Seismic Damage Model of RC Pier Repaired with CFRP Considering Initial Damage

-

摘要:

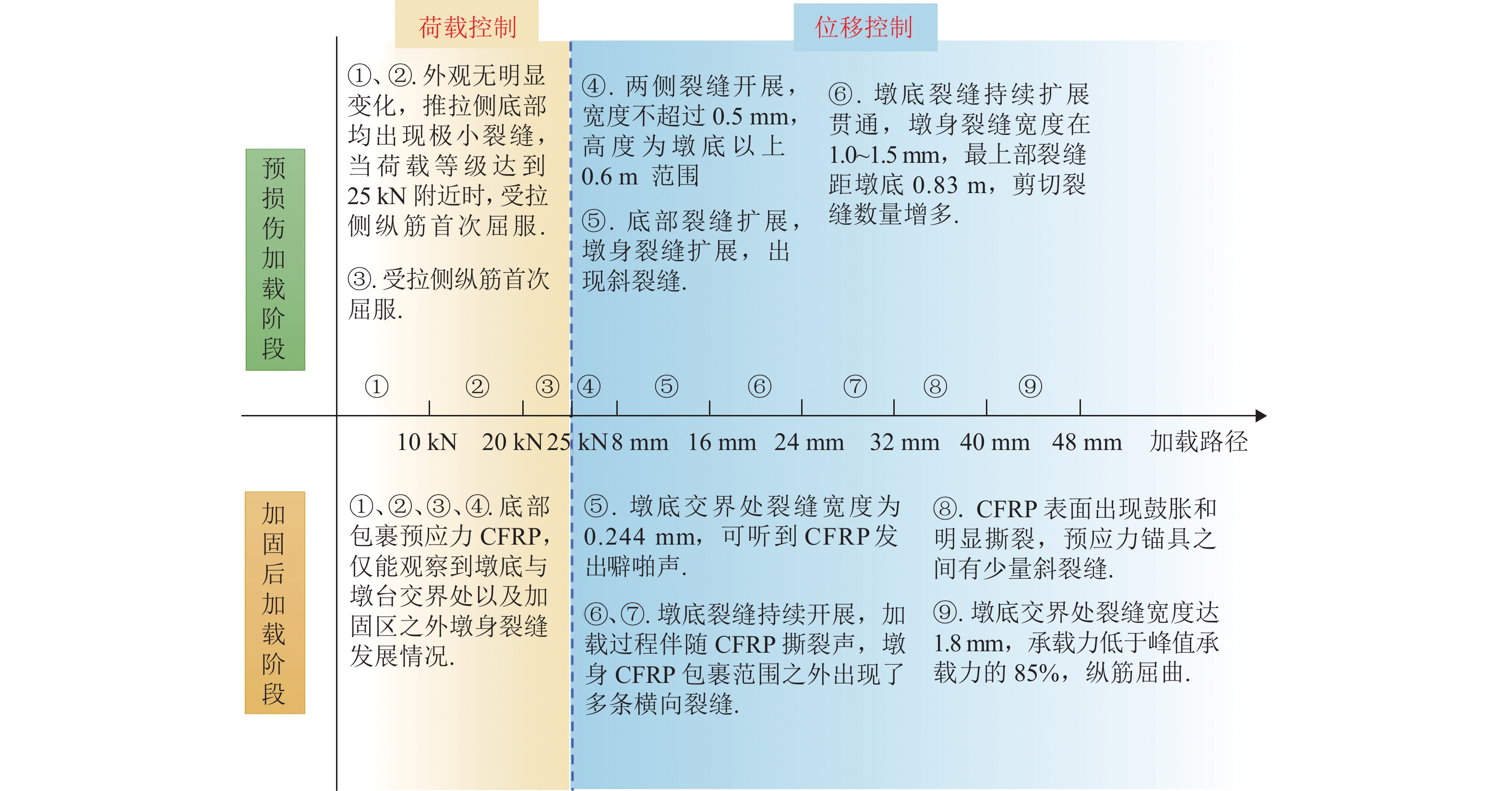

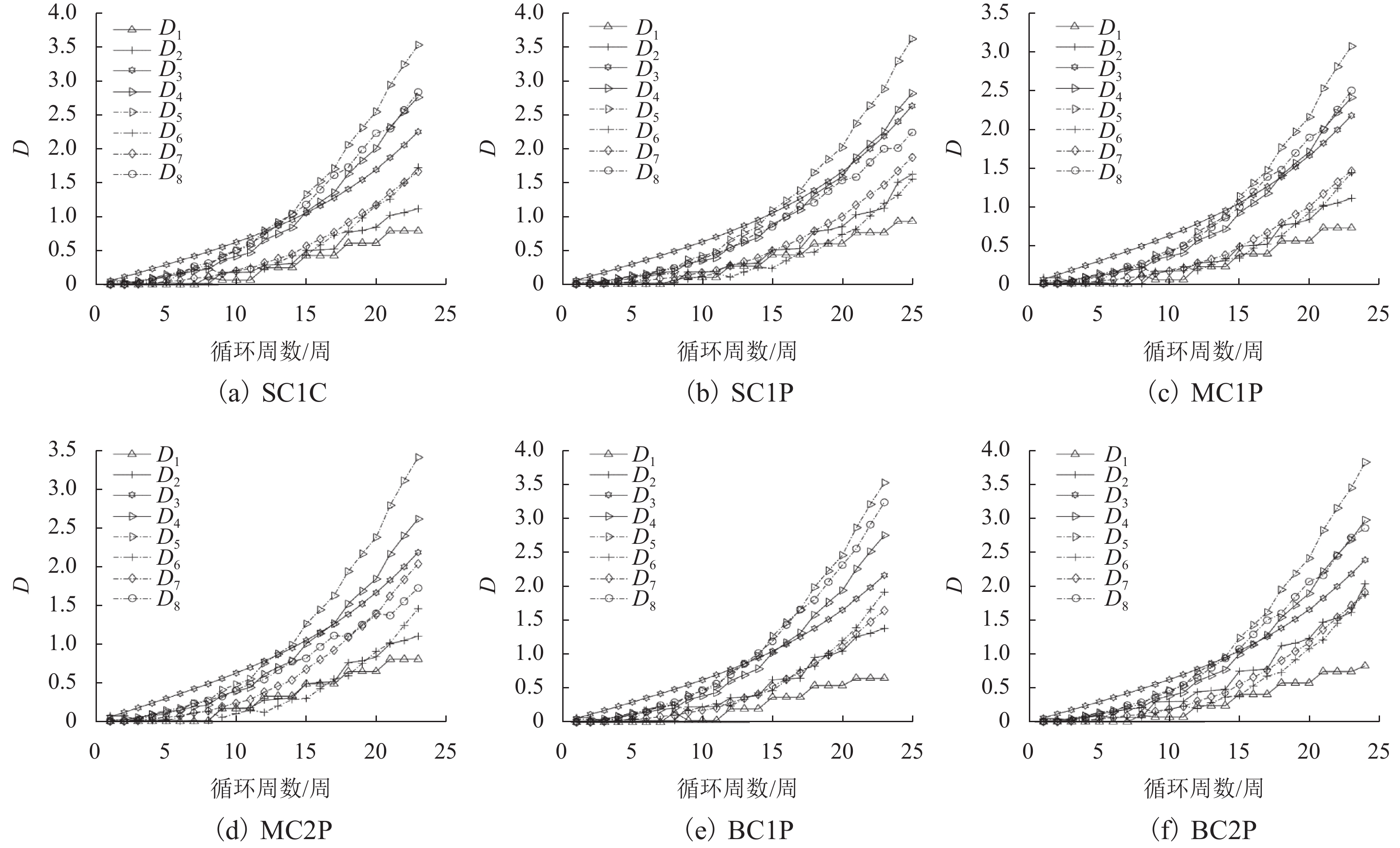

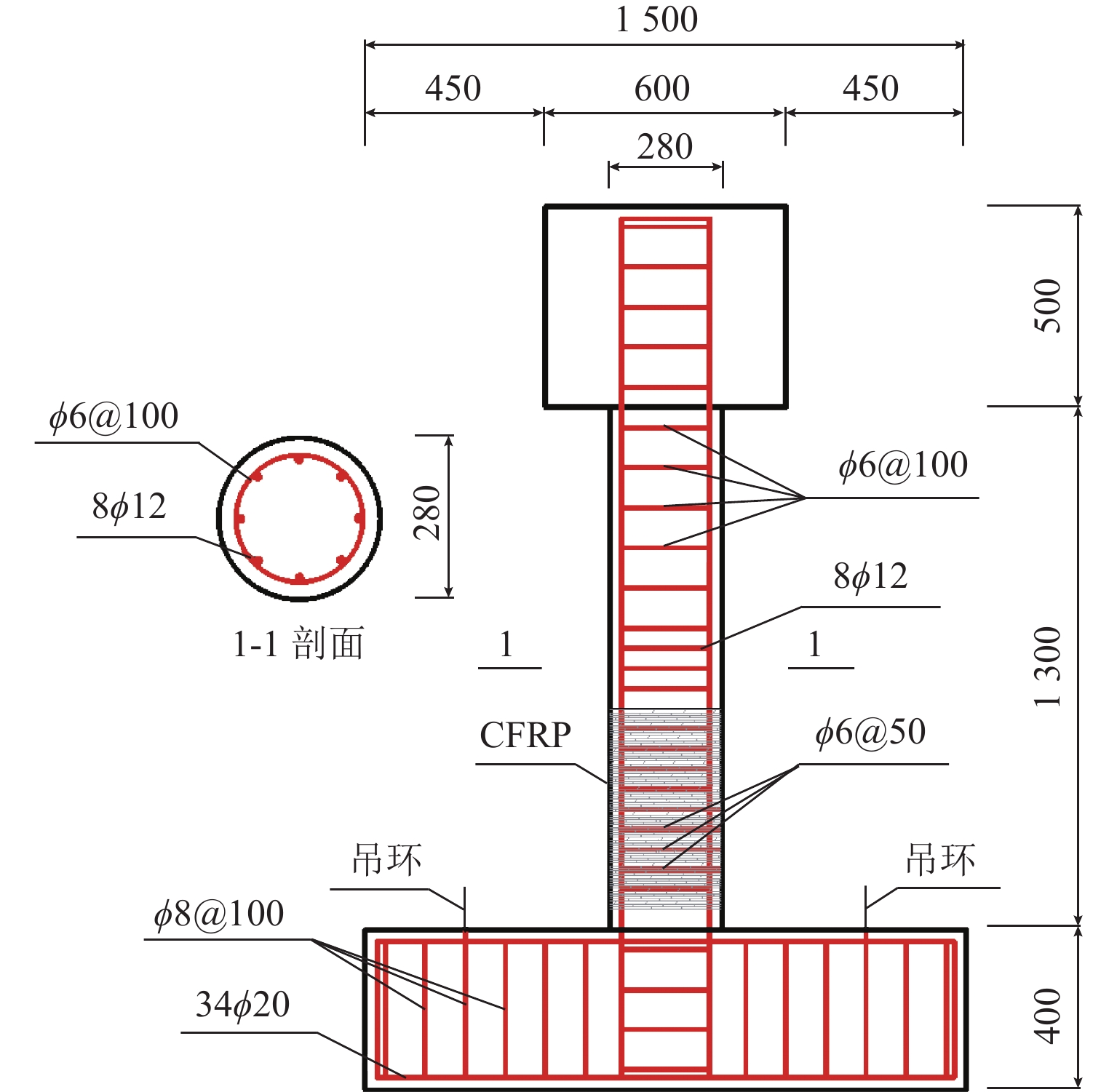

为研究碳纤维材料(CFRP)修复损伤钢筋混凝土(RC)结构遭受地震作用的损伤演化规律,准确量化修复损伤结构状态,进行了10个钢筋混凝土圆墩柱拟静力试验,其中,8个墩柱试件为使用不同CFRP加固方法进行修复的损伤试件. 基于试验结果,对8个典型地震损伤模型进行研究分析,引入材料性能折减系数来考虑结构初始损伤,建立了CFRP修复RC墩柱的双参数地震损伤模型,并根据试验现象和改进的损伤模型对钢筋混凝土结构的损伤程度进行量化分析. 研究表明:使用典型地震损伤模型计算修复柱的损伤指标时,计算试件破坏时的损伤指标普遍偏大,且同一墩柱模型损伤指数的变化趋势有较大差异,损伤指数发展趋势与试验现象不符;根据试件参数进行非线性回归分析,得到了组合系数与设计参数的经验表达式,建议的损伤模型能够较好模拟CFRP修复加固墩柱的地震损伤演化过程;定义了钢筋混凝土结构损伤的5个等级,并给出5个等级的损伤指标界限值;对中等损伤($0.3 < D \leqslant 0.6$,

D 为损伤指标)的墩柱结构,建议对结构表面修复平整后使用预应力CFRP加固以达到更好的效果.-

关键词:

- 地震损伤模型 /

- 损伤钢筋混凝土圆墩柱 /

- CFRP /

- 加固方法 /

- 修复

Abstract:In order to study the damage evolution law of damaged reinforced concrete (RC) structures repaired with carbon fiber reinforced plastics (CFRP) under earthquake action and accurately quantify the damage status of repaired structures, a quasi-static test of 10 circular RC piers was carried out, eight of which were repaired by different CFRP reinforcement methods. The test results were studied based on eight typical earthquake damage models, and a two-parameter seismic damage model for RC piers repaired with CFRP was established, in which the reduction coefficient of material properties was introduced to analyze the initial damage to the structure. The damage degree of RC structures was quantified according to the experimental phenomenon and the improved damage model. The results show that when the damage index of the repaired pier is calculated by using the typical earthquake damage model, the damage index of the damaged specimens is generally too large, and the variation of the damage index of the same pier model is quite different. The development trend of the damage index is not consistent with the experimental phenomenon. Based on the nonlinear regression analysis of the specimen parameters, the empirical expressions of the combination coefficients and design parameters are obtained. The proposed damage model can better simulate the seismic damage evolution process of piers repaired with CFRP. Five grades of RC structure damage are defined, and the damage index limit value of the five grades is given. For moderately damaged pier structures ($0.3 < D \leqslant 0.6$,

D is the damage index), it is recommended to use pre-stressed CFRP reinforcement after repairing and leveling the structural surface to achieve better results.-

Key words:

- seismic damage model /

- damaged circular RC pier /

- CFRP /

- reinforcement method /

- repair

-

表 1 试件主要设计参数及结果

Table 1. Main design parameters and results of specimens

序号 试件编号 加固方式 设计参数 试验主要结果 损伤程度 d0/mm $ {t}_{\mathrm{f}} $/mm 预应力度 $ {P}_{\mathrm{m}\mathrm{a}\mathrm{x}} $/kN $ {k}_{\mathrm{h}} $ $\int \mathrm{d}E$/(kN·mm) 1 CC 无 0 0 0 0 34.69 18716.05 2 CC1C 普通 CFRP 0 0 0.167 0 37.31 0.28 27577.85 3 SC1C 普通 CFRP 0.1 0.1~0.5 0.167 0 36.61 0.26 26065.93 4 SC1P 预应力 CFRP 0.1 0.1~0.5 0.167 0.2 40.62 0.56 32374.62 5 MC1C 普通 CFRP 0.3 0.5~1.0 0.167 0 36.22 0.30 24803.49 6 MC1P 预应力 CFRP 0.3 0.5~1.0 0.334 0.2 40.22 0.48 30781.58 7 MC2P 预应力 CFRP 0.3 0.5~1.0 0.334 0.2 42.09 0.52 34563.85 8 BC1C 普通 CFRP 0.6 1.0~1.5 0.167 0 28.69 0.23 19941.42 9 BC1P 预应力 CFRP 0.6 1.0~1.5 0.167 0.2 35.45 0.44 25161.48 10 BC2P 预应力 CFRP 0.6 1.0~1.5 0.334 0.2 36.43 0.55 28356.57 表 2 单参数地震损伤模型

Table 2. Single-parameter seismic damage model

编号 研究者 模型表达式 D1 Powell 等[16] $ D_1 = {\left( {\dfrac{{{\delta _{\text{m}}} - {\delta _{\text{y}}}}}{{{\delta _{\text{u}}} - {\delta _{\text{y}}}}}} \right)^c} $ D2 Roufaiel 等[17] $ D_2 = \dfrac{{{k_{\text{f}}}\left( {{k_{\text{m}}} - {k_{\text{0}}}} \right)}}{{{k_{\text{m}}}\left( {{k_{\text{f}}} - {k_0}} \right)}} $ D3 Wang 等[18] $D_3=\dfrac{\mathrm{exp}(s\alpha )}{\mathrm{exp}(s)-1},\alpha =c\displaystyle\sum _{i=1}^{N}\dfrac{ {\delta }_{\text{m},i} }{ {\delta }_{\text{f} } }$ 表 3 双参数地震损伤模型

Table 3. Two-parameter seismic damage model

编号 研究者 模型表达式 D4 Park 等[11] $\begin{gathered} {\text{ } }D_4 = \dfrac{ { {\delta _{\text{m} } } }}{ { {\delta _{\text{u} } } }} + \beta \dfrac{ {\smallint {\text{d} }E} }{ { {F_{\text{y} } }{\delta _{\text{u} } } }}, \; \beta = \left( { - 0.447 + 0.073\lambda + 0.24{n_0} + 0.314{\rho _{\text{t} } } } \right) {0.7^{ {\rho _{\text{w} } } }}{\text{ } } \\ \end{gathered}$ D5 Chai 等[5] $\begin{gathered} D_5 = \dfrac{ { {\delta _{\text{m} } } }}{ { {\delta _{\text{u} } } }} + {\beta ^ * }\dfrac{ { {E_{} } } }{ { {F_{\text{y} } }{\delta _{\text{u} } } }}, \; \dfrac{ { {\beta ^*} } }{ { {\beta _{} } } } = \dfrac{ { {\mu _{\text{m} } } }}{ { {\mu _{\text{m} } } + \left( {1 - {\mu _{\text{m} } } } \right){\beta _{} } } }, \; {\mu _{\text{m} } } = {\delta _{\text{u} } }/{\delta _{\text{y} } } \\ \end{gathered}$ D6 王东升等[19] $ \begin{gathered} D_6 = (1 - \beta )\dfrac{{{\delta _{\text{m}}} - {\delta _{\text{y}}}}}{{{\delta _{\text{u}}} - {\delta _{\text{y}}}}} + \frac{{\beta \displaystyle\sum {{\beta_i}} {E_i}}}{{{F_{\text{y}}}\left( {{\delta _{\text{u}}} - {\delta _{\text{y}}}} \right)}},\quad{\delta _{\text{m}}} > {\delta _{\text{y}}}, {\text{ }}{\beta_i} = \left\{ {\begin{array}{*{20}{l}} {{\mathop \gamma \nolimits_{\rm{E}}},\quad{\text{ }}{\mu_i} \leqslant {\mu _0}}, \\ {{\mathop \gamma \nolimits_{\rm{E}}} + \dfrac{{{\mu_i} - {\mu _0}}}{{{\mu_{\rm{p}}} - {\mu _0}}}(1 - {\mathop \gamma \nolimits_{\rm{E}}}),\quad{\mu_i} > {\mu _0}} \end{array}} \right.\begin{array}{*{20}{c}} {{\text{ }}} \\ {{\text{ }}} \end{array} \\ \end{gathered} $ D7 付国等[20] $\begin{gathered} {\text{ } }D_7 = \dfrac{ { {\delta _{\text{m} } } }}{ { {\delta _{\text{u} } } }} + \dfrac{ {\displaystyle\sum { { {e} }_i}{ { {E} }_i} } }{ { {F_{\text{y} } }{\delta _{\text{u} } } }}, \; { { {e} }_i} = \dfrac{1}{ { { {\text{δ} }_{i{\text{m} } } }/{ { {\varDelta } }_{\text{y} } } }}{\log {\left( {\dfrac{ { {\delta _{\text{u} } } }}{ { { {{\varDelta } }_{\text{y} } } } } } \right)} }\left( {\dfrac{ { {\delta _{i{\text{m} } } } } }{ { { {{\varDelta } }_{\text{y} } } } } } \right) \\ \end{gathered}$ D8 傅剑平等[21] $ D_8 = {{\rm{e}}^{\left( {0.13{\mu _{\text{m}}} - 0.39} \right)}}\dfrac{{{\delta _{\text{m}}}}}{{{\delta _{\text{u}}}}} + {{\rm{e}}^{\left( {3.35 - 0.18{\mu _{\text{m}}}} \right)}}\dfrac{{\beta \smallint {\text{d}}E}}{{{F_{\text{y}}}{\delta _{\text{u}}}}} $ 表 4 试件破坏时损伤指标均值

Table 4. Mean value of damage index during specimen damage

编号 所有试件破坏时均值 对比柱 SC MC BC 修复试件均值 D1 0.48 0.47 0.86 0.75 0.75 0.79 D2 0.67 0.63 1.40 1.06 1.31 1.25 D3 1.30 1.24 2.56 2.05 2.10 2.24 D4 1.40 1.33 2.91 2.39 2.73 2.67 D5 1.77 1.71 3.73 3.06 3.47 3.42 D6 0.77 0.63 1.76 1.36 1.78 1.63 D7 0.87 0.98 1.86 1.58 1.58 1.67 D8 1.35 1.01 2.65 2.14 3.02 2.60 表 5 损伤试件材料性能退化系数

Table 5. Degradation coefficient of material property of damaged specimens

试件名称 Park 损伤指数 $ {\alpha }_{\rm{F}} $ SC1C 0.1 0.95 SC1P 0.1 0.95 MC1C 0.3 0.86 MC1P 0.3 0.86 MC2P 0.3 0.86 BC1C 0.6 0.73 BC1P 0.6 0.73 BC2P 0.6 0.73 表 6 损伤模型组合系数

Table 6. Combination coefficient of damage model

试件编号 $\varepsilon $ 能量项比例/% 位移项比例/% CC 0.037 55 45 CC1C 0.027 48 52 SC1C 0.025 45 55 SC1P 0.024 44 56 MC1C 0.023 44 56 MC1P 0.021 41 59 MC2P 0.019 38 62 BC1C 0.020 40 60 BC1P 0.021 40 60 BC2P 0.022 42 58 表 7 损伤指标量化

Table 7. Quantification of damage index

损伤程度 损伤量 损伤状态 具体描述 基本完好 $ 0\leqslant D\leqslant 0.100 $ 未损伤 柱侧向变形不明显,混凝土未开裂或少量裂缝且裂缝宽度小于 0.1 mm,CFRP 平整完好,结构处于弹性阶段,此阶段使用普通 CFRP 修复试件,性能便可得到恢复甚至一定程度增强 轻微破坏 $ 0.100 < D\leqslant 0.300 $ 轻度损伤 柱身有一定数量水平裂缝,裂缝宽度小于 0.5 mm,柱底部混凝土开裂,CFRP 较平整,使用普通 CFRP 或预应力 CFRP 修复结构都可以得到较好效果 中度破坏 $ 0.300 < D\leqslant 0.600 $ 可修复 柱脚出现细微斜裂缝,裂缝宽度小于 1.0 mm,柱底水平裂缝一定程度开展,应该对已有裂缝进行处理后外包 CFRP 修复,此阶段建议使用预应力 CFRP 进行修复,对于重要结构预应力 CFRP 加固可作为应急修复方法 严重破坏 $ 0.600 < D\leqslant 0.900 $ 不可修复 试件在此阶段承载力急速下降,刚度退化严重,CFRP 鼓曲变形,纵筋屈曲,有效约束面积急剧减小 倒塌 $ 0.900 < D\leqslant 1.00 $ 结构失效 纵筋屈曲、断裂,混凝土压溃,结构完全失效 -

[1] 吴波,欧进萍. 钢筋砼结构在主余震作用下的反应与损伤分析[J]. 建筑结构学报,1993,14(5): 45-53. doi: 10.14006/j.jzjgxb.1993.05.006WU Bo, OU Jinping. Response and damage analysis of reinforced concrete structures under main shock and aftershocks[J]. Journal of Building Structures, 1993, 14(5): 45-53. doi: 10.14006/j.jzjgxb.1993.05.006 [2] 贾宏宇,杨健,郑史雄,等. 跨断层桥梁抗震综述[J]. 西南交通大学学报,2021,56(5): 1075-1093.JIA Hongyu, YANG Jian, ZHENG Shixiong, et al. A review on aseismic bridges crossing fault rupture regions[J]. Journal of Southwest Jiaotong University, 2021, 56(5): 1075-1093. [3] MAI A D, SHEIKH M N, HADI M. Investigation on the behaviour of partial wrapping in comparison with full wrapping of square RC columns under different loading conditions[J]. Construction and Building Materials, 2018, 168: 153-168. doi: 10.1016/j.conbuildmat.2018.02.003 [4] 周长东,田腾,吕西林,等. 预应力碳纤维条带加固混凝土圆墩抗震性能试验[J]. 中国公路学报,2012,25(4): 57-66. doi: 10.3969/j.issn.1001-7372.2012.04.010ZHOU Changdong, TIAN Teng, LÜ Xilin, et al. Test on seismic performance of RC circular piers strengthened with pre-stressed CFRP belts[J]. China Journal of Highway and Transport, 2012, 25(4): 57-66. doi: 10.3969/j.issn.1001-7372.2012.04.010 [5] CHAI Y H, ROMSTAD K M, BIRD S M. Energy-based linear damage model forhigh-intensity seismic loading[J]. Journal of Structural Engineering, 1995, 32(8): 857-864. [6] SUN Z G, LI H N, BI K M, et al. Rapid repair techniques for severely earthquake-damaged circular bridge piers with flexural failure mode[J]. Earthquake Engineering and Engineering Vibration, 2017, 16(2): 415-433. doi: 10.1007/s11803-017-0390-0 [7] WU R Y, PANTELIDES C P. Rapid repair and replacement of earthquake-damaged concrete columns using plastic hinge relocation[J]. Composite Structures, 2017, 180(15): 467-483. [8] 苏磊,陆洲导,张克纯,等. BFRP加固震损混凝土框架节点抗震性能试验研究[J]. 东南大学学报(自然科学版),2010,40(3): 559-564. doi: 10.3969/j.issn.1001-0505.2010.03.024SU Lei, LU Zhoudao, ZHANG Kechun, et al. Experimental study on BFRP-reinforced pre-damaged concrete column-beam joints by simulated earthquake[J]. Journal of Southeast University (Natural Science Edition), 2010, 40(3): 559-564. doi: 10.3969/j.issn.1001-0505.2010.03.024 [9] 陶毅,古金本,信任,等. CFRP网格修复后多层砌体结构墙体的抗震性能[J]. 西南交通大学学报,2019,54(6): 1258-1267. doi: 10.3969/j.issn.0258-2724.20170491TAO Yi, GU Jinben, XIN Ren, et al. seismic performance of multi-storey masonry wall repaired by carbon fiber reinforced polymer grids[J]. Journal of Southwest Jiaotong University, 2019, 54(6): 1258-1267. doi: 10.3969/j.issn.0258-2724.20170491 [10] 陈伟宏,乔泽惠,首维荣. CFRP加固震损非延性RC框架抗震性能试验研究[J]. 西南交通大学学报,2020,55(5): 1009-1016. doi: 10.3969/j.issn.0258-2724.20181068CHEN Weihong, QIAO Zehui, SHOU Weirong. Experimental study on seismic performance of carbon fibre reinforced plastics-retrofitted earthquake-damaged non-ductile reinforced concrete frames[J]. Journal of Southwest Jiaotong University, 2020, 55(5): 1009-1016. doi: 10.3969/j.issn.0258-2724.20181068 [11] PARK Y J, ANG A H S, ASCE F. Mechanistic seismic damage model for reinforced concrete[J]. Journal of Structural Engineering, 1985, 111(4): 722-739. doi: 10.1061/(ASCE)0733-9445(1985)111:4(722) [12] 郑山锁,石磊,周炎,等. 考虑锈蚀的钢框架柱地震损伤模型研究[J]. 地震工程学报,2018,40(6): 1211-1216.ZHENG Shansuo, SHI Lei, ZHOU Yan, et al. Research on a seismic damage model of steel frame columns considering corrosion[J]. China Earthquake Engineering Journal, 2018, 40(6): 1211-1216. [13] 王东升,冯启民,王国新. 考虑低周疲劳寿命的改进Park-Ang地震损伤模型[J]. 土木工程学报,2004,32(11): 41-49. doi: 10.3321/j.issn:1000-131X.2004.11.007WANG Dongsheng, FENG Qimin, WANG Guoxin. A modified park-ang seismic damage model considering low-cycle fatigue life[J]. China Civil Engineering Journal, 2004, 32(11): 41-49. doi: 10.3321/j.issn:1000-131X.2004.11.007 [14] 欧进萍,何政,吴斌,等. 钢筋混凝土结构基于地震损伤性能的设计[J]. 地震工程与工程振动,1999,19(1): 21-30.OU Jinping, HE Zheng, WU Bin, et al. Seismic damage performance-based design of reinfored concrete structures[J]. Earthquake Engineering and Engineering Vibration, 1999, 19(1): 21-30. [15] 陆本燕,刘伯权,吴涛,等. 基于RC桥梁墩柱的地震损伤模型比较分析[J]. 土木工程学报,2010,43(增1): 186-191. doi: 10.15951/j.tmgcxb.2010.s1.024LU Benyan, LIU Boquan, WU Tao, et al. Comparative analysis of seismic damage models for reinforced concrete bridge piers[J]. China Civil Engineering Journal, 2010, 43(S1): 186-191. doi: 10.15951/j.tmgcxb.2010.s1.024 [16] POWELL G H, ALLAHABADI R. Seismic damage prediction by deterministic methods: concepts and procedures[J]. Earthquake Engineering & Structural Dynamics, 1988, 16(5): 719-734. [17] ROUFAIEL M S L, MEYER C. Analytical modeling of hysteretic behavior of R/C frames[J]. Journal of Structural Engineering, 1987, 113(3): 429-444. doi: 10.1061/(ASCE)0733-9445(1987)113:3(429) [18] WANG M L, SURENDRA P S. Reinforced concrete hysteresis model based on the damage concept[J]. Mathematical and Computer Modelling, 1989, 12(3): 377-378. [19] 王东升,司炳君,艾庆华,等. 改进的Park-Ang地震损伤模型及其比较[J]. 工程抗震与加固改造,2005,27(增1): 144-150.WANG Dongsheng, SI Bingjun, AI Qinghua, et al. A comparative study of modified park-ang model and park-ang model for structural seismic damage evaluation[J]. Earthquake Resistant Engineering, 2005, 27(S1): 144-150. [20] 付国,刘伯权,邢国华. 基于有效耗能的改进Park-Ang双参数损伤模型及其计算研究[J]. 工程力学,2013,30(7): 84-90. doi: 10.6052/j.issn.1000-4750.2012.01.0051FU Guo, LIU Boquan, XING Guohua. The research and calculation on modified park-ang double parameter seismic damage model based on energy dissipation[J]. Engineering Mechanics, 2013, 30(7): 84-90. doi: 10.6052/j.issn.1000-4750.2012.01.0051 [21] 傅剑平,王敏,白绍良. 对用于钢筋混凝土结构的Park-Ang双参数破坏准则的识别和修正[J]. 地震工程与工程振动,2005,25(5): 73-79.FU Jianping, WANG Min, BAI Shaoliang. Identification and modification of the Park-Ang criterion for failure of RC structures[J]. Earthquake Engineering and Engineering Vibration, 2005, 25(5): 73-79. [22] 刘杰东. 震损钢筋混凝土框架滞回模型研究[D]. 重庆: 重庆大学, 2015. [23] VOSOOGHI A, SAIIDI M. Design guidelines for rapid repair of earthquake-damaged circular RC bridge columns using CFRP[J]. Journal of Bridge Engineering, 2013, 18(9): 827-836. doi: 10.1061/(ASCE)BE.1943-5592.0000426 [24] 陈林之,蒋欢军,吕西林. 修正的钢筋混凝土结构Park-Ang损伤模型[J]. 同济大学学报(自然科学版),2010,38(8): 1103-1107. doi: 10.3969/j.issn.0253-374x.2010.08.001CHEN Linzhi, JIANG Huanjun, LÜ Xilin. Modified Park-Ang damage model for reinforced concrete structures[J]. Journal of Tongji University (Natural Science), 2010, 38(8): 1103-1107. doi: 10.3969/j.issn.0253-374x.2010.08.001 [25] HARAJLI M. Axial stress-strain relationship for FRP confined circular and rectangular concrete columns[J]. Cement & Concrete Composites, 2006, 28(10): 938-948. [26] 沈祖炎,董宝,曹文衔. 结构损伤累积分析的研究现状和存在的问题[J]. 同济大学学报(自然科学版),1997,25(2): 135-140.SHEN Zuyan, DONG Bao, CAO Wenxian. Development and evaluation of researches on damage cumulation analysis for building structures[J]. Journal of Tongji University (Natural Science), 1997, 25(2): 135-140. [27] 中国地震局工程力学研究所. 建(构)筑物地震破坏等级划分: GB/T 24335—2009[S]. 北京: 中国标准出版社, 2009 [28] 刘艳辉,赵世春,强士中. 城市高架桥抗震性能水准的量化[J]. 西南交通大学学报,2010,45(1): 54-58,64.LIU Yanhui, ZHAO Shichun, QIANG Shizhong. Quantification of seismic performance levels for urban viaduct[J]. Journal of Southwest Jiaotong University, 2010, 45(1): 54-58,64. -

下载:

下载: