Welding Residual Stress Distribution and Experimental Verification of Corrugated Steel Web Girders

-

摘要:

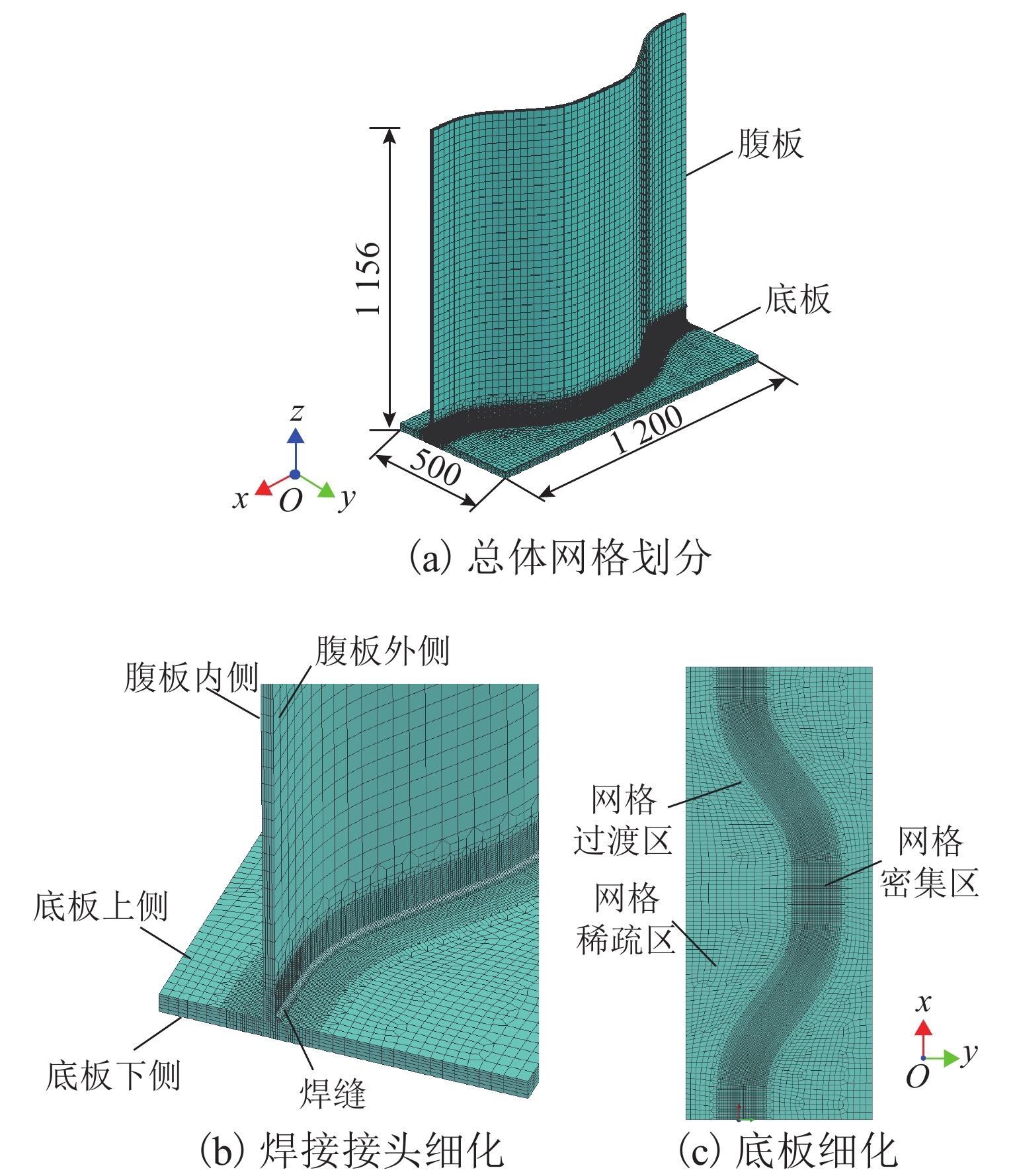

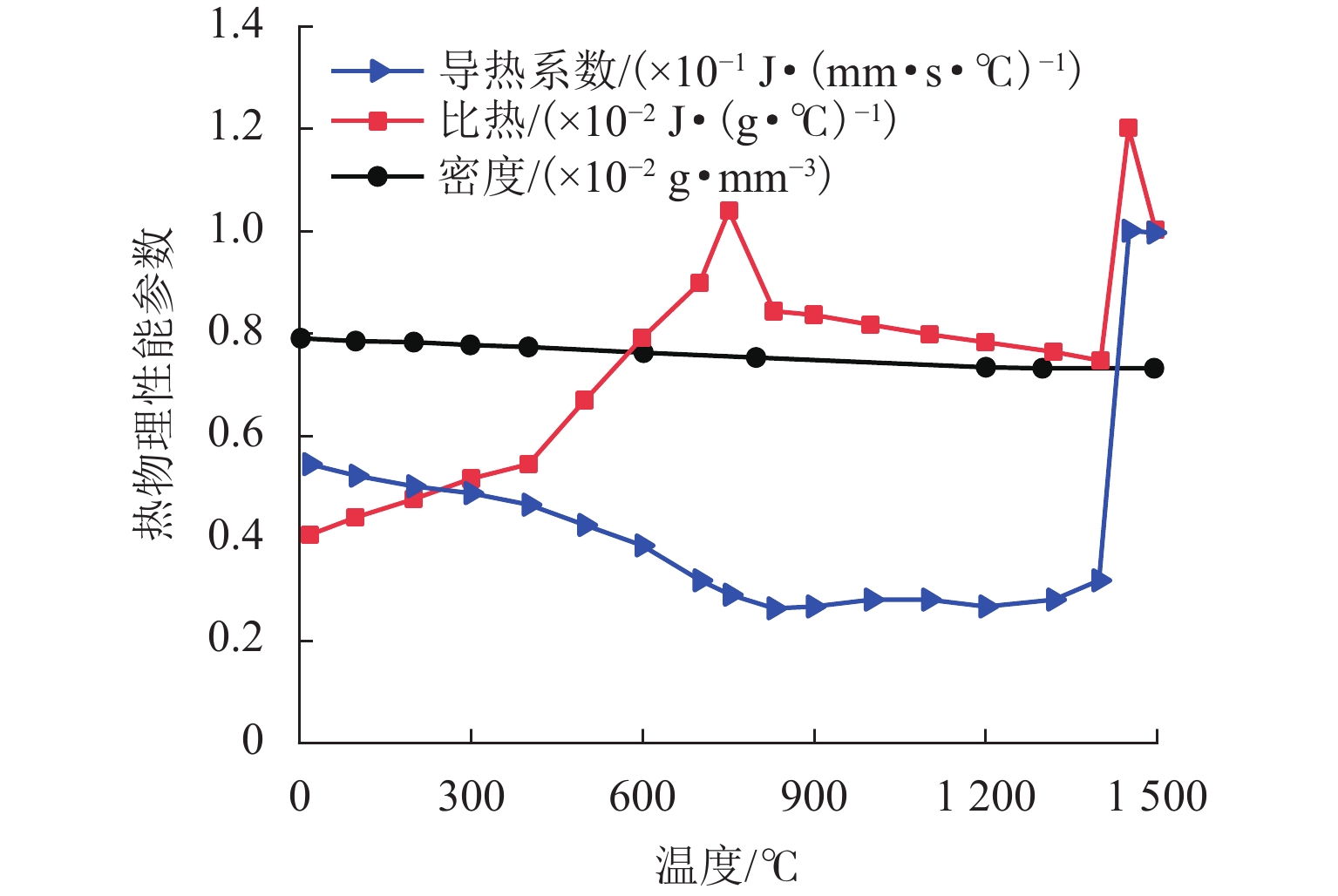

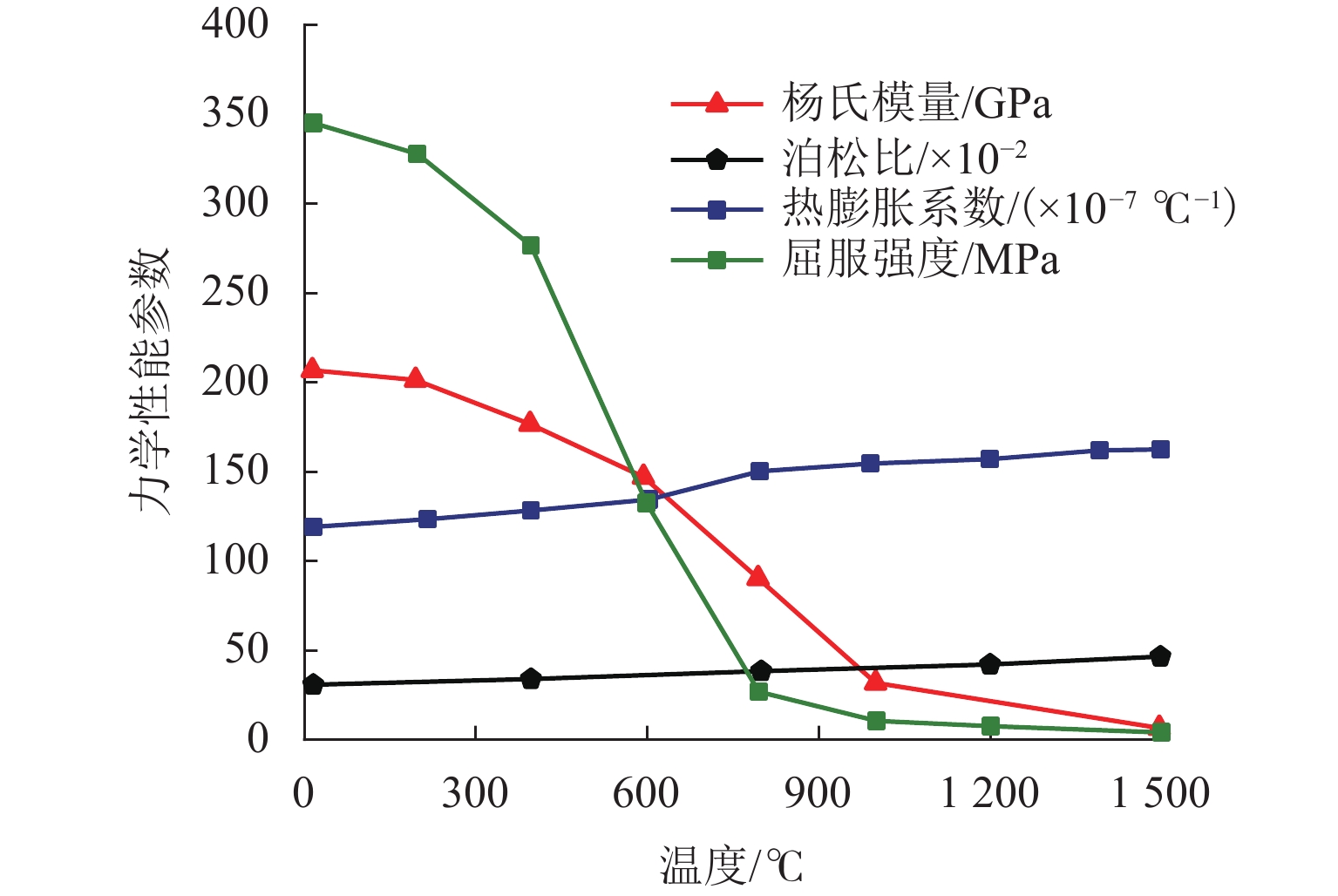

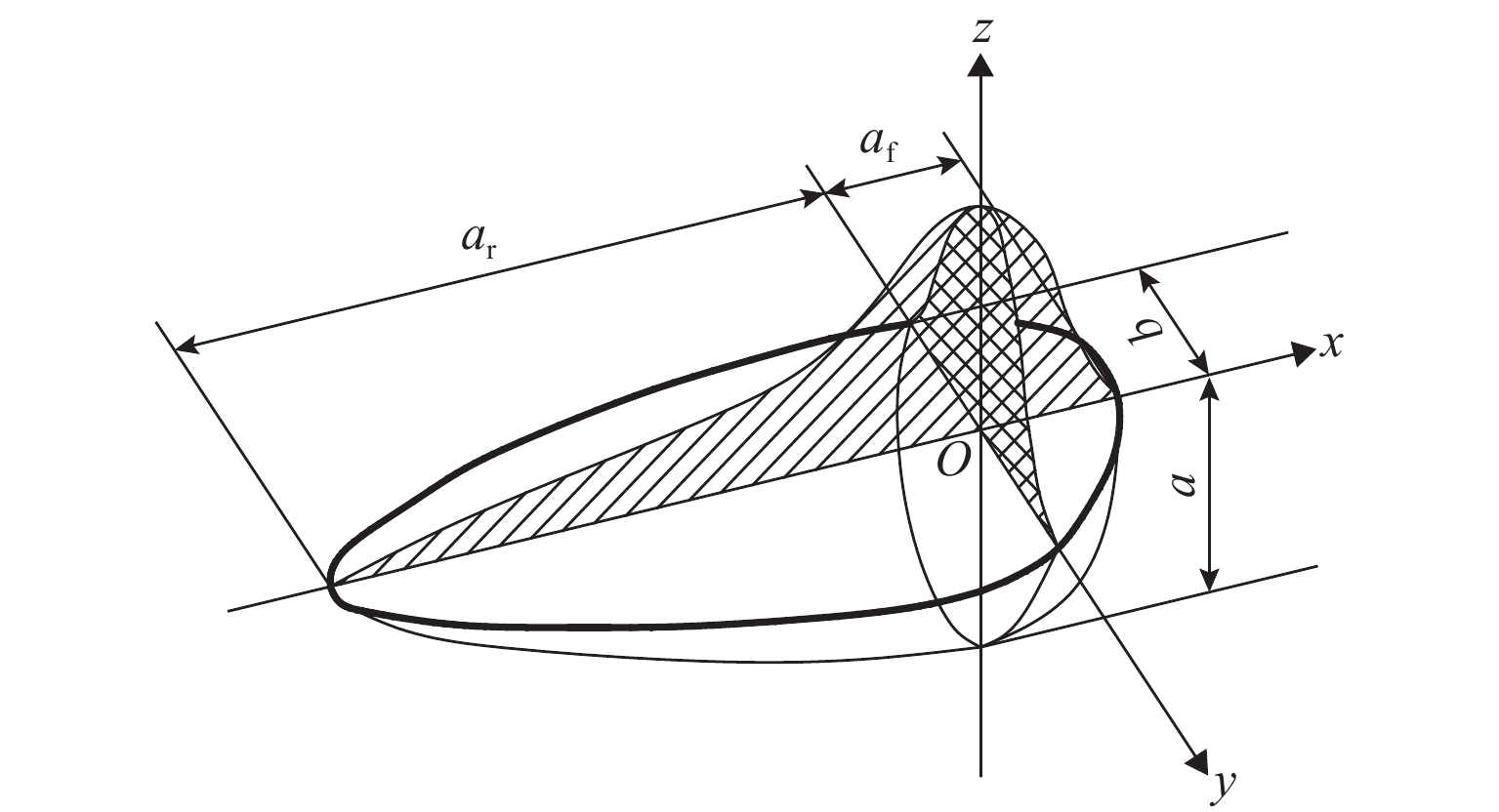

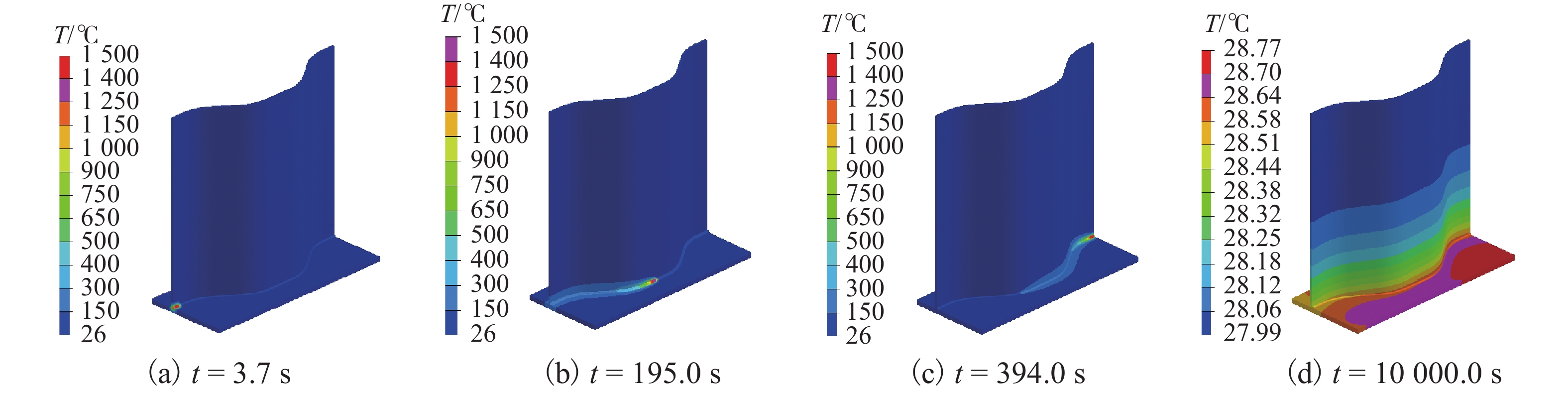

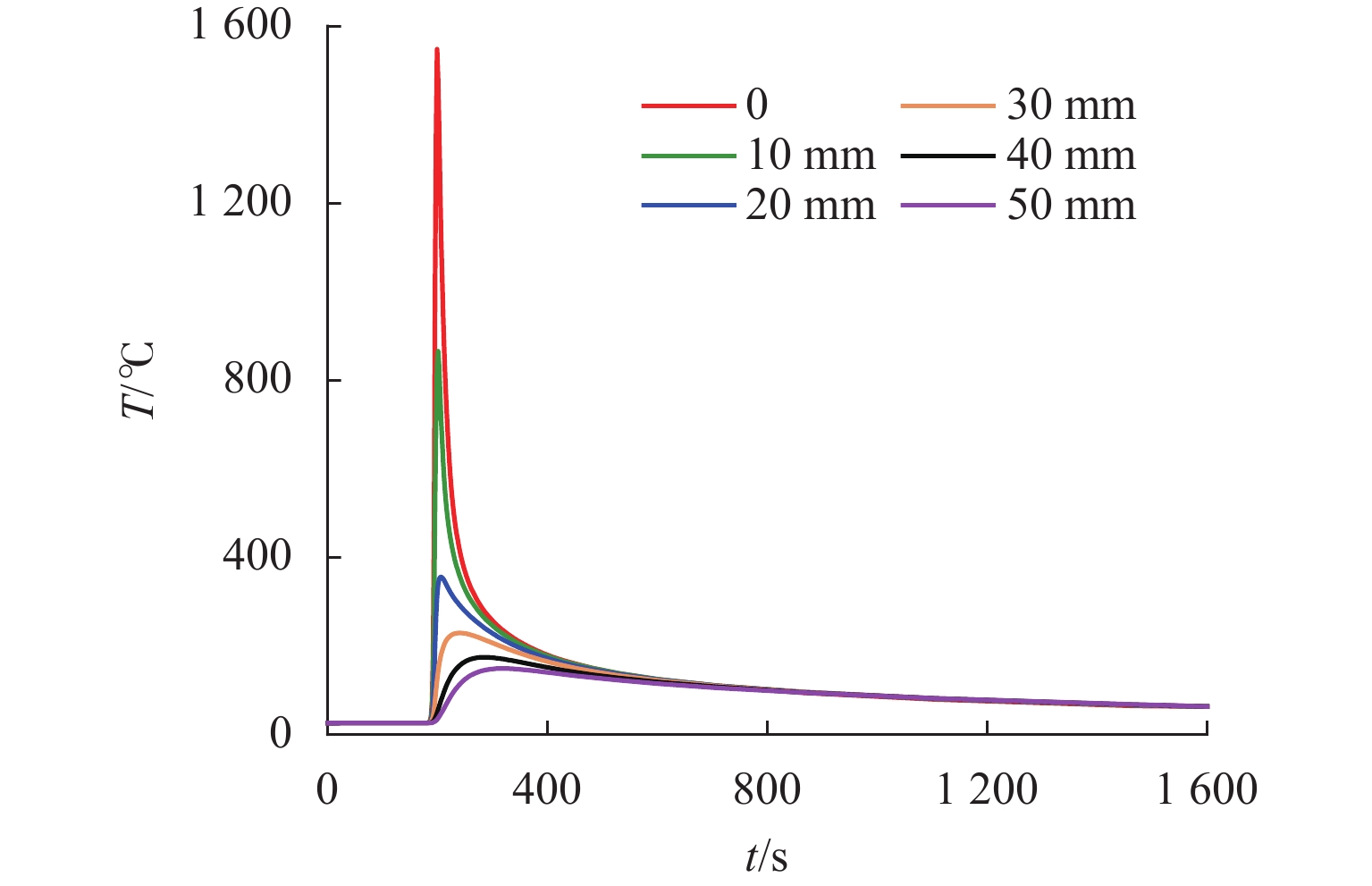

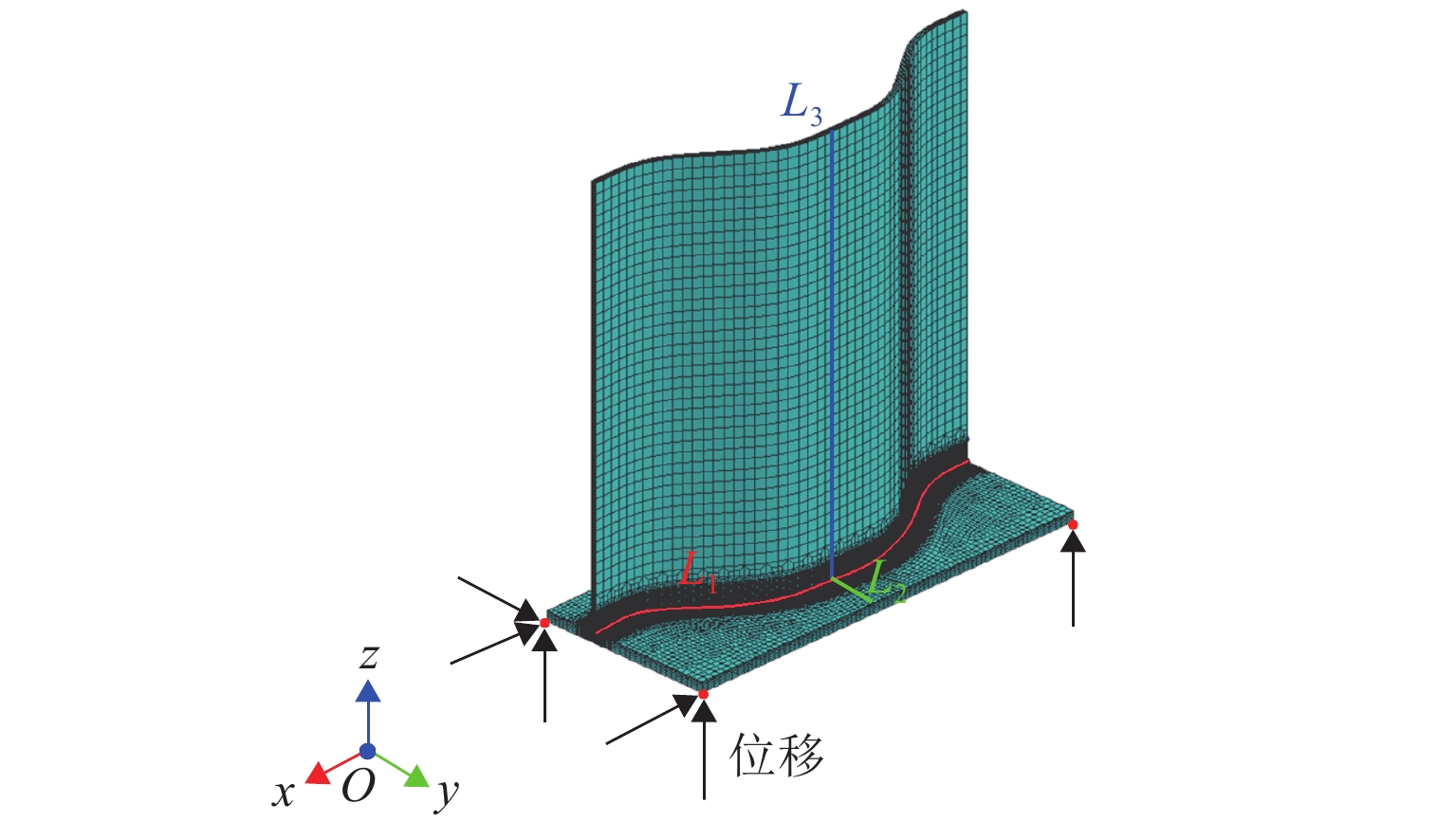

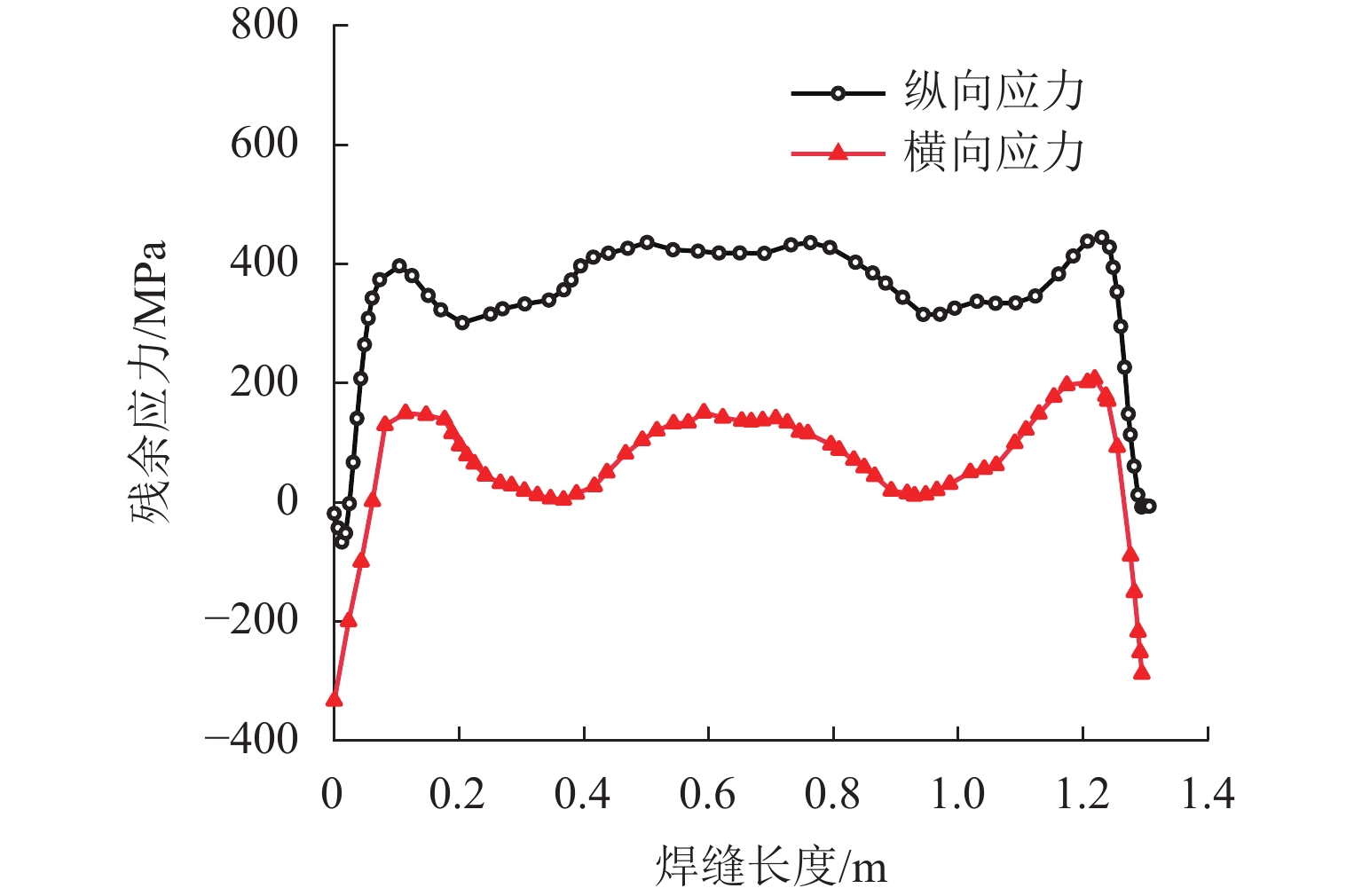

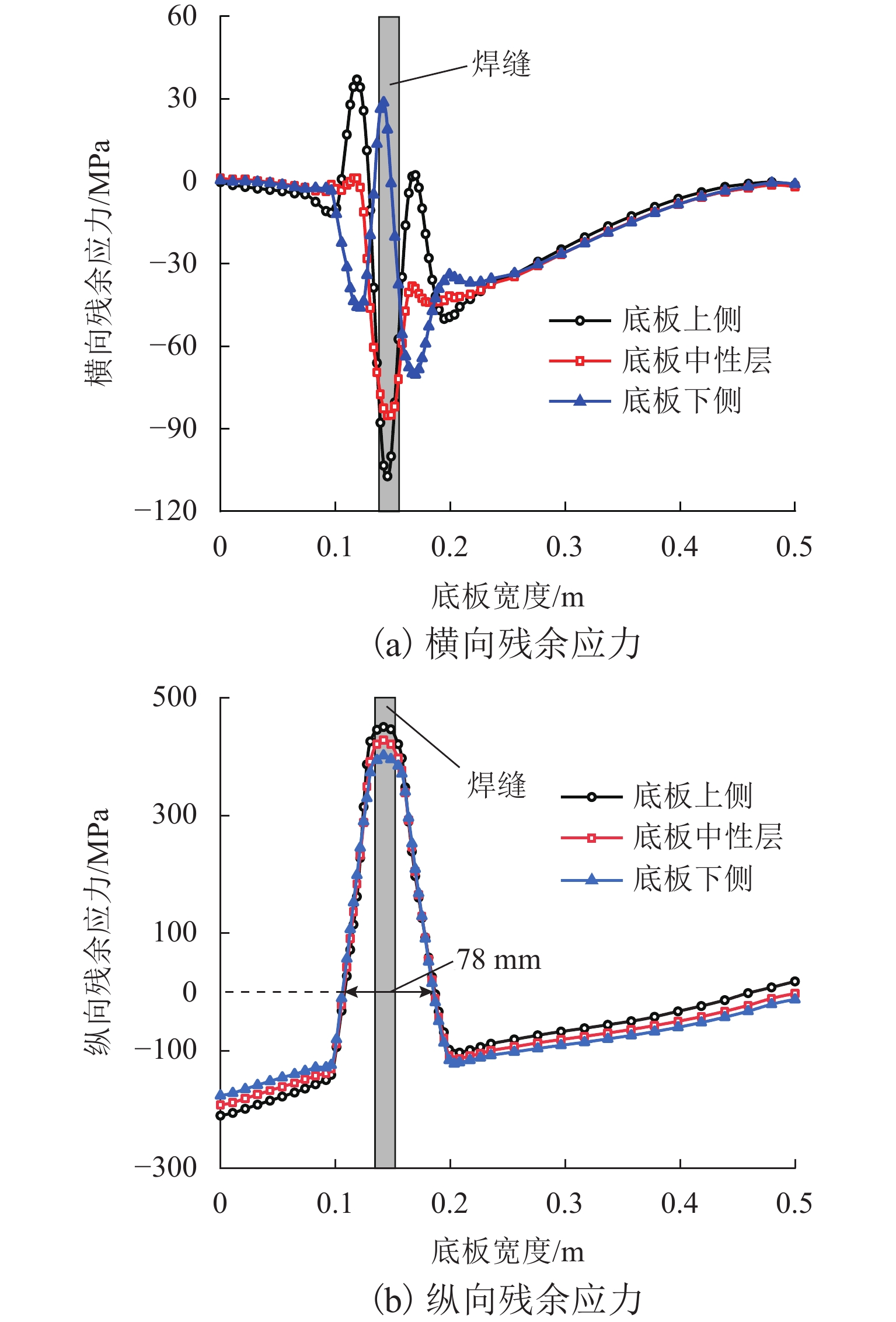

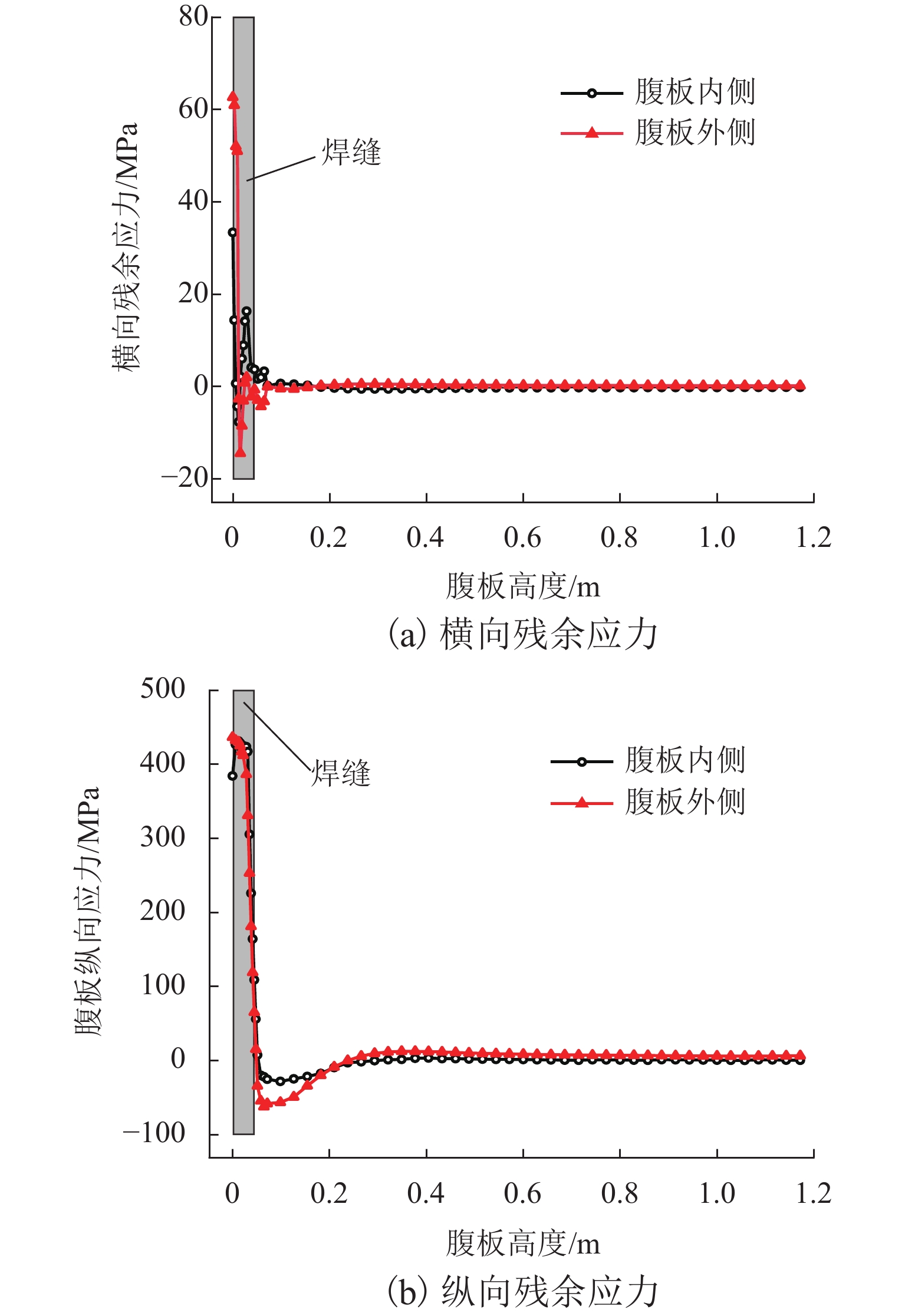

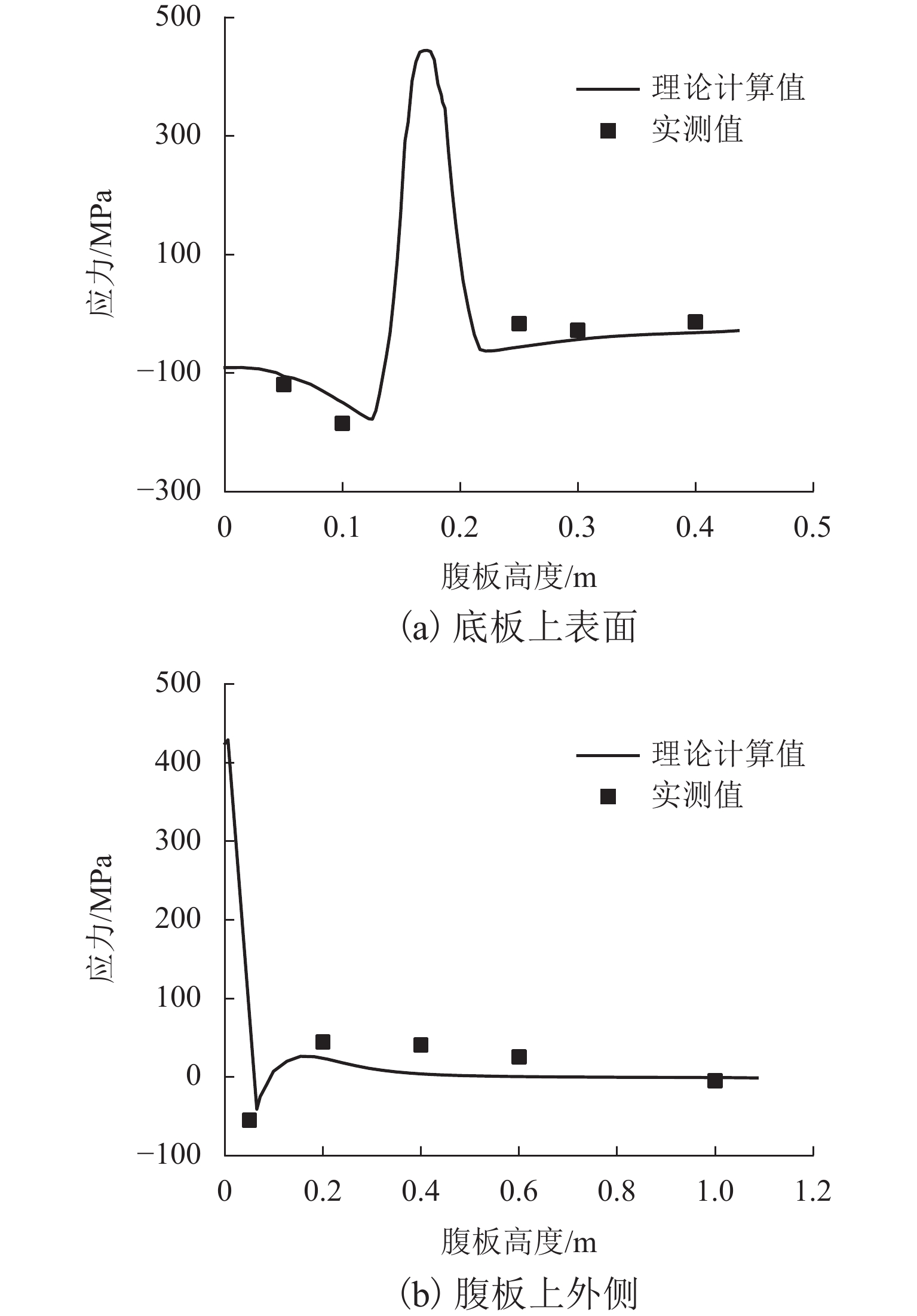

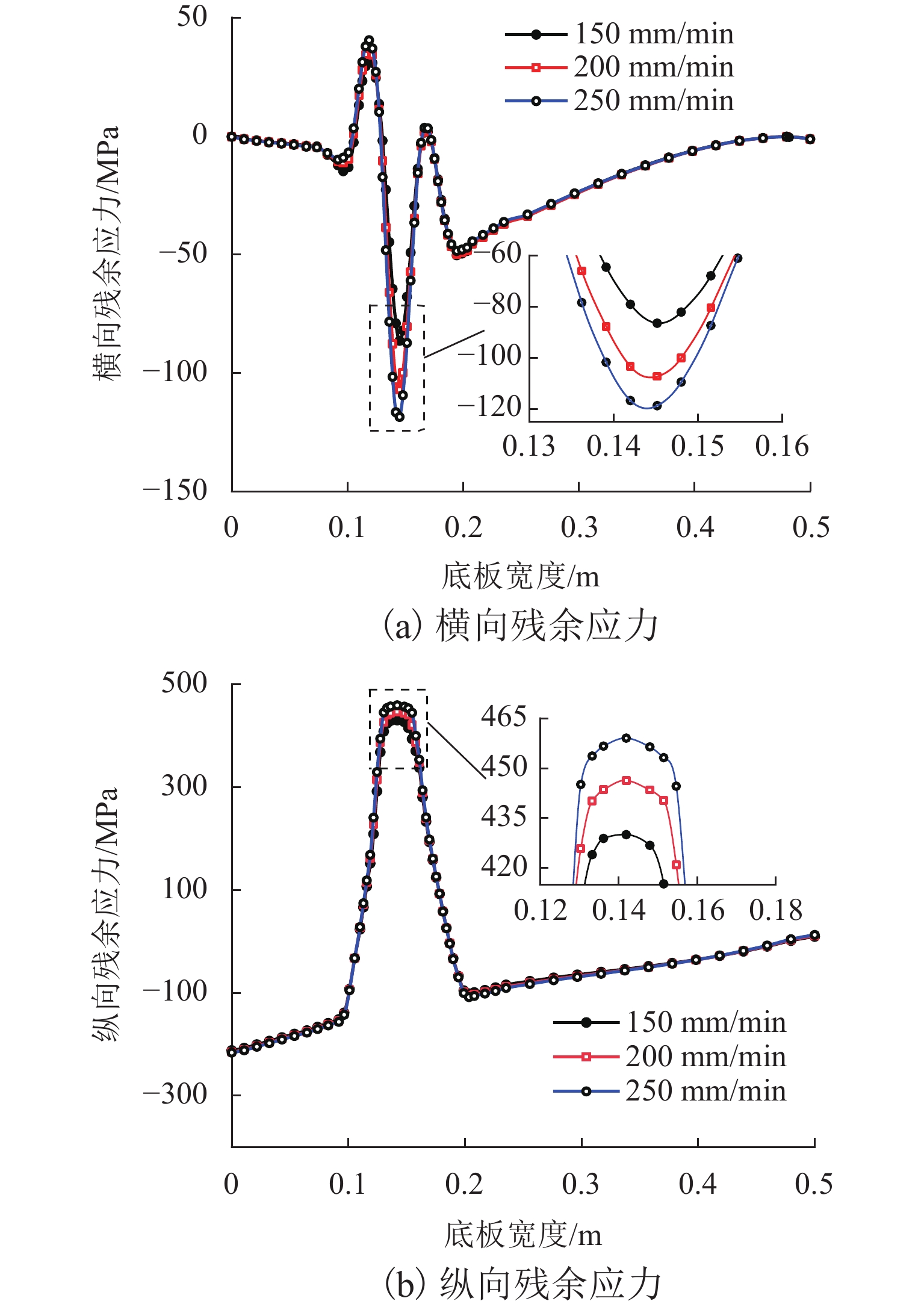

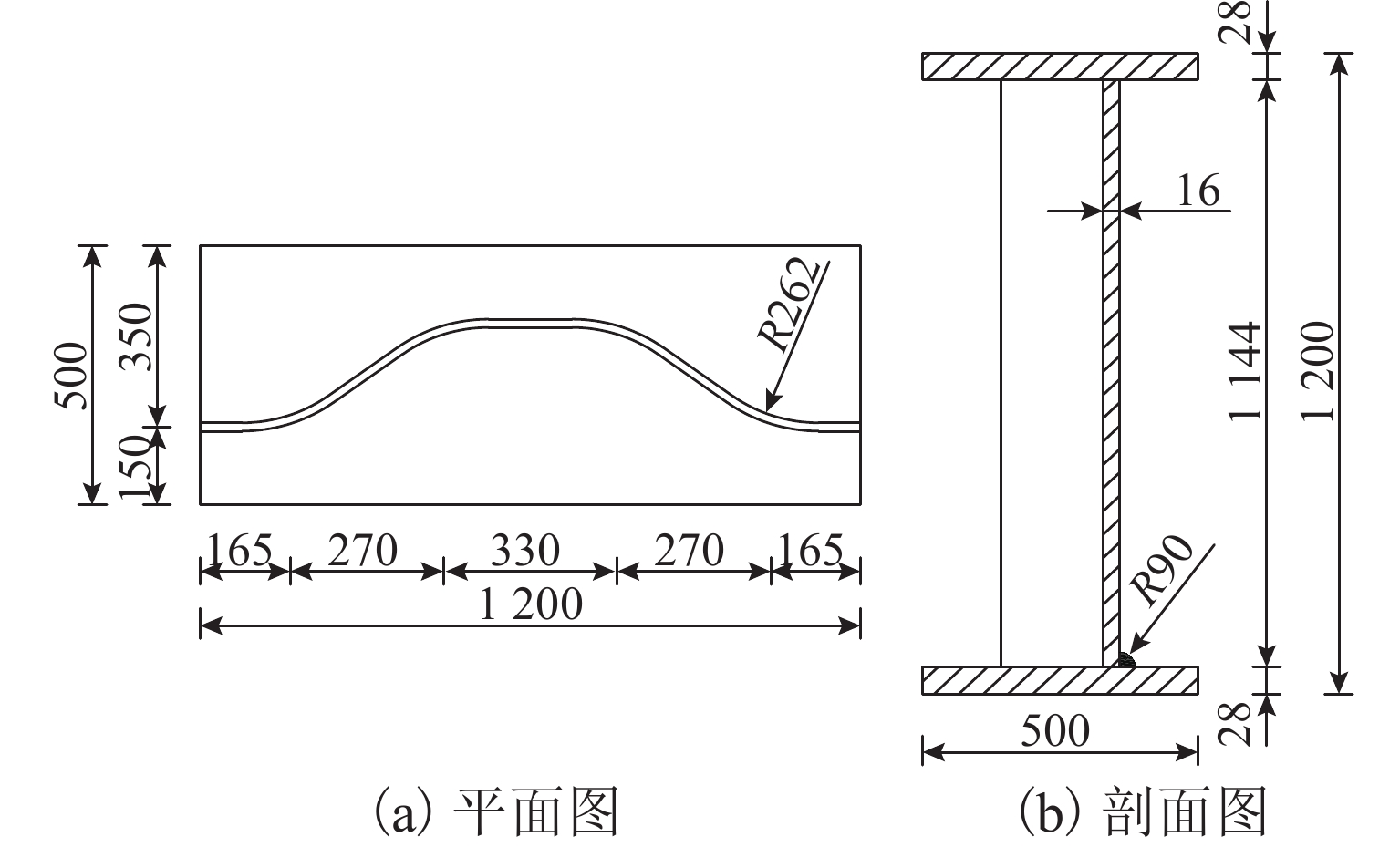

为研究波形钢腹板梁焊接残余应力的分布规律,通过有限元软件建立其三维热弹塑性模型,利用热-力耦合分析技术对其焊接温度场和应力场进行有限元数值仿真,采用双椭球体热源和修改单元材料属性的方法实现能量输入和焊缝填充,并将模拟计算结果与实测值进行对比分析. 结果表明:有限元预测的波形钢腹板梁残余应力分布与实测结果具有相同趋势,在波形钢腹板梁焊缝的弯折角处,残余应力发生一定幅度的连续应力波动;底板和腹板的残余应力峰值均出现在焊缝中心区域,其值分别为材料屈服强度的1.30倍和1.26倍;底板纵向残余拉应力在焊缝中心线两侧78 mm范围内急速下降后缓慢过渡为压应力,在底板较窄一侧压应力线性增大,最大值约为材料屈服强度的0.61倍;在底板较宽一侧压应力线性减小,并在边缘处转化为拉应力;焊接速度对残余应力分布扰动不大,而对残余应力峰值影响较显著;当焊接速度从150 mm/min增加至250 mm/min时,横向和纵向的残余应力最大值分别增加了27.11%和5.88%.

Abstract:To study the distribution law of welding residual stress of corrugated steel web girders, a three-dimensional thermo-elastoplastic model was established by finite element software, and the welding temperature field and stress field were numerically simulated by the finite element method using thermal and mechanical coupling analysis technology. Double ellipsoidal heat source and modified element material properties were used for energy input and weld filling, respectively. The simulation results were compared with the measured values. The results show that the residual stress distribution of corrugated steel web girders predicted by the finite element method has the same trend as the measured values. At the bending angle of the weld of the corrugated steel web girder, the residual stress fluctuates continuously in a certain range. The peak value of the residual stress in the bottom plate and web appears in the central area of the weld, which is 1.30 times and 1.26 times the yield strength of the material. respectively. The longitudinal residual tensile stress of the bottom plate decreases rapidly within 78 mm on both sides of the weld centerline and then slowly transitions to compressive stress. In addition, the compressive stress on the narrow side of the bottom plate increases linearly, and the maximum value is about 0.61 times the yield strength of the material. The compressive stress decreases linearly on the wider side of the bottom plate and is converted to the tensile stress at the edge. The analysis indicates that the welding speed has little effect on the residual stress distribution but has a significant effect on the peak value of residual stress. When the welding speed increases from 150 mm/min to 250 mm/min, the maximum residual stress in transverse and longitudinal directions increases by 27.11% and 5.88%, respectively.

-

表 1 焊件残余应力合力分析

Table 1. Composition of residual stress on welding section

kN 位置 拉应力合力 压应力合力 小计 合计 底板 上(外)侧 220.6 −201.9 18.7 下(内)侧 186.6 −176.5 10.1 平均 203.6 −189.2 14.4 腹板 上(外)侧 90.1 −104.6 −14.5 4.2 下(内)侧 67.3 −80.2 −12.9 −2.8 平均 78.7 −92.4 −13.7 0.7 -

[1] 卫星,邹修兴,姜苏,等. 正交异性钢桥面肋—板焊接残余应力的数值模拟[J]. 桥梁建设,2014,44(4): 27-33.WEI Xing, ZOU Xiuxing, JIANG Su, et al. Numerical simulation of residual stress in rib-to-top plate welding of orthotropic steel bridge deck[J]. Bridge Construction, 2014, 44(4): 27-33. [2] WANG Y B, LI G Q, CHEN S W. The assessment of residual stresses in welded high strength steel box sections[J]. Journal of Constructional Steel Research, 2012, 76: 93-99. doi: 10.1016/j.jcsr.2012.03.025 [3] 丁阳,郭鹏. 高强钢焊接工字梁整体稳定性能分析[J]. 建筑结构,2015,45(21): 25-29.DING Yang, GUO Peng. Investigation on overall buckling behavior of high strength steel welded I-beams[J]. Building Structure, 2015, 45(21): 25-29. [4] PASTERNAK H, LAUNET B, KRAUSCHE T. Welding of girders with thick plates-fabrication, measurement and simulation[J]. Journal of Constructional Steel Research, 2015, 115: 407-416. doi: 10.1016/j.jcsr.2015.08.037 [5] 于海丰,周建伟,张岩,等. 小截面焊接工字钢残余应力分布试验研究[J]. 建筑结构学报,2016,37(增1): 388-392,398.YU Haifeng, ZHOU Jianwei, ZHANG Yan, et al. Experimental study on residual stresses distribution on small welded I-shaped section[J]. Journal of Building Structures, 2016, 37(S1): 388-392,398. [6] KUBO M, WATANABE K. Residual stress measurement of corrugated steel web sections[J]. Journal of Japan Society of Civil Engineers, 2017, 73: 248-258. [7] KOLLÁR D, KOVESDI B. Welding simulation of corrugated web girders—part 1: effect of manufacturing on residual stresses and imperfections[J]. Thin-Walled Structures, 2020, 146: 462-477. [8] 王会利,王犇,谢常领,等. 钢桥面板U肋焊接残余应力影响因素分析[J]. 世界桥梁,2019,47(1): 53-58. doi: 10.3969/j.issn.1671-7767.2019.01.011WANG Huili, WANG Ben, XIE Changling, et al. Analysis of factors influencing welding residual stresses in U ribs of steel deck plate[J]. World Bridges, 2019, 47(1): 53-58. doi: 10.3969/j.issn.1671-7767.2019.01.011 [9] 曹宝雅,丁幼亮. 板件厚度对钢桥面板顶板纵肋焊接残余应力的影响分析[J]. 东南大学学报(自然科学版),2016,46(3): 565-571.CAO Baoya, DING Youliang. Influence analysis of plate thickness on welding residual of steel deck deck-rib[J]. Journal of Southeast University (Natural Science Edition), 2016, 46(3): 565-571. [10] HU M J, LI K J, CAI Z P, et al. A new weld material model used in welding analysis of narrow gap thick-walled welded rotor[J]. Journal of Manufacturing Processes, 2018, 34: 614-624. doi: 10.1016/j.jmapro.2018.06.036 [11] 张建勋, 刘川. 焊接应力变形有限元计算及其工程应用[M]. 北京: 科学出版社, 2017. [12] DENG D, MURAKAWA H. Prediction of welding distortion and residual stress in a thin plate butt-welded joint[J]. Computational Materials Science, 2008, 43(2): 353-365. doi: 10.1016/j.commatsci.2007.12.006 [13] 顾颖. U肋加劲钢桥面板焊接残余应力与变形研究[D]. 成都: 西南交通大学, 2016. [14] QIANG B, LI Y D, YAO C R, et al. Through-thickness welding residual stress and its effect on stress intensity factors for semi-elliptical surface cracks in a butt-welded steel plate[J]. Engineering Fracture Mechanics, 2018, 193: 17-31. doi: 10.1016/j.engfracmech.2018.02.016 [15] 周灿丰,陈智,焦向东,等. API X65管道深水铺设GMAW横向焊接温度场[J]. 焊接学报,2020,41(9): 60-68,100.ZHOU Canfeng, CHEN Zhi, JIAO Xiangdong, et al. Study on temperature field of GMAW horizontal welding for deep water laying of API X65 pipe[J]. Transactions of the China Welding Institution, 2020, 41(9): 60-68,100. [16] 秦荣. 大跨度桥梁结构[M]. 北京: 科学出版社, 2008. [17] 赵秋,吴冲. U肋加劲板焊接残余应力数值模拟分析[J]. 工程力学,2012,29(8): 262-268.ZHAO Qiu, WU Chong. Numerical analysis of welding residual stress of U-rib stiffened plate[J]. Engineering Mechanics, 2012, 29(8): 262-268. [18] 强斌,李亚东,顾颖,等. 钢桥对接焊缝残余应力及变形场数值分析与试验验证[J]. 铁道学报,2017,39(9): 134-139. doi: 10.3969/j.issn.1001-8360.2017.09.019QIANG Bin, LI Yadong, GU Ying, et al. Numerical analysis and experimental verification on welding residual stress and deformation of butt weld plate for steel bridge[J]. Journal of the China Railway Society, 2017, 39(9): 134-139. doi: 10.3969/j.issn.1001-8360.2017.09.019 [19] 李琴,王于豪,丁雅萍,等. 焊接工艺参数对Q345钢平板焊接残余应力的影响[J]. 材料科学与工艺,2020,28(6): 80-87.LI Qin, WANG Yuhao, DING Yaping, et al. Effect of welding parameters on residual stress of Q345 steel plate welding[J]. Materials Science and Technology, 2020, 28(6): 80-87. -

下载:

下载: