Durability Analysis of High-Performance Concrete Under Chloride Salt Erosion and Freeze-Thaw Cycles

-

摘要:

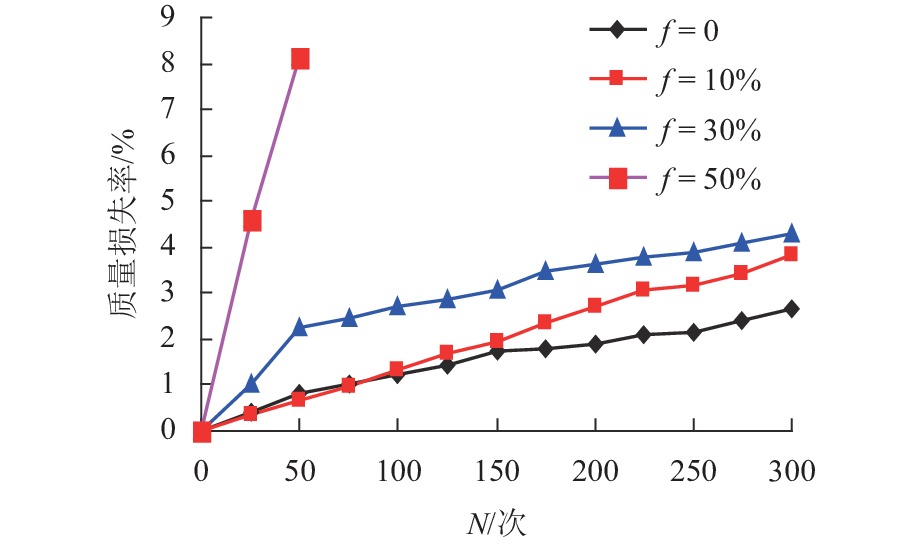

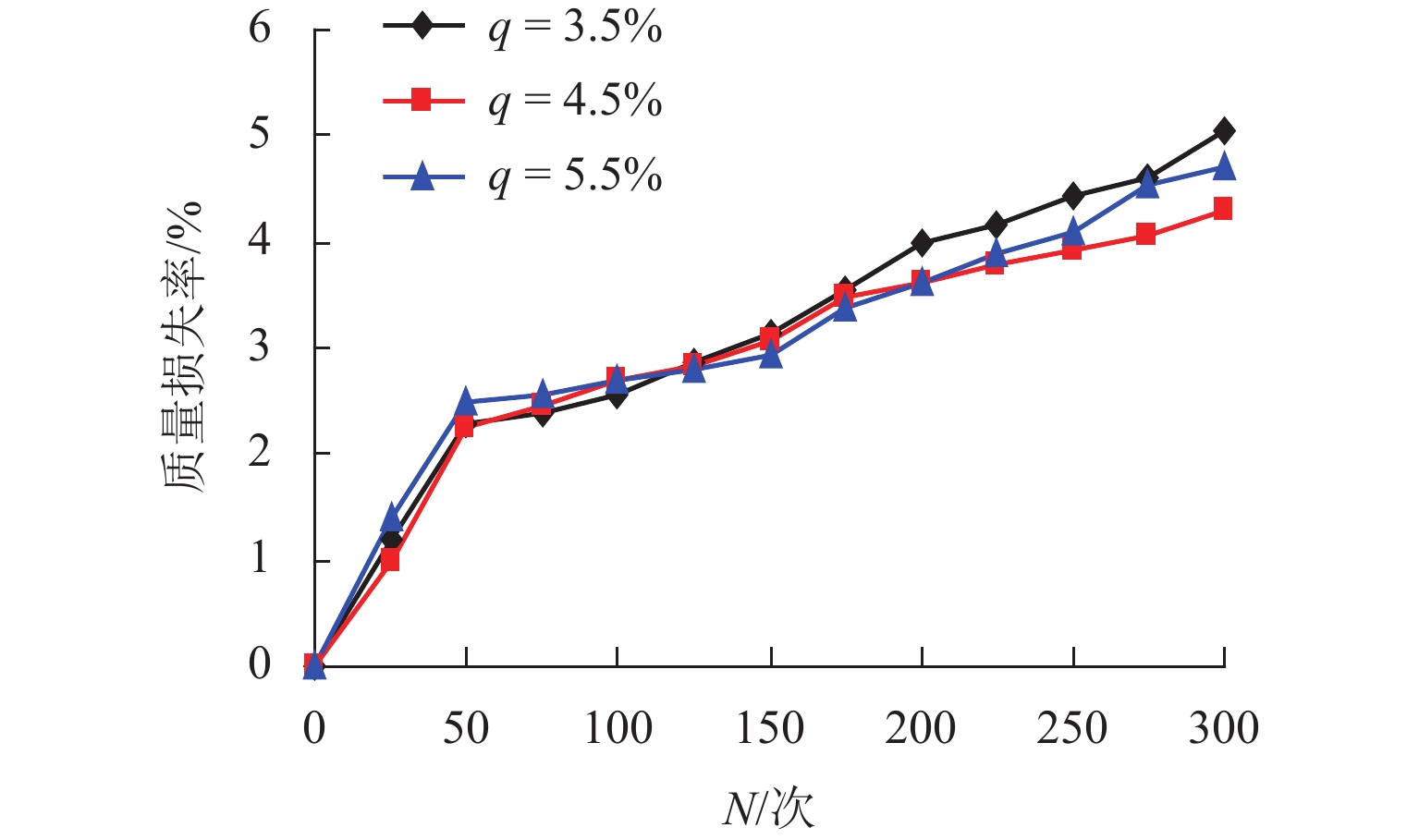

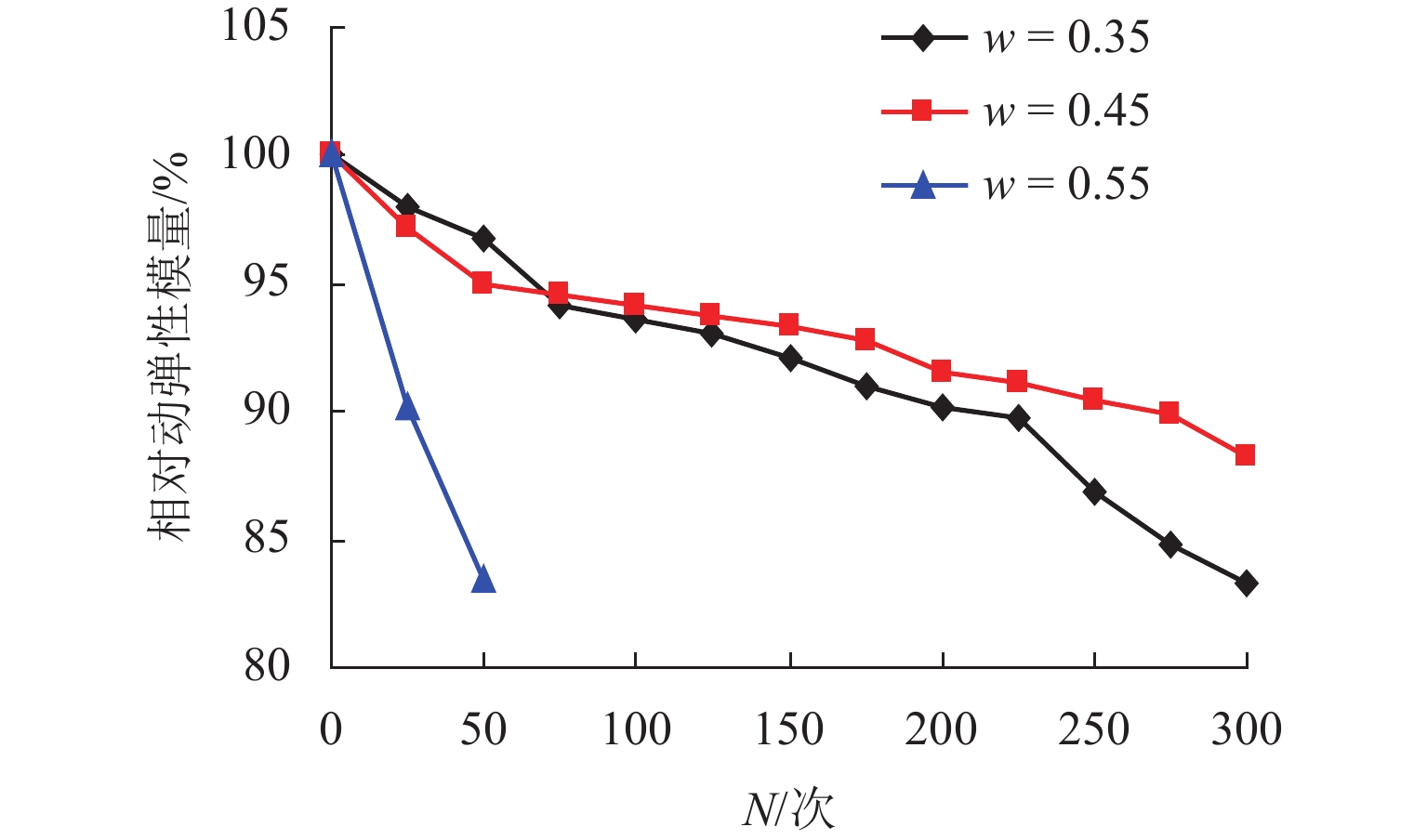

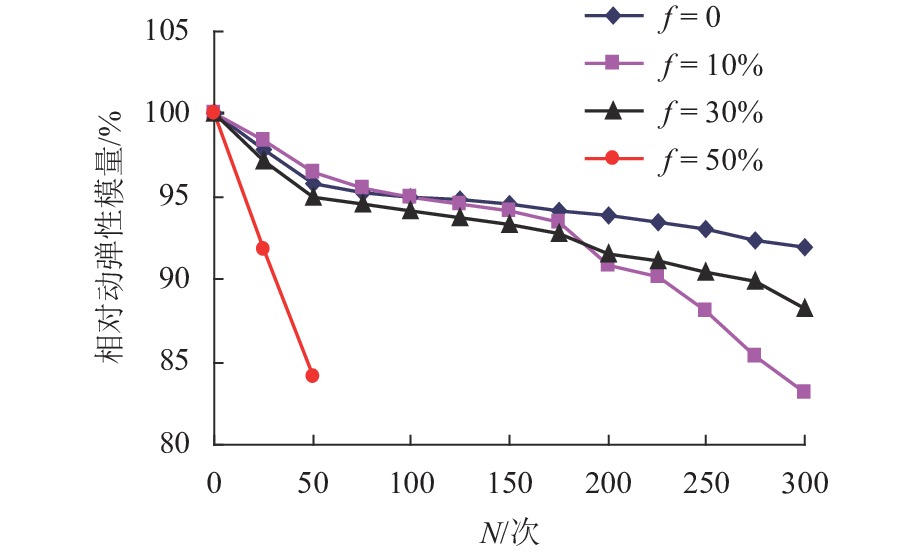

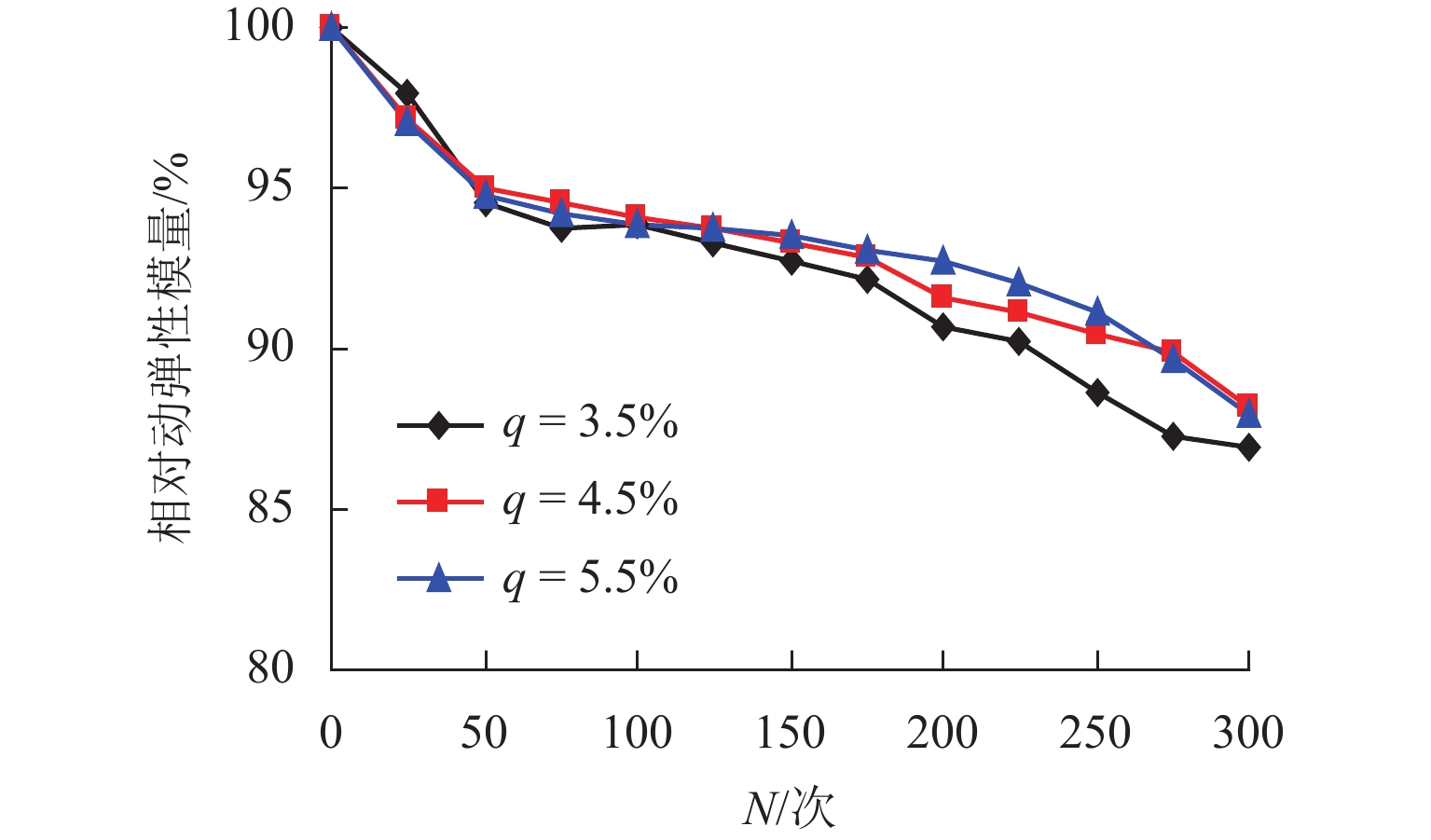

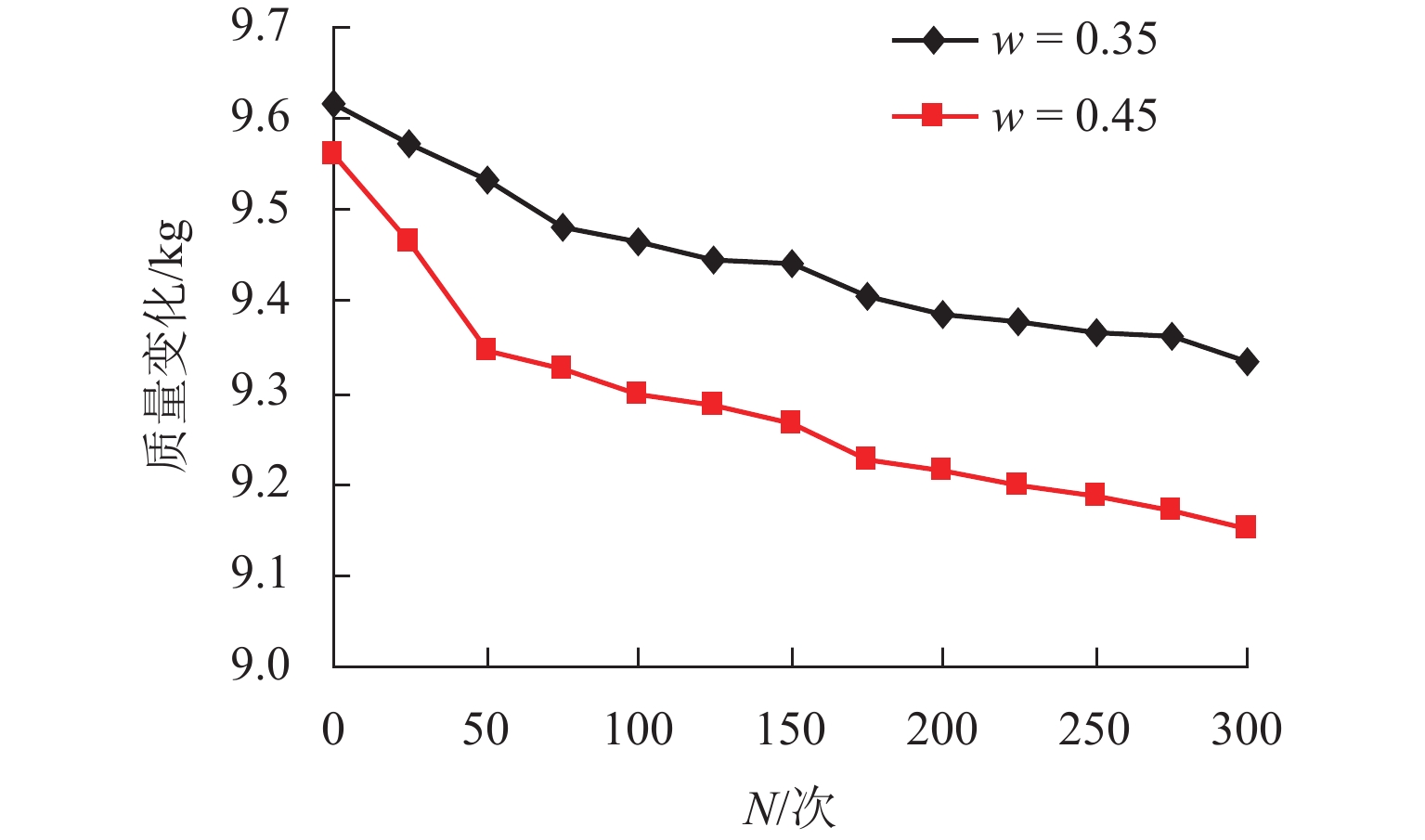

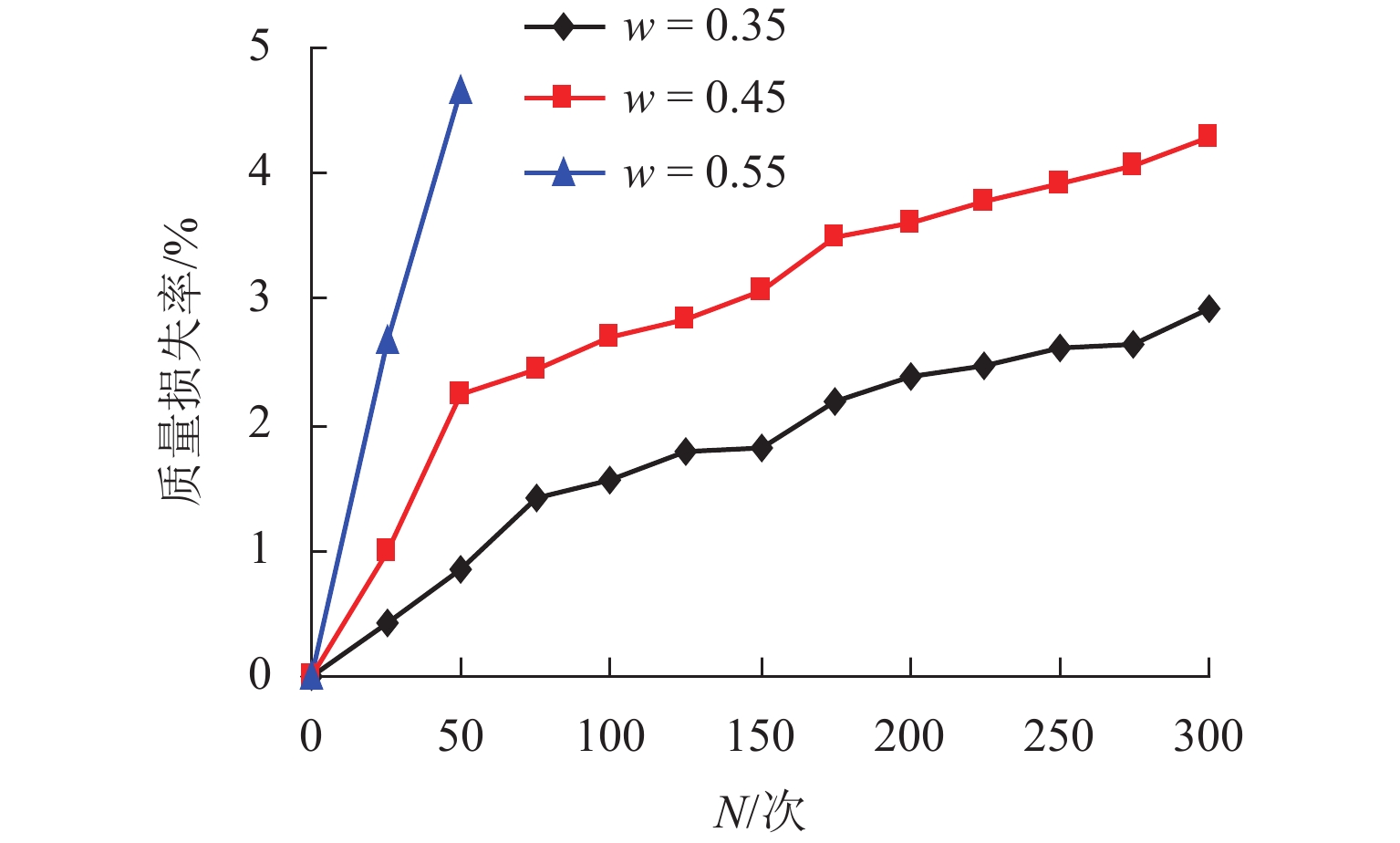

为研究海洋环境下高性能混凝土桥梁的耐久性,基于混凝土室内快速冻融试验,对高性能混凝土进行氯盐侵蚀与冻融循环耦合作用下的耐久性试验,分析混凝土在不同水胶比、粉煤灰掺量和含气量时的质量损失率和相对动弹性模量;并根据试验分析结果建立氯盐侵蚀与冻融循环耦合作用下的高性能混凝土质量预测衰减模型. 结果表明:水胶比对高性能混凝土的抗盐冻性能影响显著,混凝土抗盐冻性能随着水胶比增大而降低,建议水胶比不宜大于0.45;粉煤灰的加入会降低混凝土的抗盐冻性能,掺量较高时其抗盐冻性能难以达到满足要求,粉煤灰掺量不宜高于30%;随着含气量增加,混凝土抗盐冻性能呈现先提升后降低的变化规律,建议有考虑抗盐冻要求的混凝土其含气量在4.5%~5.5%内选取.

Abstract:In order to study the durability of high-performance concrete (HPC) bridges in the marine environment, based on the rapid indoor freeze-thaw test of concrete, the durability of HPC under the coupled action of chloride salt erosion and freeze-thaw cycles was tested, and the mass loss rate and relative dynamic elastic modulus of concrete under different water-binder ratios, fly ash contents, and air contents were analyzed. According to the test analysis results, a quality prediction attenuation model of HPC under the coupled action of chloride salt erosion and freeze-thaw cycles was established. The results show that the water-binder ratio has a great influence on the salt-freezing resistance of HPC. The salt-freezing resistance of concrete decreases with the increase in the water-binder ratio, and it is suggested that the water-binder ratio should not be greater than 0.45; the addition of fly ash will reduce the salt-freezing resistance of concrete, and the salt-freezing resistance can hardly meet the requirements when the fly ash content is high. Therefore, the fly ash content should not be higher than 30%; as air content increases, the salt-freezing resistance of concrete first increases and then decreases. The air content of concrete considering the salt-freezing resistance requirements is recommended to be selected within the range of 4.5%–5.5%.

-

Key words:

- high-performance concrete /

- chloride salt erosion /

- freeze-thaw cycle /

- durability

-

表 1 试验混凝土配合比

Table 1. Concrete mix ratio in test

编号 影响因素 混凝土原材用量/(kg•m−3) w f/% q/% 水泥 粉煤灰 水 砂 碎石 A1 0.35 30 4.5 396 170 198 589 1047 A2 0.45 30 4.5 308 132 198 634 1128 A3 0.55 30 4.5 252 108 198 663 1179 A4 0.45 0 4.5 440 0 198 634 1128 A5 0.45 10 4.5 396 44 198 634 1128 A6 0.45 50 4.5 220 220 198 634 1128 A7 0.45 30 3.5 308 132 198 634 1128 A8 0.45 30 5.5 308 132 198 634 1128 表 2 模型验证

Table 2. Model validation

工况号 试验工况 剩余相对质量 文献[1]计算结果 本文计算结果 相对误差/% 工况 1 w = 0.42,f = 30%,q = 4.8%,N = 200 次 0.965 0.957 0.81 工况 2 w = 0.35,f = 30%,q = 4.8%,N = 250 次 0.975 0.950 2.61 工况 3 w = 0.42,f = 0%,q = 4.8%,N = 275 次 0.978 0.951 2.87 工况 4 w = 0.42,f = 10%,q = 4.8%,N = 100 次 0.990 0.969 2.07 工况 5 w = 0.42,f = 30%,q = 4.8%,N = 300 次 0.972 0.941 3.09 工况 6 w = 0.42,f = 30%,q = 5.5%,N = 250 次 0.963 0.885 8.12 工况 7 w = 0.42,f = 30%,q = 3.8%,N = 50 次 0.981 0.915 6.63 表 3 梁体试验与模型计算对比

Table 3. Comparison of beam test and model calculation

N/次 剩余相对质量 梁体试验 模型计算 相对误差/% 50 0.996 0.965 3.11 100 0.993 0.960 3.32 150 0.988 0.951 4.30 200 0.983 0.935 4.89 -

[1] 刘青. 寒冷地区海洋环境下混凝土桥梁耐久性研究[D]. 成都: 西南交通大学, 2017. [2] 张立群,穆柏林,孙婧,等. 冻融和碳化共同作用下硅灰自密实混凝土耐久性试验研究[J]. 混凝土,2019(11): 90-93.ZHANG Liqun, MU Bailin, SUN Jing, et al. Experimental study on durability of silica fume self-compacting concrete under joint action of freeze-thawing and carbonization[J]. Concrete, 2019(11): 90-93. [3] 姜文镪,刘清风. 冻融循环下混凝土中氯离子传输研究进展[J]. 硅酸盐学报,2020,48(2): 258-272.JIANG Wenqiang, LIU Qingfeng. Chloride transport in concrete subjected to freeze-thaw cycles−a short review[J]. Journal of the Chinese Ceramic Society, 2020, 48(2): 258-272. [4] 王月. 氯盐冻融循环与侵蚀作用下活性粉末混凝土的耐久性研究[D]. 北京: 北京交通大学, 2016. [5] 南雪丽,王超杰,刘金欣,等. 冻融循环和氯盐侵蚀耦合条件对聚合物快硬水泥混凝土抗冻性的影响[J]. 材料导报,2017,31(23): 177-181.NAN Xueli, WANG Chaojie, LIU Jinxin, et al. Influence of the freeze-thaw cycle and chlorine salt erosion coupling conditions on frost-resistance of polymer-modified rapid hardening concrete[J]. Materials Review, 2017, 31(23): 177-181. [6] 龙广成,杨振雄,白朝能,等. 荷载-冻融耦合作用下充填层自密实混凝土的耐久性及损伤模型[J]. 硅酸盐学报,2019,47(7): 855-864.LONG Guangcheng, YANG Zhenxiong, BAI Chaoneng, et al. Durability and damage constitutive model of filling layer self-compacting concrete subjected to coupling action of freeze-thaw cycles and load[J]. Journal of the Chinese Ceramic Society, 2019, 47(7): 855-864. [7] 郑山锁,张艺欣,裴培,等. 冻融循环作用下钢筋混凝土柱抗震性能试验研究[J]. 建筑结构学报,2020,41(6): 84-91.ZHENG Shansuo, ZHANG Yixin, PEI Pei, et al. Experimental research on seismic behavior of reinforced concrete columns subjected to freeze-thaw cycles[J]. Journal of Building Structures, 2020, 41(6): 84-91. [8] 王晨霞,刘军,曹芙波,等. 冻融-碳化耦合作用下矿渣-粉煤灰再生混凝土试验研究[J]. 建筑结构,2020,50(15): 85-90.WANG Chenxia, LIU Jun, CAO Fubo, et al. Experimental study on slag-fly ash recycled concrete under the action of freeze-thaw-carbonation coupling[J]. Building Structure, 2020, 50(15): 85-90. [9] 田立宗,逯静洲,朱孔峰,等. 冻融循环与疲劳荷载作用下混凝土损伤研究[J]. 长江科学院院报,2018,35(2): 140-144,150.TIAN Lizong, LU Jingzhou, ZHU Kongfeng, et al. Damage of concrete under freeze-thaw cycles and fatigue load[J]. Journal of Yangtze River Scientific Research Institute, 2018, 35(2): 140-144,150. [10] 王家滨,牛荻涛. 弯曲应力作用下喷射混凝土氯离子扩散研究[J]. 土木工程学报,2018,51(2): 95-102,120.WANG Jiabin, NIU Ditao. Investigation of chloride ion diffusion in shotcrete under bending loading[J]. China Civil Engineering Journal, 2018, 51(2): 95-102,120. [11] 邹洪波,罗小勇. 压应力作用下混凝土中氯离子侵蚀性能研究[J]. 中国公路学报,2017,30(4): 87-96.ZOU Hongbo, LUO Xiaoyong. Research on performance of chloride ion corrosion in concrete under compressive stress[J]. China Journal of Highway and Transport, 2017, 30(4): 87-96. [12] 任娟娟,杜威,邓世杰,等. 疲劳荷载下无砟轨道混凝土中氯离子传输研究[J]. 西南交通大学学报,2021,56(3): 510-516.REN Juanjuan, DU Wei, DENG Shijie, et al. Chloride ion transport in concrete of ballastless track under fatigue loading[J]. Journal of Southwest Jiaotong University, 2021, 56(3): 510-516. [13] 王喜彬,张进,马志鸣,等. 表面防水混凝土在冻融环境下抗氯离子侵蚀性能研究[J]. 混凝土,2016(7): 57-60.WANG Xibin, ZHANG Jin, MA Zhiming, et al. Chloride penetration behavior of surface water-proofing concrete under freeze-thaw environment[J]. Concrete, 2016(7): 57-60. [14] ALMUSALLAM A A, KHAN F M, DULAIJAN S U, et al. Effectiveness of surface coatings in improving concrete durability[J]. Cement and Concrete Composites, 2003, 25(4/5): 473-481. [15] HAO L C, LIU Y Z, XIAO J Z. Durability of recycled aggregate thermal insulation concrete under combined flexural loading and freeze-thaw cycles[J]. Construction and Building Materials, 2021, 272: 121652.1-121652.14. [16] AL-LEBBAN M F, KHAZALY A I, SHABBAR R, et al. Effect of polypropylene fibers on some mechanical properties of concrete and durability against freezing and thawing cycles[J]. Key Engineering Materials, 2021, 895: 130-138. doi: 10.4028/www.scientific.net/KEM.895.130 [17] 中华人民共和国住房和城乡建设部. 普通混凝土长期性能和耐久性能试验方法标准: GB/T 50082—2009[S]. 北京: 中国建筑工业出版社, 2009. [18] 李雁. 海洋腐蚀与冻融环境下掺合料混凝土物理力学性能及损伤机理研究[D]. 徐州: 中国矿业大学, 2015. [19] 李田, 刘西拉. 混凝土结构耐久性分析与设计[M]. 北京: 科学出版社, 1999. [20] 金祖权,陈惠苏,侯保荣,等. 引气混凝土在冻融循环过程中的氯离子渗透与孔结构[J]. 中南大学学报(自然科学版),2012,43(5): 1963-1968.JIN Zuquan, CHEN Huisu, HOU Baorong, et al. Chloride penetration and pore structure of air entrained concrete subjected to freeze-thaw cycles[J]. Journal of Central South University (Science and Technology), 2012, 43(5): 1963-1968. [21] 中华人民共和国住房和城乡建设部. 混凝土结构耐久性设计标准: GB/T 50476—2019[S]. 北京: 中国建筑工业出版社, 2019. -

下载:

下载: