Scale Effect of Aerodynamic Characteristics in Evacuated Tube Maglev Transport

-

摘要:

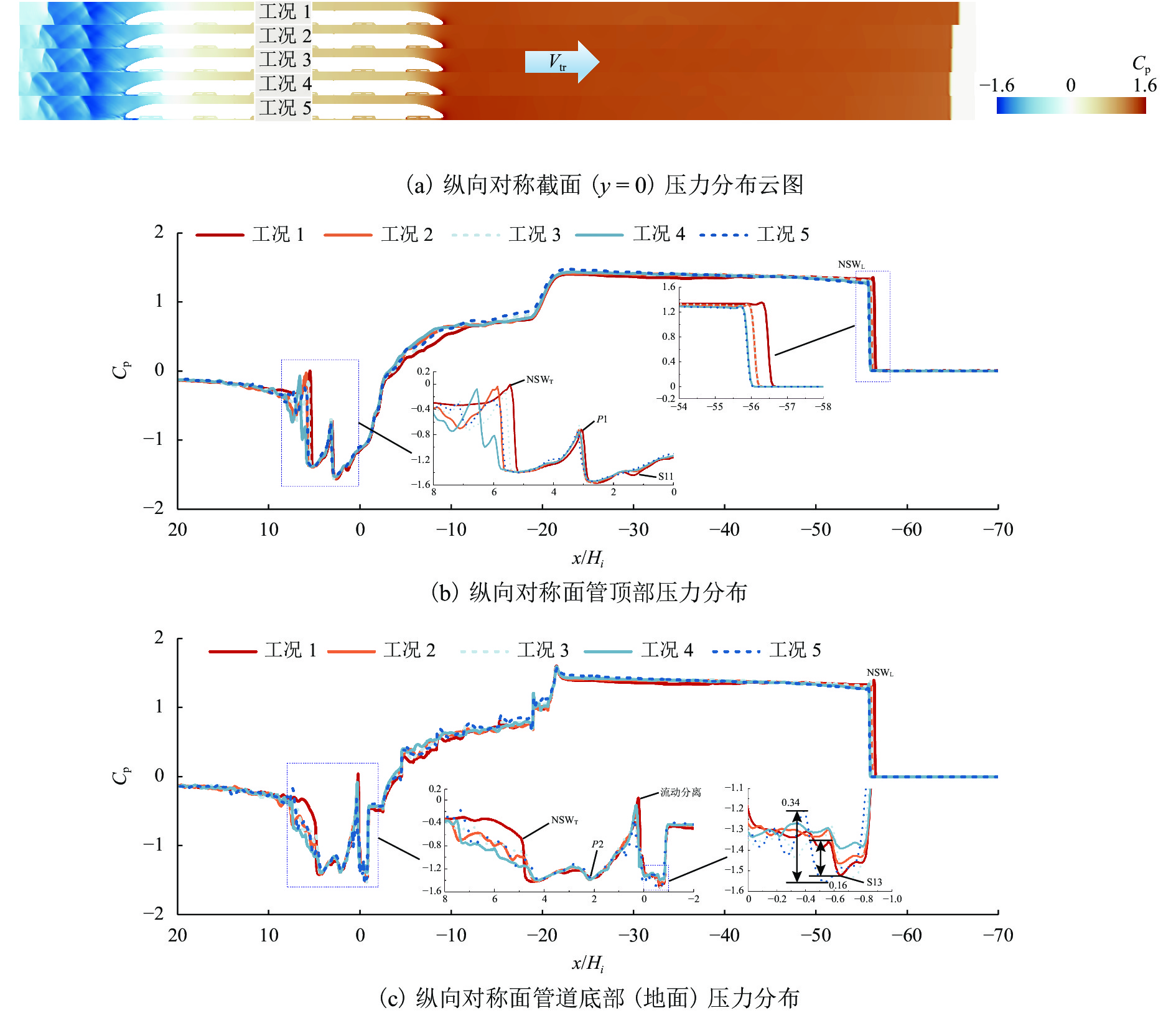

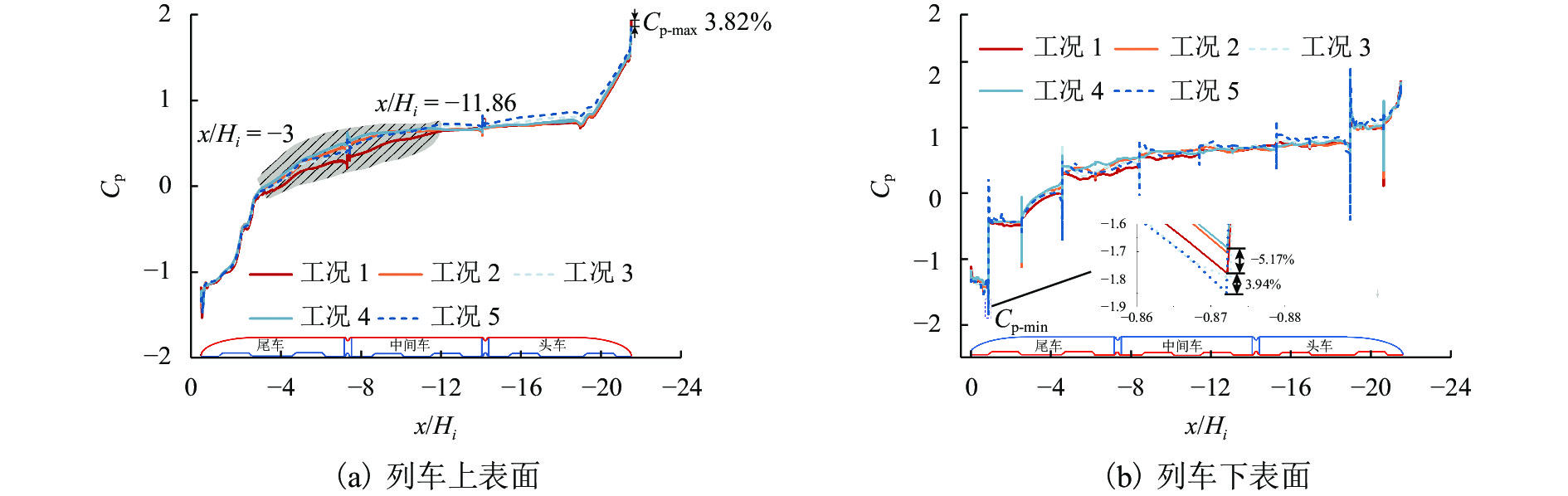

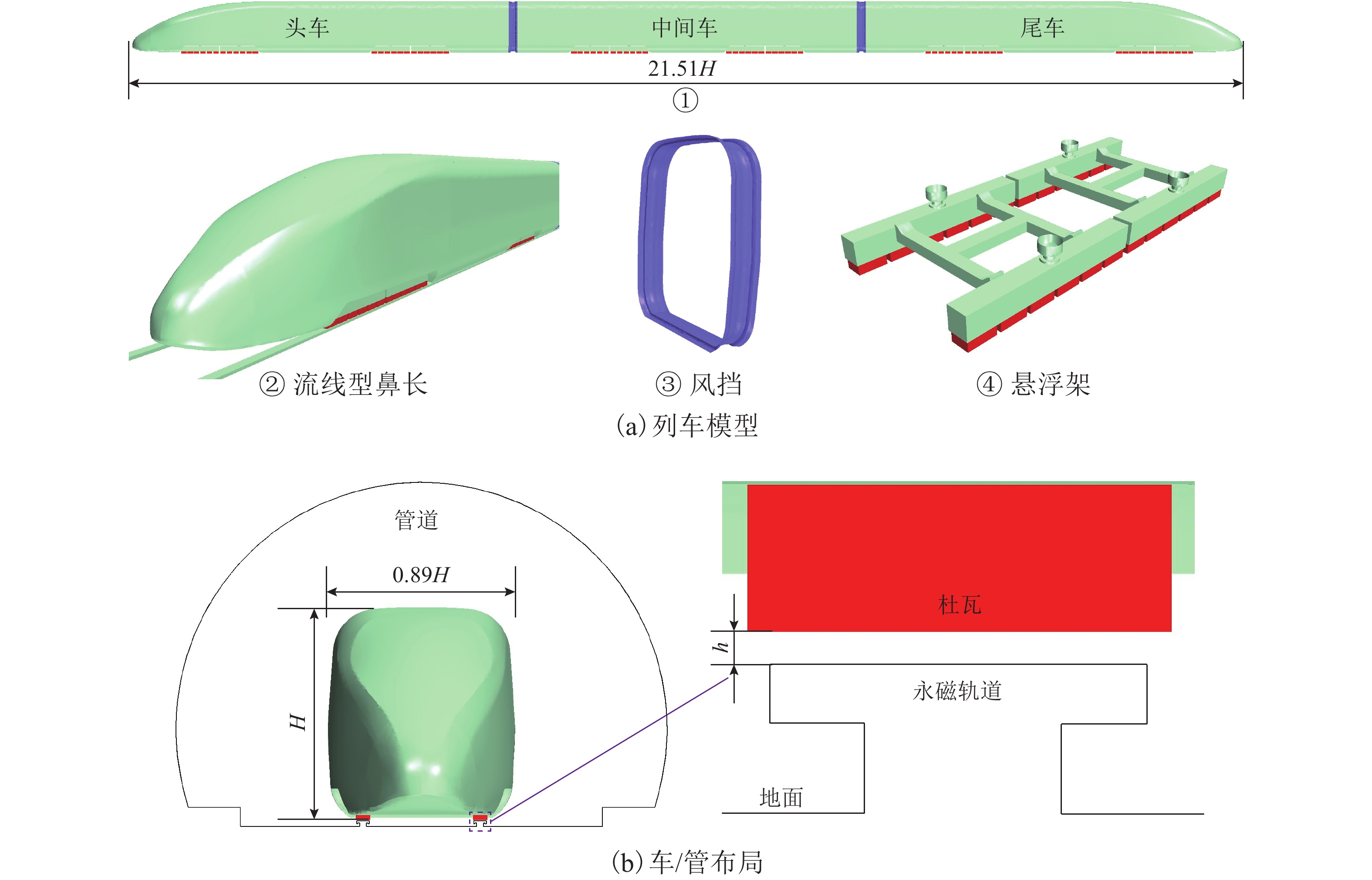

为了探究管道列车的尺度对波系、尾涡以及气动载荷的影响,基于CFD软件建立三种模型尺度(1∶1,1∶5和1∶10),同时考虑两种悬浮间隙关系(车轨相对间隙不变和绝对悬浮高度不变)的模型;采用改进的延迟分离涡模拟(IDDES)湍流模型和重叠网格技术模拟了列车在管道动态运动,并用风洞试验数据验证了数值方法和网格策略的合理性. 研究结果表明:列车尺度(雷诺数)增大,车前活塞区域变长,尾流扰动区范围缩短;雷诺数对近尾流区的涡对演化影响较小,但在远尾流区,随着列车尺度减小,涡对脉动变强,涡对强度的差异导致了车后正激波形态的差异;列车表面最大正压值和最大负压值均随着列车尺度增大而增大,悬浮间隙对最大正压值影响较小,但与最大负压值成正相关关系;尺度效应从压差阻力和摩擦阻力两方面共同影响气动阻力,整车摩擦阻力和头、中间车的压差阻力与雷诺数正相关,但是尾车压差阻力受附着激波的强度影响恰恰相反;列车尺度和悬浮高度均对升力影响较大. 相对于全尺寸模型,1∶10模型(悬浮高度20 mm)的最大正压值减小3.82%,最大负压值增大3.94%,整车总阻力增大8.64%,头车升力减小101.56%,尾车升力增大15.88%.

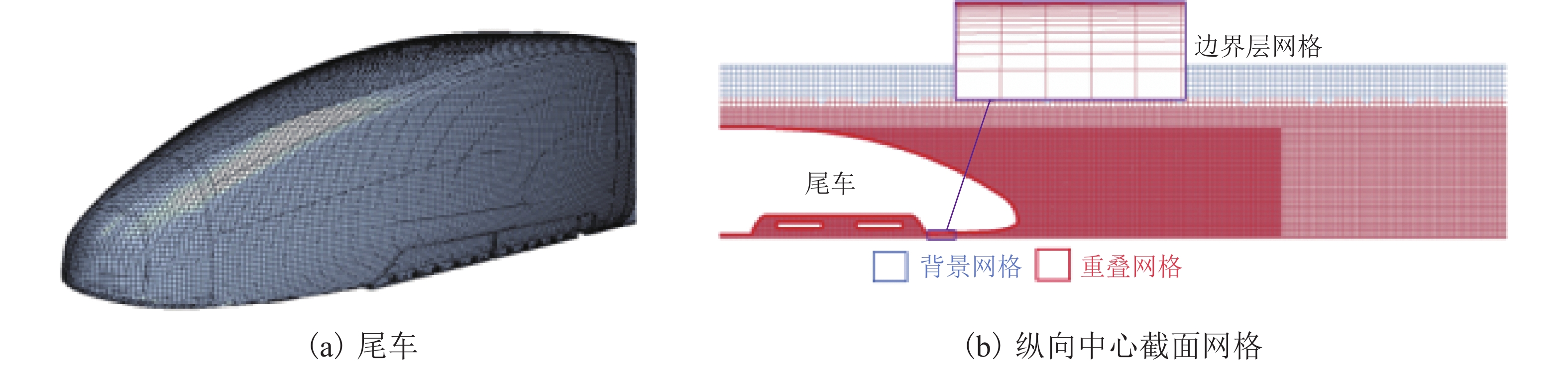

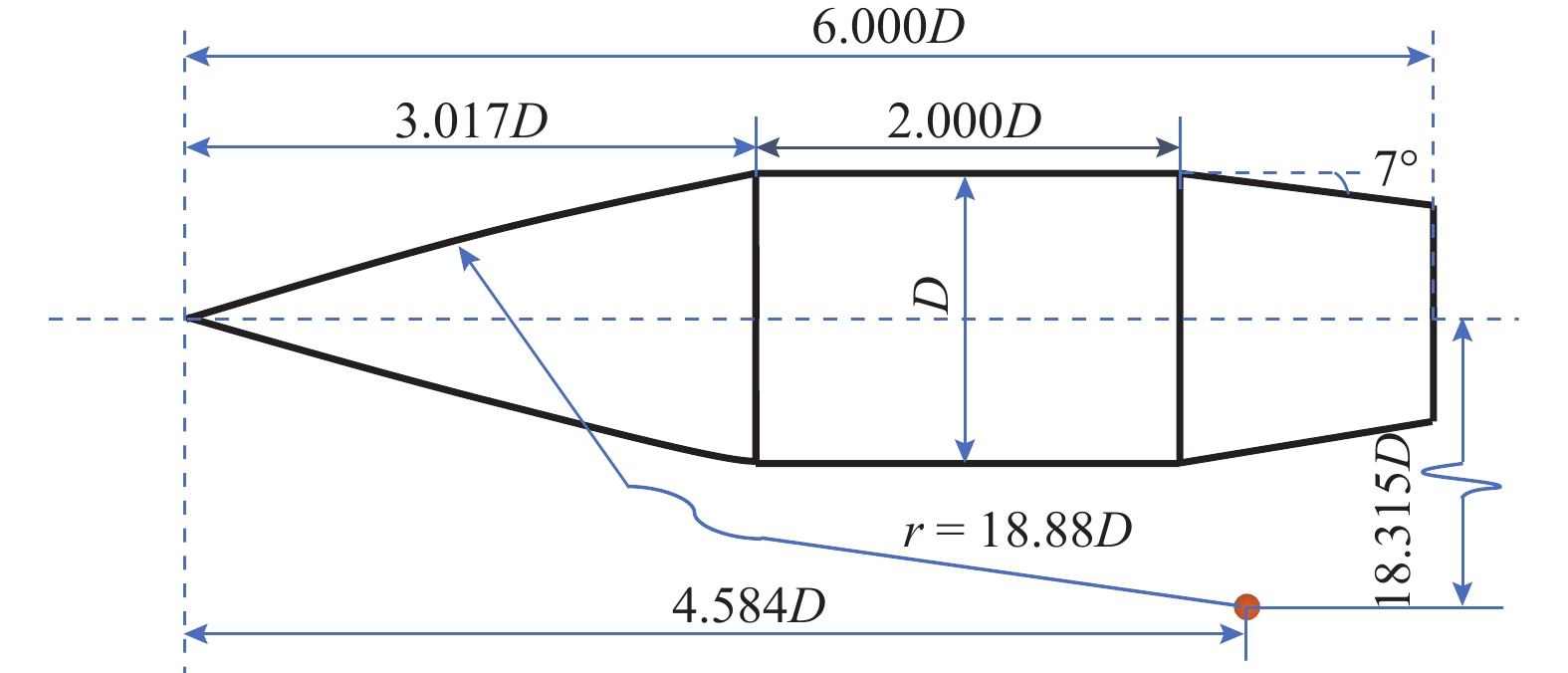

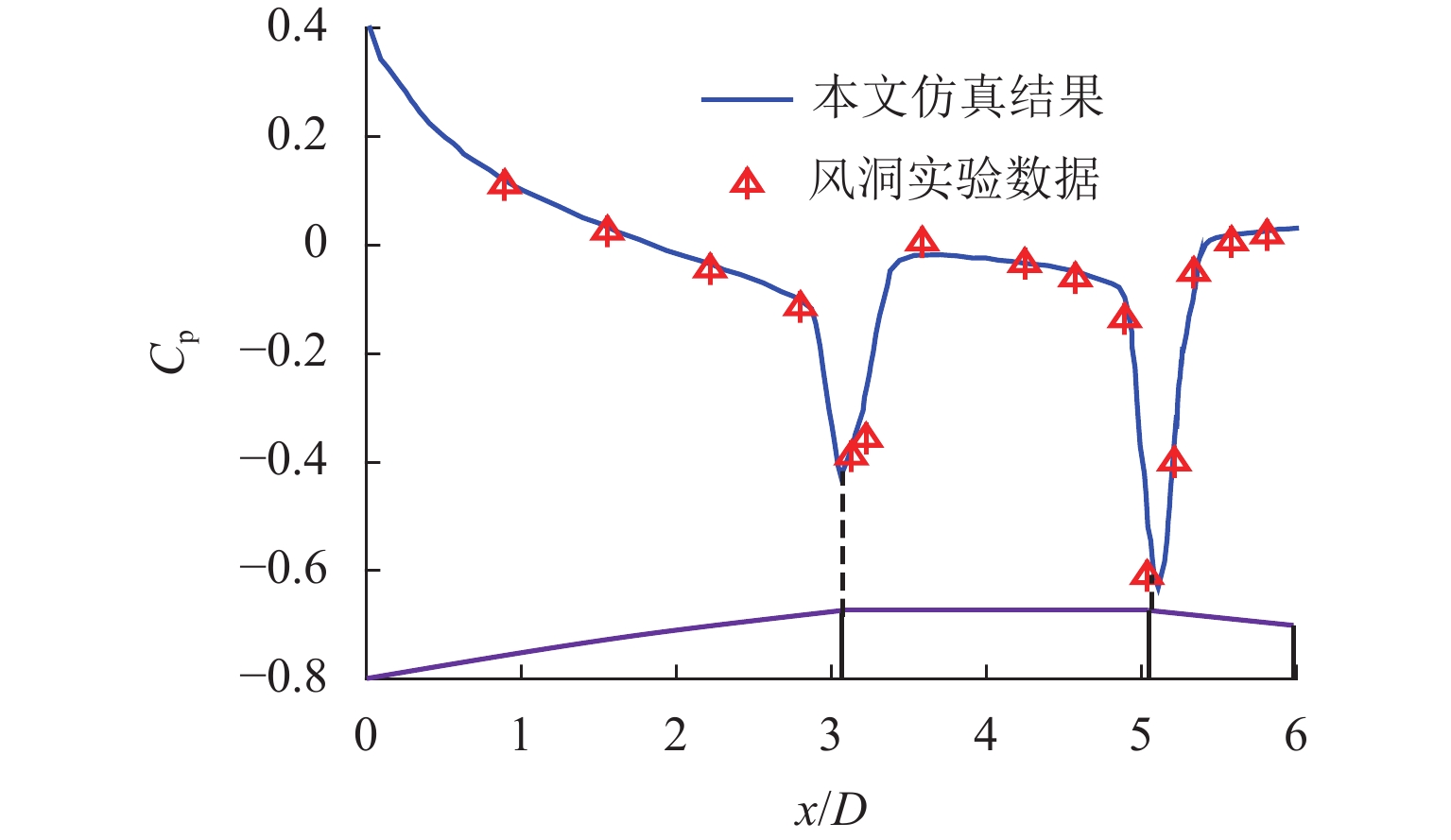

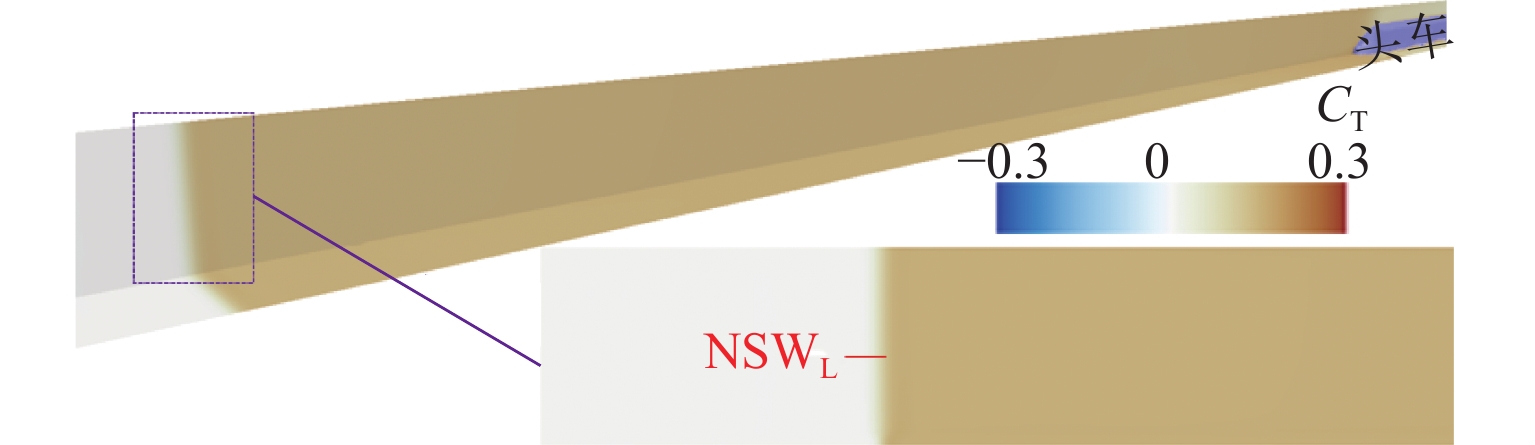

Abstract:In order to investigate the effect of the scale of a tube train on wave systems, wake vortices, and aerodynamic loads, three model scales (1∶1, 1∶5, and 1∶10) were established based on computational fluid dynamics(CFD) software, and two types of suspension gap relationships (constant relative gap between tracks and constant absolute suspension height) were considered. The improved delayed detached eddy simulation (IDDES) turbulence model and the overlapping mesh method were utilized to simulate the train’s dynamic motion in the tube, and wind tunnel test data were used to validate the numerical method and mesh strategy. The study results demonstrate that as the train scale (Reynolds number) increases, the front piston region lengthens, and the wake disturbance region shrinks in extent; Reynolds number has less effect on vortex pair evolution in the near wake region, but in the far wake region, vortex pair pulsation becomes stronger as the train scale decreases, and the difference in vortex pair strength leads to differences in the normal shock wave pattern in the rear of the train; the maximum positive and negative pressure values on the train surface increase as the scale of the train increases; the suspension gap has less influence on the maximum positive pressure value, but it is positively correlated with the maximum negative pressure value. The scale effect affects the aerodynamic drag from both pressure drag and friction drag. The friction drag of the whole train and the pressure drag of the head and middle trains are positively related to the Reynolds number; the pressure drag of the tail train, however, is influenced by the strength of the attached shock wave in an opposite way. Both train scale and suspension height significantly affect the lift. Compared with the full-scale model, the 1∶10 model (suspension height of 20 mm) has a 3.82% reduction in maximum positive pressure, a 3.94% increase in maximum negative pressure, an 8.64% increase in total drag, a 101.56% reduction in the lift of the head train, and a 15.88% increase in the lift of the tail train.

-

Key words:

- evacuated tube /

- overlapping mesh /

- scale effect /

- suspension height /

- aerodynamic characteristics

-

表 1 计算工况参数

Table 1. Parameters of calculation cases

工况 缩尺

比例列车速度/

(km·h−1)雷诺

数/×105悬浮

高度/m1 1∶1 1000 7.240 0.020 2 1∶5 1000 1.448 0.004 3 1∶5 1000 1.448 0.020 4 1∶10 1000 0.724 0.002 5 1∶10 1000 0.724 0.020 表 2 不同尺度下列车平均阻力系数

Table 2. Average drag coefficient of trains with different scales

工况 头车 中间车 尾车 整车 压差

阻力摩擦

阻力总阻力 压差

阻力摩擦

阻力总阻力 压差

阻力摩擦

阻力总阻力 压差

阻力摩擦

阻力总阻力 1 1.2144 0.0622 1.2766 0.0132 0.0537 0.0669 1.1826 0.0815 1.2641 2.4359 0.1980 2.6339 2 1.2309 0.0795 1.3104 0.0147 0.0706 0.0854 1.1615 0.1119 1.2734 2.4198 0.2629 2.6827 3 1.2591 0.0799 1.3390 0.0225 0.0728 0.0953 1.1795 0.1139 1.2934 2.4746 0.2665 2.7412 4 1.2363 0.0863 1.3226 0.0163 0.0808 0.0970 1.1519 0.1313 1.2832 2.4144 0.2993 2.7137 5 1.2854 0.0865 1.3719 0.0400 0.0860 0.1260 1.2149 0.1357 1.3506 2.5522 0.3093 2.8615 表 3 不同尺度下列车平均升力系数

Table 3. Average lift coefficient of trains with different scales

工况 头车 中间车 尾车 整车 1 0.1156 −0.0029 0.3368 0.4363 2 0.0534 −0.0190 0.3659 0.3920 3 0.0171 −0.0252 0.3754 0.3562 4 0.0491 −0.0167 0.3688 0.3883 5 −0.0018 −0.0424 0.3903 0.3368 -

[1] 邓自刚,张勇,王博,等. 真空管道运输系统发展现状及展望[J]. 西南交通大学学报,2019,54(5): 1063-1072.DENG Zigang, ZHANG Yong, WANG Bo, et al. Present situation and prospect of evacuated tube transportation system[J]. Journal of Southwest Jiaotong University, 2019, 54(5): 1063-1072. [2] VAN GOEVERDEN K, MILAKIS D, JANIC M, et al. Analysis and modelling of performances of the HL (Hyperloop) transport system[J]. European Transport Research Review, 2018, 10(2): 1-17. [3] MA T H, HU X, WANG J K, et al. Effect of air pressure on aerodynamic characteristics of the HTS maglev running in a tube[J]. IEEE Transactions on Applied Superconductivity, 2021, 31(8): 0501004.1-0501004.4. [4] SUI Y, NIU J Q, RICCO P, et al. Impact of vacuum degree on the aerodynamics of a high-speed train capsule running in a tube[J]. International Journal of Heat and Fluid Flow, 2021, 88: 108752.1-108752.14. [5] KANG H, JIN Y M, KWON H, et al. A study on the aerodynamic drag of transonic vehicle in evacuated tube using computational fluid dynamics[J]. International Journal of Aeronautical and Space Sciences, 2017, 18(4): 614-622. doi: 10.5139/IJASS.2017.18.4.614 [6] 周鹏,李田,张继业,等. 真空管道超级列车激波簇结构研究[J]. 机械工程学报,2020,56(2): 86-97. doi: 10.3901/JME.2020.02.086ZHOU Peng, LI Tian, ZHANG Jiye, et al. Research on shock wave trains generated by the hyper train in the evacuated tube[J]. Journal of Mechanical Engineering, 2020, 56(2): 86-97. doi: 10.3901/JME.2020.02.086 [7] BAO S J, HU X, WANG J K, et al. Numerical study on the influence of initial ambient temperature on the aerodynamic heating in the tube train system[J]. Advances in Aerodynamics, 2020, 2: 28.1-28.18. [8] 梅元贵, 周朝晖, 许建林. 高速铁路隧道空气动力学[M]. 北京: 科学出版社, 2009. [9] ZHOU P, ZHANG J Y, LI T, et al. Numerical study on wave phenomena produced by the super high-speed evacuated tube maglev train[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2019, 190: 61-70. doi: 10.1016/j.jweia.2019.04.003 [10] ZHOU P, ZHANG J Y. Aerothermal mechanisms induced by the super high-speed evacuated tube maglev train[J]. Vacuum, 2020, 173: 109142.1-109142.9. [11] NIU J Q, SUI Y, YU Q J, et al. Numerical study on the impact of Mach number on the coupling effect of aerodynamic heating and aerodynamic pressure caused by a tube train[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2019, 190: 100-111. doi: 10.1016/j.jweia.2019.04.001 [12] NIU J Q, SUI Y, YU Q J, et al. Effect of acceleration and deceleration of a capsule train running at transonic speed on the flow and heat transfer in the tube[J]. Aerospace Science and Technology, 2020, 105: 105977.1-105977.12. [13] 张晓涵,李田,张继业,等. 亚音速真空管道列车气动壅塞及激波现象[J]. 机械工程学报,2021,57(4): 182-190. doi: 10.3901/JME.2021.04.182ZHANG Xiaohan, LI Tian, ZHANG Jiye, et al. Aerodynamic choked flow and shock wave phenomena of subsonic evacuated tube train[J]. Journal of Mechanical Engineering, 2021, 57(4): 182-190. doi: 10.3901/JME.2021.04.182 [14] HU X, DENG Z G, ZHANG J W, et al. Effect of tracks on the flow and heat transfer of supersonic evacuated tube maglev transportation[J]. Journal of Fluids and Structures, 2021, 107: 103413.1-103413.16. [15] HU X, DENG Z G, ZHANG J W, et al. Aerodynamic behaviors in supersonic evacuated tube transportation with different train nose lengths[J]. International Journal of Heat and Mass Transfer, 2022, 183: 122130.1-122130.13. [16] ZHONG S, QIAN B S, YANG M Z, et al. Investigation on flow field structure and aerodynamic load in vacuum tube transportation system[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2021, 215: 104681.1-104681.14. [17] YU Q J, YANG X F, NIU J Q, et al. Aerodynamic thermal environment around transonic tube train in choked/unchoked flow[J]. International Journal of Heat and Fluid Flow, 2021, 92: 108890.1-108890.15. [18] BIZZOZERO M, SATO Y, SAYED M A. Aerodynamic study of a Hyperloop pod equipped with compressor to overcome the Kantrowitz limit[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2021, 218: 104784.1-104784.16. [19] ZHOU K Y, DING G F, WANG Y M, et al. Aeroheating and aerodynamic performance of a transonic hyperloop pod with radial gap and axial channel: a contrastive study[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2021, 212: 104591.1-104591.16. [20] HU X, DENG Z G, ZHANG W H. Effect of cross passage on aerodynamic characteristics of super-high-speed evacuated tube transportation[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2021, 211: 104562.1-104562.15. [21] JIA W G, WANG K, CHENG A P, et al. Air flow and differential pressure characteristics in the vacuum tube transportation system based on pressure recycle ducts[J]. Vacuum, 2018, 150: 58-68. doi: 10.1016/j.vacuum.2017.12.023 [22] DENG Z G, ZHANG W H, ZHENG J, et al. A high-temperature superconducting maglev-evacuated tube transport (HTS maglev-ETT) test system[J]. IEEE Transactions on Applied Superconductivity, 2017, 27(6): 3602008.1-3602008.8. [23] 刘英杰. 真空管道高速交通系统气动特性试验装置的研制[D]. 青岛: 青岛科技大学, 2015. [24] 田红旗. 列车空气动力学[M]. 北京: 中国铁道出版社, 2007. [25] 韩运动,姚松. 高速列车气动性能的尺度效应分析[J]. 浙江大学学报(工学版),2017,51(12): 2383-2391. doi: 10.3785/j.issn.1008-973X.2017.12.010HAN Yundong, YAO Song. Scale effect analysis in aerodynamic performance of high-speed train[J]. Journal of Zhejiang University (Engineering Science), 2017, 51(12): 2383-2391. doi: 10.3785/j.issn.1008-973X.2017.12.010 [26] NIU J Q, ZHOU D, LIANG X F, et al. Numerical simulation of the Reynolds number effect on the aerodynamic pressure in tunnels[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2018, 173: 187-198. doi: 10.1016/j.jweia.2017.12.013 [27] TSCHEPE J, NAYERI C N, PASCHEREIT C O. On the influence of Reynolds number and ground conditions on the scaling of the aerodynamic drag of trains[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2021, 213: 104594.1-104594.22. [28] 孟石,周丹,孟爽. 轨道间隙对磁浮列车气动性能的影响[J]. 中南大学学报(自然科学版),2020,51(12): 3537-3545.MENG Shi, ZHOU Dan, MENG Shuang. Effect of rail gap on aerodynamic performance of maglev train[J]. Journal of Central South University (Science and Technology), 2020, 51(12): 3537-3545. [29] 胡啸,孔繁冰,梁永廷,等. 线间距对高速列车隧道内交会压力波影响的数值模拟研究[J]. 振动与冲击,2020,39(21): 79-88.HU Xiao, KONG Fanbing, LIANG Yongting, et al. Numerical simulation for influence of line spacing on crossing pressure wave of high-speed trains in tunnel[J]. Journal of Vibration and Shock, 2020, 39(21): 79-88. [30] 胡啸,余以正,陈然,等. 隧道内高速列车交会时车体两侧压差波动特性数值模拟研究[J]. 铁道机车车辆,2019,39(3): 124-130.HU Xiao, YU Yizheng, CHEN Ran, et al. Numerical simulation study on pressure difference fluctuation on both sides of car when high-speed trains crossing in tunnel[J]. Railway Locomotive & Car, 2019, 39(3): 124-130. [31] 王慕之,梅元贵,贾永兴. 重叠网格法应用于模拟高速列车隧道气动效应[J]. 应用力学学报,2017,34(3): 589-595.WANG Muzhi, MEI Yuangui, JIA Yongxing. Simulation of aerodynamic effects generated by a high-speed train passing through a tunnel with overset grid method[J]. Chinese Journal of Applied Mechanics, 2017, 34(3): 589-595. [32] ZHOU P, QIN D, ZHANG J Y, et al. Aerodynamic characteristics of the evacuated tube maglev train considering the suspension gap[J]. International Journal of Rail Transportation, 2022, 10(2): 195-215. doi: 10.1080/23248378.2021.1885514 [33] DONG T Y, MINELLI G, WANG J B, et al. The effect of ground clearance on the aerodynamics of a generic high-speed train[J]. Journal of Fluids and Structures, 2020, 95: 102990.1-102990.20. [34] WANG S B, BURTON D, HERBST A H, et al. The effect of the ground condition on high-speed train slipstream[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2018, 172: 230-243. doi: 10.1016/j.jweia.2017.11.009 [35] KAYSER L, WHITON F. Surface pressure measurements on a boattailed projectile shape at transonic speeds[R]. Maryland: Army Ballistic Research Laboratory, 1982. -

下载:

下载: