Friction and Wear Performance of Pantograph-Catenary System in Electrified Railways: State of the Art

-

摘要:

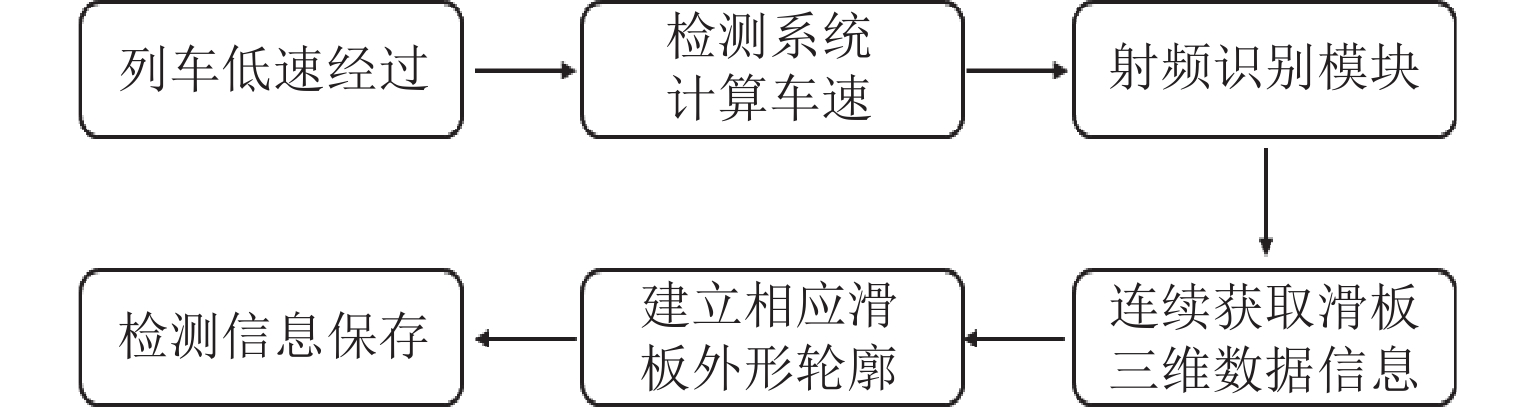

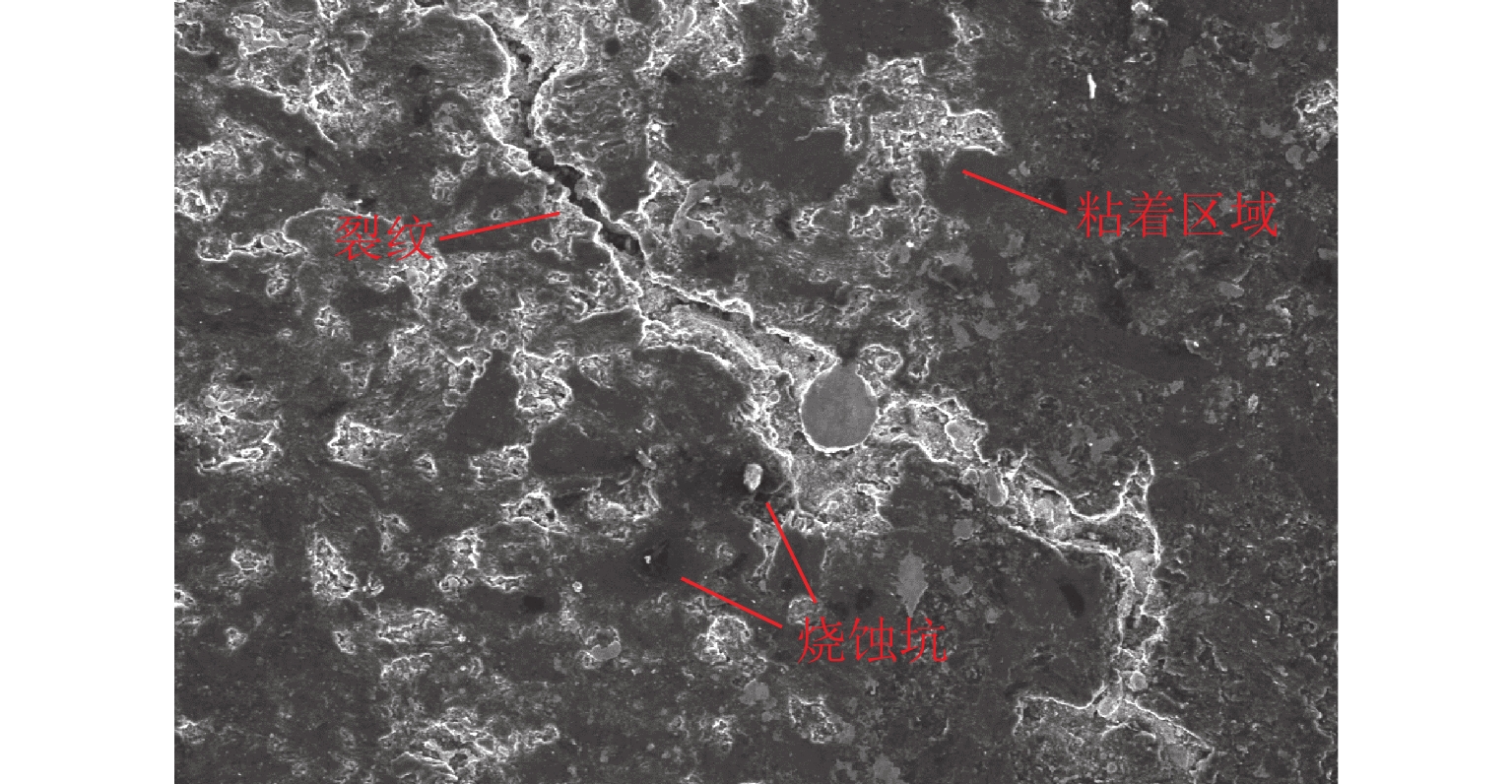

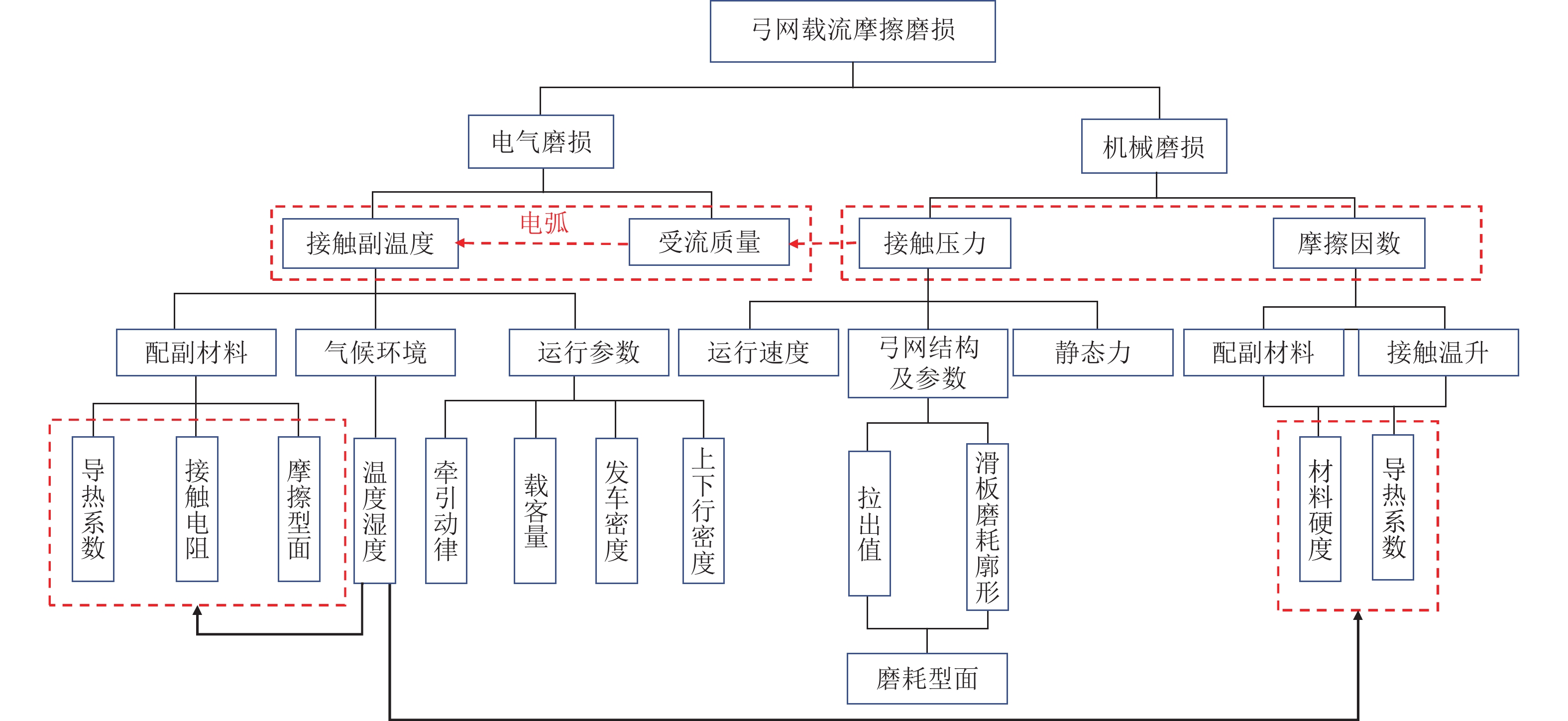

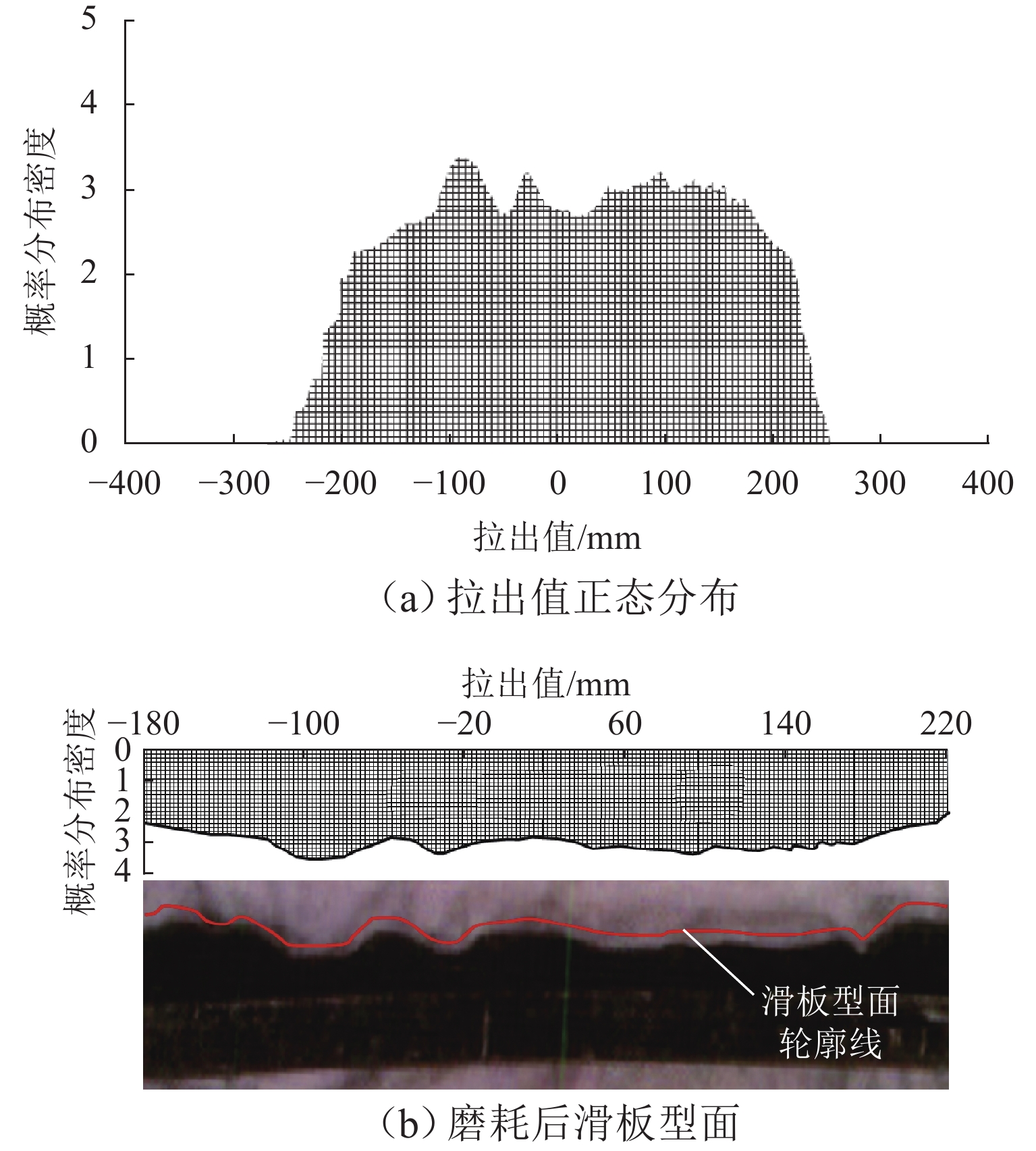

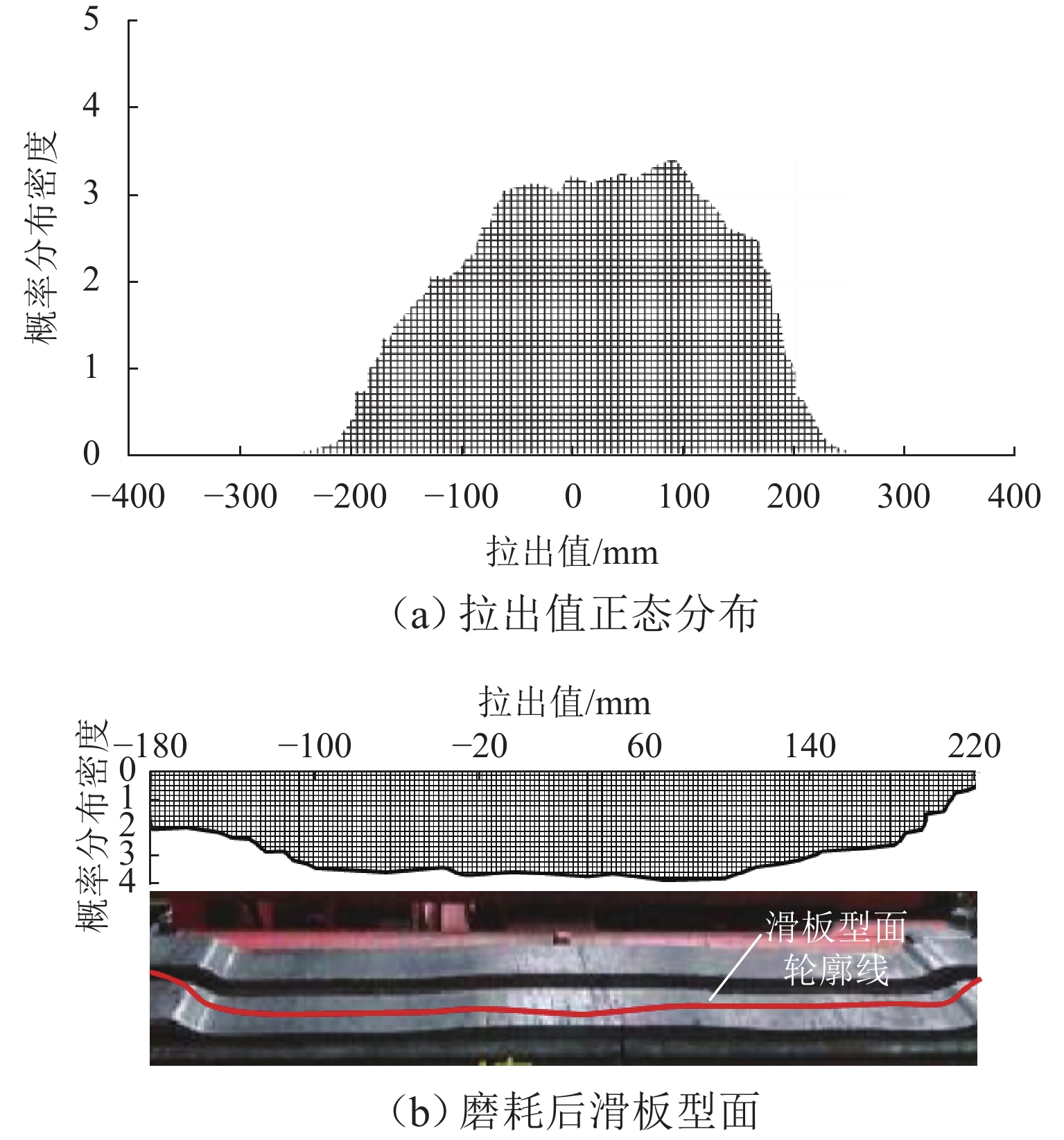

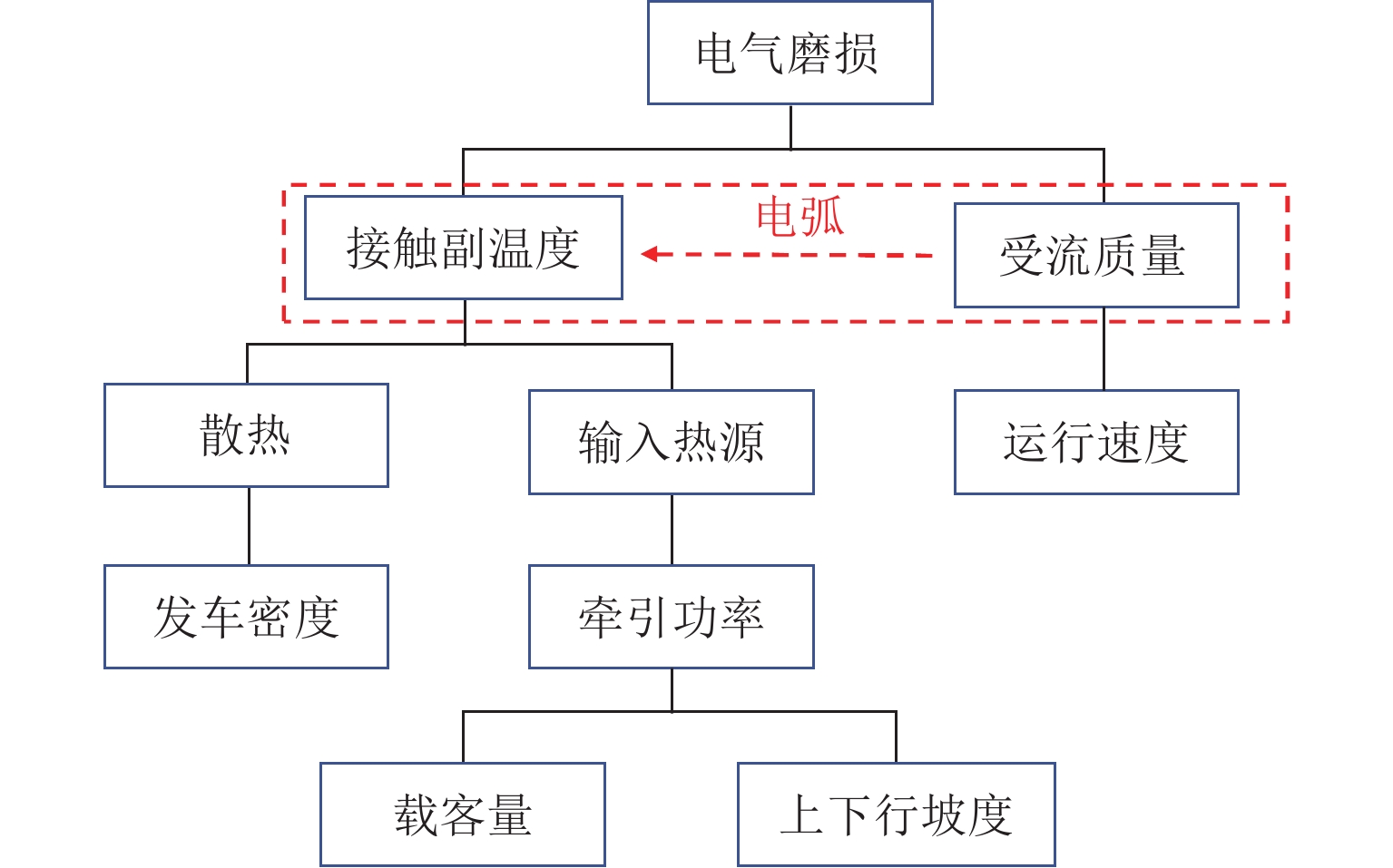

针对电气化铁路弓网正常和异常状态的接触副,分析受电弓滑板磨耗周期内的摩擦磨损性能差异性,特别是受电弓滑板的磨耗率和磨耗型面的差异性,包括:发生异常磨损时受电弓滑板磨损率数倍甚至数十倍的增长差异,以及局部偏磨、波浪型磨耗和贯穿性凹坑等磨耗型面差异;着重归纳不同弓网系统载流摩擦磨损试验台的特点及异同,总结磨耗检测接触式测量方法与非接触式测量方法的优劣;分析弓网系统结构及参数、列车运行参数、弓网系统载流参数及外界环境等因素的影响,归纳总结弓网载流摩擦磨损特性的演变规律. 在此基础上,综合分析弓网系统磨耗机理分析模型和数据拟合模型的研究现状和进展,并给出弓网系统载流摩擦磨损性能在后续研究中所需重点关注的研究方向和发展趋势,包括:弓网摩擦副的真实服役工况在实验室条件下的等效模拟;弓网磨耗性能的在线高精度检测;复杂气候条件及多物理场耦合作用下弓网磨耗性能的仿真和优化;结合大数据和智能算法的弓网磨耗预测,以及智能运维策略和全生命周期的能力保持技术等.

Abstract:For pantograph-catenary contact pairs in electrified railways operating in normal and abnormal states, the friction and wear performance of pantograph strip differentiates in a wear cycle, highlighted by differences in wear rate and wear profile. When abnormal wear occurs, the wear rate of pantograph strip will have a multifold increase or even dozens of times increase, but the wear profile acts differently, revealing partial eccentric wear, wavy wear, and penetrating wear. The similarities and differences in current-carrying friction and wear platforms are summarized for pantograph-catenary systems, as well as the advantages and disadvantages of contact and non-contact detection methods. The influential factors and evolution law are analyzed in view of the structure and parameters, train operation parameters, current-carrying parameters and external environment of pantograph-catenary system. Following above work, the state of the art of pantograph-catenary wear models, including mechanism analysis model and data fitting model, are analyzed extensively, and the prospective direction and development trend are put forward, such as, the equivalent simulation of a pantograph-catenary friction pair in real service under laboratory conditions, online high-precision detection of pantograph-catenary wear performance, simulation and optimization of pantograph-catenary wear performance in complex climatic conditions and multi-physical field coupling, pantograph-catenary wear prediction using big data and intelligent algorithms, intelligent operation and maintenance strategies, and capability maintenance in the whole life cycle.

-

表 1 滑板材料分类及优劣

Table 1. Classification, advantages and disadvantages of strip materials

滑板种类 优点 缺点 纯金属滑板 机械强度高、导电性能好、使用寿命长、成本低、取材方便、引发故障率低 对导线磨损严重,易与导线发生黏着效应、耐高温性能差、易熔融 粉末冶金滑板 机械强度较好、表面硬度适中、抗冲击性能、导电性能良好 对导线磨损严重 纯碳滑板 对导线磨耗小、较强的自润滑性能和减磨性能、电磁噪声小、耐高温 机械强度低、抗冲击性能差、易磨损、发生断裂和掉块 浸金属碳滑板 机械强度高、耐冲击、导热性能好、与导线接触电阻小、耐磨、使用寿命长、耐电弧烧蚀 抗冲击性能差、易掉块、维护成本高 复合材料滑板 良好的自润滑性、抗冲击性和抗折强度 易发生导电性能恶化、生产周期长,成本高 表 2 常见滑板的主要技术参数

Table 2. Main technical parameters of strip

滑 板 体积密度/

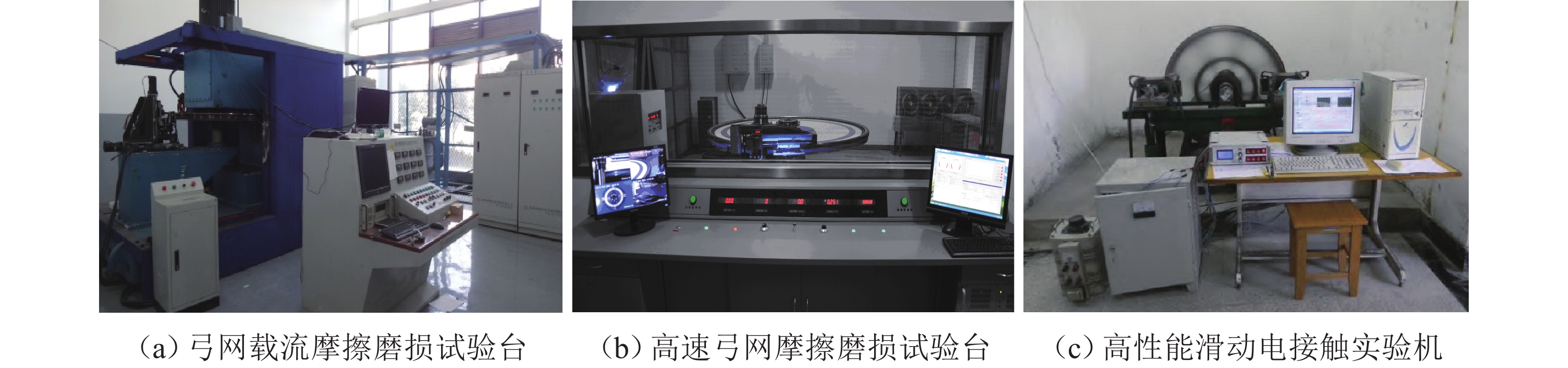

(g·cm−3)硬度 电阻率/

(μΩ·m)冲击韧性/

(J·cm−2)抗拉/抗折

强度/MPa抗压强度/MPa 磨损率/

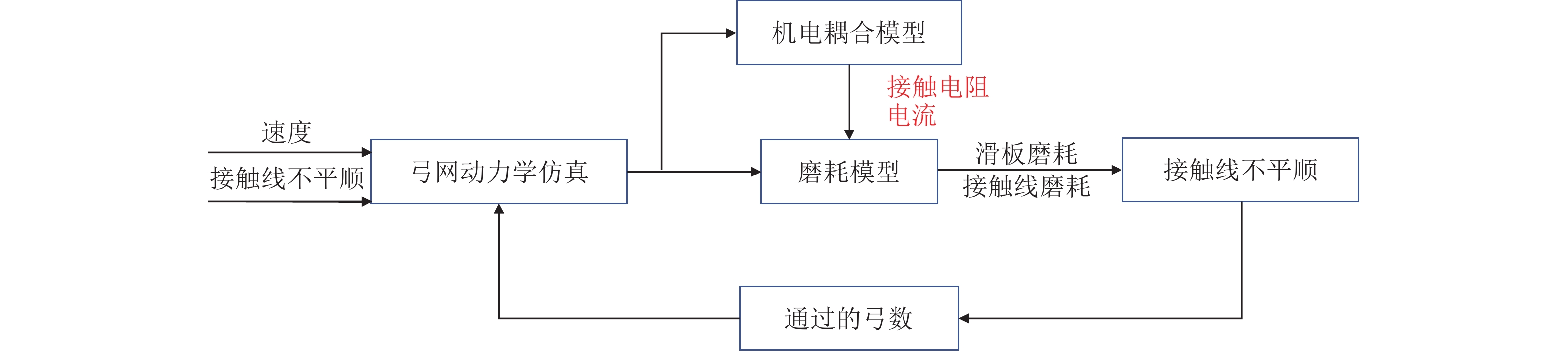

(mm·万公里−1)粉末冶金

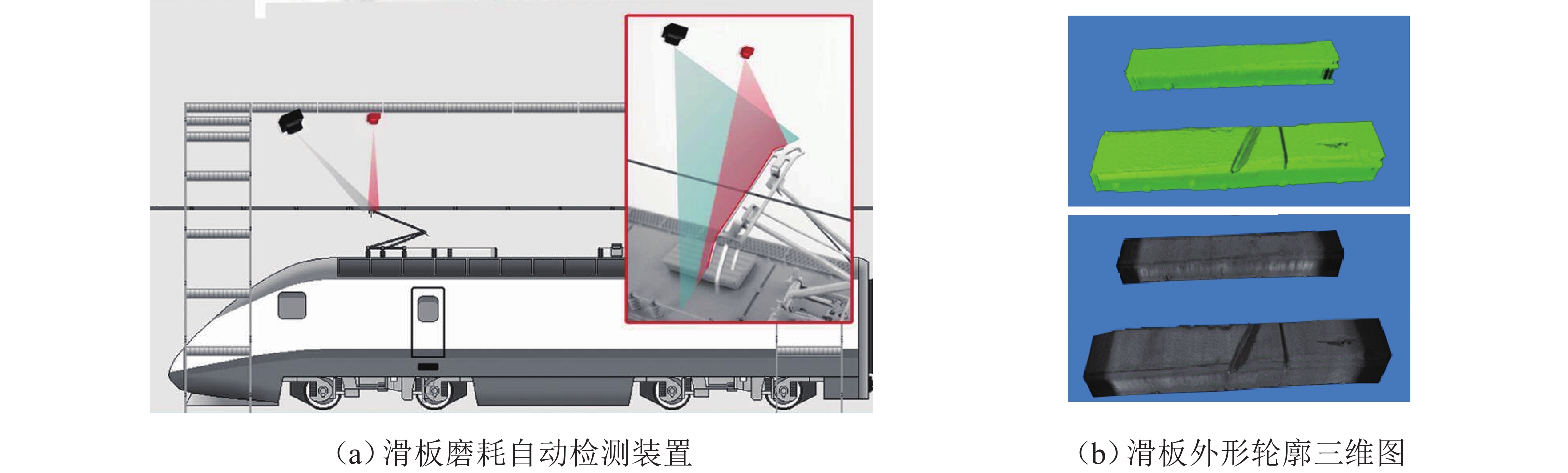

滑板(铁基)<8.0 HBS≤140 ≤0.35 ≥7.00 抗拉≥140 ≥290 ≤9.0 粉末冶金

滑板(铜基)7.8~8.2 HBS:60~90 ≤0.35 ≥7.00 抗拉≥120 — ≤12.0 浸金属滑板 ≤3.0 HS≥85 ≤12.00 ≥0.25 抗折≥85 ≥280 ≤13.0 碳滑板 ≤1.8 HS:60~100 ≤40.00 ≥0.10 抗折≥30 ≥40 ≤12.0 表 3 预测模型对比

Table 3. Comparison of prediction models

模型类型 优点 缺点 机理分析模型 精度较高、可通过实时数据对磨耗量实时预测 各影响因素贡献度量化较困难;机理分析阶段对设备精度要求较高 数据拟合模型 通过较短期试验量化各影响因素,且可保证较好的精度 拟合所需数据量较大;线路应用较困难 -

[1] 张卫华. 高速列车耦合大系统动力学理论与实践[M]. 北京: 科学出版社,2013. [2] 吴积钦. 受电弓与接触网系统[M]. 成都:西南交通大学出版社,2010. [3] 宋冬利,江亚男,张卫华. 滑板磨耗对受电弓系统服役性能的影响研究[J]. 西南交通大学学报,2017,52(3): 450-457.SONG Dongli, JIANG Yanan, ZHANG Weihua. Effects of contact strips wear on service performance of pantograph system[J]. Journal of Southwest Jiaotong University, 2017, 52(3): 450-457. [4] NAGASAWA H, KATO K. Wear mechanism of copper alloy wire sliding against iron-base strip under electric current[J]. Wear, 1998, 216(2): 179-183. doi: 10.1016/S0043-1648(97)00162-2 [5] KUBO S, KATO K. Effect of arc discharge on the wear rate and wear mode transition of a copper-impregnated metallized carbon contact strip sliding against a copper disk[J]. Tribology International, 1999, 32(7): 367-378. doi: 10.1016/S0301-679X(99)00062-6 [6] SENOUCI A, ZAIDI H, FRENE J, et al. Damage of surfaces in sliding electrical contact copper/steel[J]. Applied Surface Science, 1999, 144/145: 287-291. doi: 10.1016/S0169-4332(98)00915-5 [7] SENOUCI A, FRENE J, ZAIDI H. Wear mechanism in graphite–copper electrical sliding contact[J]. Wear, 1999, 225/226/227/228/229: 949-953. [8] HE D H, MANORY R R, GRADY N. Wear of railway contact wires against current collector materials[J]. Wear, 1998, 215(1/2): 146-155. [9] HE D H, MANORY R. A novel electrical contact material with improved self-lubrication for railway current collectors[J]. Wear, 2001, 249(7): 626-636. doi: 10.1016/S0043-1648(01)00700-1 [10] 林修洲,朱旻昊,陈光雄,等. 高速电气化铁路弓/网系统的摩擦磨损研究进展[J]. 润滑与密封,2007,32(2): 180-183.LIN Xiuzhou, ZHU Minhao, CHEN Guangxiong, et al. Research progresses on friction and wear of pantograph/contact wire system in high speed electrified railway[J]. Lubrication Engineering, 2007, 32(2): 180-183. [11] 郭凤仪,赵汝彬,陈忠华,等. 滑动电接触磨耗测控系统的研究[J]. 计算机测量与控制,2010,18(3): 508-511.GUO Fengyi, ZHAO Rubin, CHEN Zhonghua, et al. Investigation on electric sliding contact wear measurement and control system[J]. Computer Measurement & Control, 2010, 18(3): 508-511. [12] 姜国强,郭凤仪,王智勇,等. 高性能滑动电接触实验机的设计与研制[J]. 机械设计,2010,27(1): 31-34.JIANG Guoqiang, GUO Fengyi, WANG Zhiyong, et al. Design and development of high performance sliding electrical contact testing machine[J]. Journal of Machine Design, 2010, 27(1): 31-34. [13] 王亚春,陈立明,杨才智. 高速铁路弓网关系模拟试验研究[J]. 中国铁道科学,2018,39(3): 79-85.WANG Yachun, CHEN Liming, YANG Caizhi. Simulation test study on pantograph-catenary relation of high speed railway[J]. China Railway Science, 2018, 39(3): 79-85. [14] 许思思. 弓网系统电弧机理试验与研究[D]. 成都: 西南交通大学,2014. [15] BUCCA G, COLLINA A. A procedure for the wear prediction of collector strip and contact wire in pantograph–catenary system[J]. Wear, 2009, 266(1/2): 46-59. [16] 曾攀,王俊玮,邓久强,等. 基于计算机视觉的受电弓滑板磨耗图像的识别[J]. 无线互联科技,2016(7): 104-106.ZENG Pan, WANG Junwei, DENG Jiuqiang, et al. Image recognition of slide abrasion for locomotive pantograph[J]. Wireless Internet Technology, 2016(7): 104-106. [17] LU S F, LIU Z, LI D, et al. Automatic wear measurement of pantograph slider based on multiview analysis[J]. IEEE Transactions on Industrial Informatics, 2021, 17(5): 3111-3121. doi: 10.1109/TII.2020.2997724 [18] KARADUMAN G, AKIN E. A deep learning based method for detecting of wear on the current collector strips’ surfaces of the pantograph in railways[J]. IEEE Access, 2020, 8: 183799-183812. doi: 10.1109/ACCESS.2020.3029555 [19] 闵泳. 新型电力机车受电弓碳基复合材料滑板研究[D]. 大连: 大连交通大学,2005. [20] 冀盛亚,孙乐民,上官宝,等. 受电弓滑板材料的研究现状及展望[J]. 热加工工艺,2009,38(6): 80-83.JI Shengya, SUN Lemin, SHANGGUAN Bao, et al. Research status and prospects of pantograph slide material[J]. Hot Working Technology, 2009, 38(6): 80-83. [21] 张晓娟,孙乐民. 受电弓滑板和接触网导线材料的现状及展望[J]. 河南科技大学学报(自然科学版),2006,27(6): 4-7,105.ZHANG Xiaojuan, SUN Lemin. Status and expectation of pantograph slide and contact wire[J]. Journal of Henan University of Science and Technology (Natural Science), 2006, 27(6): 4-7,105. [22] 中华人民共和国铁道部. 电力机车受电弓滑板 粉末冶金滑板:TB/T 1842.1—2002[S]. 北京:中国铁道出版社,2002. [23] 中华人民共和国铁道部. 电力机车受电弓滑板 浸金属碳滑板:TB/T 1842.2—2002[S]. 北京:中国铁道出版社,2002. [24] 中华人民共和国铁道部. 电力机车受电弓滑板 第3部分:碳滑板:TB/T 1842.3—2008[S]. 北京:中国铁道出版社,2008. [25] KANG S. A study of friction and wear characteristics of copper- and iron-based sintered materials[J]. Wear, 1993, 162/163/164: 1123-1128. [26] 杨连威,姚广春,陆阳. 新型铜-碳复合受电弓滑板的制备[J]. 过程工程学报,2005,5(4): 460-463.YANG Lianwei, YAO Guangchun, LU Yang. Research on new copper-carbon composite pantograph slide plate[J]. The Chinese Journal of Process Engineering, 2005, 5(4): 460-463. [27] 刘军,严红革,陈刚,等. 铜基复合材料受电弓滑板摩擦磨损及电阻率的研究[J]. 矿冶工程,2007,27(2): 71-74.LIU Jun, YAN Hongge, CHEN Gang, et al. Frictional wear and resistivity of copper matrix composites pantograph slider[J]. Mining and Metallurgical Engineering, 2007, 27(2): 71-74. [28] 罗骥,曹慧钦,贾步超,等. 新型铜基受电弓滑板材料的制备与性能[J]. 复合材料学报,2012,29(2): 103-108.LUO Ji, CAO Huiqin, JIA Buchao, et al. Preparation and properties of the new type copper matrix pantograph slider[J]. Acta Materiae Compositae Sinica, 2012, 29(2): 103-108. [29] 余亚岚,袁楠,江丹露,等. 镍与石墨含量对新型铜基粉末冶金受电弓滑板材料性能的影响[J]. 粉末冶金材料科学与工程,2015,20(3): 419-424.YU Yalan, YUAN Nan, JIANG Danlu, et al. Effects of nickel and graphite content on new copper matrix P/M materials for pantograph slider[J]. Materials Science and Engineering of Powder Metallurgy, 2015, 20(3): 419-424. [30] KUBOTA Y. Relationship between wear profile of pantograph contact strip and arc discharge energy distribution[C]//2018 IEEE Holm Conference on Electrical Contacts. Albuquerque: IEEE, 2018: 150-154. [31] HUANG J X, WANG M, LI Y C, et al. Effect of flake graphite content on wear between behavior between P/M copper-based pantograph slide and contact wire[J]. Materials Research Express, 2020, 7(7): 076510.1-076510.14. doi: 10.1088/2053-1591/aba3e3 [32] 翟洪祥,汪长安. Ti3SiC2材料在受电弓滑板中的应用研究[J]. 机车电传动,2003(增1):43-45.ZHAI Hongxiang, WANG Chang’an. Study on the application of Ti3SiC2 material in pantograph slide plate[J]. Electric Drive for Locomotives,2003(S1):43-45. [33] 刘新. Ti3SiC2、Ti3AlC2陶瓷的非载流和载流摩擦学行为研究[D]. 北京: 北京交通大学,2007. [34] 黄振莺. 高速列车受电弓滑板用TiSiC系材料的制备与性能研究[D]. 北京: 北京交通大学,2008. [35] ZHAO J, PENG Y T, ZHOU Q G, et al. The current-carrying tribological properties of Cu/graphene composites[J]. Journal of Tribology, 2021, 143(10): 102101.1-102101.9. doi: 10.1115/1.4049696 [36] 柴昌盛,徐立新,韦强,等. 铜对碳纤维/酚醛树脂受电弓滑板材料的性能影响[J]. 广州化工,2010,38(12): 102-104.CHAI Changsheng, XU Lixin, WEI Qiang, et al. Effect of Cu mass fraction on properties of carbon-fiber fabric/phenolic resin pantograph slider composites[J]. Guangzhou Chemical Industry, 2010, 38(12): 102-104. [37] 袁华. 碳纤维增强受电弓滑板的制备与性能及摩擦磨损机理的研究[D]. 济南: 山东大学,2013. [38] 余先涛,莫易敏. 激光表面熔覆在机车受电弓滑板材料中的应用[J]. 武汉理工大学学报(信息与管理工程版),2005,27(4): 146-149.YU Xiantao, MO Yimin. Application of laser cladding in pantograph slide plates of electric locomotives[J]. Journal of Wuhan University of Technology (Information & Management Engineering), 2005, 27(4): 146-149. [39] 陈鹏威. 激光直接金属沉积石墨—铜功能梯度复合材料应力场数值模拟[D]. 南昌: 华东交通大学,2015. [40] 周颖. 激光沉积制备石墨/Cu复合材料的性能研究[D]. 南昌: 华东交通大学,2018. [41] WANG P, WEI F C, ZHAO Z W, et al. Effect of heat treatment temperature on mechanical and tribological properties of copper impregnated carbon/carbon composite[J]. Tribology International, 2021,164: 1-9. doi: 10.1016/j.triboint.2021.107209 [42] 张军伟,杨正海,孙乐民,等. 梯度铜碳复合材料的载流摩擦磨损性能[J]. 材料热处理学报,2020,41(7): 33-40.ZHANG Junwei, YANG Zhenghai, SUN Lemin, et al. Current-carrying friction and wear properties of gradient copper-carbon composites[J]. Transactions of Materials and Heat Treatment, 2020, 41(7): 33-40. [43] 杨广英,徐超,杨才智,等. 铜锡合金接触导线高速磨耗性能试验研究[J]. 铁道技术监督,2016,44(11): 31-33.YANG Guangying, XU Chao, YANG Caizhi, et al. Experimental study on high-speed wear performance of copper-tin alloy contact wire[J]. Railway Quality Control, 2016, 44(11): 31-33. [44] 徐超,潘利科,杨才智,等. 400 km/h高速列车受电弓滑板与接触线载流摩擦磨损研究[J]. 电气化铁道,2018,29(增1):29-31,35.XU Chao, PAN Like, YANG Caizhi, et al. Study on current-carrying friction and wear between pantograph slide plate and contact wire of 400 km/h high-speed train[J]. Electric Railway,2018,29(S1):29-31,35. [45] HU Y, CHEN G X, ZHANG S D, et al. Comparative investigation into the friction and wear behaviours of a Cu–Ag contact wire/carbon strip and a pure copper contact wire/carbon strip at high speeds[J]. Wear, 2017, 376/377: 1552-1557. doi: 10.1016/j.wear.2016.12.041 [46] WANG R Y, ZHANG Z G, ZHONG J L. Analysis and research on current-carrying friction and wear of high-speed train pantograph slide and contact wire based on computer simulation analysis[J]. Journal of Physics: Conference Series, 2020, 1648(3): 1-6. doi: 10.1088/1742-6596/1648/3/032031 [47] 黄之元,陈光雄,夏晨光. 组装式滑板对地铁接触线犁削磨损的影响[J]. 润滑与密封,2011,35(1): 33-35,78.HUANG Zhiyuan, CHEN Guangxiong, XIA Chenguang. Effect of assembled strip on plough wear of metro contact wire[J]. Lubrication Engineering, 2011, 35(1): 33-35,78. [48] 黄之元,陈光雄,夏晨光. 组装式滑板对地铁接触线犁削磨损的影响[J]. 润滑与密封,2021,46(2): 24-30.HUANG Zhiyuan, CHEN Guangxiong, XIA Chenguang. Effect of assembled strip on plough wear of metro contact wire[J]. Lubrication Engineering, 2021, 46(2): 24-30. [49] 丁涛,何宏高,陈光雄,等. 弹性条件下浸金属碳/不锈钢载流摩擦磨损性能[J]. 西南交通大学学报,2009,44(4): 558-563.DING Tao, HE Honggao, CHEN Guangxiong, et al. Friction and wear behavior of copper-impregnated metalized carbon strip sliding against stainless steel with electrical current under elastic condition[J]. Journal of Southwest Jiaotong University, 2009, 44(4): 558-563. [50] 唐志强,朱佳栋. 城市轨道交通架空刚性悬挂接触网弓网磨耗及改进措施[J]. 城市轨道交通研究,2021,24(增1):108-112.TANG Zhiqiang, ZHU Jiadong. Pantograph and catenary wear of overhead rigid suspension catenary in urban rail transit and its improvement measures[J]. Urban Mass Transit,2021,24(S1):108-112. [51] 王剑. 地铁刚性接触悬挂弓网磨耗问题研究[J]. 都市快轨交通,2012,25(4): 59-62, 66.WANG Jian. Discussion on pantograph-catenary abrasion of metro rigid overhead catenary system[J]. Urban Rapid Rail Transit, 2012, 25(4): 59-62, 66. [52] 武云龙,付文明,黄海,等. 拉出值对碳滑板/铜银合金接触线载流磨损性能的影响[J]. 润滑与密封,2017,42(10): 57-61.WU Yunlong, FU Wenming, HUANG Hai, et al. Effect of the staggering on the wear performance of carbon strip/Cu-Ag alloy contact wire with electric current[J]. Lubrication Engineering, 2017, 42(10): 57-61. [53] 谭冬华. 架空刚性悬挂弓网磨耗异常的分析与解决办法[J]. 电气化铁道,2007,18(1): 29-32.TAN Donghua. Analysis and counter measures of abnormal wear between catenary and pantograph under rigid suspension of OCS[J]. Electric Railway, 2007, 18(1): 29-32. [54] 谢风华. 单轨交通刚性接触网不均匀磨耗分析及其对策[J]. 城市轨道交通研究,2011,14(8): 73-75.XIE Fenghua. Analysis and countermeasures of the uneven wear for monorail rigid centenary[J]. Urban Mass Transit, 2011, 14(8): 73-75. [55] YANG H J, HU B, LIU Y H, et al. Influence of reciprocating distance on the delamination wear of the carbon strip in pantograph–catenary system at high sliding-speed with strong electrical current[J]. Engineering Failure Analysis, 2019, 104: 887-897. doi: 10.1016/j.engfailanal.2019.06.060 [56] 胡艳,黄盼盼,马然. 滑动速度对碳滑板载流摩擦磨损性能的影响[J]. 实验技术与管理,2020,37(1): 87-90.HU Yan, HUANG Panpan, MA Ran. Effect of sliding speed on current carrying friction and wear properties of carbon sliding plate[J]. Experimental Technology and Management, 2020, 37(1): 87-90. [57] 李克敏,上官宝,杜三明,等. 摩擦速度和电流密度对铜基复合材料载流摩擦磨损性能的影响[J]. 机械工程材料,2015,39(3): 22-27,31.LI Kemin, SHANGGUAN Bao, DU Sanming, et al. Effects of friction velocity and current density on current-carrying friction and wear properties of copper matrix composites[J]. Materials for Mechanical Engineering, 2015, 39(3): 22-27,31. [58] 杨正海,上官宝,孙乐民,等. 相对滑动速度对铜-石墨复合材料载流摩擦性能的影响[J]. 河南科技大学学报(自然科学版),2021,42(1): 1-6,117.YANG Zhenghai, SHANGGUAN Bao, SUN Lemin, et al. Effect of relative slipping speed on current-carrying friction performance of copper graphite composites[J]. Journal of Henan University of Science and Technology (Natural Science), 2021, 42(1): 1-6,117. [59] YANG H J, CHEN G X, GAO G Q , et al. Experimental research on the friction and wear properties of a contact strip of a pantograph- catenary system at the sliding speed of 350 km/h with electric current[J]. Wear, 2015, 332- 333: 949- 955. [60] 陈忠华,王铁军,回立川,等. 弓网系统滑动电接触最优压力载荷的确定[J]. 电工技术学报,2013,28(6): 86-92.CHEN Zhonghua, WANG Tiejun, HUI Lichuan, et al. Determination of the optimal contact load in pantograph-catenary system[J]. Transactions of China Electrotechnical Society, 2013, 28(6):86-92. [61] 陈忠华,孙国军,回立川,等. 波动压力载荷下弓网滑动电接触特性研究[J]. 高压电器,2018,54(12): 82-88.CHEN Zhonghua, SUN Guojun, HUI Lichuan, et al. Study on characteristics of sliding electrical contact of pantograph-catenary under fluctuating pressure load[J]. High Voltage Apparatus, 2018, 54(12): 82-88. [62] 李斌,隋意,王智勇,等. 弓网系统滑板磨损特性分析与剩余寿命预测[J]. 辽宁工程技术大学学报(自然科学版),2021,40(5): 454-459.LI Bin, SUI Yi, WANG Zhiyong, et al. Wear characteristics analysis and residual life prediction of pantograph-catenary system slide plate[J]. Journal of Liaoning Technical University (Natural Science), 2021, 40(5): 454-459. [63] 胡艳,董丙杰,周培勇,等. 滑板磨损量和弓网放电能量预测模型的研究及应用[J]. 润滑与密封,2015,40(8): 66-70.HU Yan, DONG Bingjie, ZHOU Peiyong, et al. Study and application of the prediction formula of arc discharge energy and wear volume of pantograph-OCS system[J]. Lubrication Engineering, 2015, 40(8): 66-70. [64] 胡道春,孙乐民,上官宝,等. 电弧能量对浸金属碳滑板材料载流摩擦磨损性能的影响[J]. 摩擦学学报,2009,29(1): 36-42.HU Daochun, SUN Lemin, SHANGGUAN Bao, et al. Effects of arc discharge on friction and wear properties of metal-impregnated carbon strip sliding against Cu trolley under electric current[J]. Tribology, 2009, 29(1): 36-42. [65] MEI G M. Tribological performance of rigid overhead lines against pantograph sliders under DC passage[J]. Tribology International, 2020, 151: 106538.1-106538.9. doi: 10.1016/j.triboint.2020.106538 [66] KUBO S, KATO K. Effect of arc discharge on wear rate of Cu-impregnated carbon strip in unlubricated sliding against Cu trolley under electric current[J]. Wear, 1998, 216(2): 172-178. doi: 10.1016/S0043-1648(97)00184-1 [67] CHEN G X, YANG H J, ZHANG W H, et al. Experimental study on arc ablation occurring in a contact strip rubbing against a contact wire with electrical current[J]. Tribology International, 2013, 61: 88-94. doi: 10.1016/j.triboint.2012.11.020 [68] 王英. 弓网电接触热流和电流传导及影响规律研究[D]. 成都:西南交通大学,2016. [69] BOUCHOUCHA A, KADIRI E K, ROBERT F, et al. Metals transfer and oxidation of copper—steel surfaces in electrical sliding contact[J]. Surface and Coatings Technology, 1995, 76/77: 521-527. [70] BOUCHOUCHA A, CHEKROUD S, PAULMIER D. Influence of the electrical sliding speed on friction and wear processes in an electrical contact copper–stainless steel[J]. Applied Surface Science, 2004, 223(4): 330-342. doi: 10.1016/j.apsusc.2003.09.018 [71] 卜俊,丁涛,陈光雄. 温度对受电弓滑板材料磨损的影响[J]. 润滑与密封,2010,35(5): 22-25,105.BU Jun, DING Tao, CHEN Guangxiong. Effect of temperature on the wear behaviour of a pantograph strip material[J]. Lubrication Engineering, 2010, 35(5): 22-25,105. [72] MEI G M, FU W M, CHEN G X, et al. Effect of high-density current on the wear of carbon sliders against Cu–Ag wires[J]. Wear, 2020, 452/453: 203275.1-203275.7. doi: 10.1016/j.wear.2020.203275 [73] 黄海,武云龙,闫硕,等. 电压对碳滑板磨损性能和温升的影响[J]. 润滑与密封,2017,42(8): 25-30.HUANG Hai, WU Yunlong, YAN Shuo, et al. Effect of voltage on wear behavior and temperature rise of a pantograph carbon strip[J]. Lubrication Engineering, 2017, 42(8): 25-30. [74] 付文明,武云龙,刘力,等. 大电流对碳滑块/铜银合金接触线载流摩擦磨损性能的影响[J]. 润滑与密封,2017,42(9): 52-56.FU Wenming, WU Yunlong, LIU Li, et al. Effect of high-current on friction and wear behavior of carbon strip/Cu-Ag alloy contact wire with electric current[J]. Lubrication Engineering, 2017, 42(9): 52-56. [75] DING T, CHEN G X, LI Y M, et al. Friction and wear behavior of pantograph strips sliding against copper contact wire with electric current[J]. AASRI Procedia, 2012, 2: 288-292. doi: 10.1016/j.aasri.2012.09.048 [76] LU C T, BRYANT M D. Thermoelastic evolution of contact area and mound temperatures in carbon graphite electrical contact brushes[J]. Wear, 1994, 174: 137-146. doi: 10.1016/0043-1648(94)90095-7 [77] TU C J, CHEN Z H, CHEN D, et al. Tribhological behavior and wear mechanism of resin-matrix contact strip against copper with electrical current[J]. Transactions of Nonferrous Metals society of China, 2008, 18: 1157-1163. doi: 10.1016/S1003-6326(08)60198-3 [78] DING T, CHEN G X, ZHU M H, et al. Influence of the spring stiffness on friction and wear behaviours of stainless steel/copper impregnated metallized carbon couple with electrical current[J]. Wear, 2009, 267: 1080-1086. doi: 10.1016/j.wear.2008.12.098 [79] 丁涛,王鑫,陈光雄,等. 有无电流条件下温度对碳/铜摩擦副摩擦磨损性能的影响[J]. 中国机械工程,2010(7): 843-847.Ding Tao, Wang Xin, et al. Effect of Temperature on Friction and Wear Behaviors of Carbon/Copperwith and without Electric Current[J]. China Mechanical Engineering,2010(7):843-847. [80] DING T, HE Q D, YANG Y, et al. High temperature characteristics of a carbon strip sliding against copper with electrical current[J]. Materials Performance and Characterization, 2018, 7(1): 101-112. doi: 10.1520/MPC20170087 [81] 丁涛,王鑫,陈光雄,等. 120~170 km/h条件下碳滑板/铜接触线摩擦磨损性能试验研究[J]. 机械工程学报,2010,46(16): 36-40. doi: 10.3901/JME.2010.16.036DING Tao, WANG Xin, CHEN Guangxiong, et al. Experimental study on friction and wear behavior of carbon strip/copper contact wire at speeds of 120~170 km/h[J]. Journal of Mechanical Engineering, 2010, 46(16): 36-40. doi: 10.3901/JME.2010.16.036 [82] 张会杰,孙乐民,张永振,等. 环境气氛对C/C复合材料载流摩擦学性能的影响[J]. 摩擦学学报,2015,35(2): 236-241.ZHANG Huijie, SUN Lemin, ZHANG Yongzhen, et al. The influence of environmental atmosphere on the tribological performance of C/C composites under electrical current[J]. Tribology, 2015, 35(2): 236-241. [83] DEROSA S, NÅVIK P, COLLINA A, et al. Contact point lateral speed effects on contact strip wear in pantograph–catenary interaction for railway operations under 15 kV 16.67 Hz AC systems[J]. Wear, 2021, 486/487: 204103.1-204103.9. doi: 10.1016/j.wear.2021.204103 [84] 卿涛,邵天敏,温诗铸. 相对湿度对材料表面粘附力影响的研究[J]. 摩擦学学报,2006,26(4): 295-299.QING Tao, SHAO Tianmin, WEN Shizhu. Effects of relative humidity on surface adhesion[J]. Tribology, 2006, 26(4): 295-299. [85] 卿涛,邵天敏,温诗铸. 载荷和相对湿度对微摩擦力的影响[J]. 润滑与密封,2006,31(10): 4-7,32.QING Tao, SHAO Tianmin, WEN Shizhu. Effects of load and relative humidity on micro-friction[J]. Lubrication Engineering, 2006, 31(10): 4-7,32. [86] 王蒙,郭凤仪,王智勇,等. 潮湿条件下滑板磨耗特性研究[J]. 高压电器,2018,54(7): 292-296.WANG Meng, GUO Fengyi, WANG Zhiyong, et al. Study on the wear characteristics of slide plate under wet conditions[J]. High Voltage Apparatus, 2018, 54(7): 292-296. [87] 孙逸翔,宋晨飞,李家伟,等. 转速对水环境下纯铜滚动载流摩擦损伤的影响[J]. 摩擦学学报,2021,41(3): 365-372.SUN Yixiang, SONG Chenfei, LI Jiawei, et al. Effect of rotating speed on surface damage of rolling current-carrying pairs in a water environment[J]. Tribology, 2021, 41(3): 365-372. [88] 孙逸翔,岳洋,宋晨飞,等. 相对湿度对铜材料载流磨损的影响[J]. 河南科技大学学报(自然科学版),2018,39(1): 1-4,117.SUN Yixiang, YUE Yang, SONG Chenfei, et al. Effect of relative humidity on triboelectric wear of copper[J]. Journal of Henan University of Science and Technology (Natural Science), 2018, 39(1): 1-4,117. [89] 李含欣,季德惠,沈明学,等. 环境湿度对碳/铜滑动接触副载流摩擦学行为的影响[J]. 摩擦学学报,2022,42(4): 709-718.LI Hanxin, JI Dehui, SHEN Mingxue, et al. Effect of environmental humidity on tribological behavior of carbon/copper current-carrying sliding contact pairs[J]. Tribology, 2022, 42(4): 709-718. [90] DEROSA S, NÅVIK P, COLLINA A, et al. A heuristic wear model for the contact strip and contact wire in pantograph–Catenary interaction for railway operations under 15 kV 16.67 Hz AC systems[J]. Wear, 2020, 456/457: 203401.1-20340.8. doi: 10.1016/j.wear.2020.203401 [91] ASHBY M F, LIM S C. Wear-mechanism maps[J]. Scripta Metallurgica et Materialia,1990,24(5):805-810. [92] WEI X K, MENG H F, HE J H, et al. Wear analysis and prediction of rigid catenary contact wire and pantograph strip for railway system[J]. Wear, 2020, 442/443: 203118.1-203118.15. doi: 10.1016/j.wear.2019.203118 [93] 徐文文,彭建平,邱春蓉. 基于支持向量回归的地铁受电弓滑板磨耗趋势预测模型研究[J]. 铁路计算机应用,2020,29(1): 77-81.XU Wenwen, PENG Jianping, QIU Chunrong. Prediction model of subway pantograph slide pan wear trend based on LSSVR[J]. Railway Computer Application, 2020, 29(1): 77-81. [94] 胡艳,杨红娟,董丙杰,等. 基于最小二乘法的纯碳滑板磨损量预测[J]. 铁道学报,2016,38(1): 48-53.HU Yan, YANG Hongjuan, DONG Bingjie, et al. The prediction of the wear loss of strips based on the partial least-square regression method[J]. Journal of the China Railway Society, 2016, 38(1): 48-53. -

下载:

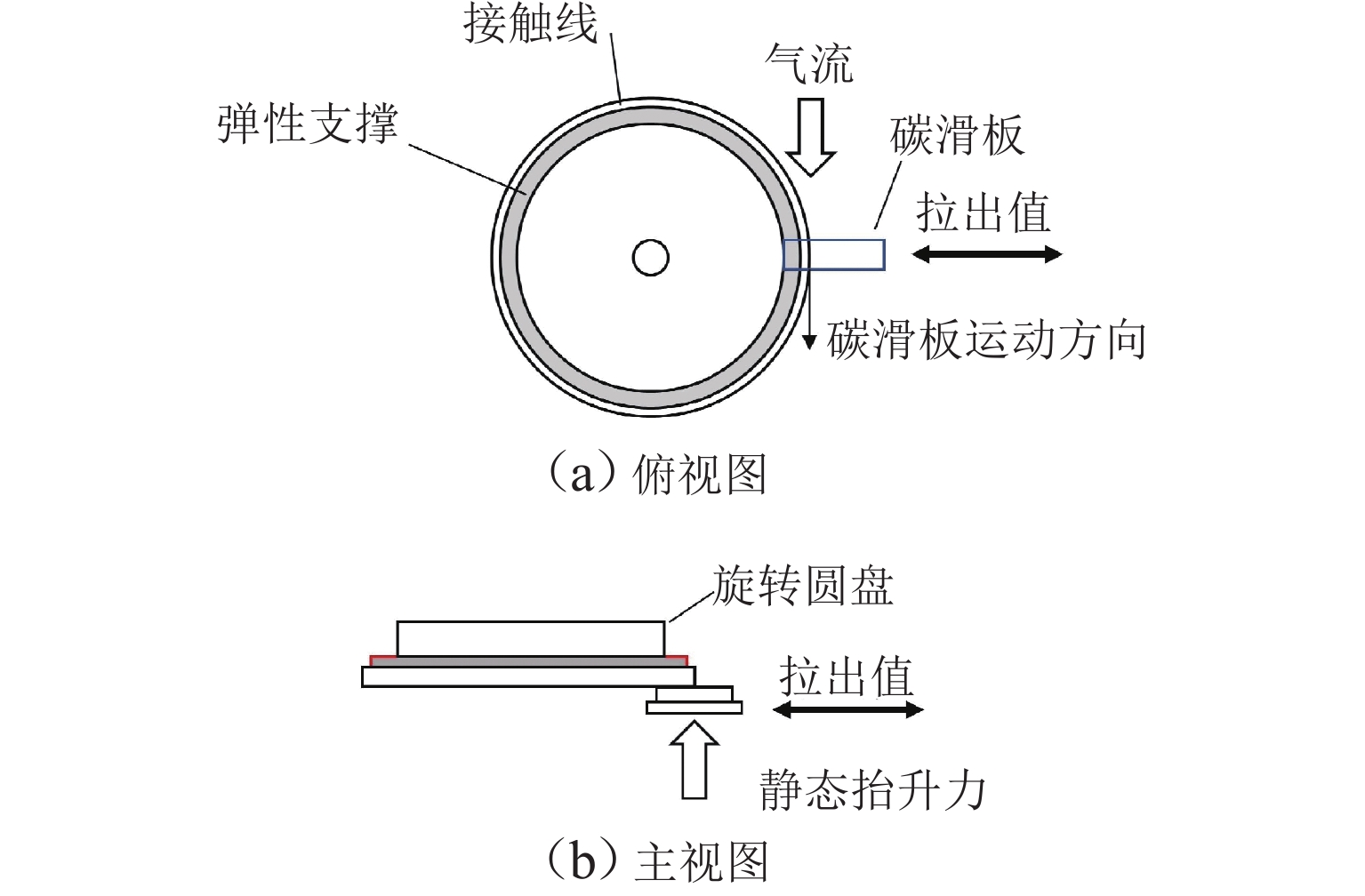

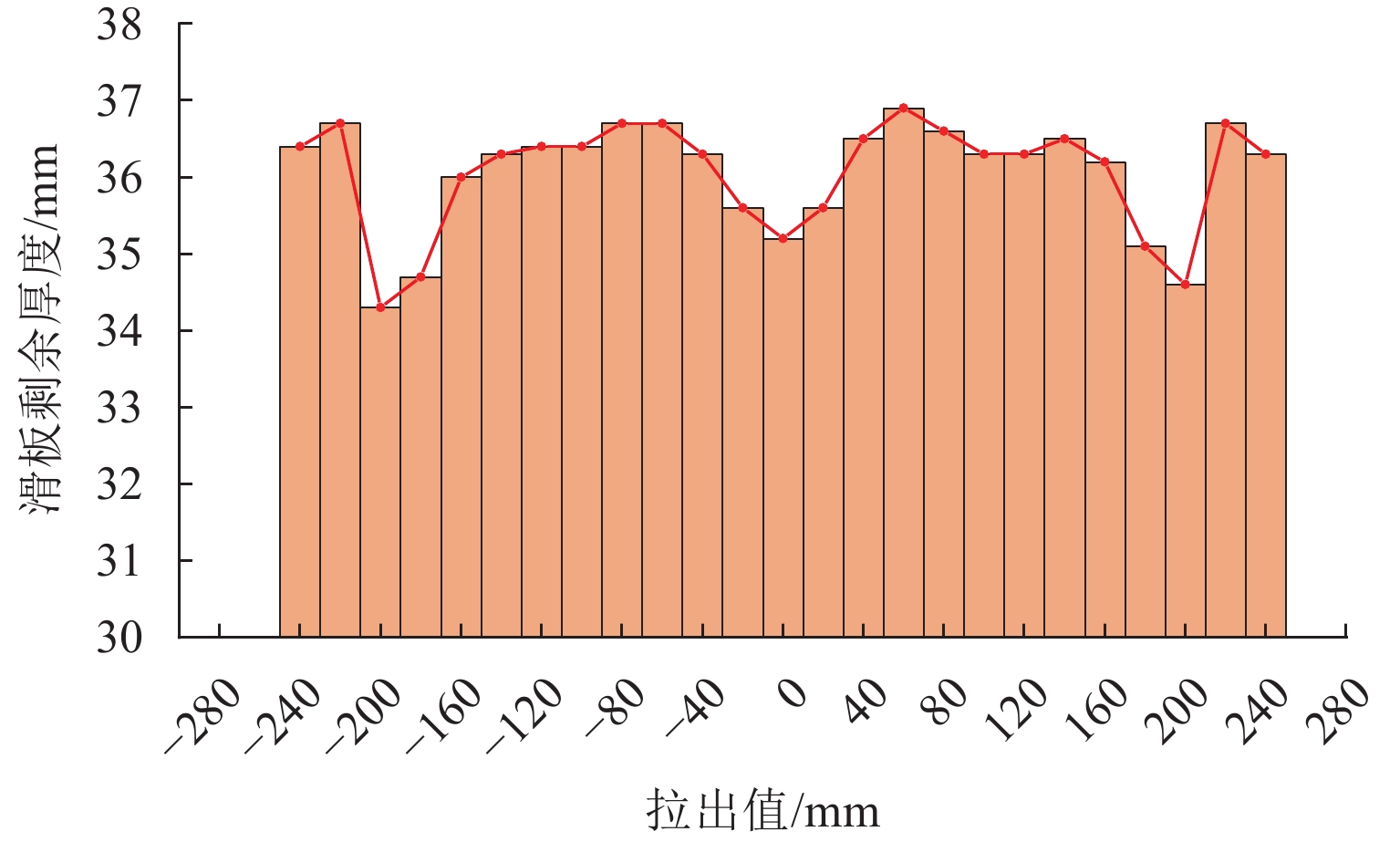

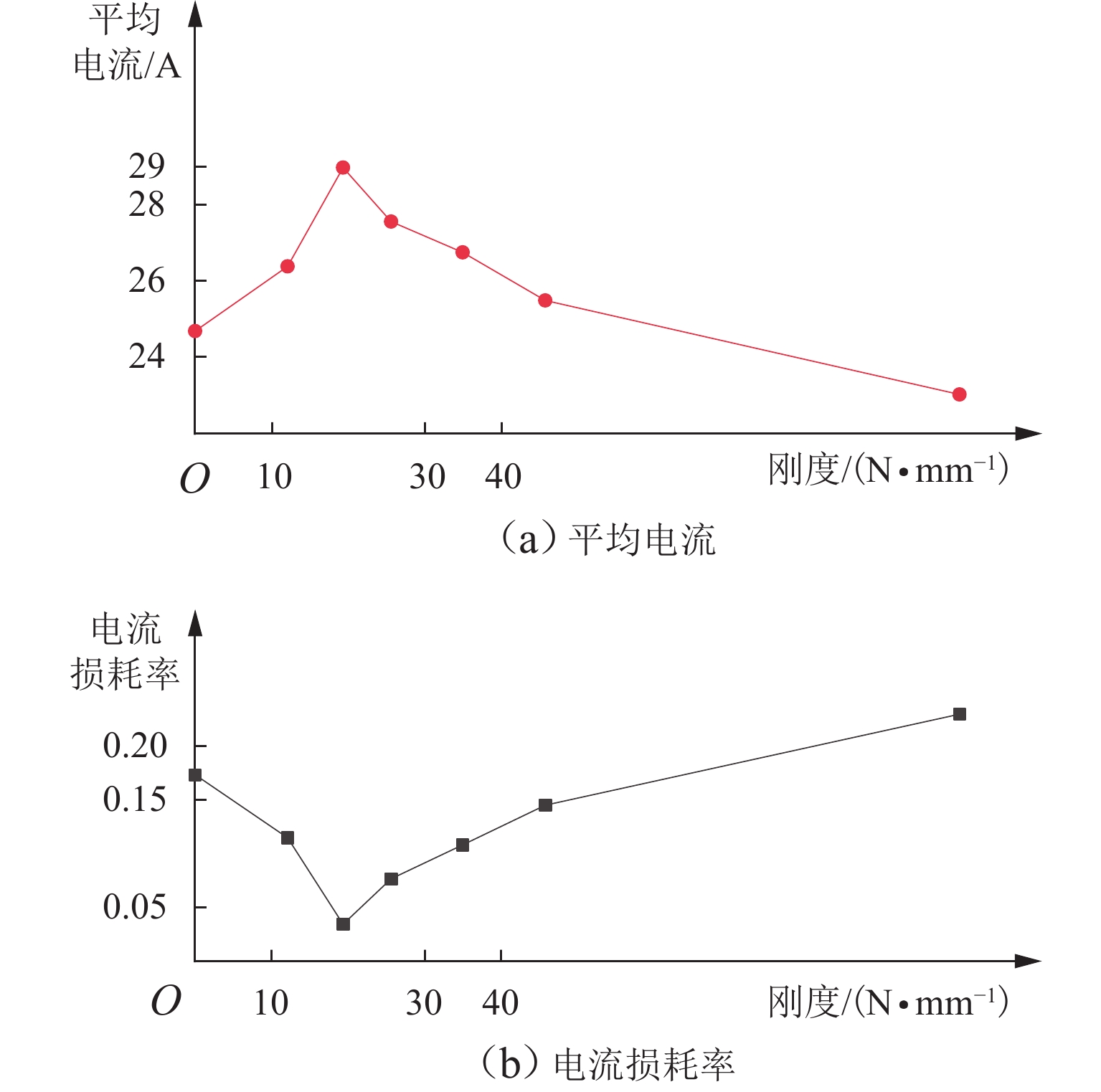

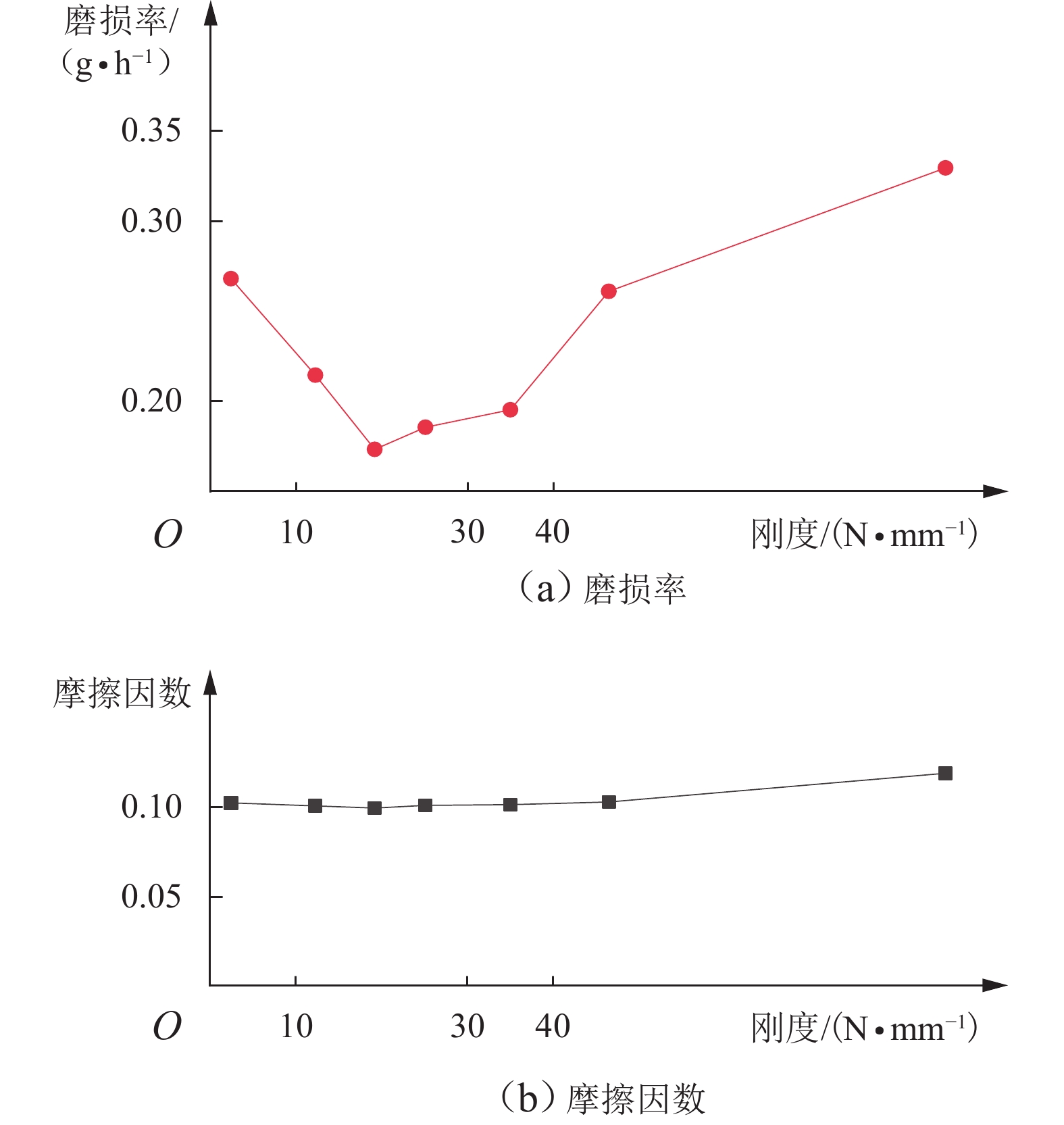

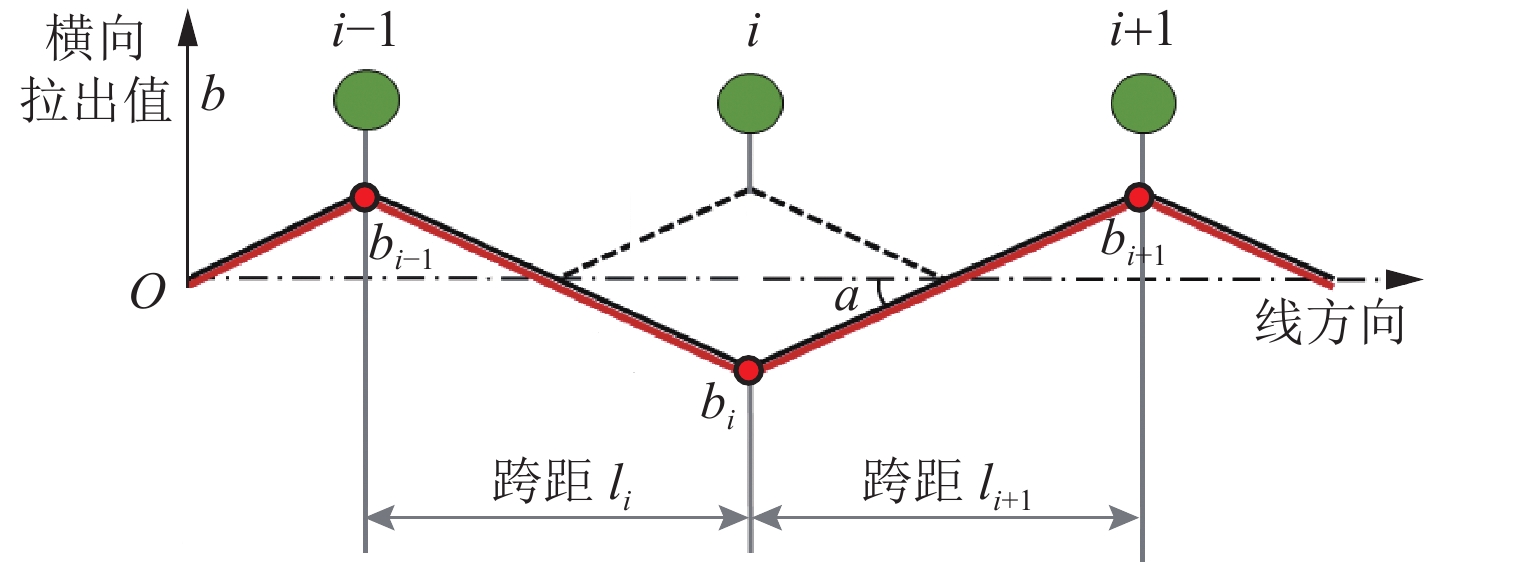

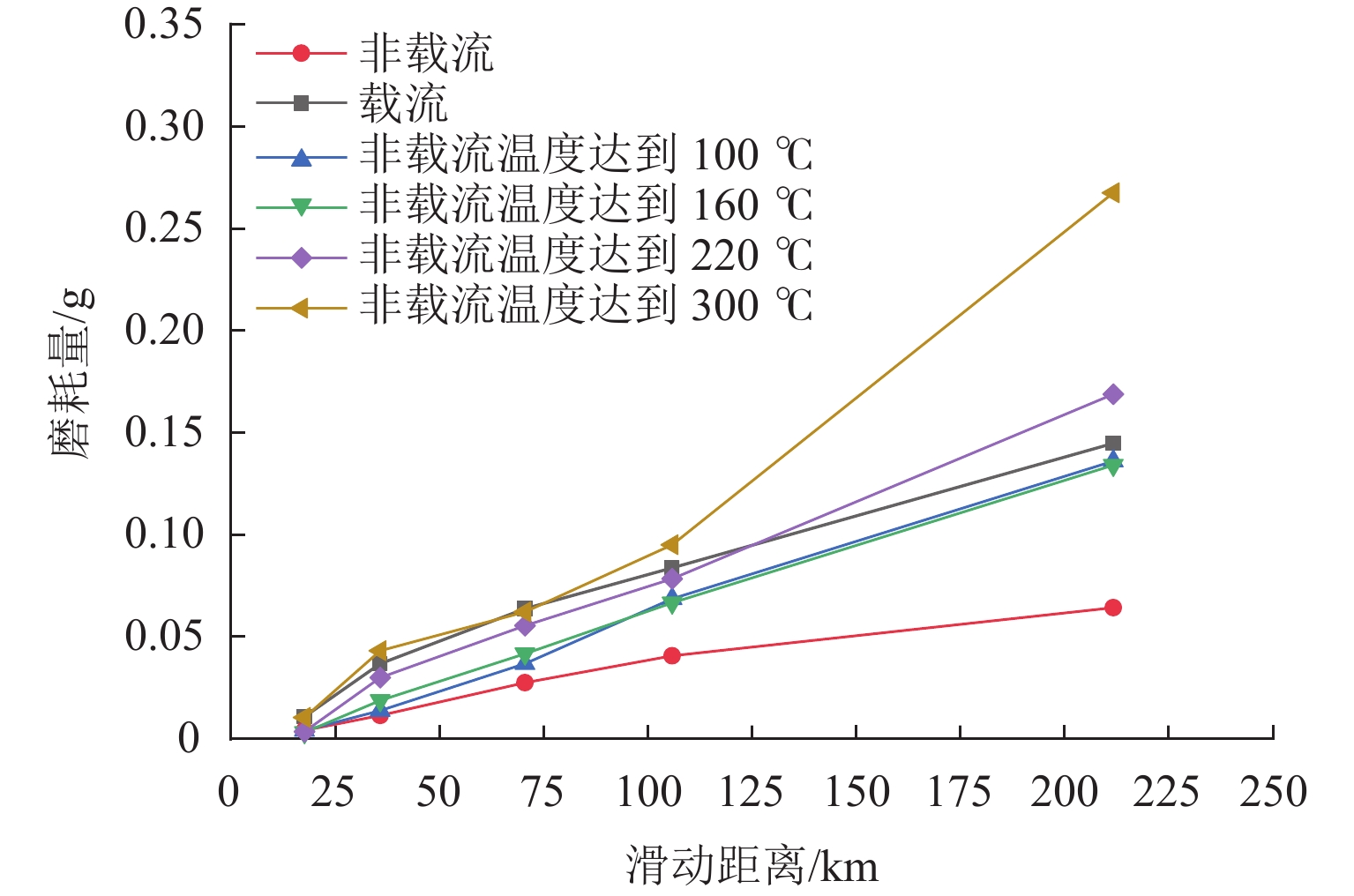

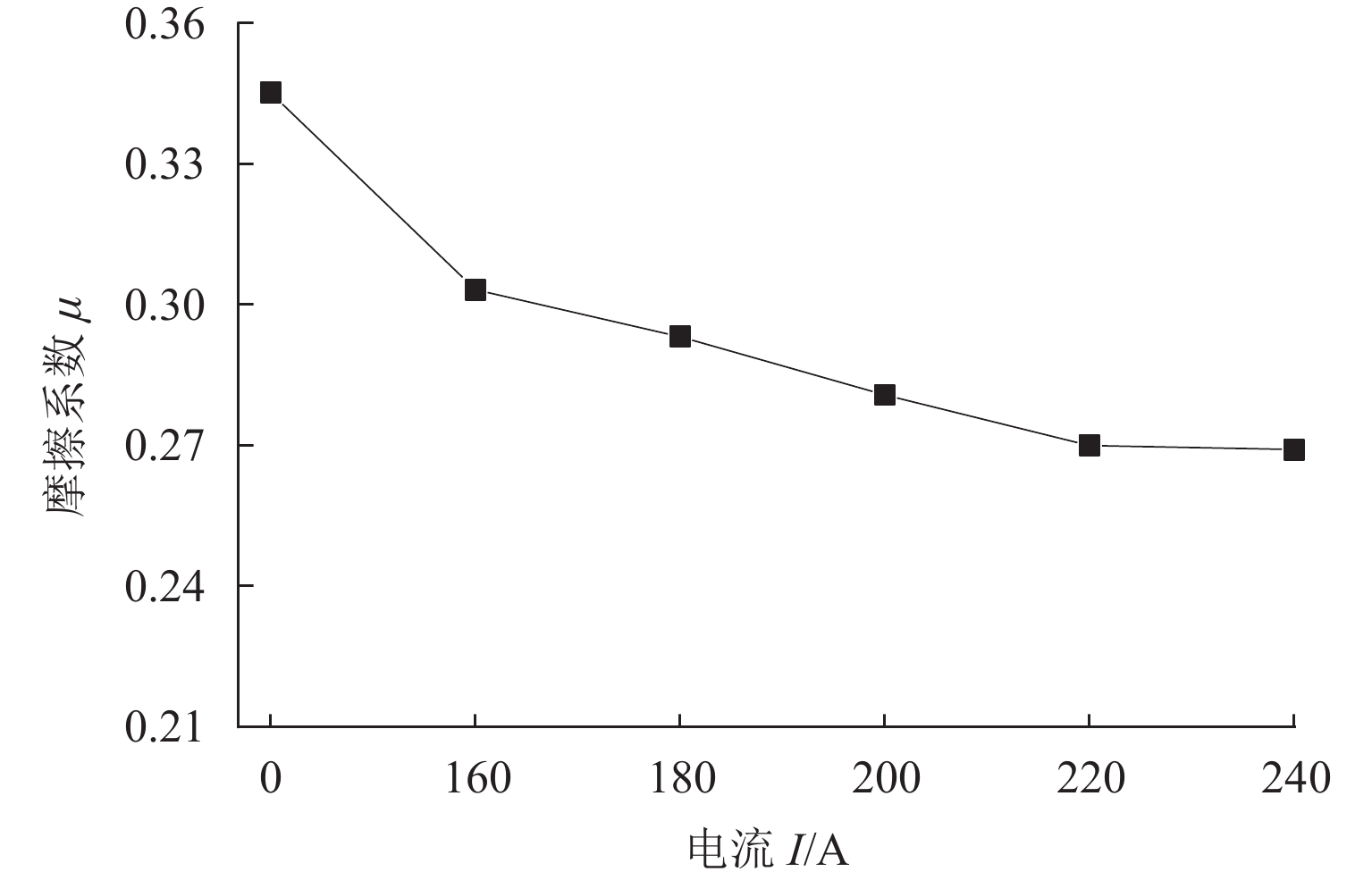

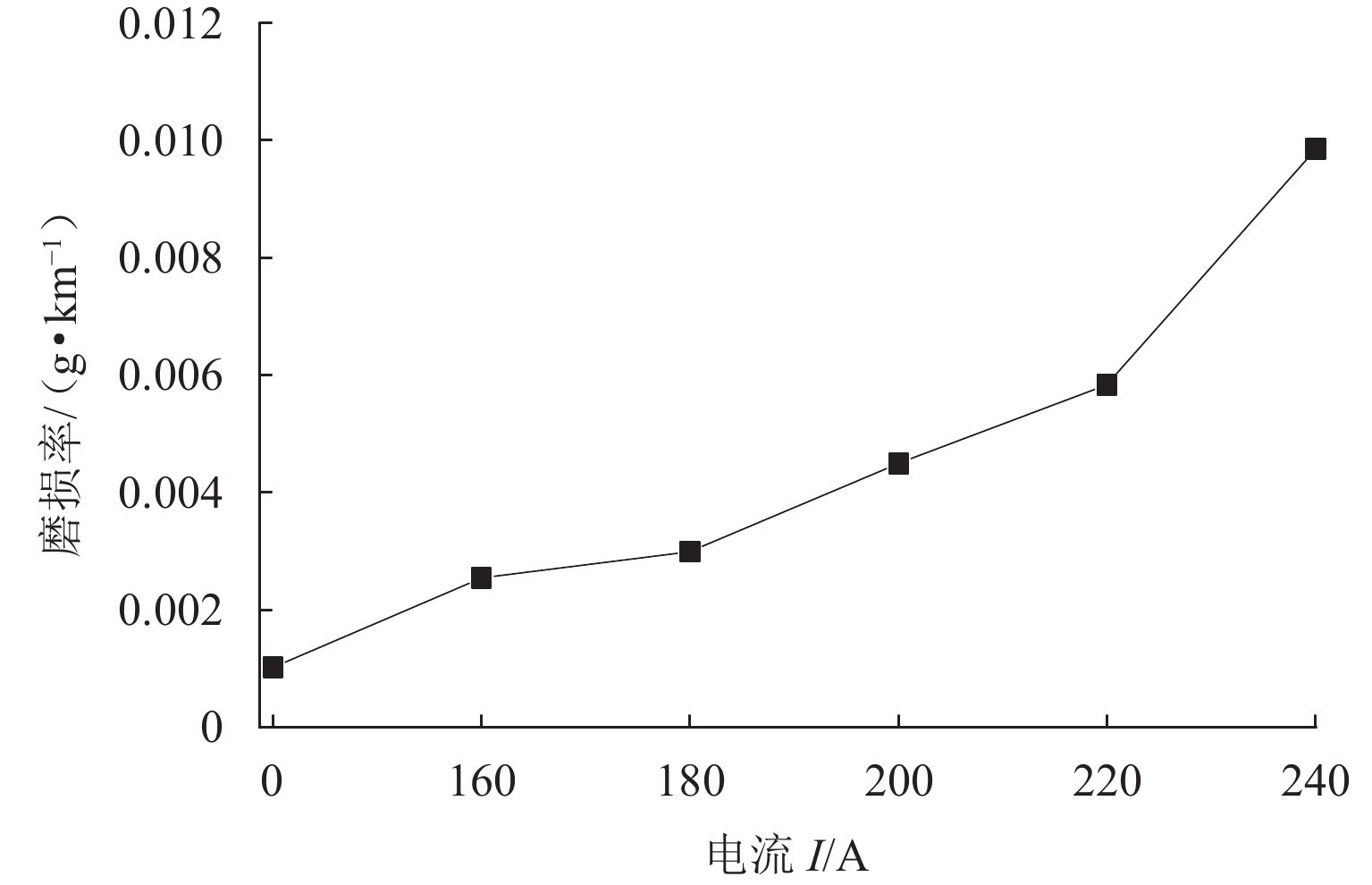

下载: