Thermal Aging Characteristics of Vehicle-Mounted Cable Terminal Stress Control Tube and Its Influence on Insulation Performance

-

摘要:

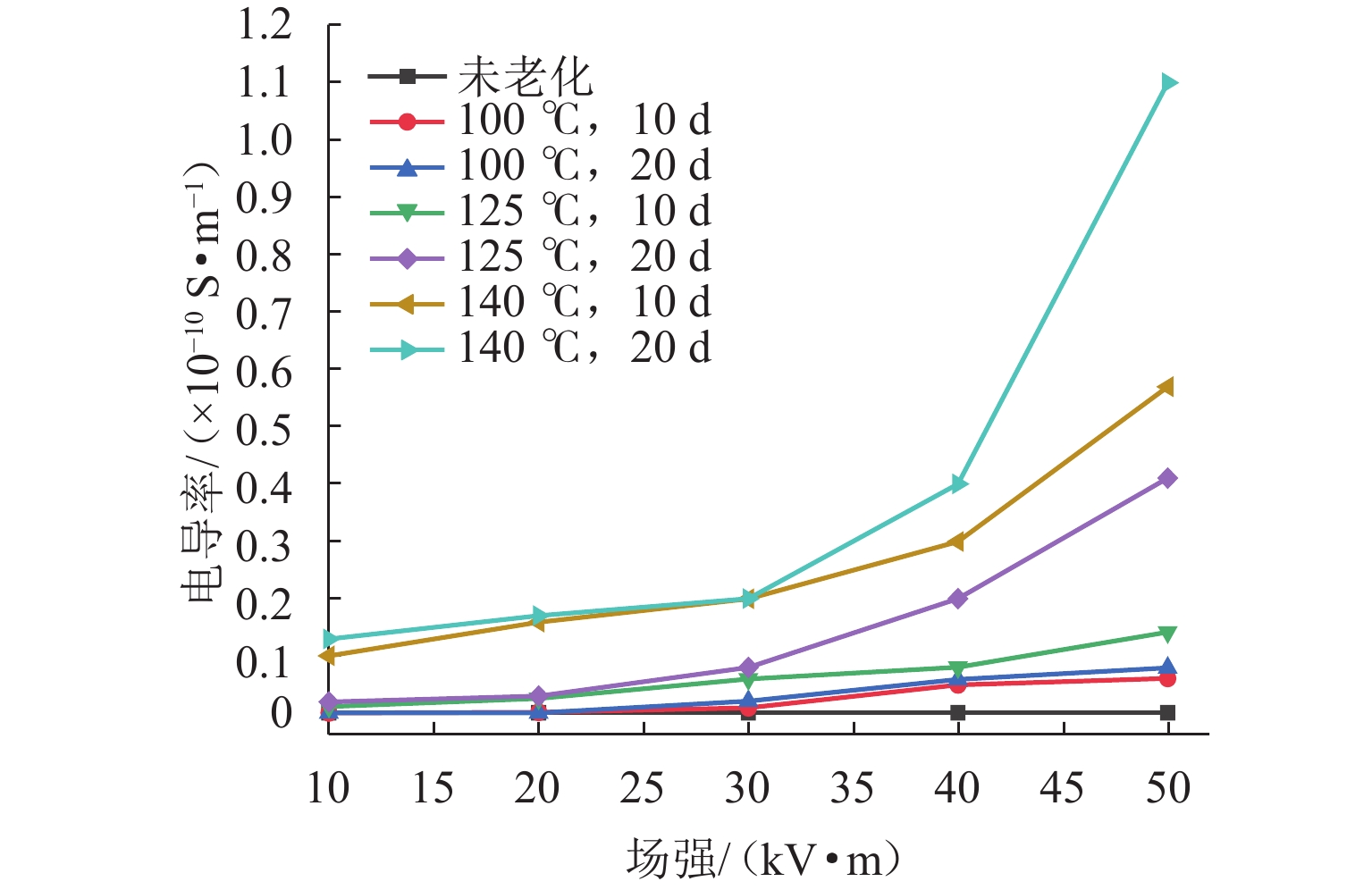

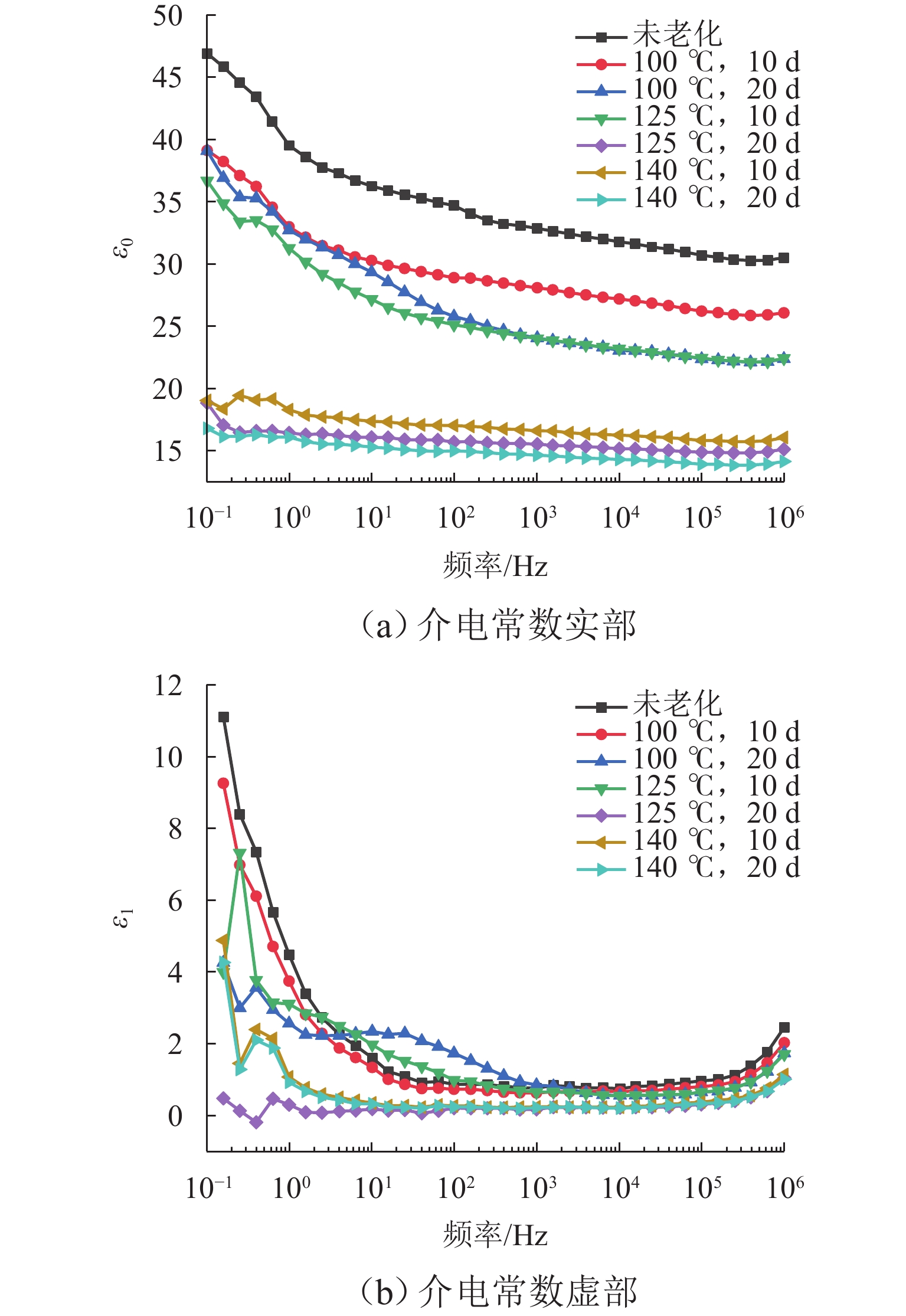

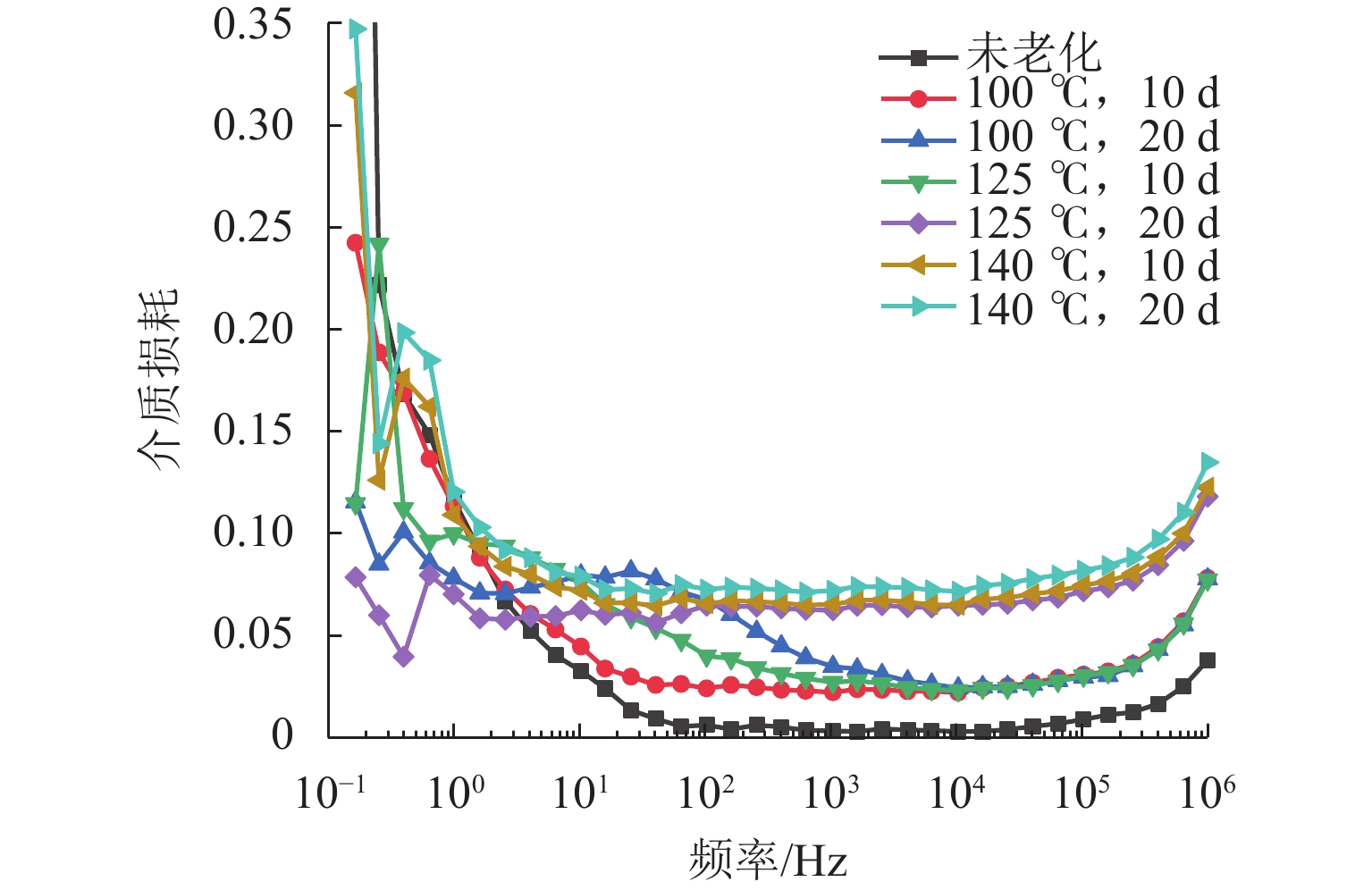

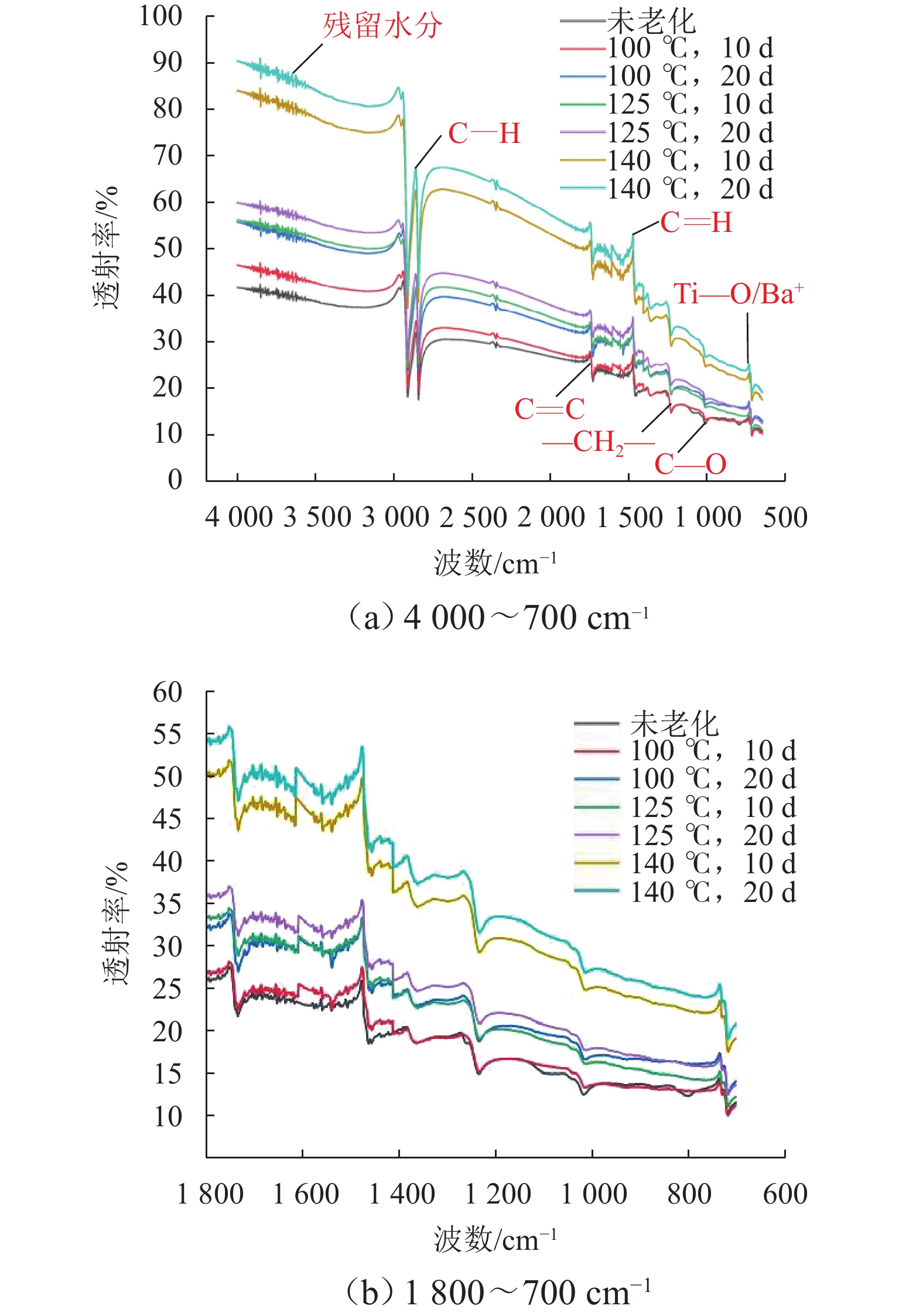

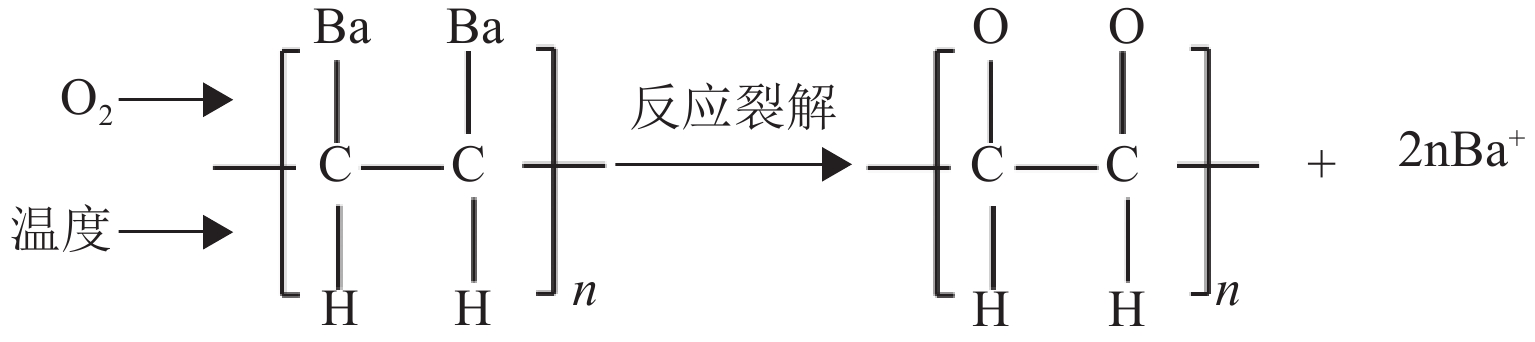

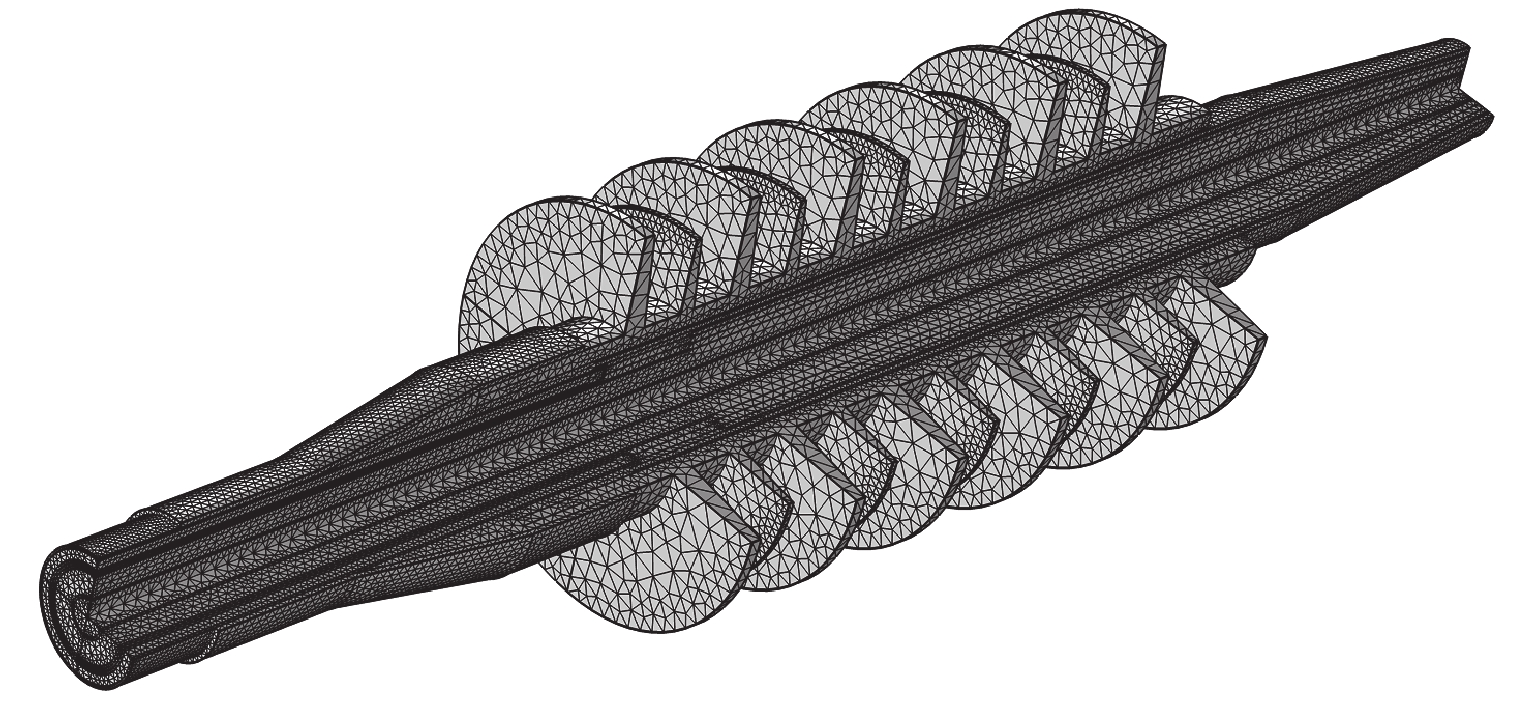

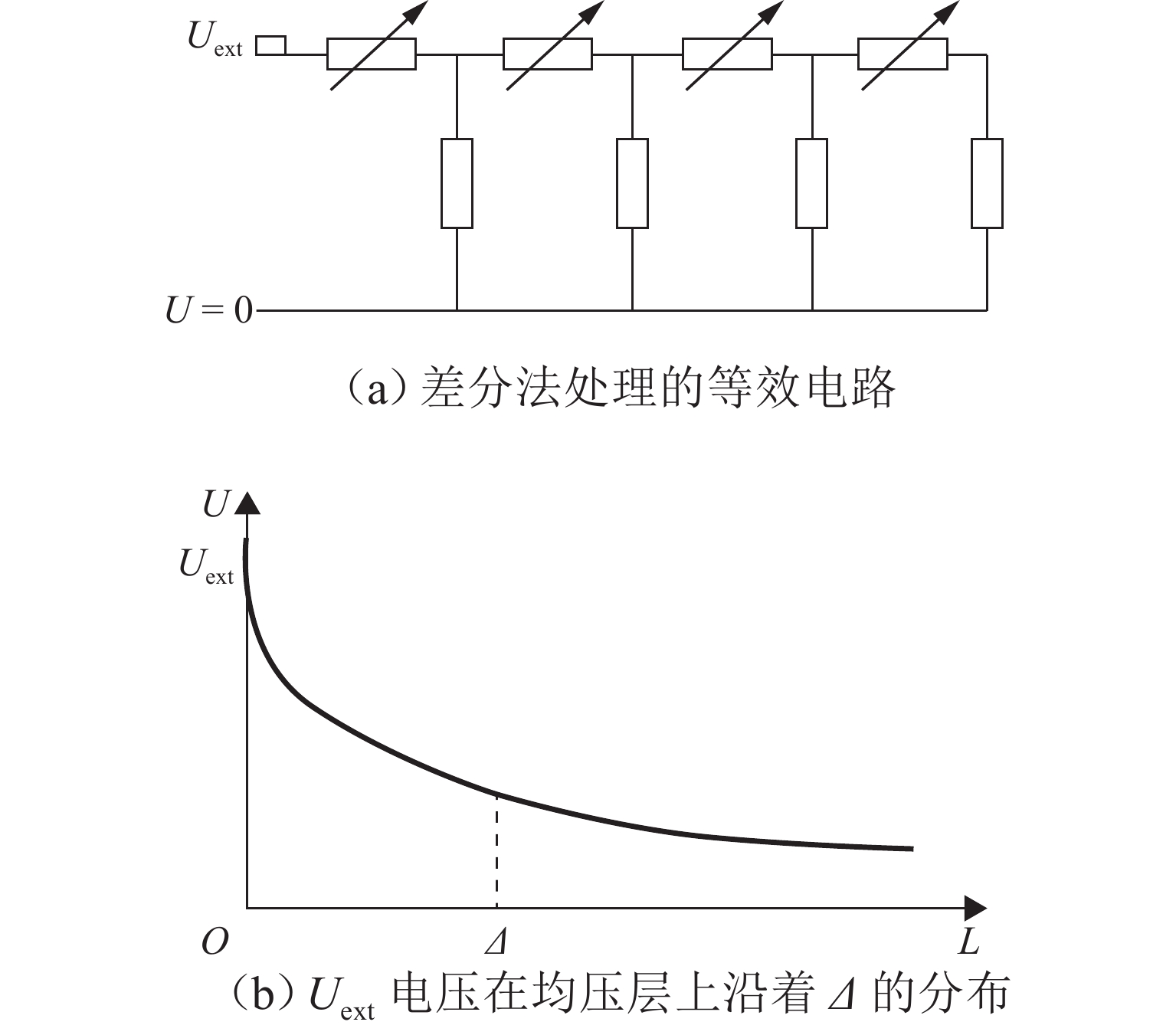

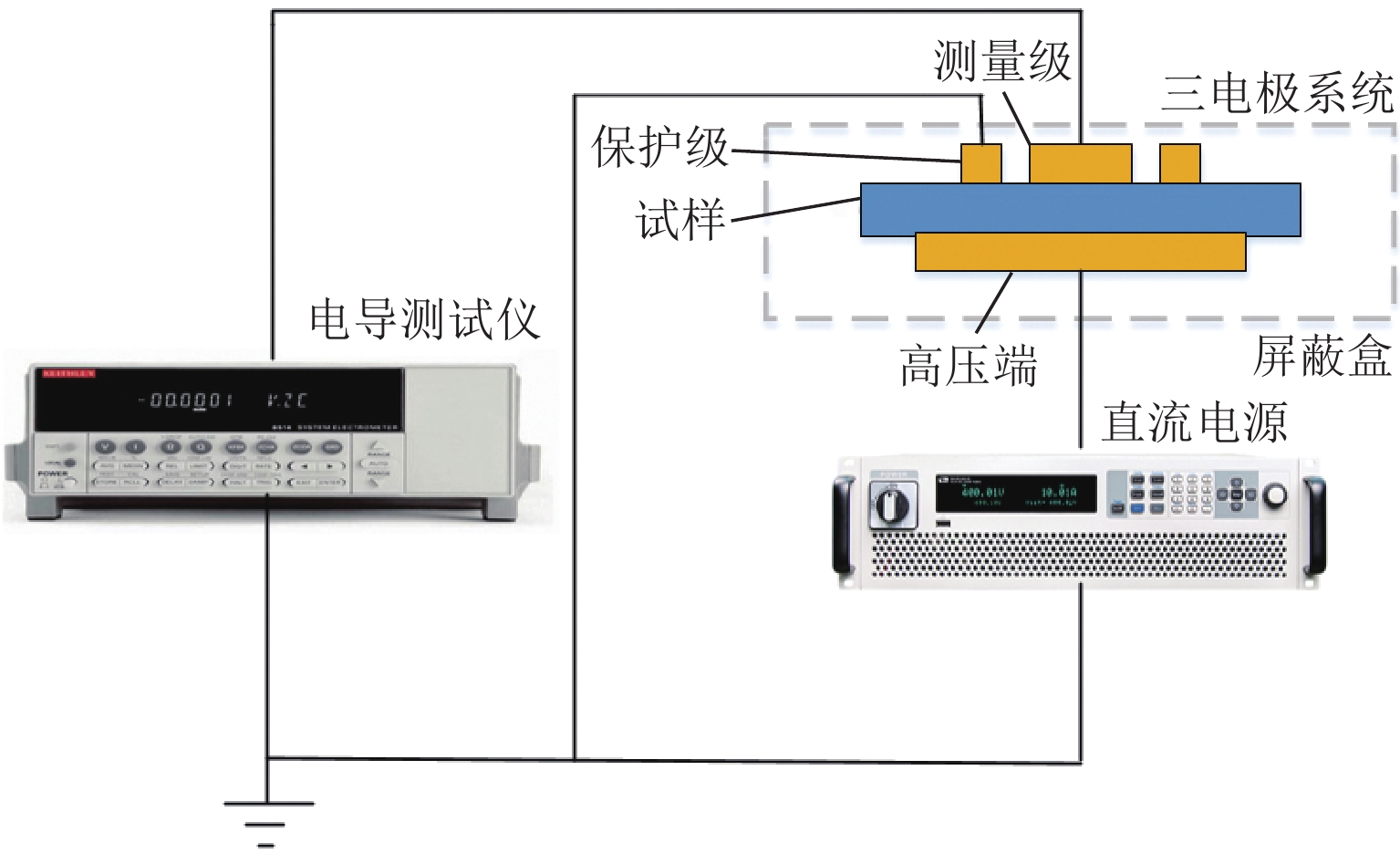

为研究车载电缆终端应控管热老化条件下的特性及热老化作用下的电缆终端绝缘性能,首先,通过试验研究确定车载电缆终端应控管宏观介电特性及微观老化规律;其次,基于对热老化下应控管材料电导、极化和损耗特性测试进行分析,得到不同老化周期下的介电特性曲线;最后,建立考虑应控管老化特性的车载电缆终端电场有限元模型,并基于热老化下介电参数计算应控管电缆终端电场分布. 研究表明:140 ℃老化条件下电导率上升趋势最为显著,50 kV/m场强下电导率达到最大值1.1 × 10−10 S/m,高温(140 ℃)老化20 d时,相对介电常数达到最小值14.00,此外,热解反应过程中聚合物长链折叠、断裂等陷阱阻碍作用增强,介质损耗有所增大;在应控管官能团特性及微观形貌上,热老化导致应控管材料烯烃类聚合物发生热解聚反应,形成化学立体缺陷,且加剧应控管试样表面聚合物球晶的裂解以及无机氧化产物的生成,试样表面理化特性发生变化. 仿真发现,在热老化条件下电缆终端内部电场畸变区域呈现扩大的趋势,电场畸变区域沿应控管向终端高压方向不断爬伸,最终稳定在乙丙橡胶主绝缘层与应控管的交界处.

Abstract:In order to determine the thermal aging characteristics of the vehicle-mounted cable terminal stress control tube and its influence on the insulation performance of cable terminal under thermal aging conditions, firstly, the macro-dielectric characteristics and micro-aging law of vehicle-mounted cable terminal stress control tube were determined through experimental research. Secondly, based on the analysis of the electrical conductivity, polarization, and loss characteristics of the stress tube material under thermal aging, the dielectric characteristic curves under different aging periods were obtained. Finally, a finite element model of the electric field of the vehicle-mounted cable terminal was established by considering the aging characteristics of the stress control tube, and the electric field distribution of the cable terminal of the stress control tube was calculated based on the dielectric parameters under thermal aging. The results show that the electrical conductivity increases most significantly at 140 ℃ and reaches the maximum value of 1.1 × 10−10 S/m at a field intensity of 50 kV/m. The relative dielectric constant reaches the minimum value of 14.00 at high temperature (140 ℃) for 20 days. In addition, trap hindrances such as folding and breaking of polymer long chain are enhanced during pyrolysis reaction, and the dielectric loss increases. In terms of functional group characteristics and microstructure of the stress control tube, thermal aging results in pyrolytic polymerization of olefin polymers in stress control tube materials, forming chemical stereoscopic defects. In addition, the cracking of polymer spherulites and the formation of inorganic oxidation products on the surface of the stress control tube sample are intensified, and the physical and chemical properties of the sample surface are changed. Simulation results show that under thermal aging conditions, the electric field distortion area inside the cable terminal presents a trend of expanding, creeps along the stress control tube towards the terminal high voltage, and finally stabilizes at the junction of the main insulation layer of ethylene propylene rubber (EPR) and stress control tube.

-

表 1 热老化应控管典型基团红外光谱吸收峰

Table 1. Infrared spectrum absorption peaks of typical groups of stress control tube under thermal aging

谱带位置/cm−1 基团(产物) 3000 ~2750 C—H 1750 ~1600 C=C 1500 ~1400 C=O 1300 ~1250 —CH2— 1200 ~1000 C—O 750~600 Ti—O/Ba + 表 2 电缆终端材料参数

Table 2. Cable terminal material parameters

名称 电导率/(S·m−1) 相对介电常数 缆芯 5.7×107 1.00 半导体层 2.0 100.00 绝缘层 1.0×10−18 2.50 应控管 1.0×10−8 25.30 屏蔽层 5.7×107 1.00 胶 7.7 0.50×10−8 热缩管 2.5×10−11 3.34 护套 1.0×10−18 2.60 伞裙 0.8×10−18 0.85 表 3 应控管老化特征参数

Table 3. Aging characteristic parameters of stress control tube

老化时间/d 相对介电常数 电导率/

(×10−11 S·m−1)频率/Hz 5 32.8 2.6 50 10 18.3 5.8 50 15 17.7 8.2 50 20 15.3 11.0 50 -

[1] 邓文丽,戴朝华,陈维荣,等. 轨道交通能源互联网背景下光伏在交/直流牵引供电系统中的应用及关键问题分析[J]. 中国电机工程学报,2019,39(19): 5692-5702,5897.DENG Wenli, DAI Chaohua, CHEN Weirong, et al. Application of photovoltaic in AC/DC traction power supply system and analysis of key issues under the background of rail transit energy Internet[J]. Proceedings of the CSEE, 2019, 39(19): 5692-5702,5897. [2] 曹建猷. 电气化铁道供电系统[M]. 北京: 中国铁道出版社,1983: 74-80. [3] 江平开,孙小金,黄宇,等. 纳米氧化镁聚丙烯复合绝缘材料的制备及其性能[J]. 高电压技术,2017,43(2): 355-366.JIANG Pingkai, SUN Xiaojin, HUANG Yu, et al. Preparation and performance of nano-magnesium oxide polypropylene composite insulating material[J]. High Voltage Technology, 2017, 43(2): 355-366. [4] HOU S , FU M, LI C, et al. Electric field calculation and analysis of HVDC cable joints with nonlinear materials[C]//Properties and Applications of Dielectric Materials. Sydney: IEEE, 2015: 184-187. [5] 刘刚,陈志娟. 10 kV交联乙丙橡胶电缆终端主绝缘含空气气隙缺陷试验[J]. 高电压技术,2012,38(3): 678-683.LIU Gang, CHEN Zhijuan. 10 kV cross-linked ethylene-propylene rubber cable terminal main insulation containing air gap defect test[J]. High Voltage Technology, 2012, 38(3): 678-683. [6] THUE W A. Electrical power cable engineering[M]. New York: Marcel Dekker, 2011: 20-30. [7] 王瑶瑶,姚周飞,谢伟,等. 基于时频域反射法的高温超导电缆故障定位研究[J]. 中国电机工程学报,2021,41(5): 1540-1547.WANG Yaoyao, YAO Zhoufei, XIE Wei, et al. Research on fault location of high-temperature superconducting cables based on time-frequency domain reflection method[J]. Proceedings of the CSEE, 2021, 41(5): 1540-1547. [8] 郭蕾,曹伟东,白龙雷,等. 热氧老化EPR电缆绝缘局部放电特性及劣化机理[J]. 高电压技术,2021,47(1): 231-240.GUO Lei, CAO Weidong, BAI Longlei, et al. Thermal oxygen aging EPR cable insulation partial discharge characteristics and deterioration mechanism[J]. High Voltage Technology, 2021, 47(1): 231-240. [9] 周远翔,张云霄,张旭,等. 热老化时间对硅橡胶电树枝起始特性的影响[J]. 高电压技术,2014,40(4): 979-986.ZHOU Yuanxiang, ZHANG Yunxiao, ZHANG Xu, et al. The effect of thermal aging time on the initial characteristics of silicone rubber electrical tree branches[J]. High Voltage Technology, 2014, 40(4): 979-986. [10] 王永强,仲钊,谢军,等. 温度对不同老化程度的绝缘纸板沿面放电的影响[J]. 高电压技术,2017(8): 1540-1547.WANG Yongqiang, ZHONG Zhao, XIE Jun, et al. The influence of temperature on the creeping discharge of insulating paperboard with different aging degrees[J]. High Voltage Technology, 2017(8): 1540-1547. [11] 尹游,周凯,李诗雨,等. 基于极化去极化电流法的水树老化XLPE电缆界面极化特性分析[J]. 电工技术学报,2020,35(12): 2643-2651.YIN You, ZHOU Kai, LI Shiyu, et al. Polarization characteristics analysis of water tree aging XLPE cable interface based on polarization depolarization current method[J]. Journal of Electrotechnical Technology, 2020, 35(12): 2643-2651. [12] 周凯,陈泽龙,李天华,等. 运行老化XLPE电缆导体屏蔽层侧绝缘缺陷分析[J]. 高电压技术,2020,46(1): 187-194.ZHOU Kai, CHEN Zelong, LI Tianhua, et al. Analysis of insulation defects on the side of the conductor shielding layer of the operating aging XLPE cable[J]. High Voltage Technology, 2020, 46(1): 187-194. [13] 刘刚,张高言,周凡,等. 基于等温松弛法的110 kV高压电缆老化状况评估[J]. 高电压技术,2014,40(2): 497-504.LIU Gang, ZHANG Gaoyan, ZHOU Fan, et al. 110 kV high-voltage cable aging evaluation based on isothermal relaxation method[J]. High Voltage Technology, 2014, 40(2): 497-504. [14] 杨帆,王位,郑维飞,等. 高原环境对电力机车高压电缆柔性终端运用的影响及应对措施[J]. 电力机车与城轨车辆,2017(3): 0312-0319.YANG Fan, WANG Wei, ZHENG Weifei, et al. The influence of plateau environment on the application of flexible terminals of high-voltage cables for electric locomotives and countermeasures[J]. Electric Locomotives and Urban Rail Vehicles, 2017(3): 0312-0319. [15] 郑维飞,康明明,成本权,等. 电力机车高压电缆柔性终端放电击穿故障分析[J]. 电力机车与城轨车辆,2017(6): 0670-0677.ZHENG Weifei, KANG Mingming, CHENG Benquan, et al. Discharge breakdown analysis of flexible terminal of high voltage cable for electric locomotive[J]. Electric Locomotives and Urban Rail Vehicles, 2017(6): 0670-0677. [16] CLABBURN C. R. J, DAVID C. The function of stress control tube in cable terminal[J]. Journal of Electro-ceramics, 2011, 3(4): 1509-1517. [17] 胡军,杨霄,何金良,等. 电导及介电自适应调控的复合界面材料及其应用[J]. 高电压技术,2016,42(9): 2902-2908.HU Jun, YANG Xiao, HE Jinliang, et al. Conductivity and dielectric self-adaptive control of composite interface materials and their applications[J]. High Voltage Technology, 2016, 42(9): 2902-2908. [18] 周利军,朱少波,白龙雷,等. 低温下应力控管界面对车载电缆终端局部放电的影响[J]. 高电压技术,2019,45(4): 1266-1273.ZHOU Lijun, ZHU Shaobo, BAI Longlei, et al. Influence of stress tubes interface on partial discharge of vehicle cable terminal at low temperature[J]. High Voltage Technology, 2019, 45(4): 1266-1273. [19] 刘源. 高寒环境中机车电缆终端局部放电与绝缘劣化机理研究[D]. 成都: 西南交通大学,2018: 20-30. [20] 朱琳. 高寒车载电缆终端与网侧柜电场仿真及结构优化[D]. 成都: 西南交通大学,2018. [21] 国家质量监督检验检疫总局. 高聚物多孔弹性材料加速老化试验:GB/T 14274—2003[S]. 北京: 中国标准出版社,2003. [22] 全国电线电缆标准化技术委员会. 电缆和光缆绝缘和保护套材料通用试验方法第12部分:热老化试验: GB/T 2951.12—2008[S]. 北京: 中国标准出版社,2008. [23] RHYNER J, BOU-DIAB M G. One-dimensional model for nonlinear stress control in cable terminations[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 1997, 4(6): 785-791. doi: 10.1109/94.654706 -

下载:

下载: