Experimental Comparison of Horseshoe Prefabricated and Spray Anchor Initial Support Structures

-

摘要:

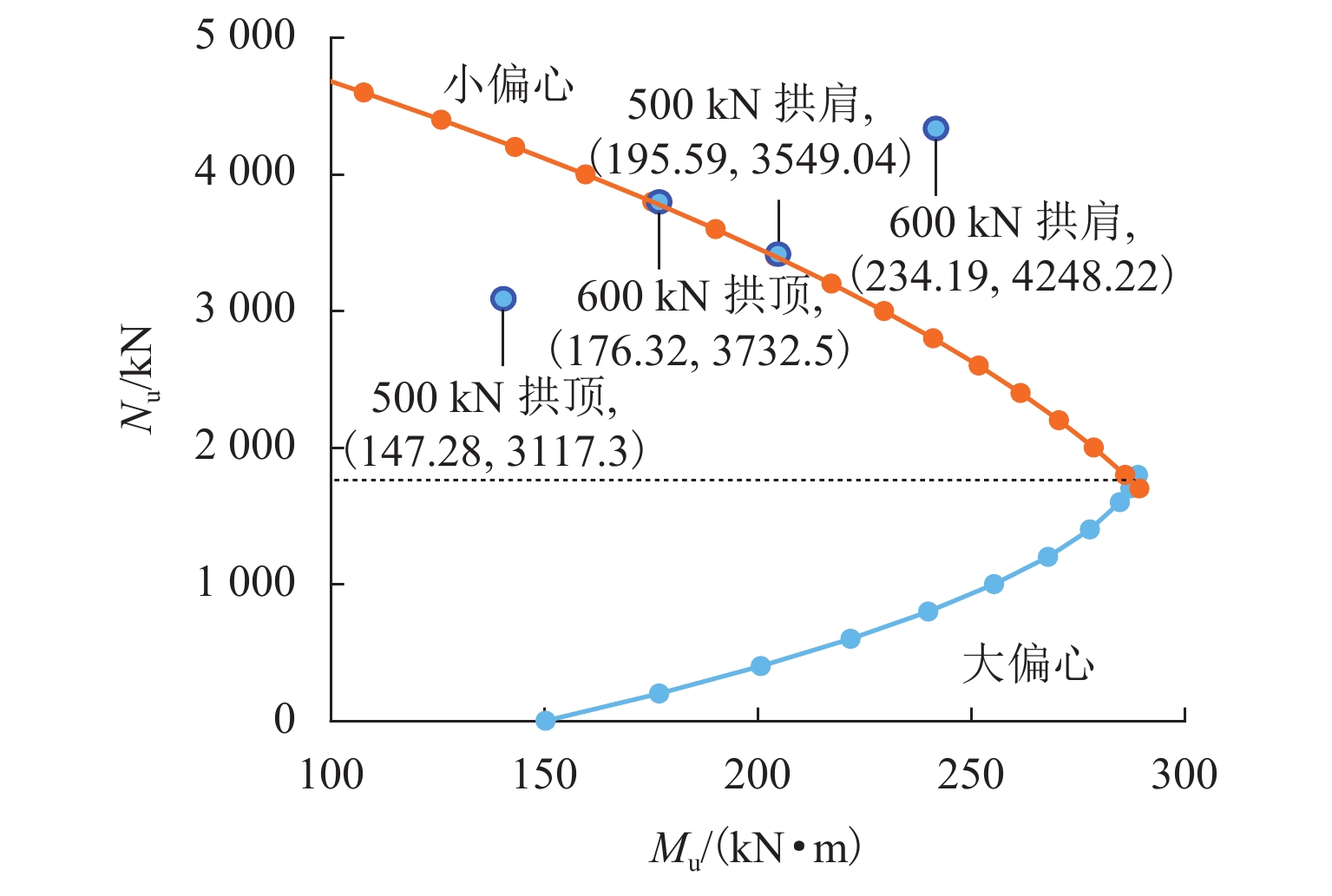

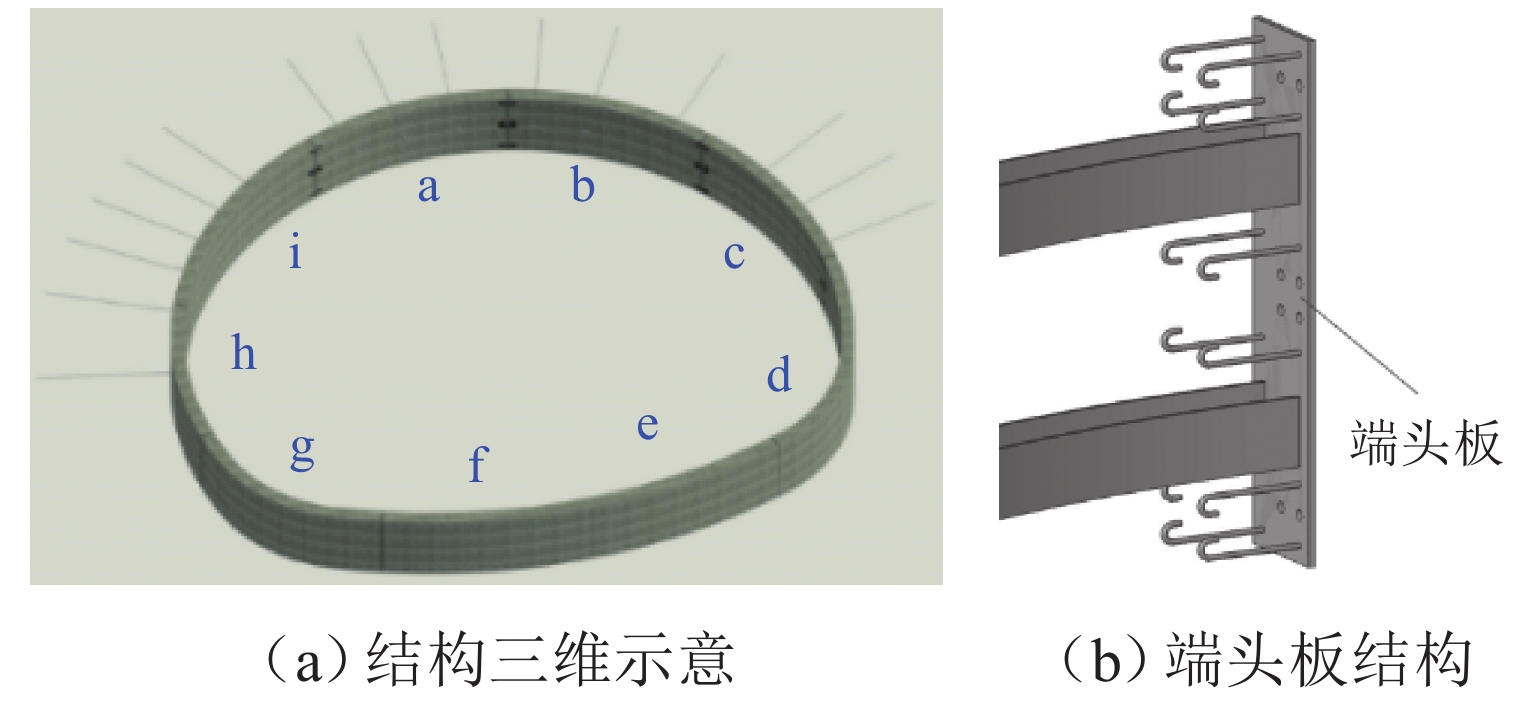

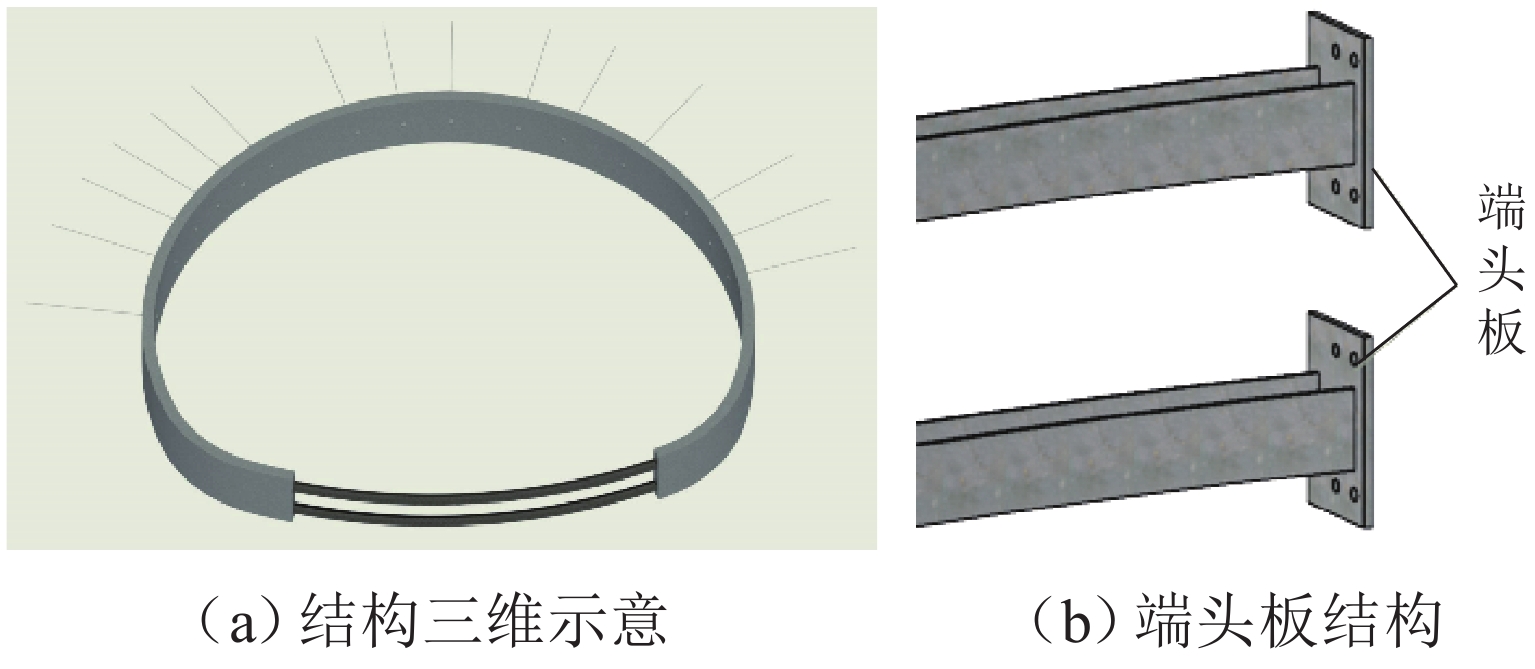

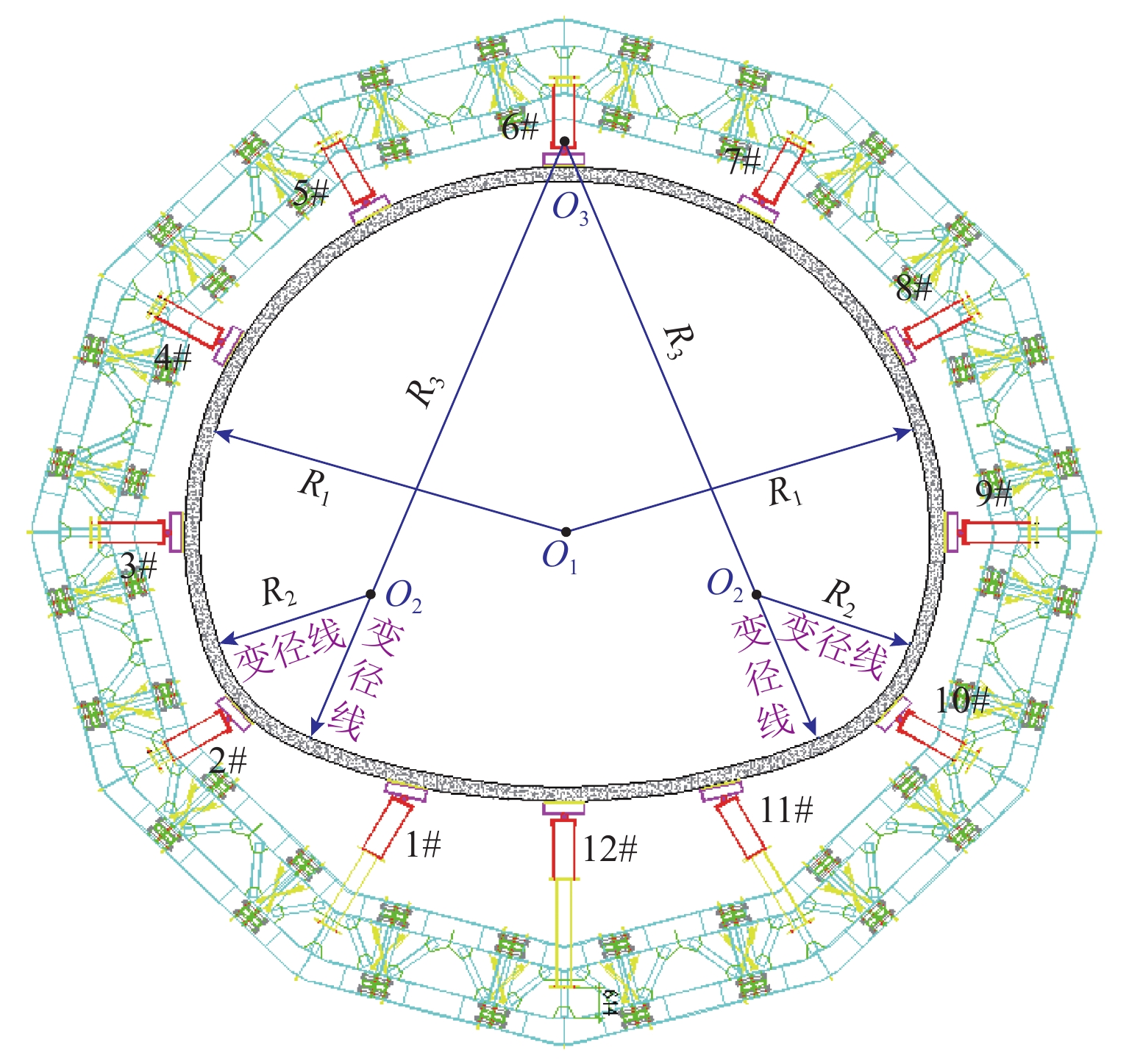

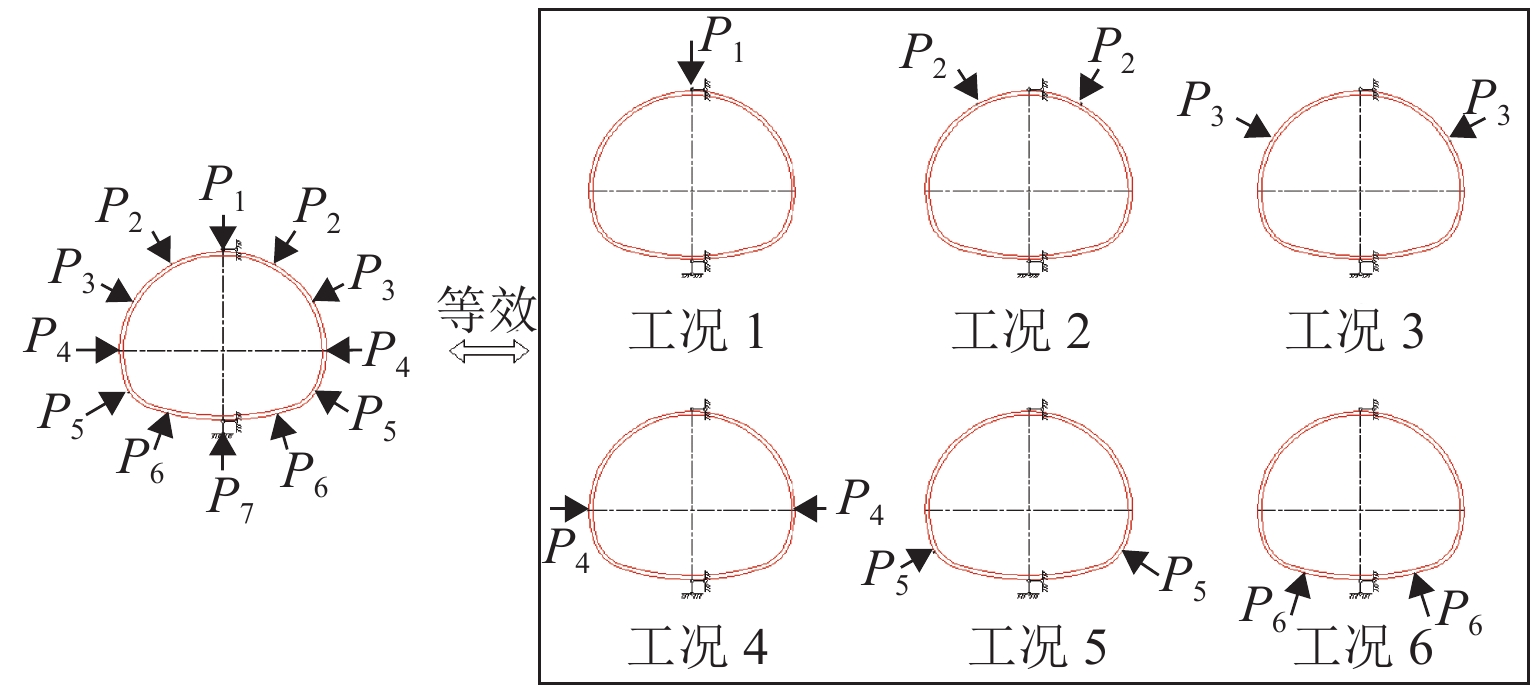

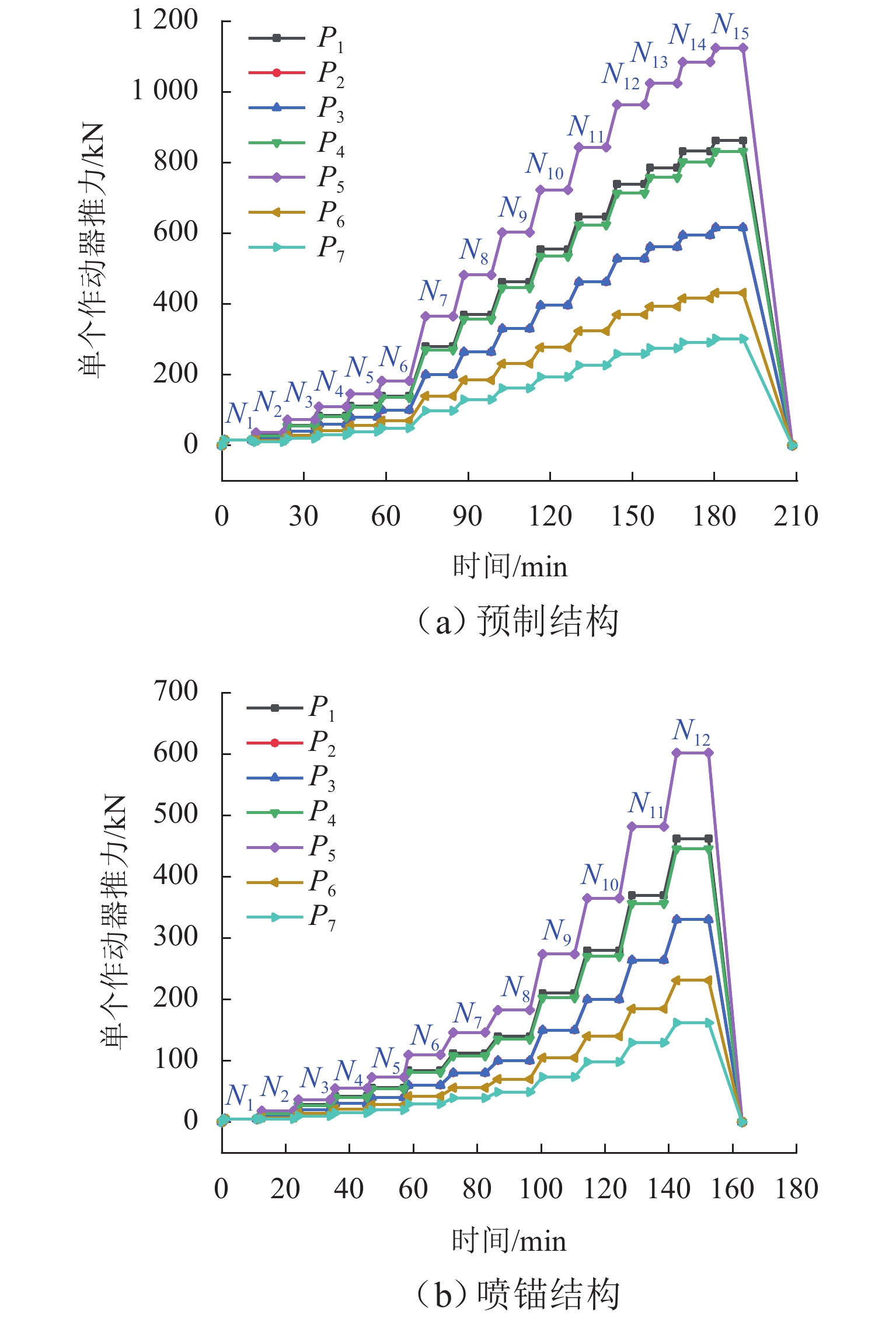

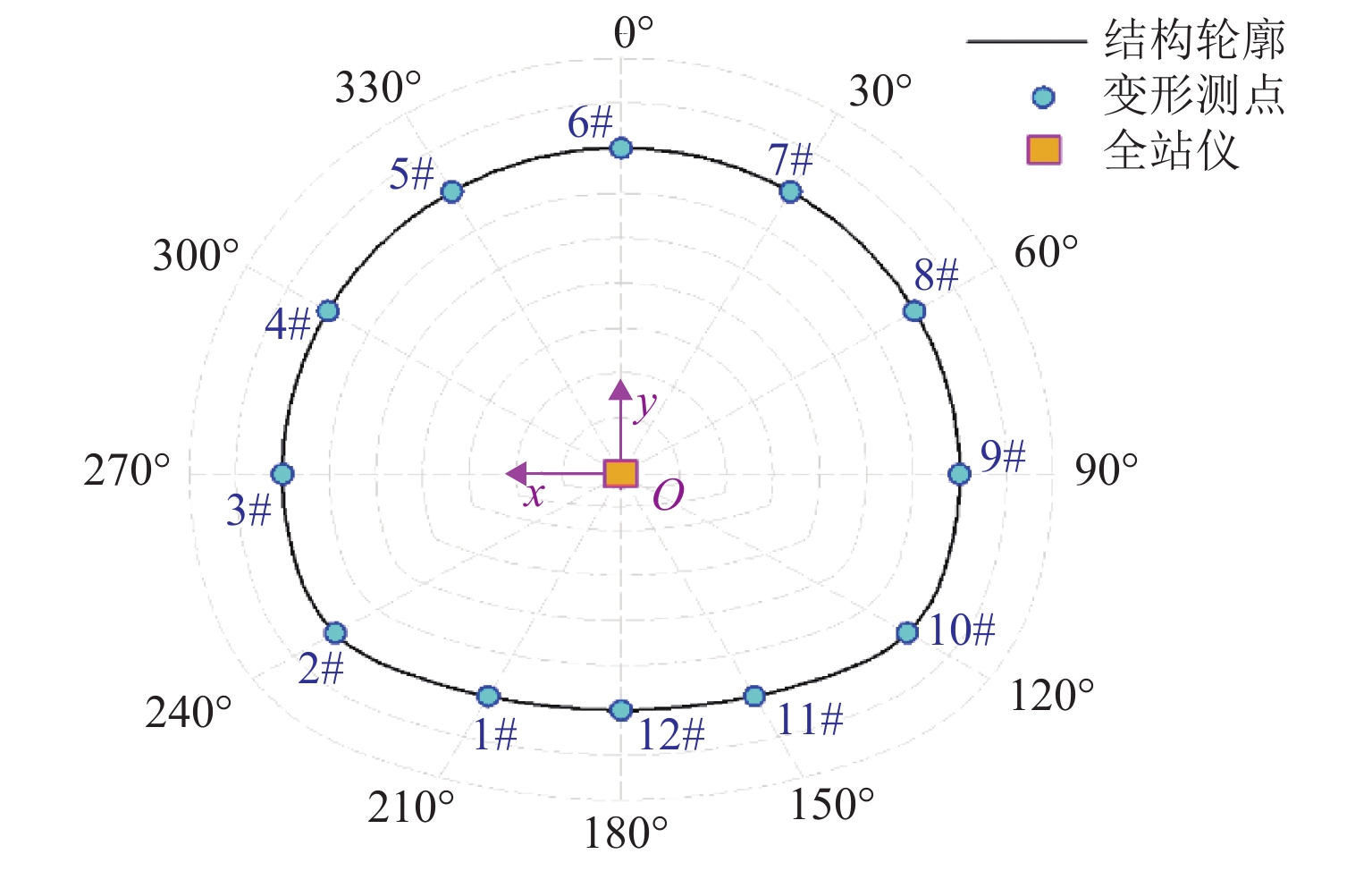

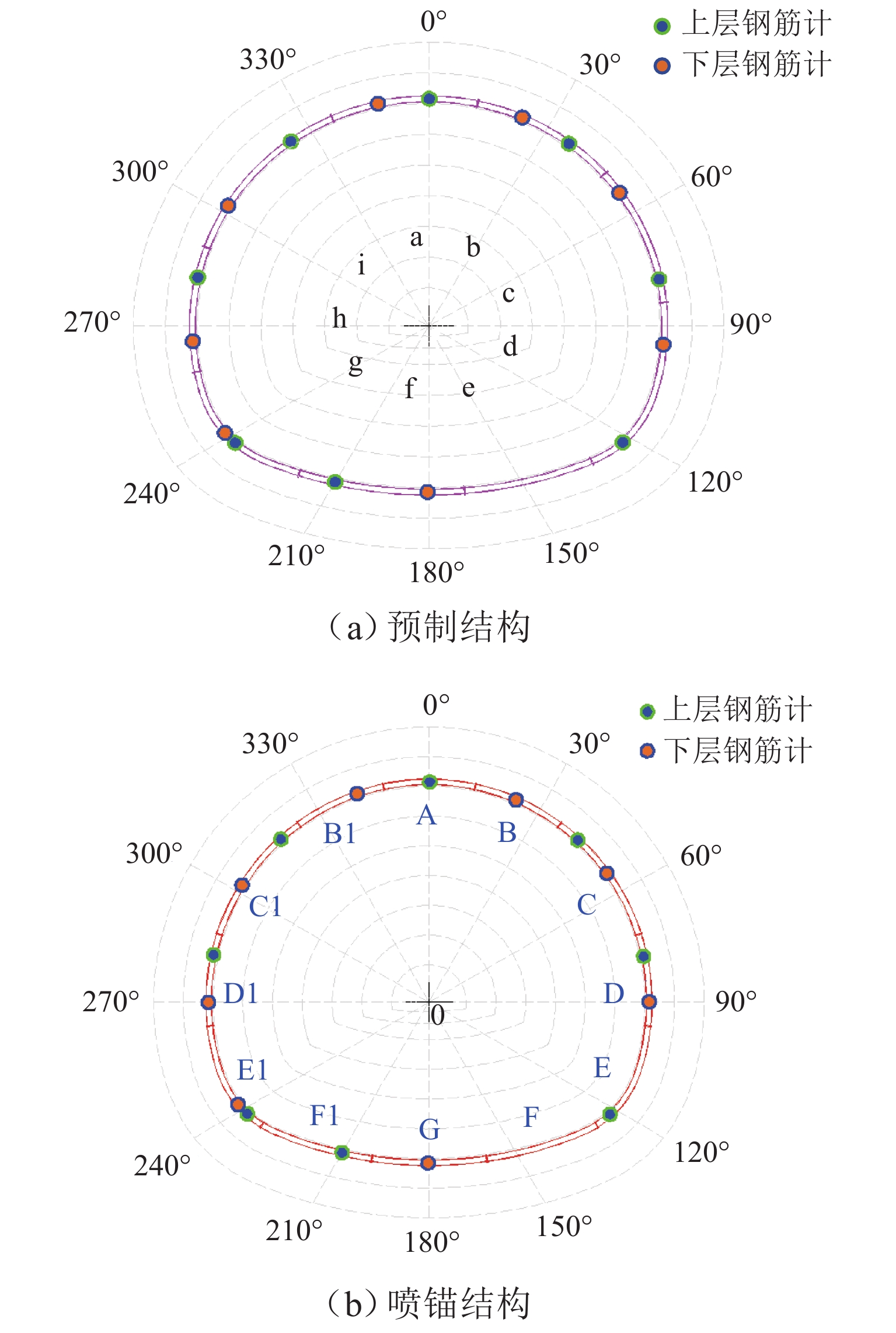

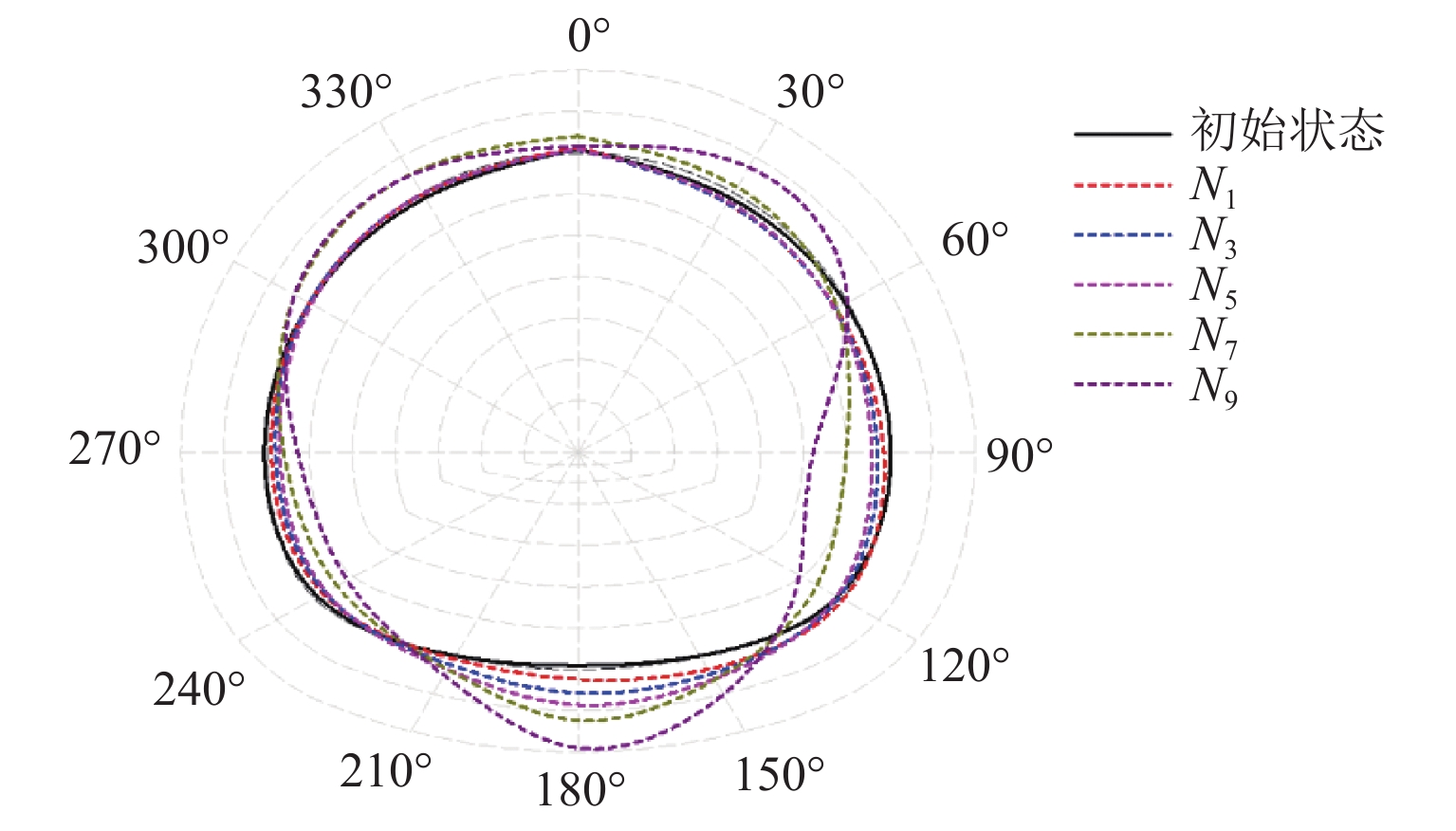

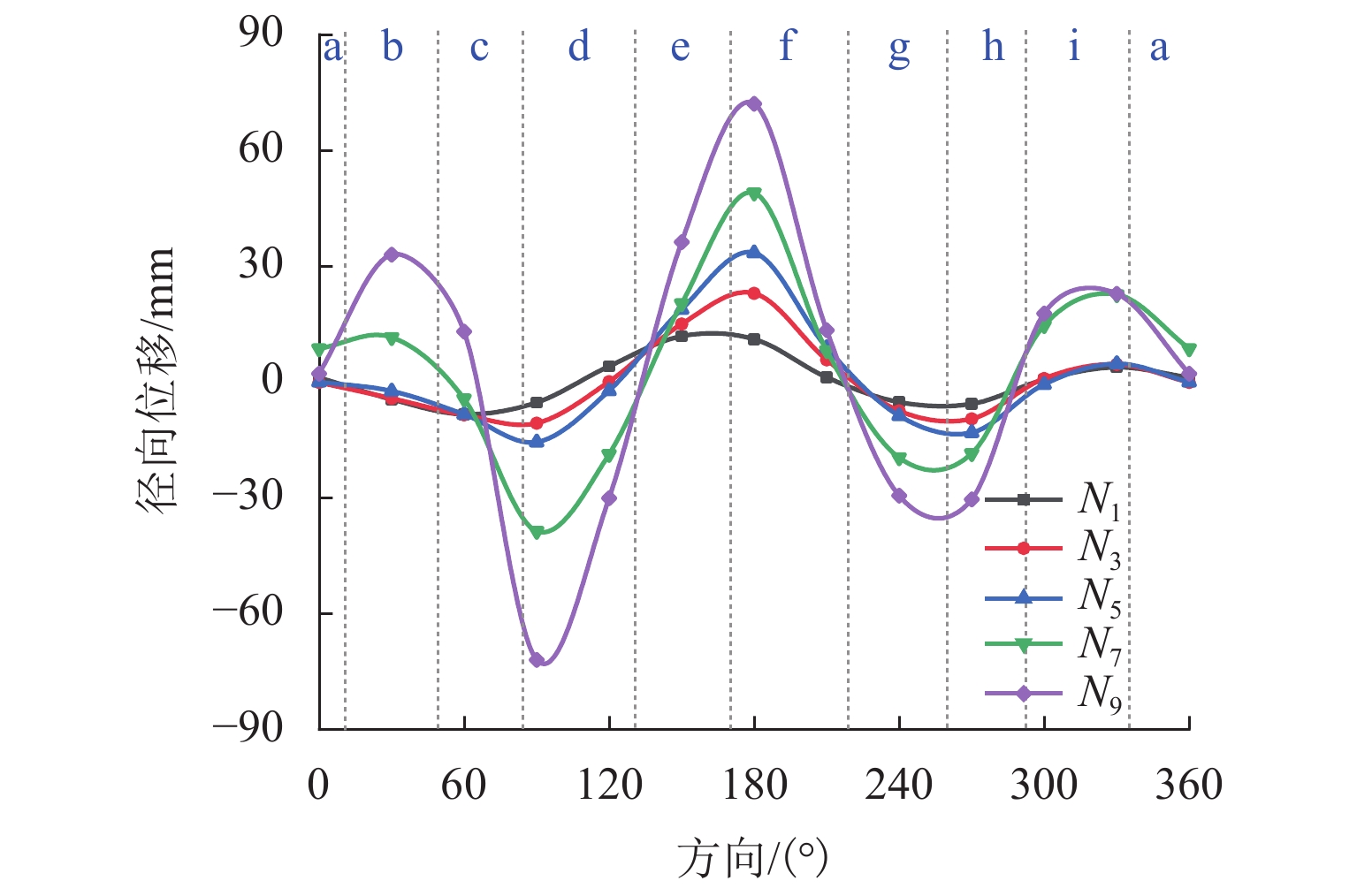

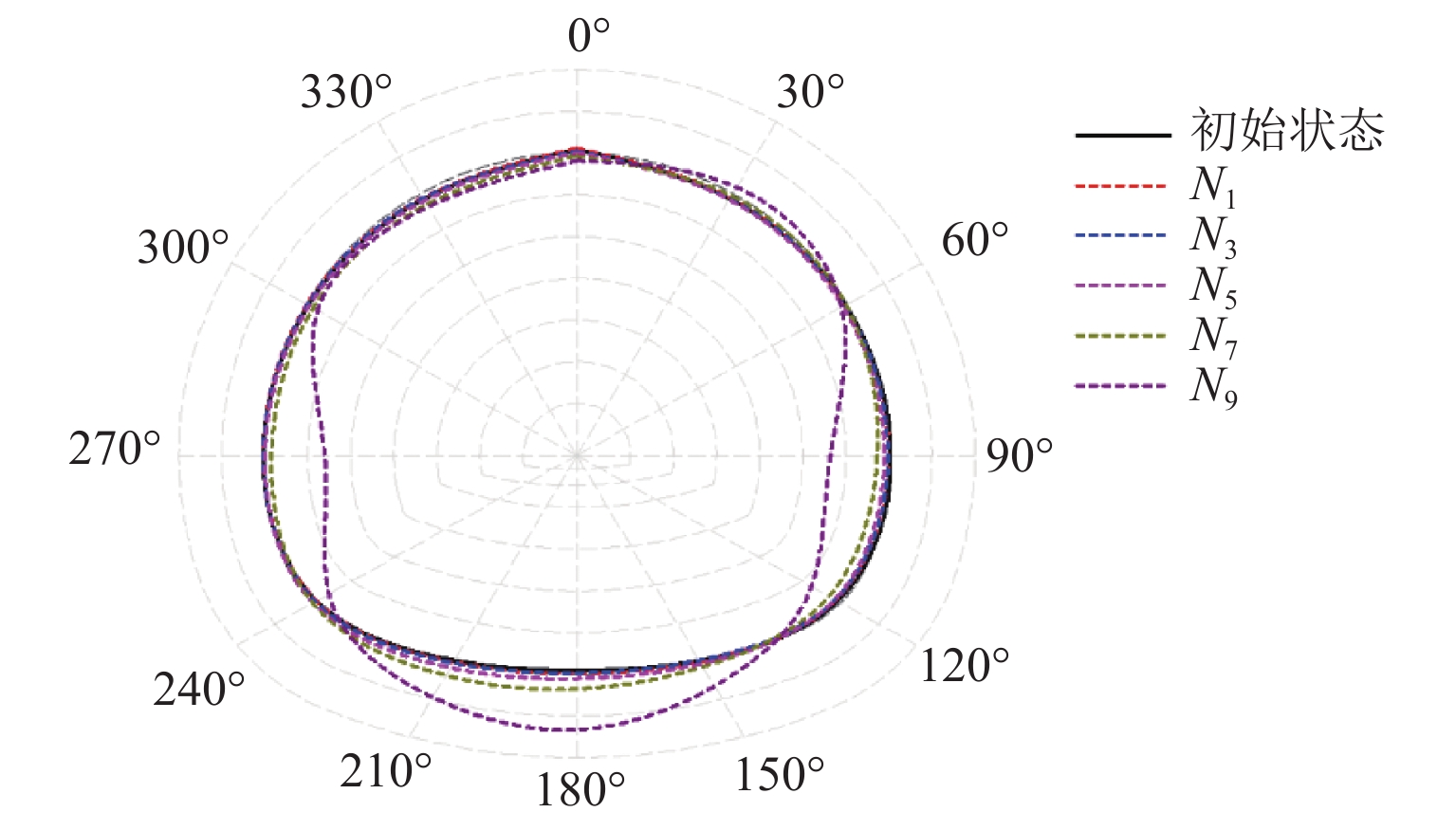

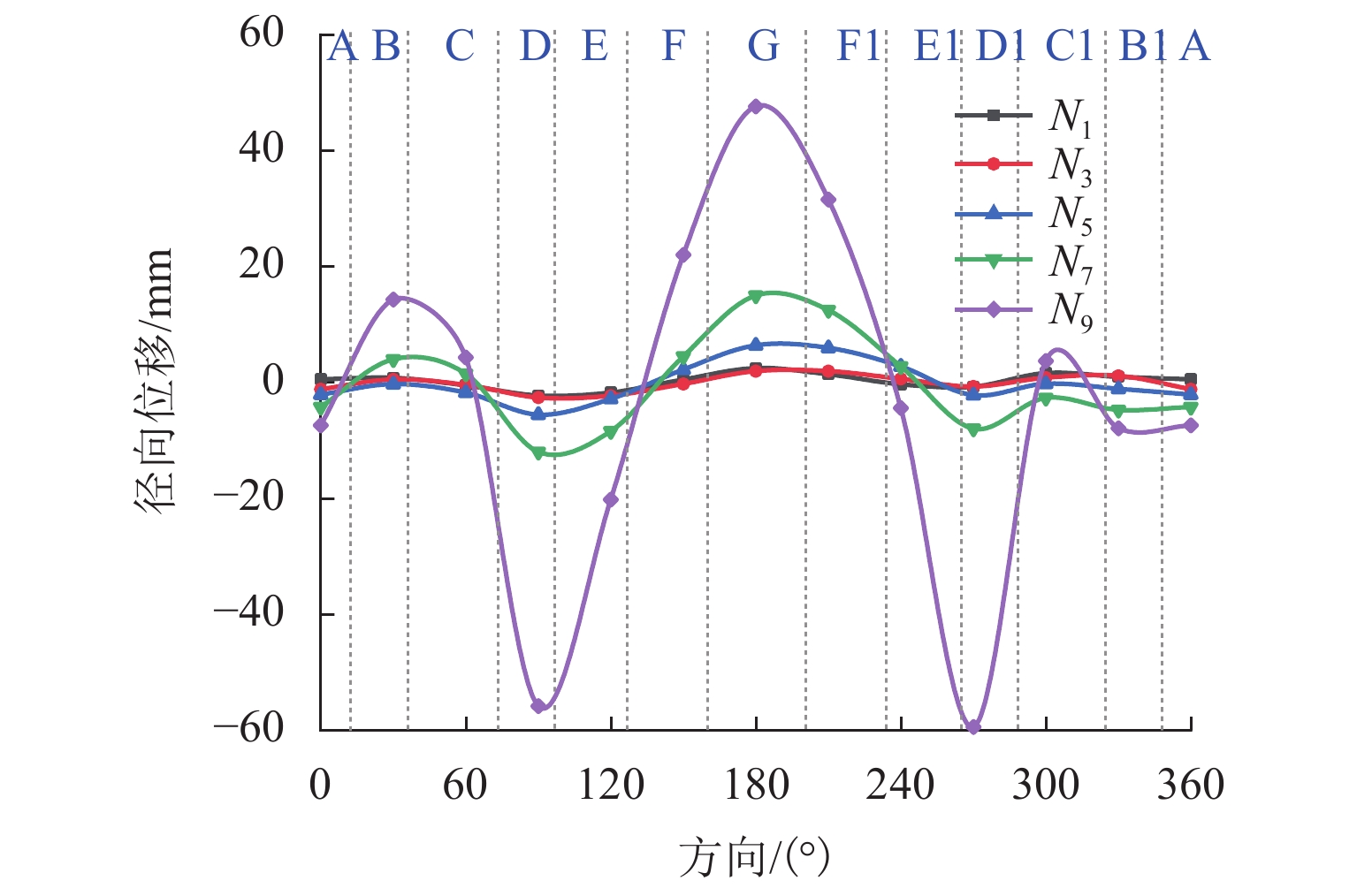

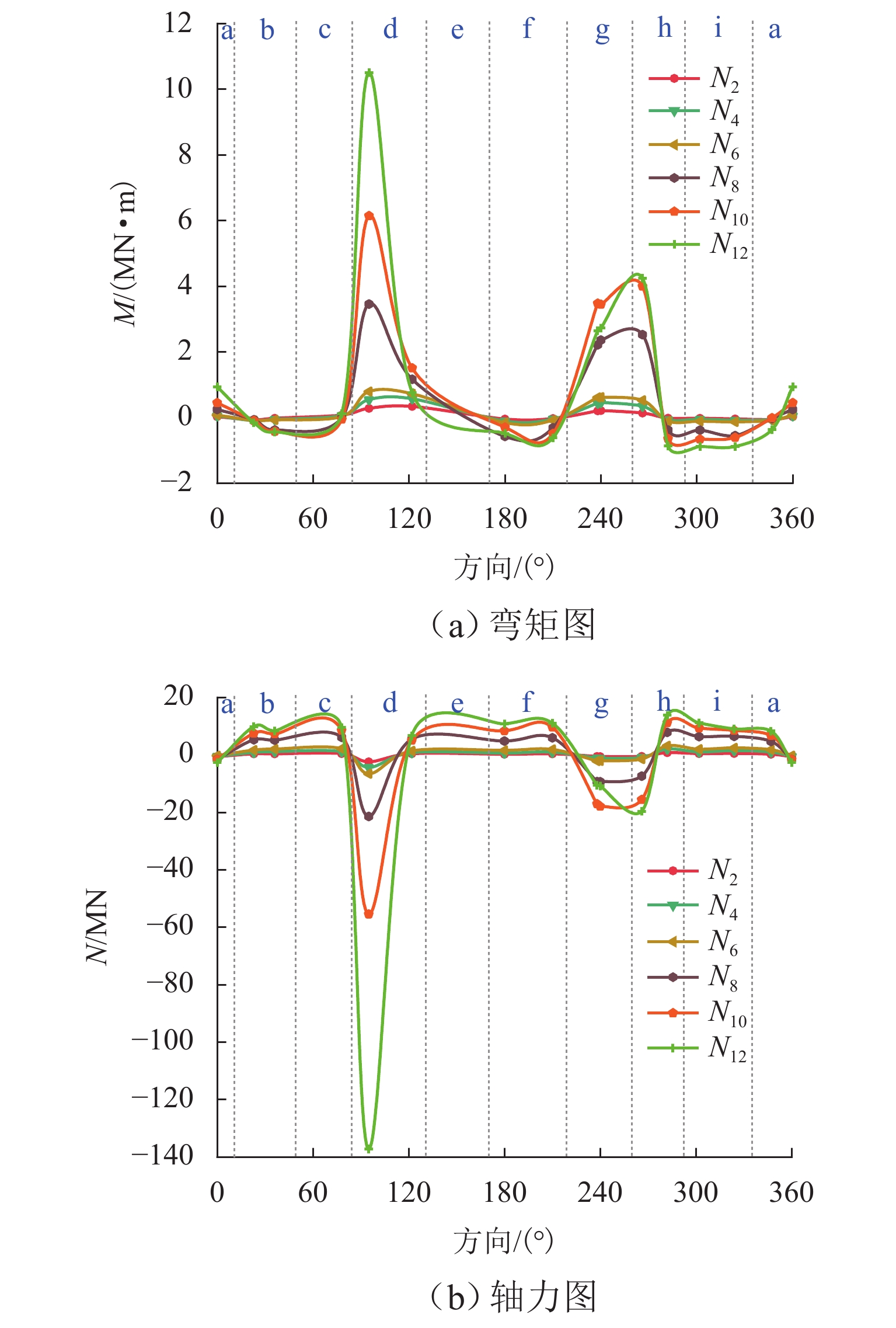

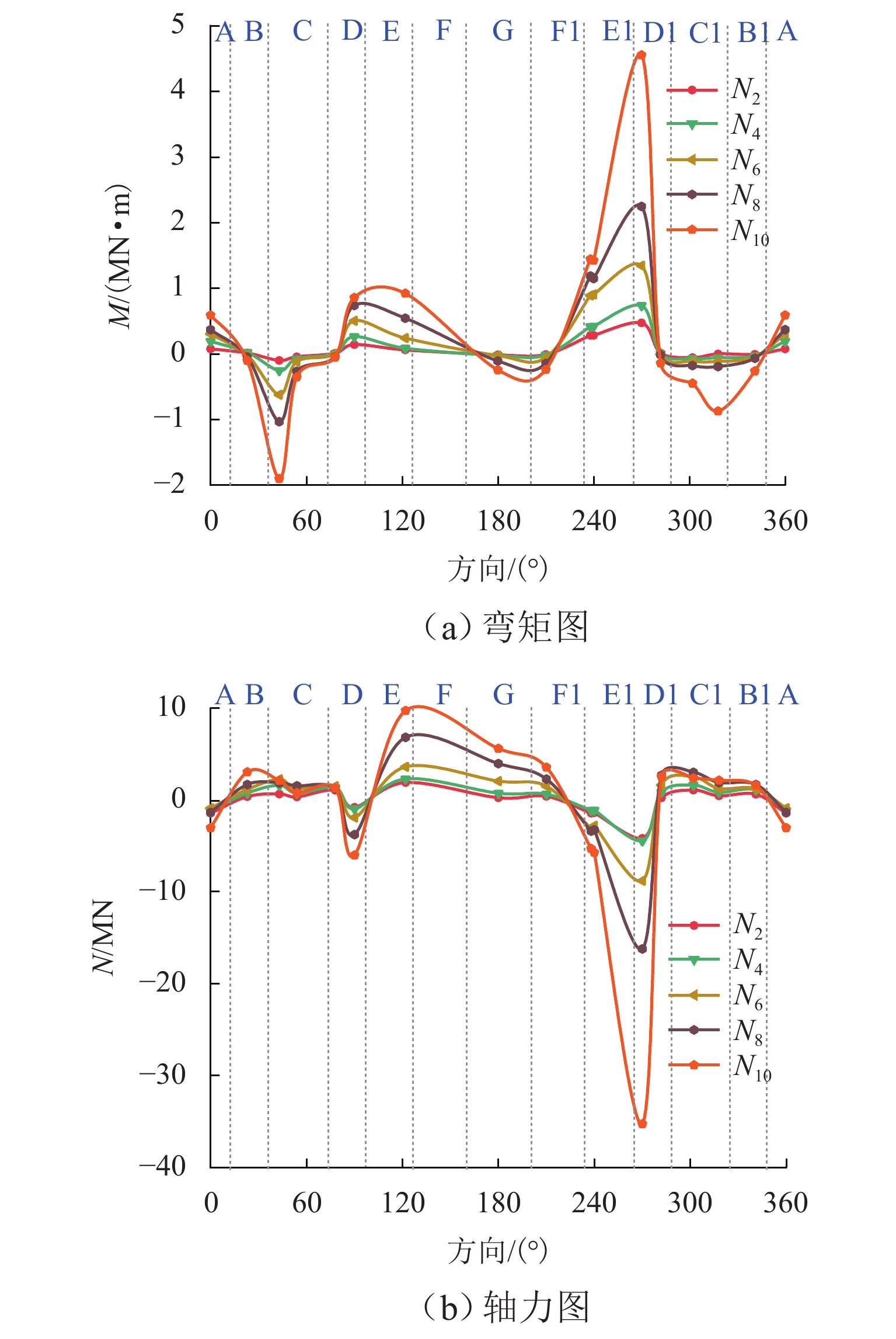

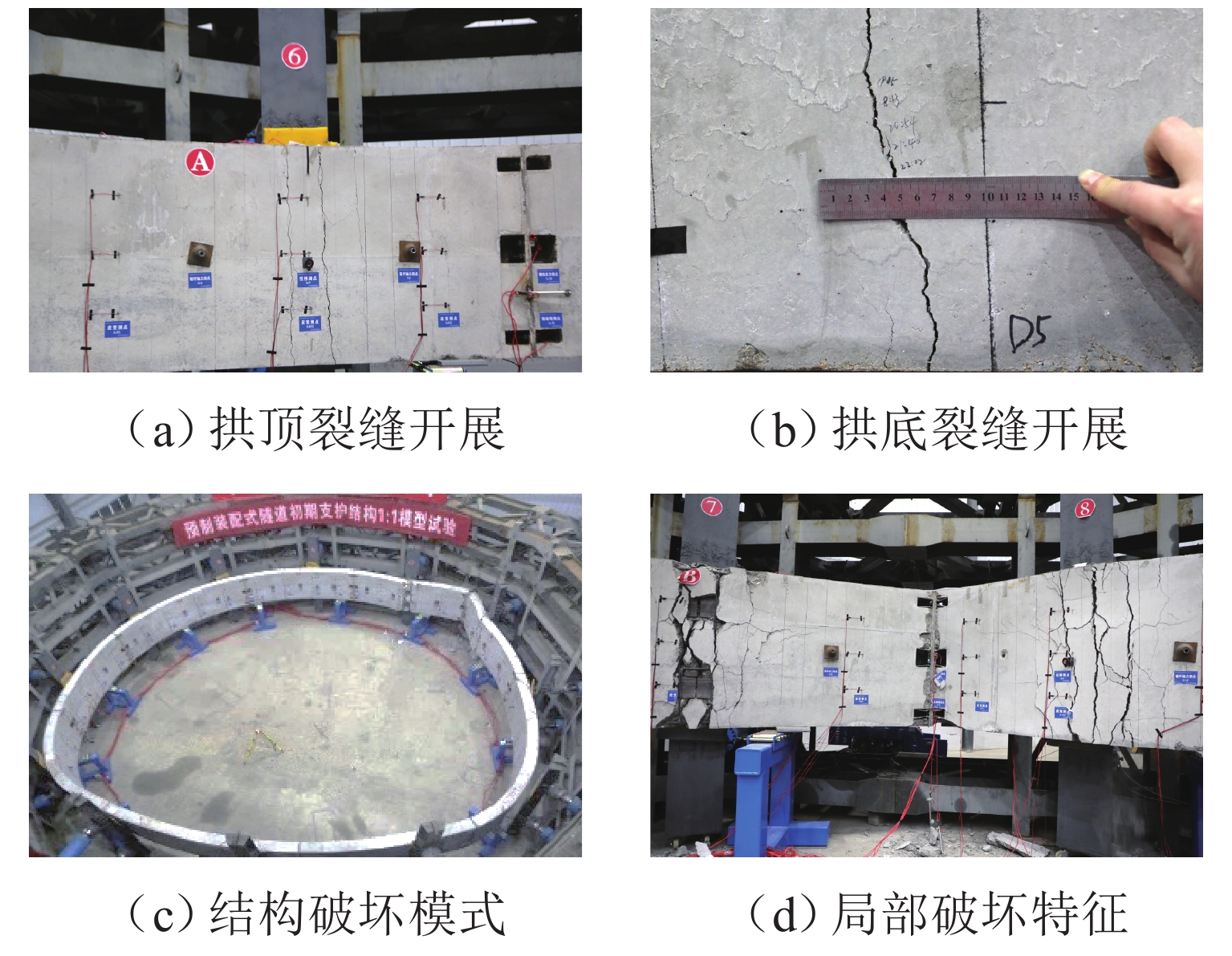

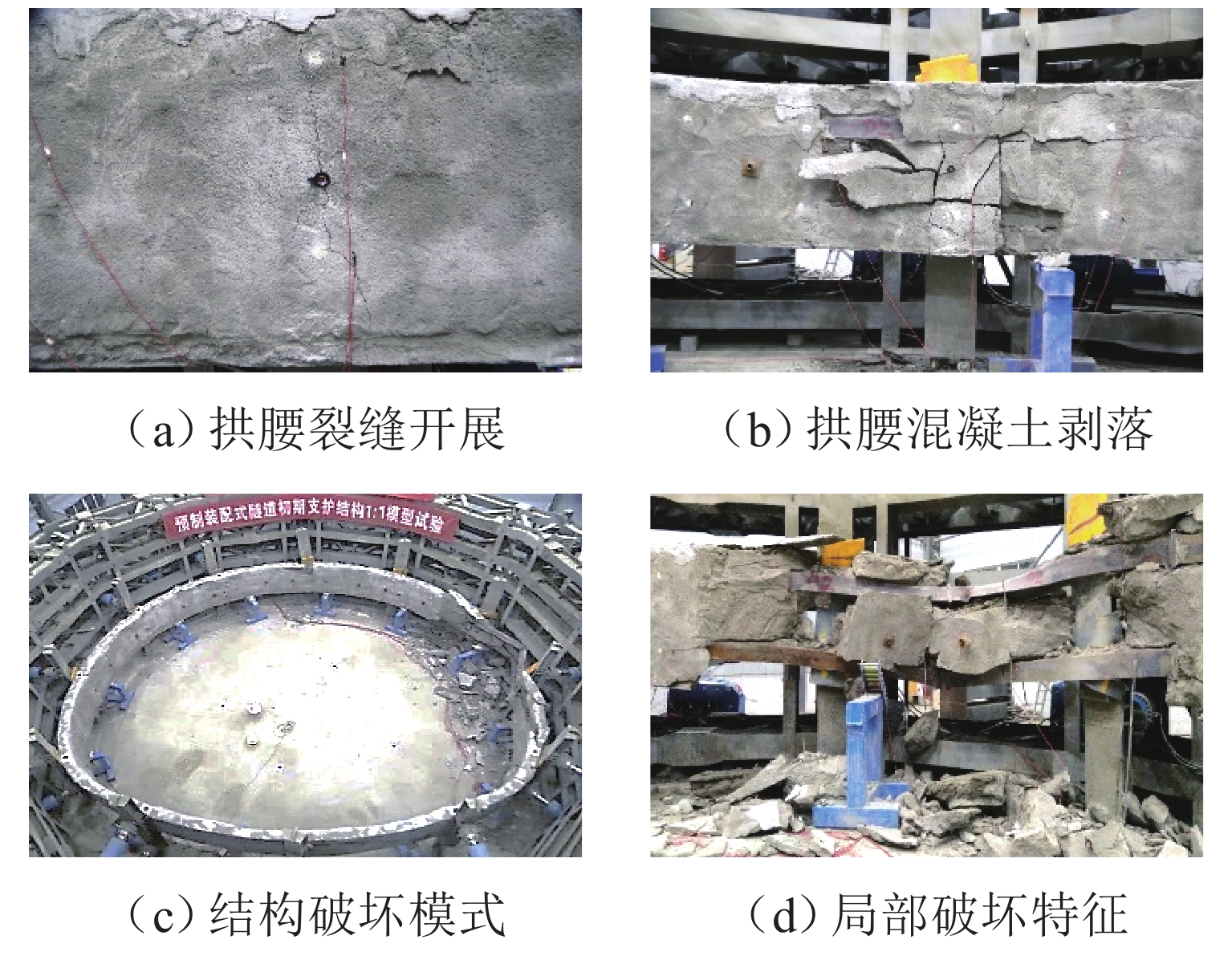

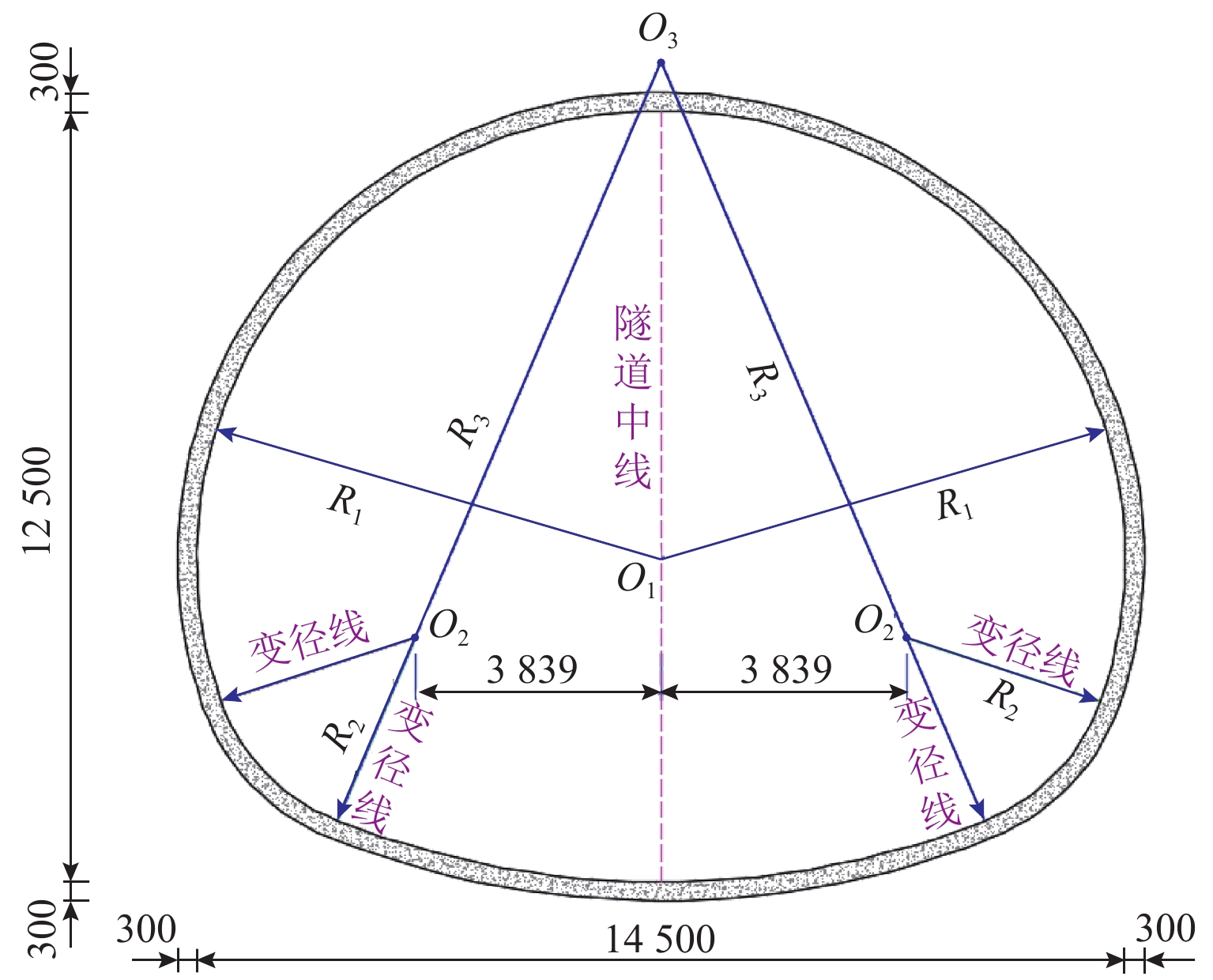

为研究新型马蹄形预制初期支护结构的力学变形特征,与喷锚初期支护结构进行比较,开展2类结构的原型加载试验,系统性地从结构设计、衬砌预制、试验加载及结果分析等方面进行详细介绍,并对试验结果进行深入分析. 研究结果表明:预制初期和喷锚初期,支护结构的极限承载力分别为2.80倍和1.32倍设计荷载,前者的极限承载能力约为后者的2.12倍;预制初期,支护结构在拱顶、拱腰位置受正弯矩和负轴力作用,在拱肩和拱底位置受负弯矩和正轴力作用,喷锚初期,支护结构与之相近,临近破坏阶段,前者的最大弯矩约为后者的1.39倍,最大轴力约为后者的1.45倍;预制初期支护结构和喷锚初期支护结构凹凸变形趋势基本一致,结构破坏时呈现右拱肩外凸,右拱腰内凹,且型钢与混凝土产生剥落,前者极限变形能力约为后者的1.20倍.

Abstract:In order to study the mechanical deformation characteristics of the new horseshoe prefabricated initial support structure and compare its difference with the spray anchor initial support structure, the prototype loading tests of two types of structures were carried out. The structural design, lining prefabrication, test loading, and result analysis were introduced systematically, and the test results were deeply analyzed. The results show that the ultimate bearing capacity of the prefabricated initial support structure is 2.80 times the design load, and that of the spray anchor initial support structure is 1.32 times the design load. The ultimate bearing capacity of the former is about 2.10 times that of the latter. The prefabricated initial support structure is affected by the positive bending moment and negative axial force at the vault and the arch waist, as well as the negative bending moment and positive axial force at the arch shoulder and the arch bottom. The spray anchor initial support structure is similar. The maximum moment and the maximum axial force of the prefabricated initial support structure are about 1.39 and 1.45 times that of the spray anchor initial support structure near the destruction phase, respectively. The concave and convex deformation trend of the prefabricated initial support structure is basically the same as that of the spray anchor initial support structure. The right arch shoulder is convex, and the right arch waist is concave, with steel and concrete spalling when the structure is damaged, and the ultimate deformation capacity of the prefabricated initial support structure is about 1.20 times that of the spray anchor initial support structure.

-

表 1 材料参数

Table 1. Material parameter

类别 参数名称 取值 围岩级别Ⅴ级 弹性抗力系数/(MPa·m−1) 150 变形模量/GPa 1.5 围岩密度/(kN·m−3) 19 内摩擦角/(°) 25 计算摩擦角/(°) 45 泊松比 0.38 衬砌材料 C30 混凝土 弹性模量/GPa 3.0 抗压强度/MPa 22.5 抗拉强度/MPa 2.2 钢筋种类 HRB400 强度标准值/MPa 400 强度设计值/MPa 360 弹性模量/GPa 200 表 2 截面每延米抗压能力

Table 2. Compressive capacity per meter of section

kN 部位 拱顶 拱肩 边墙 仰拱 抗压承载力 4789.35 4561.20 6300 6300 -

[1] 田四明,王伟,巩江峰. 中国铁路隧道发展与展望(含截至2020年底中国铁路隧道统计数据)[J]. 隧道建设(中英文),2021,41(2): 308-325.TIAN Siming, WANG Wei, GONG Jiangfeng. Development and prospect of railway tunnels in China (including statistics of railway tunnels in China by the end of 2020)[J]. Tunnel Construction, 2021, 41(2): 308-325. [2] 杨志男. 矿山法机械开挖初期支护结构研究及工程应用[D]. 北京: 北京建筑大学, 2020. [3] 徐赞. 西秦岭隧道仰拱预制块施工技术[J]. 隧道建设,2011,31(2): 256-261.XU Zan. Invert block precasting technology: case study on west Qinling tunnel[J]. Tunnel Construction, 2011, 31(2): 256-261. [4] 江帅,宋丹,赵振威,等. 新型装配式衬砌技术在地铁隧道的应用研究[J]. 隧道建设(中英文),2019,39(6): 1014-1020.JIANG Shuai, SONG Dan, ZHAO Zhenwei, et al. Application of new type of fabricated lining technology to metro tunnel[J]. Tunnel Construction, 2019, 39(6): 1014-1020. [5] 范国宇. 隧道预制装配式套拱结构力学性能研究[D]. 重庆: 重庆交通大学, 2021. [6] 张胜龙. 铁路隧道预制装配式衬砌接头力学性能及选型研究[D]. 北京: 中国铁道科学研究院, 2020. [7] 赵有明,王志伟,王子洪. 铁路隧道预制装配式建造技术研究与展望[J]. 中国铁路,2020(12): 51-60. doi: 10.19549/j.issn.1001-683x.2020.12.051ZHAO Youming, WANG Zhiwei, WANG Zihong. Research and prospect on prefabricated structure of railway tunnel[J]. China Railway, 2020(12): 51-60. doi: 10.19549/j.issn.1001-683x.2020.12.051 [8] 章龙管,李志刚,路桂珍,等. 大断面马蹄形盾构施工关键技术——以蒙华铁路白城隧道工程为例[J]. 隧道建设(中英文),2020,40(增1): 297-306.ZHANG Longguan, LI Zhigang, LU Guizhen, et al. Key construction technology of large cross-section horseshoe shaped shield: a case study on baicheng tunnel on menghua railway[J]. Tunnel Construction, 2020, 40(S1): 297-306. [9] RAMONI M, GALLUS R, ITEN R. The new Bözberg Tunnel (Switzerland)—risk management and auxiliary measures for the TBM break-through[C]//Tunnels and Underground Cities: Engineering and Innovation meet Archaeology, Architecture and Art. London: Taylor & Francis Group, 2019: 4574-4583. [10] DALLER J, DIEWALD M, LEMMERER J, et al. Expectations and reality of the mechanized tunnel drives for the wienerwald tunnel/erwartung und wirklichkeit der tbm-vortriebe am Wienerwaldtunnel[J]. Geomechan-ics and Tunnelling, 2016, 9(5): 547-555. doi: 10.1002/geot.201600043 [11] 李建斌, 白中坤, 于少辉, 等. 一种锚支组合支护体系及施工方法: CN110671125A[P]. 2020-01-10. [12] 李建斌. 我国掘进机研制现状、问题和展望[J]. 隧道建设(中英文),2021,41(6): 877-896.LI Jianbin. Current status, problems and prospects of research, design, and manufacturing of boring machine in China[J]. Tunnel Construction, 2021, 41(6): 877-896. [13] 国家铁路局. 铁路隧道设计规范: TB 10003— 2016[S]. 北京: 中国铁道出版社, 2017. [14] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB 50010—2010[S]. 北京: 中国建筑工业出版社, 2011. [15] 张顶立,陈峰宾,房倩. 隧道初期支护结构受力特性及适用性研究[J]. 工程力学,2014,31(7): 78-84. doi: 10.6052/j.issn.1000-4750.2013.01.0010ZHANG Dingli, CHEN Fengbin, FANG Qian. Study on mechanical characteristics and applicability of primary lining used in tunnel[J]. Engineering Mechanics, 2014, 31(7): 78-84. doi: 10.6052/j.issn.1000-4750.2013.01.0010 [16] 黄鸿浩. “管片-SCC-钢衬”叠合式衬砌体系足尺结构试验设计与抗外载特性研究[D]. 广州: 华南理工大学, . [17] 何川,封坤,苏宗贤. 大断面水下盾构隧道原型结构加载试验系统的研发与应用[J]. 岩石力学与工程学报,2011,30(2): 254-266.HE Chuan, FENG Kun, SU Zongxian. Development and application of loading test system of prototype structure for underwater shield tunnel with large cross-section[J]. Chinese Journal of Rock Mechanics and Engineering, 2011, 30(2): 254-266. -

下载:

下载: