Optimization Analysis and Monitoring of Construction Process of Open Spherical Reticulated Shell Structure with a Large Rise-to-Span Ratio

-

摘要:

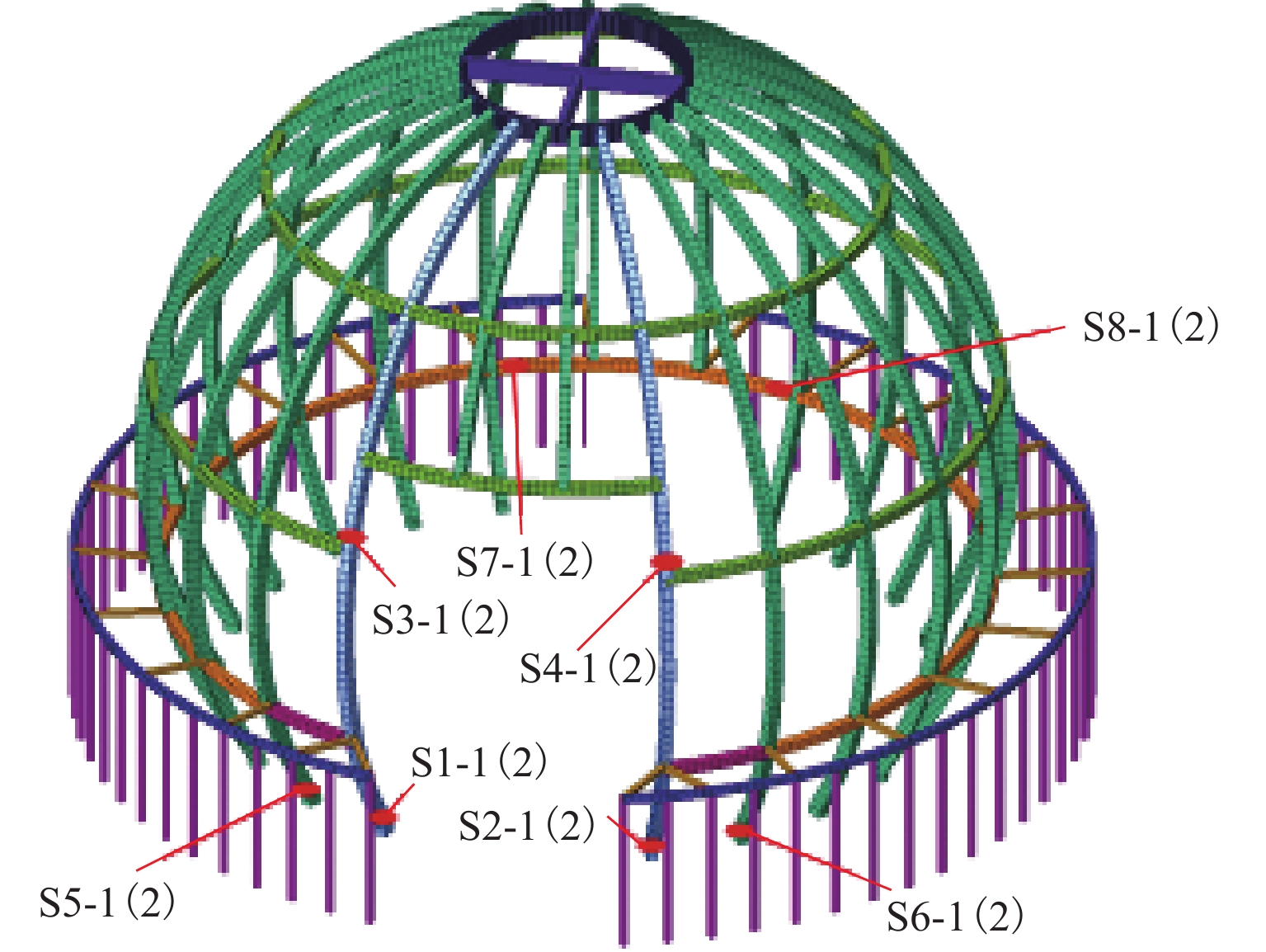

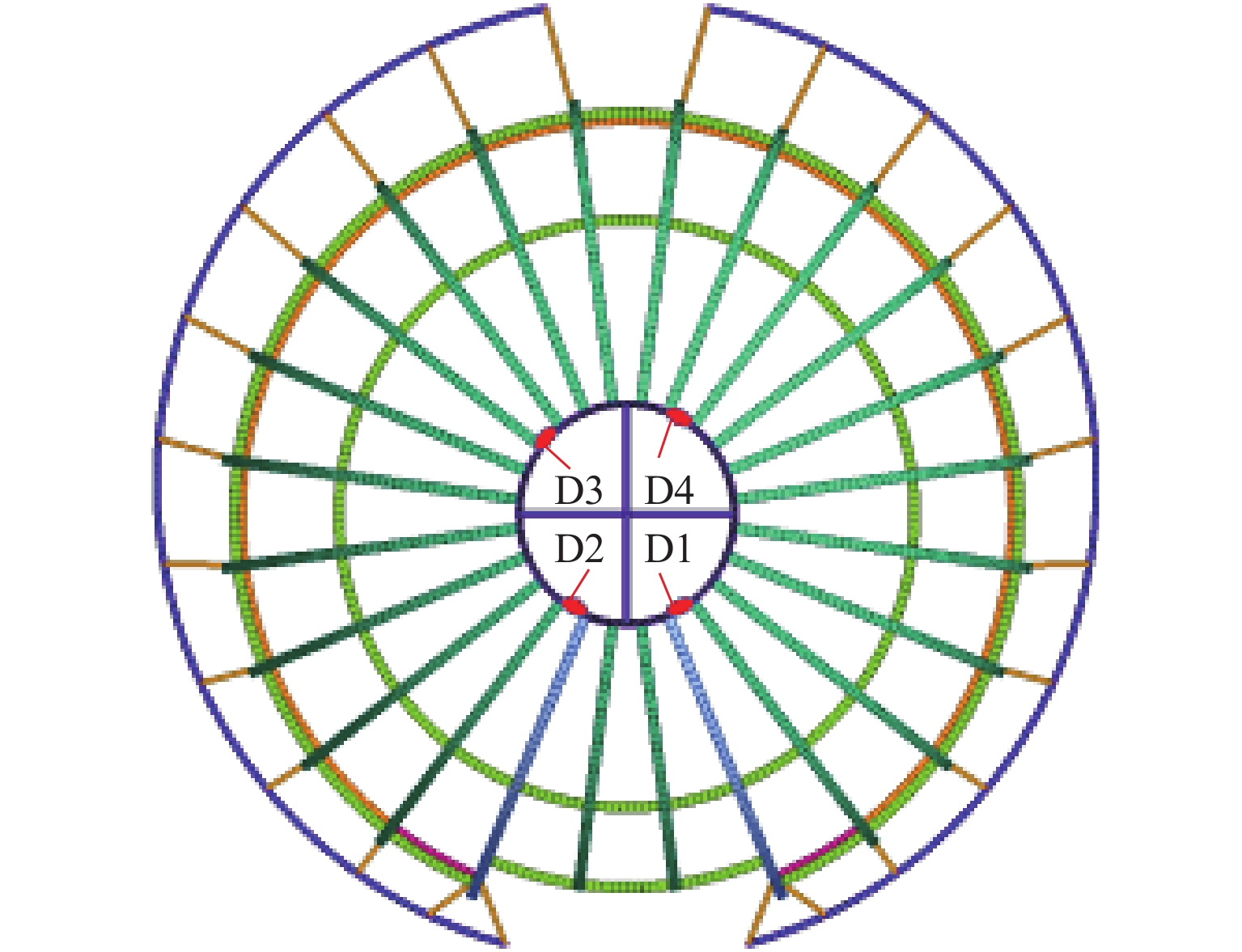

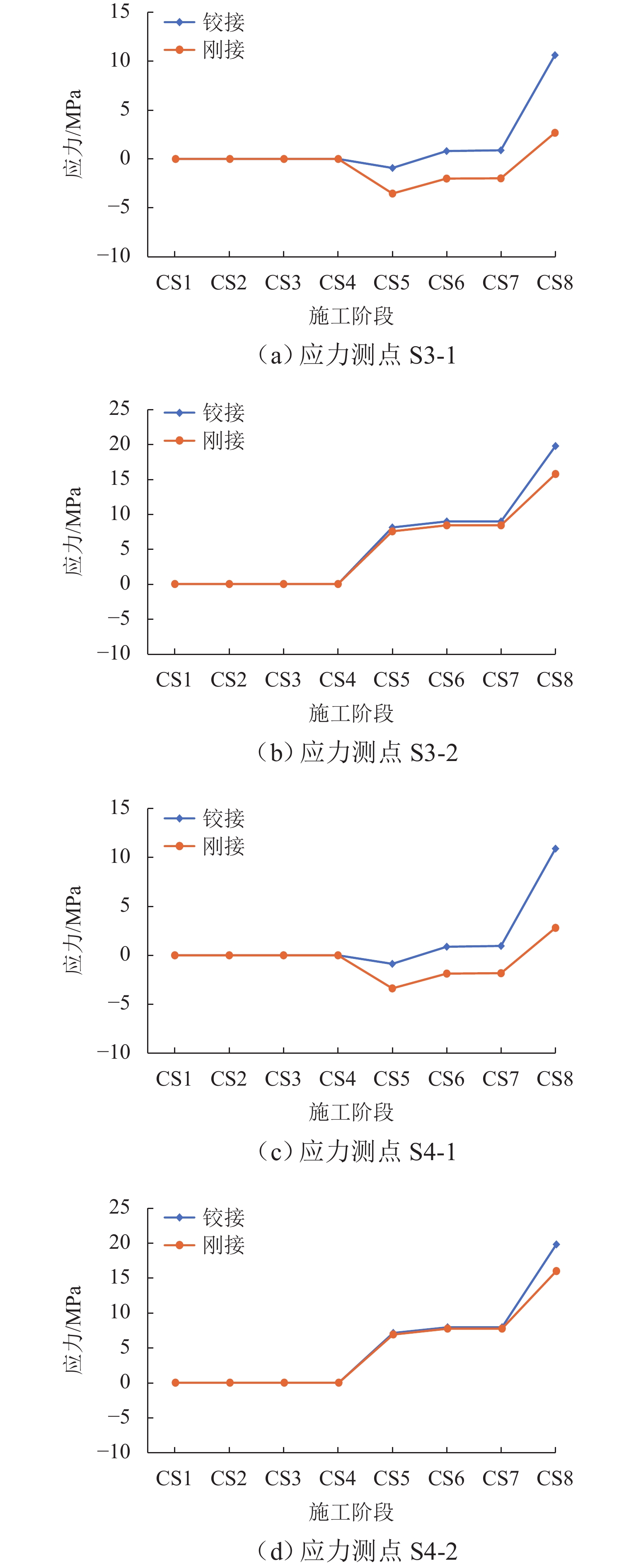

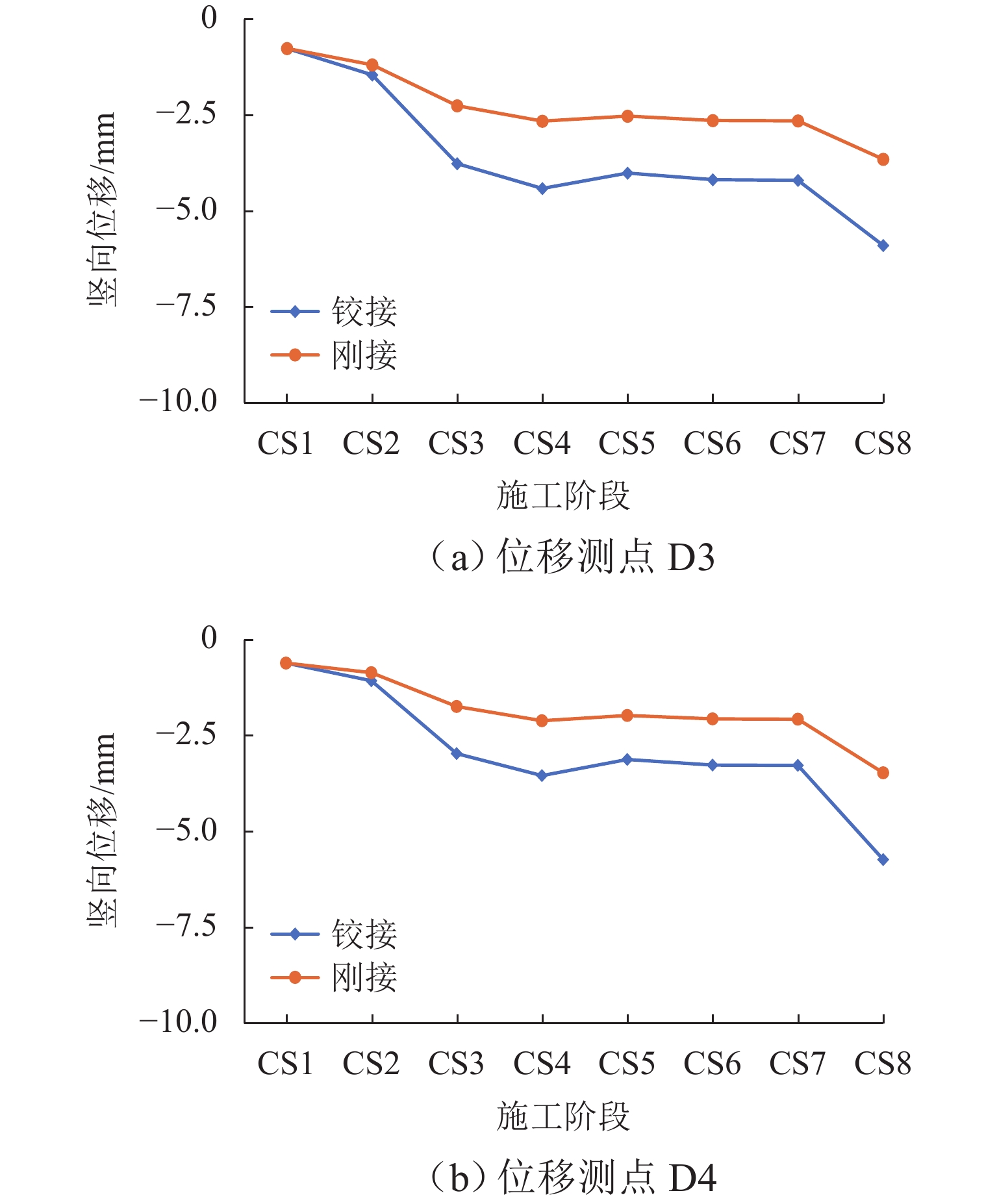

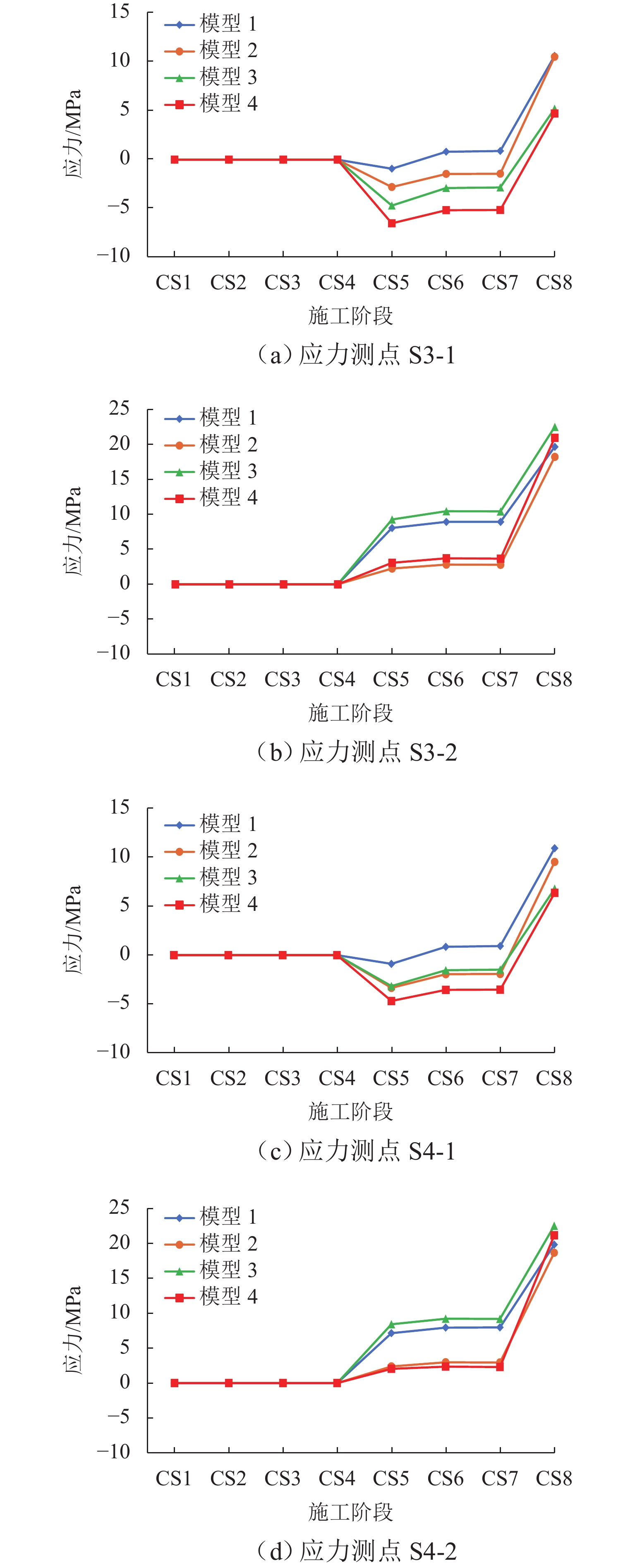

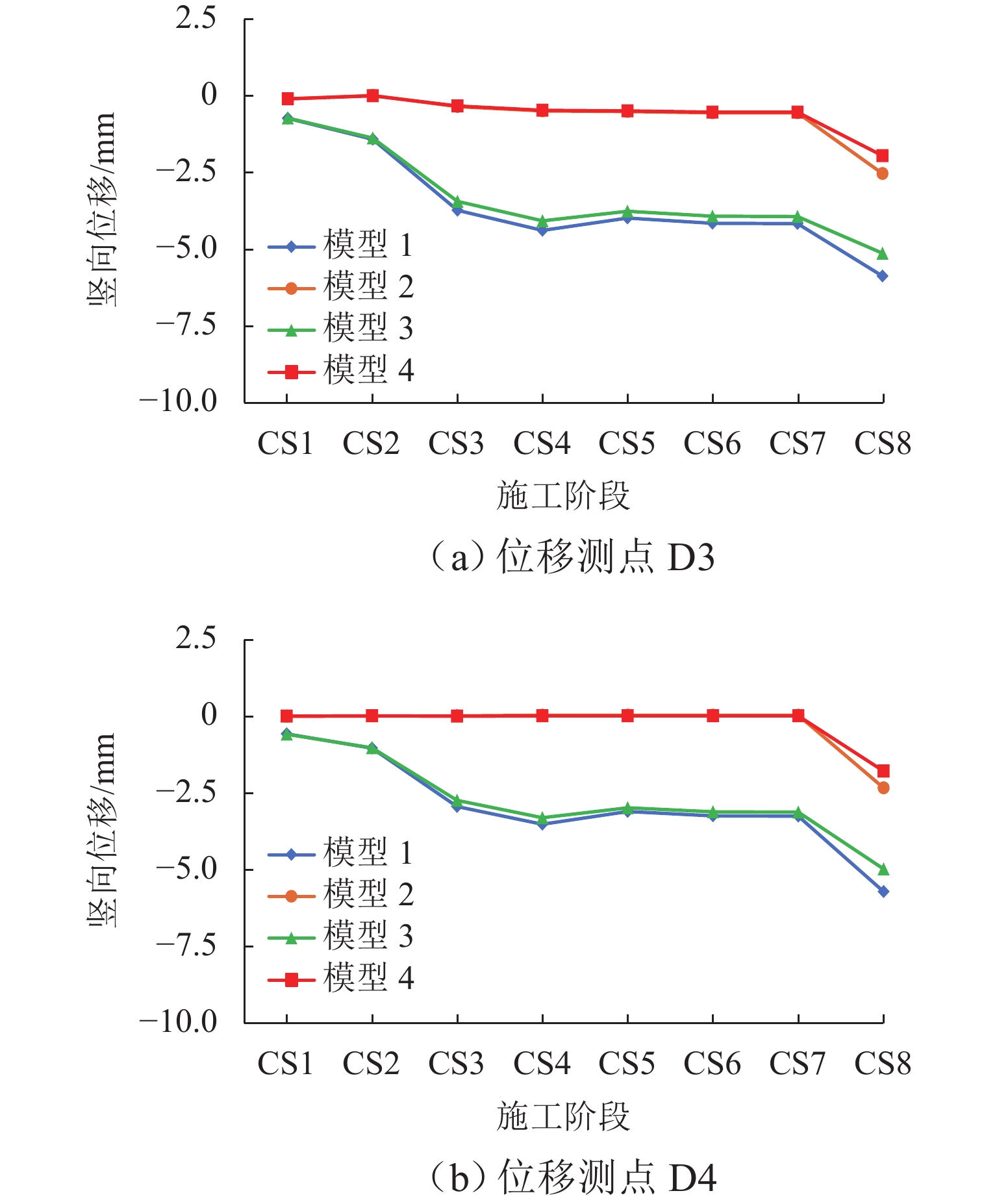

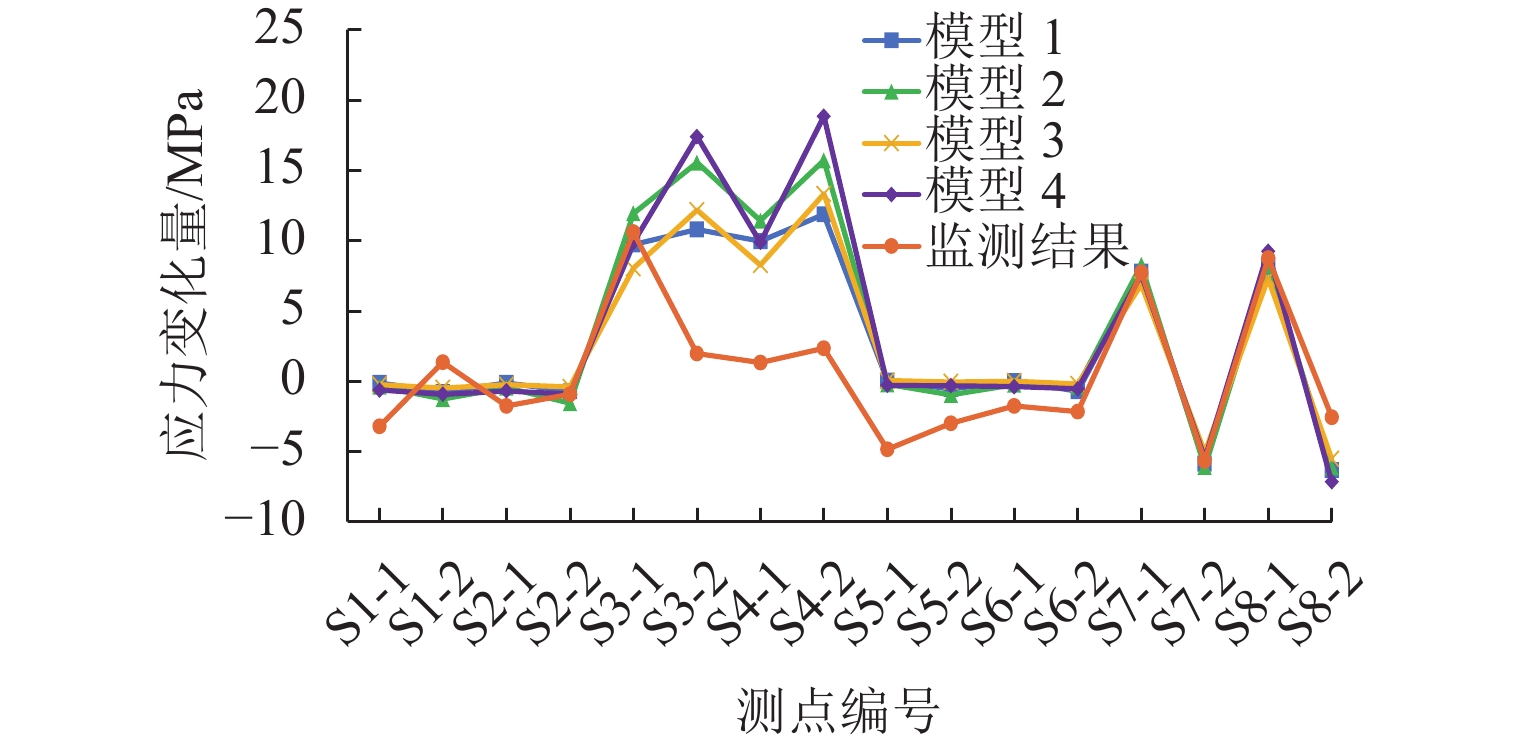

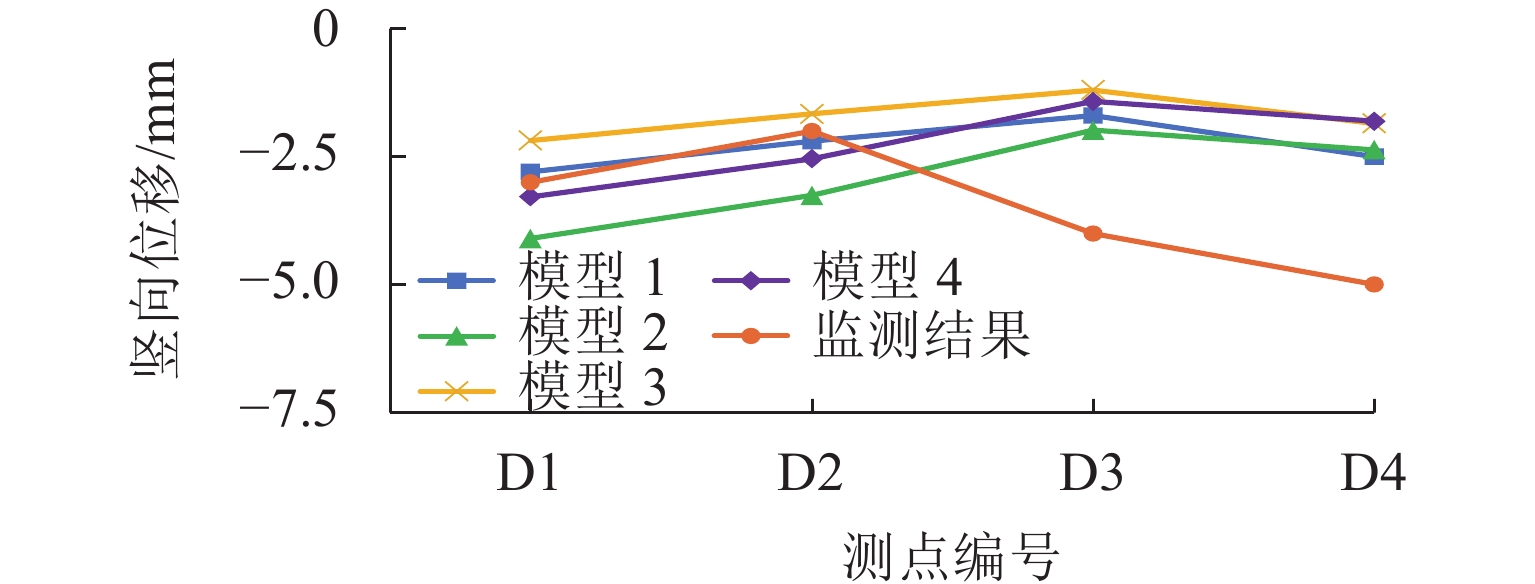

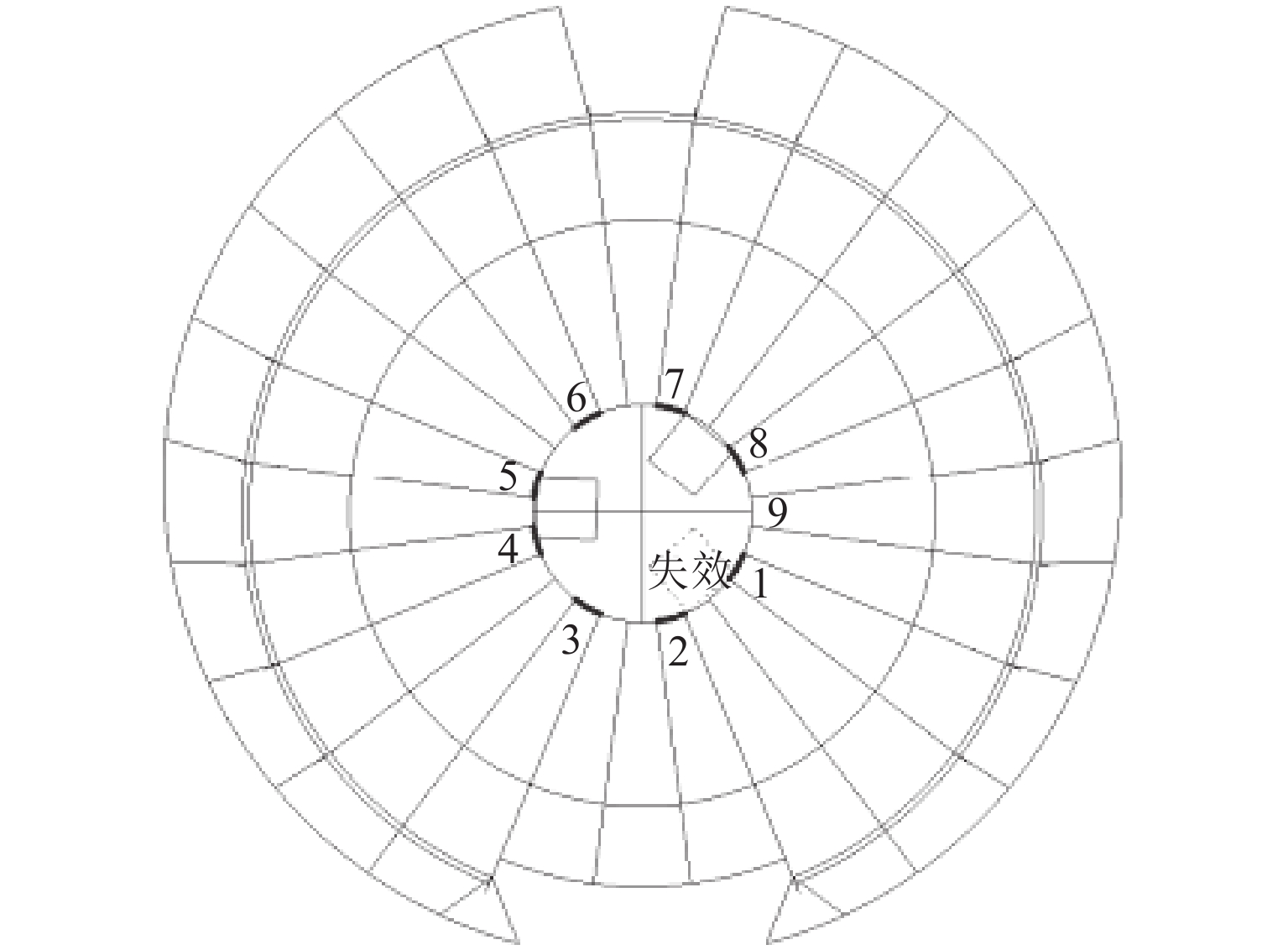

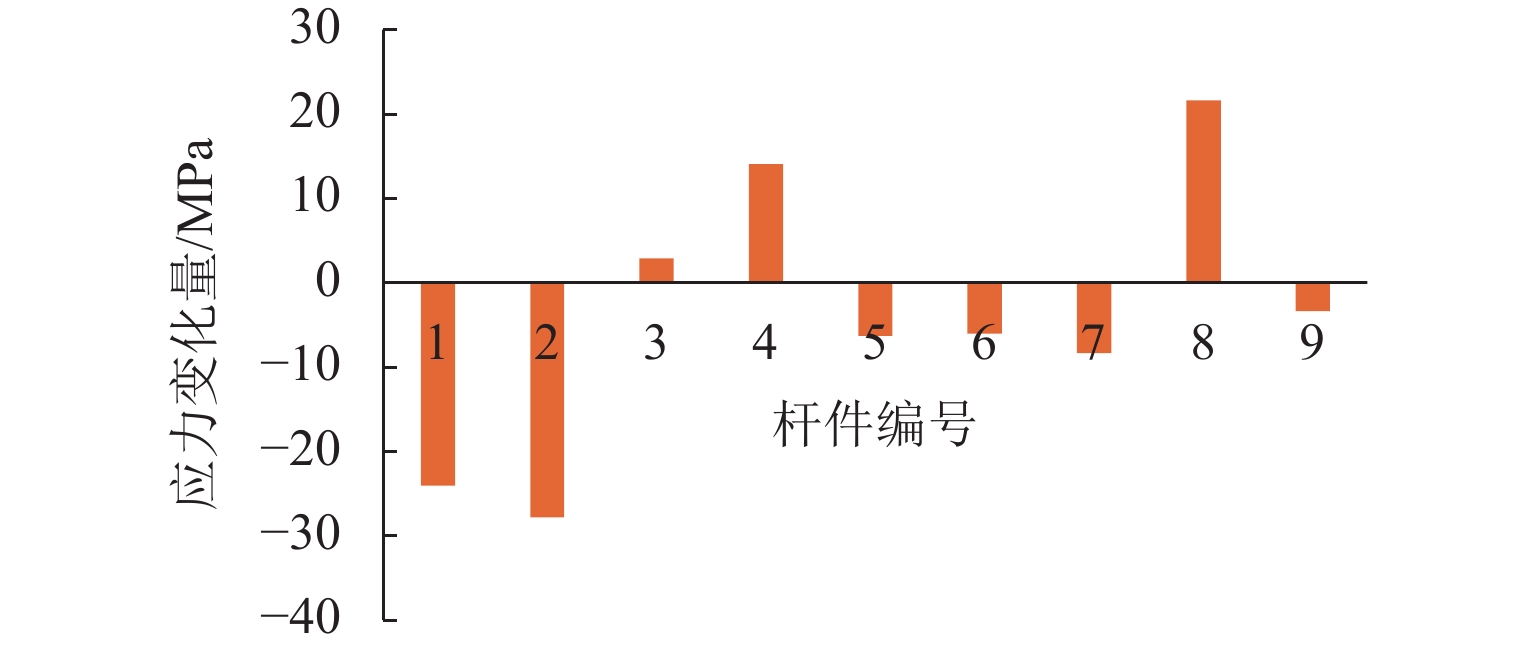

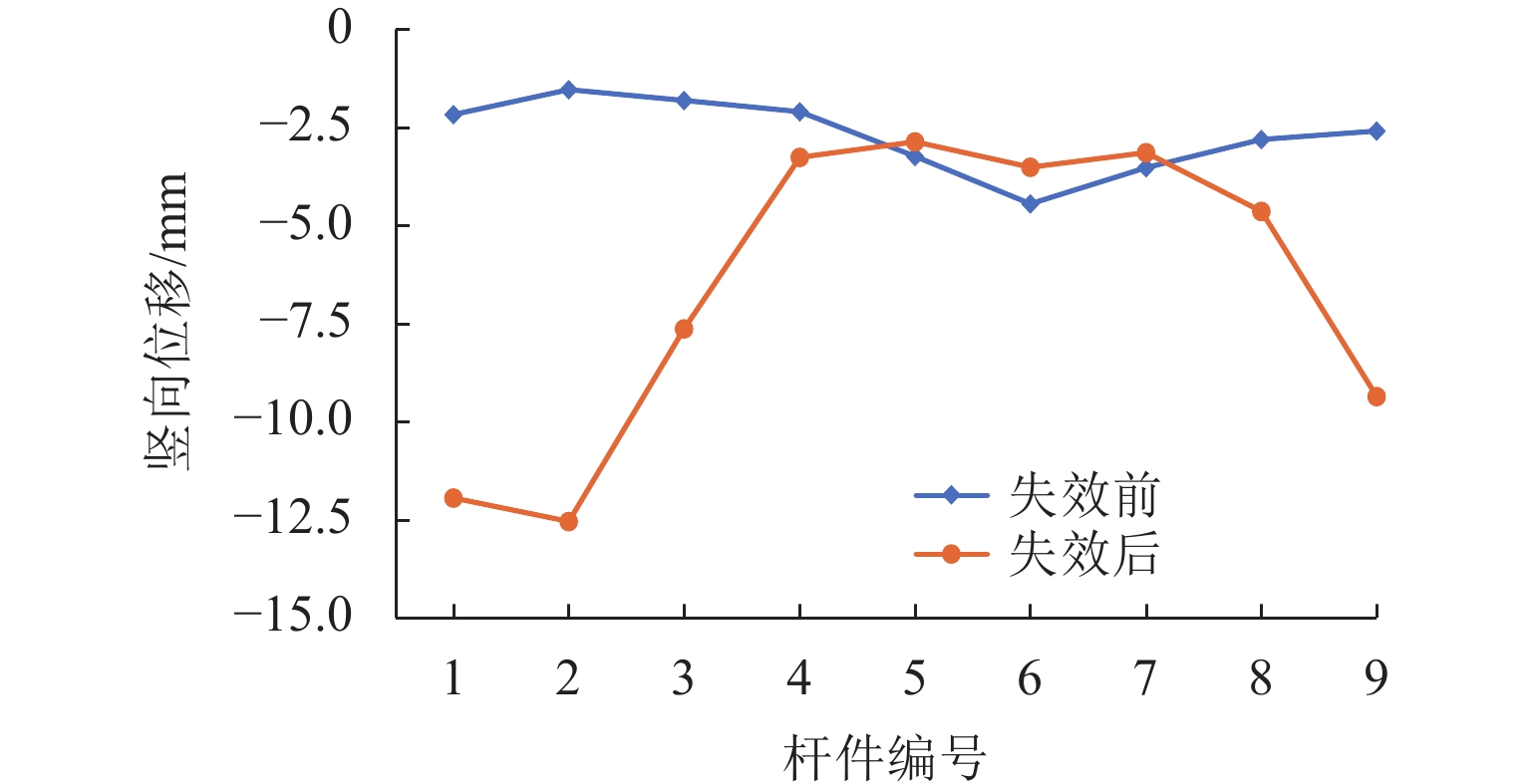

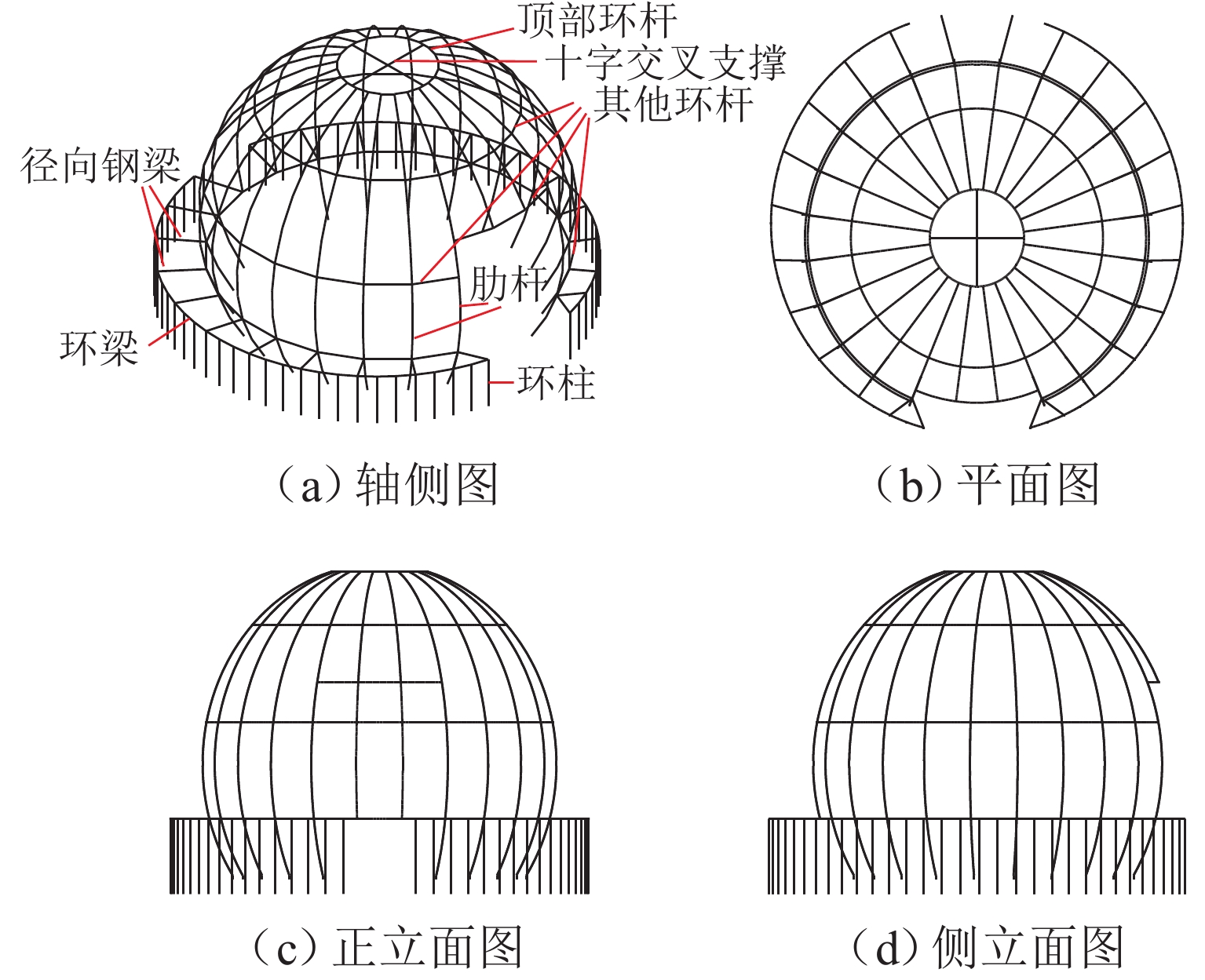

为保证复杂空间网格结构的施工安全性,对其进行施工过程优化分析与监测研究. 以某大矢跨比单层开口球面网壳结构为例,对该复杂异形结构进行施工全过程的有限元模拟,通过变化支座边界条件、肋杆轴线形状和临时支撑胎架支承方式建立不同的有限元分析模型,探讨其关键构件应力与结构位移的变化情况,以对施工过程进行优化分析;在此基础上,采用有临时支撑胎架的弧形杆模型作为最终计算模型进行施工模拟,并将卸载前后的计算结果与现场监测数据进行对比分析,以验证施工过程模拟结果的准确性;进一步对临时支撑胎架的失效敏感性进行研究,以避免出现结构安全问题. 结果表明:有限元分析模型与实际结构较为相符,卸载前后各测点的应力变化较小,最大拉、压应力变化量分别为10.61 MPa和 −5.67 MPa,该大矢跨比异形球面网壳结构在施工过程中处于可控状态;某一支撑胎架失效对其周边相邻区域的杆件应力、结构位移有较大影响,其中杆件应力最大变化为28.00 MPa,竖向位移最大变化为13 mm,因此,施工过程中应确保支撑胎架的可靠性.

Abstract:To ensure the construction safety of the complex spatial grid structure, the optimization analysis and monitoring of the construction process were carried out. An open single-layer spherical reticulated shell structure with a large rise-to-span ratio was taken as an example, and the construction process of this complex special-shaped structure was simulated through finite element analysis (FEA). By changing the boundary conditions of the support, the shape of the rib axis, and the support mode of the temporary support jig frame, different FEA models were established. The stress variations of key members and the structural displacement were analyzed to optimize the construction process. On this basis, the arc rod model with a temporary support jig frame was used as the final calculation model for construction process simulation, and the calculation results before and after unloading were compared with the on-site monitoring data to verify the accuracy of the FEA model in simulating the construction process. The failure sensitivity of the temporary support jig frame was further studied to avoid structural safety problems. The results show that the FEA model is consistent with the actual structure. The stress of each measuring point before and after unloading changes slightly, and the maximum tensile and compressive stress changes are 10.61 MPa and −5.67 MPa, respectively. The special-shaped spherical reticulated shell with a large rise-to-span ratio is in a controllable state during construction. The failure of a certain temporary support jig frame would have a great influence on member stress and structural displacement in the adjacent area. The maximum change of the member stress is 28.00 MPa, and that of the vertical displacement is 13 mm. Therefore, the reliability of the support jig frame shall be ensured during the construction.

-

Key words:

- reticulated shell structure /

- construction process /

- optimization /

- monitoring /

- unloading

-

表 1 球壳钢材材料参数表

Table 1. Steel material parameters of spherical shell

序号 杆件类型 规格/mm 材质 1 十字交叉支撑 600 × 200 × 12 × 12 焊接 Q345B 2 顶部环杆 600 × 200 × 12 × 12 焊接 Q345B 3 其他环杆 300 × 300 × 16 × 16 热轧或

300 × 300 × 30 × 30 焊接Q345B 4 肋杆 400 × 300 × 12 × 12 热轧或

400 × 300 × 20 × 20 焊接Q345B 5 环柱 Φ203 × 6 Q235B 6 环梁 200 × 200 × 8 × 8 热轧 Q235B 7 径向钢梁 150 × 150 × 6 × 6 热轧 Q235B 表 2 4种有限元模型的情况

Table 2. Conditions of four finite element analysis (FEA) models

编号 杆件情况 临时支撑胎架情况 模型 1 将肋杆、环杆细分为多段单元以模拟弧形杆件受力状态,杆件弯曲程度较为明显 支撑胎架根据实际情况进行建模 模型 2 将肋杆、环杆细分为多段单元以模拟弧形杆件受力状态,杆件弯曲程度较为明显 以竖向约束代替支撑胎架进行建模 模型 3 将肋杆、环杆简化为一段斜杆,杆件弯曲程度不明显 支撑胎架根据实际情况进行建模 模型 4 将肋杆、环杆简化为一段斜杆,杆件弯曲程度不明显 以竖向约束代替支撑胎架进行建模 -

[1] HE S, JIANG Z R, CAI J. Investigation on simulation methods of initial geometric imperfection distribution in elasto-plastic stability analysis of single-layer reticulated shells[J]. KSCE Journal of Civil Engineering, 2018, 22(4): 1193-1202. doi: 10.1007/s12205-017-0879-0 [2] 韩庆华,丁 阳,程万海,等. 河北省科技馆单层球面网壳结构的设计、施工及非线性屈曲分析[J]. 建筑结构学报,2001,22(4): 27-30.HAN Qinghua, DING Yang, CHENG Wanhai, et al. Design, construction and nonlinear nuckling analysis of single layer spherical latticed stucture used in Science and Technology Museum of Hebei Province[J]. Journal of Building Structures, 2001, 22(4): 27-30. [3] 周 克,唐建华,曹 旺,等. 杭州国际博览中心单层球面网壳施工技术[J]. 施工技术,2015,44(8): 60-62.ZHOU Ke, TANG Jianhua, CAO Wang, et al. Construction of the single-layer spherical latticed shell in Hangzhou International Expo Center[J]. Construction Technology, 2015, 44(8): 60-62. [4] 张 君,王秀丽,毕贵权,等. 天水体育中心游泳馆钢网壳结构施工模拟分析与监测[J]. 建筑结构,2020,50(17): 34-39,33.ZHANG Jun, WANG Xiuli, BI Guiquan, et al. Construction simulation analysis and monitoring of steel reticulated shell structure of natatorium for Tianshui sports center[J]. Building Structures, 2020, 50(17): 34-39,33. [5] 石开荣,吕俊锋,姜正荣,等. 高层悬挂结构卸载分析与监测[J]. 华南理工大学学报(自然科学版),2017,45(8): 110-119.SHI Kairong, LÜ Junfeng, JIANG Zhengrong, et al. Analysis and monitoring of unloading process of high-rise suspended structure[J]. Journal of South China University of Technology (Natural Science Edition), 2017, 45(8): 110-119. [6] 孙学根,牛忠荣,李兆峰,等. 大跨度空间结构卸载过程模拟分析与监测[J]. 建筑结构,2018,48(11): 70-77.SUN Xuegen, NIU Zhongrong, LI Zhaofeng, et al. Simulating analysis and monitoring of unloading process of large-span spatial structure[J]. Building Structures, 2018, 48(11): 70-77. [7] 邱冶. 大矢跨比球壳的风荷载特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2010. [8] CHOI C K, CHUNG H K, LEE D G, et al. Simplified building analysis with sequential dead loads—CFM[J]. Journal of Structural Engineering, 1992, 118(4): 944-954. doi: 10.1061/(ASCE)0733-9445(1992)118:4(944) [9] 崔晓强,郭彦林,叶可明. 大跨度钢结构施工过程的结构分析方法研究[J]. 工程力学,2006,23(5): 83-88.CUI Xiaoqiang, GUO Yanlin, YE Keming. Research on the construction mechanic method of long-span steel structures[J]. Engineering Mechanics, 2006, 23(5): 83-88. [10] 石开荣,吕俊锋,姜正荣,等. 复杂高层悬挂结构施工过程模拟分析及监测研究[J]. 工业建筑,2017,47(4): 134-139.SHI Kairong, LÜ Junfeng, JIANG Zhengrong, et al. Research on construction simulation and monitoring of the complex high-rise suspended structure[J]. Industrial Construction, 2017, 47(4): 134-139. [11] 赵 欣,关 宇,谭品峰,等. 南开大学大学生活动中心施工模拟与监测[J]. 钢结构,2017,32(3): 103-108.ZHAO Xin, GUAN Yu, TAN Pinfeng, et al. Simulation and monitoring for the construction of student activity center of Nankai University[J]. Steel Construction, 2017, 32(3): 103-108. [12] 中华人民共和国住房和城乡建设部. 空间网格结构技术规程: JGJ 7—2010[S]. 北京: 中国建筑工业出版社, 2010. -

下载:

下载: