Freeze-Thaw Damage Evolution Model of Asphalt Concrete for Waterproofing Layer in High-Speed Railways

-

摘要:

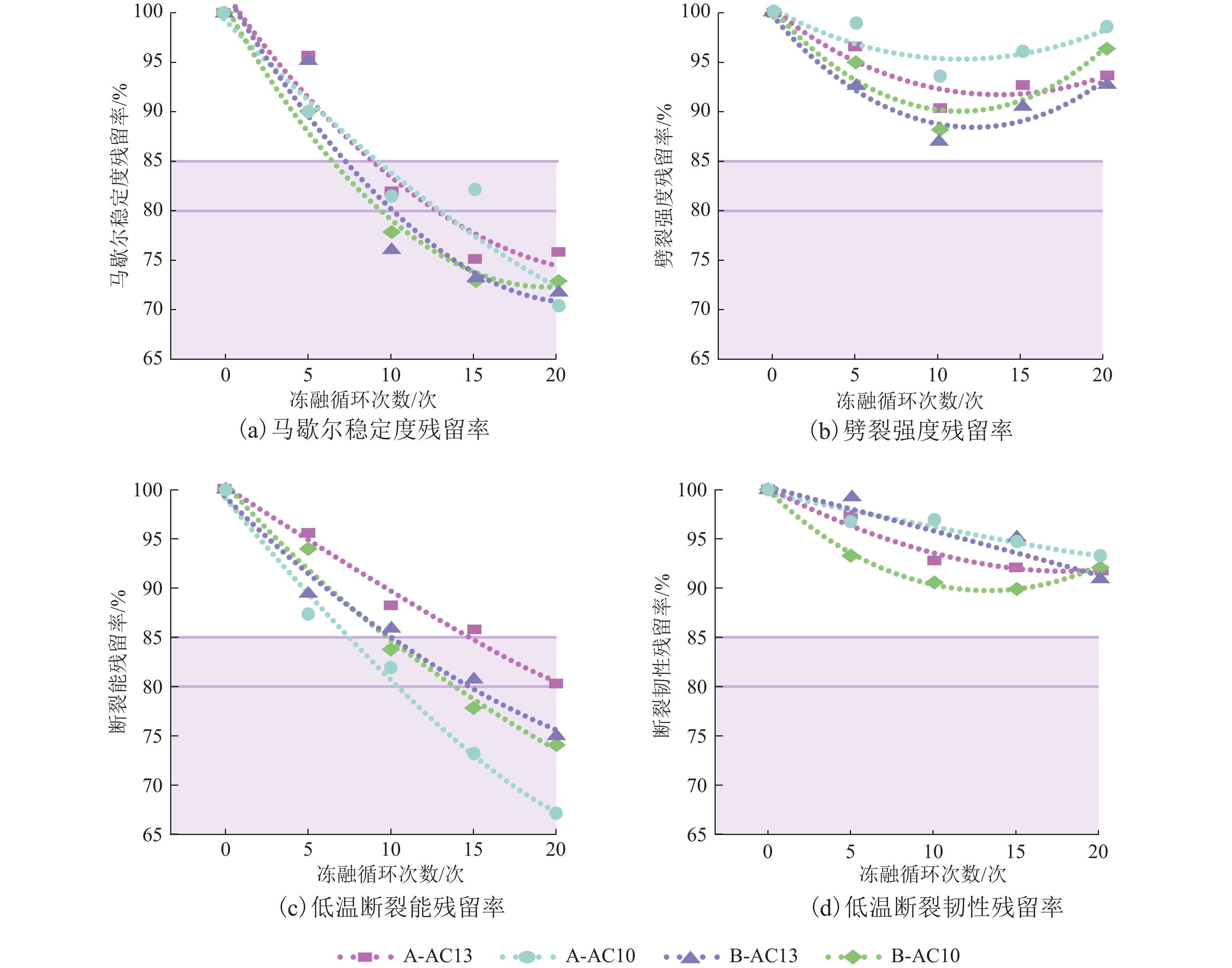

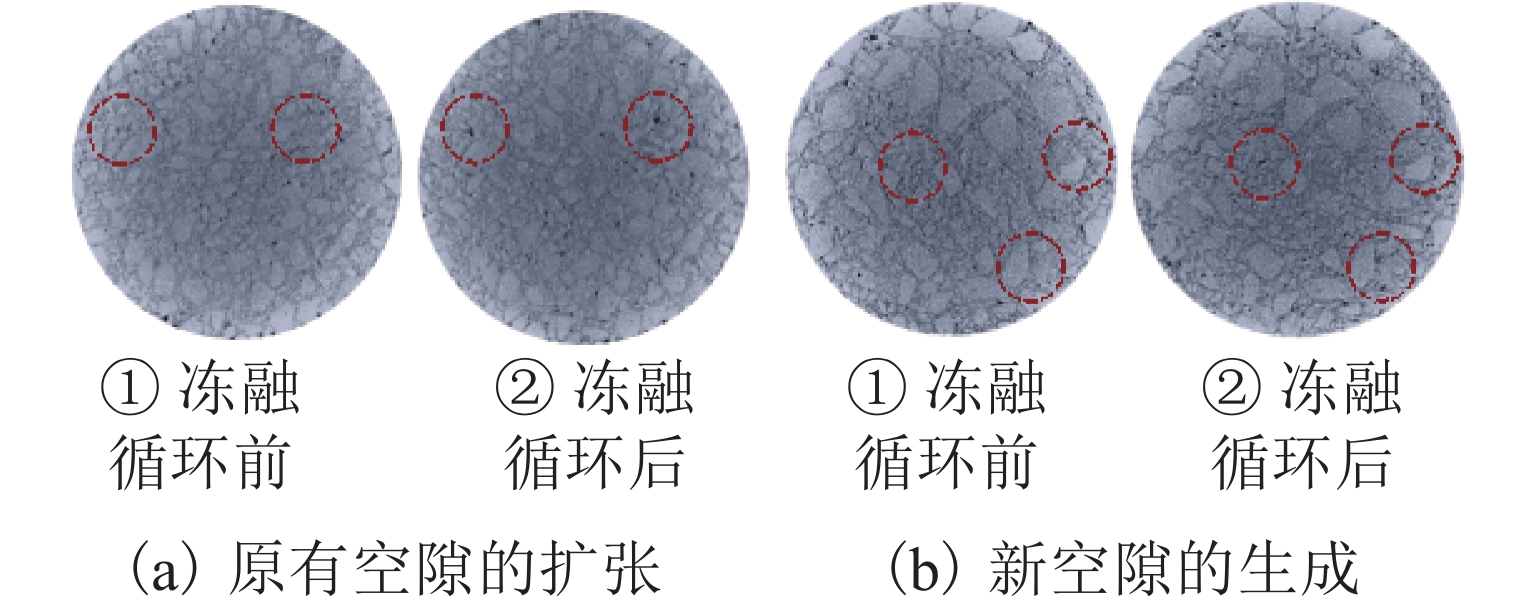

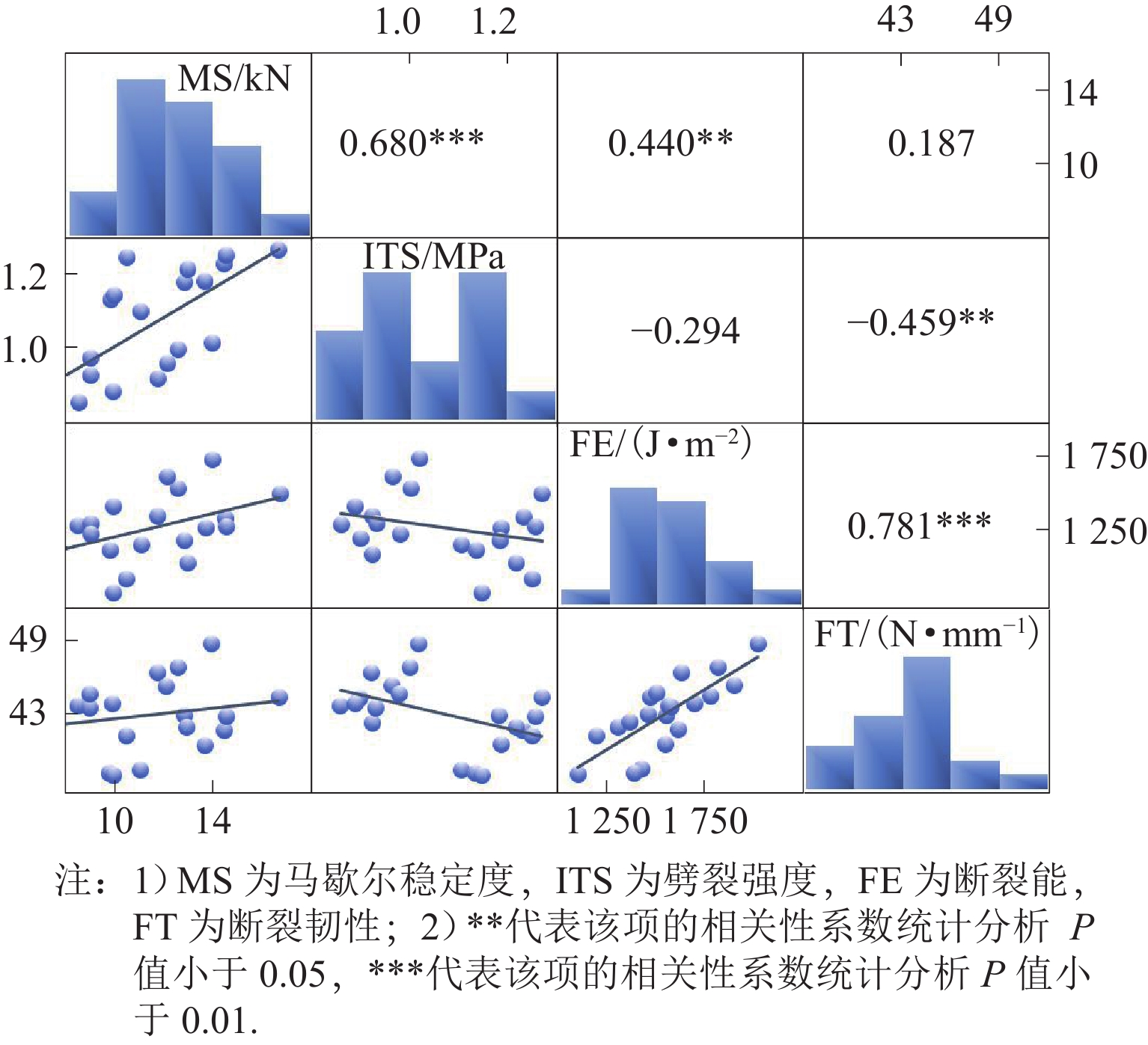

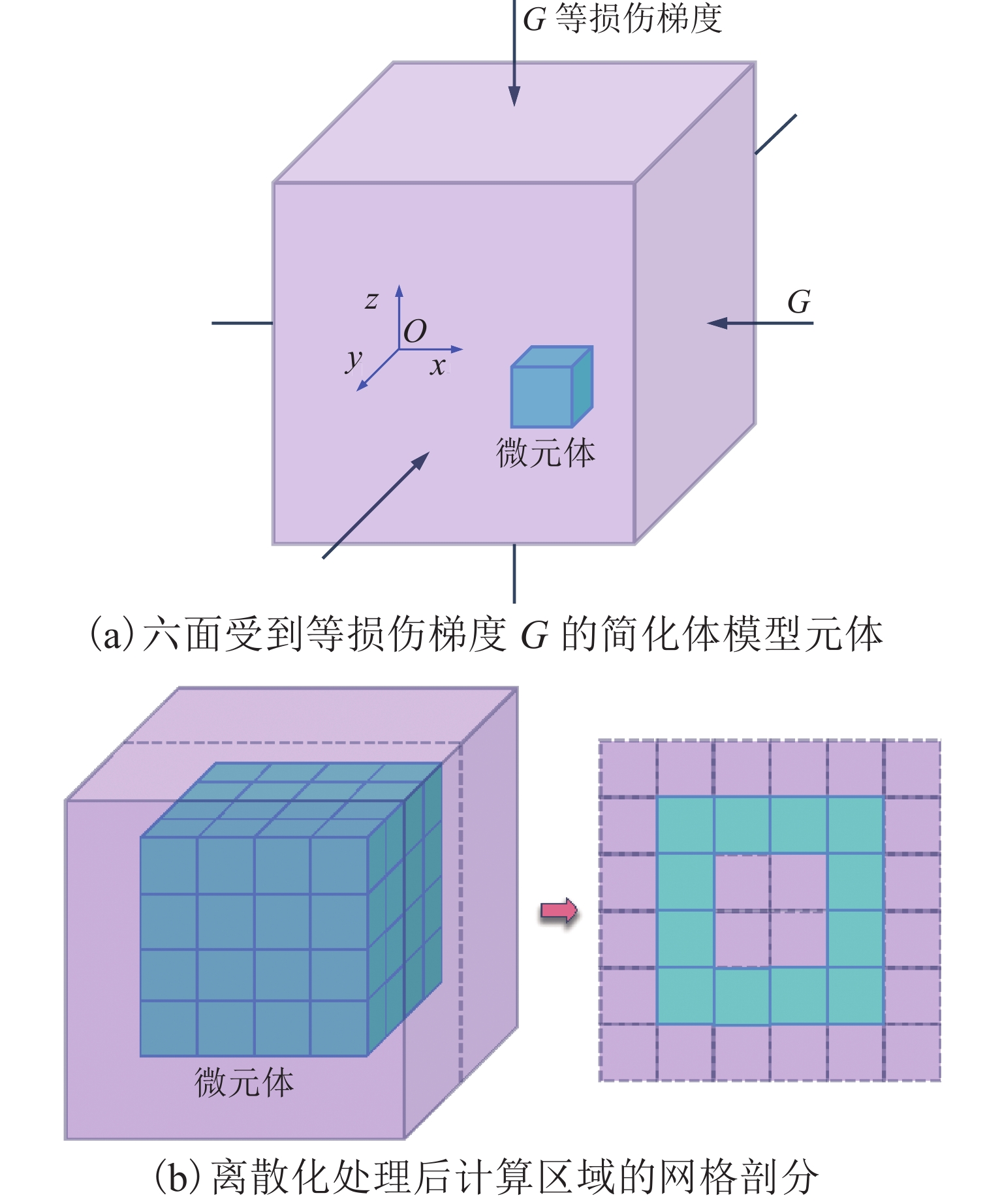

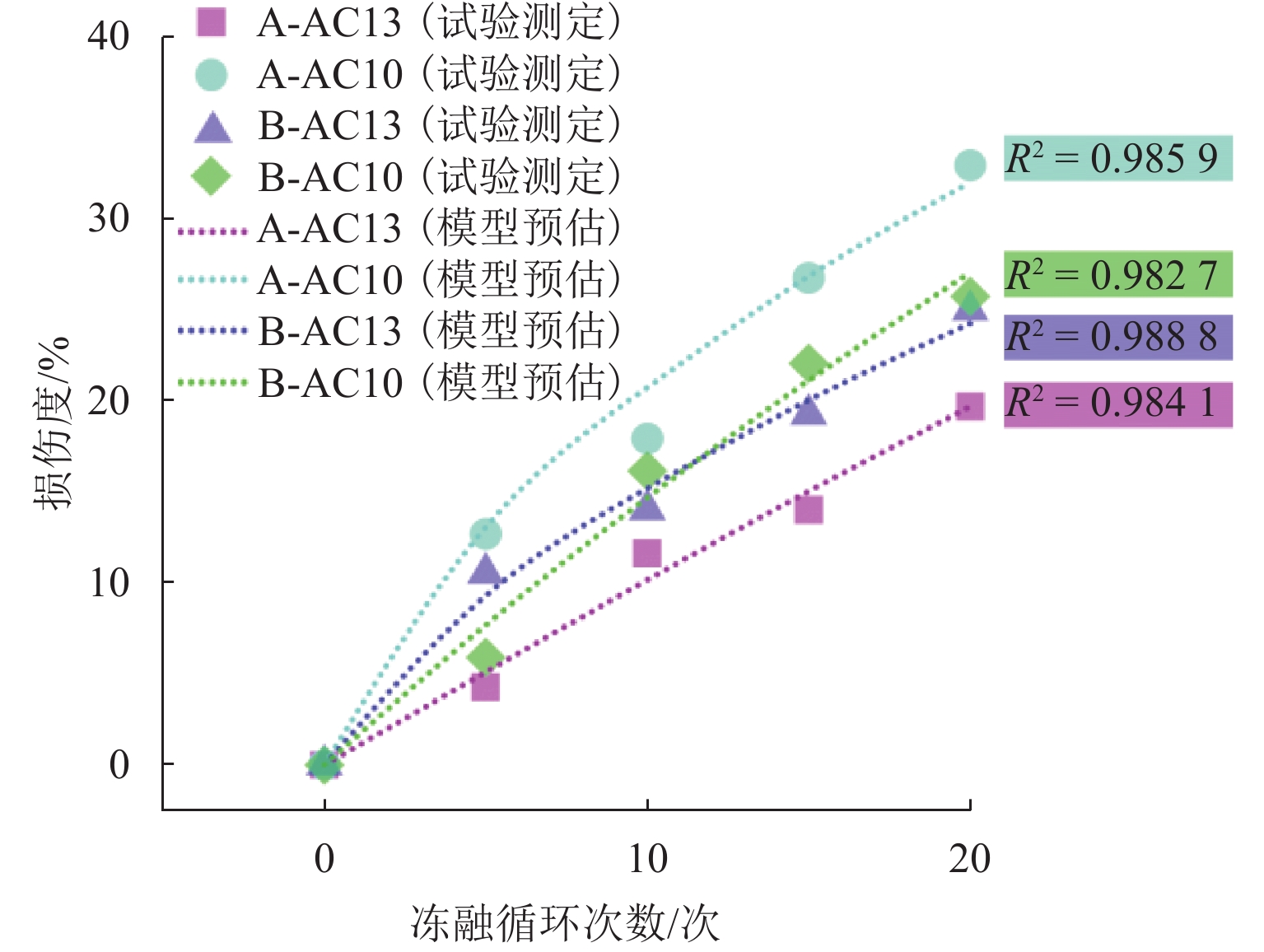

为研究高速铁路防水封闭层用沥青混凝土(简称铁路沥青混凝土)的冻融损伤演化,制备了选用不同沥青和不同目标级配的4种聚合物复合改性铁路沥青混凝土,分析重复冻融循环作用下多温域宏观力学性能的劣化规律. 构建针对冻融损伤演化模型,并对反复冻融循环作用下的损伤度进行计算. 研究发现:4种铁路沥青混凝土在10次冻融循环作用后,各项力学性能指标的残留率均在80%以上;低温断裂能指标对冻融循环次数的增加最为敏感,更能及时反映铁路沥青混凝土的力学性能劣化;基于统计可靠度理论构建的铁路沥青混凝土冻融损伤演化模型的拟合优度值均接近0.99.

Abstract:The freeze-thaw damage evolution of asphalt concrete for waterproofing layer in high-speed railways (shorted as railway asphalt concrete) was investigated. Four kinds of composite polymerized railway asphalt concrete were prepared with different asphalt binders and aggregate gradations, and the deterioration of macro mechanical properties in multiple temperature domains under repeated freeze-thaw cycles was evaluated. Models of freeze-thaw damage evolution for railway asphalt concrete were constructed, and the damage degree under the action of repeated freeze-thaw cycles was calculated. The results show that the retained rate of mechanical properties of the four kinds of railway asphalt concrete is still above 80% after 10 freeze-thaw cycles. The low-temperature fracture energy index is the most sensitive to freeze-thaw cycles, which can timely reflect the deterioration of mechanical properties of railway asphalt concrete. The goodness of fit of all freeze-thaw damage evolution models for railway asphalt concrete that are constructed through statistical reliability theory is nearly 0.99.

-

Key words:

- high-speed railway /

- waterproofing /

- asphalt concrete /

- freeze-thaw cycle /

- damage evolution model

-

表 1 铁路沥青混凝土在冻融循环作用下的多温域力学性能劣化规律

Table 1. Deterioration of mechanical properties of railway asphalt concrete in multiple temperature domains under freeze-thaw cycles

铁路沥青混

凝土类型冻融循环

次数/次高温马歇尔稳定度/kN 中温劈裂强度/MPa 低温 断裂能/(J·m−2) 断裂韧性/(N·mm−1) A-AC13 0 15.17 1.332 1613.31 45.04 5 14.53 1.286 1544.35 43.83 10 12.42 1.204 1425.63 41.79 15 11.41 1.235 1387.06 41.49 20 11.52 1.246 1283.29 41.35 A-AC10 0 16.96 1.370 1775.90 47.77 5 15.23 1.357 1550.55 46.19 10 13.85 1.282 1457.35 46.28 15 13.95 1.317 1300.80 45.26 20 11.95 1.350 1190.75 44.56 B-AC13 0 13.64 1.100 1816.15 50.20 5 12.97 1.020 1624.46 49.80 10 10.36 0.957 1561.45 47.02 15 9.99 0.997 1466.08 47.70 20 9.79 1.021 1362.22 45.66 B-AC10 0 14.76 1.118 2017.68 52.17 5 13.28 1.063 1898.64 48.68 10 11.50 0.986 1691.99 47.22 15 10.76 1.030 1572.85 46.91 20 10.76 1.079 1498.54 48.04 表 2 铁路沥青混凝土冻融损伤演化模型参数拟合结果

Table 2. Fitted parameters of freeze-thaw damage evolution model of railway asphalt concrete

沥青混凝土类型 $ \alpha $ $ {\lambda _0} $ $ \nu $/×10−7 判定系数 A-AC13 1.0327 0.01151 0.1 0.9841 A-AC10 0.7311 0.01359 0.1 0.9859 B-AC13 0.7541 0.00915 0.1 0.9888 B-AC10 0.9902 0.01290 0.1 0.9827 -

[1] LIN Z J, NIU F J, LI X L, et al. Characteristics and controlling factors of frost heave in high-speed railway subgrade, Northwest China[J]. Cold Regions Science and Technology, 2018, 153: 33-44. doi: 10.1016/j.coldregions.2018.05.001 [2] HUANG J J, SU Q A, LIU T, et al. Behavior and control of the ballastless track-subgrade vibration induced by high-speed trains moving on the subgrade bed with mud pumping[J]. Shock and Vibration, 2019, 2019: 1-14. [3] 杨国涛. 高寒地区高速铁路路基基床表层冻胀机理与轨道平顺性控制研究[D]. 北京: 北京交通大学, 2020. [4] XIAO X, CAI D G, LOU L W, et al. Application of asphalt based materials in railway systems: a review[J]. Construction and Building Materials, 2021, 304: 124630.1-124630.22. [5] FANG M J, HU T, ROSE J G. Geometric composition, structural behavior and material design for asphalt trackbed: a review[J]. Construction and Building Materials, 2020, 262: 120755.1-120755.13. [6] CHEN X H, TAO T Q, YANG G T, et al. Long-lasting waterproofing solution for the subgrade of high-speed railway in cold region[J]. Journal of Testing and Evaluation, 2019, 47(3): 20180046.1-20180046.13. [7] LUO Q, FU H, LIU K W, et al. Monitoring of train-induced responses at asphalt support layer of a high-speed ballasted track[J]. Construction and Building Materials, 2021, 298: 123909.1-123909.14. [8] 曾杰. 季冻区沥青混凝土强化基床表层轨下基础结构计算方法与耐久性研究[D]. 成都: 西南交通大学, 2018. [9] 刘亚坤. 季冻区高速铁路无砟轨道沥青混凝土强化基床力学特性研究[D]. 成都: 西南交通大学, 2018. [10] LIU S, YANG J, CHEN X H, et al. Application of mastic asphalt waterproofing layer in high-speed railway track in cold regions[J]. Applied Sciences, 2018, 8(5): 667.1-667.16. [11] YANG E H, WANG K C P, LUO Q A, et al. Asphalt concrete layer to support track slab of high-speed railway[J]. Transportation Research Record: Journal of the Transportation Research Board, 2015, 2505(1): 6-14. doi: 10.3141/2505-02 [12] ZHOU J E, CHEN X H, FU Q H, et al. Dynamic responses of asphalt concrete waterproofing layer in ballastless track[J]. Applied Sciences, 2019, 9(3): 375.1-375.19. [13] XIAO X, LI J, CAI D G, et al. Evolution evaluation of high-speed railway asphalt concrete waterproofing layer during laboratory freeze-thaw cycles[J]. Construction and Building Materials, 2022, 324: 126258.1-126258.12. [14] XU G, ZHOU J, CHEN X H, et al. Temperature features of the asphalt concrete waterproofing layer on high-speed railway in cold regions[J]. Construction and Building Materials, 2021, 305: 124665.1-124665.11. [15] LIU S, CHEN X H, YANG J, et al. Numerical study and in situ measurement of temperature features of asphalt supporting layer in slab track system[J]. Construction and Building Materials, 2020, 233: 117343.1-117343.11. [16] 徐刚. 高速铁路沥青混凝土防水封闭层细观特性演变研究[D]. 南京: 东南大学, 2019. [17] 冷严. 季冻区高速铁路沥青混凝土强化基床表层材料制备技术与综合性能试验研究[D]. 成都: 西南交通大学, 2018. [18] 任敏达,丛林,孙思林,等. 多次孔隙水压作用下沥青混合料性能演化试验[J]. 吉林大学学报(工学版),2021,51(4): 1277-1286. doi: 10.13229/j.cnki.jdxbgxb20200225REN Minda, CONG Lin, SUN Silin, et al. Experiment of performance evolution of asphalt mixtures under multiple pore water pressure cycles[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(4): 1277-1286. doi: 10.13229/j.cnki.jdxbgxb20200225 [19] 中华人民共和国交通运输部. 公路工程沥青及沥青混合料试验规程: JTG E20—2011[S]. 北京: 人民交通出版社, 2011. [20] CHENG Y C, WANG W S, GONG Y F, et al. Comparative study on the damage characteristics of asphalt mixtures reinforced with an eco-friendly basalt fiber under freeze-thaw cycles[J]. Materials, 2018, 11(12): 22488.1-22488.17. [21] 关宇刚,孙伟,缪昌文. 基于可靠度与损伤理论的混凝土寿命预测模型Ⅰ:模型阐述与建立[J]. 硅酸盐学报,2001,29(6): 530-534. doi: 10.3321/j.issn:0454-5648.2001.06.005GUAN Yugang, SUN Wei, MIAO Changwen. One service-life prediction model for the concrete based on the reliability and damage theoriesⅠ: narration and establishment of the model[J]. Journal of the Chinese Ceramic Society, 2001, 29(6): 530-534. doi: 10.3321/j.issn:0454-5648.2001.06.005 [22] 张启鹏,顾兴宇,丁济同,等. 沥青混合料蠕变损伤模型与损伤演化[J]. 交通运输工程学报,2021,21(5): 104-113. doi: 10.19818/j.cnki.1671-1637.2021.05.009ZHANG Qipeng, GU Xingyu, DING Jitong, et al. Creep damage model and damage evolution of asphalt mixtures[J]. Journal of Traffic and Transportation Engineering, 2021, 21(5): 104-113. doi: 10.19818/j.cnki.1671-1637.2021.05.009 [23] 张峰,李术才,李守凯. 混凝土随机冻融损伤三维预测模型[J]. 土木建筑与环境工程,2011,33(1): 31-35,134.ZHANG Feng, LI Shucai, LI Shoukai. Three-dimensional random damage prediction model of concrete caused by freeze-thaw[J]. Journal of Civil, Architectural & Environmental Engineering, 2011, 33(1): 31-35,134. -

下载:

下载: