Rail Corrugation Suppressing Method on Braking Sections of High-Speed Trains

-

摘要:

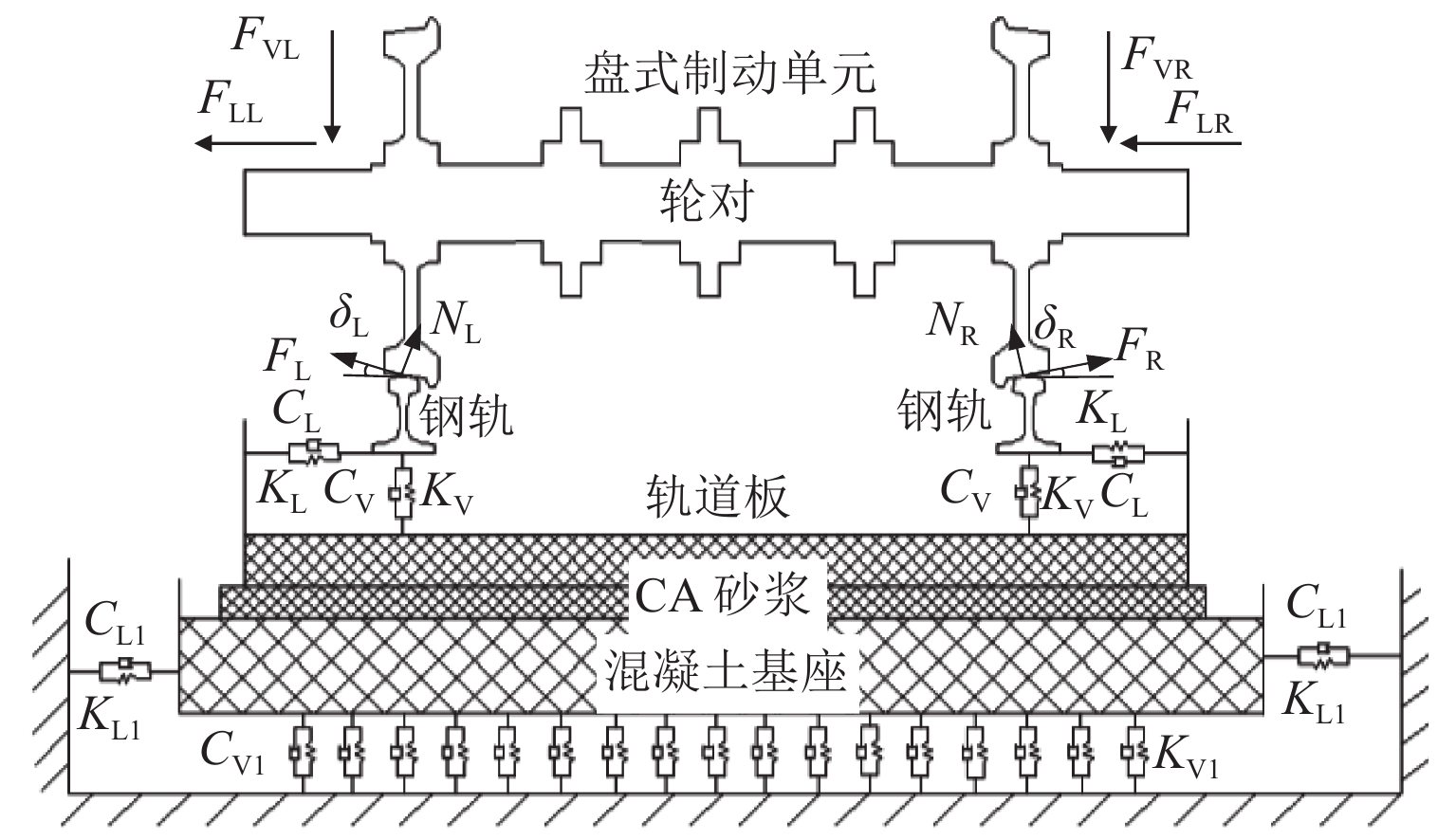

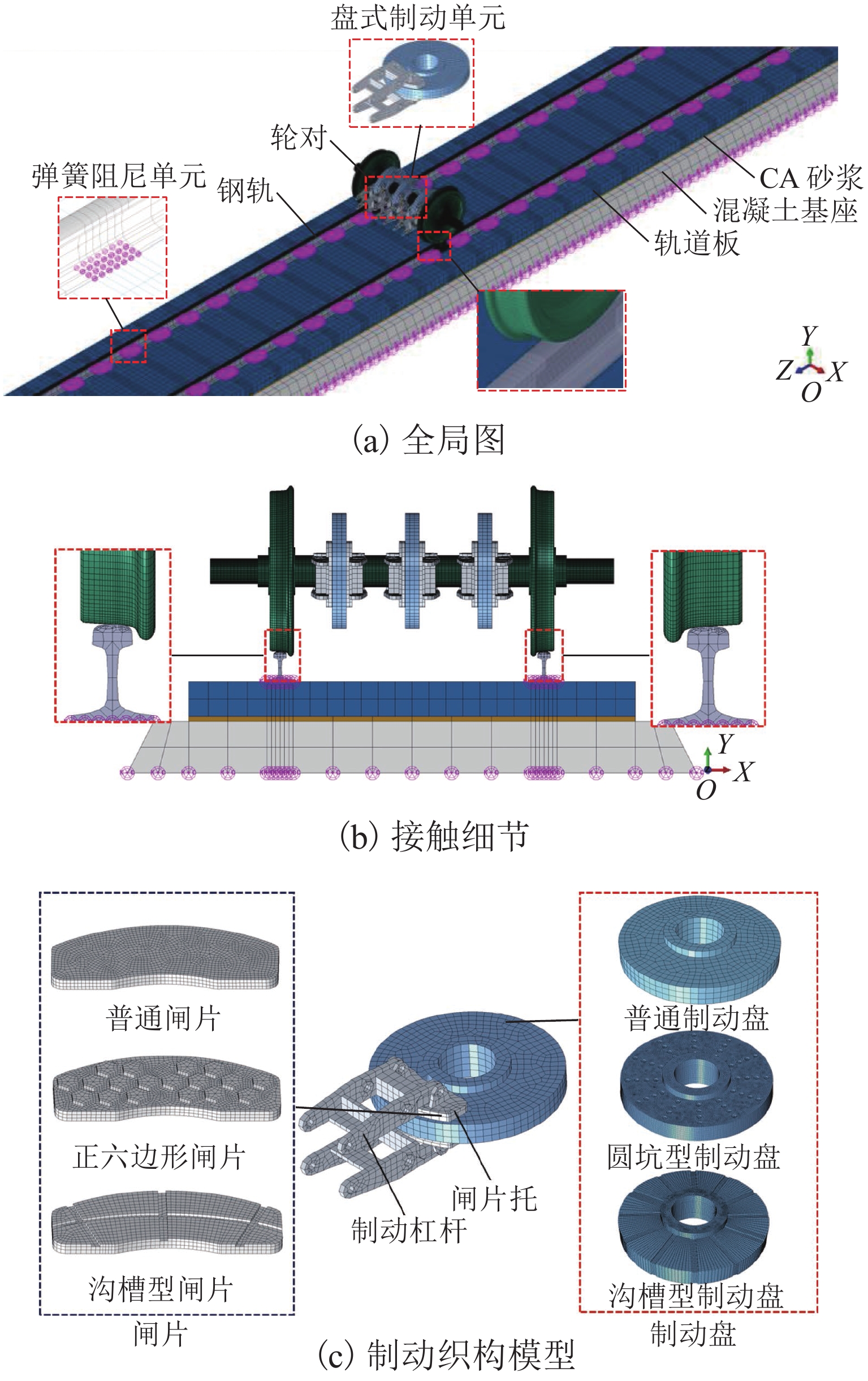

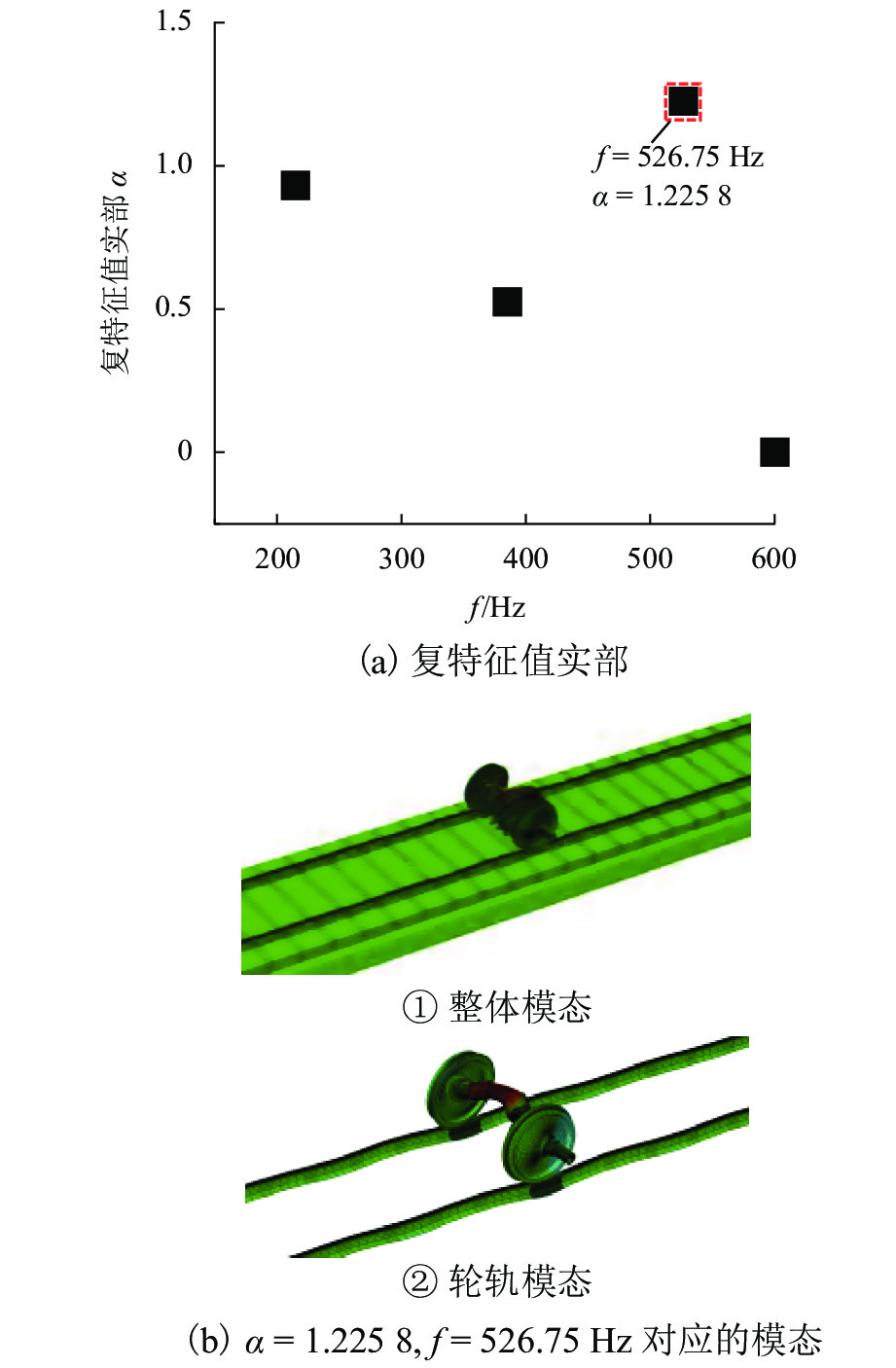

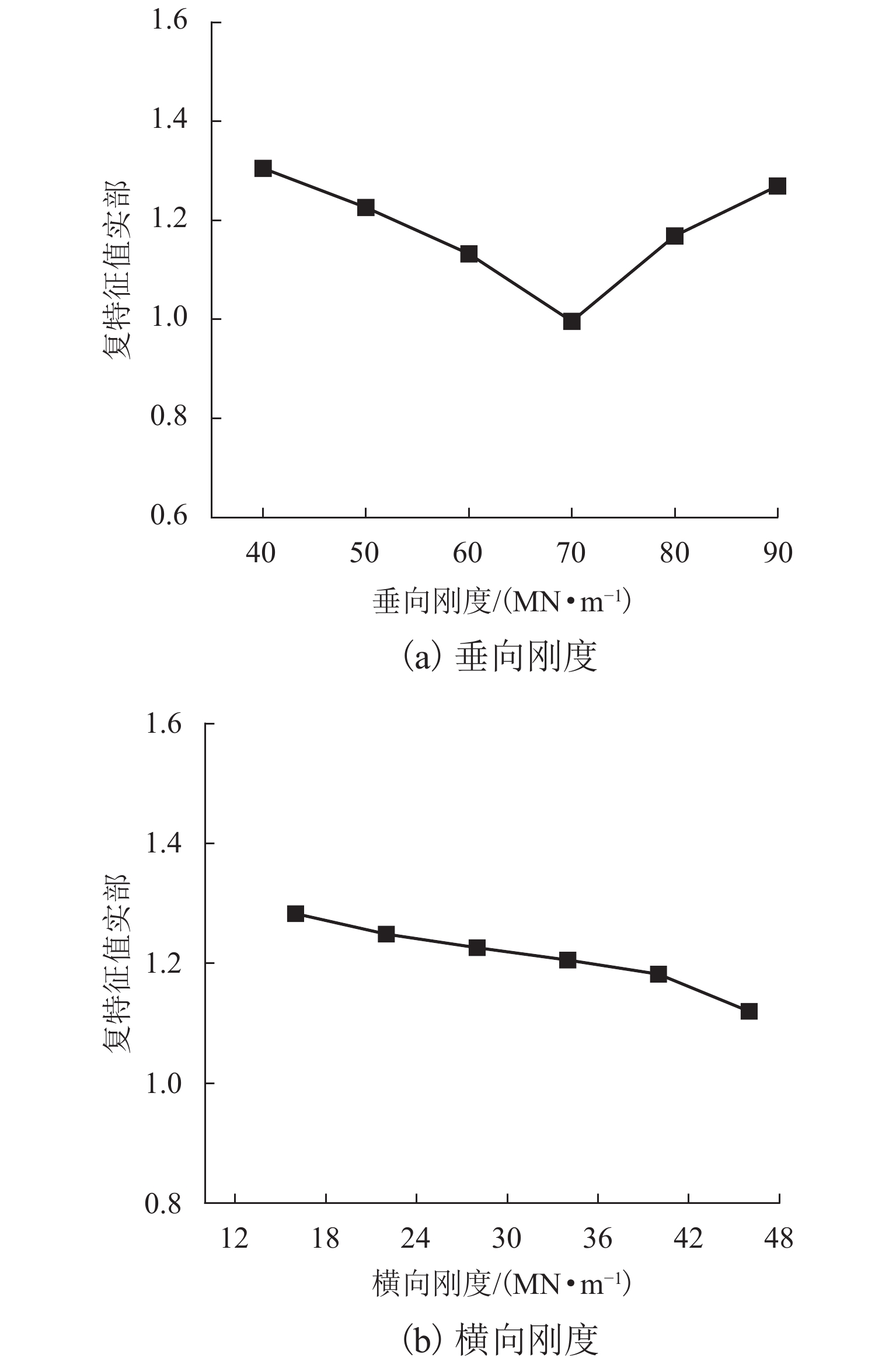

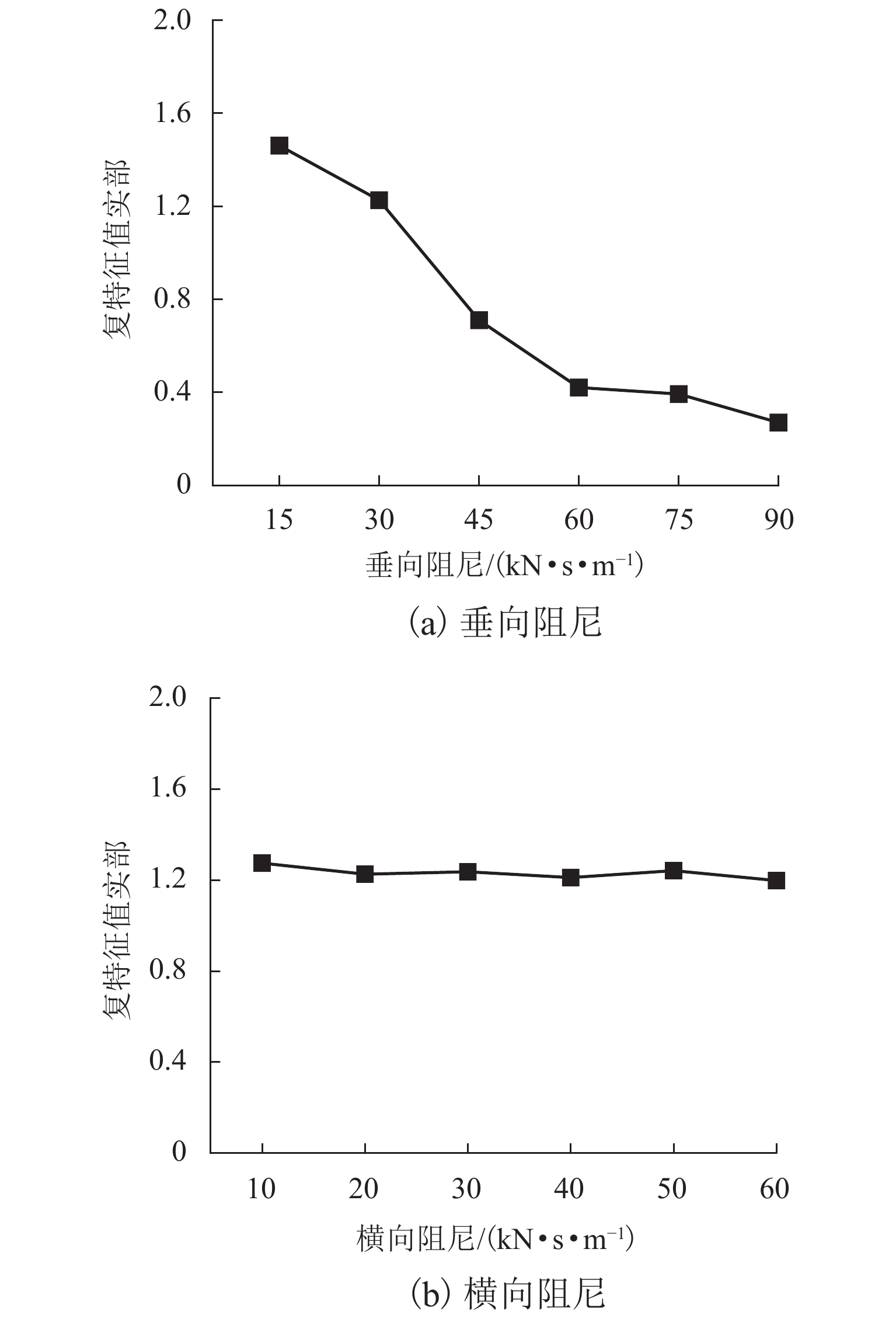

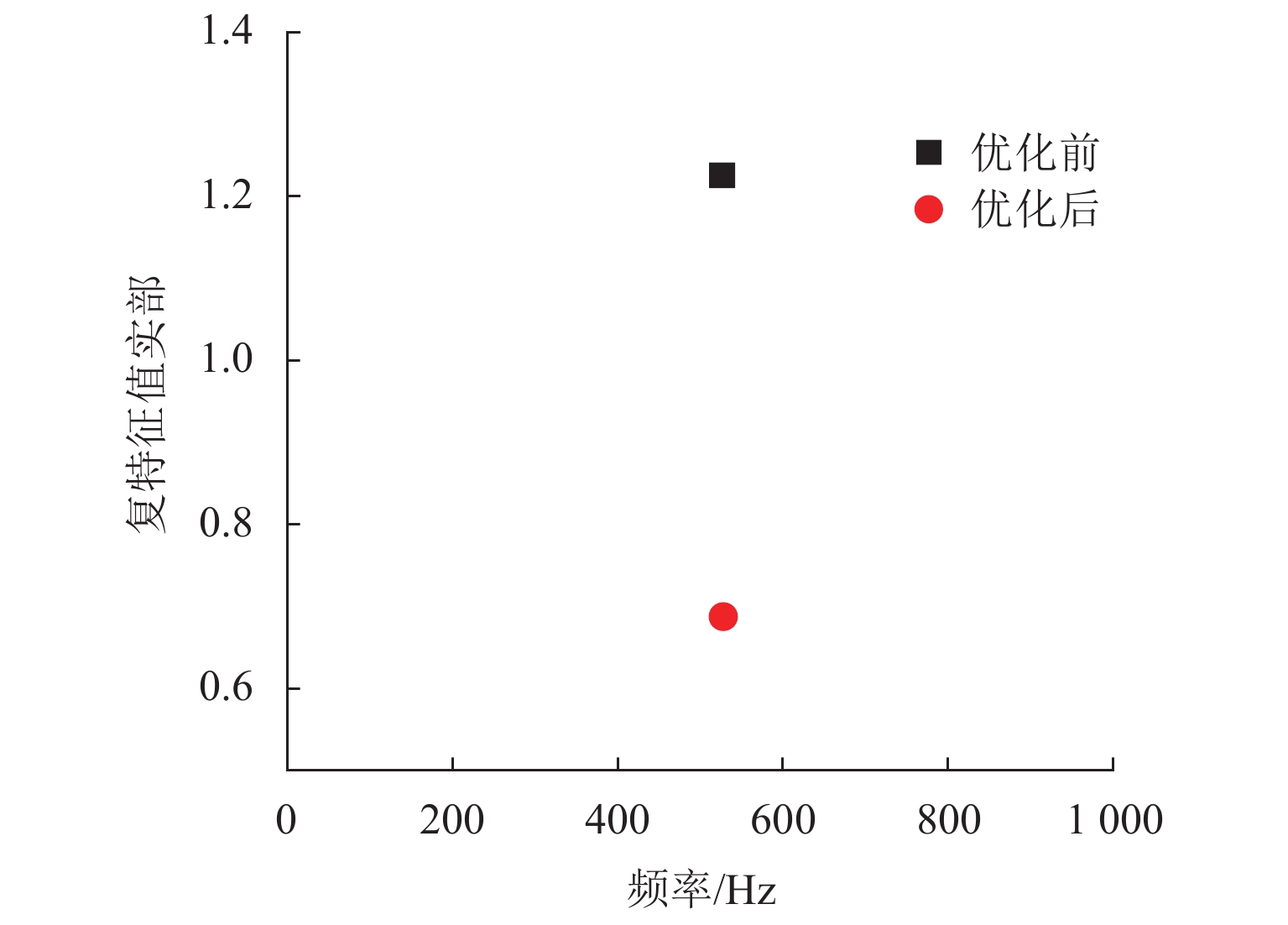

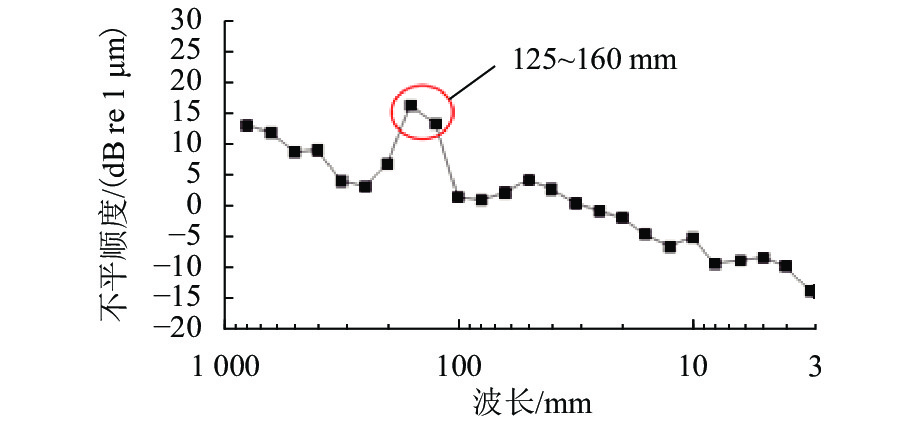

为研究高速列车制动区段制动结构/轨道结构对轮对-轨道-制动系统摩擦自激振动的影响,首先,结合现场调研,建立CRH3高速列车轮对-轨道-制动系统有限元模型;然后,采用复特征值法研究考虑轮轨粘滑和制动滚滑作用下的轮对-轨道-制动系统的摩擦自激振动特性;进而探究制动结构中表面织构对整个系统摩擦自激振动特性的影响;最后,对轨道结构中扣件参数进行参数化分析,并采用最小二乘法和粒子群算法求得抑制钢轨波磨的扣件参数的最优解. 研究结果表明:高速列车在制动区段时,轮轨粘滑和制动滚滑作用导致的轮对-轨道-制动系统摩擦自激振动的主要频率为526.75 Hz,与现场波磨特征频率接近,说明轮对-轨道-制动系统的摩擦自激振动可能是该区段钢轨波磨的主要诱因;采用具有表面织构的闸片或制动盘能有效抑制制动区段的钢轨波磨,其中沟槽型闸片的抑制效果最佳;当扣件的垂向刚度为65.5 MN/m,横向刚度为46.0 MN/m,垂向阻尼为84.0 kN·s/m和横向阻尼为23.5 kN·s/m时,可以抑制高速列车制动区段的钢轨波磨.

Abstract:To explore the influence of the braking structure/track structure on the frictional self-excited vibration of the wheelset−track−brake system on braking sections of high-speed trains, firstly, combined with on-site investigation, the finite element model of the wheelset−track−brake system of CRH3 high-speed trains is established. Then, the frictional self-excited vibration characteristics of the wheelset–track–brake system under the effects of wheel-rail stick-slip and brake roll-slip are analyzed with the complex eigenvalue method. Furthermore, the influence of the surface texture in the braking structure on the frictional self-excited vibration of the whole system is examined. The parameters of the fasteners in the track structure are parametrically analyzed. The least squares method and the particle swarm optimization algorithm are used to obtain the optimal solution of the fasteners parameters to suppress the rail corrugation. The results show that the main frequency in the frictional self-excited vibration of the wheelset–track–brake system caused by wheel-rail stick-slip and braking roll-slip is 526.75 Hz on the braking section, which is close to the characteristic frequency of the on-site corrugation. The frictional self-excited vibration of the whole system may be the main cause of rail corrugation. The rail corrugation on the braking section can be effectively suppressed by the brake pads or brake discs with surface texture, and the grooved brake pads have the best suppression effect. When the vertical stiffness of the fastener is 65.5 MN/m, the lateral stiffness is 46.0 MN/m, the vertical damping is 84.0 kN·s/m, and the lateral damping is 23.5 kN·s/m, the rail corrugation on the braking section of high-speed trains can be effectively suppressed.

-

表 1 有限元模型材料参数

Table 1. Material parameters of finite element model

部件参数 密度/(k•gm−3) 弹性模量/MPa 泊松比 轮对 7800 210000 0.30 钢轨 7800 210000 0.30 制动盘 7300 207000 0.30 制动闸片 2500 8100 0.30 闸片托 5600 100000 0.30 制动杠杆 7000 190000 0.30 轨道板 2400 29500 0.25 CA 砂浆层 2600 32500 0.20 混凝土底座 2400 22500 0.20 表 2 有限元模型连接参数

Table 2. Connection parameters of finite element model

方向 扣件刚度/

(MN·m−1)扣件阻尼/

(kN·s·m−1)地基支撑刚度/(MN·m−1) 地基支撑阻

尼/(kN·s·m−1)垂向 50 30 190 30 横向 28 20 纵向 28 20 -

[1] 金学松,李霞,李伟,等. 铁路钢轨波浪形磨损研究进展[J]. 西南交通大学学报,2016,51(2): 264-273. doi: 10.3969/j.issn.0258-2724.2016.02.006JIN Xuesong, LI Xia, LI Wei, et al. Review of rail corrugation progress[J]. Journal of Southwest Jiaotong University, 2016, 51(2): 264-273. doi: 10.3969/j.issn.0258-2724.2016.02.006 [2] 林凤涛,黄琴,张海,等. CRH3高速列车多边形磨耗车轮通过钢轨波磨区段的轮轨力研究[J]. 铁道科学与工程学报,2021,18(7): 1706-1714.LIN Fengtao, HUANG Qin, ZHANG Hai, et al. Study on wheel-rail force of CRH3 high speed train with wheel polygon when passing corrugation rail[J]. Journal of Railway Science and Engineering, 2021, 18(7): 1706-1714. [3] GRASSI E S. Rail irregularities, corrugation and acoustic roughness: characteristics, significance and effects of reprofiling[J]. Proceedings of the Institution of Mechanical Engineers Part F: Journal of Rail and Rapid Transit, 2012, 226(5): 542-557. doi: 10.1177/0954409712443492 [4] EI BESHBICHI O, WAN C, BRUNI S, et al. Complex eigenvalue analysis and parameters analysis to investigate the formation of railhead corrugation in sharp curves[J]. Wear, 2020, 450/451: 203150.1-203150.10. [5] 陈光雄,金学松,邬平波,等. 车轮多边形磨耗机理的有限元研究[J]. 铁道学报,2011,33(1): 14-18. doi: 10.3969/j.issn.1001-8360.2011.01.003CHEN Guangxiong, JIN Xuesong, WU Pingbo, et al. Finite element study on the generation mechanism of polygonal wear of railway wheels[J]. Journal of the China Railway Society, 2011, 33(1): 14-18. doi: 10.3969/j.issn.1001-8360.2011.01.003 [6] WANG Z Q, LEI Z Y. Analysis of rail corrugation characteristics on high-speed rail based on transient finite element method[J]. The International Journal of Acoustics and Vibration, 2021, 26(3): 231-239. doi: 10.20855/ijav.2021.26.31778 [7] 王立乾. 高速铁路钢轨波浪型磨耗研究及其防治建议[J]. 石家庄铁道大学学报(自然科学版),2013,26(4): 83-86, 90. doi: 10.13319/j.cnki.sjztddxxbzrb.2013.04.010WANG Liqian. Research on high-speed railway rail corrugated wear and tear[J]. Journal of Shijiazhuang Tiedao University (Natural Science), 2013, 26(4): 83-86, 90. doi: 10.13319/j.cnki.sjztddxxbzrb.2013.04.010 [8] CORREA N, OYARZABAL O, VADILLO E G, et al. Rail corrugation development in high speed lines[J]. Wear, 2011, 271(9/10): 2438-2447. doi: 10.1016/j.wear.2010.12.028 [9] 司道林,李伟,杜香刚,等. 减缓高速铁路钢轨波磨的仿真分析[J]. 中国铁道科学,2014,35(6): 79-83. doi: 10.3969/j.issn.1001-4632.2014.06.12SI Daolin, LI Wei, DU Xianggang, et al. Simulation analysis on mitigating rail corrugation for high speed railway[J]. China Railway Science, 2014, 35(6): 79-83. doi: 10.3969/j.issn.1001-4632.2014.06.12 [10] 姜子清,司道林,李伟,等. 高速铁路钢轨波磨研究[J]. 中国铁道科学,2014,35(4): 9-14. doi: 10.3969/j.issn.1001-4632.2014.04.02JIANG Ziqing, SI Daolin, LI Wei, et al. Research on rail corrugation of high-speed railway[J]. China Railway Science, 2014, 35(4): 9-14. doi: 10.3969/j.issn.1001-4632.2014.04.02 [11] CUI X L, LI T, BAO P Y, et al. Research on the dynamic cause of rail corrugation in the braking section of high-speed railways under multiple vibration inducements[J]. Journal of Vibration Engineering & Technologies, 2023, 11(7): 71-83. [12] 吴波文. 制动对车轮多边形磨耗和钢轨波磨影响的研究[D]. 成都: 西南交通大学, 2020. [13] 崔晓璐,包鹏羽,陈佳欣,等. 高速铁路制动区间钢轨摩擦自激振动研究[J]. 西南交通大学学报,2023,58(1): 141-149.CUI Xiaolu, BAO Pengyu, CHEN Jiaxin, et al. Rail friction self-excited vibration in braking section of high-speed railway[J]. Journal of Southwest Jiaotong University, 2023, 58(1): 141-149. [14] BAO P Y, CUI X L, DING H H, et al. Influences of friction self-excited vibration characteristics of various types of high-speed trains on rail corrugations in braking sections[J]. Engineering Failure Analysis, 2022, 134: 106087.1-106087.10. [15] CHEN G X, ZHOU Z R, OUYANG H, et al. A finite element study on rail corrugation based on saturated creep force-induced self-excited vibration of a wheelset-track system[J]. Journal of Sound and Vibration, 2010, 329(22): 4643-4655. doi: 10.1016/j.jsv.2010.05.011 [16] 陈光雄,钱韦吉,莫继良,等. 轮轨摩擦自激振动引起小半径曲线钢轨波磨的瞬态动力学[J]. 机械工程学报,2014,50(9): 71-76. doi: 10.3901/JME.2014.09.071CHEN Guangxiong, QIAN Weiji, MO Jiliang, et al. A transient dynamics study on wear-type rail corrugation on a tight curve due to the friction-induced self-excited vibration of a wheelset-track system[J]. Journal of Mechanical Engineering, 2014, 50(9): 71-76. doi: 10.3901/JME.2014.09.071 [17] NIELSEN J C O, LUNDÉN R, JOHANSSON A, et al. Train-track interaction and mechanisms of irregular wear on wheel and rail surfaces[J]. Vehicle System Dynamics, 2003, 40(1/2/3): 3-54. [18] PALIWAL M, MAHAJAN A, DON J, et al. Noise and vibration analysis of a disc-brake system using a stick-slip friction model involving coupling stiffness[J]. Journal of Sound and Vibration, 2005, 282(3): 1273-1284. [19] WU B W, QIAO Q F, CHEN G X. et al. Effect of the unstable vibration of the disc brake system of high-speed trains on wheel polygonalization[J]. Proceedings of the Institution of Mechanical Engineers, 2020, 234(1): 80-95. doi: 10.1177/0954409719833787 [20] ABUBAKAR A R, OUYANG H J. Complex eigenvalue analysis and dynamic transient analysis in predicting disc brake squeal[J]. International Journal of Vehicle Noise and Vibration, 2006, 2(2): 143-155. doi: 10.1504/IJVNV.2006.011051 [21] ZHU, Q, CHEN, G. X, WU, B. W, et al. Effect of the material parameter and shape of brake pads on friction-induced disc brake squeal of a railway vehicle[J]. Tribology Transactions, 2021, 64(4): 744-752. doi: 10.1080/10402004.2021.1914254 [22] 胡利鸿,莫继良,王东伟,等. 沟槽和圆坑织构抑制摩擦尖叫噪声研究[J]. 中国机械工程,2016,27(9): 1158-1164. doi: 10.3969/j.issn.1004-132X.2016.09.004HU Lihong, MO Jiliang, WANG Dongwei, et al. Groove-textured and pit-textured surfaces to suppress friction-induced squeal noise[J]. China Mechanical Engineering, 2016, 27(9): 1158-1164. doi: 10.3969/j.issn.1004-132X.2016.09.004 [23] 王东伟. 沟槽型织构化表面调控界面摩擦振动噪声行为的研究[D]. 成都: 西南交通大学, 2019. [24] 张青,崔晓璐,陈光雄,等. 沟槽织构对盘形制动噪声的影响[J]. 机械设计,2017,34(2): 62-67.ZHANG Qing, CUI Xiaolu, CHEN Guangxiong, et al. Effect of groove-texture on disc braking noise[J]. Journal of Machine Design, 2017, 34(2): 62-67. [25] 陈光雄,崔晓璐,王科. 高速列车车轮踏面非圆磨耗机理[J]. 西南交通大学学报,2016,51(2): 244-250. doi: 10.3969/j.issn.0258-2724.2016.02.004CHEN Guangxiong, CUI Xiaolu, WANG Ke. Generation mechanism for plolygonalization of wheel treads of high-speed trains[J]. Journal of Southwest Jiaotong University, 2016, 51(2): 244-250. doi: 10.3969/j.issn.0258-2724.2016.02.004 [26] ZHAO H Y, JENG D S. Accumulated pore pressures around submarine pipeline buried in trench layer with partial backfills[J]. Journal of Engineering Mechanics, 2016, 142(7): 04016042.1-04016042.15. -

下载:

下载: