Cracking Behavior of Segmental Lining in Subways Under Adverse Jacking Force During Shield Tunneling

-

摘要:

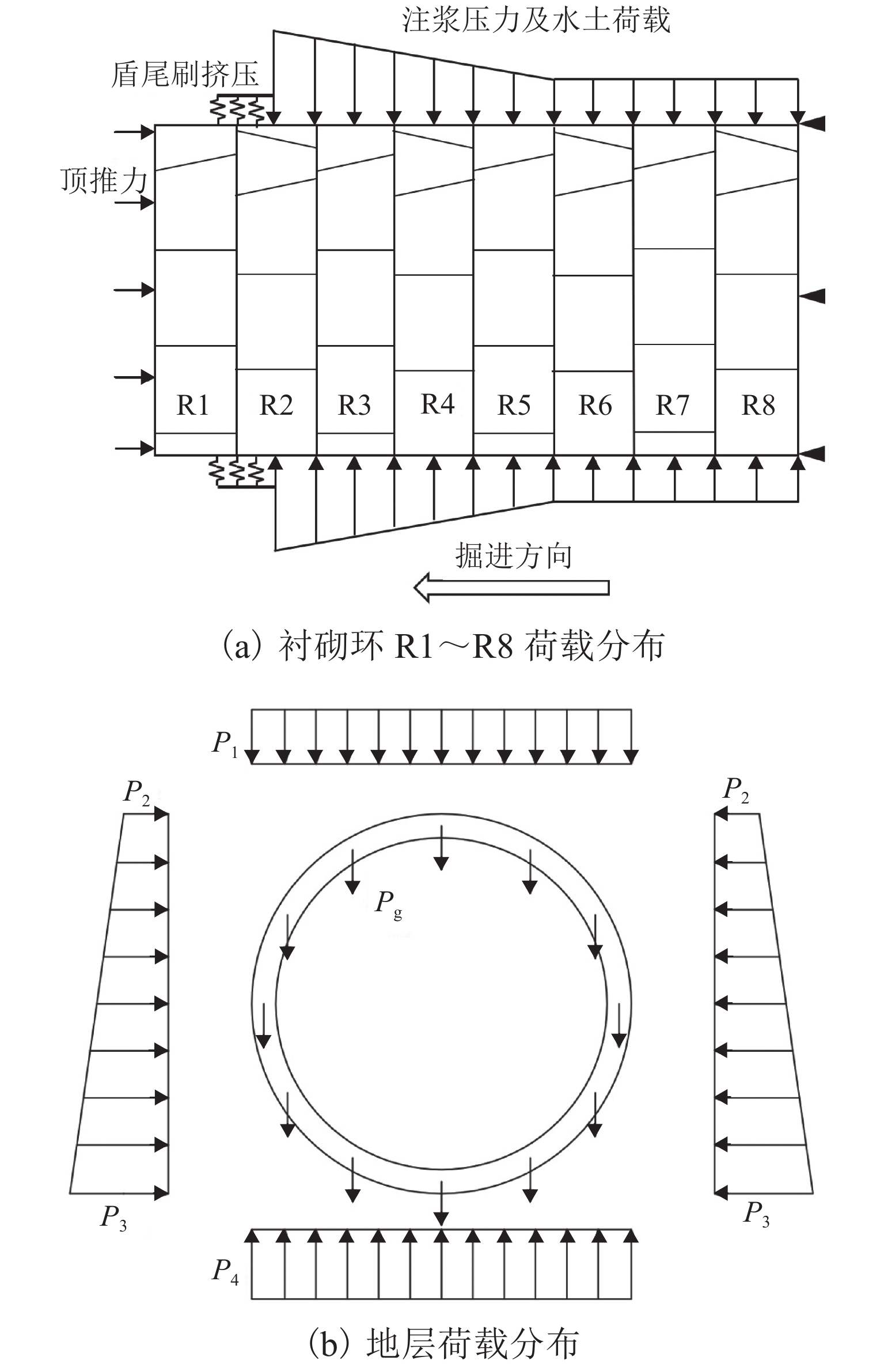

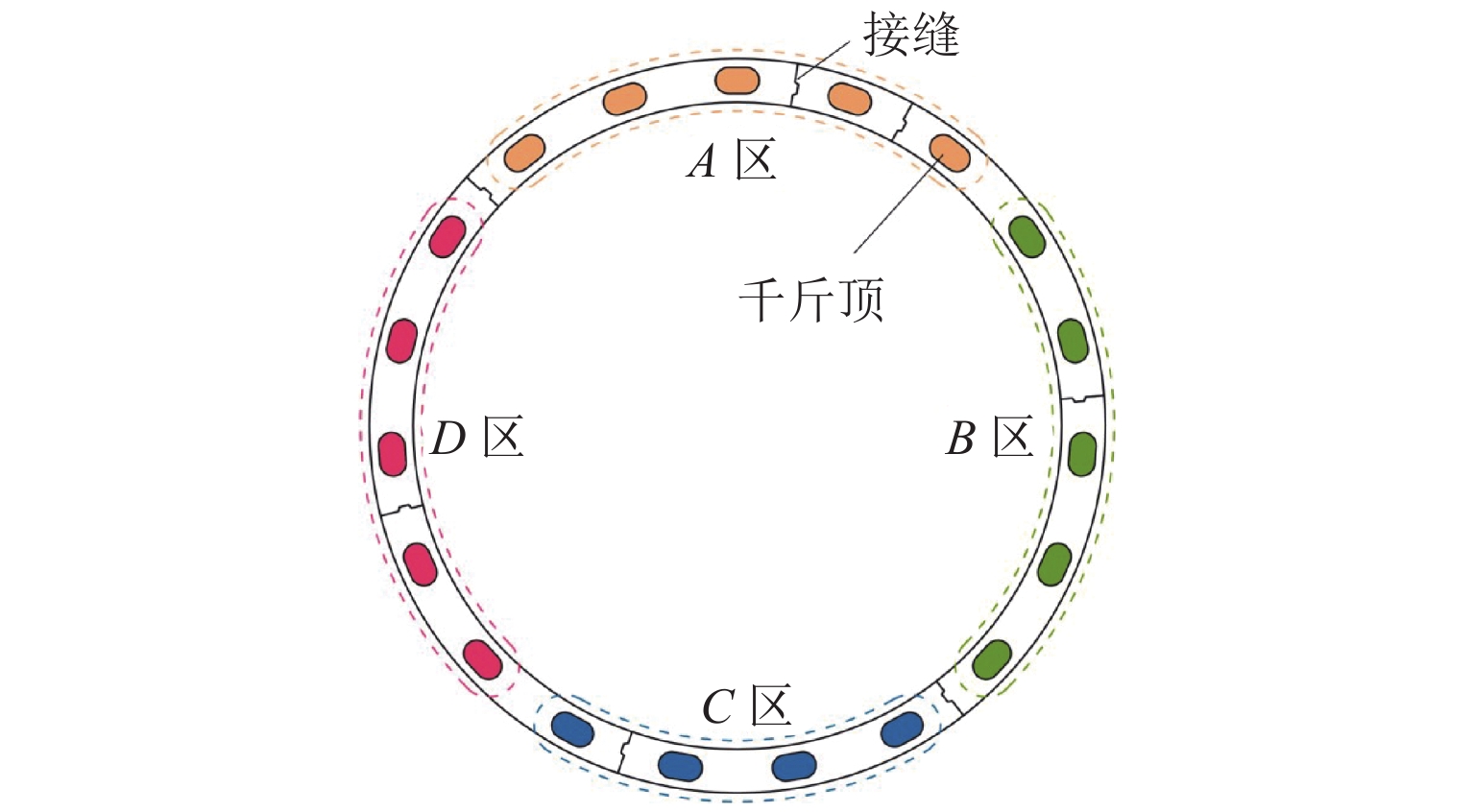

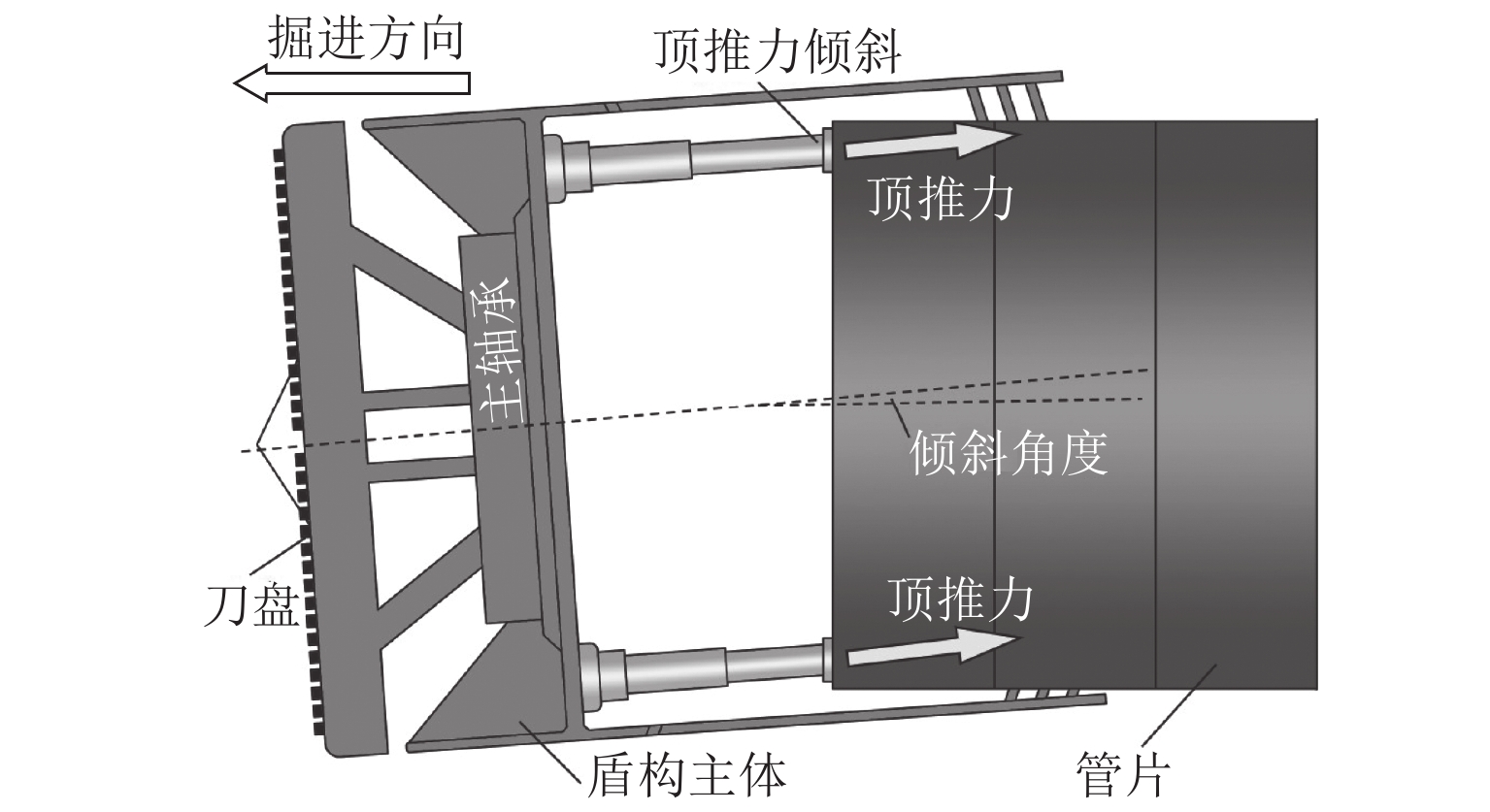

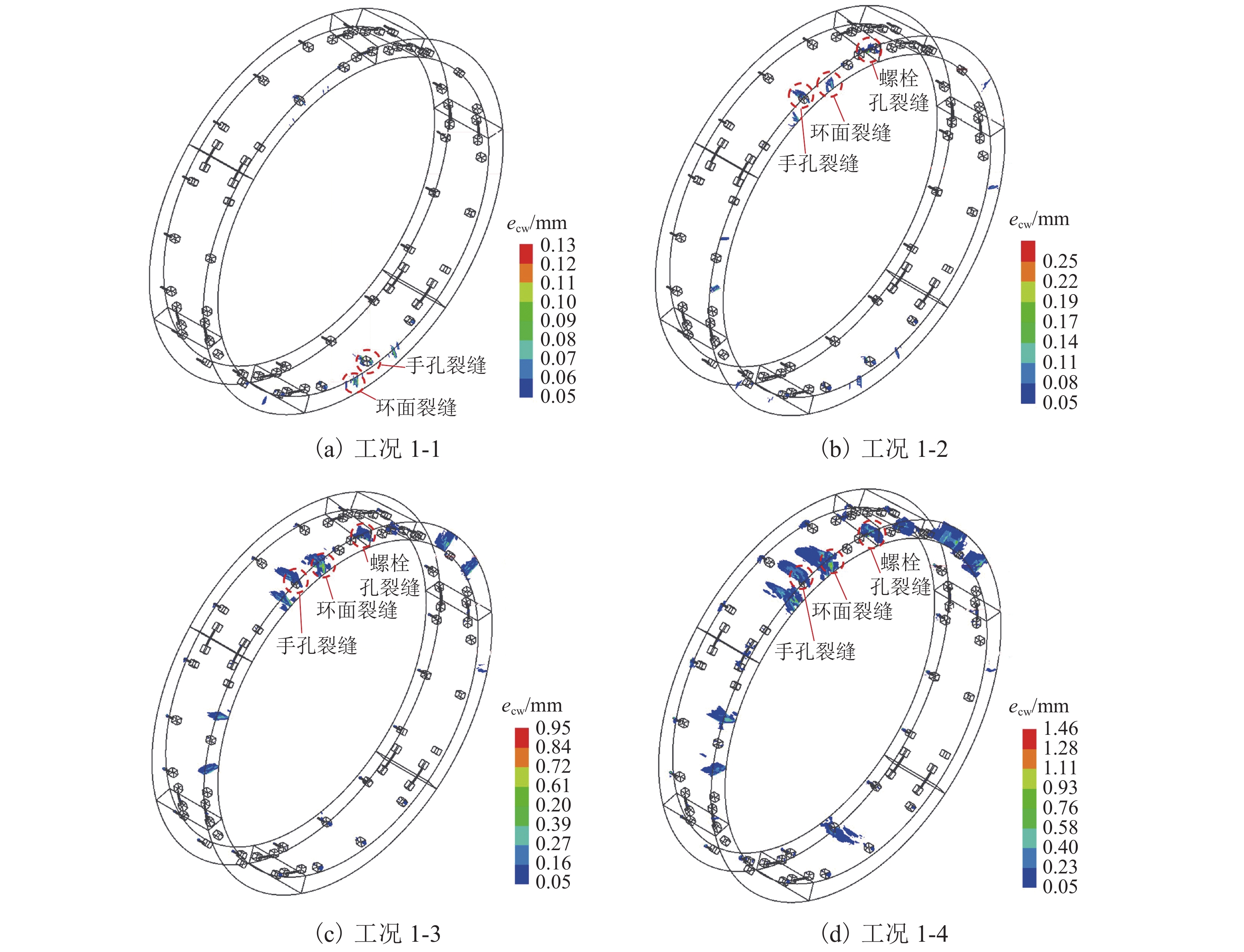

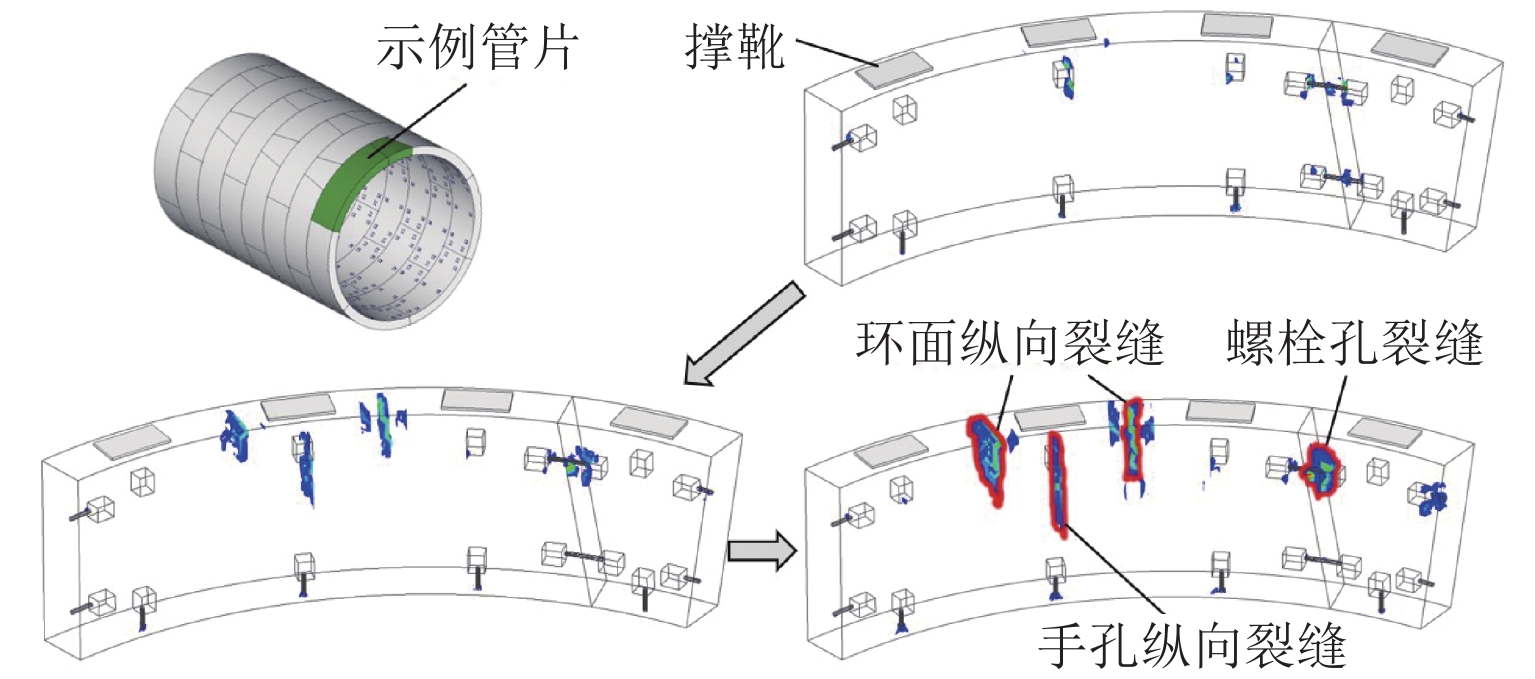

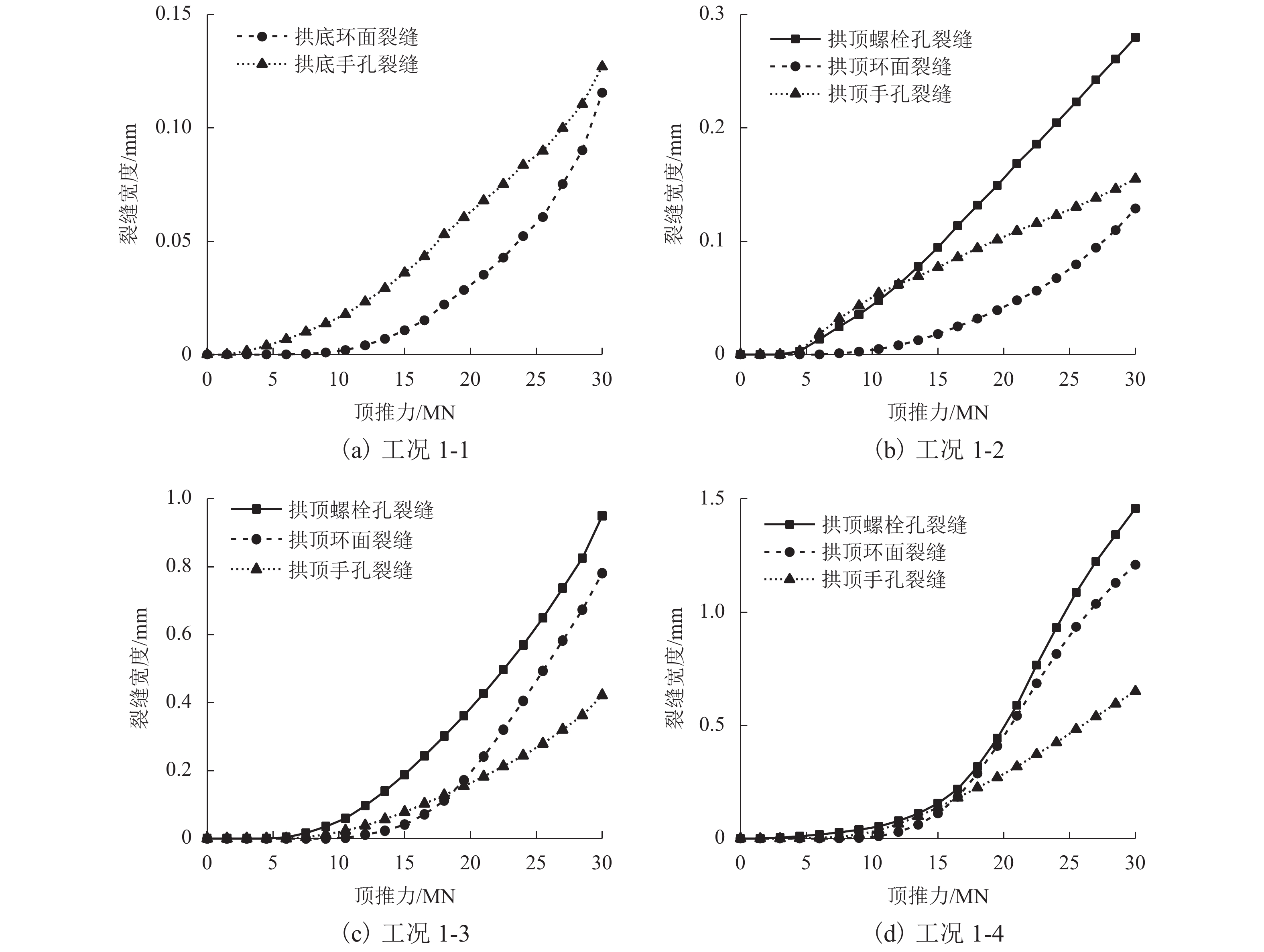

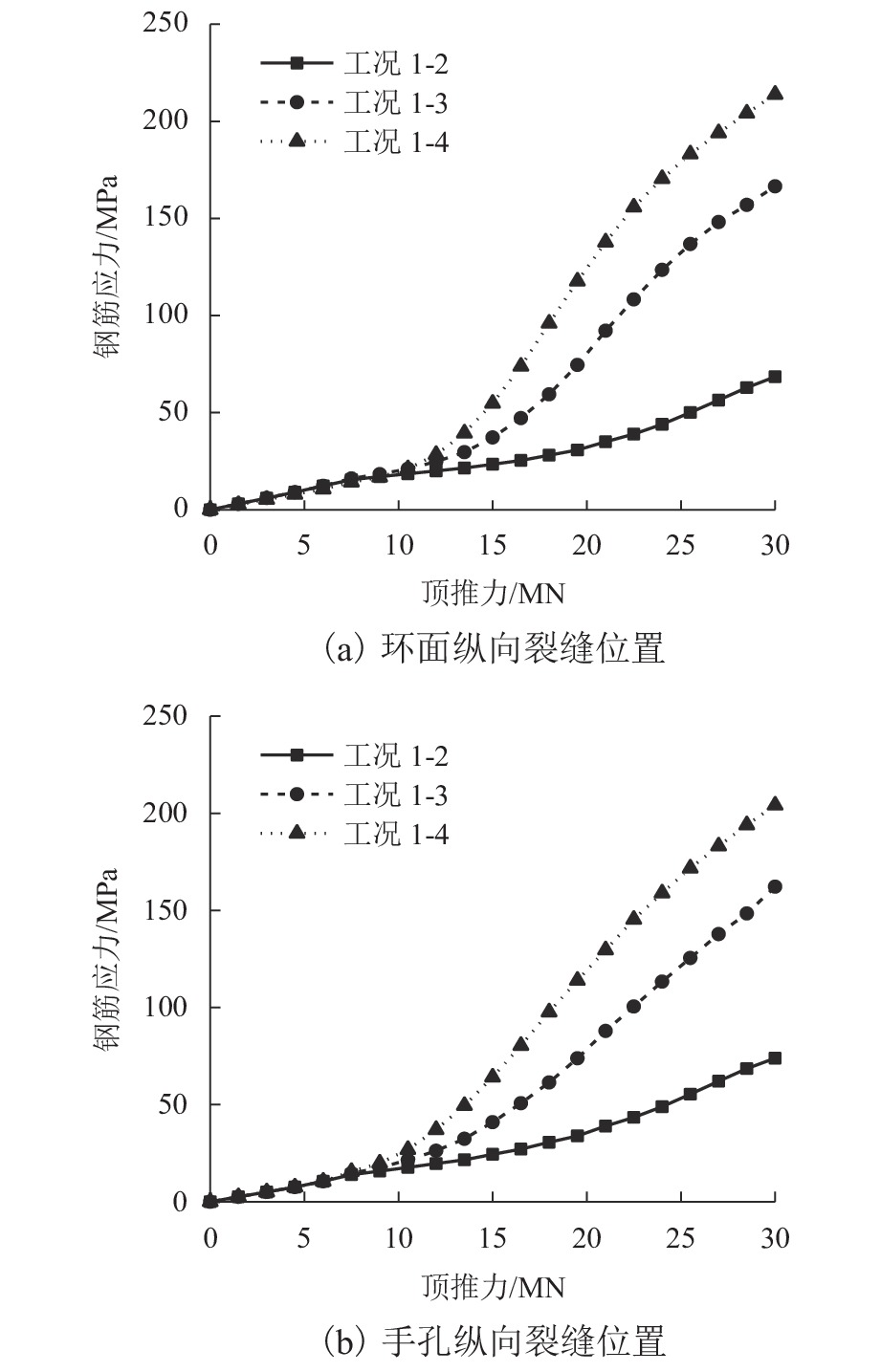

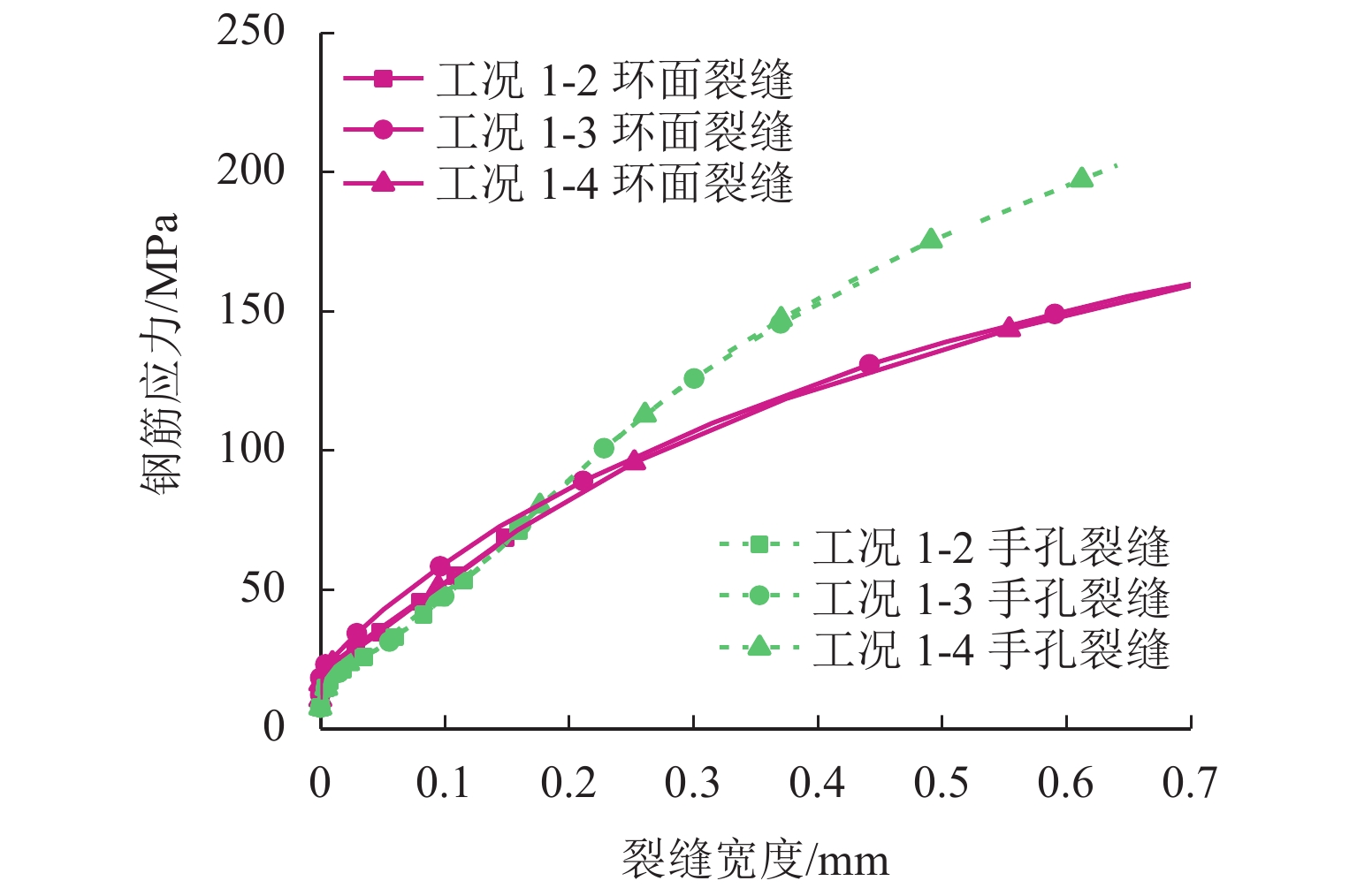

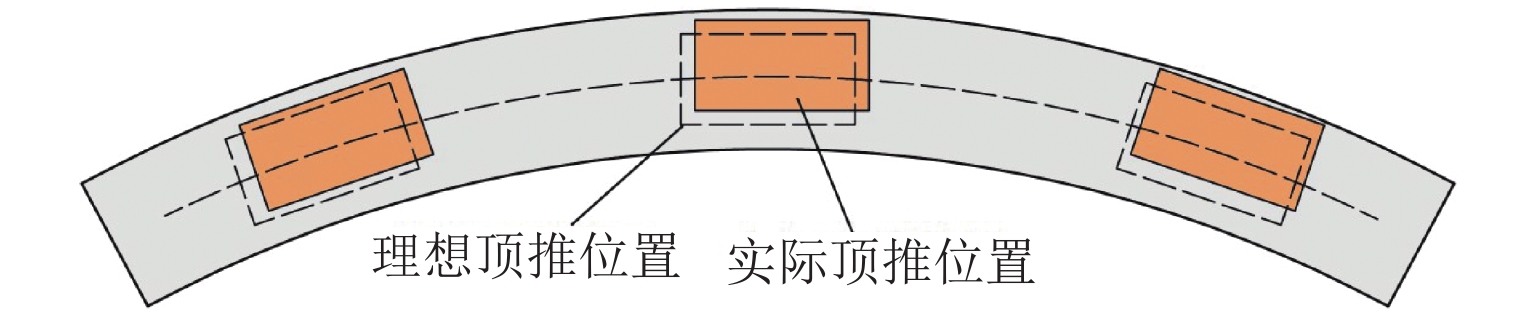

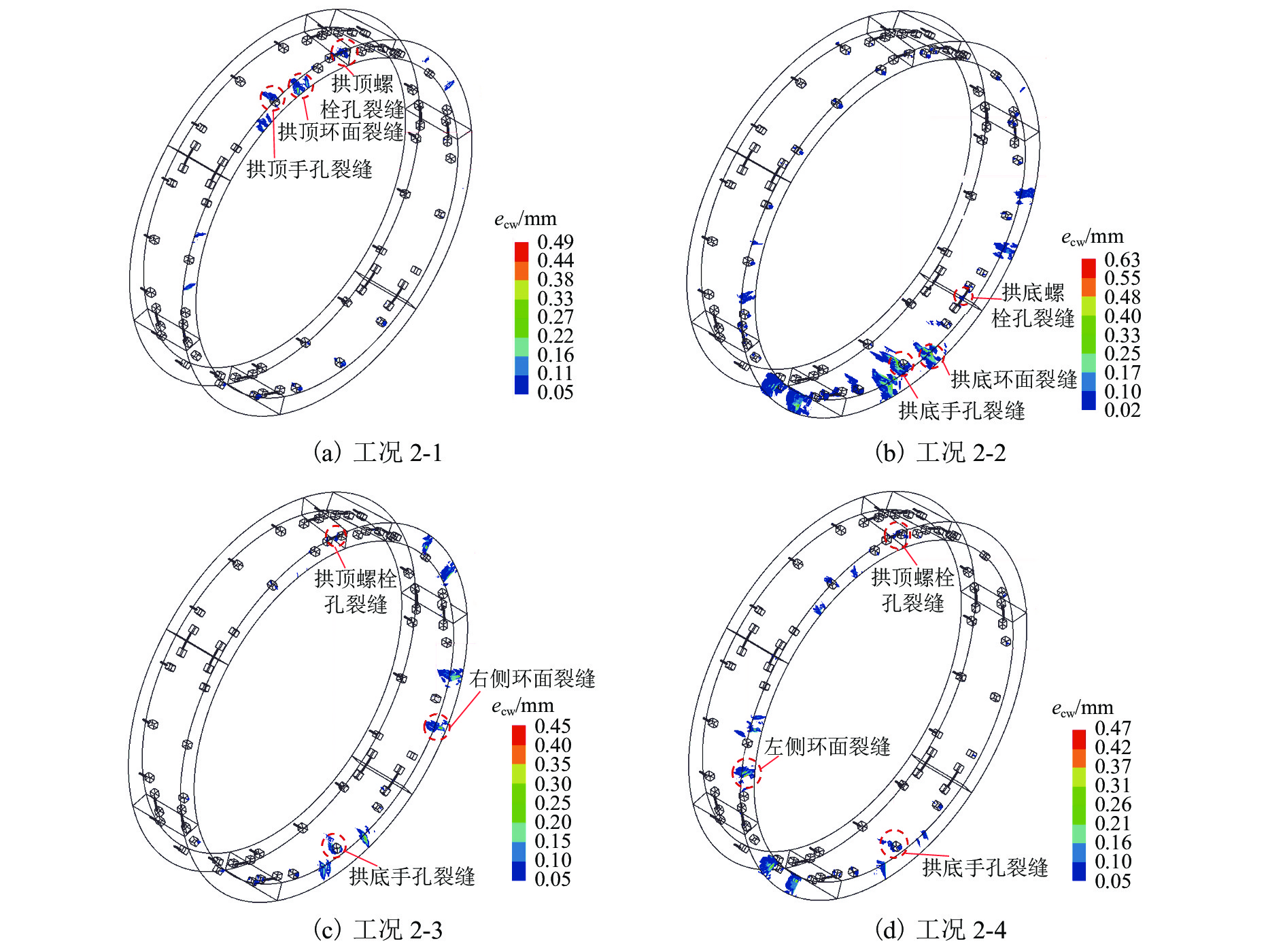

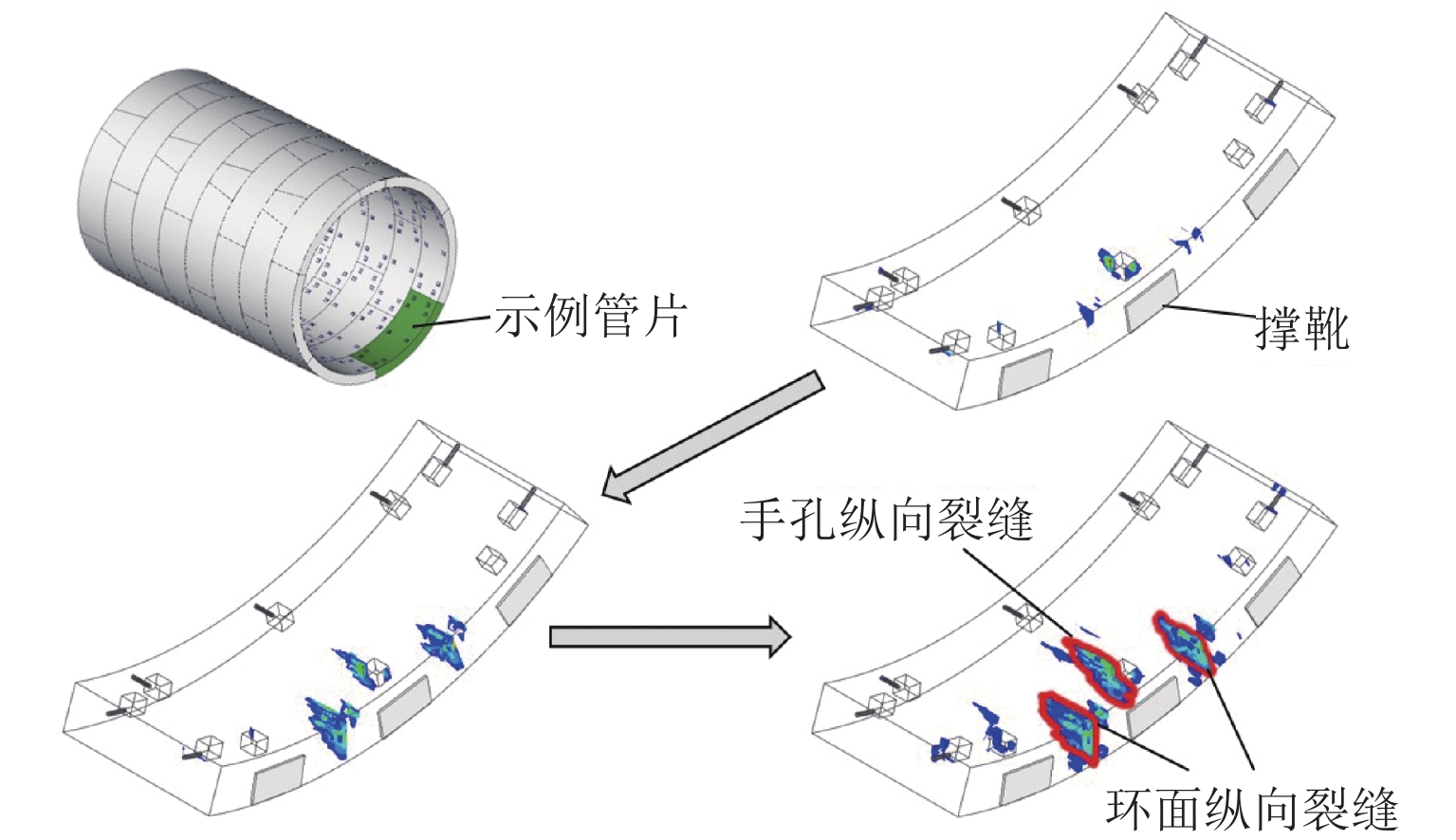

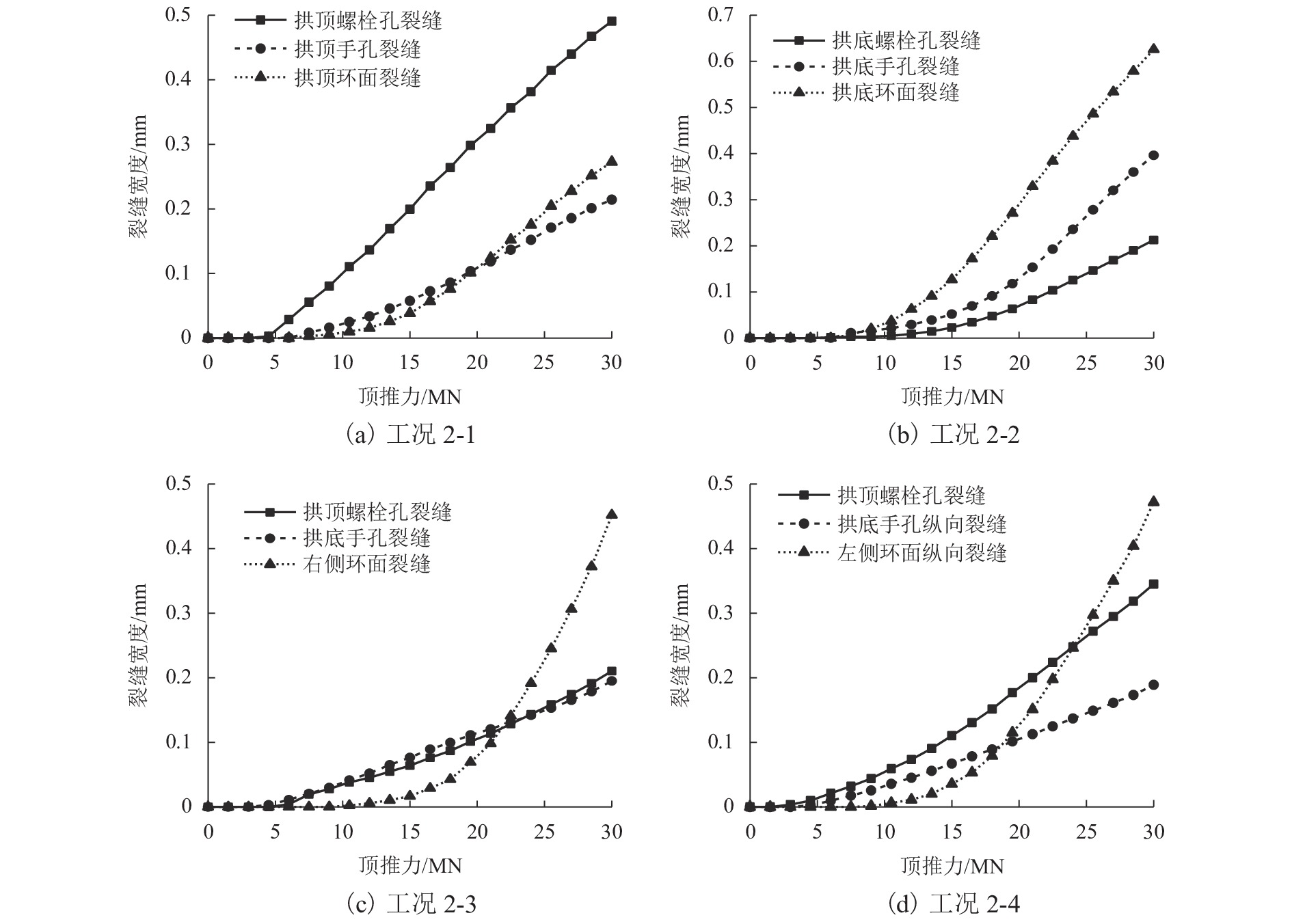

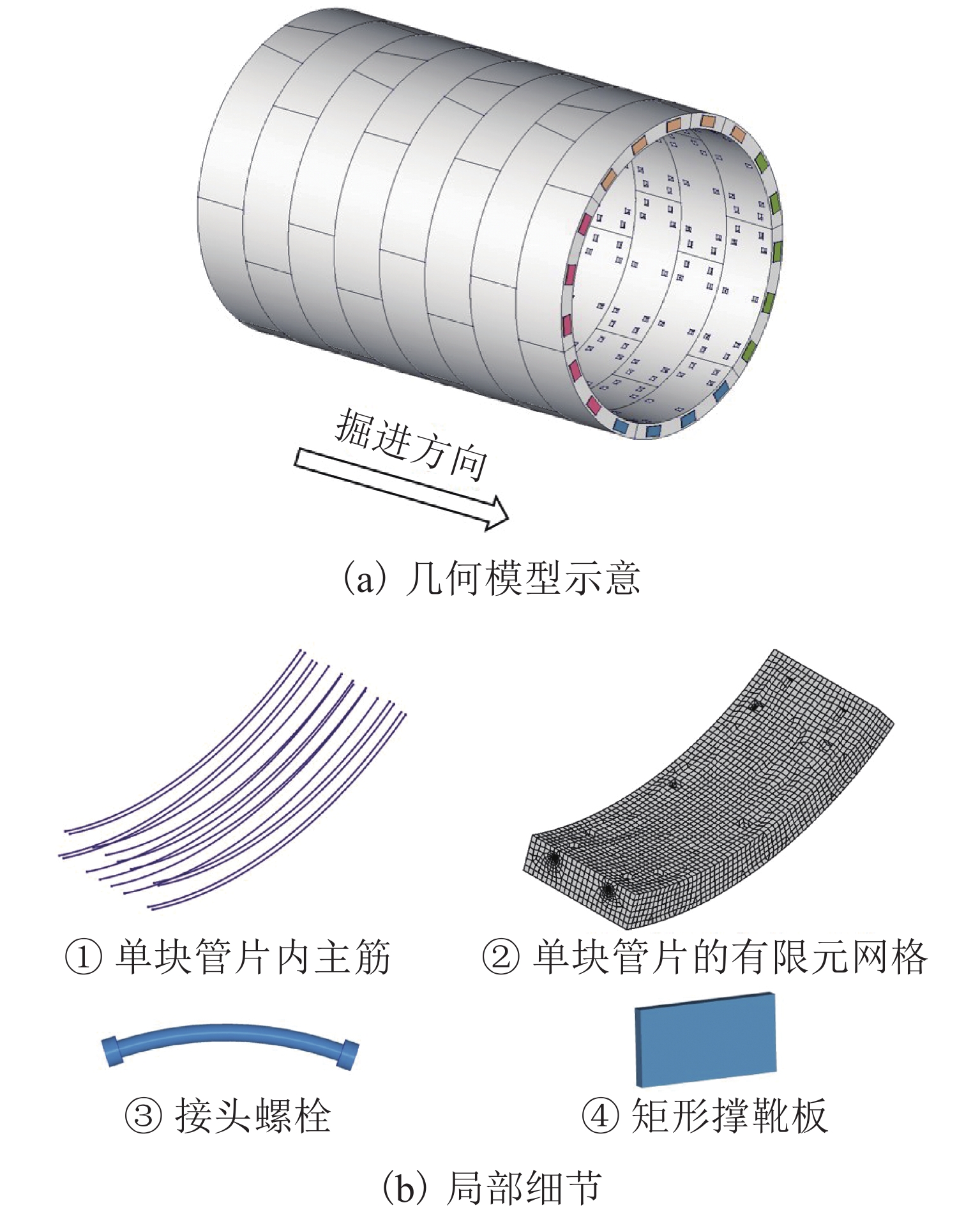

为指导地铁区间隧道施工盾构掘进控制和管片衬砌防裂设计,建立考虑接头-管片的盾构隧道装配式衬砌结构数值模型,基于混凝土弥散开裂本构模型,研究直线段管片衬砌在千斤顶轴向倾斜以及千斤顶端面侧移两种不良顶推作用下管片衬砌的开裂特性. 研究结果表明:在上述2种不良顶推力下,顶推导致的管片衬砌裂缝主要分为封顶块螺栓孔裂缝、手孔纵向裂缝和管片环面纵向裂缝3类;当千斤顶出现轴向倾斜致裂时,拱顶封顶块环向螺栓孔处的裂缝宽度最大,且当轴向倾斜角度达到3° 时,3类裂缝宽度均已超过施工的允许值;当千斤顶端面侧移致裂时,衬砌环面及封顶块环向螺栓孔位置处的宽度最大,其中端面整体向下侧移是最为不利的情况;管片衬砌开裂将导致裂缝位置处钢筋应力增大,相同开裂位置处的钢筋应力-裂缝宽度关系基本不受顶推力倾斜角度变化的影响,裂缝的宽度与钢筋的应力呈正相关关系. 盾构施工时,应严格控制盾构掘进不良顶推作用,对容易产生裂缝的位置建议加强配筋以控制裂缝的发生.

Abstract:In order to guide the shield tunneling control and crack prevention design of segmental lining during the construction of subway section tunnels, a numerical model of the fabricated lining structure of shield tunnels considering joints and segments was established. Based on the constitutive model of concrete smeared cracking, the cracking behavior of linear segmental lining under the adverse jacking force caused by axial tilt and end face lateral displacement of the jack was studied. The research results show that under the above two kinds of adverse jacking force, the segmental lining cracks caused by the jacking force can be divided into bolt hole cracks in the key block, longitudinal cracks in hand holes, and longitudinal cracks in the annular surface of the segment. The crack width is the largest at the ring-direction bolt hole in the key block when the jack axis is tilted axially, and the width of the three types of cracks exceeds the construction limit when the axial inclination angle reaches 3°. The width is the largest at the annular surface of the lining and the ring-direction bolt hole in the key block when the end face of the jack laterally shifts. Specifically, the overall downward lateral displacement of the end face is the most unfavorable situation. The cracking of segmental lining will increase steel reinforcement stress at the crack location, and the relationship between steel reinforcement stress and crack width is not affected by the change of inclination angle of the jacking force. Furthermore, the crack width is positively correlated with the steel reinforcement stress. During shield construction, the adverse jacking force of shield tunneling should be strictly controlled. In order to control the occurrence of cracks, it is suggested to strengthen the reinforcement in the position where cracks are easy to occur.

-

Key words:

- shield tunnel /

- segmental lining /

- jacking force /

- smeared crack model /

- crack propagation

-

表 1 地层材料参数

Table 1. Material parameters of soils

材料 重度/

(kN•m−3)弹性模量/

MPa泊松比 内摩擦

角/(°)黏聚力/

MPa杂填土 18.6 1.0 0.35 10.0 0.010 粉质

黏土19.7 3.9 0.28 11.0 0.026 粉土 19.0 4.8 0.30 19.7 0.018 卵石土 22.5 50.0 0.22 45.0 0 中风化

泥岩26.9 750.0 0.18 33.0 0.300 表 2 管片衬砌混凝土、钢筋和螺栓的材料参数

Table 2. Material parameters of concrete, steel reinforcement, and bolts of segmental lining

材料 弹性模量/

GPa屈服强度/

MPa密度/

(kg•m−3)泊松比 抗拉强度/

MPa抗压强度/

MPa拉伸断裂能/

(N•mm−1)压缩断裂能/

(N•mm−1)混凝土 34.5 2500 0.2 2.3 32.5 0.15 40 钢筋 200.0 400 7800 0.2 螺栓 210.0 440 7800 0.2 -

[1] 卢岱岳,何川,王士民. 千斤顶作用下带榫管片的裂纹扩展规律[J]. 西南交通大学学报,2017,52(1): 75-82.LU Daiyue, HE Chuan, WANG Shimin. Crack propagation law of segment tendon under jacking forces[J]. Journal of Southwest Jiaotong University, 2017, 52(1): 75-82. [2] 苏昂,王士民,何川,等. 复合地层盾构隧道管片施工病害特征及成因分析[J]. 岩土工程学报,2019,41(4): 683-692.SU Ang, WANG Shimin, HE Chuan, et al. Disease characteristics and causes analysis of segments of shield tunnels in composite stratum during construction[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(4): 683-692. [3] CHEN J S, MO H H. Numerical study on crack problems in segments of shield tunnel using finite element method[J]. Tunnelling and Underground Space Technology, 2009, 24(1): 91-102. doi: 10.1016/j.tust.2008.05.007 [4] 杨雨冰,谢雄耀. 基于断裂力学的盾构隧道管片结构开裂破损机制探讨[J]. 岩石力学与工程学报,2015,34(10): 2114-2124.YANG Yubing, XIE Xiongyao. Breaking mechanism of segmented lining in shield tunnel based on fracture mechanics[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(10): 2114-2124. [5] 王飞阳,黄宏伟. 盾构隧道衬砌结构裂缝演化规律及其简化模拟方法[J]. 岩石力学与工程学报,2020,39(增1): 2902-2910.WANG Feiyang, HUANG Hongwei. Crack evolution law of shield tunnel lining and its simplified simulation method[J]. Chinese Journal of Rock Mechanics and Engineering, 2020, 39(S1): 2902-2910. [6] WANG F Y, ZHOU M L, ZHANG D M, et al. Random evolution of multiple cracks and associated mechanical behaviors of segmental tunnel linings using a multiscale modeling method[J]. Tunnelling and Underground Space Technology, 2019, 90: 220-230. doi: 10.1016/j.tust.2019.05.008 [7] YAN Q X, XU Y J, ZHANG W L, et al. Numerical analysis of the cracking and failure behaviors of segmental lining structure of an underwater shield tunnel subjected to a derailed high-speed train impact[J]. Tunnelling and Underground Space Technology, 2018, 72(2): 41-54. [8] YAN Q X, SUN M H, QING S Y, et al. Numerical investigation on the damage and cracking characteristics of the shield tunnel caused by derailed high-speed train[J]. Engineering Failure Analysis, 2020, 108(8): 104205.1-104205.15. [9] 黄宏伟,刘德军,薛亚东,等. 基于扩展有限元的隧道衬砌裂缝开裂数值分析[J]. 岩土工程学报,2013,35(2): 266-275.HUANG Hongwei, LIU Ddjun, XUE Yadong, et al. Numerical analysis of cracking of tunnel linings based on extended finite element[J]. Chinese Journal of Geotechnical Engineering, 2013, 35(2): 266-275. [10] WANG S M, LIU C K, SHAO Z M, et al. Experimental study on damage evolution characteristics of segment structure of shield tunnel with cracks based on acoustic emission information[J]. Engineering Failure Analysis, 2020, 118: 104899.1-104899.14. [11] XU G W, HE C, LU D Y, et al. The influence of longitudinal crack on mechanical behavior of shield tunnel lining in soft-hard composite strata[J]. Thin-Walled Structures, 2019, 144: 106282.1-106282.23. [12] CAVALARO S H P, BLOM C B M, WALRAVEN J C, et al. Structural analysis of contact deficiencies in segmented lining[J]. Tunnelling and Underground Space Technology, 2011, 26(6): 734-749. doi: 10.1016/j.tust.2011.05.004 [13] 许学昭,李兆平,王凯,等. 基于大直径盾构隧道扩挖地铁车站的结构方案及其关键节点受力和变形[J]. 中国铁道科学,2021,42(2): 66-76.XU Xuezhao, LI Zhaoping, WANG Kai, et al. Structural scheme of metro station constructed by enlarging large diameter shield tunnel and stress and deformation of its key joints[J]. China Railway Science, 2021, 42(2): 66-76. [14] 肖明清,封坤,张忆,等. 盾构隧道同步注浆浆液浮力引起的管片错台量分析[J]. 隧道建设(中英文),2021,41(12): 2048-2057.XIAO Mingqing, FENG Kun, ZHANG Yi, et al. Analysis of segment dislocation caused by grout buoyancy during synchronous grouting of shield tunnels[J]. Tunnel Construction, 2021, 41(12): 2048-2057. [15] JIN H, YU K W, GONG Q M, et al. Load-carrying capability of shield tunnel damaged by shield shell squeezing action during construction[J]. Thin-Walled Structures, 2018, 132: 69-78. doi: 10.1016/j.tws.2018.07.057 [16] CONFORTI A, TRABUCCHI I, TIBERTI G, et al. Precast tunnel segments for metro tunnel lining: a hybrid reinforcement solution using macro-synthetic fibers[J]. Engineering Structures, 2019, 199: 109628.1-109628.11. [17] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB 50011—2010 [S]. 北京: 中国建筑工业出版社, 2011. [18] 项贻强,徐建武,唐国斌,等. 钢筋混凝土构件裂缝宽度计算的修正方法及其实桥试验研究[J]. 公路交通科技,2011,28(2): 45-51.XIANG Yiqiang, XU Jianwu, TANG Guobin, et al. Modified method for calculating crack width of reinforced concrete members and its field test[J]. Journal of Highway and Transportation Research and Development, 2011, 28(2): 45-51. -

下载:

下载: