Fatigue Properties and Life Prediction of Ultrasonic Rolling EA4T Axle Steel

-

摘要:

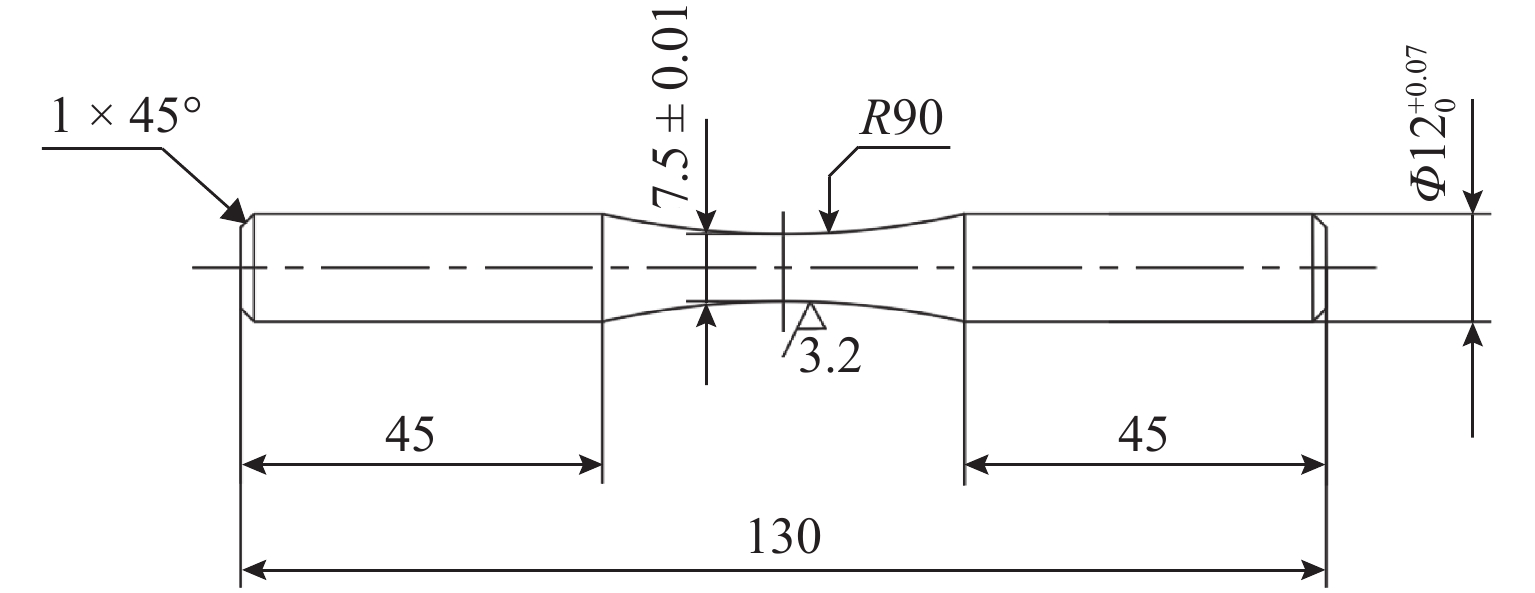

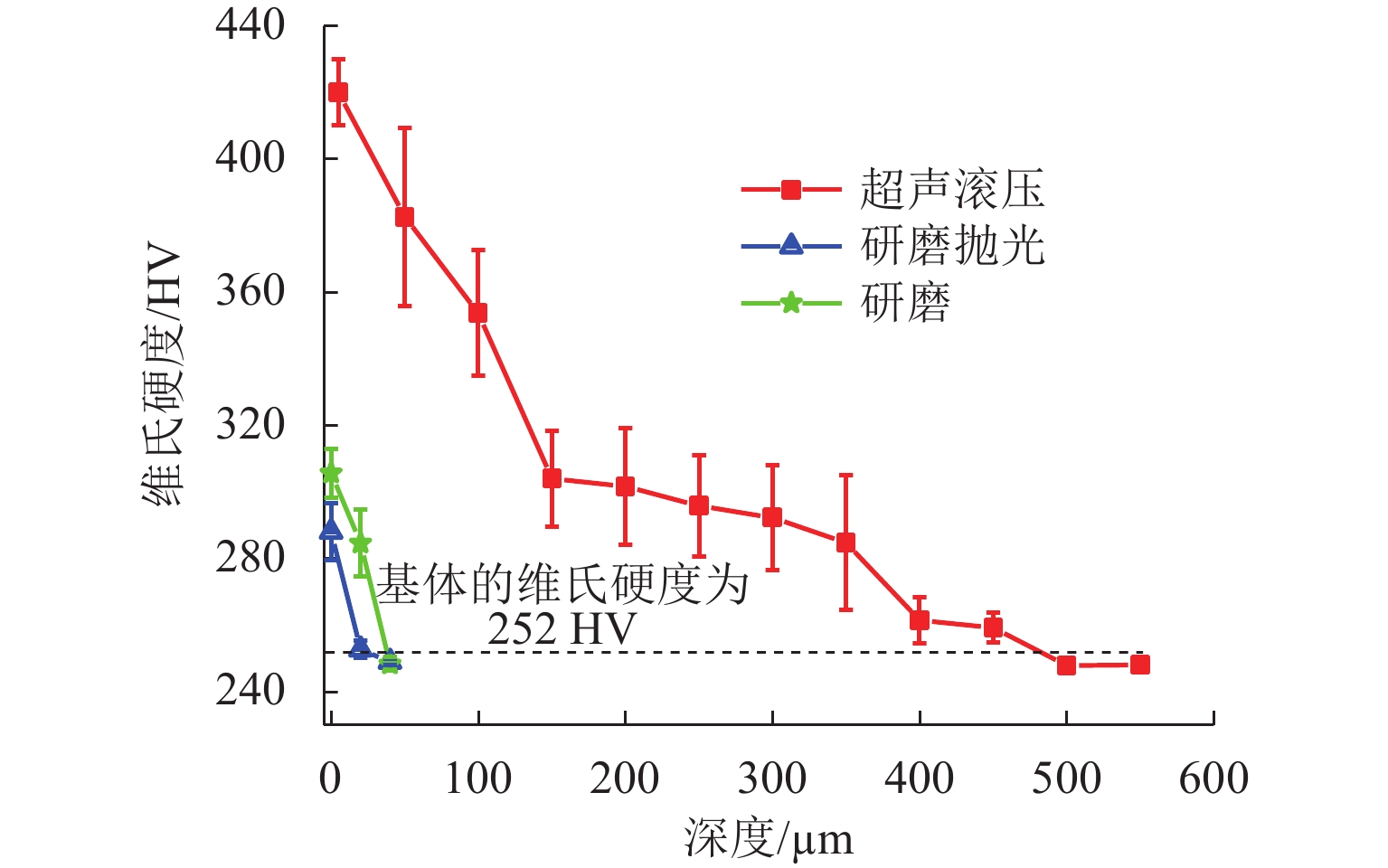

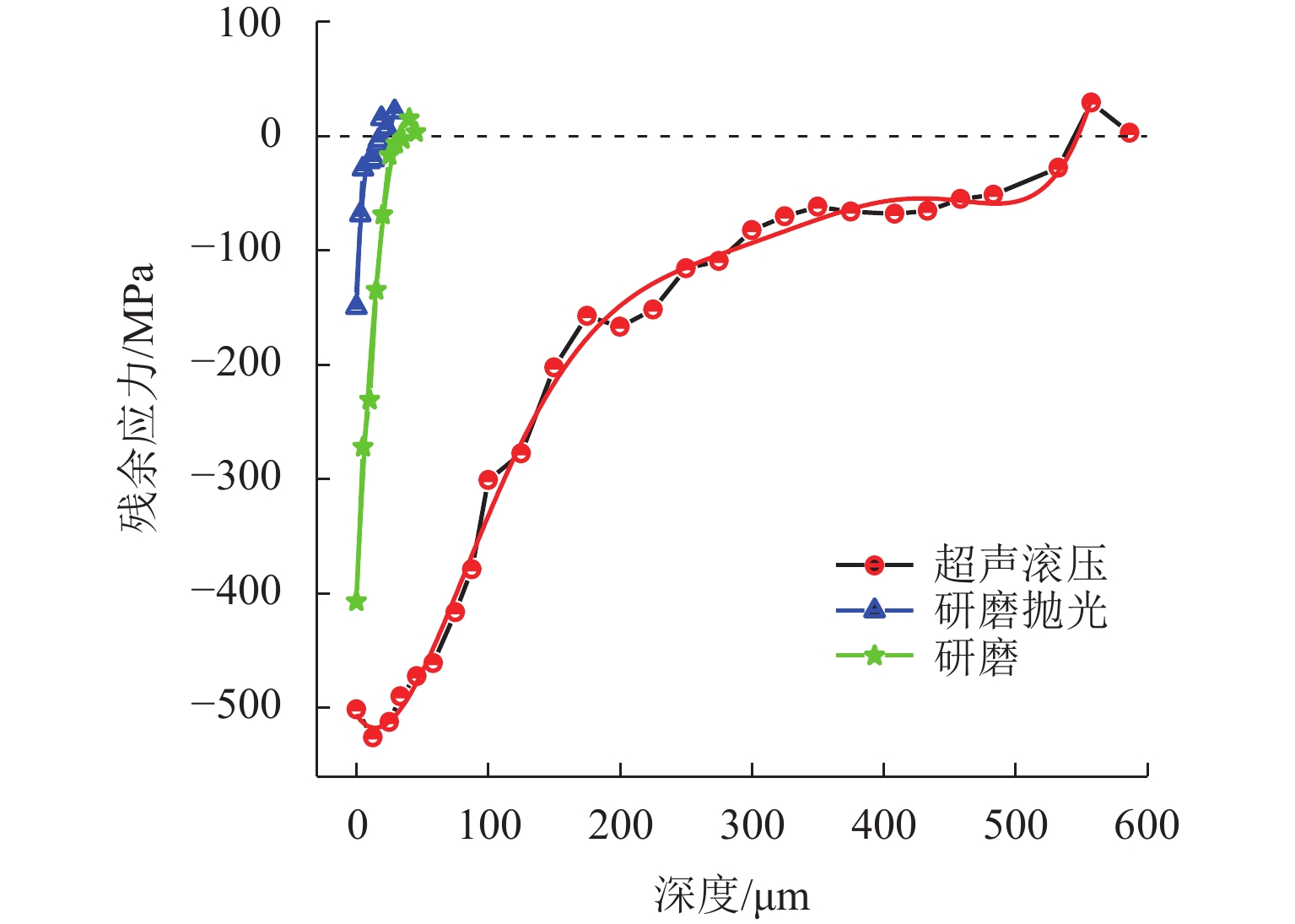

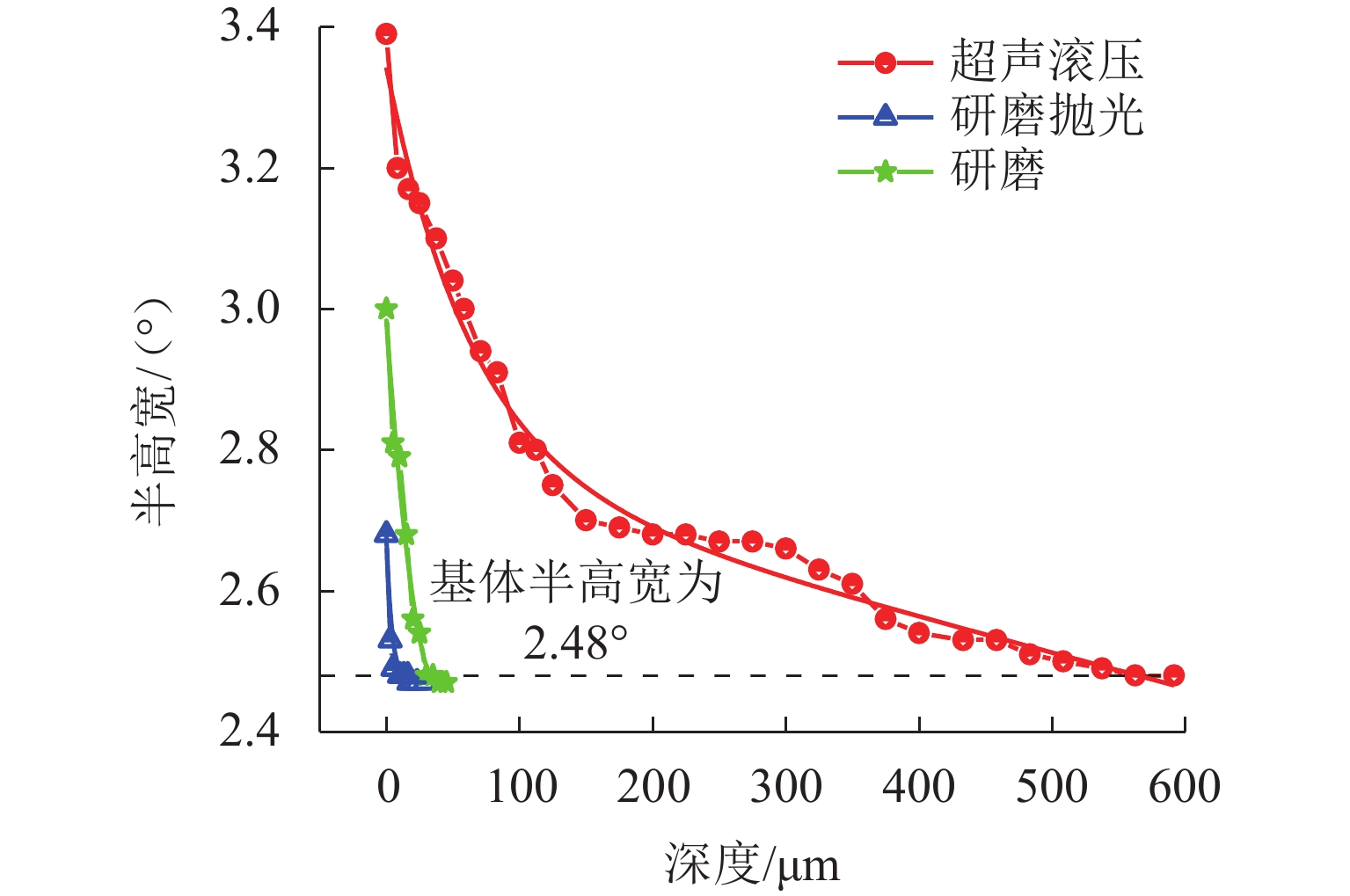

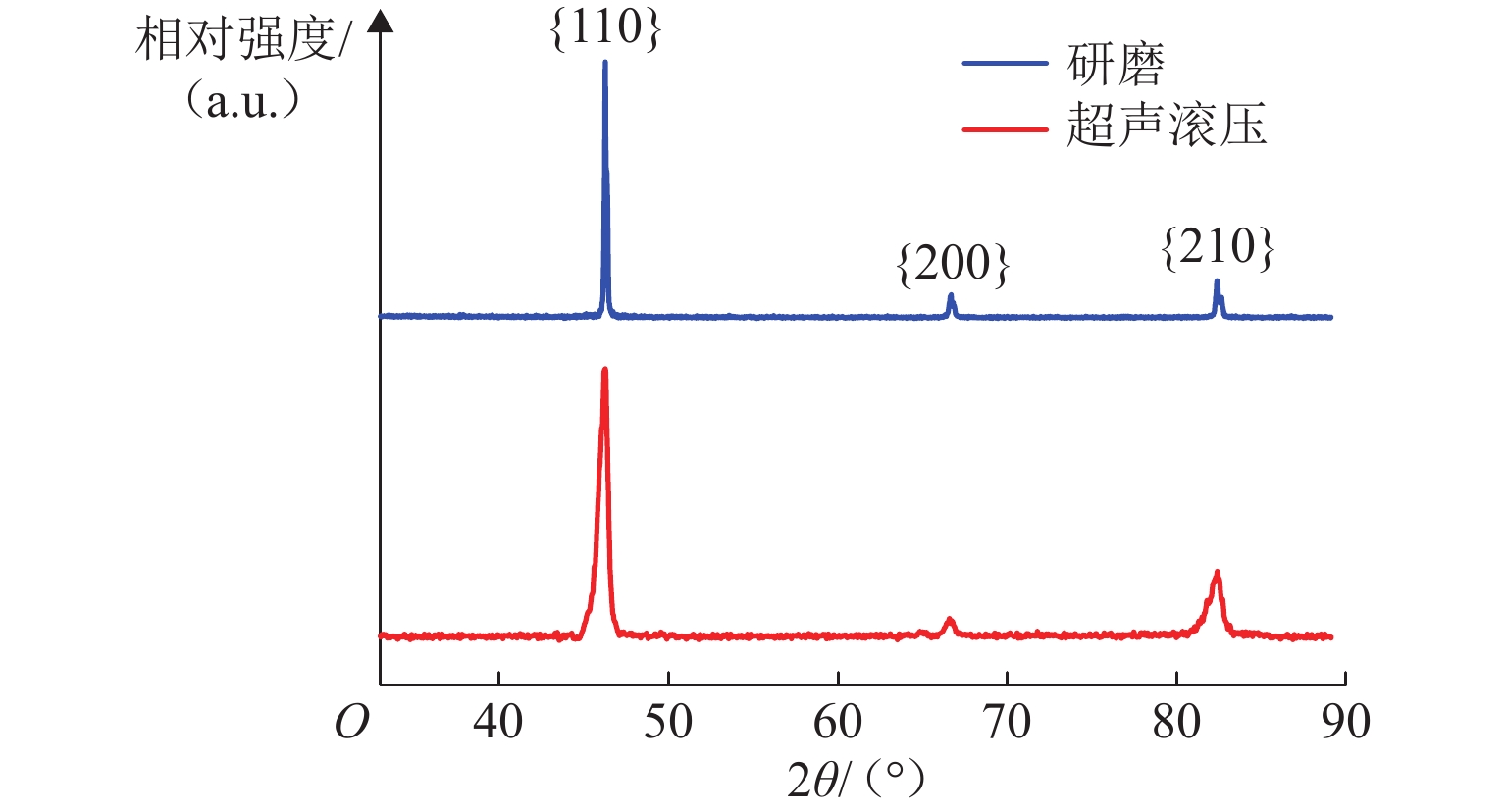

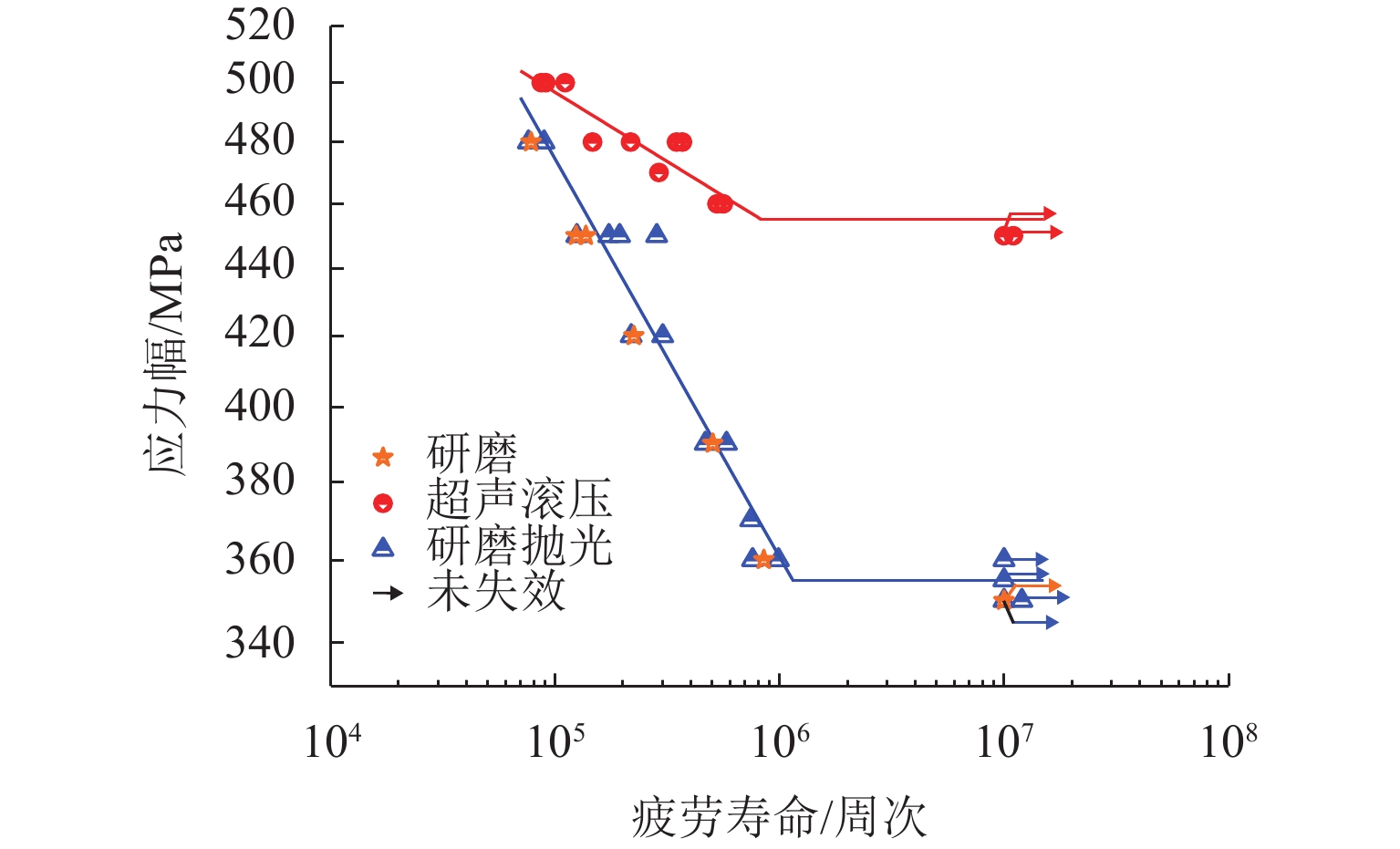

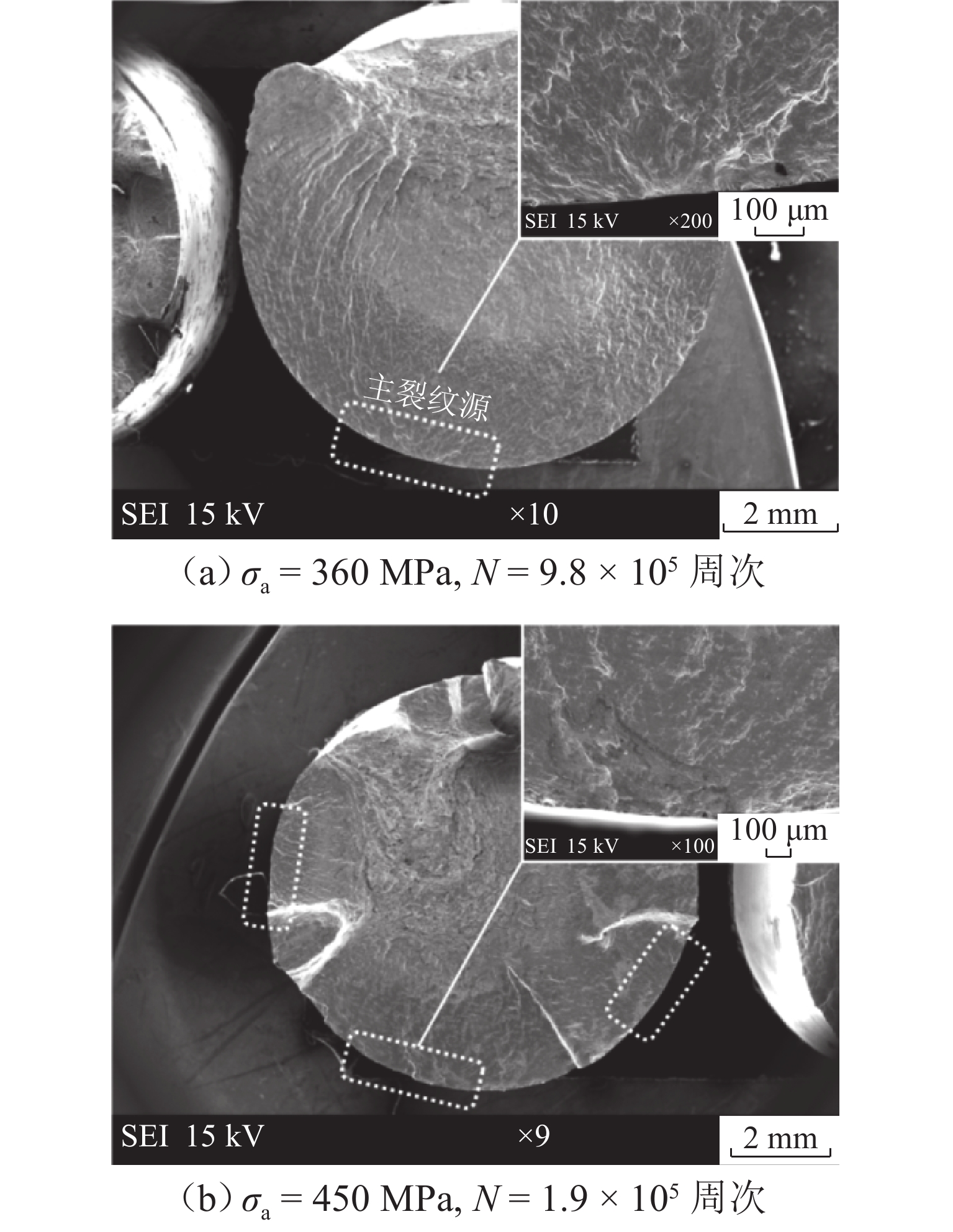

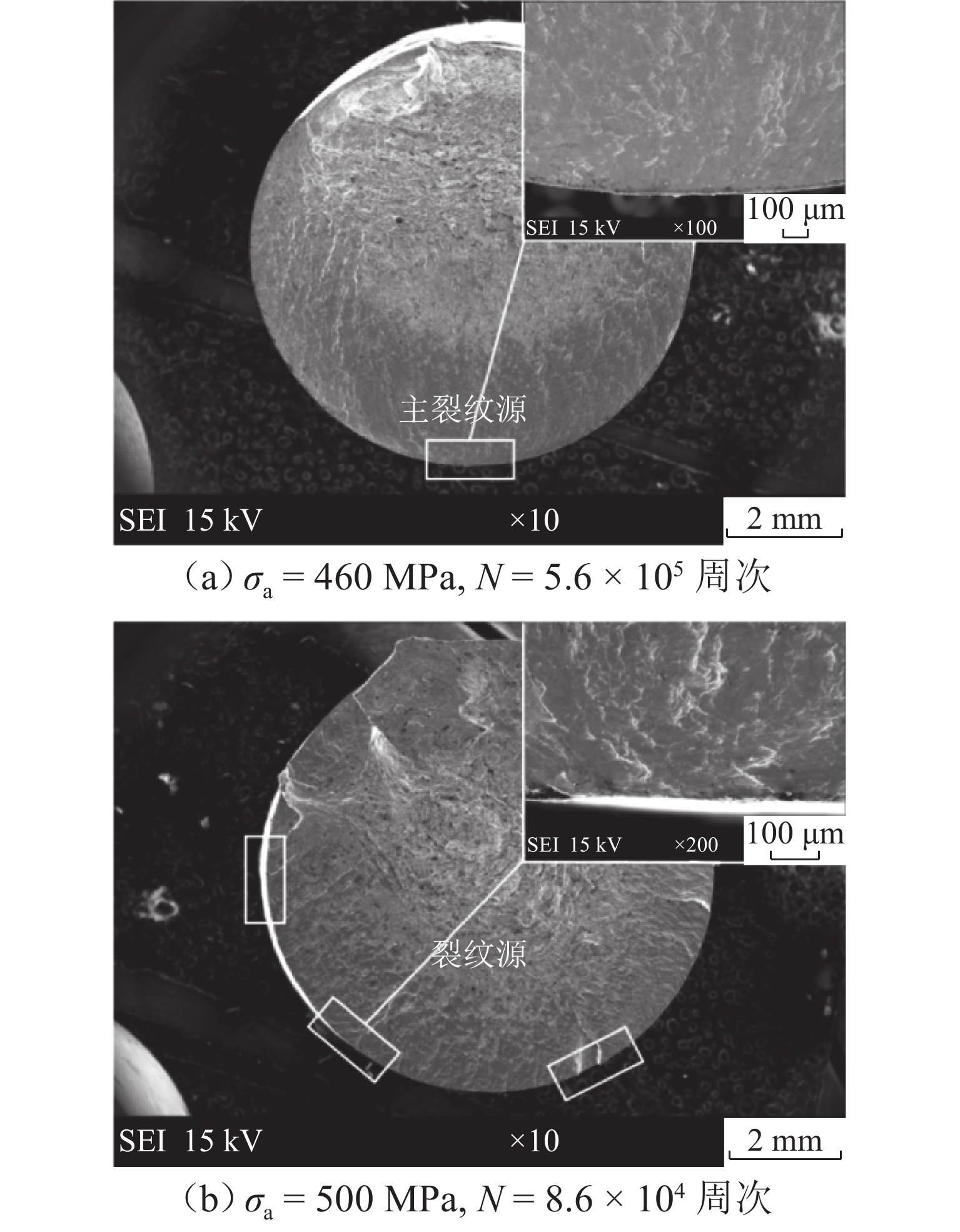

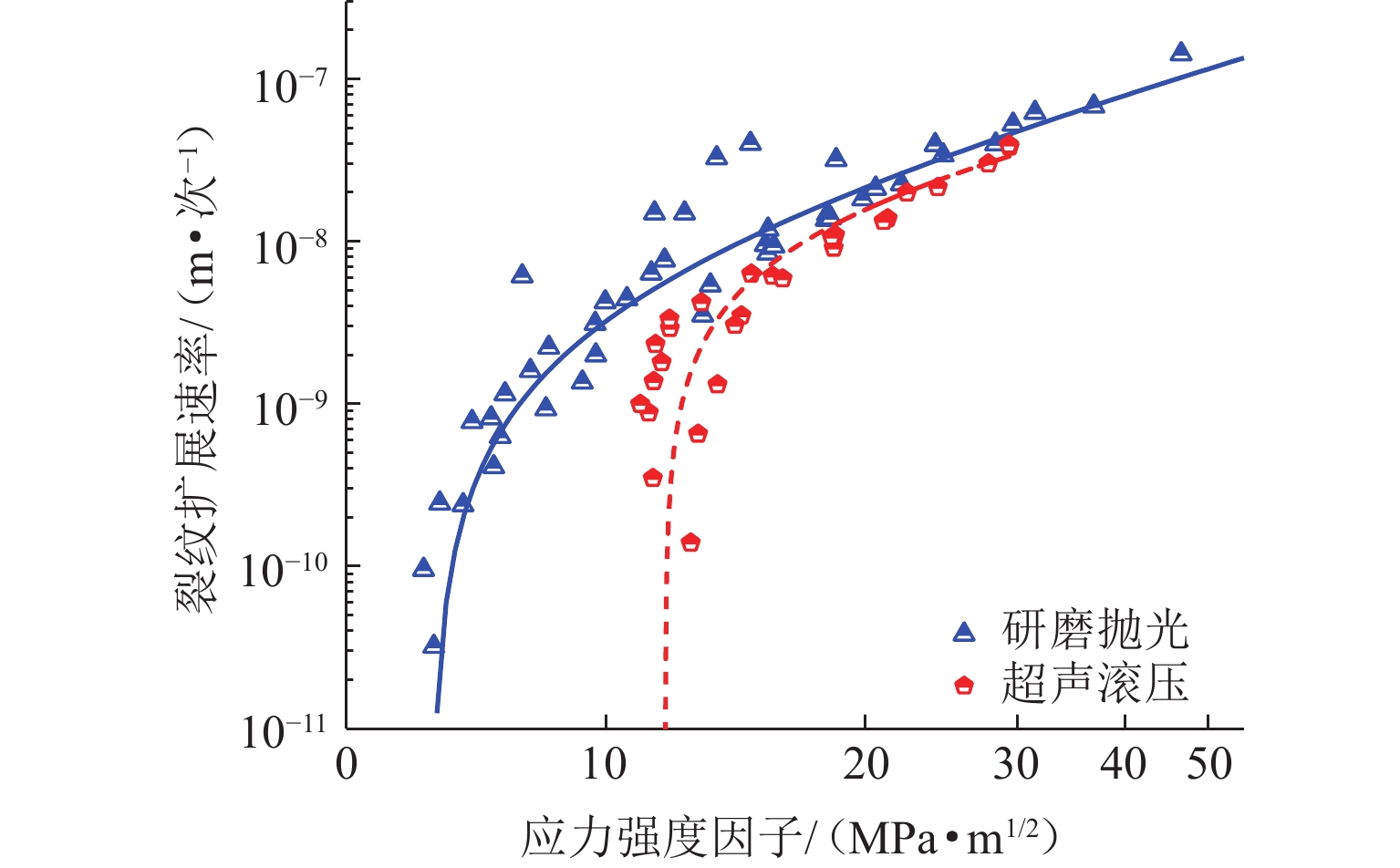

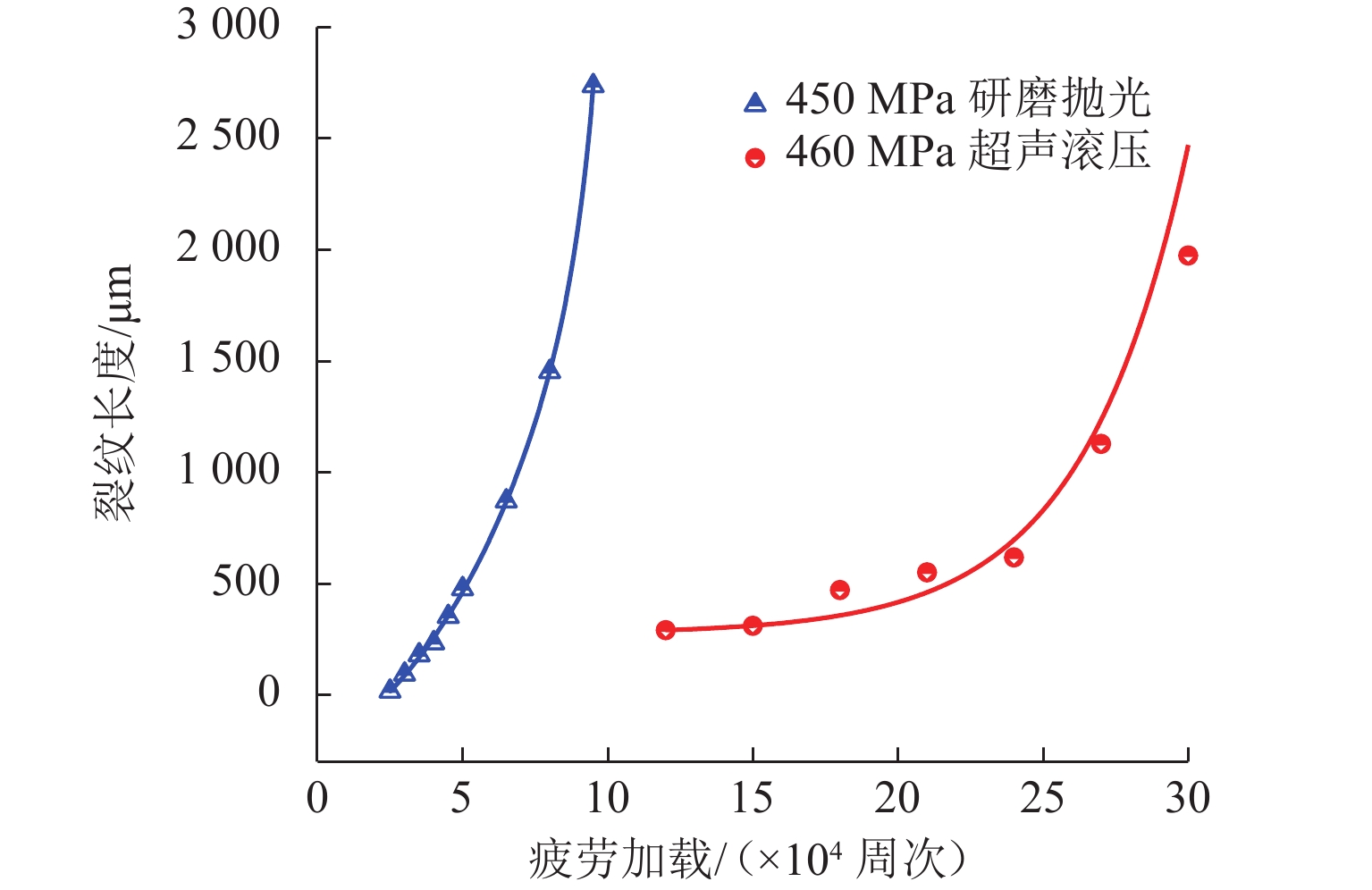

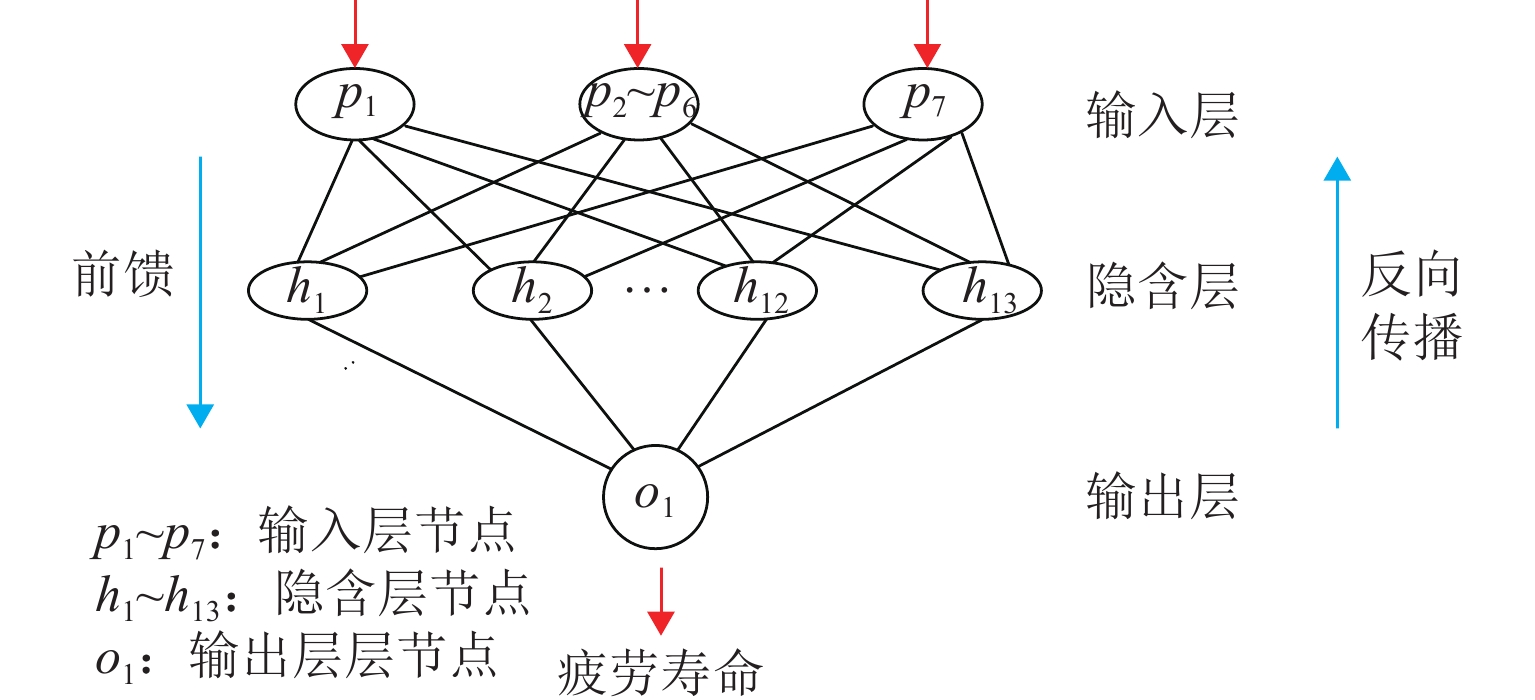

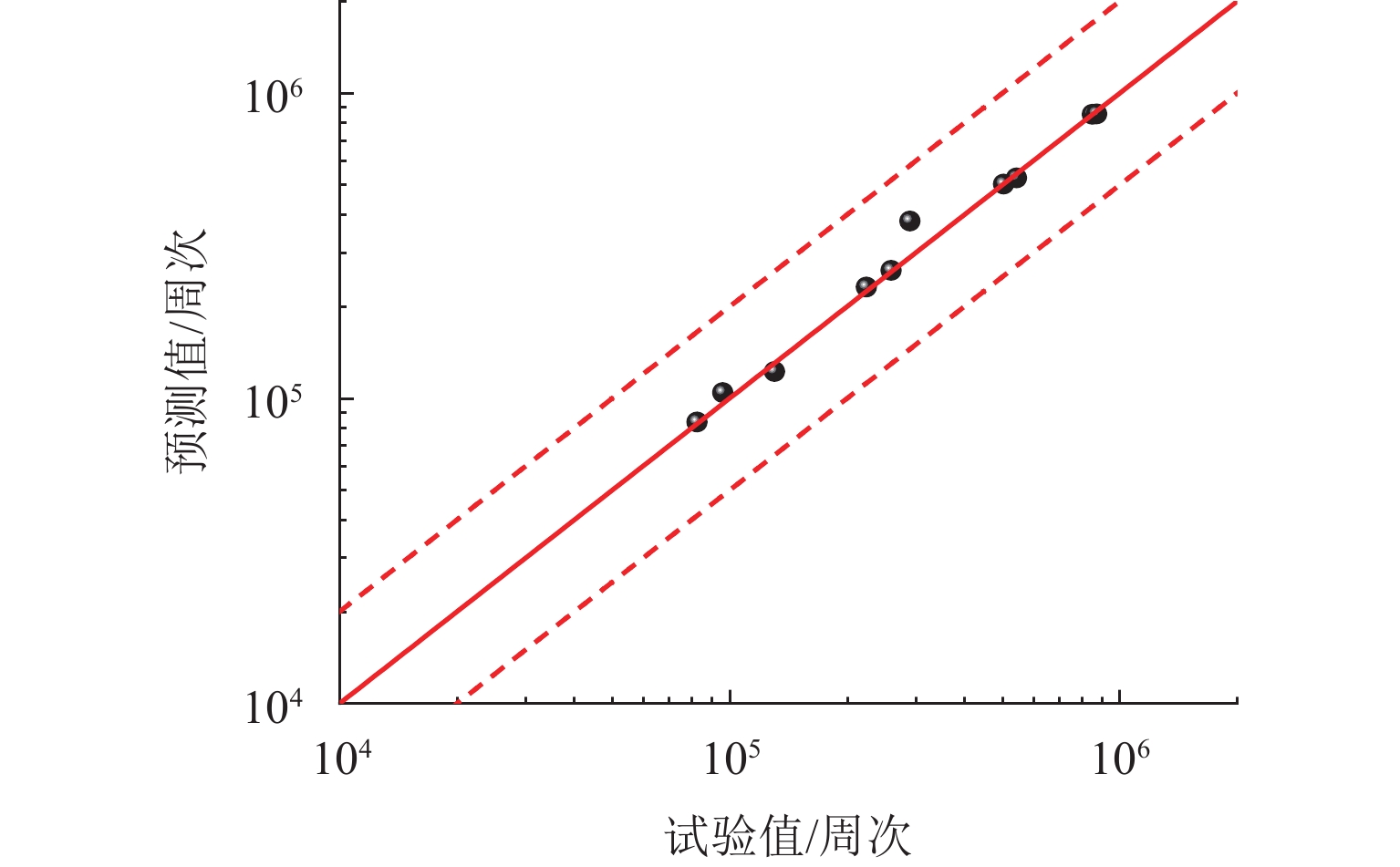

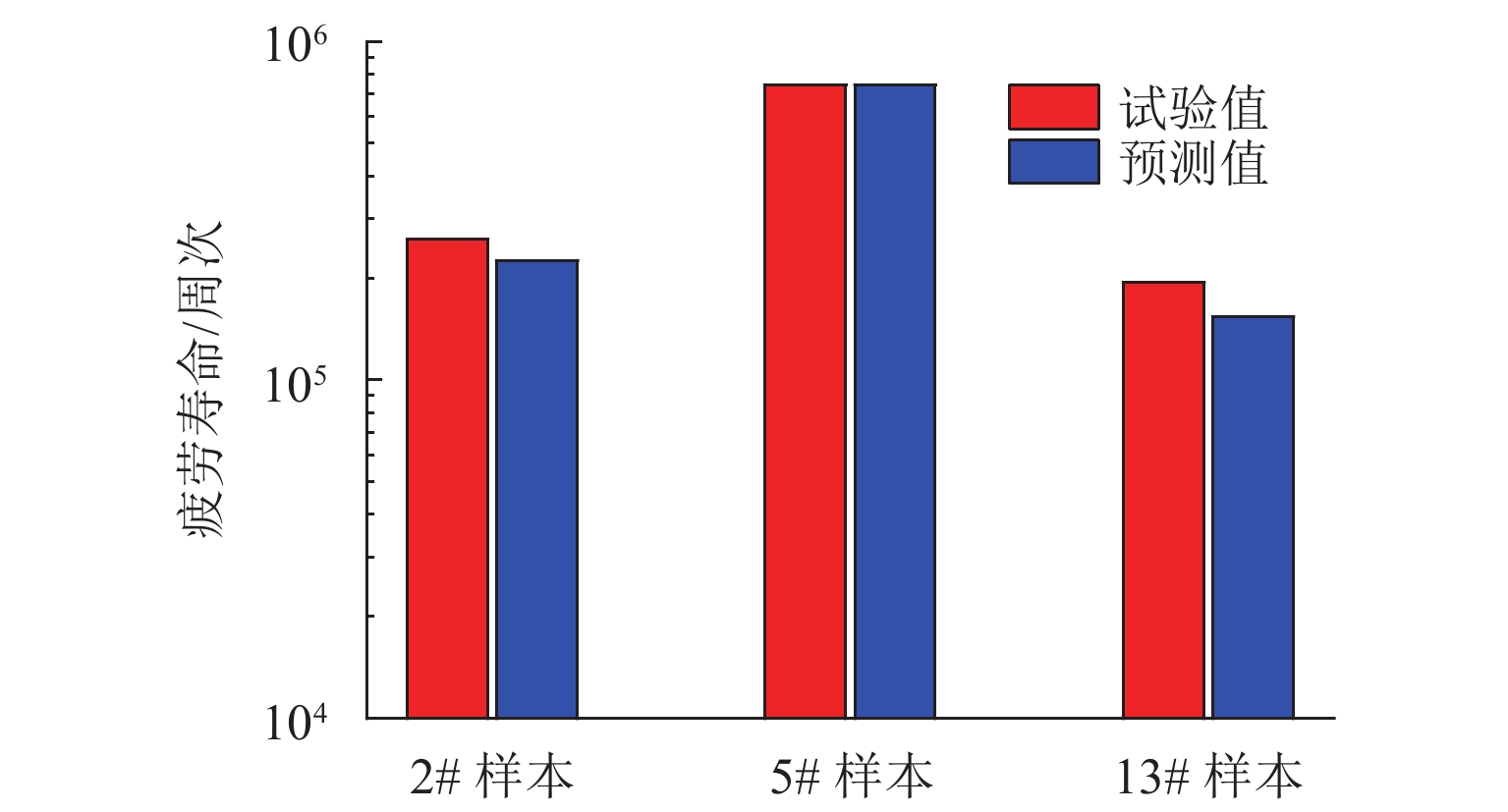

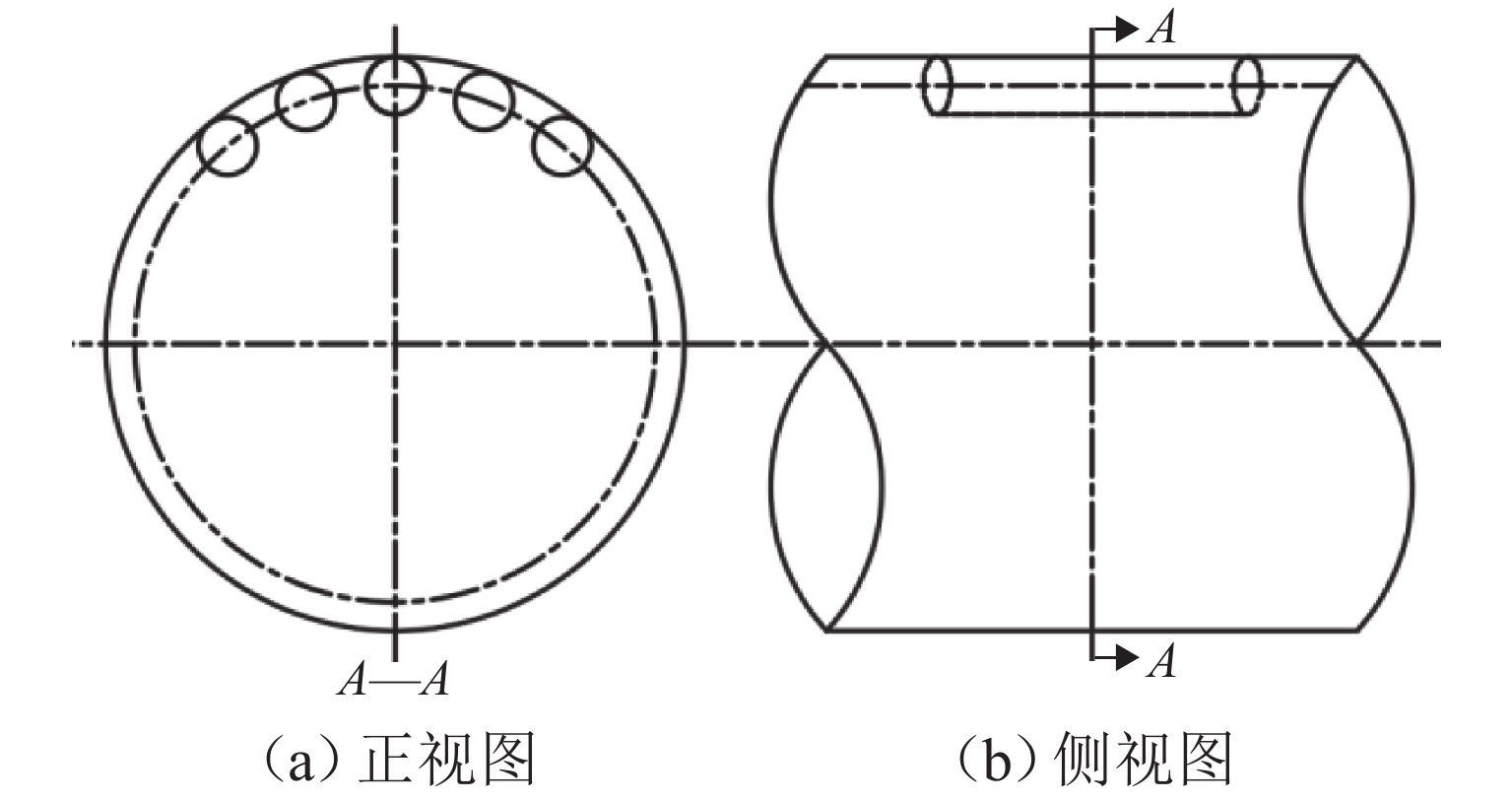

为研究表面超声滚压(SURP)处理对EA4T车轴钢疲劳性能的影响,首先,采用SURP技术对EA4T车轴钢试样进行表面处理,并对处理后的试样进行表面性能测试,分析表面三维形貌、粗糙度、硬度、残余应力、半高宽(FWHM)和晶粒尺寸的变化;然后,采用旋转弯曲疲劳试验机对EA4T车轴钢试样进行疲劳试验,获得应力-疲劳寿命(

S-N )曲线,并分析裂纹扩展规律,研究SURP处理对EA4T车轴钢疲劳性能和裂纹扩展行为的影响;最后,采用BP(back propagation)神经网络建立了以加载应力幅值、表面粗糙度、表面半高宽、表面硬度、硬化层深度、表面残余应力和残余应力层深度为输入的超声滚压EA4T车轴钢疲劳寿命预测模型,并对超声滚压EA4T车轴钢试样进行寿命预测. 研究结果表明:SURP处理可以使试样表面粗糙度降低为0.17 μm,并去除表面梨沟形貌;试样表面硬度提升至420 HV,试样表面引入约 −500 MPa的残余应力以及约550 μm深的残余应力层;研磨试样和研磨抛光试样以及SURP处理试样均具有传统疲劳极限,研磨试样和研磨抛光试样的疲劳性能基本一致,且疲劳极限均为355 MPa,SURP处理试样疲劳性能显著提升,其疲劳极限为455 MPa,相比研磨试样提升了28%;疲劳断口观察表明,所有试样的疲劳裂纹均萌生自表面,SURP处理没有改变试样的疲劳破坏机制;SURP处理使试样的裂纹扩展门槛值从6.29 MPa·m1/2增加到11.21 MPa·m1/2,同时减缓了裂纹萌生以及短裂纹扩展,从而显著提高了EA4T车轴钢疲劳性能;超声滚压EA4T车轴钢疲劳寿命预测模型预测精度为88.5%.Abstract:In order to study the influence of surface ultrasonic rolling processing (SURP) on the fatigue properties of EA4T axle steel, the EA4T axle steel specimens were firstly treated by SURP technology, and the surface properties of the treated specimens were analyzed. The 3D surface morphologies, roughness, hardness, residual stress, full width at half maximum (FWHM), and crystal size were investigated. Then, the fatigue tests were carried out on the EA4T axle steel specimens using a rotary bending fatigue testing machine. The stress–fatigue life (

S-N ) curves and crack propagation behaviors were obtained, and the effect of SURP on fatigue properties and crack propagation behaviors of EA4T axle steels was analyzed. Finally, a back propagation (BP) neural network was used to establish the fatigue life prediction model of SURP EA4T axle steel, which took load stress amplitude, surface roughness, surface FWHM, surface hardness, hardened layer depth, surface residual stress, and depth of residual stress layer as input. In addition, the life of SURP EA4T axle steel specimens was predicted. The results show that SURP can reduce the surface roughness of the specimens to 0.17 μm and remove the groove morphology. Meanwhile, the surface hardness of the specimens is improved to 420 HV, and a surface residual stress of about −500 MPa and a residual stress layer with a depth of about 550 μm are introduced. There are conventional fatigue limits for grinding specimens, grinding with polishing specimens, as well as SURP specimens. The fatigue properties of grinding specimens and grinding with polishing specimens are basically the same, with a fatigue limit of 355 MPa. The fatigue property of SURP specimens is improved significantly, with a fatigue limit of 455 MPa, an increase of 28% compared with the grinding specimens. Fatigue fracture observations show that the fatigue cracks of all specimens initiate from the surface, and SURP cannot change the fatigue damage mechanism of the specimen. SURP can increase the threshold value of crack propagation of the specimen from 6.29 MPa·m1/2 to 11.21 MPa·m1/2, and it can slow down the crack initiation and propagation of short cracks, thus significantly improving the fatigue property of EA4T axle steel. The fatigue life prediction model of SURP EA4T axle steel has a prediction accuracy of 88.5%. -

表 1 EA4T化学成分

Table 1. Chemical composition of EA4T axel steel

% 化学成分 C Si Mn P S Cr Cu Ni Mo 质量百分比 0.2700 0.3900 0.7200 0.0075 0.0013 1.1100 0.0140 0.2500 0.2470 表 2 试样的加工方式和试验内容

Table 2. Processing method and experimental content of specimens

试样种类 加工方法 试验内容 1 研磨 疲劳试验 2 研磨抛光 疲劳试验、裂纹扩展试验 3 SURP 疲劳试验、裂纹扩展试验 -

[1] 翟婉明,赵春发. 现代轨道交通工程科技前沿与挑战[J]. 西南交通大学学报,2016,51(2): 209-226.ZHAI Wanming, ZHAO Chunfa. Frontiers and challenges of sciences and technologies in modern railway engineering[J]. Journal of Southwest Jiaotong University, 2016, 51(2): 209-226. [2] 李祥志,张艳,徐良乐,等. 高速车轴的疲劳断裂及其应对措施[J]. 热加工工艺,2017,46(18): 25-29.LI Xiangzhi, ZHANG Yan, XU Liangle, et al. Fatigue fracture of high-speed axle and corresponding improvement measures[J]. Hot Working Technology, 2017, 46(18): 25-29. [3] 宮昱滨,鲁连涛,张远彬. 气体渗氮对中碳车轴钢疲劳性能的影响[J]. 实验力学,2017,32(1): 63-69.GONG Yubin, LU Liantao, ZHANG Yuanbin. Effect of gas nitriding on fatigue performance of medium carbon axle steel[J]. Journal of Experimental Mechanics, 2017, 32(1): 63-69. [4] 于鑫. 高速列车车轴加工残余应力与疲劳寿命关系研究[D]. 济南: 山东大学, 2015. [5] 任学冲,陈利钦,刘鑫贵,等. 表面超声滚压处理对高速列车车轴钢疲劳性能的影响[J]. 材料工程,2015,43(12): 1-5.REN Xuechong, CHEN Liqin, LIU Xingui, et al. Effects of surface ultrasonic rolling processing on fatigue properties of axle steel used on high speed train[J]. Journal of Materials Engineering, 2015, 43(12): 1-5. [6] 王睿,刘鹏涛,刘德义,等. 表面超声滚压工艺参数对EA4T车轴表面性能的影响[J]. 热加工工艺,2021,50(4): 88-92.WANG Rui, LIU Pengtao, LIU Deyi, et al. Influence of surface ultrasonic rolling process parameters on surface performance of EA4T axle[J]. Hot Working Technology, 2021, 50(4): 88-92. [7] 陈利钦,项彬,任学冲,等. 表面超声滚压处理工艺对高速列车车轴钢表面状态的影响[J]. 中国表面工程,2014,27(5): 96-101.CHEN Liqin, XIANG Bin, REN Xuechong, et al. Influences of surface ultrasonic rolling processing parameters on surface condition of axle steel used in high speed trains[J]. China Surface Engineering, 2014, 27(5): 96-101. [8] 张秀华,刘怀举,朱才朝,等. 基于数据驱动的零部件疲劳寿命预测研究现状与发展趋势[J]. 机械传动,2021,45(10): 1-14.ZHANG Xiuhua, LIU Huaiju, ZHU Caichao, et al. Current situation and developing trend of fatigue life prediction of components based on data-driven[J]. Journal of Mechanical Transmission, 2021, 45(10): 1-14. [9] MALEKI E, UNAL O, REZA KASHYZADEH K. Fatigue behavior prediction and analysis of shot peened mild carbon steels[J]. International Journal of Fatigue, 2018, 116: 48-67. doi: 10.1016/j.ijfatigue.2018.06.004 [10] 苏凯新,张继旺,李行,等. 基于神经网络的喷丸25CrMo合金疲劳寿命及残余应力松弛行为预测研究[J]. 稀有金属材料与工程,2020,49(8): 2697-2705.SU Kaixin, ZHANG Jiwang, LI Hang, et al. Prediction of fatigue life and residual stress relaxation behavior of shot-peened 25CrMo axle steel based on neural network[J]. Rare Metal Materials and Engineering, 2020, 49(8): 2697-2705. [11] Japanese Industrial Standards Committee. Geometrical product specifications (GPS)-surface texture: profile method-rules and procedures for the assessment of surface texture: JIS B0633—2001. Tokyo: [s.n.], 2001. [12] LIN J, MA N S, LEI Y P, et al. Measurement of residual stress in arc welded lap joints by cos α X-ray diffraction method[J]. Journal of Materials Processing Technology, 2017, 243: 387-394. doi: 10.1016/j.jmatprotec.2016.12.021 [13] 何少杰,杨文玉,郭步鹏,等. 机加工表面残余应力及其疲劳寿命评价的研究进展[J]. 表面技术,2015,44(6): 120-126,132.HE Shaojie, YANG Wenyu, GUO Bupeng, et al. Research progress on evaluation of surface residual stress and fatigue life of machined products[J]. Surface Technology, 2015, 44(6): 120-126,132. [14] HARADA Y, FUKAURA K, HAGA S. Influence of microshot peening on surface layer characteristics of structural steel[J]. Journal of Materials Processing Technology, 2007, 191(1/2/3): 297-301. [15] UNAL O, VAROL R. Almen intensity effect on microstructure and mechanical properties of low carbon steel subjected to severe shot peening[J]. Applied Surface Science, 2014, 290: 40-47. doi: 10.1016/j.apsusc.2013.10.184 [16] MALEKI E, UNAL O, KASHYZADEH K R. Effects of conventional, severe, over, and re-shot peening processes on the fatigue behavior of mild carbon steel[J]. Surface and Coatings Technology, 2018, 344: 62-74. doi: 10.1016/j.surfcoat.2018.02.081 [17] LU J Z, LUO K Y, ZHANG Y K, et al. Grain refinement of LY2 aluminum alloy induced by ultra-high plastic strain during multiple laser shock processing impacts[J]. Acta Materialia, 2010, 58(11): 3984-3994. doi: 10.1016/j.actamat.2010.03.026 [18] 徐锋,章武林,杜永强,等. EA4T车轴不同加工工艺表面完整性分析[J]. 表面技术,2017,46(12): 277-282.XU Feng, ZHANG Wulin, DU Yongqiang, et al. Analysis of surface integrity of EA4T axle being processed in different technologies[J]. Surface Technology, 2017, 46(12): 277-282. [19] NOVOVIC D, DEWES R C, ASPINWALL D K, et al. The effect of machined topography and integrity on fatigue life[J]. International Journal of Machine Tools and Manufacture, 2004, 44(2/3): 125-134. [20] YILMAZ H, SADELER R. Impact wear behavior of ball burnished 316L stainless steel[J]. Surface and Coatings Technology, 2019, 363: 369-378. doi: 10.1016/j.surfcoat.2019.02.022 [21] 袁劲松. 金属腐蚀疲劳裂纹扩展速率的近似计算[J]. 材料开发与应用,2000,15(2): 26-29. doi: 10.3969/j.issn.1003-1545.2000.02.008YUAN Jinsong. Approximate calculation of crack propagation rate of metal corrosion fatigue[J]. Development and Application of Materials, 2000, 15(2): 26-29. doi: 10.3969/j.issn.1003-1545.2000.02.008 [22] MURAKAMI Y. Metal fatigue: effects of small defects and nonmetallic inclusions[M]. [S.l.]: Elsevier, 2002. [23] 王慧军,陈林,郭飞翔,等. 残余应力对U75V重轨钢疲劳裂纹扩展速率的影响[J]. 金属热处理,2017,42(6): 23-27.WANG Huijun, CHEN Lin, GUO Feixiang, et al. Effect of residual stress on fatigue crack propagation rate of U75V heavy rail steel[J]. Heat Treatment of Metals, 2017, 42(6): 23-27. -

下载:

下载: