Fatigue Crack Repair Mechanism and Effect by Pneumatic Impact Treatment

-

摘要:

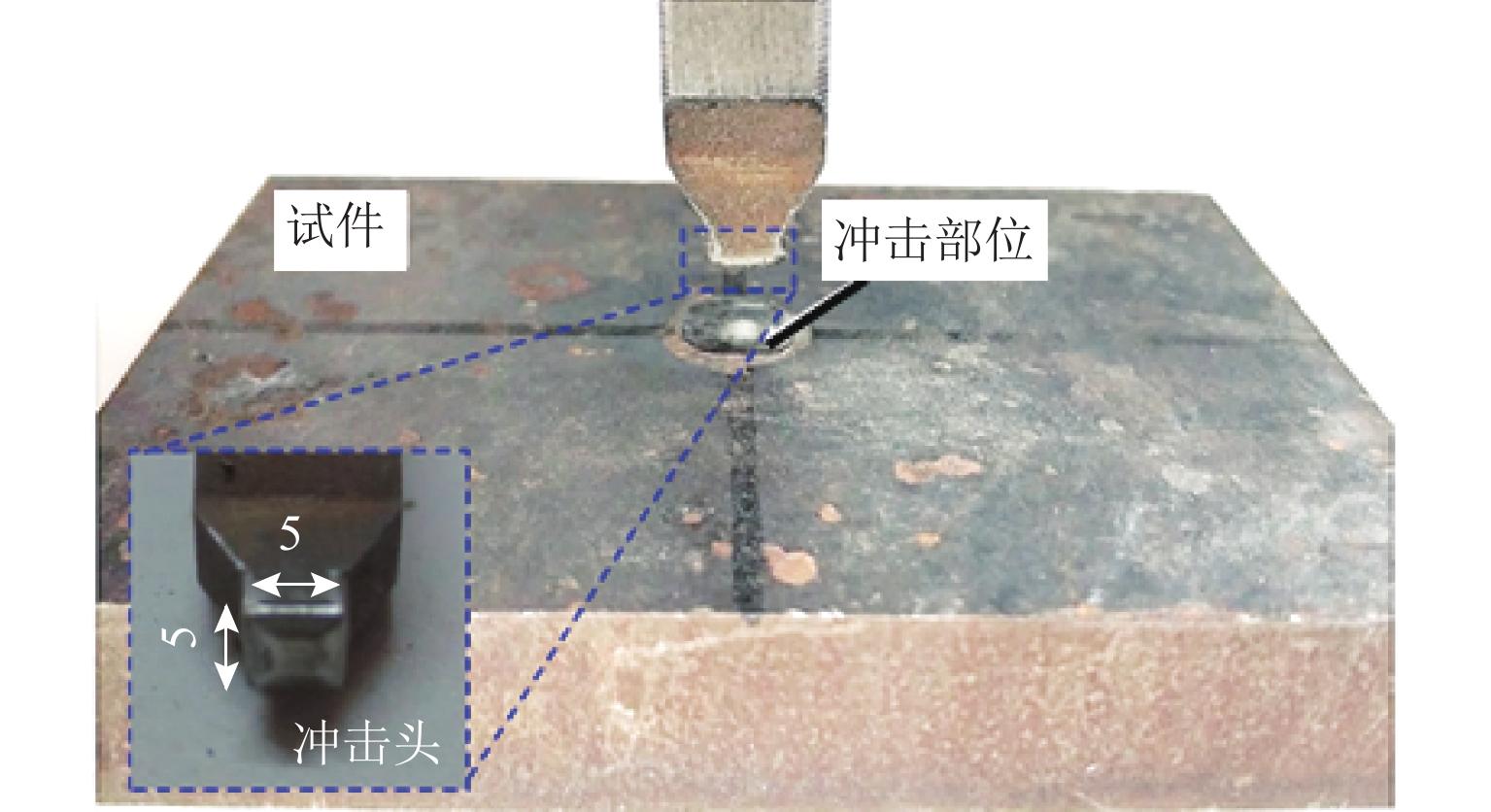

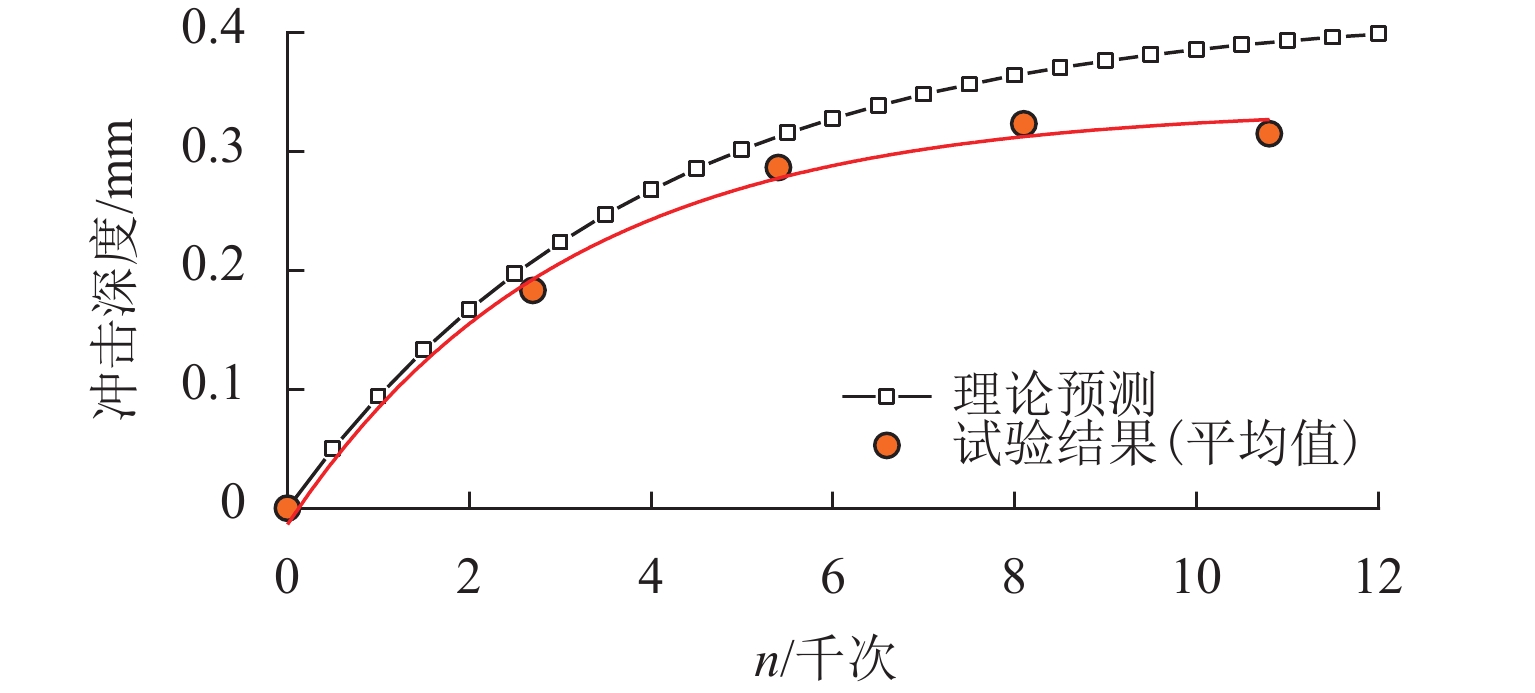

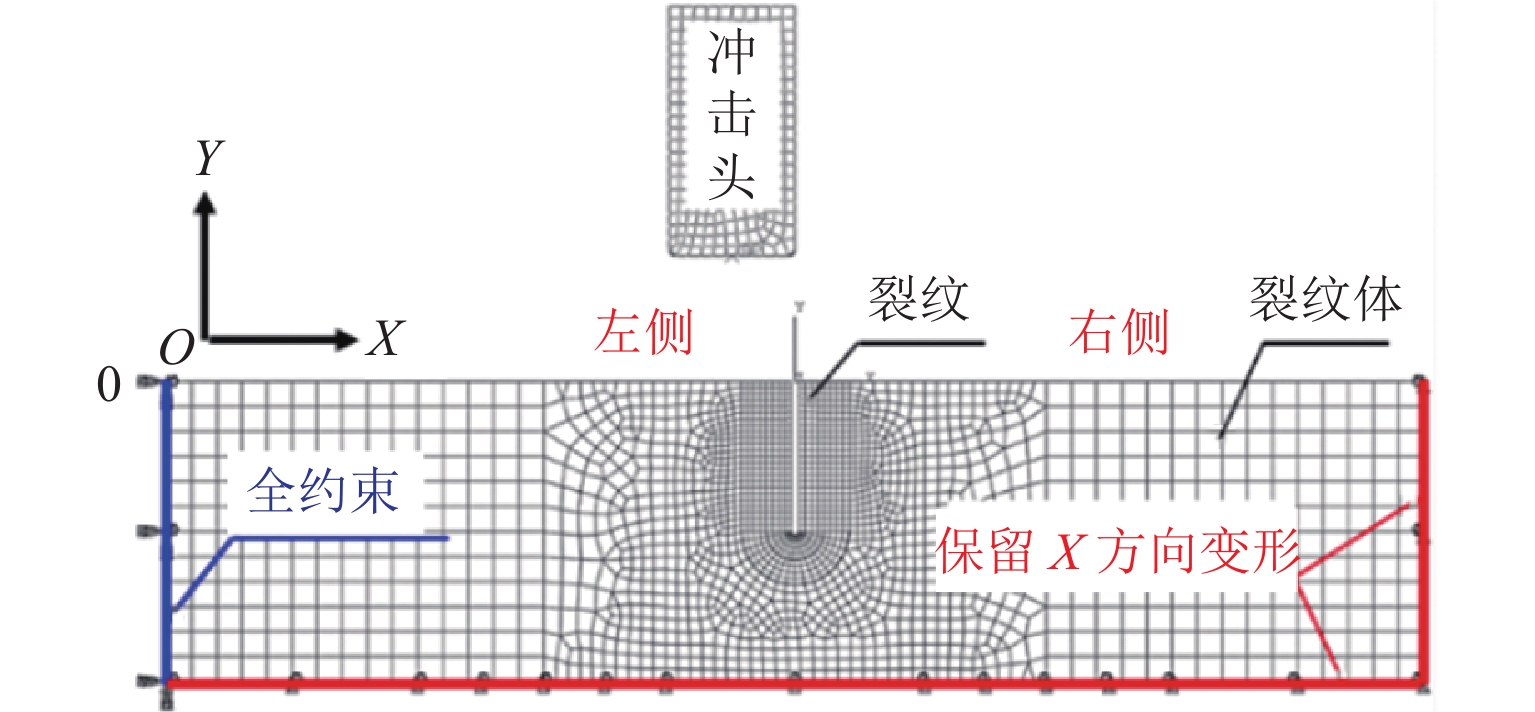

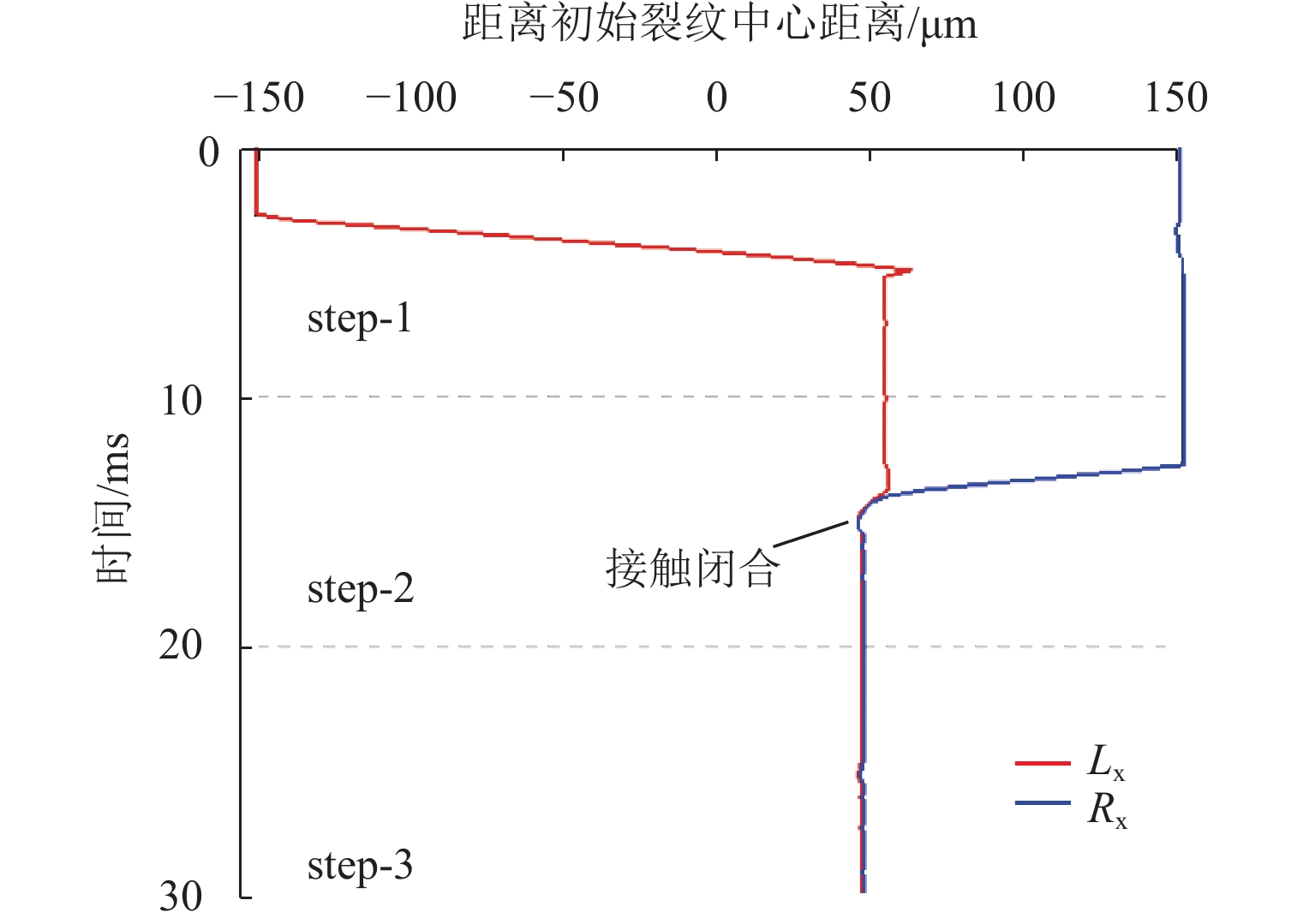

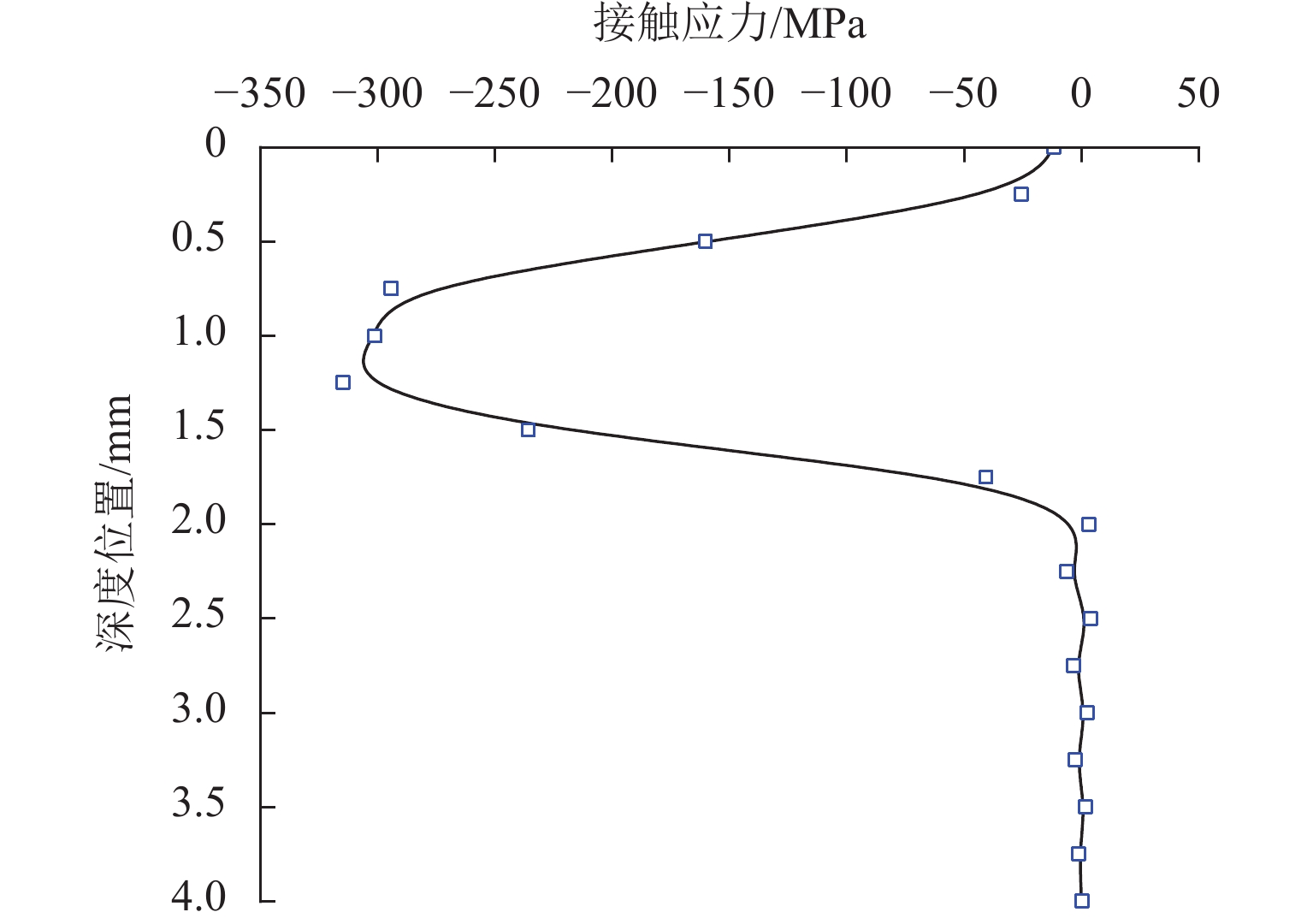

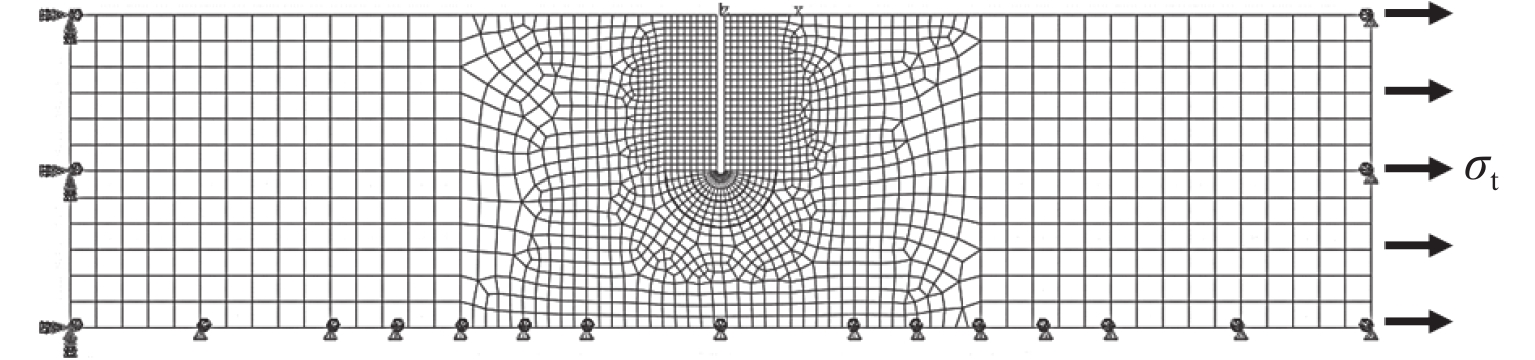

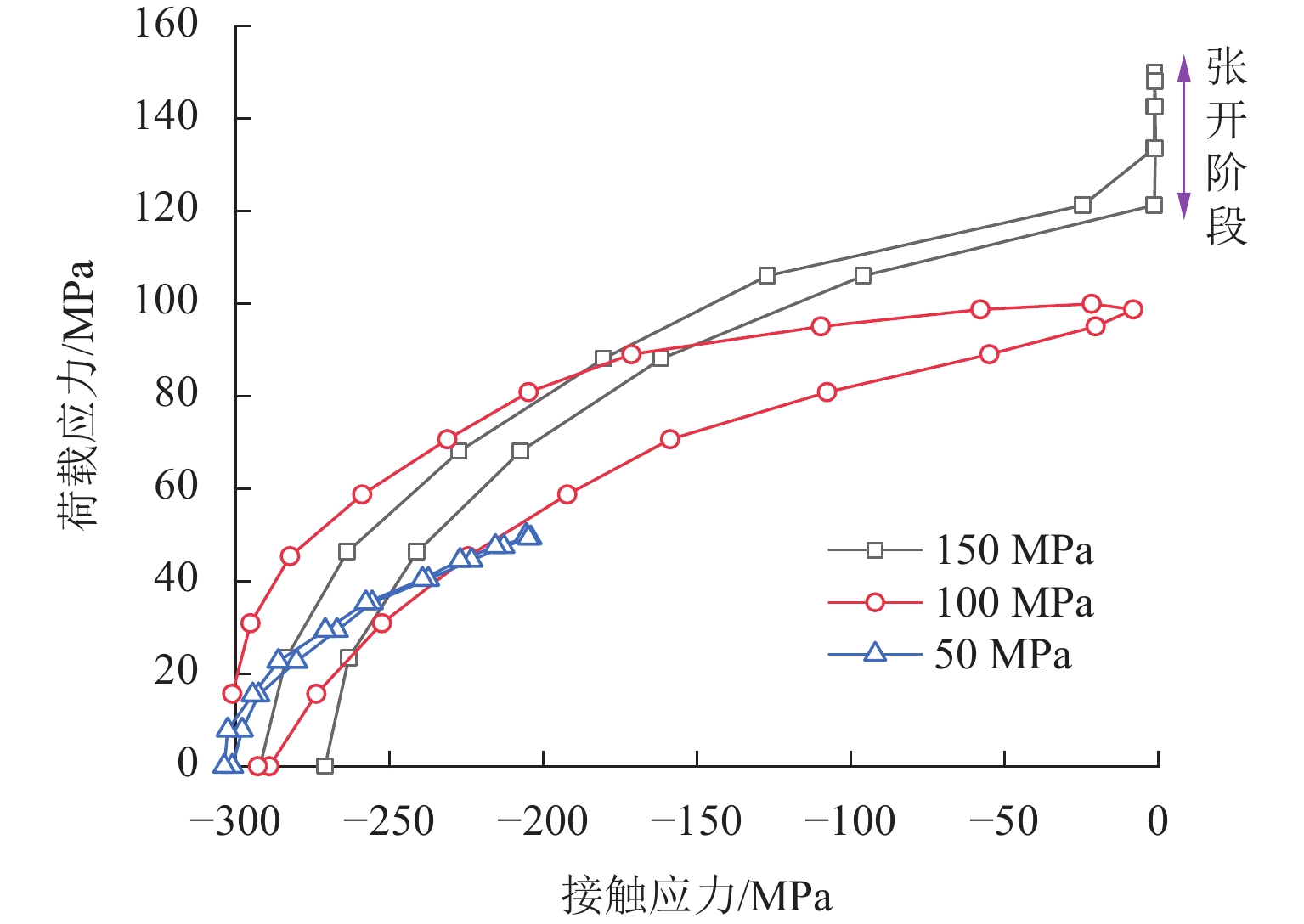

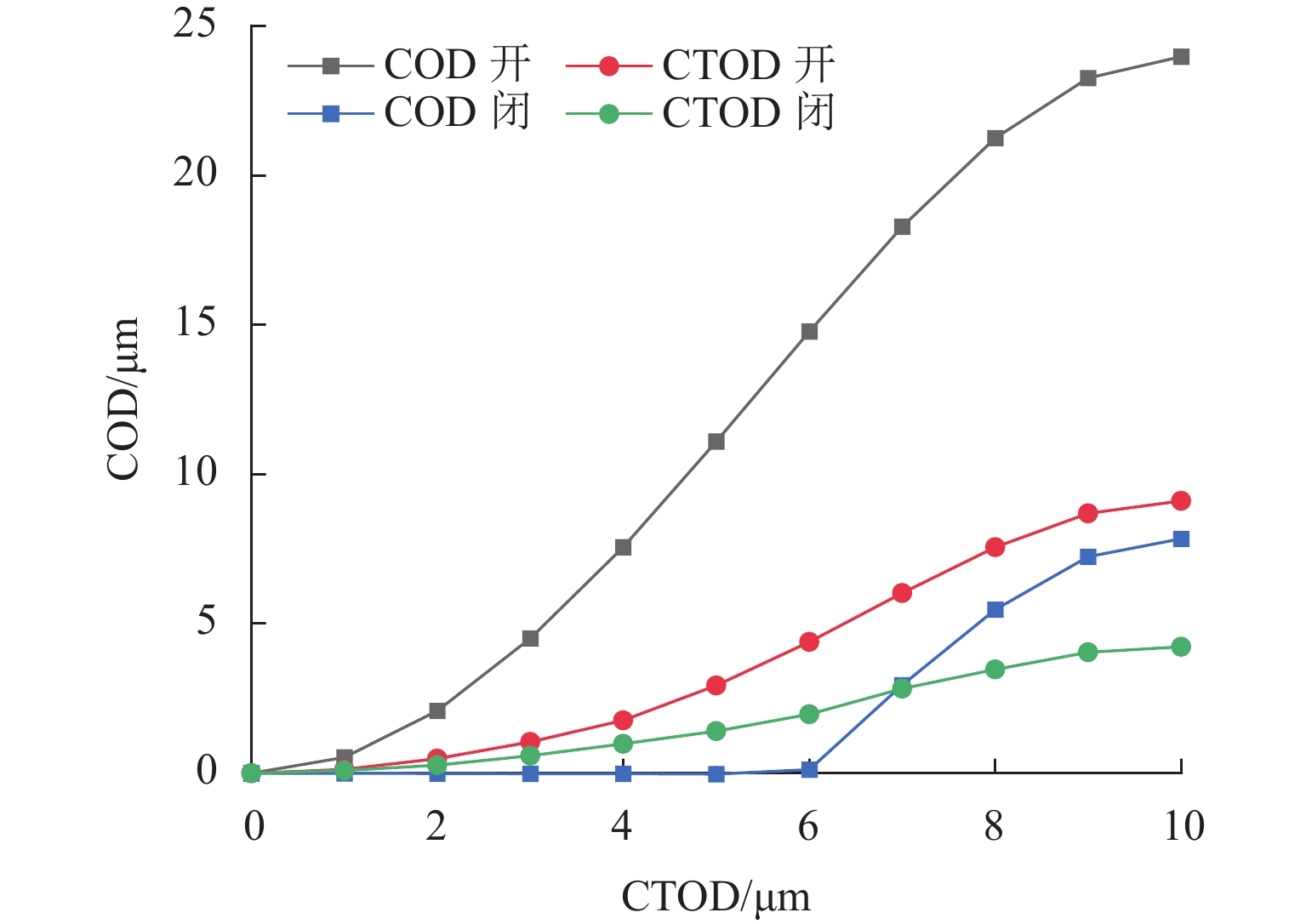

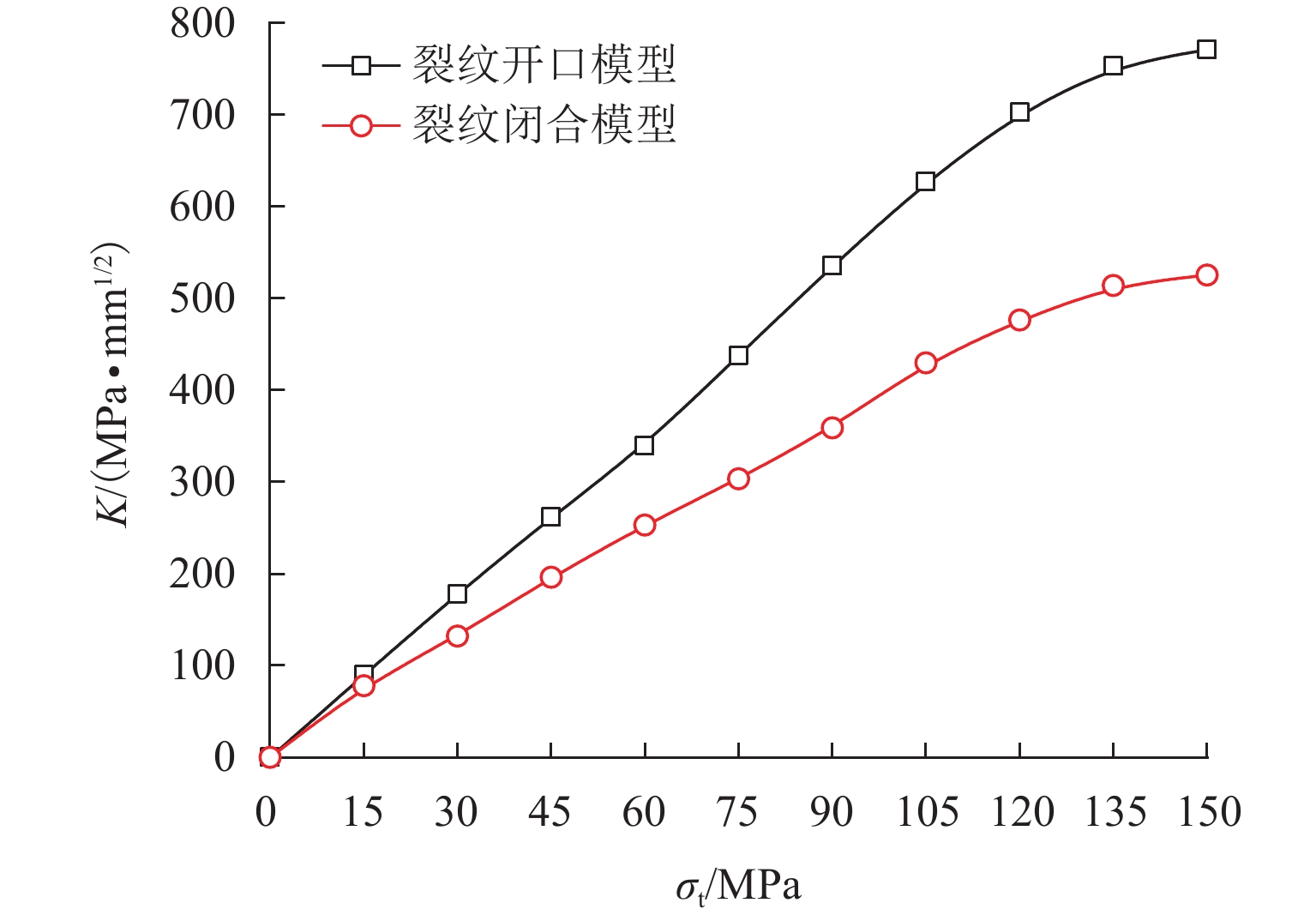

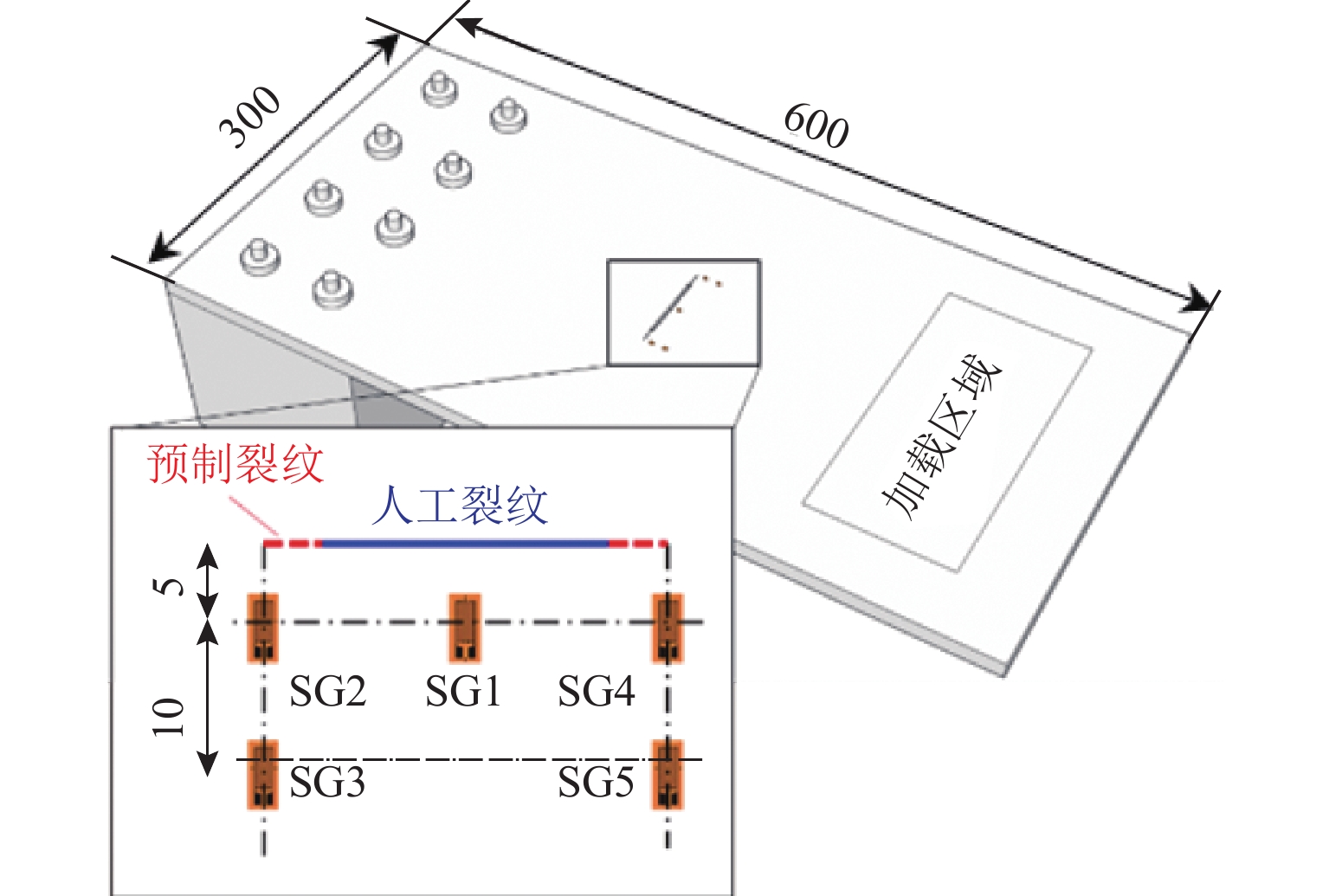

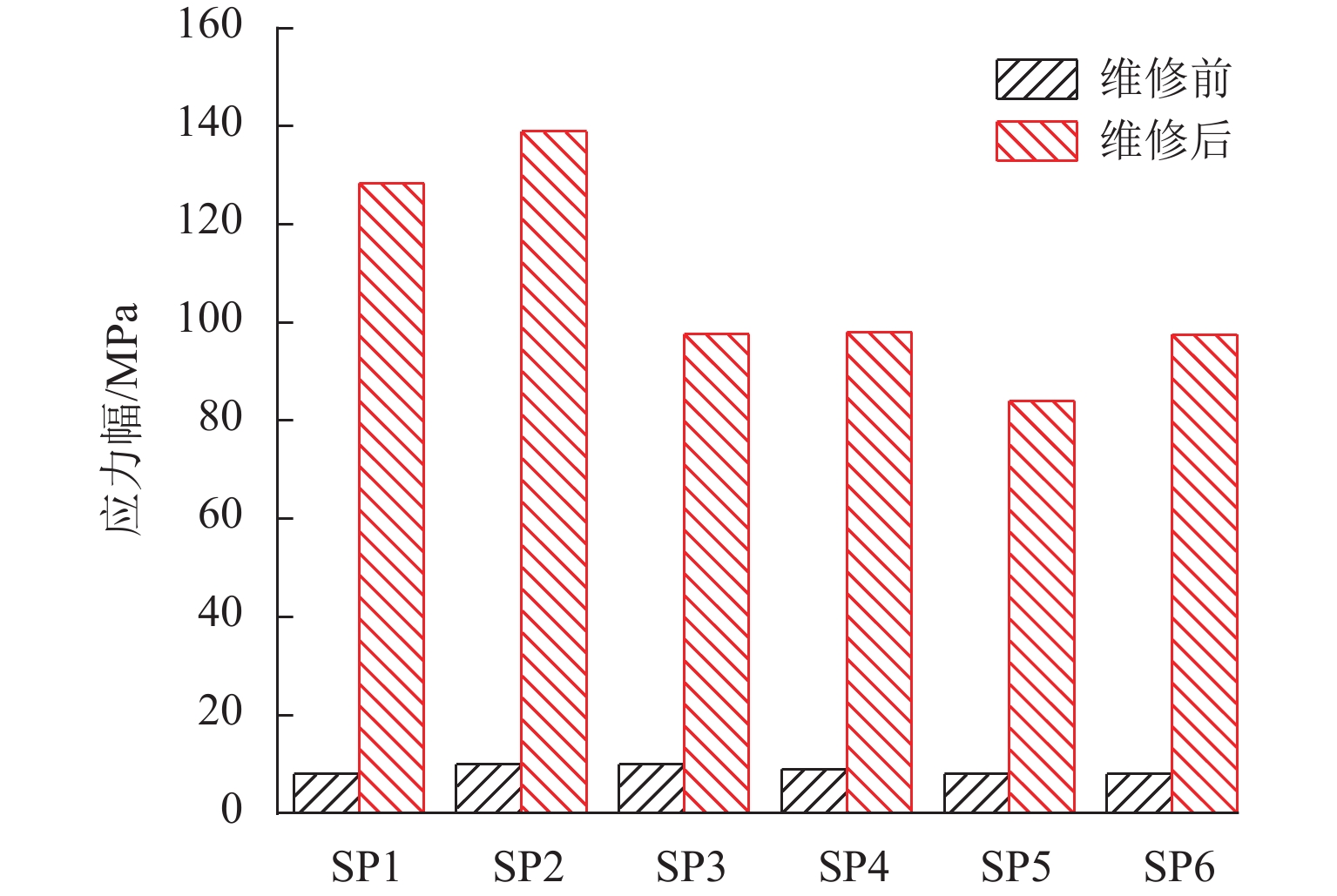

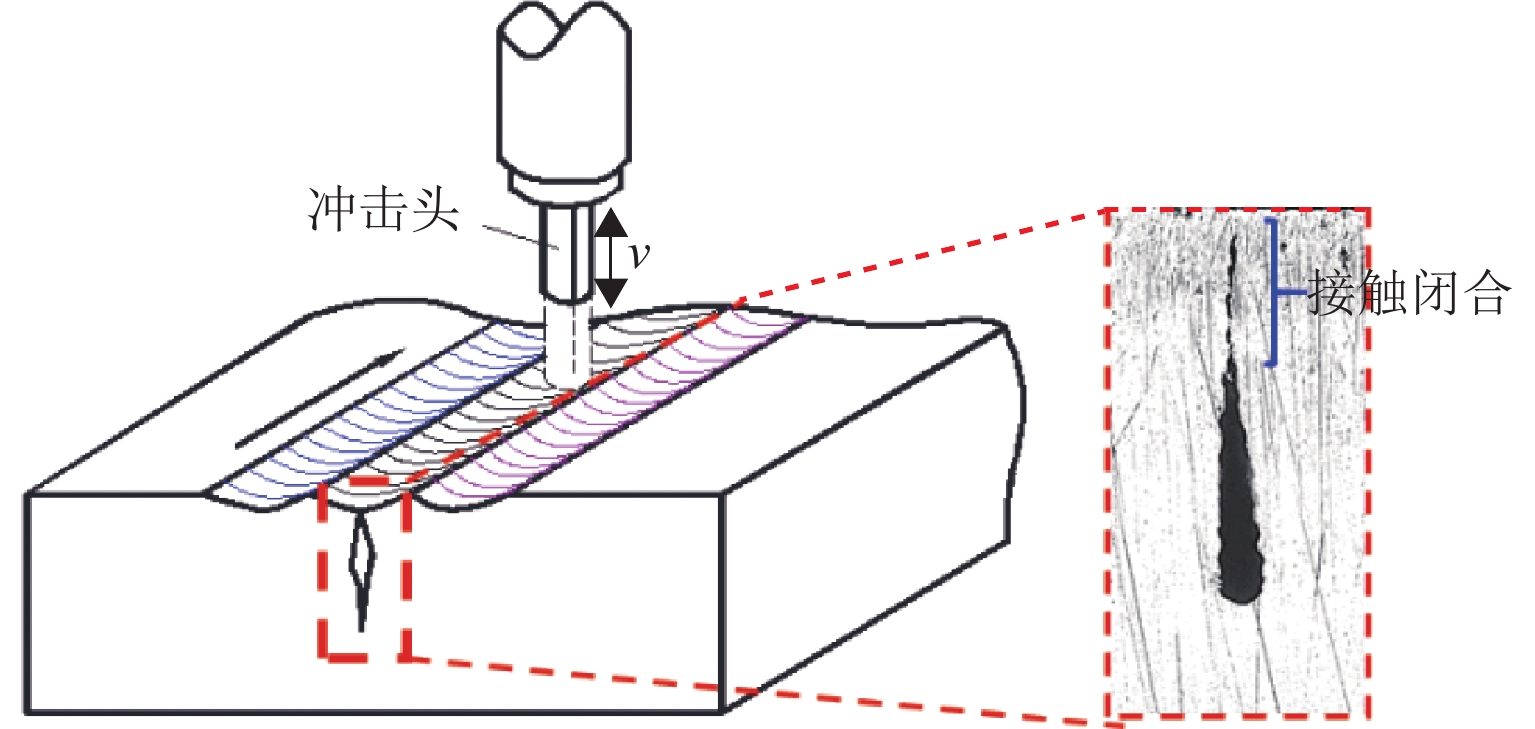

为探明气动冲击技术对钢桥面板疲劳裂纹的维修机理及修复效果,首先基于动力学理论,研究气动冲击过程中靶材的塑性变形规律,分析在塑性变形作用下的裂纹表面闭合过程;随后,采用数值模拟,探讨裂纹表面闭合部位的局部应力场及其在受载作用下的应力响应和变形规律;最后,通过疲劳试验对气动冲击的维修效果进行对比验证. 结果表明:所提出的数学模型可对冲击深度进行预测,气动冲击过程中材料表面将产生显著的塑性变形,其冲击深度与横向变形近似相等;当裂纹断面横向相对变形量大于裂纹宽度时,会产生接触闭合及相互挤压行为,从而在接触闭合部位形成局部压应力区;该压应力能够一定程度上抵抗外荷载对裂纹表面的张拉作用,降低裂纹尖端应力强度因子,从而延缓或阻碍疲劳裂纹扩展.

Abstract:To explore the repair mechanism and effect of pneumatic impact treatment on fatigue cracks of the steel bridge deck, the plastic deformation of the target material during the pneumatic impact treatment was studied based on kinetic theory, and the behaviors of crack surface closure under such plastic deformation were analyzed. Then, the local stress field in the closure part was investigated, and the stress response and its deformation under the applied load were discussed by numerical method. Fatigue tests were carried out to verify the repair effect of pneumatic impact treatment at last. The results show that the mathematical model proposed here is able to predict the impact depth. Large plastic deformation is observed on the material surface during the pneumatic impact treatment process, and the impact depth and transverse deformation are similar. When the relative transverse deformation of the crack fracture surface becomes larger than the crack width, the contact closure and compressional deformation can be found, which will introduce the contact stress at the closure part. This contact stress can resist the tension effect of the crack surface under applied load, reduce the stress intensity factor at the crack tip, and restrain the propagation of fatigue cracks, which is also proved by the tests.

-

Key words:

- bridge engineering /

- pneumatic impact /

- numerical simulation /

- crack closure /

- stress intensity factor

-

表 1 气动冲击设备参数

Table 1. Parameters of device for pneumatic impact

参数 f/Hz l/mm m/kg Ao/mm2 取值 90 6 0.367 25 25 表 2 Q345qD材料系数

Table 2. Material constant of Q345qD

参数 q λ β c

/(N·mm−1.5)γ 取值 0.999 745 4.736 × 10−8 0.367 25 8.0 × 109 0.6 表 3 疲劳试验结果

Table 3. Fatigue test results

试件编号 预制长度/mm 最终长度/mm 循环次数/万次 SP1 67.2 79.1 463 SP2 58.5 60.0 647 SP3 66.5 未变化 581 SP4 68.5 未变化 601 SP5 70.6 未变化 505 SP6 70.2 未变化 540 -

[1] 钱冬生. 关于正交异性钢桥面板的疲劳——对英国在加固其塞文桥渡时所作研究的评介[J]. 桥梁建设,1996,26(2): 8-13.QIAN Dongsheng. On fatigue of steel orthotropic deck structure: comments on researches for strengthening the severn crossing in UK[J]. Bridge Construction, 1996, 26(2): 8-13. [2] 吴冲,刘海燕,张志宏,等. 桥面铺装温度对正交异性钢桥面板疲劳的影响[J]. 同济大学学报(自然科学版),2013,41(8): 1213-1218. doi: 10.3969/j.issn.0253-374x.2013.08.016WU Chong, LIU Haiyan, ZHANG Zhihong, et al. Influence of pavements temperature on fatigue life of orthotropic deck of steel bridge[J]. Journal of Tongji University (Natural Science), 2013, 41(8): 1213-1218. doi: 10.3969/j.issn.0253-374x.2013.08.016 [3] WOLCHUK R. Steel orthotropic decks: developments in the 1990s[J]. Transportation Research Record: Journal of the Transportation Research Board, 1999, 1688(1): 30-37. doi: 10.3141/1688-04 [4] 吉伯海,袁周致远. 钢箱梁疲劳开裂维护研究现状[J]. 工业建筑,2017,47(5): 1-5,11. doi: 10.13204/j.gyjz201705001JI Bohai, YUANZHOU Zhiyuan. State of the art of fatigue cracking maintenance for steel box girder[J]. Industrial Construction, 2017, 47(5): 1-5,11. doi: 10.13204/j.gyjz201705001 [5] 饶建辉, 吉伯海. 江阴长江公路大桥钢箱梁养护报告: 1999年—2017年[M]. 北京: 人民交通出版社, 2018. [6] 王洋,邵旭东,陈杰,等. 重度疲劳开裂钢桥桥面的UHPC加固技术[J]. 土木工程学报,2020,53(11): 92-101,115. doi: 10.15951/j.tmgcxb.2020.11.010WANG Yang, SHAO Xudong, CHEN Jie, et al. UHPC-based strengthening technique for significant fatigue cracking steel bridge decks[J]. China Civil Engineering Journal, 2020, 53(11): 92-101,115. doi: 10.15951/j.tmgcxb.2020.11.010 [7] 吕志林,姜旭,强旭红,等. 高弹模CFRP粘贴法修复钢桥板疲劳裂纹[J]. 建筑钢结构进展,2022,24(5): 92-100.LYU Zhilin, JIANG Xu, QIANG Xuhong, et al. High modulus CFRP adhesion method for repairing fatigue cracks in steel bridge plates[J]. Progress in Steel Building Structures, 2022, 24(5): 92-100. [8] 李传习,李游,陈卓异,等. 钢箱梁横隔板疲劳开裂原因及补强细节研究[J]. 中国公路学报,2017,30(3): 121-131. doi: 10.3969/j.issn.1001-7372.2017.03.013LI Chuanxi, LI You, CHEN Zhuoyi, et al. Fatigue cracking reason and detail dimension of reinforcement about transverse diaphragm of steel box girder[J]. China Journal of Highway and Transport, 2017, 30(3): 121-131. doi: 10.3969/j.issn.1001-7372.2017.03.013 [9] 张清华,金通,李俊,等. 钢桥面板纵肋与横隔板焊接细节疲劳开裂的加固研究[J]. 西南交通大学学报,2020,55(1): 92-99.ZHANG Qinghua, JIN Tong, LI Jun, et al. Study on reinforcement for fatigue cracking of rib-to-diaphragm welded joints of steel bridge deck[J]. Journal of Southwest Jiaotong University, 2020, 55(1): 92-99. [10] AL-SALIH H, BENNETT C, MATAMOROS A, et al. Repairing distortion-induced fatigue in steel bridges using a CFRP-steel retrofit[C]//Structures Congress 2020. Saint Louis: American Society of Civil Engineers, 2020: 273-284. [11] YAMADA K, ISHIKAWA T, KAKIICHI T, et al. Rehabilitation and improvement of fatigue life of welded joints by ICR Treatment[J]. Advanced Steel Construction, 2015, 11(3): 294-304. [12] WANG Q D, JI B H, FU Z Q, et al. Effect of crack-closure treatment on fatigue durability of cracked rib-to-deck welded joints in steel bridge decks[J]. Journal of Central South University, 2019, 26(9): 2554-2568. doi: 10.1007/s11771-019-4194-4 [13] YUANZHOU Z Y, JI B H, FU Z Q, et al. Fatigue performance of cracked rib-deck welded joint retrofitted by ICR technique[J]. International Journal of Steel Structures, 2016, 16(3): 735-742. doi: 10.1007/s13296-015-0089-x [14] ELBER W. The significance of fatigue crack closure[C]//The Seventy-Third Annual Meeting of the American Society for Testing and Materials. Toronto: ASTM International, 1970: 230-242. [15] BROWN N, LUKENS K F. Microstrain in polycrystalline metals[J]. Acta Metallurgica, 1961, 9(2): 106-111. doi: 10.1016/0001-6160(61)90053-0 [16] 凌邦国. 碰撞过程中碰撞力定量计算[J]. 南通工学院学报,2001,17(4): 7-9.LING Bangguo. The quantitative calculation of impact in the process of collision[J]. Journal of Nantong Institute of Technology, 2001, 17(4): 7-9. [17] YUANZHOU Z Y, JI B H, SUN T, et al. Numerical model of plastic deformation on cracked surface under repeated pneumatic impact[J]. Advances in Materials Science and Engineering, 2018, 2018: 1-9. [18] 张倩苑. 冲击频率对低应力多冲碰撞塑性变形的影响研究及建模[D]. 苏州: 苏州大学, 2015. [19] YUANZHOU Z Y, JI B H, WANG Q D, et al. Investigation on crack behaviours by closing its surface using impact treatment[J]. Journal of Constructional Steel Research, 2019, 156: 1-8. doi: 10.1016/j.jcsr.2019.01.009 [20] WELLS A A. Crack opening displacements from elastic-plastic analyses of externally notched tension bars[J]. Engineering Fracture Mechanics, 1969, 1(3): 399-410. doi: 10.1016/0013-7944(69)90001-0 [21] YUANZHOU Z Y, JI B H, FU Z Q, et al. Fatigue crack retrofitting by closing crack surface[J]. International Journal of Fatigue, 2019, 119: 229-237. doi: 10.1016/j.ijfatigue.2018.10.006 [22] DUGDALE D S. Yielding of steel sheets containing slits[J]. Journal of the Mechanics and Physics of Solids, 1960, 8(2): 100-104. doi: 10.1016/0022-5096(60)90013-2 [23] WEI J, ZHAO J H. A two-strain-gage technique for determining modeⅠstress-intensity factor[J]. Theoretical and Applied Fracture Mechanics, 1997, 28(2): 135-14. doi: 10.1016/S0167-8442(97)00038-4 -

下载:

下载: