Experimental Investigation of Relative Humidity Response in Early-Age Concrete Under Tensile Stress

-

摘要:

为系统研究早龄期混凝土内部相对湿度对不同水平拉应力的响应规律,设计恒定轴拉下混凝土内部相对湿度测试方法,试验研究了不同拉应力下的相对湿度响应规律,并基于试验结果和理论分析,给出早龄期混凝土单面干燥条件下相对湿度与拉应力的线性模型. 研究结果表明:拉应力施加会造成混凝土内部相对湿度瞬时下降,当拉应力从0.8 MPa增加到3.2 MPa时,混凝土深度分别为50、75、100 mm处的相对湿度变化值从0.5%、0.4%和0.3%增加到0.8%、0.7%和0.6%;随着拉应力逐渐增大,相对湿度下降值逐渐增大;在相同拉应力下,距离混凝土暴露面近的相对湿度对拉应力的响应更为显著;拉应力持荷状态下相对湿度会逐渐恢复,恢复时间约2.5 h,在压应力持荷状态下也出现了类似现象,恢复时间约20.0 h,拉应力持荷状态下相对湿度恢复时间更短.

Abstract:In order to systematically investigate the response law of the internal relative humidity of concrete at an early age to different tensile stress levels, a test method of the internal relative humidity of the concrete under constant axial tension was developed in this paper, and the response law of the relative humidity under different tensile stresses was studied experimentally. According to the experimental results and theoretical analysis, a linear model of the relative humidity and tensile stress of early-age concrete under one-side drying conditions was presented. The results show that the tensile stress causes the instantaneous decrease in the internal relative humidity of the concrete. When the tensile stress increases from 0.8 MPa to 3.2 MPa, the relative humidity change at the depth of 50, 75, and 100 mm of the concrete increases from 0.5%, 0.4%, and 0.3% to 0.8%, 0.7%, and 0.6%, respectively. At the same time, with the increase in tensile stress, the decrease in the relative humidity gradually increases. Under the same tensile stress, the response of relative humidity of the concrete, close to the exposed surface, to tensile stress which is is more obvious. The relative humidity gradually recovers during the tensile stress loading, and the time is about 2.5 h. A similar phenomenon also occurs during the compressive stress loading, and the time is about 20.0 h. Therefore, the relative humidity recovery time is shorter during the tensile stress loading.

-

Key words:

- early age /

- concrete /

- relative humidity /

- tensile stress /

- linear model

-

混凝土浇筑后水泥等胶凝材料的水化反应消耗水并释放大量热,与环境交互产生剧烈的温湿度变化,在内外约束作用下将产生较大的拉应力[1,2],而混凝土早龄期抗拉强度相对较低,易产生开裂,严重影响混凝土服役功能和使用寿命[3].

目前研究已经认识到混凝土早龄期水化、温度和相对湿度之间的耦合现象及其对早龄期开裂的重要影响[4]. 在进行混凝土早龄期收缩应力分析中,认为水化-温-湿与应力之间是顺序耦合关系,即温湿度变化产生应力,而应力对温湿度影响忽略不计. 但Powers[5]认为应力状态对混凝土内部水分分布有影响,并进而影响相对湿度,相对湿度变化引起收缩和徐变,在约束条件下引起应力状态的变化,进而影响开裂风险,因此,对混凝土早期裂缝防控具有重要影响.

杜明月[6]进行了一系列轴心压力作用下混凝土内部相对湿度响应试验,发现混凝土内部相对湿度在轴向压力作用下发生明显变化. Zhao等[7]开展了压应力加、卸载对混凝土相对湿度影响的试验研究,发现压应力加载使相对湿度上升,而卸载使相对湿度下降. 上述研究侧重于压应力状态下相对湿度变化,但影响混凝土开裂的是拉应力. Wyrzykowski等[8]开展了拉应力对成熟砂浆相对湿度影响试验研究,发现拉应力对相对湿度有影响. 混凝土早龄期开裂现象较为普遍,甚至拆模即发现裂缝,但目前缺乏拉应力对早龄期混凝土相对湿度变化规律的研究. 基于此,本文进行了不同拉应力水平下早龄期混凝土相对湿度试验研究,并进一步构建相对湿度与拉应力之间的关系.

1. 试 验

1.1 试验原材料及配合比

试验采用符合GB 175—2007[9]标准的P·Ⅱ52.5硅酸盐水泥,比表面积和密度分别为377 m2/kg和

3150 kg/m3;采用河砂作为细骨料,主要成分为石英,细度模量为2.5;采用玄武岩质碎石作为粗骨料,粒径级配为5~20 mm;减水剂为聚羧酸减水剂. 试验混凝土水灰比为0.3,配合比如表1所示. 根据GB/T 50081—2019[10]测得混凝土7、28 d的抗压强度分别为63.7 MPa和72.1 MPa.表 1 混凝土配合比Table 1. Concrete mix proportionkg/m3 材料名称 水泥 水 细骨料 粗骨料 减水剂 配合比 533.00 160.00 597.00 1110.00 4.33 1.2 力学性能试验方法

轴向抗拉强度试验采用狗骨试件,加载装置为万能试验机,采用位移控制法,加载速率为0.3 mm/min. 轴向拉伸试件四周安装4个长度为150 mm的位移传感器,数据采集系统将自动绘制荷载-位移曲线. 在标准养护((20 ± 1) ℃,95%相对湿度以上)到规定龄期后进行轴向拉伸试验[9]. 将轴拉试验过程中的荷载位移曲线转化为应力-应变曲线,根据应力从0~1/3破坏应力的割线弹性模量求得抗拉弹性模量[9],即混凝土受拉静弹性模量为

Estat=σ1/3ε1/3, (1) 式中:σ1/3为1/3的破坏应力(MPa),ε1/3为σ1/3对应的应变值(με).

采用尺寸为300 mm × 150 mm × 150 mm棱柱体试件,标准养护到规定龄期后,利用超声波仪器测量纵向传播时间,通过式(2)[11]转化为动弹性模量(Edyn).

Edyn=ρv2(1+v)(1−2v)/(1−v), (2) 式中:ρ为混凝土密度( kg/m3);v为混凝土泊松比,取值为0.2.

1.3 拉应力状态下相对湿度测试试验方法

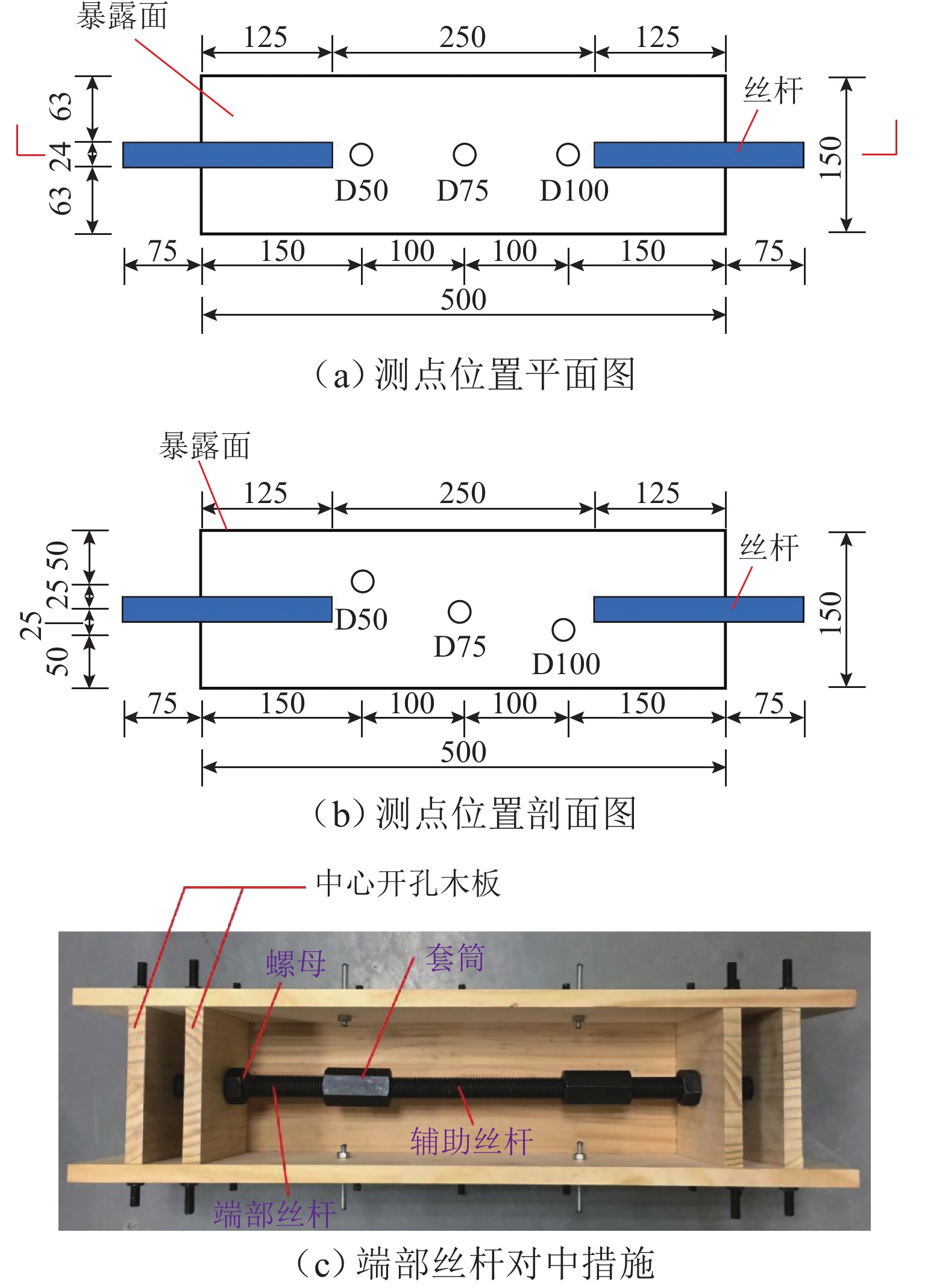

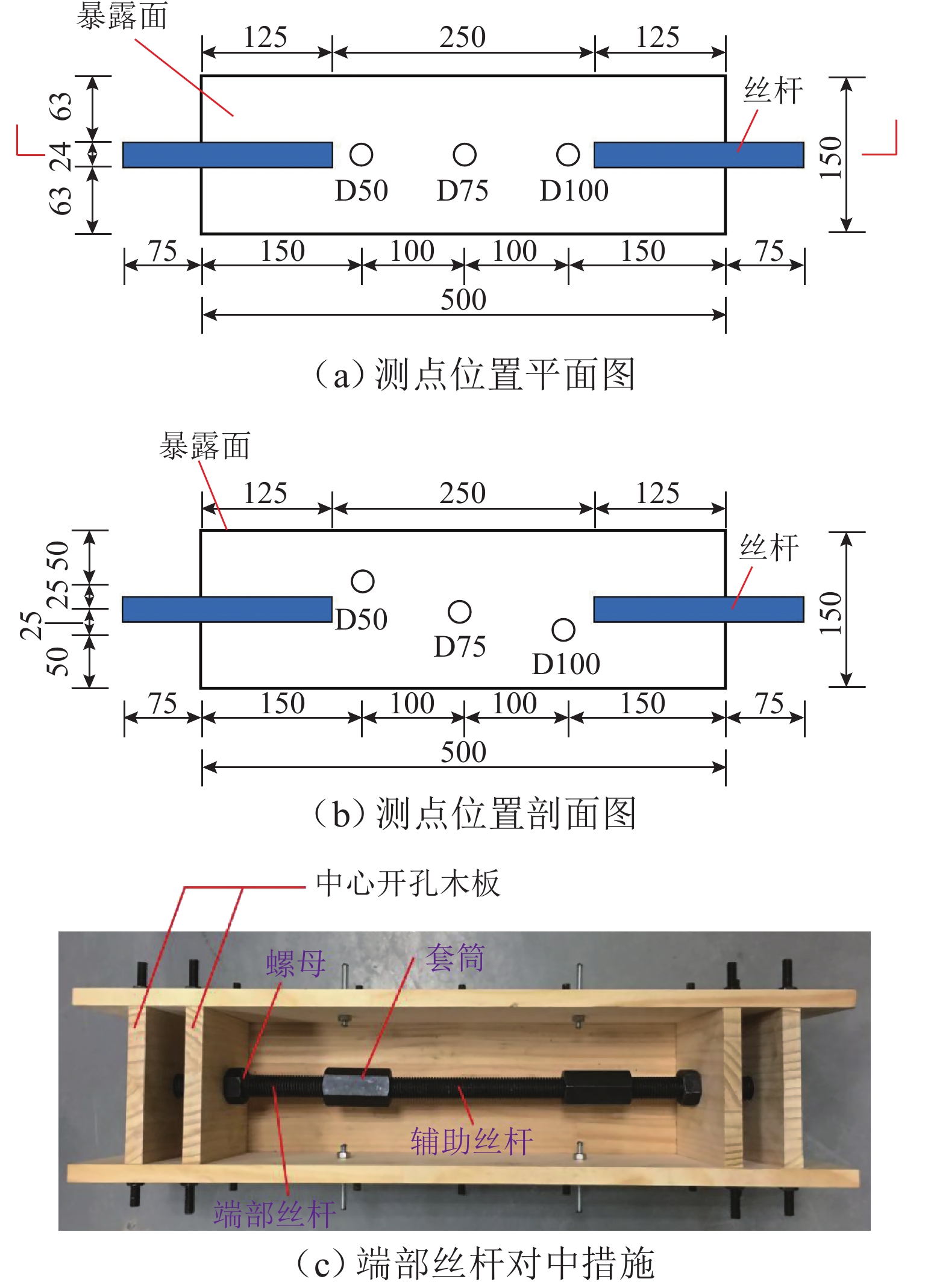

拉应力状态下早龄期混凝土相对湿度试验采用尺寸为500 mm × 150 mm × 150 mm的棱柱体. 混凝土试件沿两端长度方向埋入丝杆,埋入深度为125 mm[12],受到轴拉作用的混凝土有效长度为250 mm. 本次试验共布置3个相对湿度测点,分别距离混凝土暴露面50、75、100 mm,命名为D50、D75以及D100. 测点位置平面和剖面分别如图1(a)和图1(b)所示. 为最大限度避免试件荷载偏心,在浇筑用模具两端分别设计了2个中心开孔木板,并采用辅助丝杆和套筒对中连接两边端部丝杆,最后利用螺母将端部丝杆固定在2块中心开孔木板上,如图1(c)所示. 试验浇筑混凝土前,去掉套筒与辅助丝杆,在模具内侧铺两层聚四氟乙烯薄膜,以阻止混凝土中水分被木模板吸收及侧面散失.

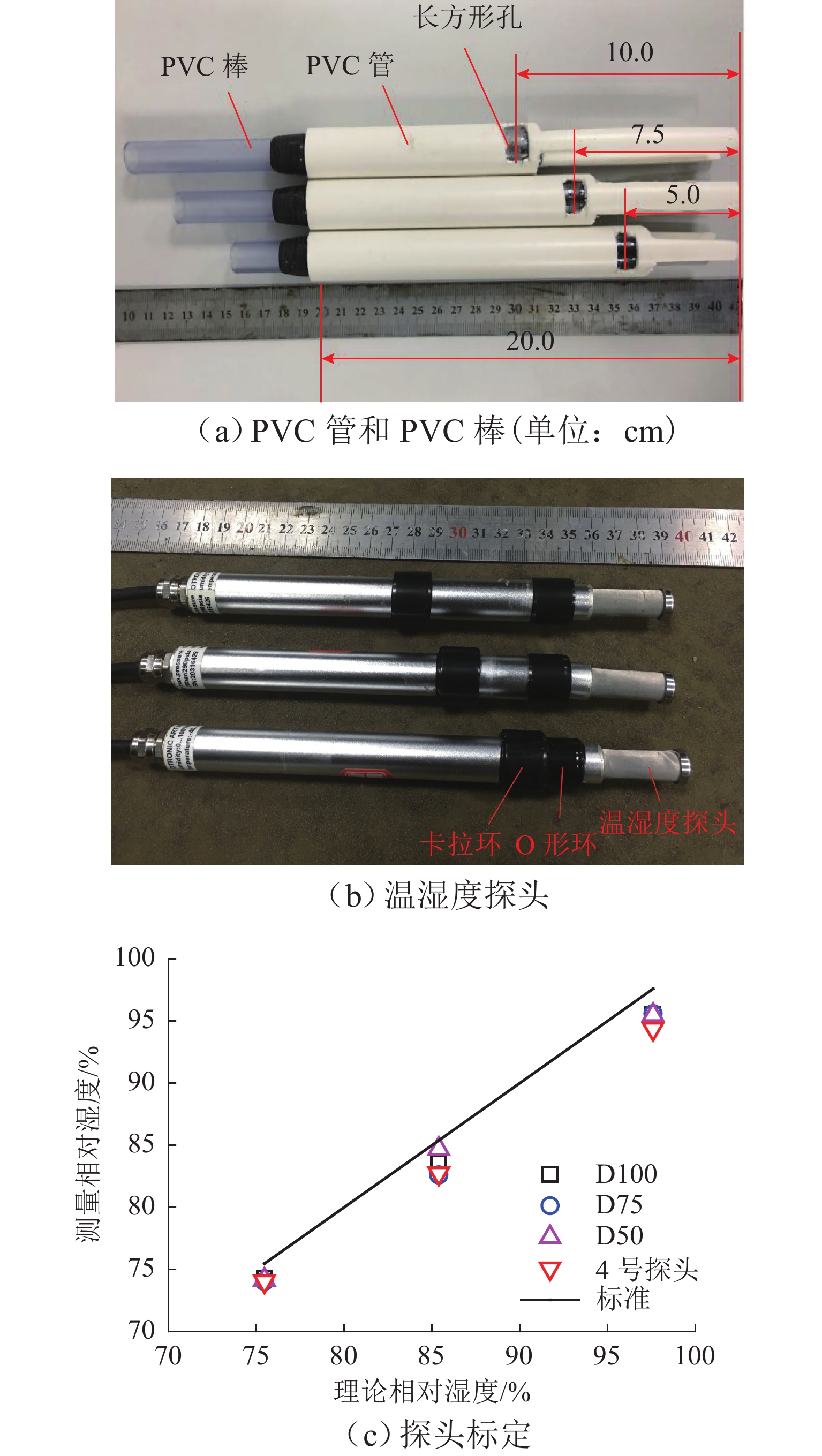

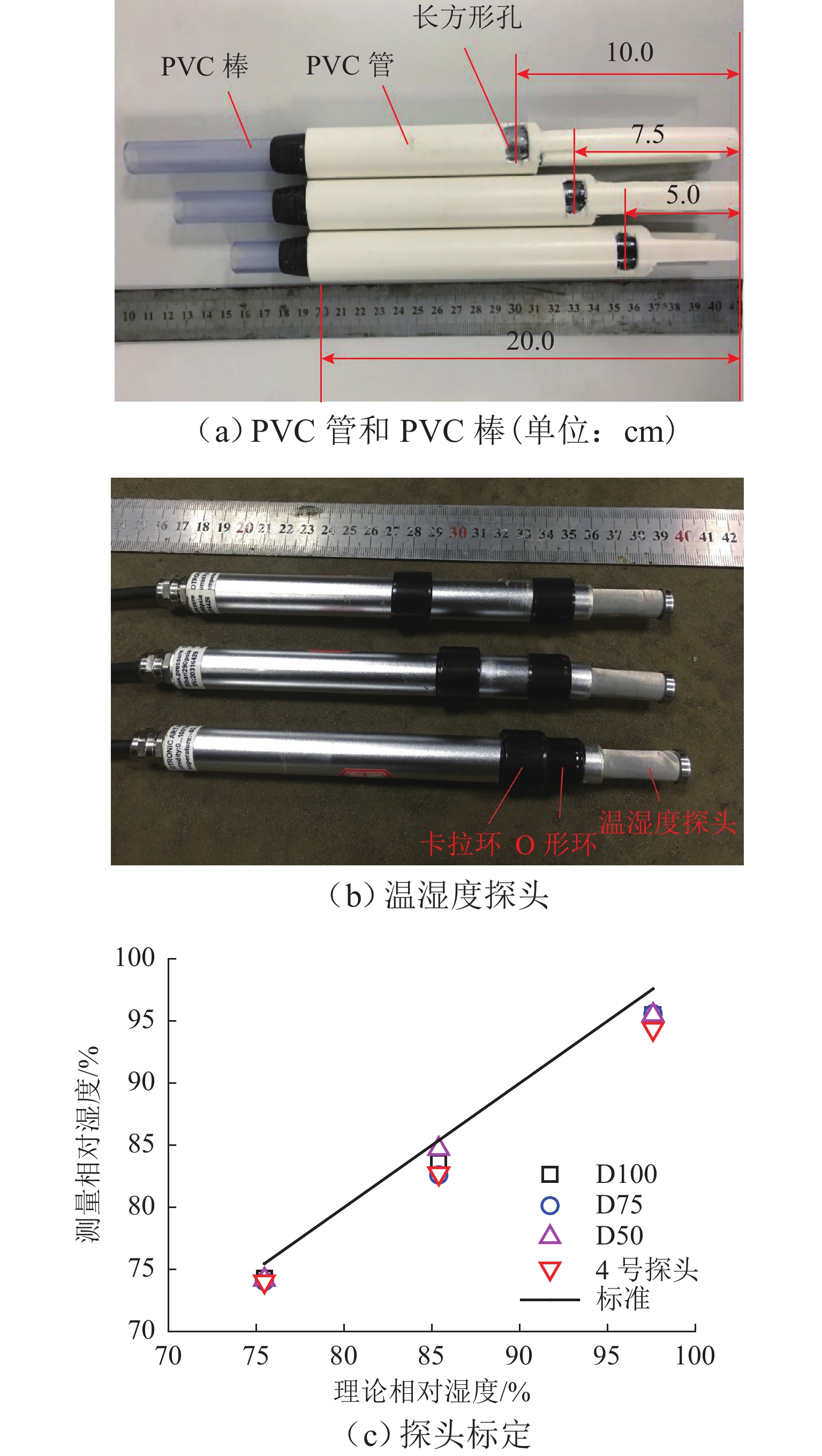

试验前准备3根内径25 mm的PVC管,根据试验设计的测点位置将PVC管预留2个对侧长方形孔,埋置前将PVC棒底部与PVC管预留孔位置齐平,防止浇筑时混凝土涌入PVC管,如图2(a)所示. 混凝土相对湿度通过放入PVC管的瑞士罗卓尼克温湿度探头测得(4号探头),如图2(b)所示. 本次试验使用的瑞士罗卓尼克探头型号为HC2A-S,相对湿度量程范围0~100%,精度±0.8%. 温度量程范围−50~100 ℃,精度±0.1 ℃. 探头在测试前后,采用饱和NaCl、KCl和K2SO4盐溶液进行校准,20 ℃时饱和NaCl、KCl和K2SO4盐溶液的相对湿度理论值分别为75.47%、85.39%和97.59%[13],校准曲线如图2(c)所示.

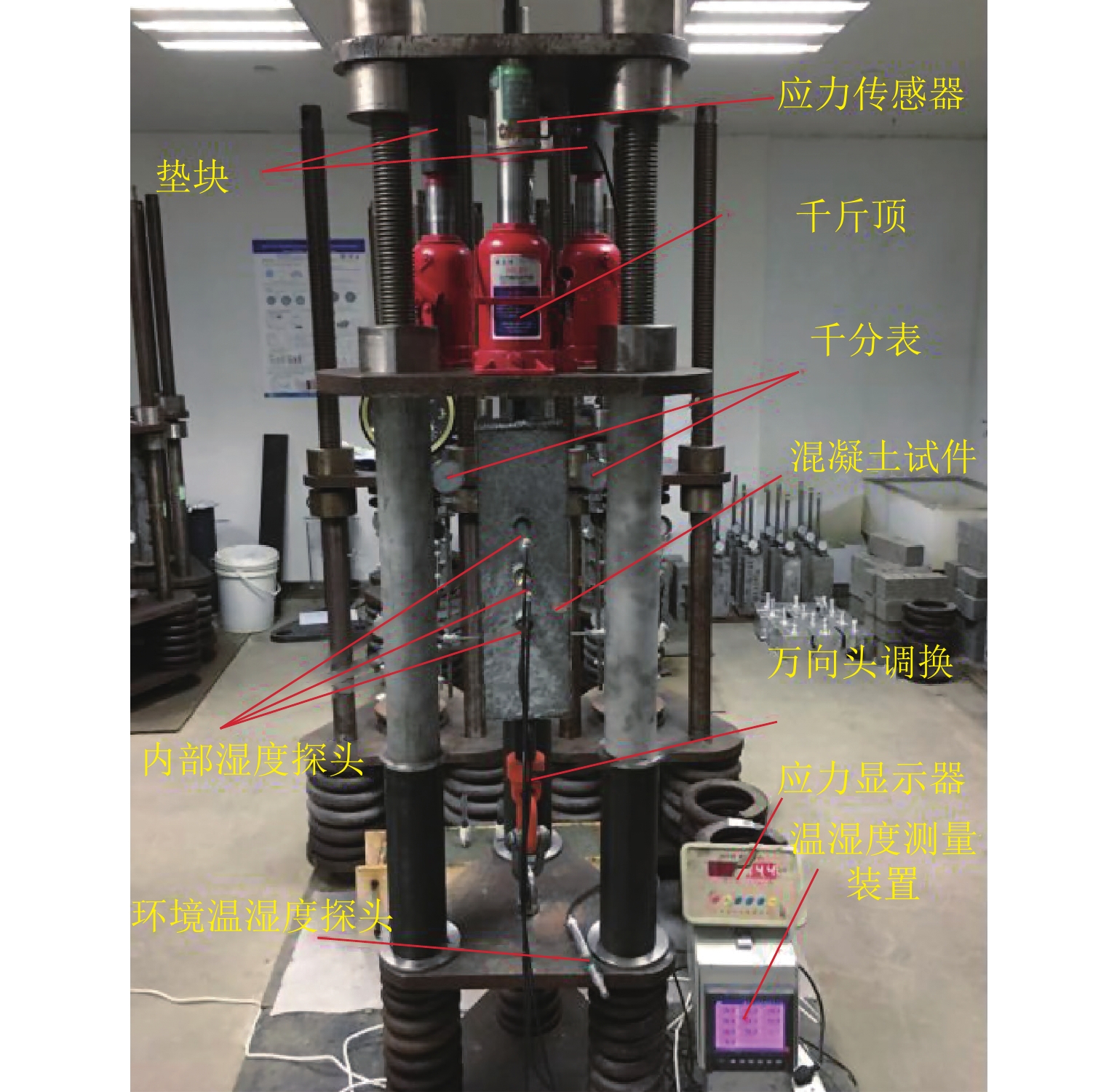

在浇筑混凝土前,按照测点位置垂直固定好PVC管并插入PVC棒. 混凝土在浇筑入模后直接放入恒温恒湿养护室. 待混凝土初凝之后,拔出PVC棒,放入探头,并用防水胶带将探头与PVC管间空隙封住. 3 d之后试件脱模,用自粘铝箔纸包裹混凝土试件的5个面,上表面暴露在空气中. 当混凝土试件养护到7 d龄期时,移入恒定轴拉试验机加载架,用液压千斤顶进行加载,利用本文设计的加载反力架,将千斤顶对铁板的压力转化为连接件对混凝土施加拉力. 拉应力状态下的相对湿度测量如图3所示,拉(压)应力加载方案如表2所示.

表 2 加载试验方案Table 2. Loading test scheme工况 拉(压)应力/

抗拉(压)强度/%施加拉(压)应力/MPa 7 d 抗拉(压)强度/MPa 截面面积/m2 施加荷载/kN 备注 T1 20 0.8 3.95 0.01875 15 拉力 T2 40 1.6 3.95 0.01875 30 拉力 T3 60 2.4 3.95 0.01875 45 拉力 T4 80 3.2 3.95 0.01875 60 拉力 C1 20 12.8 63.7 0.01875 240 压力 2. 试验结果与分析

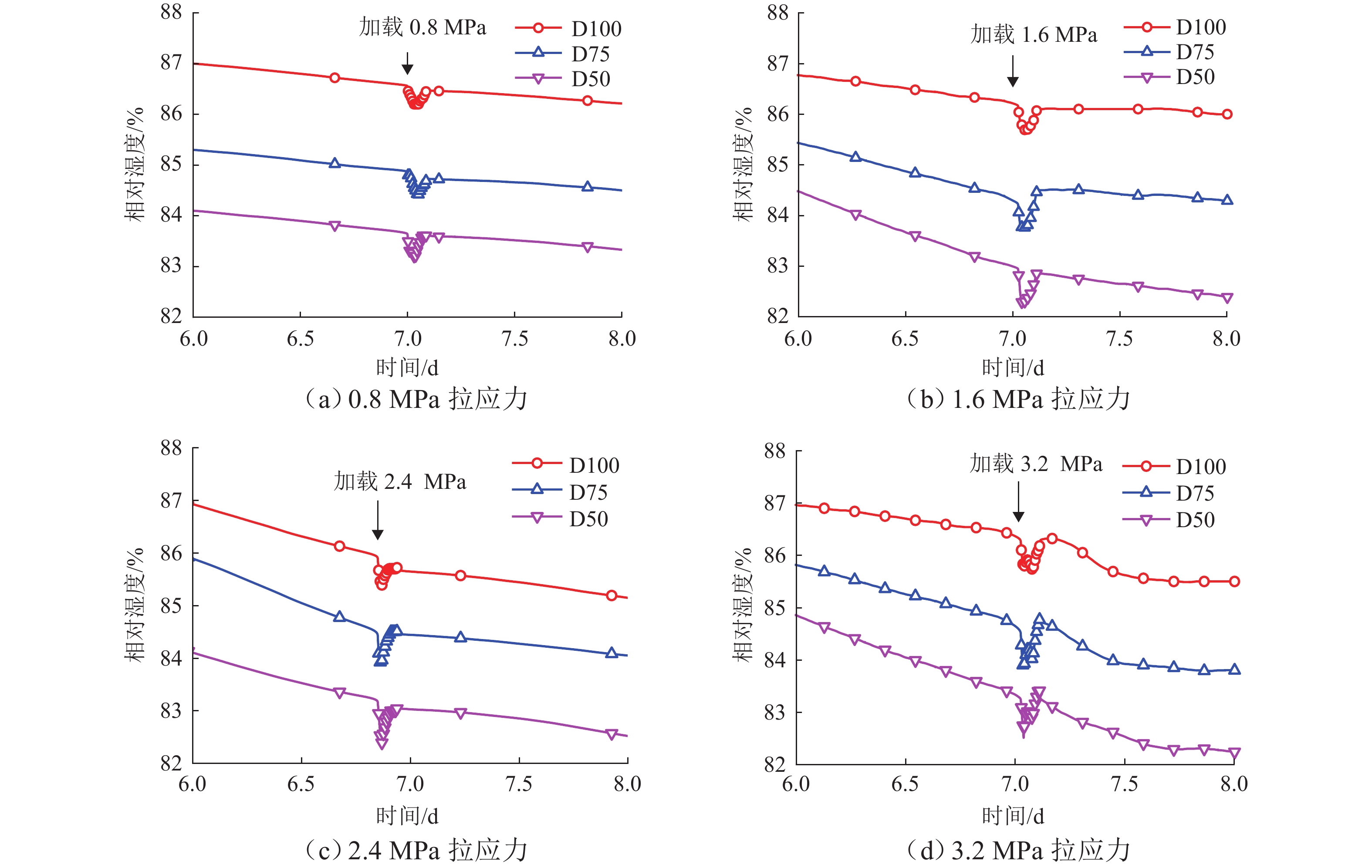

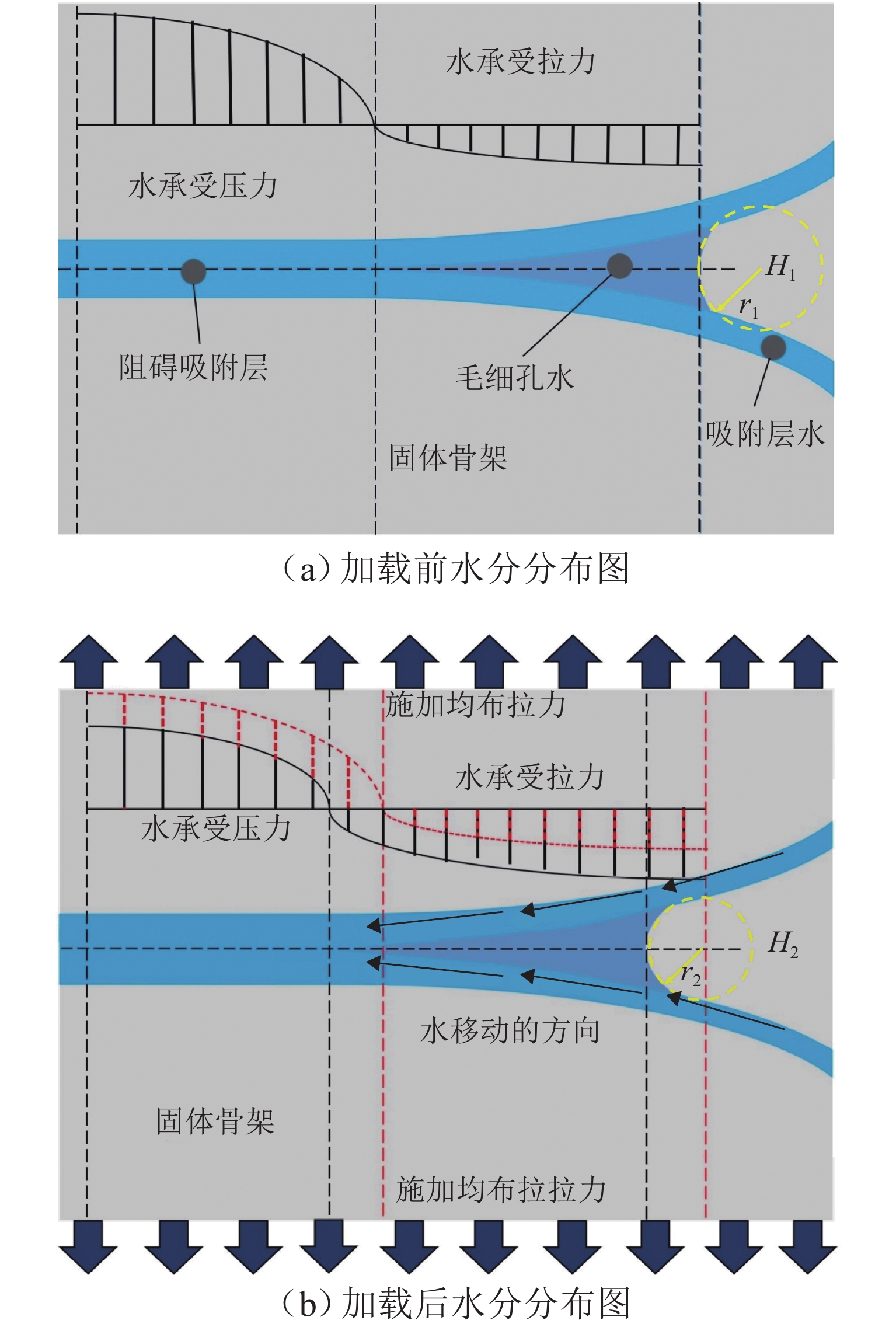

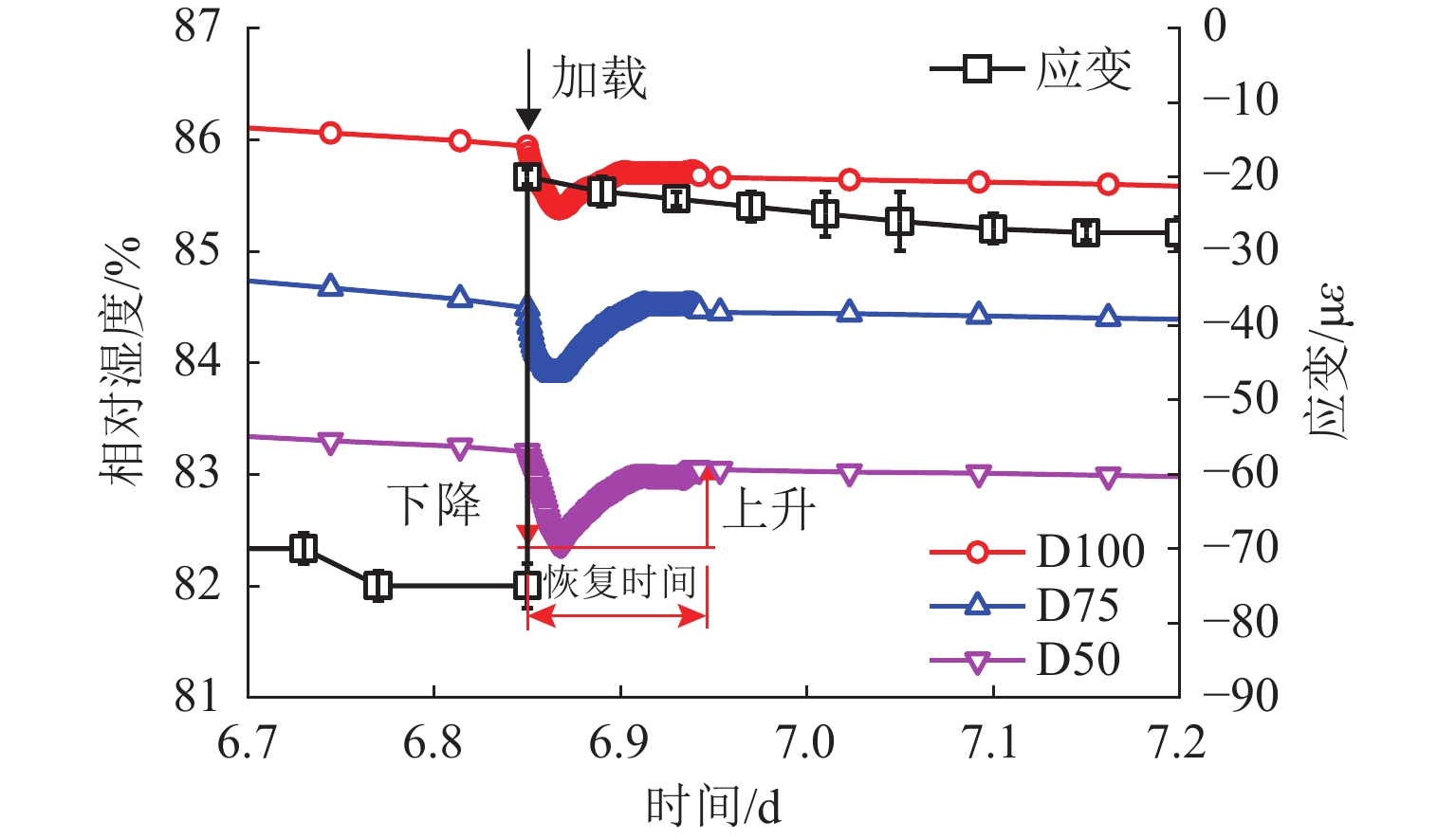

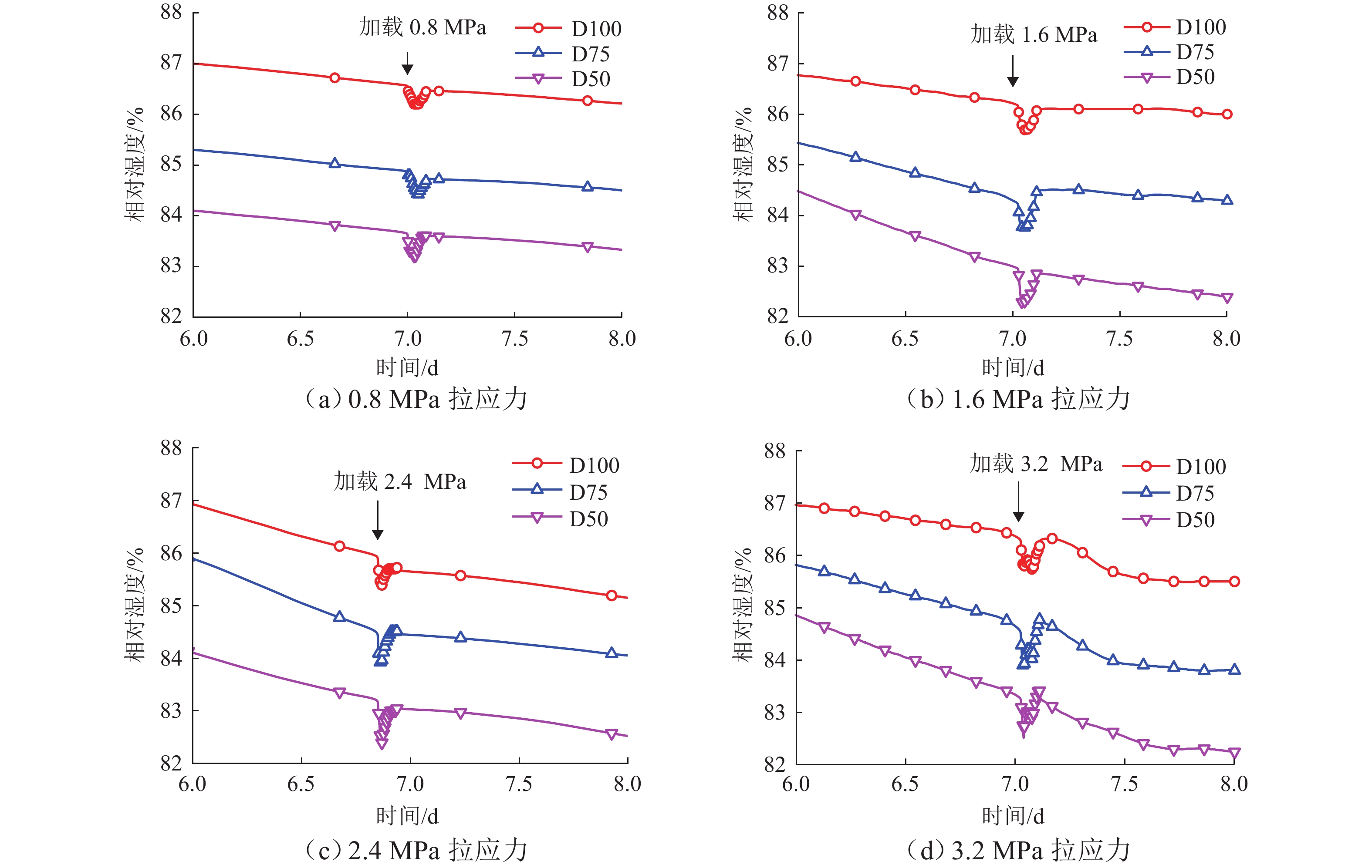

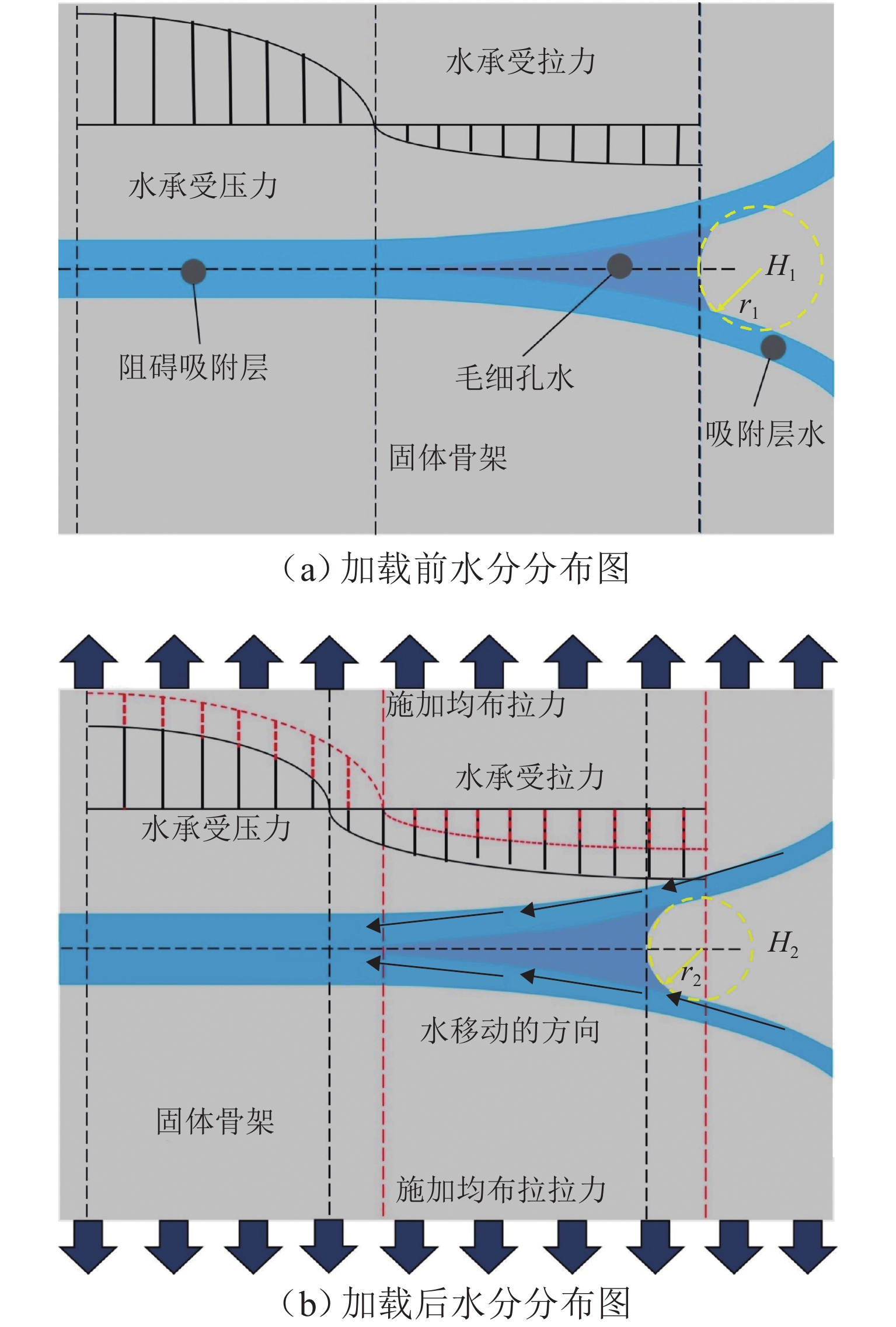

图4为不同拉应力水平下的相对湿度发展曲线. 从图中可以发现:相对湿度对拉应力有较为明显的响应, 拉应力施加导致D50、D75和D100 3个测点的相对湿度均出现了下降,且随着施加的拉应力增大,相对湿度下降值也增大;当拉应力从0.8 MPa增加到3.2 MPa时,测点D50、D75、D100相对湿度下降值分别从0.5%、0.4%、0.3%增加到0.8%、0.7%、0.6%;拉应力引起相对湿度出现瞬时下降,主要是由于在拉应力作用下,基体发生了水分重分布,如图5所示. 图中:r1、r2分别为加载前、后液态水弯液面半径,H1、H2为加载前、后相对湿度.

在图5(a)中,施加拉应力前,吸附在水化产物之间狭窄空间内即阻碍吸附层水处于平衡状态,同时受到来自固体挤压的压应力[14]. 在给定的初始相对湿度下,自由吸附区的水,即毛细孔水和吸附层水,也处于热力学平衡状态. 当施加拉应力时,基体被拉伸,处于压缩状态的阻碍吸附层水受到拉力影响,与毛细孔负压的平衡被打破,自由吸附区的毛细孔水和吸附层水迁移到阻碍吸附层,导致毛细孔水弯液面下降,Kelvin半径减小,引起相对湿度下降[15],达到新平衡,如图5(b)所示. 拉应力水平越大,引起基体含水孔的Kelvin半径越小,相对湿度响应则会更加明显.

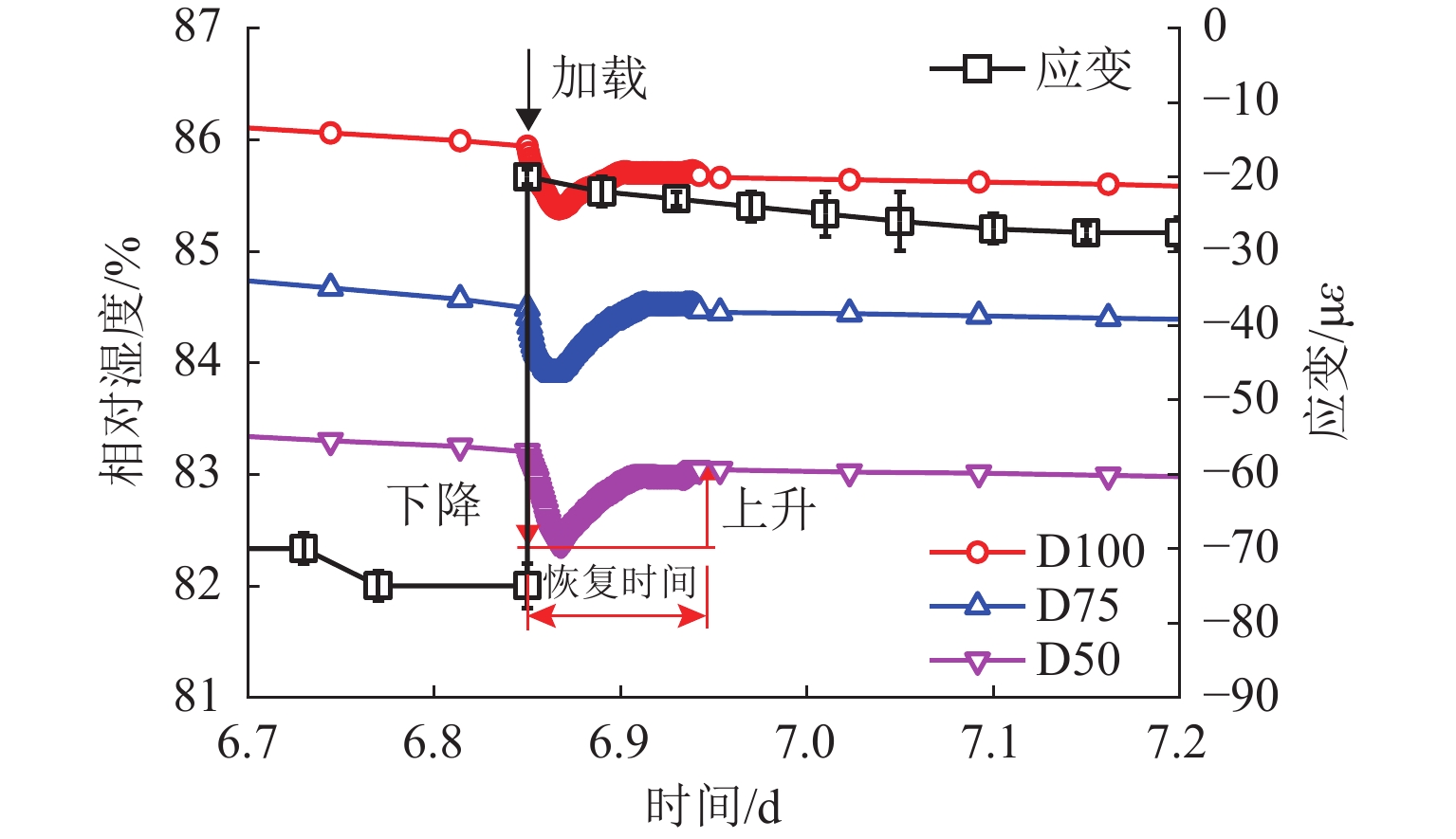

如图4所示:1) 相同拉应力水平下,3个测点的相对湿度下降值随测点深度增大而减小. 这是由于加载时测点相对湿度越高,孔中的含湿量越大,应力对弯液面曲率的影响越小[6]. 以2.4 MPa拉应力为例,测点D50、D75和D100 相对湿度下降值分别为0.7%、0.6%和0.5%. 2) 拉应力水平越大,从50 mm深度到100 mm深度的相对湿度下降值越小,当施加的拉应力分别为0.8、1.6、2.4、3.2 MPa时,50 mm深度的相对湿度比100 mm深度的相对湿度分别下降了40%、33%、28%和25%. 图4中值得注意的是:不同拉应力水平持荷期间,3个测点的相对湿度均出现了逐渐恢复的趋势. 基于热力学原理,Powers[5]提出了混凝土变形与孔中不同状态水分迁移的耦合关系. 以2.4 MPa拉应力作用下的变形为例,如图6所示:拉应力加载瞬间,混凝土产生了60 με的拉应变,引起水分的重分布;持荷期间,相对湿度出现了逐渐恢复的趋势,这一方面是由于短期徐变造成了应力松弛[16];另一方面是拉应力造成微裂纹,使得毛细孔的连通性增强[17],高湿度区域可以更快地向低湿度区域水分转移引起的.

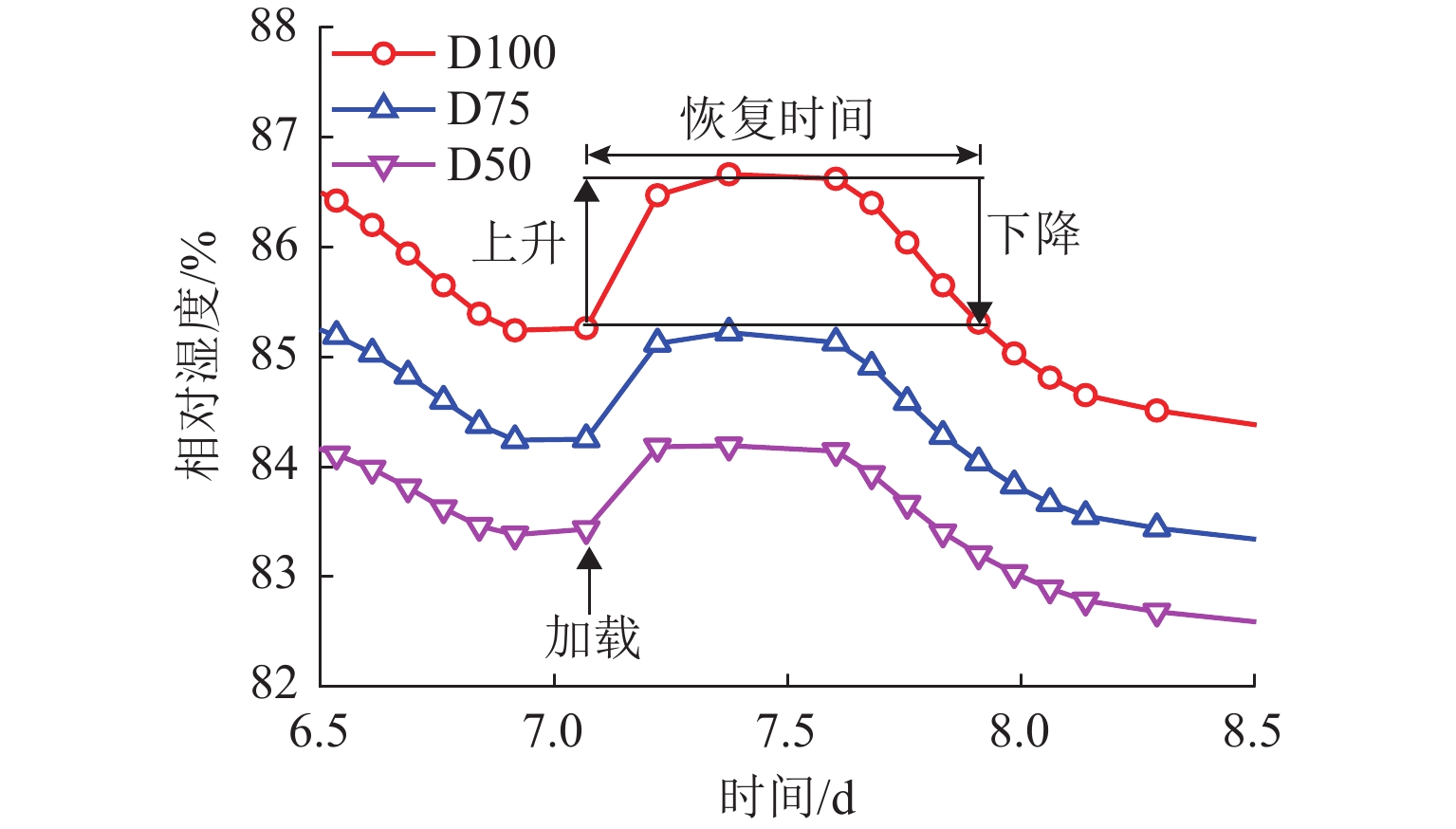

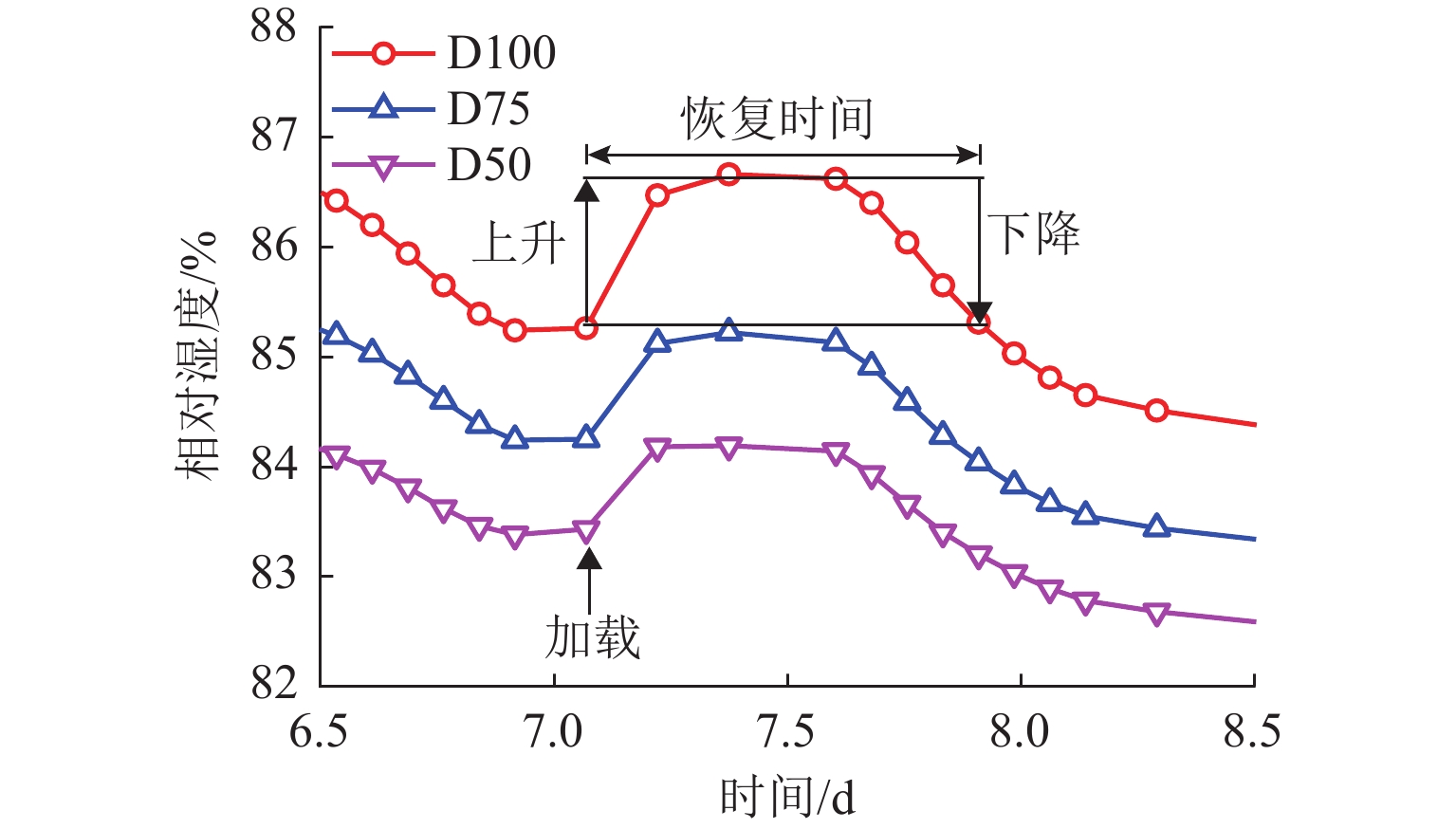

压应力状态下的相对湿度发展曲线如图7所示. 压应力状态下的相对湿度测量方法见文献[7],此处不再赘述. 从图中可以发现:压应力加载导致了混凝土相对湿度瞬时上升,测点D50、D75、D100的相对湿度瞬时上升值分别为0.8%、1.0%和1.4%,这是由于压应力引起基体内部水分重分布,即Kelvin半径增大造成的[18];持荷期间,混凝土的相对湿度也出现了逐渐恢复的趋势,与拉应力持荷状态下发展趋势相同;压应力状态下相对湿度恢复时间约20 h,远大于拉应力状态下相对湿度恢复时间,约2.5 h (见图6). 相对湿度恢复时间受所施加的应力绝对值影响,施加的压应力(12.8 MPa)明显大于施加的拉应力绝对值(0.8~3.2 MPa),出现了上述相对湿度恢复时间长短现象.

3. 拉应力与相对湿度关系构建

将饱和程度S视为Bishop参数,即自由水所占孔隙空间的体积分数,同时,将Mackenzie[19]提出的饱和条件下的应变推广到非饱和情况下的应变,可得到毛细孔负压力与自收缩应变的关系[20]为

εau=Spc(1K−1Ks), (3) 式中:εau为自收缩(με),pc为毛细孔负压力(MPa),K为多孔介质的体积模量(GPa),Ks为固体骨架的体积模量(GPa).

根据Kelvin-Laplace方程,水泥基材料内毛细管水与弯液面上方水蒸气平衡时有式(4)关系[21].

pc=RTρLlnHMw, (4) 式中:pc为弯液面约来水分子的力;T为温度值(K);R为理想气体常数,取值为8.314 J/(mol·K);ρL为水的密度,取值为

1000 kg/m3;Mw为水的摩尔重量,0.01802 kg/mol;H为相对湿度.多孔介质的体积模量K与弹模E之间的关系为

K=E3(1−2v). (5) 体积应变差值∆ε1与引起该应变差值的相对湿度变化关系[22]为

Δε1=[(pc2−pc1)S1+pc1(S2−S1)](1/K−1/Ks), (6) 式中:S1和S2分别为加载前、后相对湿度H1和H2的饱和度,pc2和pc1分别为H1和H2的毛细管负压力(MPa).

在液态水中,弯液面约束水分子的力是其曲率的函数[23]:

pc=2γr, (7) 式中:r为液态水弯液面半径(nm);γ为液态水的表面张力,纯水为0.073 N/m.

含水量we (kg/m3)与相对湿度H、水化度α的关系如式(8)所示[24].

we=G1(1−1exp(10(g1α∞−α)H))+K1(exp(10(g1α∞−α)H)−1), (8) 式中:右边第1项代表凝胶孔水;右边第2项代表毛细孔水;g1为与毛细孔水相关的材料参数,g1>1;G1为凝胶孔隙在H=100%时的单位体积含水量(如式(9) [24]),K1为描述含水量的经验参数,α∞ 为混凝土最大水化度.

G1=k1αc, (9) 式中:k1为与凝胶孔水相关的材料参数,c为水泥含量(kg/m3).

对于水化度为α,单位体积水泥基材料的最大含水量we1,如式(10)所示.

we1=w0−0.188cα, (10) 式中:w0为初始含水量(kg/m3).

联立式(8)和式(10),可得

S=wew0−0.188cα. (11) 根据式(8)~(10)与H = 100%,得

K1=w0−0.188cα−G1(1−1exp(10(g1α∞−α)))exp(10(g1α∞−α))−1. (12) α∞ 由水灰比决定[25],如式(13).

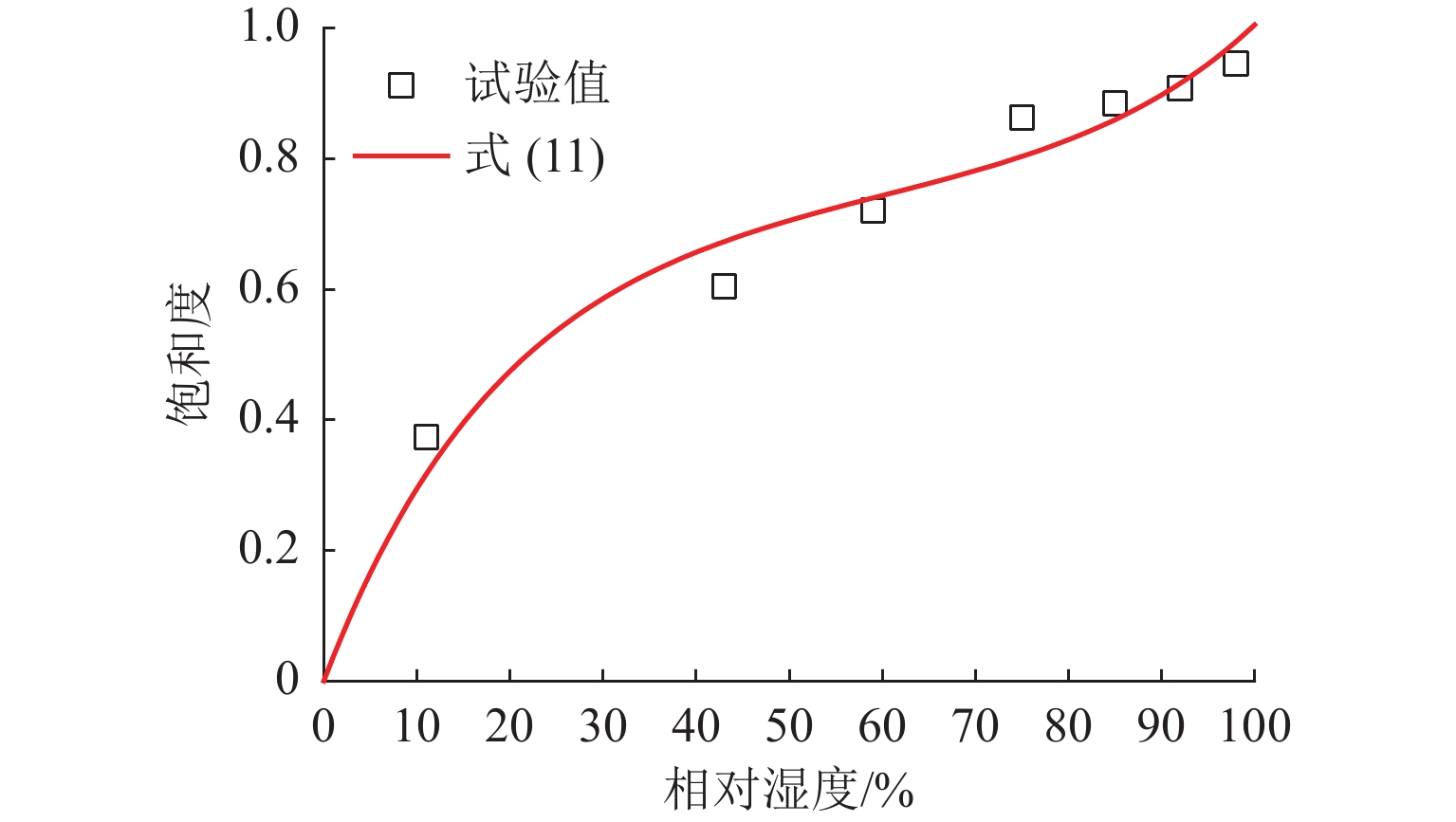

α∞=1.032w/c0.194+w/c. (13) 文献[26]进行了解吸试验,采用的混凝土原材料和配合比与本文试验类似,因此,基于文献[26],试验值与式(11)结果如图8所示. 由此可得材料参数k1=0.208 9,g1=1.806 4.

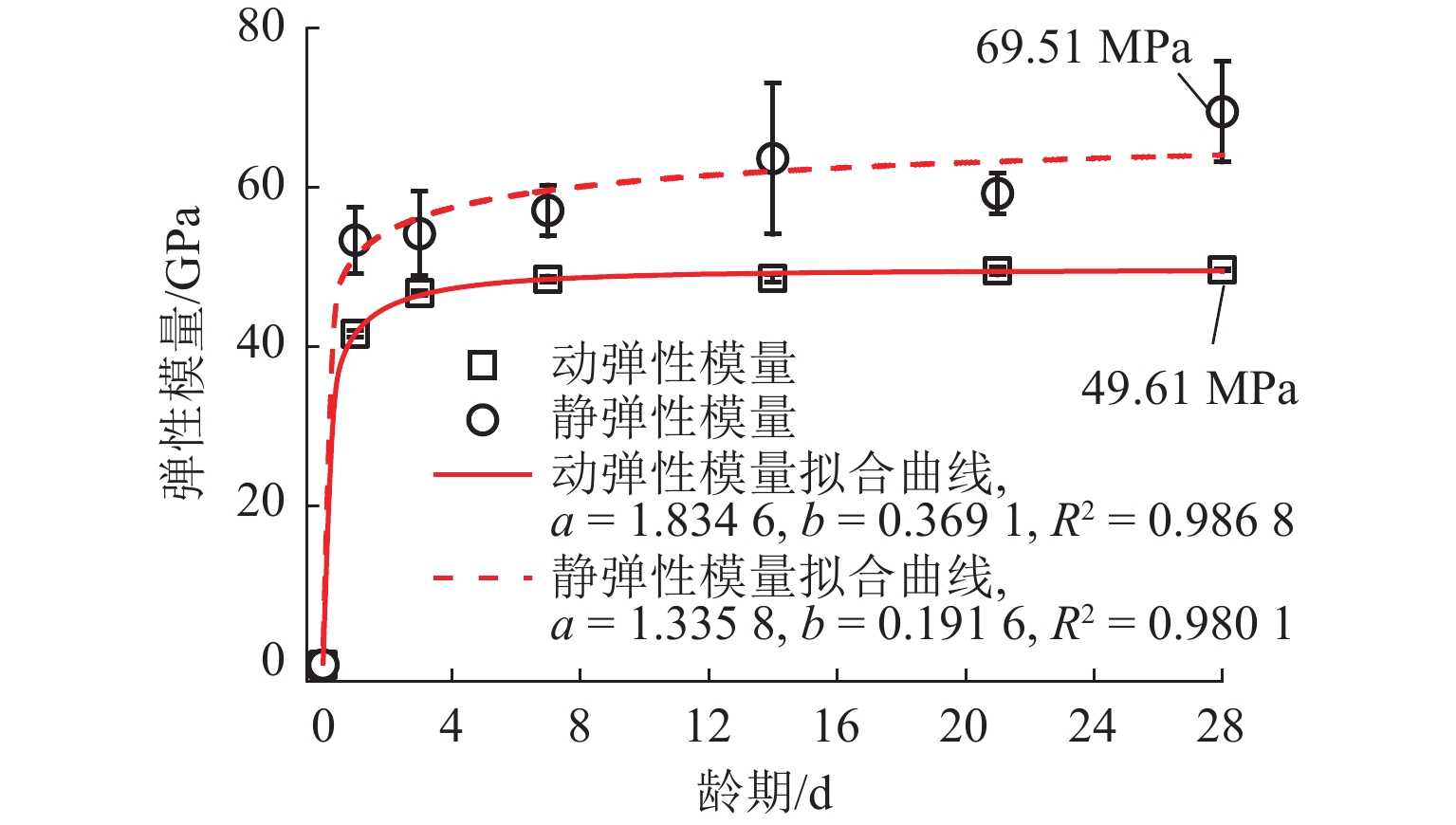

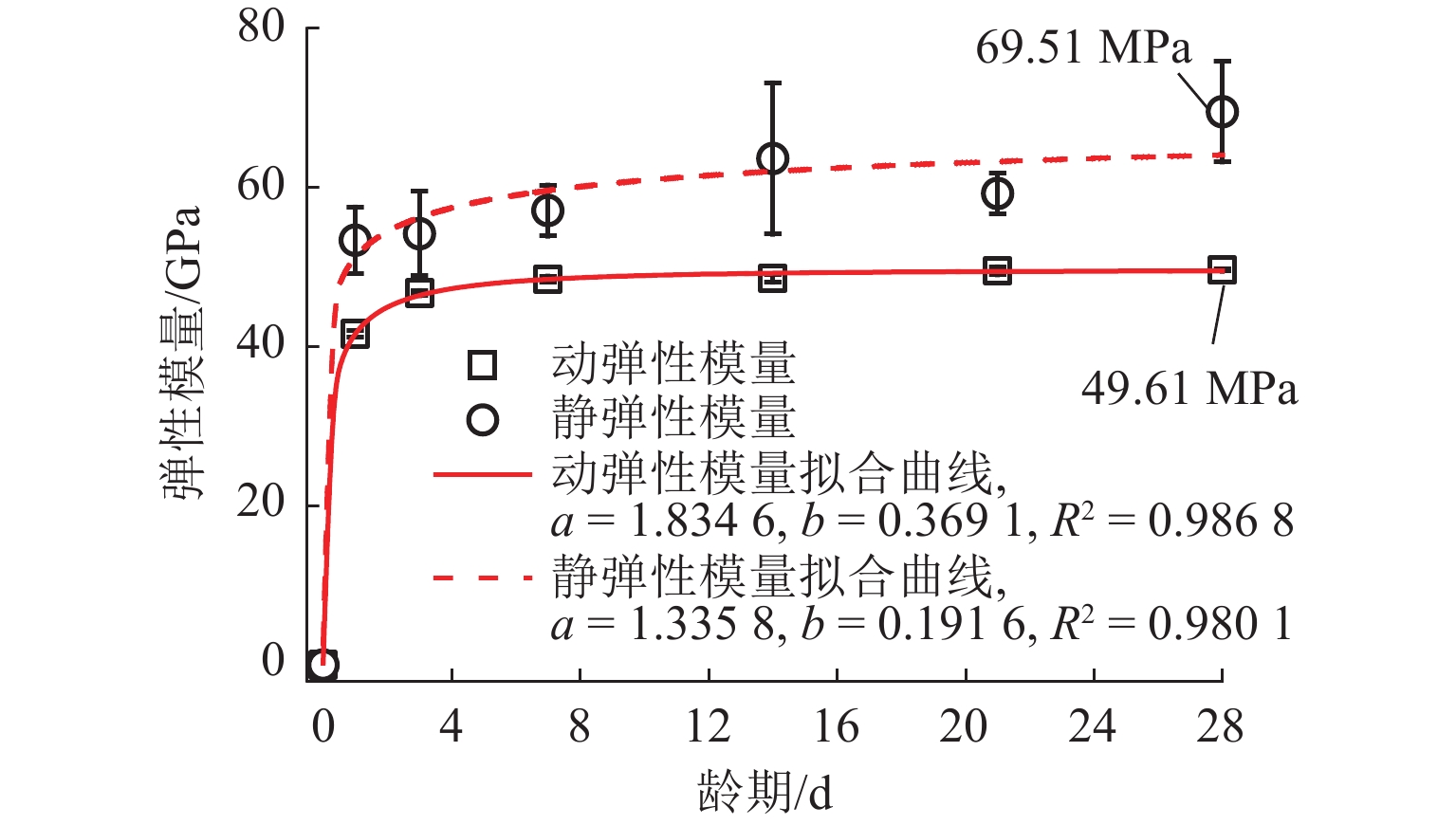

单轴外力荷载将导致混凝土整体变形,其中,包括弹性变形和非弹性变形[27]. 混凝土早期静、动弹性模量与龄期的关系如图9所示. 图中:a、b为拟合的材料参数. 可以发现:同一龄期由拉应力-应变曲线求得的静弹性模量高于动弹性模量. 弹性模量与龄期的关系可用式(14)表示[28-29].

E=E28[1−exp(−atb)], (14) 式中:E28为28 d弹性模量(GPa),a和b为材料参数,t为混凝土标准养护条件下的龄期.

由于静弹性模量高于动弹性模量,因此,在相同应力σ条件下,分别采用静弹性模量和动弹性模量计算应变时会产生差异,这种差异即应变差值Δε2,如式(15)所示.

Δε2=σ(1−2v)Estat−σ(1−2v)Edyn. (15) 由外力荷载引起的上述应变差值,与由外力荷载施加引起的相对湿度变化关系如式(6)所示. 根据文献[18],对于密封状态下的混凝土试件而言,在压应力状态下,当泊松比v = 0.2时,∆ε1 = 99%∆ε2. 说明压应力引起加载前、后的相对湿度变化造成的应变差值,与压应力作用下由静、动弹性模量差造成的应变差值可以认为是相等的. 因此,借鉴这种方法,拉应力作用有式(16)成立.

Δε2=Δε1. (16) 根据图4的相对湿度曲线及式(8) ~ (13),可以得到加载前、后混凝土的相对湿度H1和H2和加载前、后的饱和度S1和S2见表3.

表 3 拉应力加载前后相对湿度和饱和度Table 3. Relative humidity and saturation before and after tensile stress loading测点 0.8 MPa 1.6 MPa 2.4 MPa 3.2 MPa H1/% (S1) H2/% (S2) H1/% (S1) H2/% (S2) H1/% (S1) H2/% (S2) H1/% (S1) H2 /% (S2) D100 86.6

(0.7941 )86.3

(0.7914 )86.2

(0.7905 )85.8

(0.7870 )86.0

(0.7887 )85.5

(0.7844 )86.3

(0.7914 )85.7

(0.7861 )D75 84.9

(0.7794 )84.5

(0.7762 )84.3

(0.7746 )83.8

(0.7708 )84.5

(0.7762 )83.9

(0.7715 )84.6

(0.7770 )83.9

(0.7715 )D50 83.7

(0.7700 )83.2

(0.7663 )83.0

(0.7649 )82.4

(0.7607 )83.2

(0.7663 )82.5

(0.7614 )83.3

(0.7671 )82.5

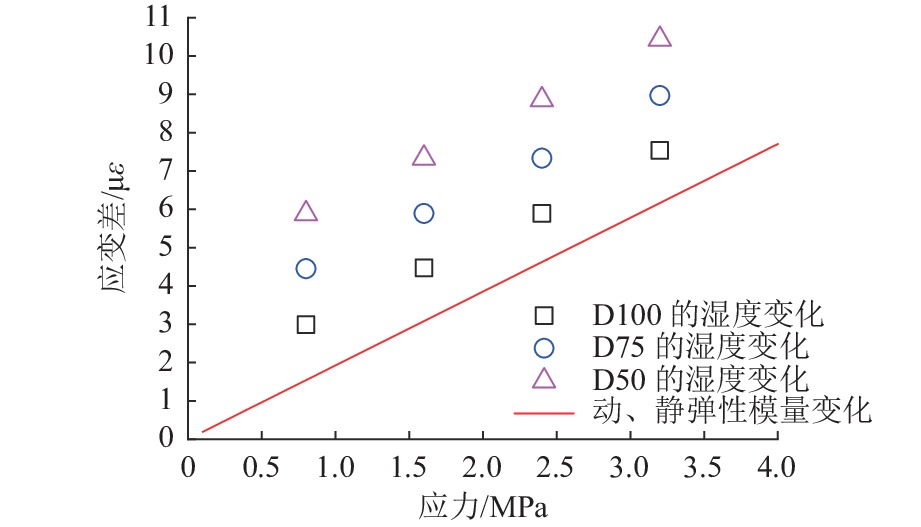

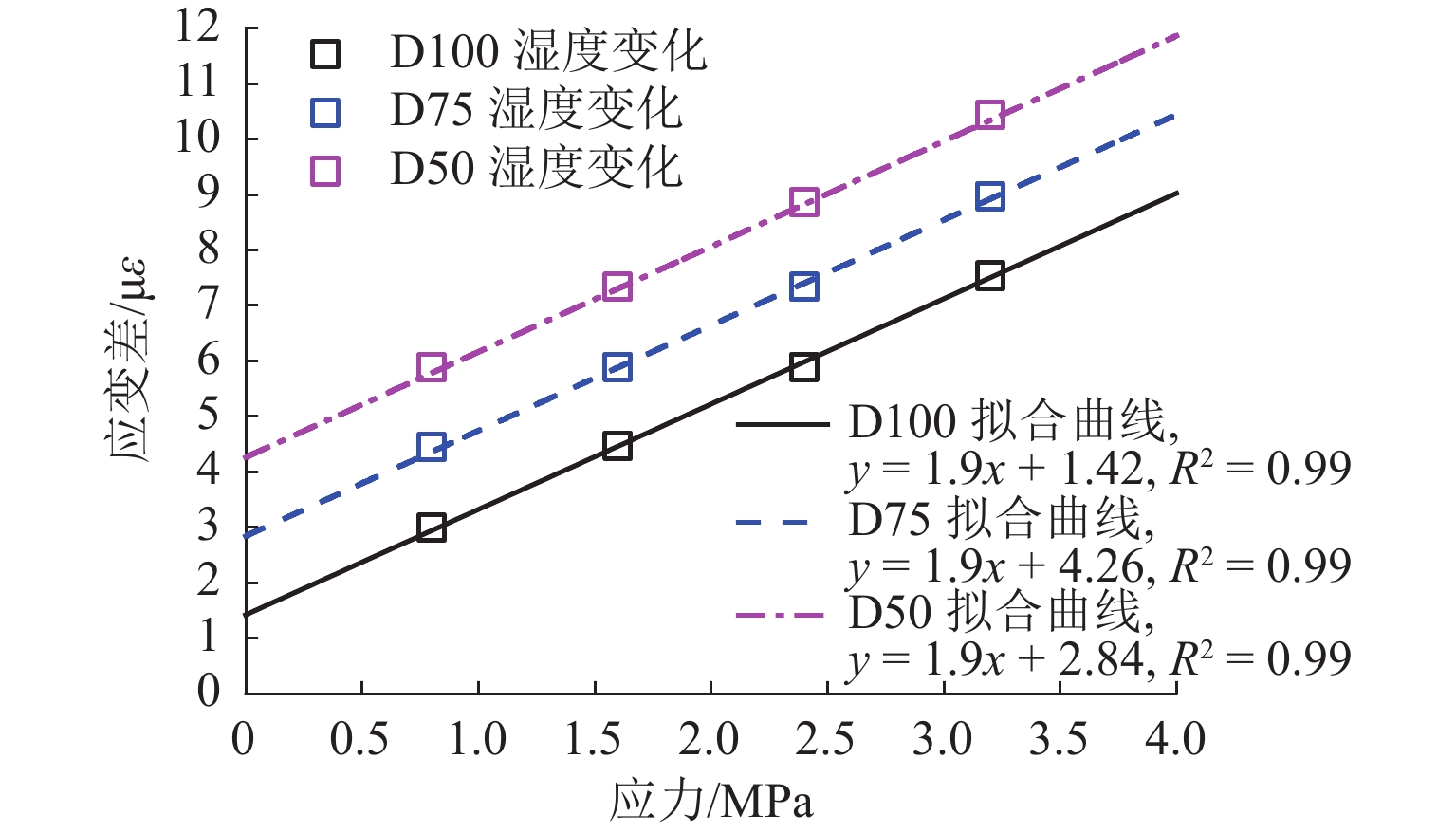

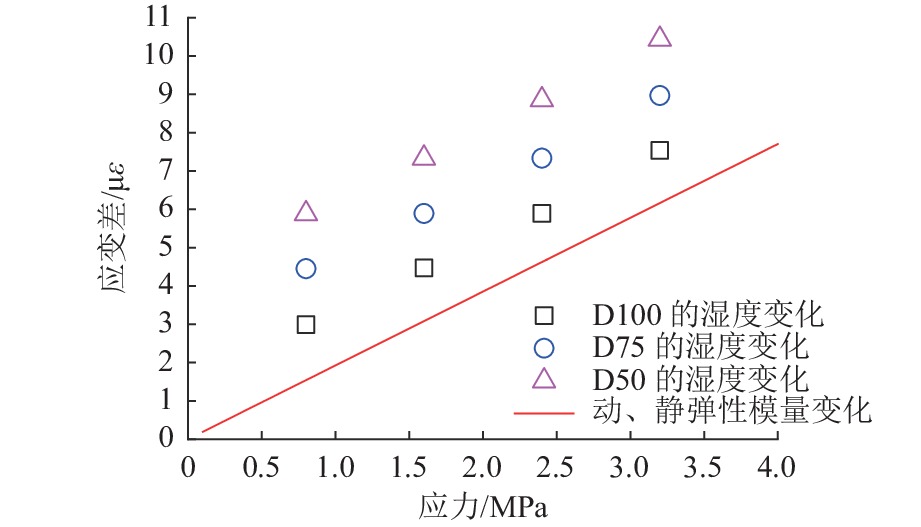

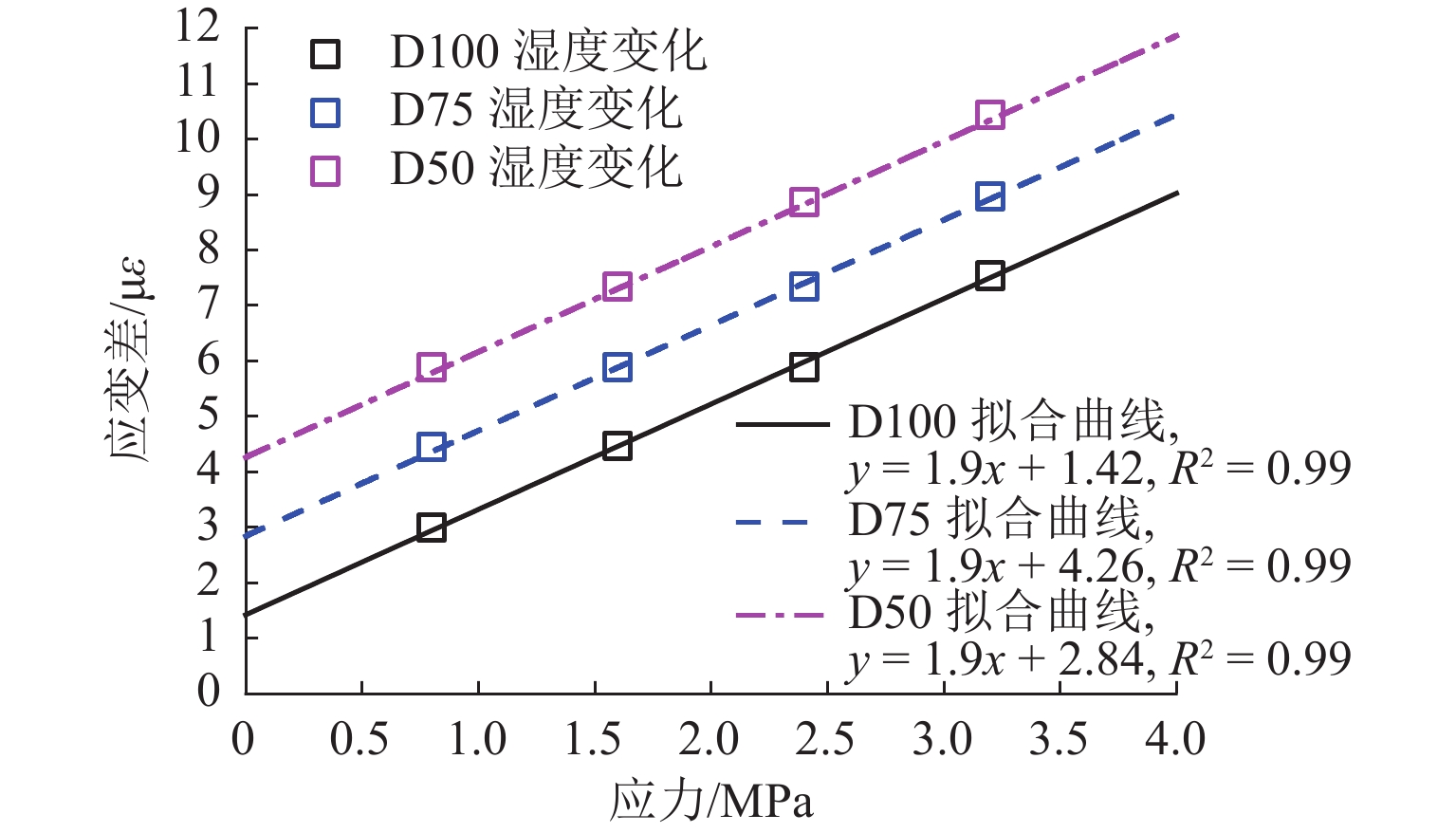

(0.7614 )针对净浆以及砂浆,式(6)中的固体骨架体积模量Ks在文献[23,30]中取值为44.0 GPa. 文献[30]研究认为,粗骨料的Ks与净浆和砂浆的Ks接近. 本次试验使用的粗骨料为玄武岩,取其平均弹性模量68.5 GPa,v = 0.2,可得其体积模量为41.1 GPa,略小于44.0 GPa. 因此,本文所用混凝土试件的Ks取值为44.0 GPa. 根据式(6)、(15)和表3中的值,相对湿度变化以及静、动弹性模量差引起的应变差值如图10所示. 在图10中:对于同一测点,随着拉应力增加,应变差值呈线性增加,并且随着测点距离暴露面越近,应变差值越大;由于静、动弹性模量差引起的应变差值斜率为1.9,而由相对湿度变化引起的应变差值斜率为1.88,二者几乎相等.

3个测点相对湿度变化引起的应变差值均高于由静、动弹模差引起的应变差值,这是因为拉应力状态下早龄期混凝土相对湿度试验试件的密封和养护与力学性能试验试件不同,导致7 d加载时相对湿度不同.

针对干燥情况,式(16)需要进行修正,即

Δε2=Δε1+ω, (17) 式中:ω为修正项.

具体到本文试验,7 d加载时,利用式(17)拟合测点相对湿度变化引起的应变差值,如图11所示.

从图可以发现:随着加载时测点深度的增加,相对湿度变化引起的应变差值越接近由静、动弹性模量差引起的应变差值,这是由于力学性能试验试件养护相对湿度较高,7 d龄期时相对湿度较高. 上述结果可以说明式(16)的合理性.

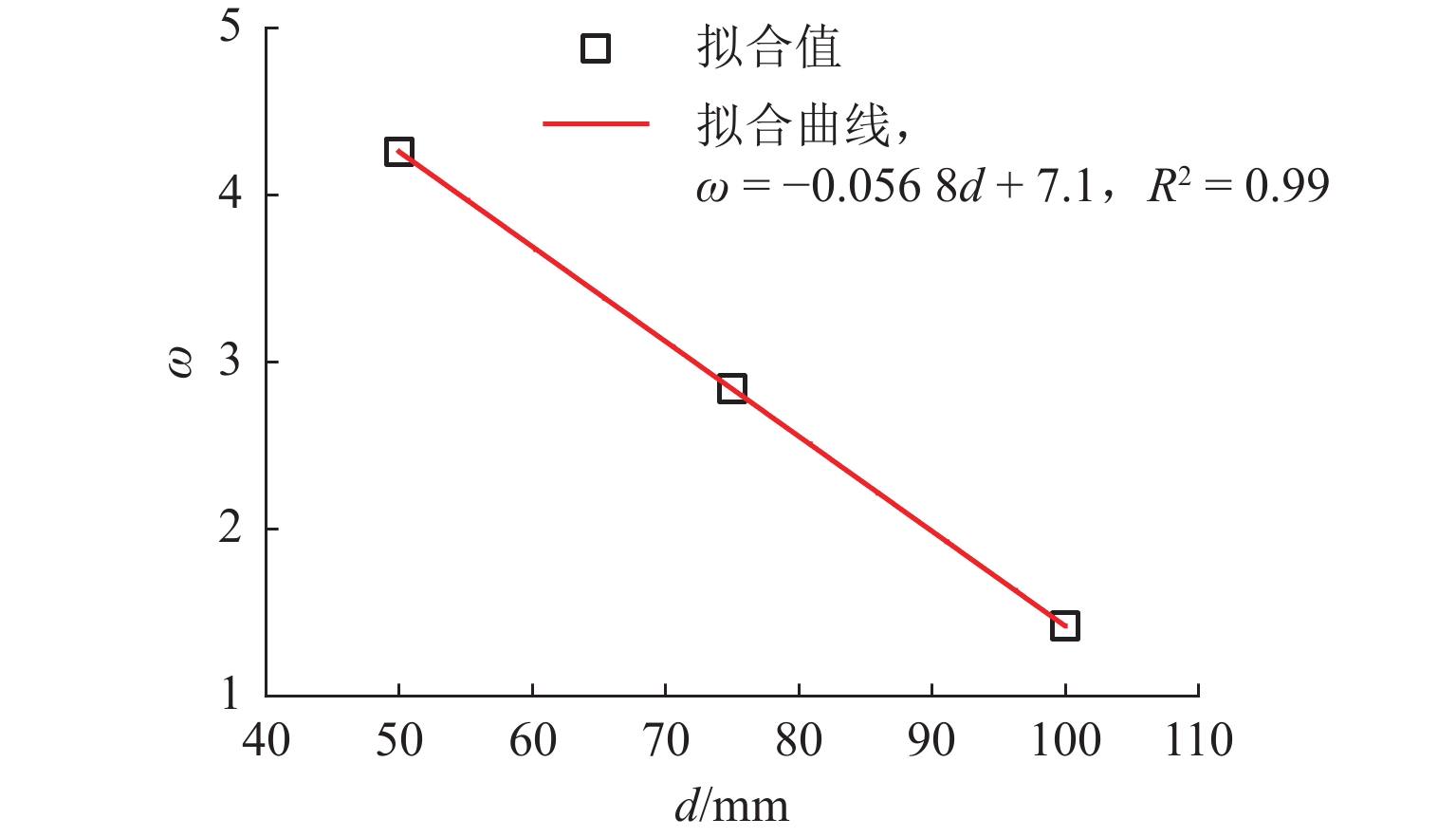

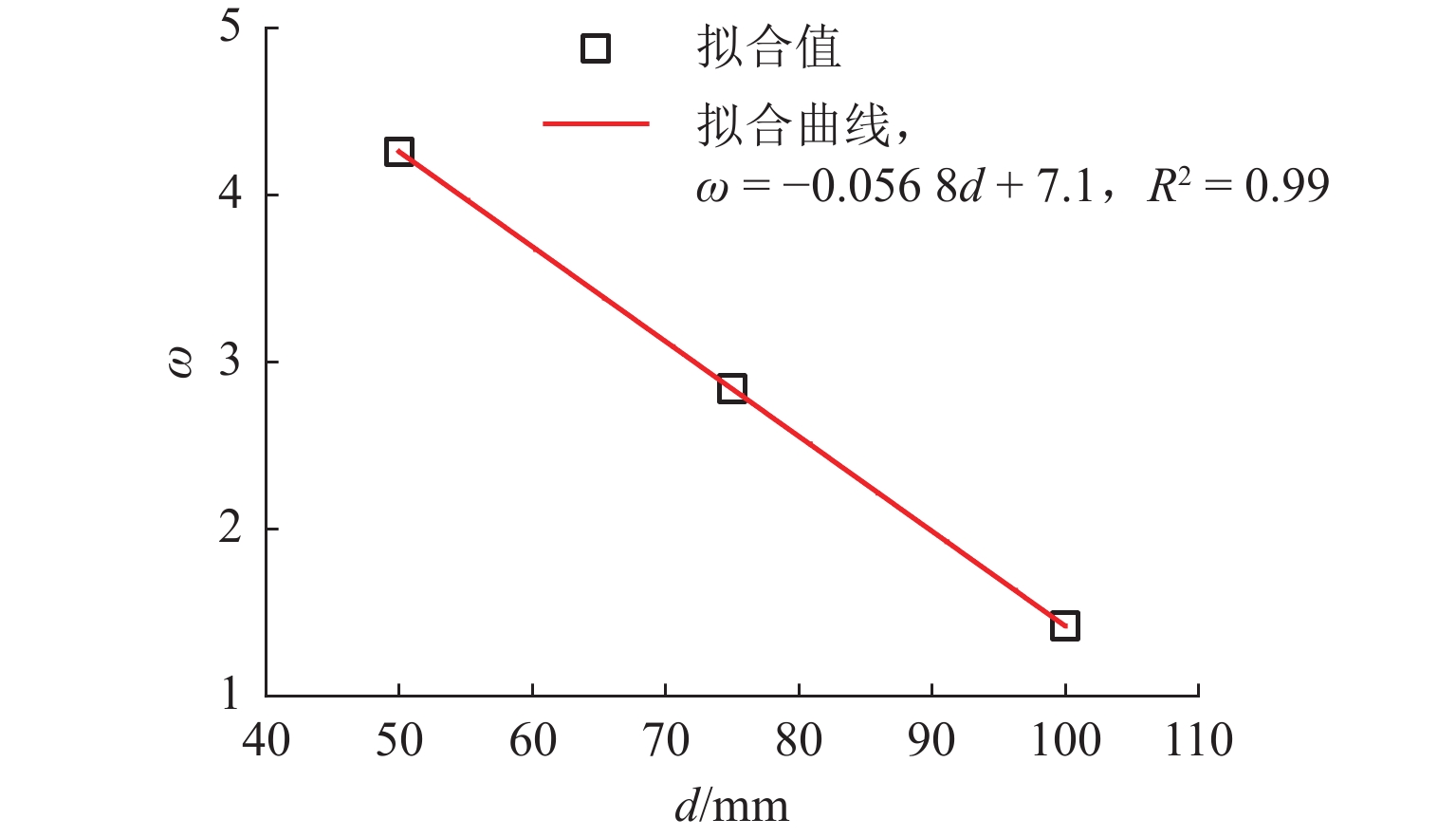

图12给出了修正项ω与测点测量深度d (mm)的关系.

考虑混凝土暴露面,加载前、后相对湿度H1和H2与应力σ最终构建的关系为

S1lnH2+(S2−2S1)lnH1=σ(1−2v)(1Estat−1Edyn)−0.0568d+7.1RTρLMw[(1−2v)Edyn−1Ks]. (18) 式(18)中的v、R、T、ρL、Mw和Ks等参数采用本文推荐的值,式(18)整理得式(19).

H2=exp(1S1(0.6σ(1/Estat−1/Edyn)−0.0568d+7.181.694/Edyn−3.057+2S1lnH1−S2lnH1)). (19) 因此,根据应力σ,联立式(19)和式(11),可以预测拉应力加载后的相对湿度H2.

4. 结 论

本文针对早龄期混凝土展开了不同拉应力水平对其相对湿度影响试验研究,并得到了以下结论:

1) 拉应力加载时,混凝土的相对湿度出现瞬时下降;同时,随着拉应力水平逐渐增大,相对湿度对拉应力的响应也逐渐增大,当拉应力从0.8 MPa增加到3.2 MPa,混凝土深度分别为50、75、100 mm处的相对湿度变化值从0.5%、0.4%和0.3%增加到0.8%、0.7%和0.6%,这是由基体内部水分重分布引起的. 在相同拉应力水平下,距离暴露面越近,其相对湿度对拉应力的响应越明显,这主要是由加载前基体内部孔中含湿量控制.

2) 拉应力持荷状态下,混凝土的相对湿度会逐渐恢复,主要是由于短期徐变以及暴露面引起的高湿区域对低湿区域的水分转移补充;同时,压应力持荷状态下也出现了类似的现象,但拉应力持荷状态下相对湿度恢复现象更加明显,压应力状态下相对湿度恢复时间约20.0 h,远大于拉应力状态下相对湿度的恢复时间(约2.5 h),主要原因是拉应力水平明显低于压应力水平.

3) 以相对湿度变化以及静弹性模量和动弹性模量差异引起的应变差值作为桥梁,发现相对湿度的变化与拉应力具有线性关系,并基于试验结果给出了单面干燥条件下相对湿度与拉应力的线性模型.

-

表 1 混凝土配合比

Table 1. Concrete mix proportion

kg/m3 材料名称 水泥 水 细骨料 粗骨料 减水剂 配合比 533.00 160.00 597.00 1110.00 4.33 表 2 加载试验方案

Table 2. Loading test scheme

工况 拉(压)应力/

抗拉(压)强度/%施加拉(压)应力/MPa 7 d 抗拉(压)强度/MPa 截面面积/m2 施加荷载/kN 备注 T1 20 0.8 3.95 0.01875 15 拉力 T2 40 1.6 3.95 0.01875 30 拉力 T3 60 2.4 3.95 0.01875 45 拉力 T4 80 3.2 3.95 0.01875 60 拉力 C1 20 12.8 63.7 0.01875 240 压力 表 3 拉应力加载前后相对湿度和饱和度

Table 3. Relative humidity and saturation before and after tensile stress loading

测点 0.8 MPa 1.6 MPa 2.4 MPa 3.2 MPa H1/% (S1) H2/% (S2) H1/% (S1) H2/% (S2) H1/% (S1) H2/% (S2) H1/% (S1) H2 /% (S2) D100 86.6

(0.7941 )86.3

(0.7914 )86.2

(0.7905 )85.8

(0.7870 )86.0

(0.7887 )85.5

(0.7844 )86.3

(0.7914 )85.7

(0.7861 )D75 84.9

(0.7794 )84.5

(0.7762 )84.3

(0.7746 )83.8

(0.7708 )84.5

(0.7762 )83.9

(0.7715 )84.6

(0.7770 )83.9

(0.7715 )D50 83.7

(0.7700 )83.2

(0.7663 )83.0

(0.7649 )82.4

(0.7607 )83.2

(0.7663 )82.5

(0.7614 )83.3

(0.7671 )82.5

(0.7614 ) -

[1] 王晓莹. 早龄期高性能约束砂浆环开裂机制数值模拟[D]. 重庆: 重庆大学, 2015. [2] 杨荣山,李莹,许钊荣,等. 多雨地区双块式无砟轨道湿态混凝土力学性能[J]. 西南交通大学学报,2022,57(4): 840-847. doi: 10.3969/j.issn.0258-2724.2017.01.008YANG Rongshan, LI Ying, XU Zhaorong, et al. Mechanical properties of wet concrete inside double-block ballastless tracks in rainy areas[J]. Journal of Southwest Jiaotong University, 2022, 57(4): 840-847. doi: 10.3969/j.issn.0258-2724.2017.01.008 [3] LIU J P, TIAN Q, WANG Y, et al. Evaluation method and mitigation strategies for shrinkage cracking of modern concrete[J]. Engineering, 2021, 7(3): 348-357. doi: 10.1016/j.eng.2021.01.006 [4] ZHAO H T, JIANG K D, YANG R, et al. Experimental and theoretical analysis on coupled effect of hydration, temperature and humidity in early-age cement-based materials[J]. International Journal of Heat and Mass Transfer, 2020, 146: 118784.1-118784.9. [5] POWERS T C. The thermodynamics of volume change and creep[J]. Matériaux et Construction, 1968, 1(6): 487-507. [6] 杜明月. 基于微孔结构演化的早龄期混凝土热-湿-力耦合模型研究[D]. 杭州: 浙江大学, 2015. [7] ZHAO H T, JIANG K D, HONG B, et al. Experimental and numerical analysis on coupled hygro-thermo-chemo-mechanical effect in early-age concrete[J]. Journal of Materials in Civil Engineering, 2021, 33(5): 04021064.1-04021064.12. [8] WYRZYKOWSKI M, LURA P. RH dependence upon applied load: experimental study on water redistribution in the microstructure at loading[C]//Proceedings of the 10th International Conference on Mechanics and Physics of Creep, Shrinkage and Durability of Concrete and Concrete Structures. Vienna: American Society of Civil Engineers, 2015: 339-347. [9] 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 通用硅酸盐水泥: GB 175—2007[S]. 北京: 中国标准出版社, 2007. [10] 中华人民共和国住房和城乡建设部. 混凝土物理力学性能试验方法标准: GB/T 50081—2019[S]. 北京: 中国建筑工业, 2019. [11] KOMLOS̆ K, POPOVICS S, NÜRNBERGEROVÁ T, et al. Ultrasonic pulse velocity test of concrete properties as specified in various standards[J]. Cement and Concrete Composites, 1996, 18(5): 357-364. doi: 10.1016/0958-9465(96)00026-1 [12] 国家能源局. 水工混凝土试验规程: DL/T 5150—2017[S]. 北京: 中国电力出版社, 2018. [13] ZHANG J, HOU D W, SHE W. Experimental study on the relationship between shrinkage and interior humidity of concrete at early age[J]. Magazine of Concrete Research, 2010, 62(3): 191-199. doi: 10.1680/macr.2010.62.3.191 [14] DERJAGUIN B. A theory of capillary condensation in the pores of sorbents and of other capillary phenomena taking into account the disjoining action of polymolecular liquid films[J]. Progress in Surface Science, 1992, 40: 46-61. doi: 10.1016/0079-6816(92)90032-D [15] BROUWERS H J H. The work of powers and brownyard revisited: Part 1[J]. Cement and Concrete Research, 2004, 34: 1697-1716. doi: 10.1016/j.cemconres.2004.05.031 [16] DELSAUTE B, BOULAY C, STÉPHANIE S. Creep testing of concrete since setting time by means of permanent and repeated minute-long loadings[J]. Cement and Concrete Composites, 2016, 73: 75-88. doi: 10.1016/j.cemconcomp.2016.07.005 [17] LIU C, LIU H W, XIAO J Z, et al. Effect of old mortar pore structure on relative humidity response of recycled aggregate concrete[J]. Construction and Building Materials, 2020, 247: 118600.1-118600.10. [18] WYRZYKOWSKI M, LURA P. The effect of external load on internal relative humidity in concrete[J]. Cement and Concrete Research, 2014, 65: 58-63. doi: 10.1016/j.cemconres.2014.07.011 [19] MACKENZIE J K. The elastic constants of a solid containing spherical holes[J]. Proceedings of the Physical Society. Section B, 1950, 63(1): 2-11. doi: 10.1088/0370-1301/63/1/302 [20] BENTZ D P, GARBOCZI E J, QUENARD D A. Modelling drying shrinkage in reconstructed porous materials: application to porous Vycor glass[J]. Modelling and Simulation in Materials Science and Engineering, 1998, 6(3): 211-236. doi: 10.1088/0965-0393/6/3/002 [21] 周航. 自密实自养护混凝土研制及性能试验研究[D]. 重庆: 重庆大学, 2016. [22] VLAHINIĆ I, JENNINGS H M, THOMAS J J. A constitutive model for drying of a partially saturated porous material[J]. Mechanics of Materials, 2009, 41(3): 319-328. [23] LURA P, JENSEN O M, BREUGEL K V. Autogenous shrinkage in high-performance cement paste: an evaluation of basic mechanisms[J]. Cement and Concrete Research, 2003, 33(2): 223-232. [24] NORLING M K. A model on self-desiccation in high-performance concrete[C]//In: self-desiccation and its importance in concrete technology, proceedings of the international research seminar. Sweden: [s.n.], 1997: 141-157. [25] PANTAZOPOULOU S J, MILLS R H. Microstructural aspects of the mechanical response of plain concrete[J]. ACI Materials Journal, 1995, 92: 605-616. [26] ZHOU C S, CHEN W, WANG W, et al. Indirect assessment of hydraulic diffusivity and permeability for unsaturated cement-based material from sorptivity[J]. Cement and Concrete Research, 2016, 82: 117-129. doi: 10.1016/j.cemconres.2016.01.002 [27] SHKOLNIK I E. Effect of nonlinear response of concrete on its elastic modulus and strength[J]. Cement and Concrete Composites, 2005, 27(7/8): 747-757. [28] 张子明,周红军,殷波. 基于等效时间的混凝土徐变[J]. 河海大学学报(自然科学版),2005,33(2): 173-176.ZHANG Ziming, ZHOU Hongju, YIN Bo. Equivalent time based concrete creep[J]. Journal of Hohai University (Natural Sciences), 2005, 33(2): 173-176. [29] 周济,陈宗平,唐际宇,等. 一年龄期内超高泵送SCC力学性能时变研究[J]. 西南交通大学学报,2022,57(6): 1175-1183. doi: 10.3969/j.issn.0258-2724.20200746ZHOU Ji, CHEN Zongping, TANG Jiyu, et al. Time variation of mechanical properties of ultra-high pumped self-compacting concrete within one year of age[J]. Journal of Southwest Jiaotong University, 2022, 57(6): 1175-1183. doi: 10.3969/j.issn.0258-2724.20200746 [30] GRASLEY Z C, SCHERER G W, LANGE D A, et al. Dynamic pressurization method for measuring permeability and modulus: Ⅱ. cementitious materials[J]. Materials and Structures, 2007, 40(7): 711-721. doi: 10.1617/s11527-006-9184-y -

下载:

下载:

下载:

下载: