Development Status and Prospect of Maglev Train

-

摘要:

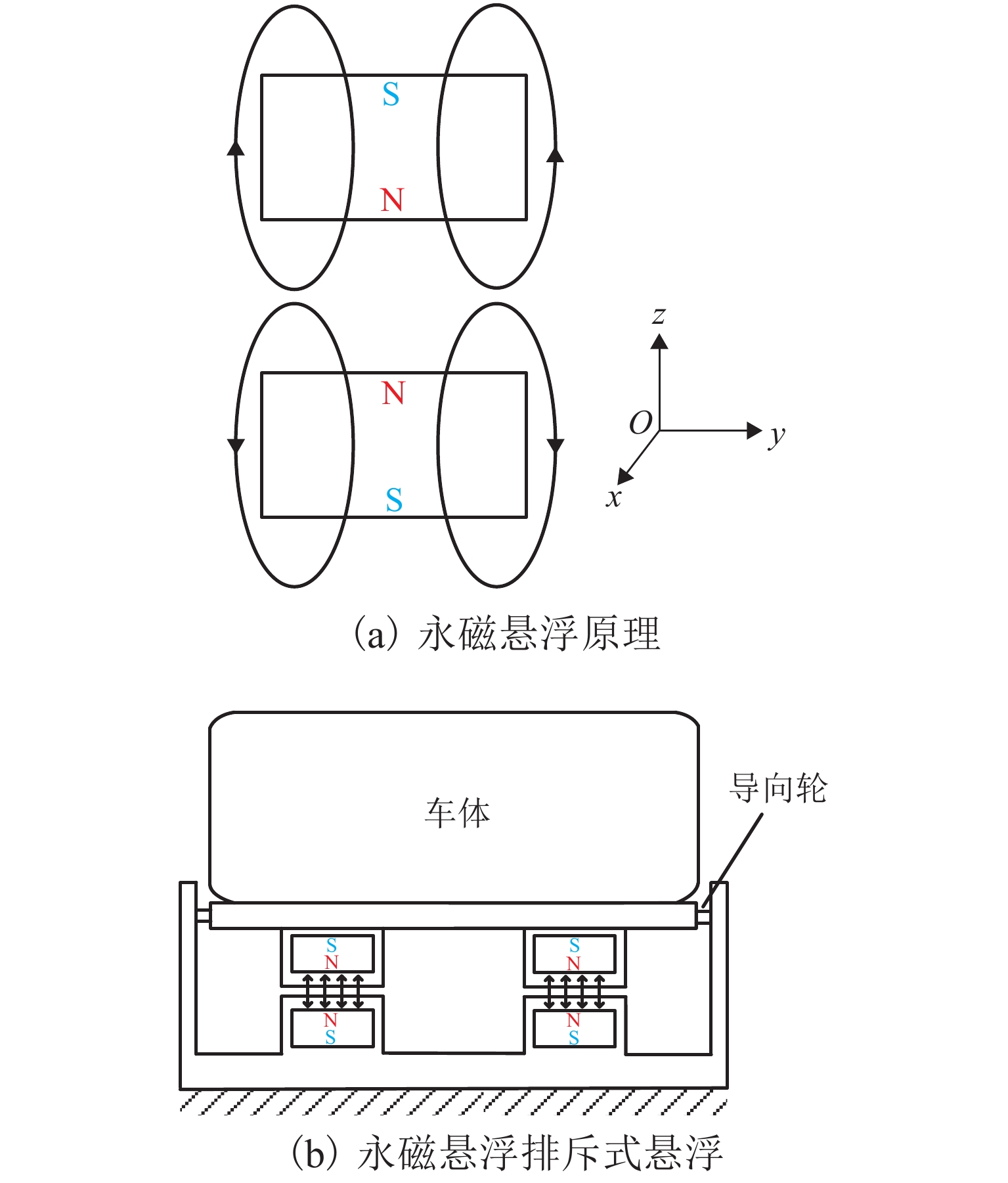

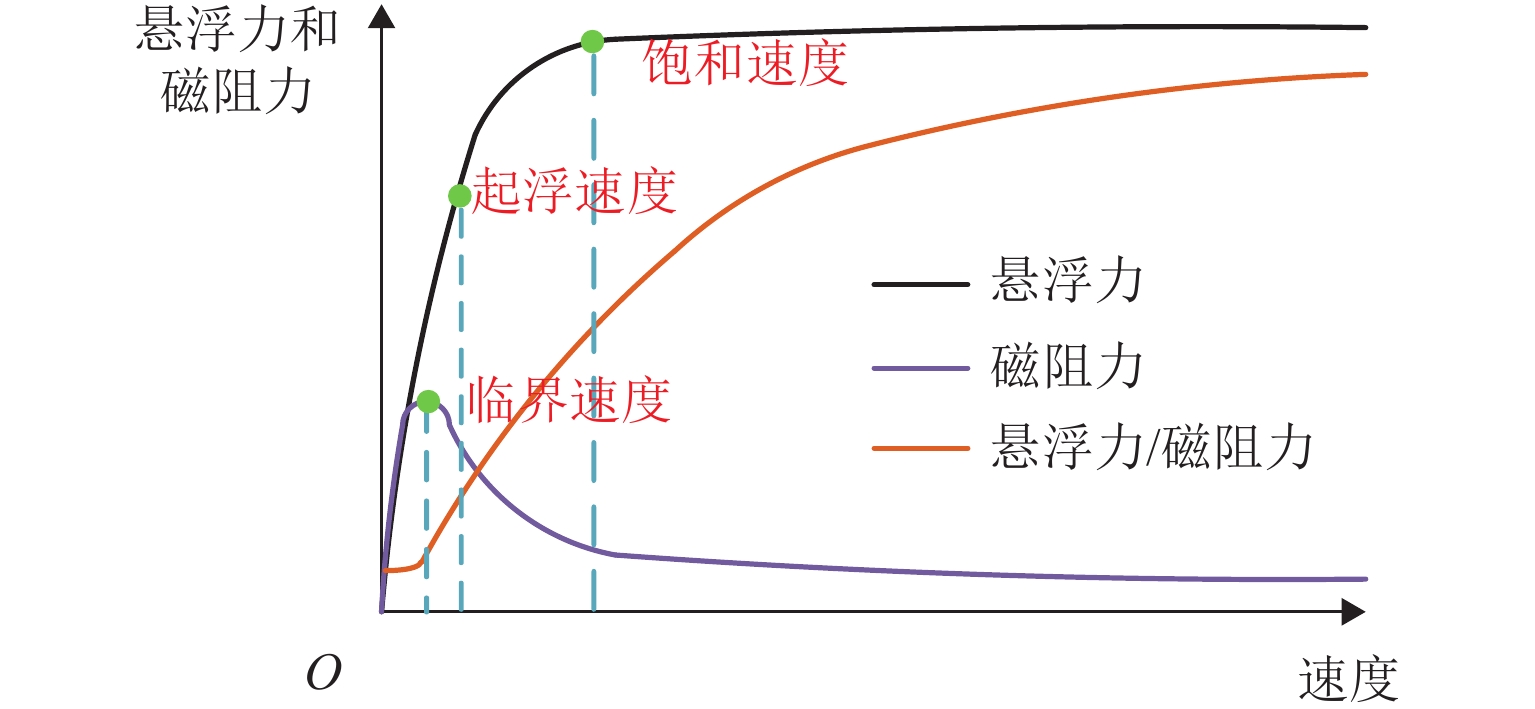

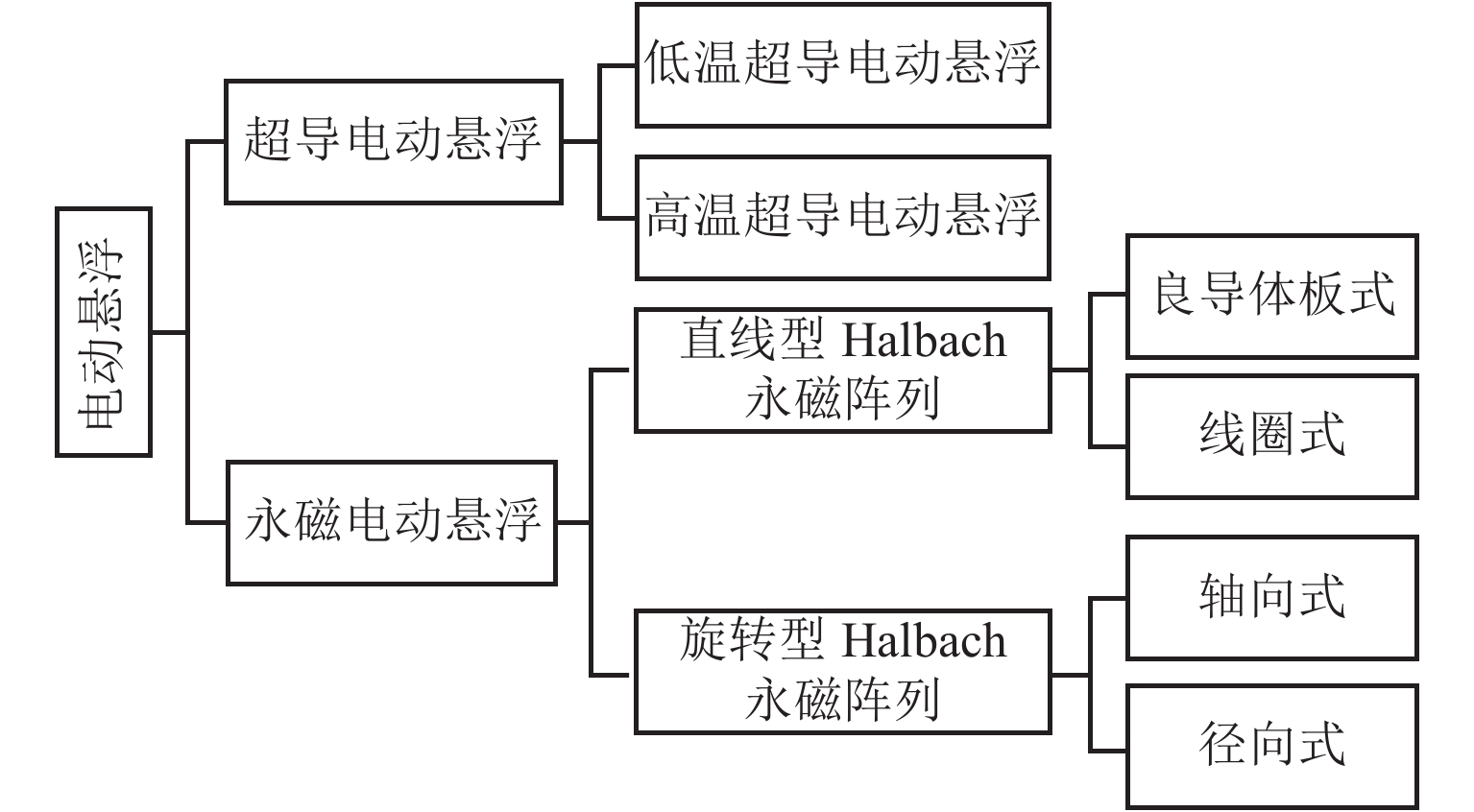

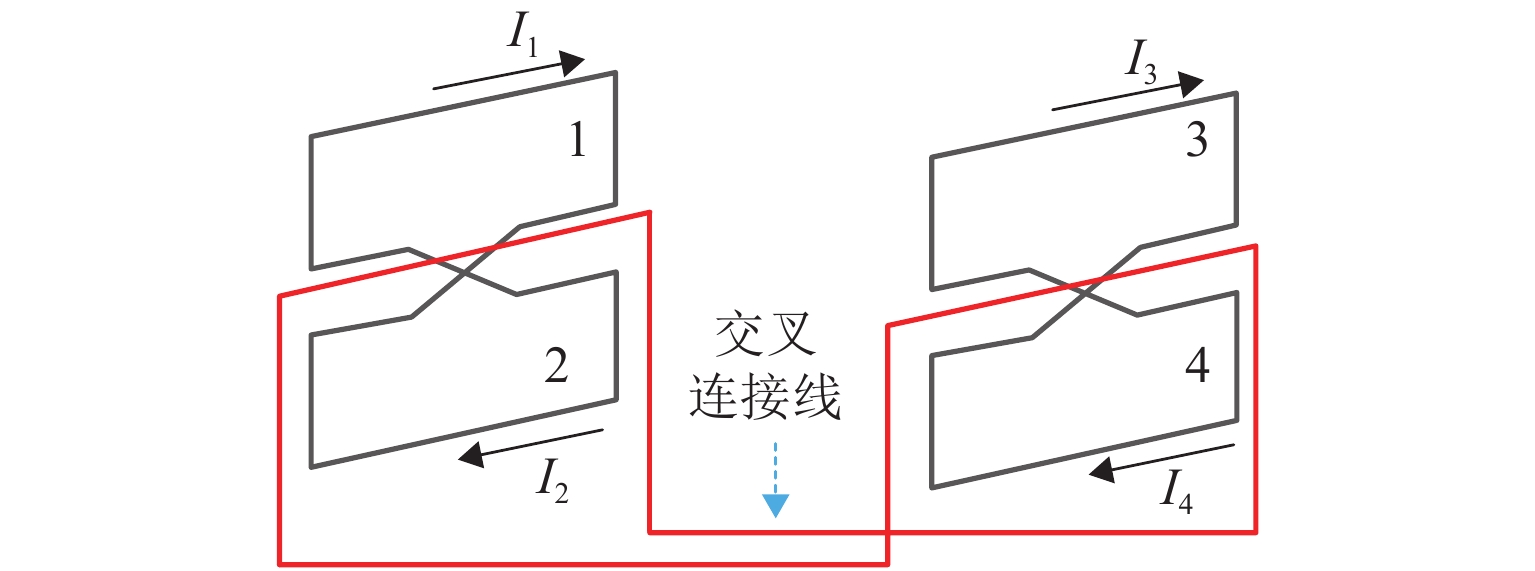

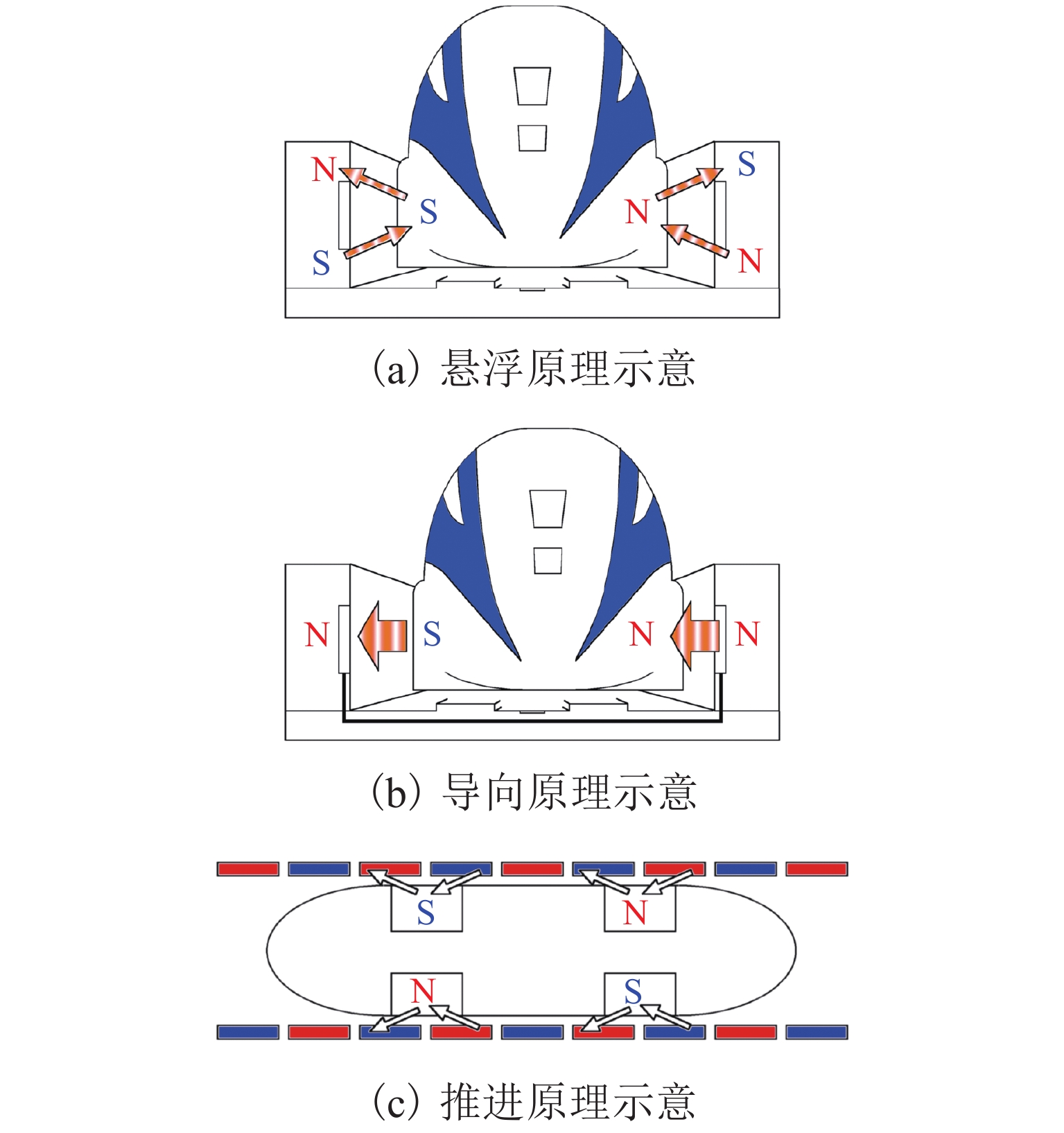

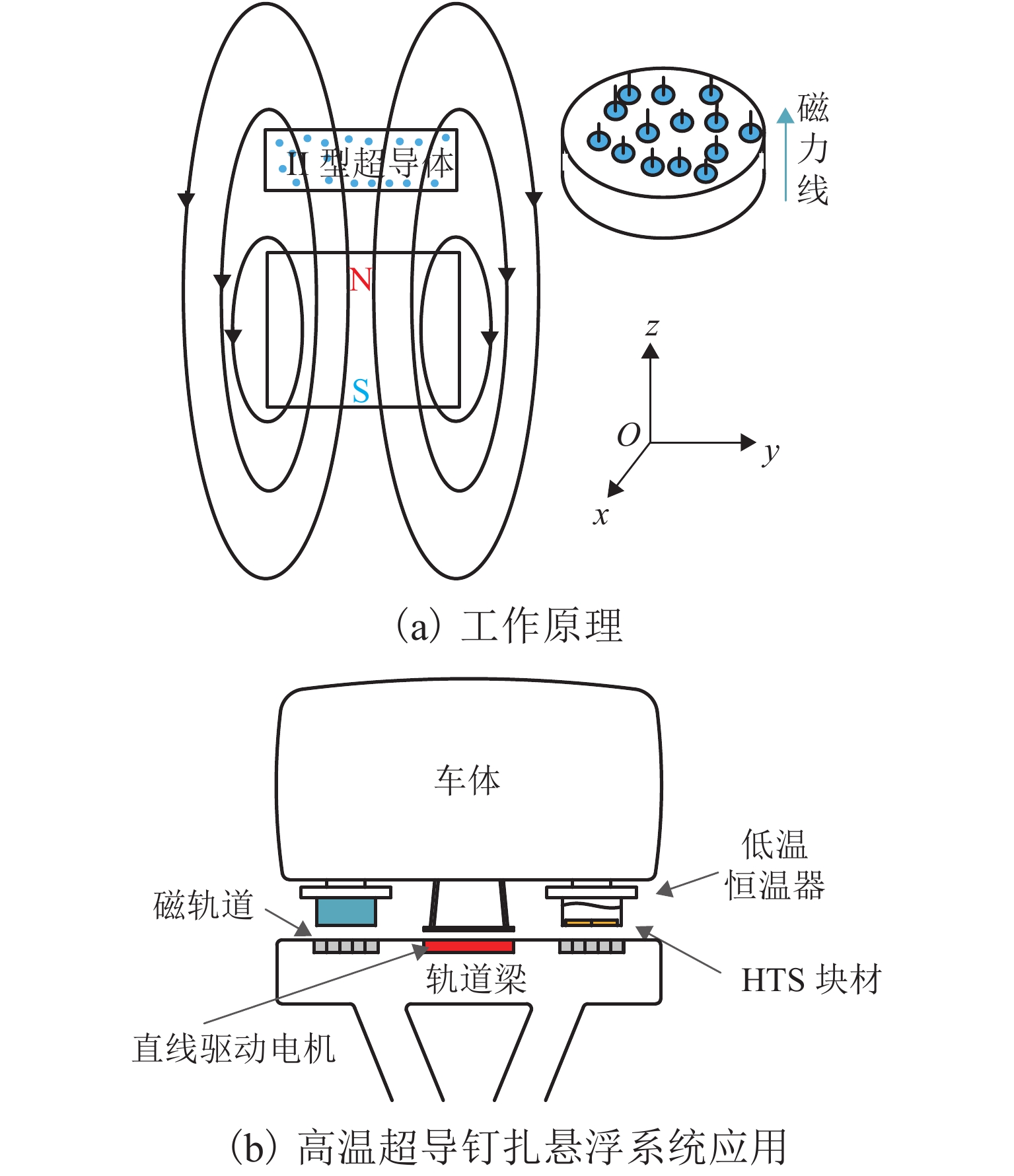

作为新型轨道交通技术的典型代表,磁悬浮交通具有无机械接触磨损、运行速度高、安全可靠、环境友好等优点,经过60年的发展,正逐渐走向成熟. 本文首先对国内外磁悬浮列车的发展历史作了简要回顾;然后,从结构原理、核心技术和应用场景等方面对永磁悬浮、电磁悬浮、电动悬浮和超导钉扎悬浮4大类磁悬浮交通系统进行了详细介绍,对其悬浮特点、悬浮间隙、磁力计算、驱动技术与技术成熟度等进行了阐述,并指出发展时速600公里级高速磁浮列车亟须解决的试验平台搭建、电机控制策略、紧急制动、线路维护、无线传能、无线通信、气动噪声、磁浮道岔等8个关键问题;最后,对超高速真空管道磁悬浮交通系统的研究进展以及需要研究的课题进行了探讨与展望.

Abstract:As a typical representative of the new rail transit technology, magnetic levitation (maglev) transport has the advantages of no mechanical contact wear, high running speed, being safe and reliable, environment-friendly and so on. After 60 years of development, maglev transport is gradually becoming mature. Firstly, the developments of maglev trains at home and abroad were reviewed. Subsequently, permanent magnet suspension (PMS), electromagnetic suspension (EMS), electrodynamic suspension (EDS), and high-temperature superconducting pinning levitation (HTSPL) were presented from the structural principles, core technologies, and application fields. Then, the suspension characteristics, suspension gap, electromagnetic force calculation, and technology maturity of these four magnetic levitation modes were described. After that, eight key problems for the development of the 600 km/h high-speed maglev train were proposed which include construction of test platform, motor control strategy, emergency braking, line maintenance, wireless energy transmission, wireless communication, aerodynamic noise, and maglev turnout. Finally, the research progress and the research topics of ultra-high-speed evacuated tube transportation system were discussed and prospected.

-

表 1 高温超导钉扎悬浮-真空管运输原型“Super-Maglev”参数

Table 1. Parameters of HTSPL-ETT prototype “Super-Maglev”

特点 描述 管道 直径 2 m,长度 45 m 线路 跑道型,两条直径 6 m的曲线 +

两条 3.6 m 长的直线压强 10~100 kPa (0.1~1.0 atm) 牵引制动 直线感应电机 + 机械制动 速度范围 0~50 km/h -

[1] 王念先,张锦光,胡业发. 小型磁悬浮风力发电机起动阻力矩研究[J]. 武汉理工大学学报(信息与管理工程版),2010,32(6): 896-899.WANG Nianxian, ZHANG Jinguang, HU Yefa. Starting resistance torque of small scale maglev wind turbine[J]. Journal of Wuhan University of Technology (Information & Management Engineering), 2010, 32(6): 896-899. [2] 杨文将,温正,丘明,等. 航天发射超导磁浮平台设计的初步实验研究[J]. 低温物理学报,2005,27(增刊1): 1040-1044.YANG Wenjiang, WEN Zheng, QIU Ming, et al. Primary experimental study of superconducting maglev test vehicle design for space launch[J]. Chinese Journal of Low Temperature Physics, 2005, 27(S1): 1040-1044. [3] 钱漾漾. 磁悬浮变频离心式冷水机组可应用性研究[D]. 北京: 清华大学, 2017. [4] 洪毅. 超高速磁浮电梯[J]. 机电产品开发与创新,2008,21(4): 91-92. doi: 10.3969/j.issn.1002-6673.2008.04.037 [5] 钱坤喜,曾培,茹伟民,等. 无源磁浮人工心脏泵的改进型设计[J]. 生物医学工程学杂志,2002,19(4): 593-595. doi: 10.3321/j.issn:1001-5515.2002.04.016QIAN Kunxi, ZENG Pei, RU Weimin, et al. Improved design of permanent maglev impeller assist heart[J]. Journal of Biomedical Engineering, 2002, 19(4): 593-595. doi: 10.3321/j.issn:1001-5515.2002.04.016 [6] 周瑾,倪佐僖. 基于不平衡响应的磁悬浮轴承刚度阻尼辨识方法研究[J]. 振动与冲击,2013,32(3): 29-34. doi: 10.3969/j.issn.1000-3835.2013.03.006ZHOU Jin, NI Zuoxi. Identification method for stiffness and damping of magnetic bearings based on rotor unbalance responses[J]. Journal of Vibration and Shock, 2013, 32(3): 29-34. doi: 10.3969/j.issn.1000-3835.2013.03.006 [7] LEE H W, KIM K C, LEE J. Review of maglev train technologies[J]. IEEE Transactions on Magnetics, 2006, 42(7): 1917-1925. doi: 10.1109/TMAG.2006.875842 [8] 罗炜宁,王强. 磁悬浮列车未来发展与展望[J]. 硅谷,2013,6(5): 2,11. [9] SMITH F S. Transportation system: U. S. Patent 859, 018[P]. 1907-7-2. [10] BACHELET E. Levitating transmitting apparatus: U. S. Patent 1, 020, 942[P]. 1912-3-19. [11] KEMPER H. Schwebebahn mit raederlosen Fahrzeugen, die mittels magnetischer Felder an eisernen Fahrschienen schwebend entlang gefuehrt werden: German Patent 644, 302[P]. 1937-4-5. [12] RICHARD P G. Magnetic system of transportation: U. S. Patent 3, 158, 765[P]. 1964-11-24. [13] GOU J S. Development status and global competition trends analysis of maglev transportation technology based on patent data[J]. Urban Rail Transit, 2018, 4(3): 117-129. doi: 10.1007/s40864-018-0087-3 [14] 卞吉. 我国第一台载人磁浮列车制成[J]. 现代物理知识,1995,7(4): 43. [15] 单子晓张. 磁悬浮列车向我们驶来[J]. 科学时代,1996(2): 42-43. [16] 林一平. 我国磁浮列车研制取得重大进展[J]. 交通与运输,2017,33(3): 50-53. doi: 10.3969/j.issn.1671-3400.2017.03.020 [17] 柳贺. 中国磁浮交通产业发展概览[EB/OL]. [2021-11-25]. http://www.istis.sh.cn/list/list.aspx?id=10218 [18] 吴祥明. 高速磁浮上海示范线的建设[J]. 综合运输,2003,25(8): 38-39,48. [19] 都市轨道交通网. 构建大湾区“123”快速轨道交通圈[EB/OL]. [2021-11-25]. https://www.sohu.com/a/452578394_120763103 [20] 侯大伟. 中国首辆磁悬浮列车运行试验成功[J]. 发明与创新(综合版),2006(6): 27. [21] 吴可超. 国内首列实用型中低速磁悬浮列车开始运行试验[J]. 机车电传动,2009(4): 62. [22] 岳海霏. 我国首条自主研发磁悬浮铁路即将开通“追风者”列车多项成果达到国际领先水平[J]. 科技中国,2015(12): 44-45. [23] 新华日报. 我国自研中低速磁悬浮问世 时速可达140公里[EB/OL]. [2021-11-25]. https://news.sina.com.cn/c/2014-08-21/150930722637.shtml [24] 付敬懿. 长沙中低速磁浮快线开通试运营[J]. 城市轨道交通研究,2016,19(6): 116. [25] 新华网. 长沙磁浮: 贴地飞行, 领跑全球[EB/OL]. [2021-11-25]. http://m.xinhuanet.com/hn/2019-07/26/c_1124799834_2.htm [26] 孙晨,闫晓言. 军民融合落地生根, 北京S1线试运营[J]. 人民公交,2018(1): 72-73. doi: 10.3969/j.issn.1674-8050.2018.01.018 [27] 维基百科. Beijing subway airport express[EB/OL]. [2021-11-25]. https://zh.wikipedia.org/wiki/File:Beijing_Subway_Airport_Express_01.jpg [28] 张旭东. 我国将在2020年研制出时速600公里高速磁浮样车[J]. 广东交通,2018(1): 46. [29] 中国中车. 青岛高速磁浮交通系统[EB/OL]. [2021-11-25]. https://www.crrcgc.cc/sj/g16998/s30989/t323860.aspx [30] 产城. 新筑股份内嵌式中低速磁浮交通系统试验线 全球首条内嵌式中低速磁浮模拟运营线[J]. 产城,2018(12): 16. [31] 陈贵荣,龙志强. 日本低速磁悬浮列车发展[J]. 国外铁道车辆,2008,45(1): 1-3. doi: 10.3969/j.issn.1002-7610.2008.01.001CHEN Guirong, LONG Zhiqiang. Development of low speed maglev train in Japan[J]. Foreign Rolling Stock, 2008, 45(1): 1-3. doi: 10.3969/j.issn.1002-7610.2008.01.001 [32] 刘少克,常文森,尹力明. 日本磁悬浮列车 HSST-100 运行试验综述[J]. 机车电传动,1997(6): 29-31. [33] 维基百科. 东部丘陵线[EB/OL]. [2021-11-25]. https://zh.wikipedia.org/wiki/%E6%9D%B1%E9%83%A8%E4%B8%98%E9%99%B5%E7%B7%9A [34] 宫崎聡夫,张芳. 磁悬浮列车的液压制动装置[J]. 国外机车车辆工艺,2017(4): 20-23. [35] 巩京. 日本超导磁悬浮列车研究及进展[J]. 全球科技经济瞭望,1995,9(9): 44-45. [36] 中岛洋,王渤洪. 日本磁悬浮铁路的开发现状[J]. 电力牵引快报,1994(4): 1-5,17. [37] 观察者网. 日媒: 未来高速磁悬浮市场, 中日“水火不容”[EB/OL]. [2021-11-25]. http://news.sina.com.cn/o/2017-10-26/doc-ifynffnz2617008.shtml. [38] 蓝建中. 日本超导磁浮列车时速创纪录[J]. 城市轨道交通研究,2015,18(5): 134. [39] 马卫华,罗世辉,张敏,等. 中低速磁浮车辆研究综述[J]. 交通运输工程学报,2021,21(1): 199-216.MA Weihua, LUO Shihui, ZHANG Min, et al. Research review on medium and low speed maglev vehicle[J]. Journal of Traffic and Transportation Engineering, 2021, 21(1): 199-216. [40] 詹佳雯. 中低速磁浮列车直线感应电机及悬浮电磁铁分析[D]. 杭州: 浙江大学, 2019. [41] 于加兴. 磁悬浮列车用直线同步电机控制系统的研究[D]. 成都: 西南交通大学, 2007. [42] 舒光伟,Reinhold Meisinger. 德国电磁型磁浮列车40年回顾[J]. 上海应用技术学院学报(自然科学版),2012,12(4): 305-309.SHU Guangwei, MEISINGER R. Review of German EMS maglev vehicles in the past 40 years[J]. Journal of Shanghai Institute of Technology (Natural Science), 2012, 12(4): 305-309. [43] MNICH P,王渤洪. 德国和日本磁悬浮高速铁路系统的现状和比较[J]. 变流技术与电力牵引,2001(6): 1-8. [44] 维基百科. 仁川机场磁悬浮线[EB/OL]. [2021-11-25]. https://zh.wikipedia.org/wiki/%E4%BB%81%E5%B7%9D%E6%9C%BA%E5%9C%BA%E7%A3%81%E6%82%AC%E6%B5%AE%E7%BA%BF. [45] LONG G A, FISKE O J, PADEN B E. Design of a small-scale prototype for a stabilized permanent magnet levitated vehicle[C]// Proceedings of the Asme Dynamic Systems and Control Conference 2009, Pts A and B. New York: Amer Soc Mechanical Engineers, 2009: 211-216. [46] 武瑛严,陆光,徐善纲. Inductrack磁浮技术及其在磁浮列车系统中的应用[J]. 电气应用,2006,25(1): 1-3. [47] RICHARD F. Toward more efficient transport: the inductrack maglev svstem[EB/OL]. [2021-11-25]. https://gcep.stanford.edu/pdfs/ChEHeXOTnf3dHH5qjYRXMA/09_Post_10_11_trans.pdf. [48] 吕刚. 直线电机在轨道交通中的应用与关键技术综述[J]. 中国电机工程学报,2020,40(17): 5665-5675.LYU Gang. Review of the application and key technology in the linear motor for the rail transit[J]. Proceedings of the CSEE, 2020, 40(17): 5665-5675. [49] 孙凤,王亚刚,李东生,等. 悬挂式永磁悬浮系统的悬浮特性研究[J]. 组合机床与自动化加工技术,2012,53(11): 25-28. doi: 10.3969/j.issn.1001-2265.2012.11.008SUN Feng, WANG Yagang, LI Dongsheng, et al. Characteristics analysis of a hanging type permanent magnetic suspension system[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2012, 53(11): 25-28. doi: 10.3969/j.issn.1001-2265.2012.11.008 [50] EARNSHAW S. On the nature of the molecular forces which regulate the constitution of the luminiferous ether[J]. Cambridge Philosophical Society, 1848, 18(7): 97-112. [51] MEINS J, MILLER L, MAYER W J. The high speed Maglev transport system TRANSRAPID[J]. IEEE Transactions on Magnetics, 1988, 24(2): 808-811. doi: 10.1109/20.11347 [52] YASUDA Y. The First HSST Maglev commercial train in japan[C]//MAGLEV 2004. Shanghai: [s.n.], 2004: 76-85. [53] HEKLER M, KLÜHSPIES J. Disruptive technologies transforming urban mobility? the role of the ecobee urban maglev system in the Seoul traffic vision 2030, South Korea[J]. Transportation Systems and Technology, 2018, 4(3S): 115-123. [54] LIN G B, SHENG X W. Application and further development of maglev transportation in China[J]. Transportation Systems and Technology, 2018, 4(3): 36-43. doi: 10.17816/transsyst20184336-43 [55] TAN Q L, QI H F, LI J S, et al. The reliability modeling and analysis on brake system of medium-low speed maglev train[C]//2012 International Conference on Computer Distributed Control and Intelligent Environmental Monitoring. Zhangjiajie: IEEE, 2012: 772-777. [56] 邓自刚,张勇,王博,等. 真空管道运输系统发展现状及展望[J]. 西南交通大学学报,2019,54(5): 1063-1072. doi: 10.3969/j.issn.0258-2724.20180204DENG Zigang, ZHANG Yong, WANG Bo, et al. Present situation and prospect of evacuated tube transportation system[J]. Journal of Southwest Jiaotong University, 2019, 54(5): 1063-1072. doi: 10.3969/j.issn.0258-2724.20180204 [57] 贾少锋,刘紫薇,梁得亮. 多相电机容错控制策略综述[J]. 西安交通大学学报,2021,55(6): 176-184.JIA Shaofeng, LIU Ziwei, LIANG Deliang. Review of fault-tolerant control strategies for multiphase machines[J]. Journal of Xi’an Jiaotong University, 2021, 55(6): 176-184. [58] 王厚生,杜玉梅,夏平畴,等. 电动式磁悬浮列车金属板轨道结构的研究[J]. 中国电机工程学报,2005,25(7): 162-165. doi: 10.3321/j.issn:0258-8013.2005.07.029WANG Housheng, DU Yumei, XIA Pingchou, et al. Research on dms train metal guideways construction[J]. Proceedings of the CSEE, 2005, 25(7): 162-165. doi: 10.3321/j.issn:0258-8013.2005.07.029 [59] 维基百科. SCMaglev[EB/OL]. [2021-11-25]. https://en.wikipedia.org/wiki/SCMaglev [60] TERAI M, IGARASHI M, KUSADA S, et al. The R&D project of HTS magnets for the superconducting maglev[J]. IEEE Transactions on Applied Superconductivity, 2006, 16(2): 1124-1129. doi: 10.1109/TASC.2006.871342 [61] FUJII N, CHIDA M, OGAWA K. Three dimensional force of magnet wheel with revolving permanent magnets[J]. IEEE Transactions on Magnetics, 1997, 33(5): 4221-4223. doi: 10.1109/20.619716 [62] BIRD J. An investigation into the use of electrodynamic wheels for high-speed ground transportation[D]. Madison: University of Wisconsin--Madison, 2007. [63] WATANABE K, YOSHIOKA H, SUZUKI E, et al. A study of vibration control systems for superconducting maglev vehicles (vibration control of lateral and rolling motions)[J]. Journal of System Design and Dynamics, 2007, 1(3): 593-604. doi: 10.1299/jsdd.1.593 [64] HOSHINO H, SUZUKI E, WATANABE K. Reduction of vibrations in maglev vehicles using active primary and secondary suspension control[J]. Quarterly Report of RTRI, 2008, 49(2): 113-118. doi: 10.2219/rtriqr.49.113 [65] 张娟. 超导电动悬浮磁力特性及超导磁浮车辆动力学仿真分析[D]. 成都: 西南交通大学, 2020. [66] CAI Y, MA G T, WANG Y Y, et al. Semianalytical calculation of superconducting electrodynamic suspension train using figure-eight-shaped ground coil[J]. IEEE Transactions on Applied Superconductivity, 2020, 30(5): 3602509.1-3602509.9. [67] 张瑞华,刘育红,徐善纲. 美国Magplane磁悬浮列车方案介绍[J]. 变流技术与电力牵引,2005,12(5): 40-43.ZHANG Ruihua, LIU Yuhong, XU Shangang. American magplane schemes[J]. Converter Technology & Electric Traction, 2005, 12(5): 40-43. [68] 熊嘉阳,邓自刚. 高速磁悬浮轨道交通研究进展[J]. 交通运输工程学报,2021,21(1): 177-198.XIONG Jiayang, DENG Zigang. Research progress of high-speed maglev rail transit[J]. Journal of Traffic and Transportation Engineering, 2021, 21(1): 177-198. [69] 邓自刚,李海涛. 高温超导磁悬浮车研究进展[J]. 中国材料进展,2017,36(5): 329-334,351.DENG Zigang, LI Haitao. Recent development of high-temperature superconducting maglev[J]. Materials China, 2017, 36(5): 329-334,351. [70] AWAJI S, WATANABE K, KOBAYASHI N. Crossover from intrinsic to extrinsic pinning for YBa2Cu3O7 films[J]. Cryogenics, 1999, 39(7): 569-577. doi: 10.1016/S0011-2275(99)00079-X [71] 任仲友. 永磁导轨上高温超导磁悬浮的实验研究与数值计算[D]. 成都: 西南交通大学, 2004. [72] WANG J R, WU M Z, MAY H, et al. High-Tc superconductive vehicle for maglev model[J]. Rare Metal Materials and Engineering, 1998, 27(4): 240-242. [73] SCHULTZ L, DE HAAS O, VERGES P, et al. Superconductively levitated transport system-the SupraTrans project[J]. IEEE Transactions on Applied Superconductivity, 2005, 15(2): 2301-2305. doi: 10.1109/TASC.2005.849636 [74] LANZARA G, D'OVIDIO G, CRISI F. UAQ4 levitating train: Italian maglev transportation system[J]. IEEE Vehicular Technology Magazine, 2014, 9(4): 71-77. doi: 10.1109/MVT.2014.2362859 [75] MOTTA E S, DIAS D H N, SOTELO G G, et al. Optimization of a linear superconducting levitation system[J]. IEEE Transactions on Applied Superconductivity, 2011, 21(5): 3548-3554. doi: 10.1109/TASC.2011.2161986 [76] OKANO M, IWAMOTO T, FURUSE M, et al. Running performance of a pinning-type superconducting magnetic levitation guide[J]. Journal of Physics: Conference Series, 2006, 43: 999-1002. doi: 10.1088/1742-6596/43/1/244 [77] KOVALEV K L, KONEEV S M A, POLTAVEC V N, et al. Magnetically levitated high-speed carriages on the basis of bulk HTS elements[C]//Proc. 8th Int. Symp. Magn. Suspension Technol. Cambridge: [s. n.], 2005: 45-49. [78] WANG S Y, WANG J S, WANG X R, et al. The man-loading high-temperature superconducting Maglev test vehicle[J]. IEEE Transactions on Applied Superconductivity, 2003, 13(2): 2134-2137. doi: 10.1109/TASC.2003.813017 [79] WANG J S, WANG S Y, ZENG Y W, et al. The first man-loading high temperature superconducting maglev test vehicle in the world[J]. Physica C: Superconductivity, 2002, 378/379/380/381: 809-814. [80] 中国青年报. 与新中国铁路同进步[EB/OL]. [2021-11-25]. http://zqb.cyol.com/content/2009-12/02/content_2963501.htm. [81] DENG Z G, ZHANG W H, ZHENG J, et al. A high-temperature superconducting maglev ring test line developed in Chengdu, China[J]. IEEE Transactions on Applied Superconductivity, 2016, 26(6): 3602408.1-3602408.8. [82] KINGLEKAN. “SupraTrans II”高温超导钉扎悬浮车[EB/OL]. [2021-11-25]. https://adiguntech.wordpress.com/2015/11/07/lexus-hoverboard-its-works/. [83] SCHULTZ L, KUEHN L, DE H O, et al. Supratrans II-research facility for large scale HTS applications[C]//The Superconductivity Centennial Conference, EUCAS/ICEC/CMC2011(SCC2011). Hague: [s.n.], 2011: 18-23. [84] Ciclo Vivo. UFRJ has magnetic levitation train and solar powered[EB/OL]. [2021-11-25]. https://www.a-folhadovale.com/single-post/2019/07/02/ufrj-possui-trem-de-levita%C3%A7%C3%A3o-magn%C3%A9tica-e-movido-a-energia-solar [85] WANG J S, WANG S Y, DENG C Y, et al. Laboratory-scale high temperature superconducting maglev launch system[J]. IEEE Transactions on Applied Superconductivity, 2007, 17(2): 2091-2094. doi: 10.1109/TASC.2007.898367 [86] YANG W J, QIU M, LIU Y, et al. Levitation characteristics in an HTS maglev launch assist test vehicle[J]. Superconductor Science and Technology, 2007, 20(3): 281-286. doi: 10.1088/0953-2048/20/3/029 [87] YANG W J, WEN Z, DUAN Y, et al. Construction and performance of HTS maglev launch assist test vehicle[J]. IEEE Transactions on Applied Superconductivity, 2006, 16(2): 1108-1111. doi: 10.1109/TASC.2006.870013 [88] HUANG H, ZHENG J, LIAO H P, et al. Effect laws of different factors on levitation characteristics of high-T_c superconducting maglev system with numerical solutions[J]. Journal of Superconductivity and Novel Magnetism, 2019, 32(8): 2351-2358. doi: 10.1007/s10948-018-4985-0 [89] LI J P, ZHENG J, HUANG H, et al. Motion stability of the magnetic levitation and suspension with YBa2Cu3O7- x high-Tc superconducting bulks and NdFeB magnets[J]. Journal of Applied Physics, 2017, 122(15): 153902.1-153902.8. doi: 10.1063/1.4994903 [90] LI J P, LI H T, ZHENG J, et al. Nonlinear vibration behaviors of high-Tc superconducting bulks in an applied permanent magnetic array field[J]. Journal of Applied Physics, 2017, 121(24): 243901.1-243901.6. [91] LI H T, DENG Z G, JIN L, et al. Lateral motion stability of high-temperature superconducting maglev systems derived from a nonlinear guidance force hysteretic model[J]. Superconductor Science and Technology, 2018, 31(7): 075010.1-075010.8. [92] LI J P, DENG Z G, XIA C C, et al. Subharmonic resonance in magnetic levitation of the high-temperature superconducting bulks YBa2Cu3O7-x under harmonic excitation[J]. IEEE Transactions on Applied Superconductivity, 2019, 29(4): 3600908.1-3600908.8. [93] LI H T, LIU D, HONG Y, et al. Modeling and identification of the hysteresis nonlinear levitation force in HTS maglev systems[J]. Superconductor Science and Technology, 2020, 33(5): 054001. doi: 10.1088/1361-6668/ab7845 [94] 叶常青. 高温超导磁悬浮智能优化算法及其应用[D]. 成都: 西南交通大学, 2016. [95] LI H T, HUANG H, YU J B, et al. Nonlinear vibration suppression of HTS maglev utilizing electromagnetic shunt damper[C]//2020 IEEE International Conference on Applied Superconductivity and Electromagnetic Devices. Tianjin: IEEE, 2020: 1-2. [96] JIN L W, ZHENG J, LI H T, et al. Effect of eddy current damper on the dynamic vibration characteristics of high-temperature superconducting maglev system[J]. IEEE Transactions on Applied Superconductivity, 2017, 27(3): 3601706.1-3601706.6. [97] DENG Z G, ZHANG J K, WANG W, et al. The new high-temperature superconducting maglev vehicle developed in ASCLab[C]//2020 IEEE International Conference on Applied Superconductivity and Electromagnetic Devices. Tianjin: IEEE, 2020: 1-2. [98] WANG H D, DENG Z G, MA S S, et al. Dynamic simulation of the HTS maglev vehicle-bridge coupled system based on levitation force experiment[J]. IEEE Transactions on Applied Superconductivity, 2019, 29(5): 3601606.1-3601606.6. [99] DENG Z G, LI J P, WANG H D, et al. Dynamic simulation of the vehicle/bridge coupled system in high-temperature superconducting maglev[J]. Computing in Science & Engineering, 2019, 21(3): 60-71. [100] DENG Z G, ZHANG W F, CHEN Y, et al. Optimization study of the Halbach permanent magnetic guideway for high temperature superconducting magnetic levitation[J]. Superconductor Science and Technology, 2020, 33(3): 034009.1-034009.11. [101] LI Y J, DAI Q, ZHANG Y, et al. Design and analysis of an electromagnetic turnout for the superconducting Maglev system[J]. Physica C: Superconductivity and Its Applications, 2016, 528: 84-89. doi: 10.1016/j.physc.2016.07.021 [102] ZHENG J, SUN R X, LI H T, et al. A manned hybrid maglev vehicle applying permanent magnetic levitation (PML) and superconducting magnetic levitation (SML)[J]. IEEE Transactions on Applied Superconductivity, 2020, 30(1): 3600107.1-3600107.7. [103] DENG Z G, ZHANG W H, KOU L, et al. An ultra-high-speed maglev test rig designed for HTS pinning levitation and electrodynamic levitation[J]. IEEE Transactions on Applied Superconductivity, 2021, 31(8): 3603605.1-3603605.5. [104] 许德智,黄泊珉,杨玮林. 神经网络自适应的永磁直线同步电机超扭曲终端滑模控制[J]. 电力系统保护与控制,2021,49(13): 64-71.XU Dezhi, HUANG Bomin, YANG Weilin. Neural network adaptive super twist terminal sliding mode control for a permanent magnet linear synchronous motor[J]. Power System Protection and Control, 2021, 49(13): 64-71. [105] 王凯,刘留,于蒙,等. 超高速列车车地无线通信系统性能分析[J]. 北京交通大学学报,2021,45(4): 117-126. doi: 10.11860/j.issn.1673-0291.20210074WANG Kai, LIU Liu, YU Meng, et al. System performance analysis on train-ground wireless communication for the ultra high-speed train[J]. Journal of Beijing Jiaotong University, 2021, 45(4): 117-126. doi: 10.11860/j.issn.1673-0291.20210074 [106] 刘振玉,杨凯,樊亮,等. 真空管道超高速磁悬浮列车通信信号系统展望[J]. 控制与信息技术,2021,28(4): 103-108.LIU Zhenyu, YANG Kai, FAN Liang, et al. Outlook of the communication & signaling system for vacuum pipeline ultra high speed maglev train[J]. Control and Information Technology, 2021, 28(4): 103-108. [107] 裘陈成,刘留,张嘉驰,等. 基于漏波电磁透镜的高速飞行列车无线接入研究[J]. 电波科学学报,2020,35(5): 776-784.QIU Chencheng, LIU Liu, ZHANG Jiachi, et al. Wireless access of high speed flying train based on leaky electromagnetic lens[J]. Chinese Journal of Radio Science, 2020, 35(5): 776-784. [108] 李倩. 600 km/h真空管高速列车车内气动噪声仿真分析[D]. 北京: 北京交通大学, 2019. [109] GERASIMENKO A A, LI H T, KORCHAGIN V O, et al. Design optimization of the electromagnetic turnout by using a compensation coil[J]. IEEE Transactions on Applied Superconductivity, 2021, 31(8): 1-4. [110] KWON H B, PARK Y W, LEE D H, et al. Wind tunnel experiments on Korean high-speed trains using various ground simulation techniques[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2001, 89(13): 1179-1195. doi: 10.1016/S0167-6105(01)00107-6 [111] HU X, DENG Z G, ZHANG J W, et al. Aerodynamic behaviors in supersonic evacuated tube transportation with different train nose lengths[J]. International Journal of Heat and Mass Transfer, 2022, 183: 122-130. [112] 徐飞,罗世辉,邓自刚. 磁悬浮轨道交通关键技术及全速度域应用研究[J]. 铁道学报,2019,41(3): 40-49. doi: 10.3969/j.issn.1001-8360.2019.03.006XU Fei, LUO Shihui, DENG Zigang. Study on key technologies and whole speed range application of maglev rail transport[J]. Journal of the China Railway Society, 2019, 41(3): 40-49. doi: 10.3969/j.issn.1001-8360.2019.03.006 [113] BERTA N I. Apparatus for dip coating product: US5503673[P]. 1996-04-02. [114] FOA J V. High-speed transport in non-evacuated tubes[C]//Proceedings of the Transportation Engineering Conference. Washington D. C. : [s.n.], 1966: 364-372 [115] Julian Hechler . Crossing the finish line at 463 km/h: the TU Munich team wins the SpaceX Hyperloop competition again[EB/OL]. [2021-11-21]. https://www.invest-in-bavaria.com/en/blog/post/crossing-the-finish-line-at-463-km-h-the-tu-munich-team-wins-the-spacex-hyperloop-competition-again [116] 冯仲伟,方兴,李红梅,等. 低真空管道高速磁悬浮系统技术发展研究[J]. 中国工程科学,2018,20(6): 105-111.FENG Zhongwei, FANG Xing, LI Hongmei, et al. Technological development of high speed maglev system based on low vacuum pipeline[J]. Engineering Science, 2018, 20(6): 105-111. [117] ANDREW J H. Milestone: the first human passenger test[EB/OL]. [2021-11-21]. https://virginhyperloop.com/pegasus. [118] Spanishports. Spain’s Zeleros raises ?7M in funding to lead hyperloop development in Europe[EB/OL]. [2021-11-21]. http://www.spanishports.es/texto-diario/mostrar/1978522/espanola-zeleros-capta-7m-financiacion-liderar-desarrollo-hyperloop-europa [119] 沈志云. 沈志云院士提出真空管道高速交通设想[J]. 西南交通大学学报,2005,40(1): 68. [120] 王家素,王素玉. 高温超导磁悬浮列车研究综述[J]. 电气工程学报,2015,10(11): 1-10. doi: 10.11985/2015.11.001WANG Jiasu, WANG Suyu. High temperature superconducting maglev train[J]. Journal of Electrical Engineering, 2015, 10(11): 1-10. doi: 10.11985/2015.11.001 [121] DENG Z G, ZHANG W H, ZHENG J, et al. A high-temperature superconducting maglev-evacuated tube transport (HTS maglev-ETT) test system[J]. IEEE Transactions on Applied Superconductivity, 2017, 27(6): 3602008.1-3602008.8. [122] ZHOU D J, CUI C Y, ZHAO L F, et al. Running stability of a prototype vehicle in a side-suspended HTS maglev circular test track system[J]. IEEE Transactions on Applied Superconductivity, 2017, 27(1): 3600107.1-3600107.7. [123] ZHAO L, DU Y, PAN X, et al. Improvement of the side-suspended high-temperature superconductor maglev rotating system in evacuated tube[J]. Rare Metal Materials and Engineering, 2019, 48(4): 1046-1050. [124] ZHOU D J, ZHAO L F, KE C, et al. High-Tc superconducting maglev prototype vehicle running at 160 km/h in an evacuated circular track[J]. IEEE Transactions on Applied Superconductivity, 2018, 28(4): 3600504.1-3600504.4. [125] DENG Z G, ZHANG W H, WANG L, et al. A high-speed running test platform for high-temperature superconducting maglev[J]. IEEE Transactions on Applied Superconductivity, 2022, 32(4): 3600905.1-3600905.5. [126] 沈志云. 关于我国发展真空管道高速交通的思考[J]. 西南交通大学学报,2005,40(2): 133-137. doi: 10.3969/j.issn.0258-2724.2005.02.001SHEN Zhiyun. On developing high-speed evacuated tube transportation in China[J]. Journal of Southwest Jiaotong University, 2005, 40(2): 133-137. doi: 10.3969/j.issn.0258-2724.2005.02.001 -

下载:

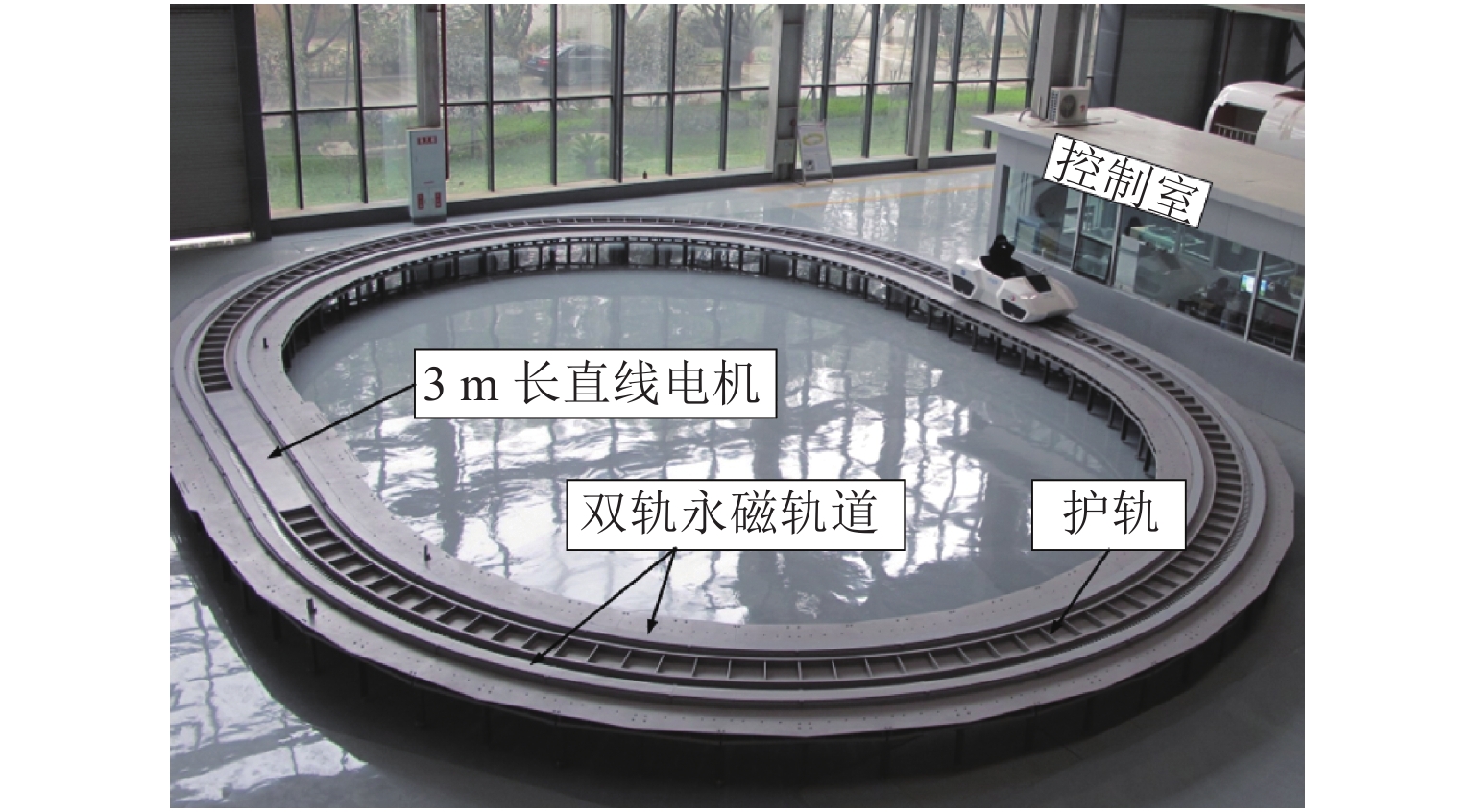

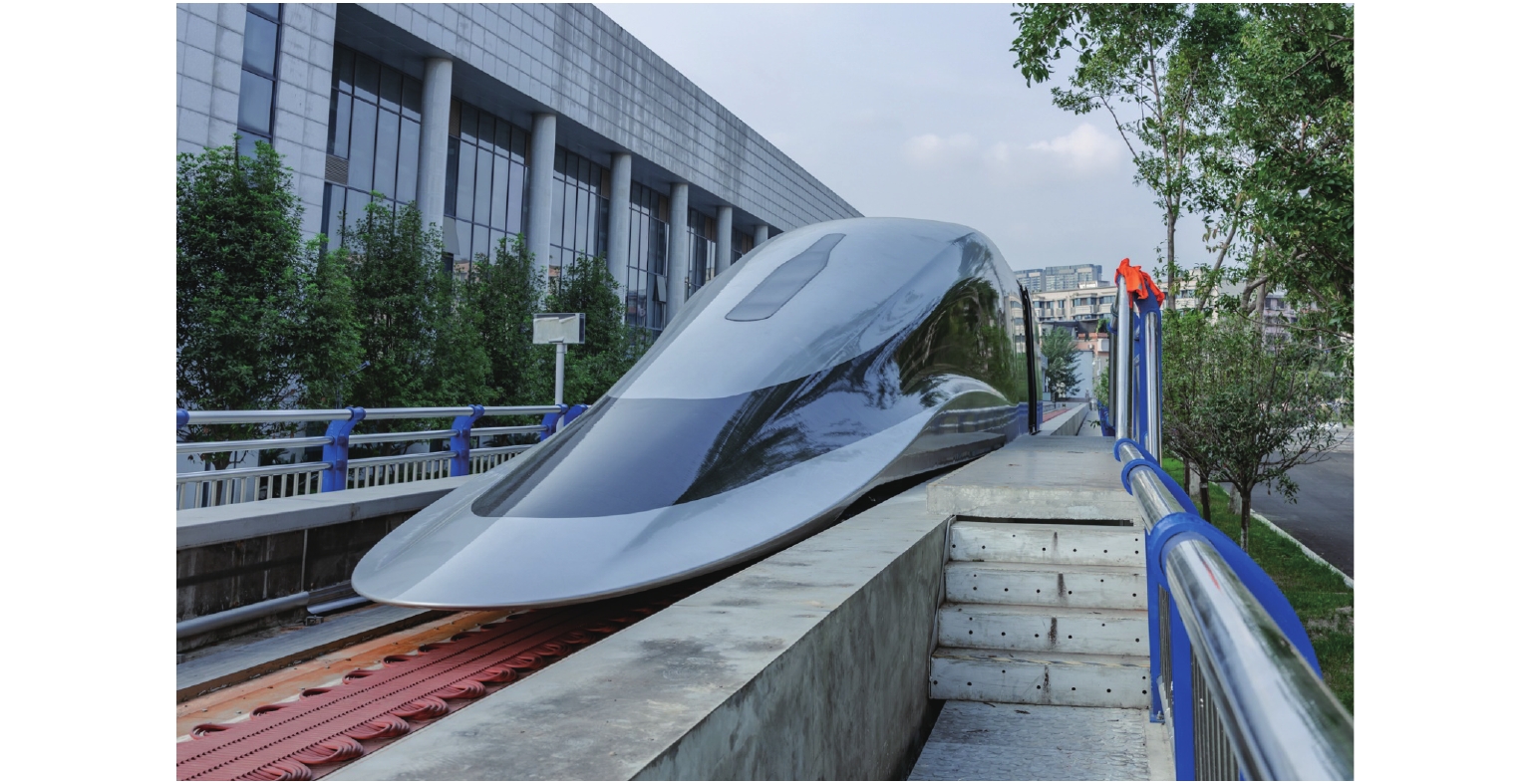

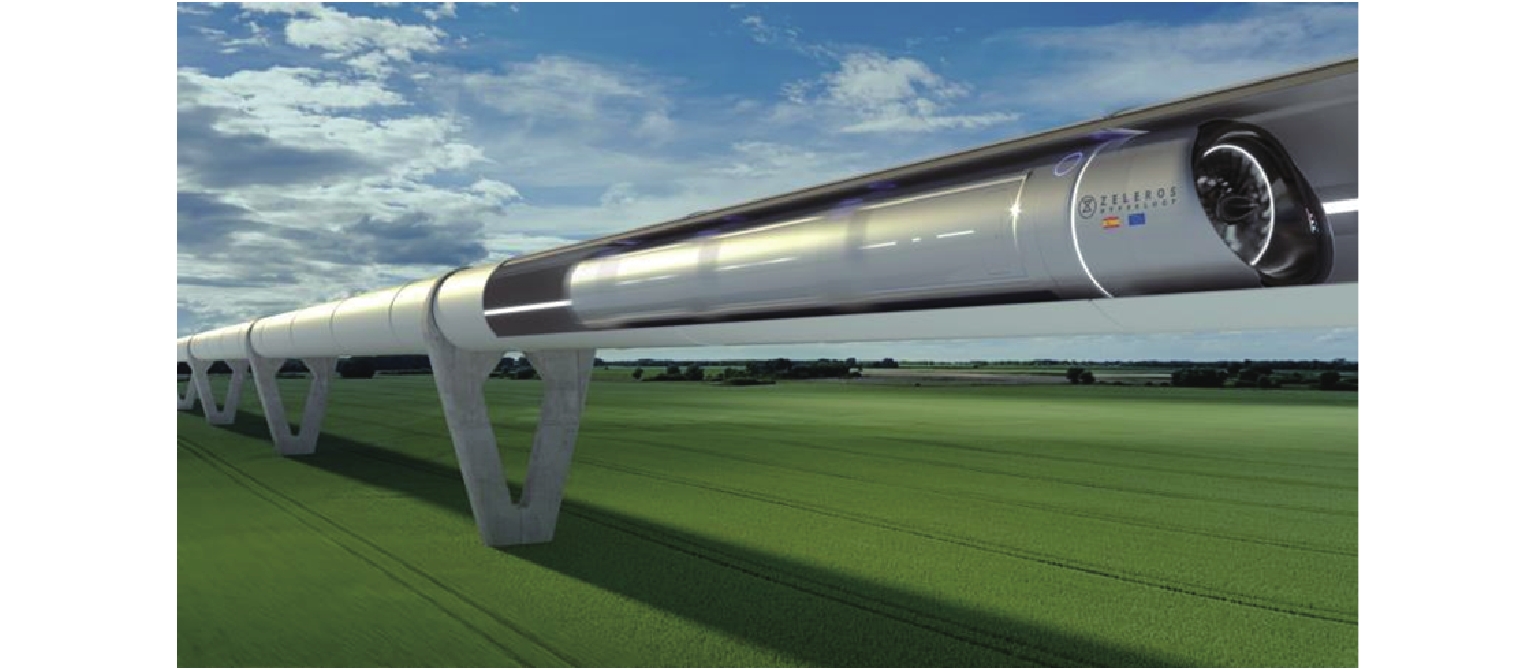

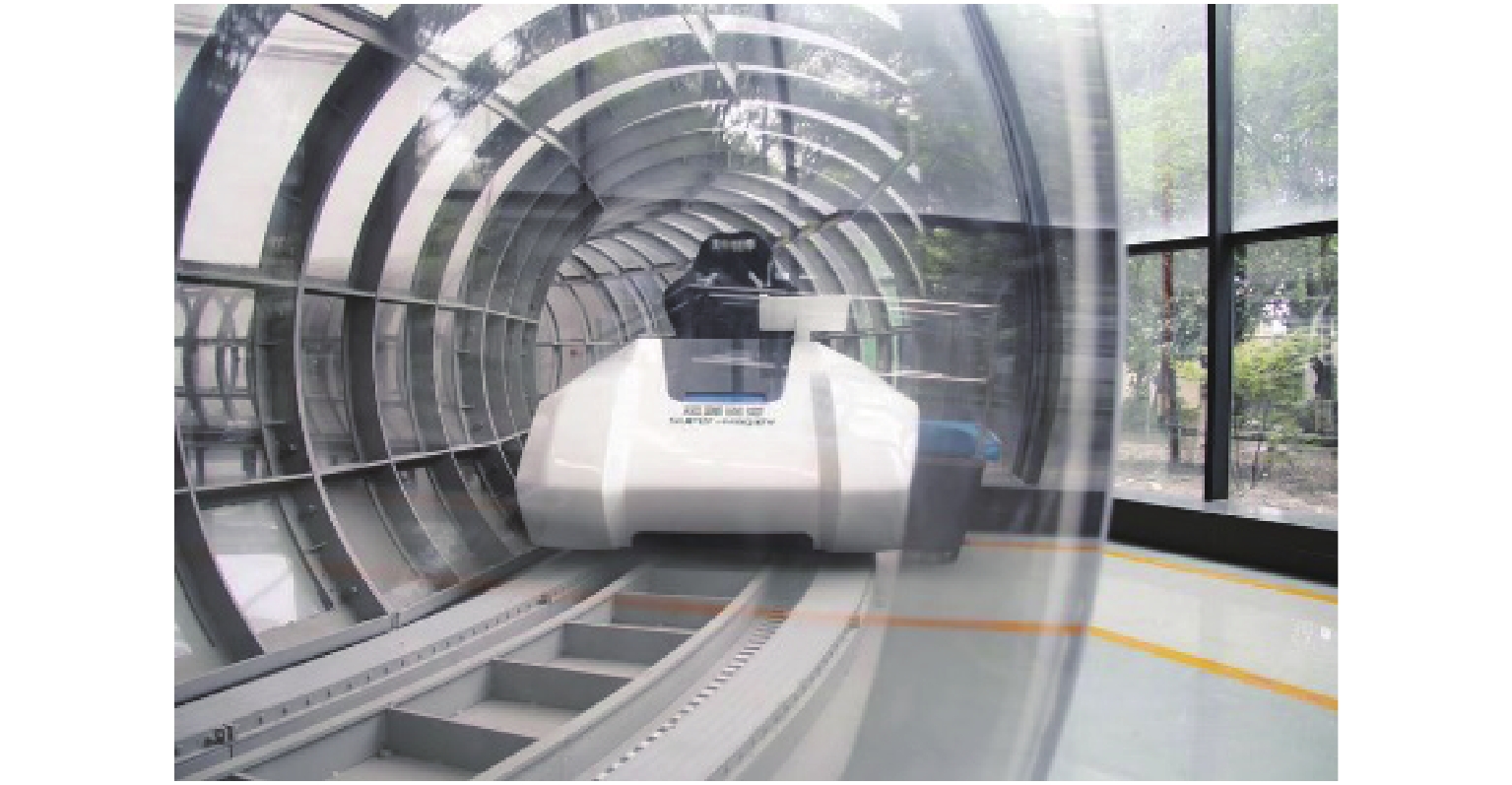

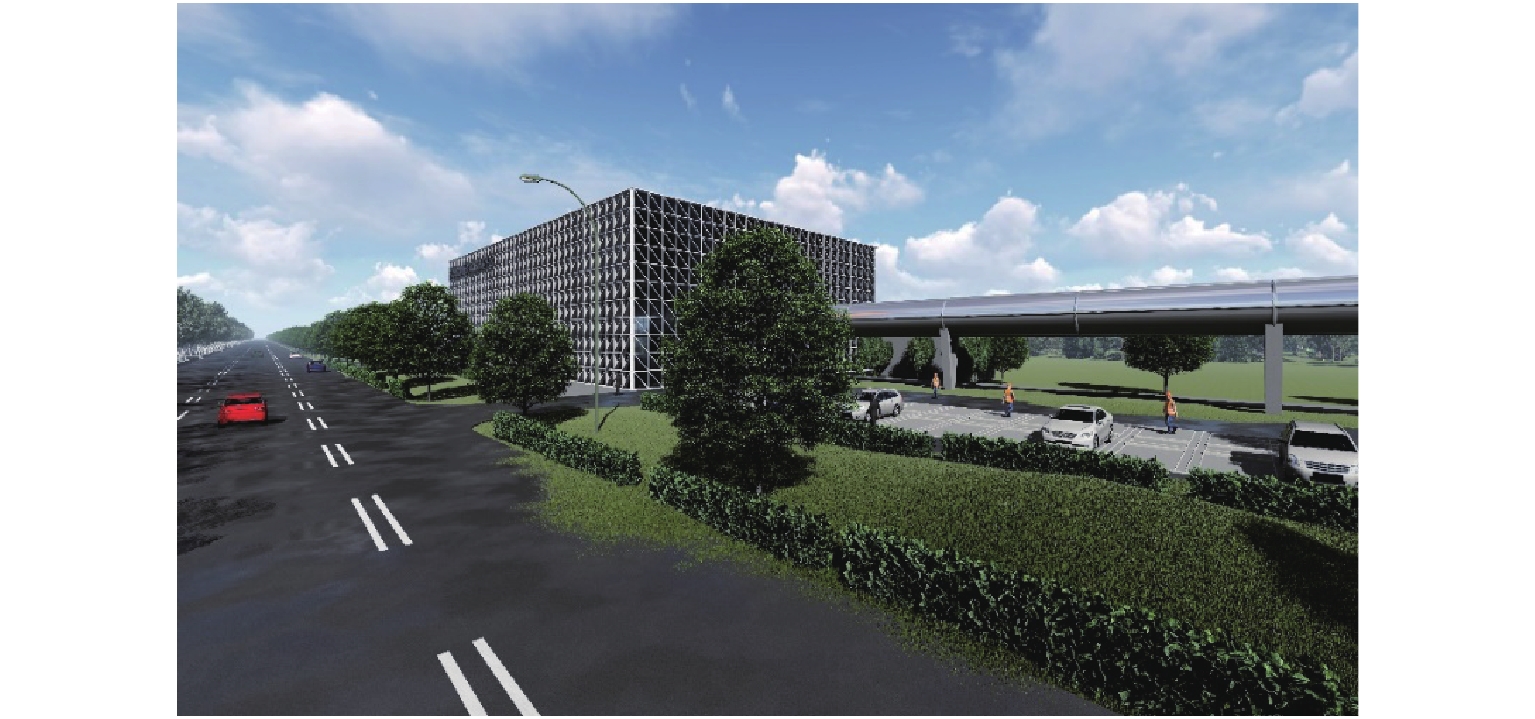

下载: