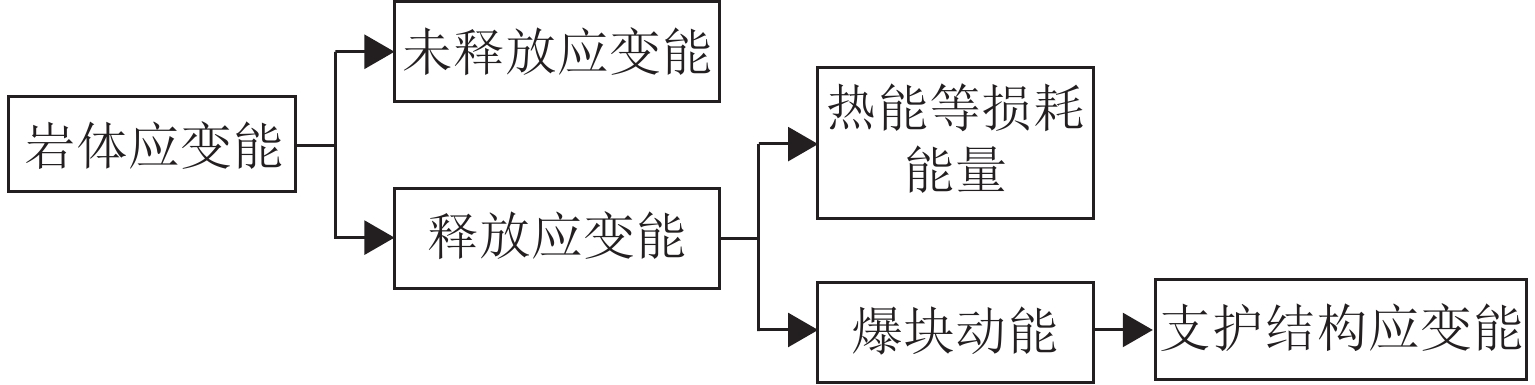

隧道中的硬脆围岩在高地应力情况下易发生岩爆,而目前国内针对岩爆隧道的支护结构设计主要采用工程类比法. 为了量化作用在支护结构上的岩爆冲击荷载,从能量角度分析岩爆过程中的能量转化关系,利用动能定理及能量守恒原理计算冲击荷载,并结合隧道松散压力提出隧道发生岩爆时的荷载计算方法,同时探明洞径等不同因素对岩爆作用范围的影响规律;结合某高地应力隧道岩爆段对其合理性进行验证. 研究结果表明:岩爆冲击荷载计算公式中,动荷因数与隧道支护所采用结构刚度正相关;在相同跨度与地应力条件下,圆形隧道的岩爆深度小于马蹄形隧道,岩爆横向范围大于马蹄形隧道;在相同洞形和地应力条件下,随着隧道跨度越大,岩爆深度与横向范围越大;在相同洞形和跨度条件下,地应力值越高,岩爆深度与横向范围越大;单线隧道Ⅱ级围岩岩爆荷载为12.02~337.75 kPa,单线隧道Ⅲ级围岩岩爆荷载为25.36~352.12 kPa,双线隧道Ⅱ级围岩岩爆荷载为8.54~288.55 kPa,双线隧道Ⅲ级围岩岩爆荷载为33.11~300.83 kPa.

Abstract:The hard and brittle surrounding rock in tunnels is prone to rockburst under high ground stress conditions. Currently, the support structure design for rockburst tunnels in China mainly adopts the engineering analogy method. In order to quantify the impact load of the rockburst on the support structure, the energy conversion relationship during the rockburst process was analyzed from an energy perspective. Then, the kinetic energy theorem and energy conservation principle were used to calculate the impact load. Combined with the loose pressure of the tunnel, a load calculation method for rockburst in tunnels was proposed. At the same time, the influence of different factors such as tunnel diameter on the range of rockburst action was explored. Finally, the rationality was verified based on the rockburst section of a high ground stress tunnel. The research results indicate that the dynamic load factor in the formula for rockburst impact load is positively correlated with the structural stiffness used for tunnel support. Under the same span and ground stress conditions, the rockburst depth of a circular tunnel is smaller than that of a horseshoe tunnel, and the lateral range of the rockburst is larger than that of a horseshoe tunnel. Under the same tunnel shape and ground stress conditions, as the tunnel span increases, the depth and lateral range of the rockburst also increase. Under the same tunnel shape and span conditions, a higher ground stress value indicates a greater depth and lateral range of the rockburst. The rockburst load of Grade Ⅱ surrounding rock in a single-track tunnel ranges from 12.02 kPa to 337.75 kPa, and that of Grade Ⅲ surrounding rock in a single-track tunnel ranges from 25.36 kPa to 352.12 kPa. Moreover, the rockburst load of Grade Ⅱ surrounding rock in a double-track tunnel ranges from 8.54 kPa to 288.55 kPa, and that of Grade Ⅲ surrounding rock in a double-track tunnel ranges from 33.11 kPa to 300.83 kPa.

-

Key words:

- high ground stress /

- rockburst tunnel /

- energy method /

- impact load

-

表 1 岩体应变能及爆块动能计算表

Table 1. Calculation for strain energy of rock mass and kinetic energy of rockburst

岩爆

分级选取岩石强度

应力比最大主应

力值/MPa单位体积岩体

蕴含能量/kJ$ {W}_{\mathrm{e}\mathrm{t}} $ 弹性应变能

释放率 δ单位体积转化

爆块动能/kJ轻微 7 11.43 3.27 Wet<2.0 δ<66.7% 2.18 中等 4 20.00 10.00 2.0≤Wet<3.5 66.7%≤δ<77.8% 7.78 强烈 2 40.00 40.00 3.5≤Wet<5.0 77.8%≤δ<83.3% 33.32 极强 1 80.00 160.00 Wet≥5.0 δ≥83.3% 140.00 表 2 岩爆影响深度

Table 2. Influence depth of rockburst

岩爆等级 影响深度/m 轻微 ≤0.5 中等 (0.5, 1.0] 强烈 (1.0, 3.0] 极强 >3.0 表 3 爆块速度计算表

Table 3. Calculation of rockburst speed

岩爆分级 影响深度/m 爆块体积/m3 密度/(t·m−3) 质量/t 动能/kJ 速度/(m·s−1) 轻微 0.5 0.04 2.75 0.115 0.09 1.25 中等 1.0 0.33 2.75 0.917 2.57 2.37 强烈 3.0 9.00 2.75 24.750 299.88 4.92 极强 4.0 21.33 2.75 58.670 2986.20 10.09 表 4 各岩爆等级对应的地应力值

Table 4. Ground stress values at different rockburst grades

MPa 岩爆等级 水平 垂直 中等 43.0 29.7 强烈 70.5 48.6 极强 80.0 55.17 表 5 计算工况

Table 5. Calculation conditions

工况 岩爆等级 隧道跨度/m 洞型 1 中等 12.0 圆形 2 强烈 12.0 3 极强 12.0 4 中等 8.5 5 强烈 8.5 6 极强 8.5 7 中等 8.5 马蹄形 8 强烈 8.5 9 极强 8.5 10 中等 12.0 11 强烈 12.0 12 极强 12.0 表 6 Ⅱ级围岩力学参数

Table 6. Mechanical parameters of Grade Ⅱ surrounding rock

容重/(kN·m−3) 变形模量/GPa 泊松比 内摩擦角/(°) 黏聚力/MPa 25~27 20~33 0.20~0.25 50~60 1.5~2.1 表 7 不同地应力、洞形以及跨度隧道的岩爆范围

Table 7. Rockburst range of tunnels with different ground stresses, tunnel shapes, and tunnel spans

洞形 隧道跨

度/m岩爆

等级岩爆发生

部位岩爆深度/m 岩爆作用

范围/m圆形 12.0 中等 拱部 0.65 8.0 强烈 拱部 1.67 9.1 极强 拱部 2.10 10.4 8.5 中等 拱部 0.48 5.6 强烈 拱部 1.28 6.9 极强 拱部 1.78 7.7 马蹄形 8.5 中等 拱部 0.50 5.2 强烈 拱部 1.52 6.5 极强 拱部 1.88 7.2 12.0 中等 拱部 0.73 6.5 强烈 拱部 1.77 8.4 极强 拱部 2.20 9.2 表 8 Ⅲ级围岩力学参数

Table 8. Mechanical parameters of Grade Ⅲ surrounding rock

容重/(kN•m−3) 变形模量/GPa 泊松比 内摩擦角/(°) 黏聚力/MPa 23~25 6~20 0.25~0.30 39~50 0.7~1.5 表 9 单线钻爆法岩爆地段支护参数

Table 9. Support parameters of rockburst section by single-track drilling and blasting method

岩爆等级 围岩级别 喷砼/ cm 钢筋网 锚杆 钢架 轻微 Ⅱ 5 局部设置(岩爆部位),直径 6 mm 钢筋网,间距 25 cm 局部设置(岩爆部位),直径 25 mm,长度=3 m Ⅲ 8 拱部设置,直径 6 mm 钢筋网,间距 25 cm 拱墙设置,直径 25 mm,长度=3 m,间距 1.5 m 中等 Ⅱ 5 拱墙设置,直径 6 mm 钢筋网,间距 25 cm 拱墙设置,直径 25 mm,长度=4 m,间距 1.0 m (数量按 50% 计列) Ⅲ 8 拱墙设置,直径 6 mm 钢筋网,间距 25 cm 强烈 Ⅱ、Ⅲ 初喷 5 cm,复喷 15 cm 拱墙设置,直径 6 mm 高强钢丝网或热处理钢筋,间距 25 cm 拱墙设置,直径 25 mm,长度=5 m,间距 1.0 m (数量按 50% 计列) 拱墙设置,HW125 钢架,间距 1.2 m (数量按 1/3 计列) 极强 Ⅱ、Ⅲ 初喷 5 cm,复喷 18 cm 拱墙设置,直径 6 mm 高强钢丝网或热处理钢筋,间距 25 cm 拱墙设置,直径 25 mm,长度=6 m,间距 1.0 m (数量按 50% 计列) 拱墙设置,HW150 钢架,间距 1.0 m (数量按 1/3 计列) 注:喷砼采用C30高性能钢纤维喷混凝土;锚杆采用25低预应力涨壳式中空注浆锚杆. 表 10 双线钻爆法岩爆地段支护参数

Table 10. Support parameters of rockburst section by double-track drilling and blasting method

岩爆等级 围岩级别 喷砼/cm 钢筋网 锚杆 钢架 轻微 Ⅱ 5 局部设置(岩爆部位),直径 6 mm 钢筋网,间距 25 cm 局部设置(岩爆部位),直径 25 mm,长度=3 m Ⅲ 12 拱部设置,直径 6 mm 钢筋网,间距 25 cm 拱墙设置,直径 25 mm,长度=3 m,间距 1.5 m 中等 Ⅱ 5 拱墙设置,直径 6 mm 钢筋网,间距 25 cm 拱墙设置,直径 25 mm,长度=4 m,间距 1.0 m (数量按 50% 计列) Ⅲ 12 拱墙设置,直径 6 mm 钢筋网,间距 25 cm 强烈 Ⅱ、Ⅲ 初喷 5 cm,复喷 19 cm 拱墙设置,直径 6 mm 高强钢丝网或热处理钢筋,间距 25 cm 拱墙设置,直径 25 mm,长度=5 m,间距 1.0 m (数量按 50% 计列) 拱墙设置,HW150 钢架,间距 1.2 m (数量按 1/3 计列) 极强 Ⅱ、Ⅲ 初喷 5 cm,复喷 21 cm 拱墙设置,直径 6 mm 高强钢丝网或热处理钢筋,间距 25 cm 拱墙设置,直径 25 mm,长度=6 m,间距 1.0 m (数量按 50% 计列) 拱墙设置,HW175 钢架,间距 1.0 m (数量按 1/3 计列) 注:喷砼采用C30高性能钢纤维喷混凝土;锚杆采用25低预应力涨壳式中空注浆锚杆. 表 11 隧道岩爆冲击荷载计算

Table 11. Impact load calculation of tunnel rockburst

围岩

级别隧道

类型岩爆

等级岩石强度

应力比单位体积岩体

蕴含能量/kJ弹性应变能

释放率/%单位体积转化

爆块动能/kJ速度/

(m•s−1)构件截面抗弯

刚度/(kN·m2)动荷

因数冲击荷载/

kPaⅡ级 单线 轻微 7 3.27 δ≤66.7 2.18 1.25 291.67 2.67 12.02 中等 4 10.00 66.7<δ≤77.8 7.78 2.37 291.67 1.79 16.08 强烈 2 40.00 77.8<δ≤83.3 33.32 4.92 20141.92 5.72 154.20 极强 1 160.00 δ>83.3 140.00 10.09 31791.67 9.40 337.75 双线 轻微 7 3.27 δ≤66.7 2.18 1.25 291.67 1.89 8.54 中等 4 10.00 66.7<δ≤77.8 7.78 2.37 291.67 1.27 11.43 强烈 2 40.00 77.8<δ≤83.3 33.32 4.92 35091 5.35 144.08 极强 1 160.00 δ>83.3 140.00 10.09 47138.47 8.03 288.55 Ⅲ级 单线 轻微 7 2.14 δ≤66.7 1.43 1.06 1194.67 5.62 25.36 中等 4 6.54 66.7<δ≤77.8 5.09 2.00 1194.67 3.78 33.94 强烈 2 26.17 77.8<δ≤83.3 21.80 4.14 20141.92 5.97 160.76 极强 1 104.69 δ>83.3 92.13 8.50 31791.67 9.80 352.12 双线 轻微 7 2.14 δ≤66.7 1.43 1.06 4032.00 7.34 33.11 中等 4 6.54 66.7<δ≤77.8 5.09 2.00 4032.00 4.93 44.32 强烈 2 26.17 77.8<δ≤83.3 21.80 4.14 35091.00 5.57 150.21 极强 1 104.69 δ>83.3 92.13 8.50 47138.47 8.37 300.83 -

[1] 陈旭光,张强勇. 岩石剪切破坏过程的能量耗散和释放研究[J]. 采矿与安全工程学报,2010,27(2): 179-184. doi: 10.3969/j.issn.1673-3363.2010.02.008CHEN Xuguang, ZHANG Qiangyong. Research on the energy dissipation and release in the process of rock shear failure[J]. Journal of Mining and Safety Engineering, 2010, 27(2): 179-184. doi: 10.3969/j.issn.1673-3363.2010.02.008 [2] 陈滔,黎立云,邓建辉,等. 岩爆问题中岩块弹射速度的数值计算与实验研究[J]. 四川大学学报(工程科学版),2014,46(增1): 26-31.CHEN Tao, LI Liyun, DENG Jianhui, et al. Numerical simulation and experimental research on rock ejection velocity in rockburst[J]. Journal of Sichuan University (Engineering Science Edition), 2014, 46(S1): 26-31. [3] 孙扬,郭相参. 基于能量分析的岩爆倾向井巷支护方法[J]. 中国矿业,2019,28(增2): 369-372.SUN Yang, GUO Xiangcan. Method on rockburst shaft and roadway support based on energy analysis[J]. China Mining Magazine, 2019, 28(S2): 369-372. [4] 汪波,何川. 预应力中空注浆锚杆在苍岭隧道防岩爆设计中的应用[J]. 公路,2011,56(10): 206-210.WANG Bo, HE Chuan. Application of prestressed hollow grouting anchor in rock burst prevention design of cangling tunnel[J]. Highway, 2011, 56(10): 206-210. [5] 国家铁路局. 铁路隧道设计规范:TB 10003—2016[S]. 北京:中国铁道出版社,2017. [6] 轩俊杰,严松宏. 基于应力场反演和弹性应变能积聚的岩爆预测[J]. 铁道工程学报,2021,38(11): 79-85. doi: 10.3969/j.issn.1006-2106.2021.11.013XUAN Junjie, YAN Songhong. Rockburst prediction based on the geo-stress field inversion and elastic strain energy accumulation theory[J]. Journal of Railway Engineering Society, 2021, 38(11): 79-85. doi: 10.3969/j.issn.1006-2106.2021.11.013 [7] 李天斌,孟陆波,王兰生. 高地应力隧道稳定性及岩爆、大变形灾害防治[M]. 北京:科学出版社,2016. [8] 朱宏锐. 锦屏引水隧洞岩爆特征及其影响因素分析[J]. 铁道建筑,2009,49(5): 71-74. doi: 10.3969/j.issn.1003-1995.2009.05.023ZHU Hongrui. Analysis of rock burst characteristics and its influencing factors in Jinping diversion tunnel[J]. Railway Engineering, 2009, 49(5): 71-74. doi: 10.3969/j.issn.1003-1995.2009.05.023 [9] CAI M, KAISER P K. Assessment of excavation damaged zone using a micromechanics model[J]. Tunnelling and Underground Space Technology, 2005, 20(4): 301-310. doi: 10.1016/j.tust.2004.12.002 [10] 高玉生,张宏,赵国斌. 深埋长隧洞岩爆机理研究及防治实践[M]. 北京:中国水利水电出版社,2014. [11] 陶振宇. 若干电站地下工程建设中的岩爆问题[J]. 水力发电,1988,14(7): 40-45.TAO Zhenyu. Rockburst in underground engineering construction of some power stations[J]. Water Power, 1988, 14(7): 40-45. [12] 王志成. 开挖卸荷与扰动荷载作用下岩爆弹射破坏的离散元模拟[D]. 南宁:广西大学,2013. [13] 唐杰灵,李天斌,曾鹏,等. 岩爆柔性防护网及其动力特性分析[J]. 岩石力学与工程学报,2019,38(4): 793-802.TANG Jieling, LI Tianbin, ZENG Peng, et al. Study on rockburst flexible protective net and its dynamic characteristics[J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(4): 793-802. [14] 秦剑峰,卓家寿. 岩爆问题中块体速度探讨[J]. 岩土力学,2011,32(5): 1365-1368. doi: 10.3969/j.issn.1000-7598.2011.05.014QIN Jianfeng, ZHUO Jiashou. A discussion on rock velocity in rockburst[J]. Rock and Soil Mechanics, 2011, 32(5): 1365-1368. doi: 10.3969/j.issn.1000-7598.2011.05.014 [15] 张镜剑, 傅冰骏. 岩爆及其判据和防治[J]. 岩石力学与工程学报,2008,27(10):2034-2042.ZHANG Jingjian, FU Bingjun. Rockburst and its criteria and control[J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(10):2034-2042. [16] 李天斌,钟雨奕,潘皇宋,等. 高地应力隧道岩爆破坏特征物理模型试验研究[J]. 地下空间与工程学报,2019,15(6): 1639-1645.LI Tianbin, ZHONG Yuyi, PAN Huangsong, et al. Failure characteristics analysis on physical model of rock burst in high In-situ stress tunnel[J]. Chinese Journal of Underground Space and Engineering, 2019, 15(6): 1639-1645. [17] 田红涛. 基于能量法的岩爆隧道支护体系及其计算模型研究[D]. 成都:西南交通大学,2021. [18] 徐林生. 二郎山公路隧道岩爆特征与防治措施的研究[J]. 土木工程学报,2004,37(1): 61-64. doi: 10.3321/j.issn:1000-131X.2004.01.011XU Linsheng. Research of rockburst character and prevention measure in erlang mountain highway tunnel[J]. China Civil Engineering Journal, 2004, 37(1): 61-64. doi: 10.3321/j.issn:1000-131X.2004.01.011 [19] 于丽,杨涅,吕城,等. 型钢混凝土钢架等效弹性模量研究[J]. 铁道建筑,2018,58(9): 42-45. doi: 10.3969/j.issn.1003-1995.2018.09.12YU Li, YANG Nie, LYU Cheng, et al. Study on equivalent elastic modulus of steel reinforced concrete frame[J]. Railway Engineering, 2018, 58(9): 42-45. doi: 10.3969/j.issn.1003-1995.2018.09.12 [20] 秦世伦. 材料力学[M]. 2版. 成都:四川大学出版社,2011. [21] 中华人民共和国住房和城乡建设部. 岩土锚杆与喷射混凝土支护工程技术规范:GB 50086—2015[S]. 北京:中国计划出版社,2016. [22] 新建川藏铁路雅安至林芝段施工图设计原则:隧道专业[R]. 成都:中铁二院工程集团有限责任公司,2020. -

下载:

下载: