Bearing Fault Diagnosis Method Based on Order Tracking Without Rotational Speed

-

摘要:

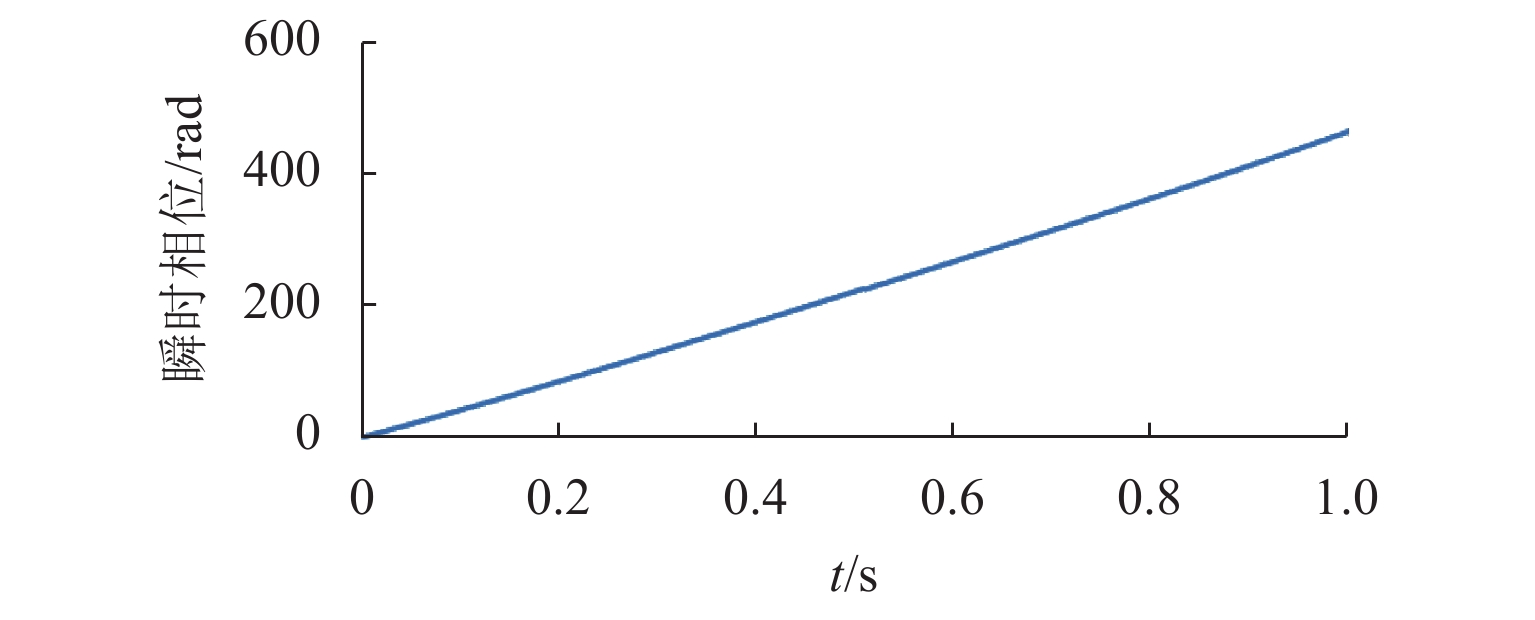

机械装备轴承运行速度多变导致振动监测信号频谱模糊,一定程度影响了轴承故障诊断的准确性. 目前的无转速阶次跟踪技术在转速波动较小且转频谐波不重叠时效果较好,但当轴承转频谐波重叠时则难以进行分析. 针对以上问题,提出了一种基于广义解调的无转速阶次跟踪轴承故障诊断方法. 首先,采用广义傅里叶变换和改进的基于成本函数脊线提取技术准确提取出轴承的转频谐波分量;同时,采用快速谱峭度算法和带通滤波器对轴承振动信号进行去噪处理;然后,通过角度重采样将去噪后的时域信号转换为角域信号;最后,通过包络谱分析得到轴承的阶次谱信息,从而识别轴承的故障类型. 研究结果表明:通过数值模拟信号和实际轴承监测信号验证了提出方法的有效性,通过与传统包络谱方法对比可知,提出的方法可进行无转速信息时的滚动轴承阶次跟踪故障诊断.

Abstract:The variable operating speed of mechanical equipment bearings leads to blurred spectrum of vibration monitoring signals, which to some extent affects the accuracy of bearing fault diagnosis. The current tacholess order tracking technology works well when the rotational speed fluctuation is small and the rotational frequency harmonics do not overlap, but it is difficult to conduct analysis when the bearing rotational frequency harmonics overlap. Aiming at the above problems, this paper proposes a tacholess order tracking fault diagnosis method of bearings based on the generalized demodulation. First, the generalized Fourier transform and the improved cost function-based ridge extraction technology are used to accurately extract the rotational frequency harmonic components of the bearings. At the same time, the fast spectral kurtosis algorithm and a band-pass filter are used to de-noise the bearing vibration signal. Then, the denoised time-domain signal is converted into an angular-domain signal through angle resampling. Finally, the order spectrum information of the bearing is obtained through the envelope spectrum analysis, so as to identify the fault type of the bearing. In addition, the effectiveness of the proposed method is verified using the numerical simulation signal and the actual bearing monitoring signal. The results show that the proposed method has an error of less than 5% in reconstructing the phase and an accuracy of more than 94% in characterizing the order frequency of bearing faults, which can be used for the order tracking fault diagnosis of rolling bearings without rotational speed information.

-

Key words:

- order tracking /

- fault diagnosis /

- generalized Fourier transform /

- cost function

-

-

[1] ZHAO M, LIN J, XU X, et al. Tacholess envelope order analysis and its application to fault detection of rolling element bearings with varying speeds[J]. Sensors, 2013, 13(8): 10856-10875. doi: 10.3390/s130810856 [2] RANDALL R B, ANTONI J. Rolling element bearing diagnostics—a tutorial[J]. Mechanical Systems and Signal Processing, 2011, 25(2): 485-520. doi: 10.1016/j.ymssp.2010.07.017 [3] 郭瑜,秦树人,梁玉前. 时频分析阶比跟踪技术[J]. 重庆大学学报(自然科学版),2002,25(5): 17-20,24.GUO Yu, QIN Shuren, LIANG Yuqian. Order tracking method based on time-frequency analysis[J]. Journal of Chongqing University (Natural Science Edition), 2002, 25(5): 17-20,24. [4] 张亢,程军圣. 基于LMD和阶次跟踪分析的滚动轴承故障诊断[J]. 振动.测试与诊断,2016,36(3): 586-591,611.ZHANG Kang, CHENG Junsheng. Roller bearing fault diagnosis based on LMD and order tracking analysis[J]. Journal of Vibration, Measurement & Diagnosis, 2016, 36(3): 586-591,611. [5] SCHMIDT S, HEYNS P S, DE VILLIERS J P. A tacholess order tracking methodology based on a probabilistic approach to incorporate angular acceleration information into the maxima tracking process[J]. Mechanical Systems and Signal Processing, 2018, 100: 630-646. doi: 10.1016/j.ymssp.2017.07.053 [6] 汤宝平,何启源,魏玉果,等. 基于角加速度的复合计算阶次跟踪方法[J]. 机械工程学报,2008,44(8): 143-147. doi: 10.3321/j.issn:0577-6686.2008.08.025TANG Baoping, HE Qiyuan, WEI Yuguo, et al. Hybrid computed order tracking method based on angular acceleration[J]. Chinese Journal of Mechanical Engineering, 2008, 44(8): 143-147. doi: 10.3321/j.issn:0577-6686.2008.08.025 [7] WU J, ZI Y Y, CHEN J L, et al. A modified tacho-less order tracking method for the surveillance and diagnosis of machine under sharp speed variation[J]. Mechanism and Machine Theory, 2018, 128: 508-527. doi: 10.1016/j.mechmachtheory.2018.06.016 [8] HOU B C, WANG Y, TANG B P, et al. A tacholess order tracking method for wind turbine planetary gearbox fault detection[J]. Measurement, 2019, 138: 266-277. doi: 10.1016/j.measurement.2019.02.010 [9] ZHAO M, LIN J, WANG X F, et al. A tacho-less order tracking technique for large speed variations[J]. Mechanical Systems and Signal Processing, 2013, 40(1): 76-90. doi: 10.1016/j.ymssp.2013.03.024 [10] QI X X, YUAN Z H, HAN X W. Diagnosis of misalignment faults by tacholess order tracking analysis and RBF networks[J]. Neurocomputing, 2015, 169: 439-448. doi: 10.1016/j.neucom.2014.09.088 [11] GRYLLIAS K C, ANTONIADIS I A. Estimation of the instantaneous rotation speed using complex shifted Morlet wavelets[J]. Mechanical Systems and Signal Processing, 2013, 38(1): 78-95. doi: 10.1016/j.ymssp.2012.06.026 [12] BONNARDOT F, BADAOUI M E, RANDALL R B, et al. Use of the acceleration signal of a gearbox in order to perform angular resampling (with limited speed fluctuation)[J]. Mechanical Systems and Signal Processing, 2005, 19(4): 766-785. doi: 10.1016/j.ymssp.2004.05.001 [13] COMBET F, GELMAN L. An automated methodology for performing time synchronous averaging of a gearbox signal without speed sensor[J]. Mechanical Systems and Signal Processing, 2007, 21(6): 2590-2606. doi: 10.1016/j.ymssp.2006.12.006 [14] HEYNS T, HEYNS P S, ZIMROZ R. Combining discrepancy analysis with sensorless signal resampling for condition monitoring of rotating machines under uctuating operations[J]. International Journal of Condition Monitoring, 2012, 2(2): 52-58. doi: 10.1784/204764212804729714 [15] WANG Y, XU G H, LUO A L, et al. An online tacholess order tracking technique based on generalized demodulation for rolling bearing fault detection[J]. Journal of Sound and Vibration, 2016, 367: 233-249. doi: 10.1016/j.jsv.2015.12.041 [16] RANDALL R B, SAWALHI N, COATS M. Separation of gear and bearing fault signals from a wind turbine transmission under varying speed and load[M]. Berlin: Springer, 2012. [17] 赵明. 变转速下机械动态信息的自适应提取与状态评估[D]. 西安: 西安交通大学, 2017. [18] LIU H, CARTWRIGHT A N, BASARAN C. Moiré interferogram phase extraction: a ridge detection algorithm for continuous wavelet transforms[J]. Applied Optics, 2004, 43(4): 850-857. doi: 10.1364/AO.43.000850 [19] LIU S, CHEN J L, HE S L, et al. Subspace network with shared representation learning for intelligent fault diagnosis of machine under speed transient conditions with few samples[J]. ISA Transactions, 2022, 128: 531-544. doi: 10.1016/j.isatra.2021.10.025 [20] SHI Z, CHEN J L, ZI Y Y, et al. A novel multitask adversarial network via redundant lifting for multicomponent intelligent fault detection under sharp speed variation[J]. IEEE Transactions on Instrumentation and Measurement, 2021, 70: 1-10. -

下载:

下载: