Investigation of FRP-Confined UHPC Circular Stub Columns Under Axial Compression

-

摘要:

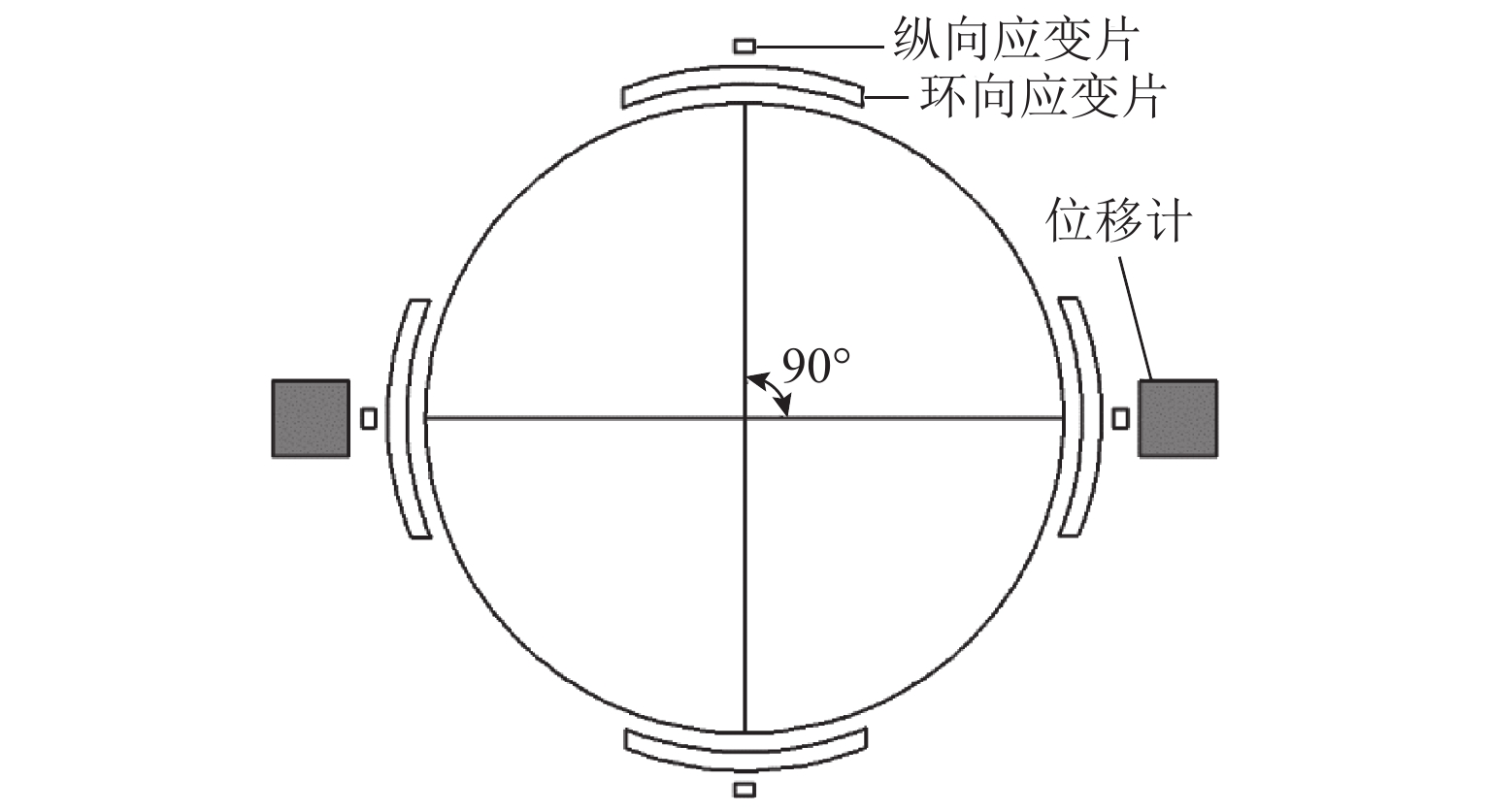

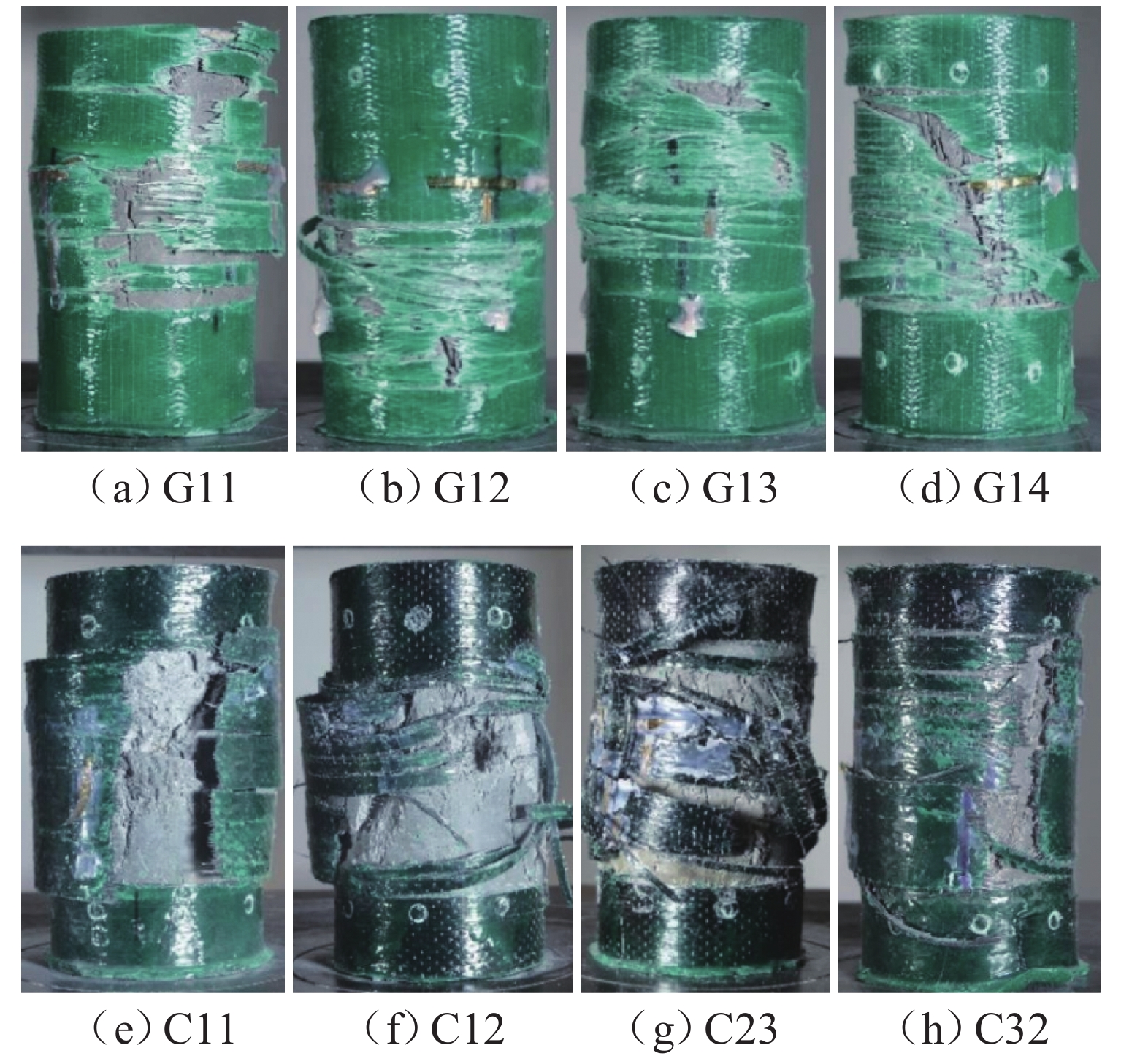

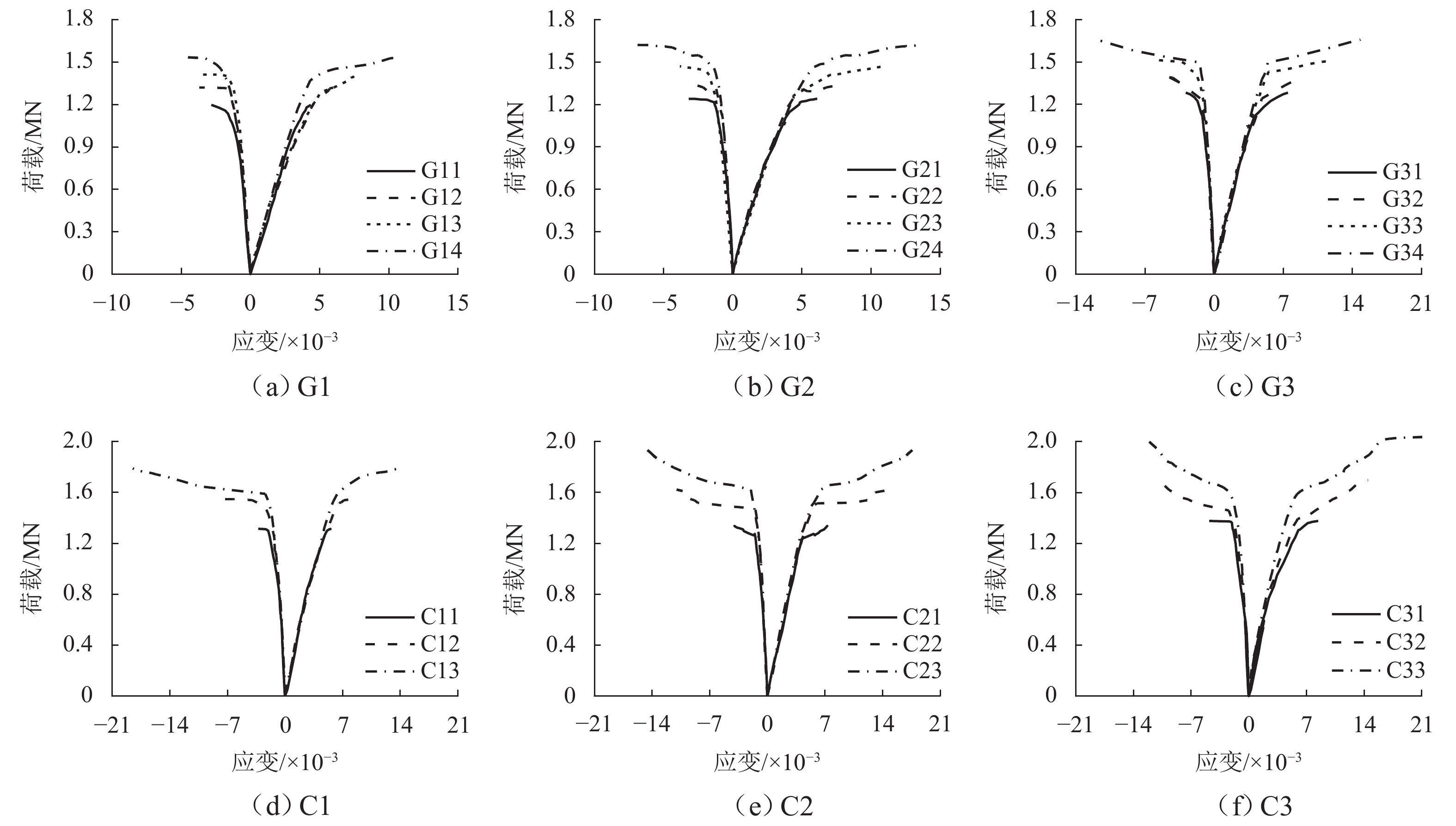

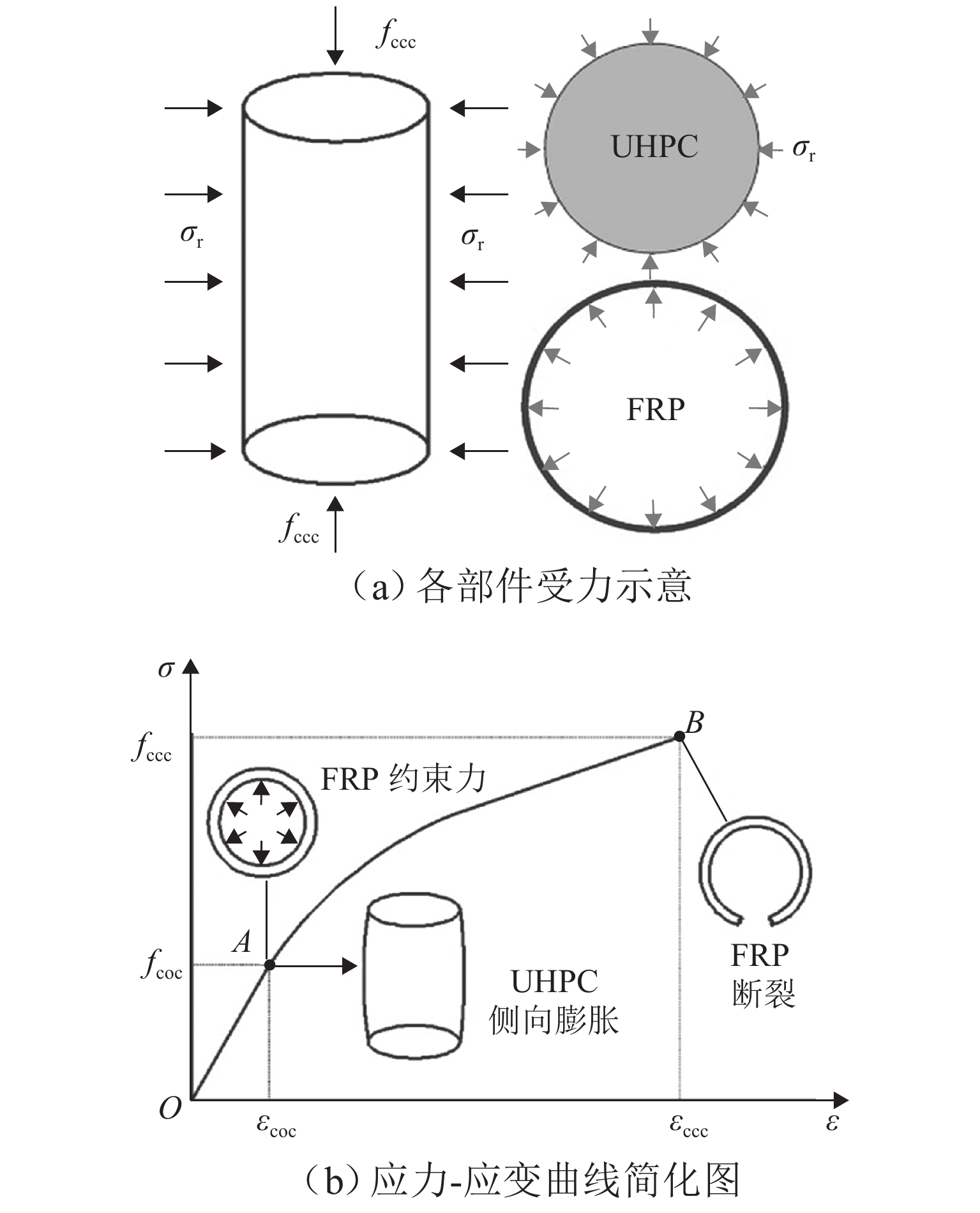

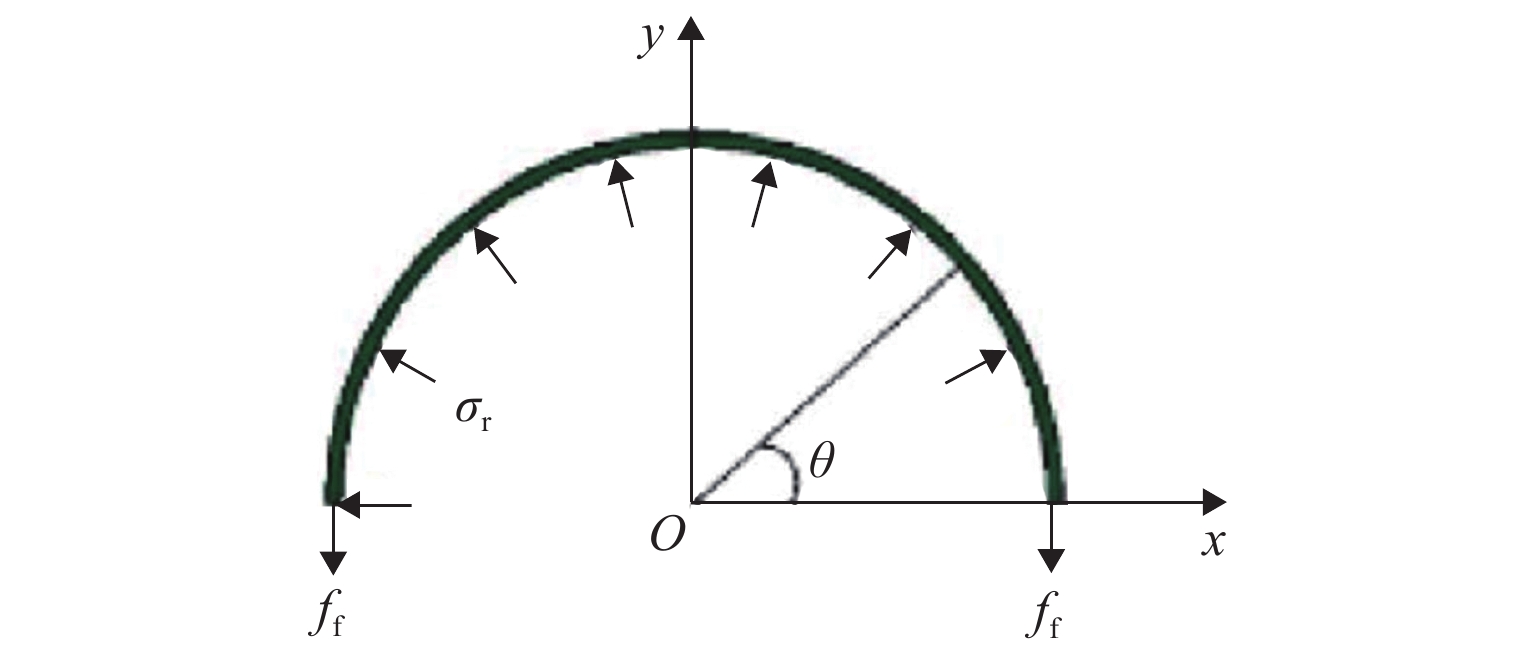

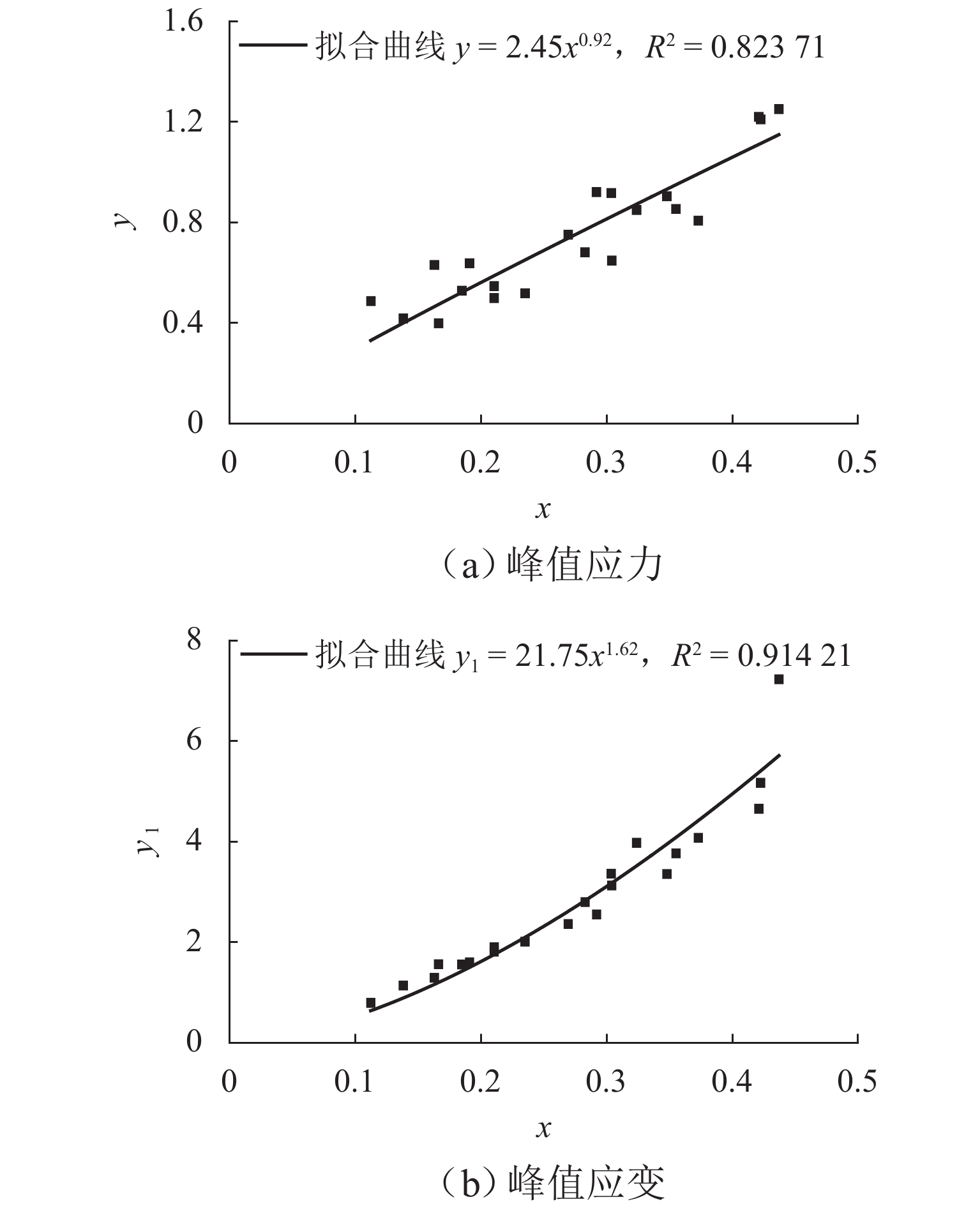

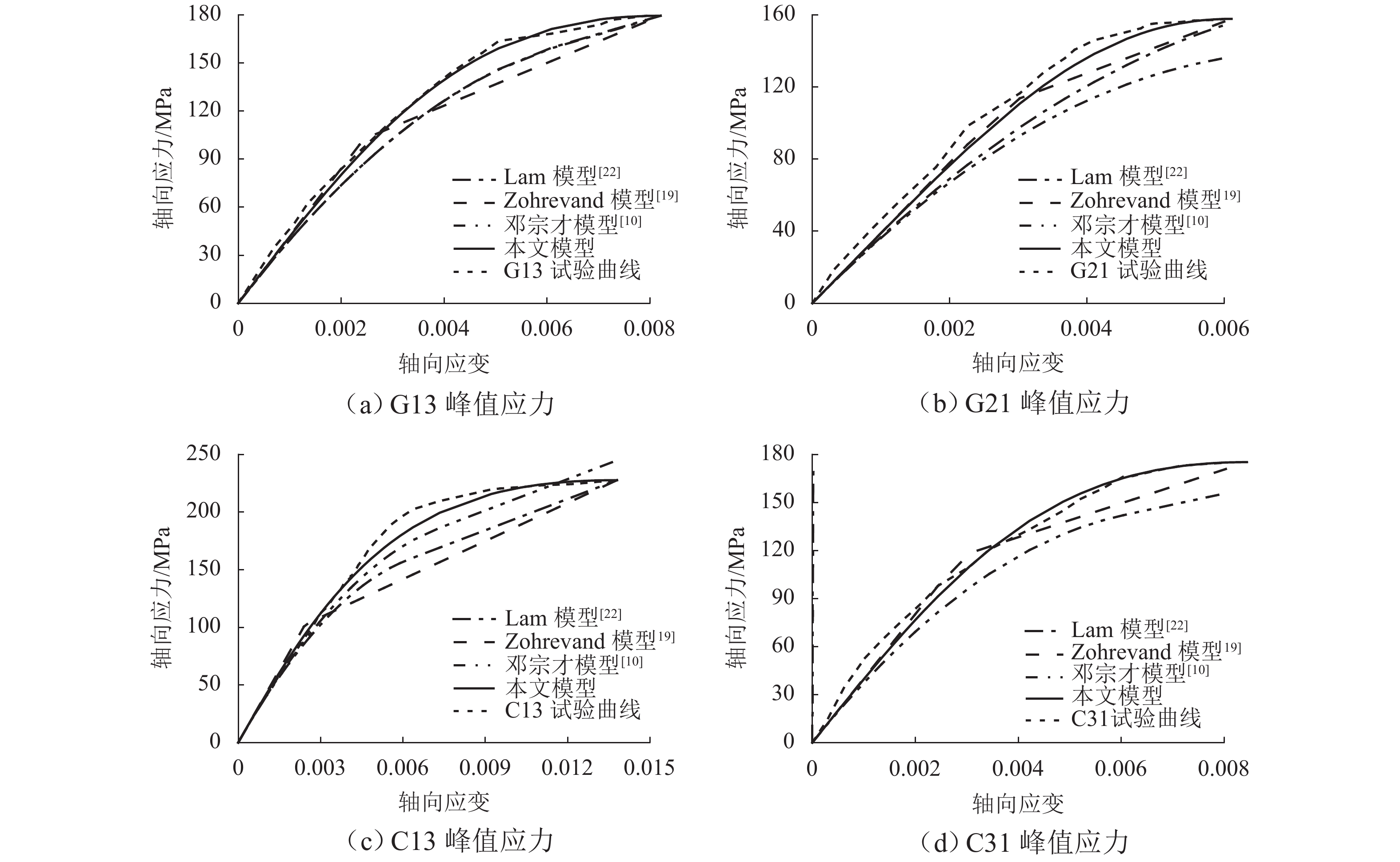

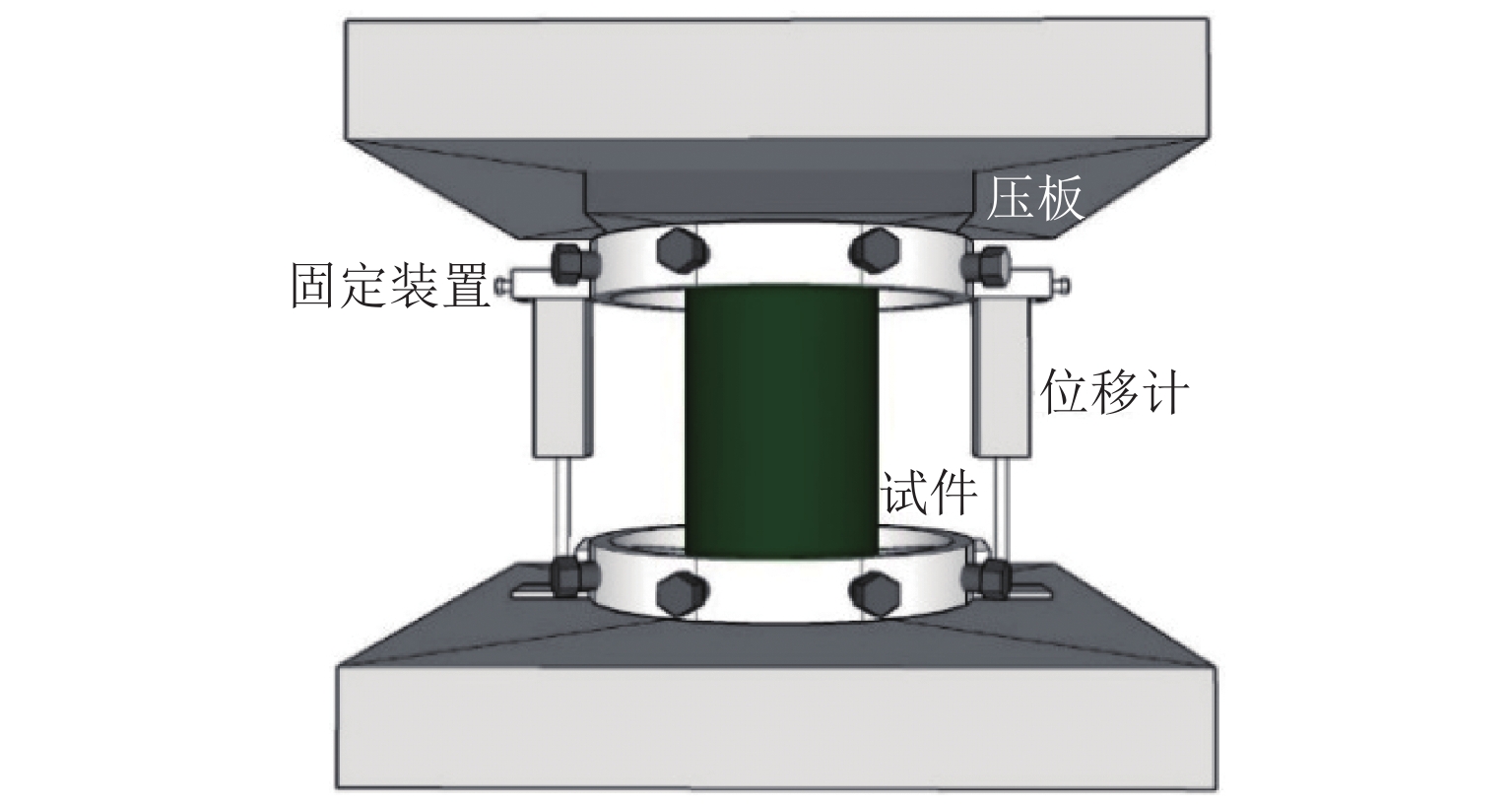

为研究纤维增强复合材料(FRP) 种类、FRP层数和钢纤维体积掺量对超高性能混凝土(UHPC)圆形短柱轴压性能的影响,对21个FRP约束UHPC圆形短柱进行轴心受压试验,分析试件的失效破坏特征及受力机理,研究各参数对试件极限强度和极限应变的影响规律. 研究结果表明:FRP层数的增加可以提高UHPC圆形短柱的极限强度,试件C12、C22、C32的极限强度比C11、C21、C31分别提高了17.8%、25.4%、23.4%;钢纤维体积掺量的增加可以使UHPC圆形短柱的极限强度和极限应变得到提高,并可以在一定程度上改善试件的脆性,试件C31的极限强度和极限应变比试件C21分别提高了2.9%和15.1%,比试件C11分别提高了4.7%和50%;在FRP层数和钢纤维体积掺量相同的情况下,碳纤维增强复合材料(CFRP)对圆形短柱极限强度的改善程度明显优于玻璃纤维增强复合材料(GFRP),试件C11、C12和C13的极限强度比试件G11、G12和G13的分别提高了9.7%、7.8%和7.2%;考虑钢纤维的约束影响,提出FRP约束UHPC圆形短柱的抗压强度和极限应变的计算模型,并进一步给出FRP约束UHPC的本构模型.

Abstract:In order to study the influences of the number of fiber reinforced polymer (FRP) layers, the type of FRP, and the volume of steel fiber on the axial compression performance of ultra-high performance concrete (UHPC) circular stub columns, 21 FRP-confined UHPC circular stub columns were tested under axial compression. The typical failure characteristics and stress mechanism of the specimens were analyzed. In addition, the influence of various parameters on the ultimate strength and ultimate strain of the specimens was studied. The experimental results show that the ultimate strength of UHPC circular stub columns can be improved by increasing the number of FRP layers. The ultimate strength of C12, C22, and C32 is 17.8%, 25.4%, and 23.4% higher than that of C11, C21, and C31, respectively. With the increase in the volume of steel fiber, the ultimate strength and ultimate strain, and the ductility of UHPC circular stub columns are improved. The ultimate strength and ultimate strain of C31 are increased by 2.9% and 15.1%, respectively, compared with C21, as well as 4.7% and 50%, respectively, compared with C11. Under the same FRP layers and volume of steel fiber, the improvement of the ultimate strength of confined UHPC circular stub columns by carbon fiber reinforced polymer (CFRP) is significantly better than that by glass fiber reinforced polymer (GFRP). The ultimate strength of C11, C12, and C13 is 9.7%, 7.8%, and 7.2% higher than that of G11, G12, and G13, respectively. In view of the constraint of the steel fiber, calculation models of compressive strength and ultimate strain of FRP-confined UHPC circular stub columns are proposed. Furthermore, the constitutive model of FRP-confined UHPC is given.

-

表 1 试件编号及试验结果

Table 1. Specimen numbering and experimental results

试件

编号钢纤维掺量/% FRP 层数/层 N/kN ɛy 试件

编号钢纤维掺量/% FRP 层数/层 N/kN ɛy P1 1 805.0 0.0024 G32 3 2 1392.2 0.0088 P2 2 874.2 0.0029 G33 3 3 1511.9 0.0120 P3 3 917.3 0.0029 G34 3 4 1657.5 0.0148 G11 1 1 1197.1 0.0044 C11 1 1 1312.9 0.0056 G12 1 2 1318.1 0.0063 C12 1 2 1546.4 0.0087 G13 1 3 1409.6 0.0082 C13 1 3 1787.3 0.0138 G14 1 4 1532.8 0.0106 C21 2 1 1336.0 0.0073 G21 2 1 1239.3 0.0061 C22 2 2 1675.7 0.0125 G22 2 2 1351.6 0.0080 C23 2 3 1931.9 0.0176 G23 2 3 1469.5 0.0109 C31 3 1 1375.4 0.0084 G24 2 4 1620.4 0.0136 C32 3 2 1696.8 0.0145 G31 3 1 1283.1 0.0075 C33 3 3 2065.1 0.0210 表 2 UHPC的配合比

Table 2. Mix proportion of UHPC

kg/m3 名称 水胶比 水泥 硅灰 石英砂 粉煤灰 配合比 0.15 1.00 0.32 1.46 0.30 表 3 FRP的性能指标

Table 3. Performance index of FRP

型号 抗拉强度/MPa 弹性模量/GPa 伸长率/% GFRP 2381 114 2.7 CFRP 3961 240 1.8 表 4 试件极限强度和极限应变计算值与试验值对比

Table 4. Comparison between calculated and test results of ultimate strength and ultimate strain of specimens

参考文献 试件编号 Vf/% fcc/MPa ɛcc fccc/MPa ɛccc fccc/fcc ɛccc/ɛcc 文献[10] 2 130.7 0.0078 175.2 0.0082 1.340 1.047 2 180.8 0.0116 217.2 0.0155 1.201 1.332 2 148.8 0.0073 185.3 0.0097 1.245 1.325 2 162.3 0.0094 211.1 0.0102 1.301 1.085 2 156.5 0.0065 172.7 0.0078 1.103 1.202 2 191.4 0.0104 211.8 0.0144 1.107 1.382 文献[19] 2 226.6 0.0086 264.8 0.0075 1.168 0.874 2 273.5 0.0106 281.8 0.0090 1.030 0.853 2 298.9 0.0115 298.2 0.0107 0.998 0.934 2 254.1 0.0068 267.4 0.0077 1.052 1.138 2 372.2 0.0105 319.7 0.0133 0.859 1.263 文献[20] UHPC-1C 1 168.0 0.0068 178.1 0.0057 1.060 0.836 UHPC-2C 1 180.8 0.0073 194.2 0.0071 1.074 0.970 UHPC-3G 1 171.5 0.0076 195.0 0.0072 1.137 0.942 UHPC-5G 1 182.0 0.0073 214.5 0.0094 1.178 1.291 -

[1] MONALDO E, NERILLI F, VAIRO G. Basalt-based fiber-reinforced materials and structural applications in civil engineering[J]. Composite Structures, 2019, 214: 246-263. doi: 10.1016/j.compstruct.2019.02.002 [2] 闫清峰,张纪刚. 纤维增强复合材料在土木工程中的应用与发展[J]. 科学技术与工程,2021,21(36): 15314-15322. doi: 10.3969/j.issn.1671-1815.2021.36.003YAN Qingfeng, ZHANG Jigang. Applications and development of fiber reinforced polymer in civil engineering[J]. Science Technology and Engineering, 2021, 21(36): 15314-15322. doi: 10.3969/j.issn.1671-1815.2021.36.003 [3] 王晖. 超高性能混凝土(UHPC)研究综述[J]. 混凝土与水泥制品,2022(4): 25-28.WANG Hui. Review of research on ultra-high performance concrete[J]. China Concrete and Cement Products, 2022(4): 25-28. [4] 张云升,张文华,陈振宇. 综论超高性能混凝土:设计制备·微观结构·力学与耐久性·工程应用[J]. 材料导报,2017,31(23): 1-16. doi: 10.11896/j.issn.1005-023X.2017.023.001ZHANG Yunsheng, ZHANG Wenhua, CHEN Zhenyu. A complete review of ultra-high performance concrete: design and preparation, microstructure, mechanics and durability, engineering applications[J]. Materials Review, 2017, 31(23): 1-16. doi: 10.11896/j.issn.1005-023X.2017.023.001 [5] 梁旭宇,池寅,曾彦钦,等. GFRP管约束超高性能混凝土单轴受压应力-应变关系试验研究[J]. 武汉大学学报(工学版),2020,53(6): 498-506.LIANG Xuyu, CHI Yin, ZENG Yanqin, et al. Experimental studies on stress-strain relationship of ultra-high performance concrete confined by GFRP tube under uniaxial compression[J]. Engineering Journal of Wuhan University, 2020, 53(6): 498-506. [6] LAM L, HUANG L, XIE J H, et al. Compressive behavior of ultra-high performance concrete confined with FRP[J]. Composite Structures, 2021, 274: 114321.1-114321.15. doi: 10.1016/j.compstruct.2021.114321 [7] GULER S. Axial behavior of FRP-wrapped circular ultra-high performance concrete specimens[J]. Structural Engineering and Mechanics, 2014, 50(6): 709-722. doi: 10.12989/sem.2014.50.6.709 [8] WANG W Q, WU C Q, LIU Z X, et al. Compressive behavior of ultra-high performance fiber-reinforced concrete (UHPFRC) confined with FRP[J]. Composite Structures, 2018, 204: 419-437. doi: 10.1016/j.compstruct.2018.07.102 [9] 邓宗才,刘少新. FRP管约束超高性能混凝土的试验及理论研究[J]. 应用基础与工程科学学报,2016,24(4): 792-803.DENG Zongcai, LIU Shaoxin. Test and modeling of ultra-high performance concrete confined by fiber reinforced polymer tube[J]. Journal of Basic Science and Engineering, 2016, 24(4): 792-803. [10] 邓宗才,王义超. FRP约束超高性能混凝土圆柱轴压本构模型[J]. 西南交通大学学报,2015,50(4): 641-647. doi: 10.3969/j.issn.0258-2724.2015.04.011DENG Zongcai, WANG Yichao. Axial compression stress-strain model for UHPC cylinders confined by FRP[J]. Journal of Southwest Jiaotong University, 2015, 50(4): 641-647. doi: 10.3969/j.issn.0258-2724.2015.04.011 [11] 黄美珍. 基于细观力学方法的超高性能混凝土轴压本构模型研究[D]. 福州: 福州大学, 2019. [12] 田会文,周臻,陆纪平,等. 纤维增强树脂复合材料约束超高性能混凝土轴压性能的细观数值模拟[J]. 复合材料学报,2020,37(7): 1629-1638.TIAN Huiwen, ZHOU Zhen, LU Jiping, et al. Meso-scale numerical simulation of axial compression performance of fiber reinforced polymer composite-confined ultra-high performance concrete[J]. Acta Materiae Compositae Sinica, 2020, 37(7): 1629-1638. [13] 上海市建筑科学研究院有限公司. 超高性能混凝土试验方法标准: T/CECS864—2021[S]. 北京:中国建筑工业出版社, 2021. [14] 中华人民共和国建设部. 普通混凝土拌合物性能试验方法标准: GB/T 50080—2016[S]. 北京: 中国建筑工业出版社, 2016. [15] 曹玉贵,李龙龙,谯理格. FRP约束橡胶混凝土的轴心受压承载力分析[J]. 江苏大学学报(自然科学版),2021,42(5): 616-620.CAO Yugui, LI Longlong, QIAO Lige. Analysis of axial compressive bearing capacity of FRP confined rubber concrete[J]. Journal of Jiangsu University (Natural Science Edition), 2021, 42(5): 616-620. [16] 李稳. FRP-混凝土界面破坏行为的断裂力学分析[D]. 广州: 华南理工大学, 2020. [17] TANG W S, LIU Z Z, LU Y Y, et al. Hybrid confinement mechanism of large-small rupture strain FRP on concrete cylinder[J]. Journal of Building Engineering, 2022, 51: 104335.1-104335.20. [18] HOSINIEH M M, AOUDE H, COOK W D, et al. Behavior of ultra-high performance fiber reinforced concrete columns under pure axial loading[J]. Engineering Structures, 2015, 99: 388-401. doi: 10.1016/j.engstruct.2015.05.009 [19] ZOHREVAND P, MIRMIRAN A. Stress-strain model of ultrahigh performance concrete confined by fiber-reinforced polymers[J]. Journal of Materials in Civil Engineering, 2013, 25(12): 1822-1829. doi: 10.1061/(ASCE)MT.1943-5533.0000769 [20] 安凯旋,王旭月,刘中宪,等. 纤维布约束超高性能混凝土短柱轴压性能[J]. 建筑结构,2021,51(11): 129-135.AN Kaixuan, WANG Xuyue, LIU Zhongxian, et al. Study on axial compression performance research on UHPC short columns confined by fiber reinforced polymer[J]. Building Structure, 2021, 51(11): 129-135. [21] MANDER J B, PRIESTLEY M J N, PARK R. Theoretical stress-strain model for confined concrete[J]. Journal of Structural Engineering, 1988, 114(8): 1804-1826. doi: 10.1061/(ASCE)0733-9445(1988)114:8(1804) [22] LAM L, TENG J G. Design-oriented stress-strain model for FRP-confined concrete[J]. Construction and Building Materials, 2003, 17(6/7): 471-489. -

下载:

下载: