Calibration Method of Bi-block Ballastless Track Monitoring on Sleeper Pressure

-

摘要:

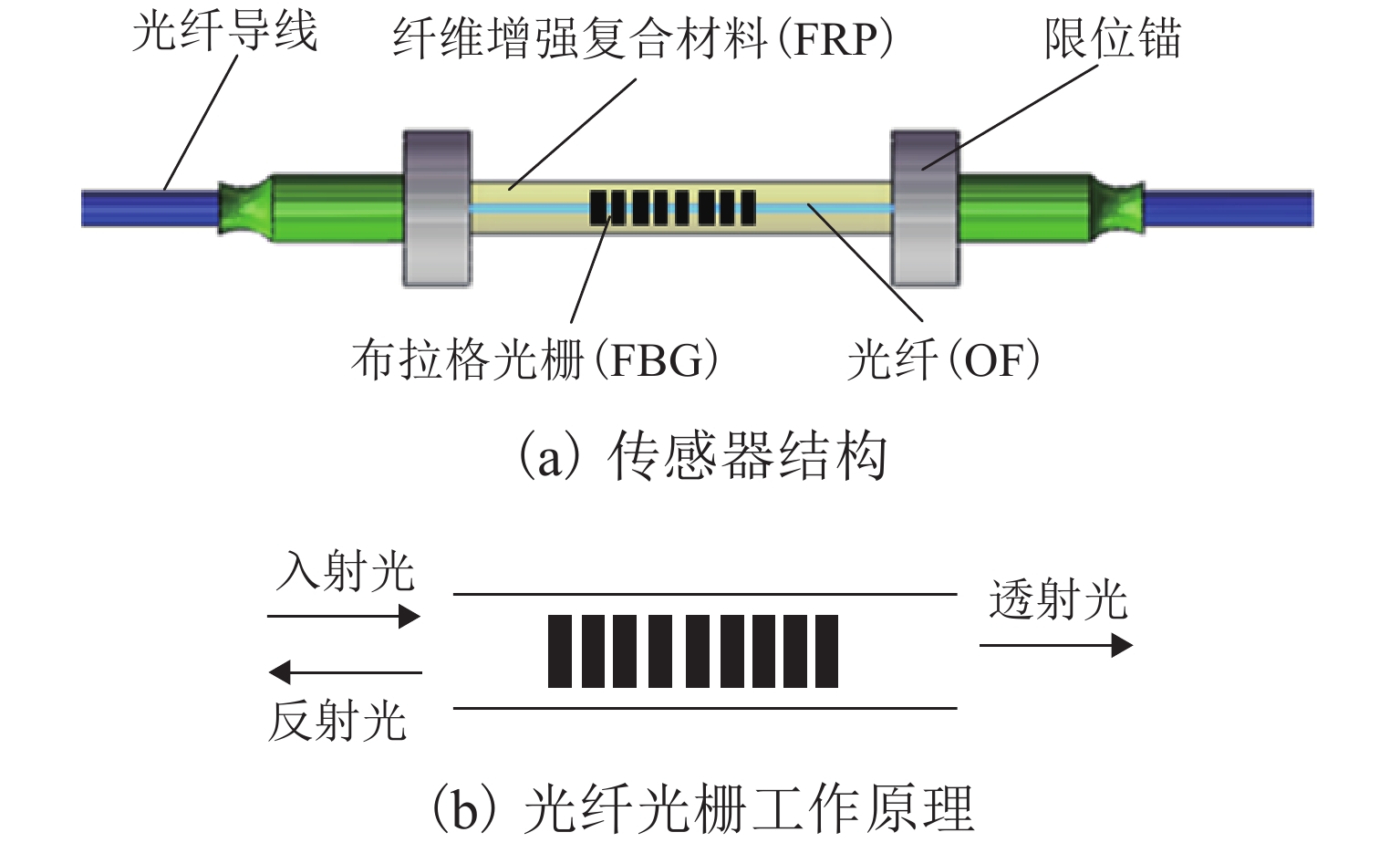

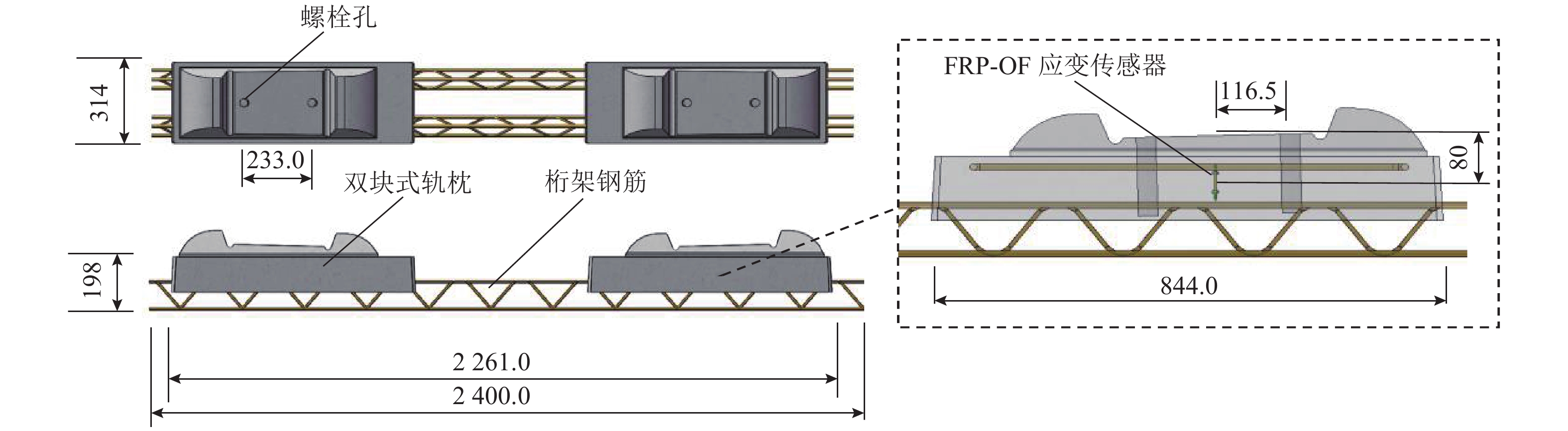

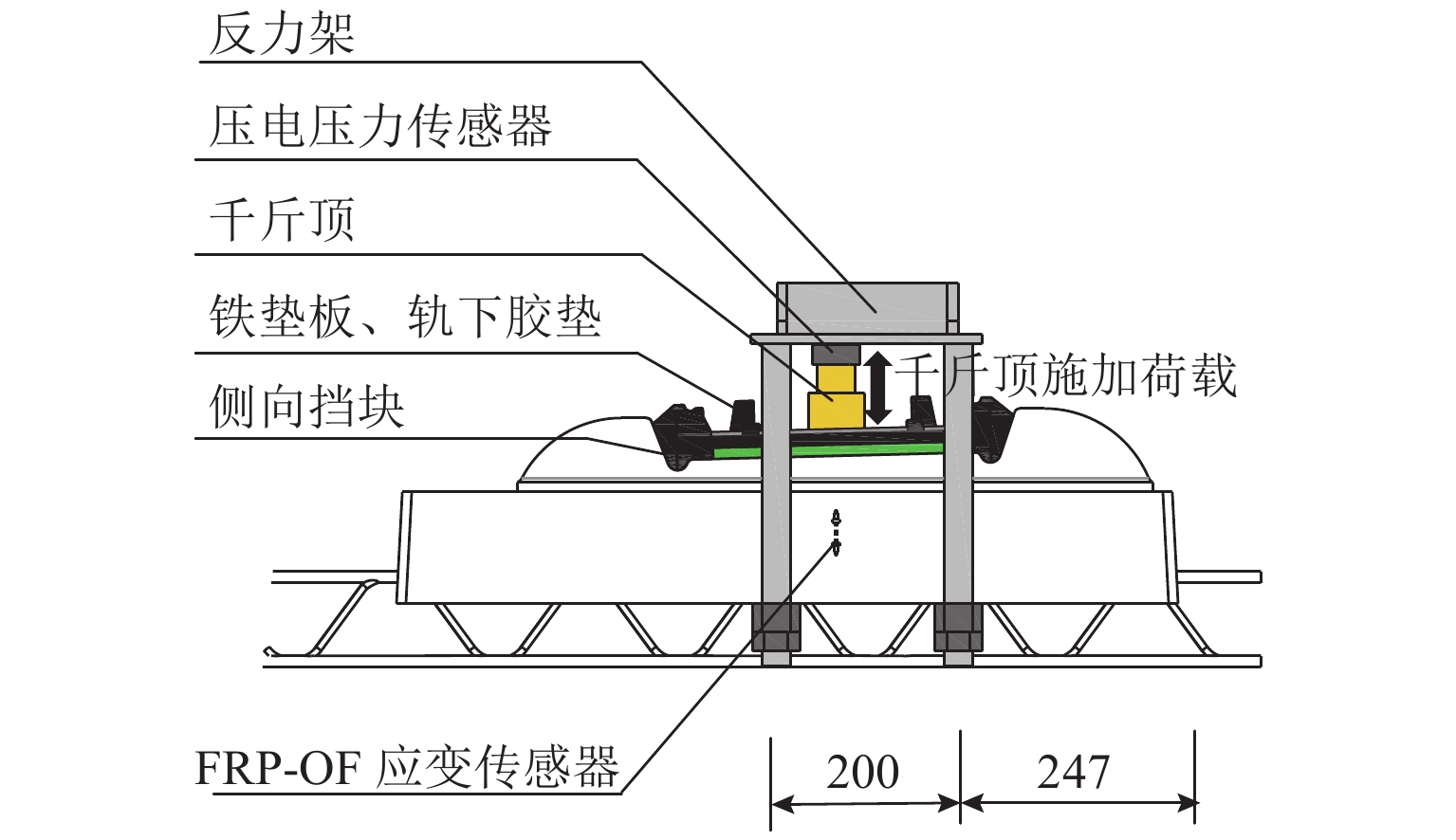

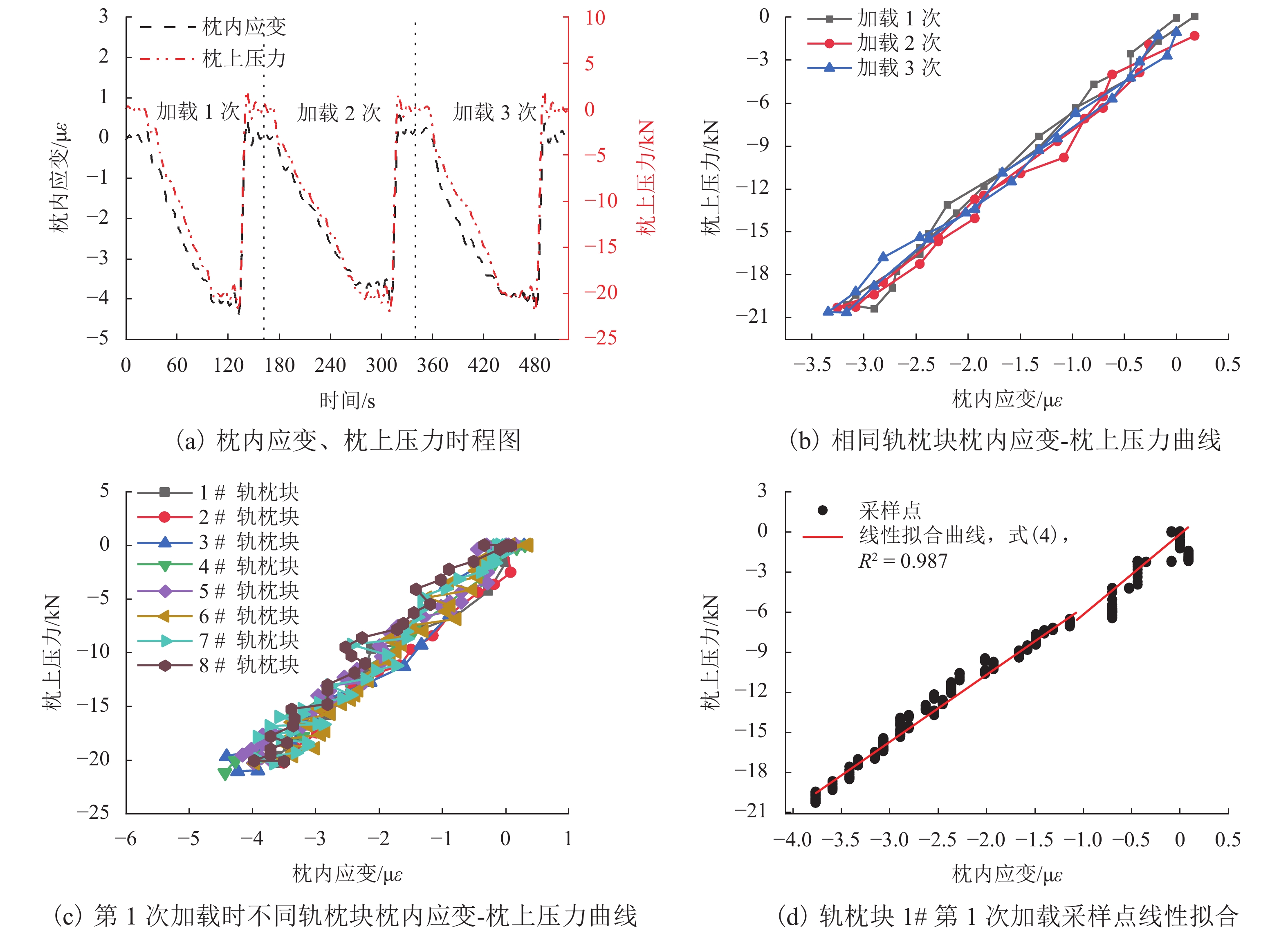

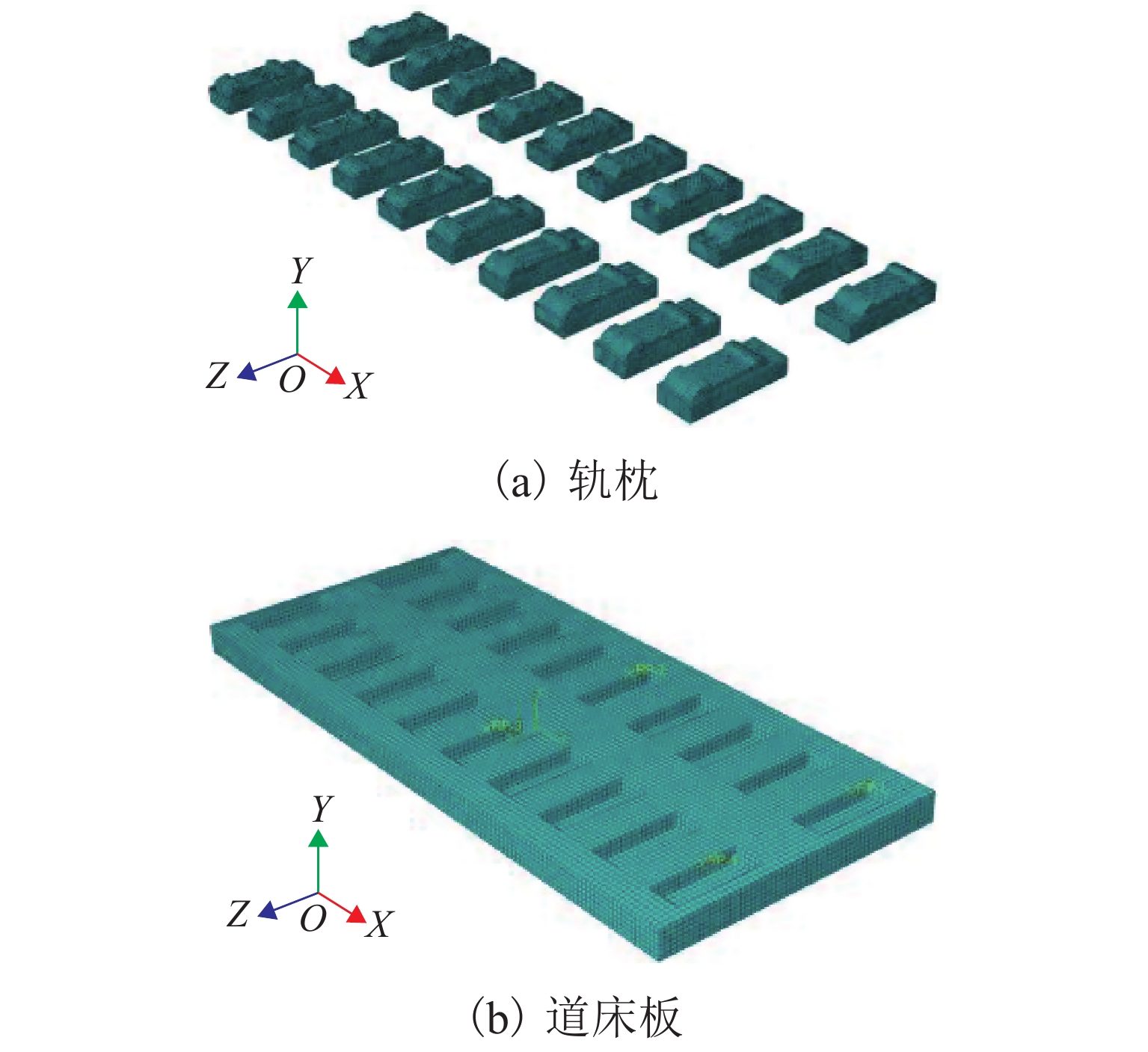

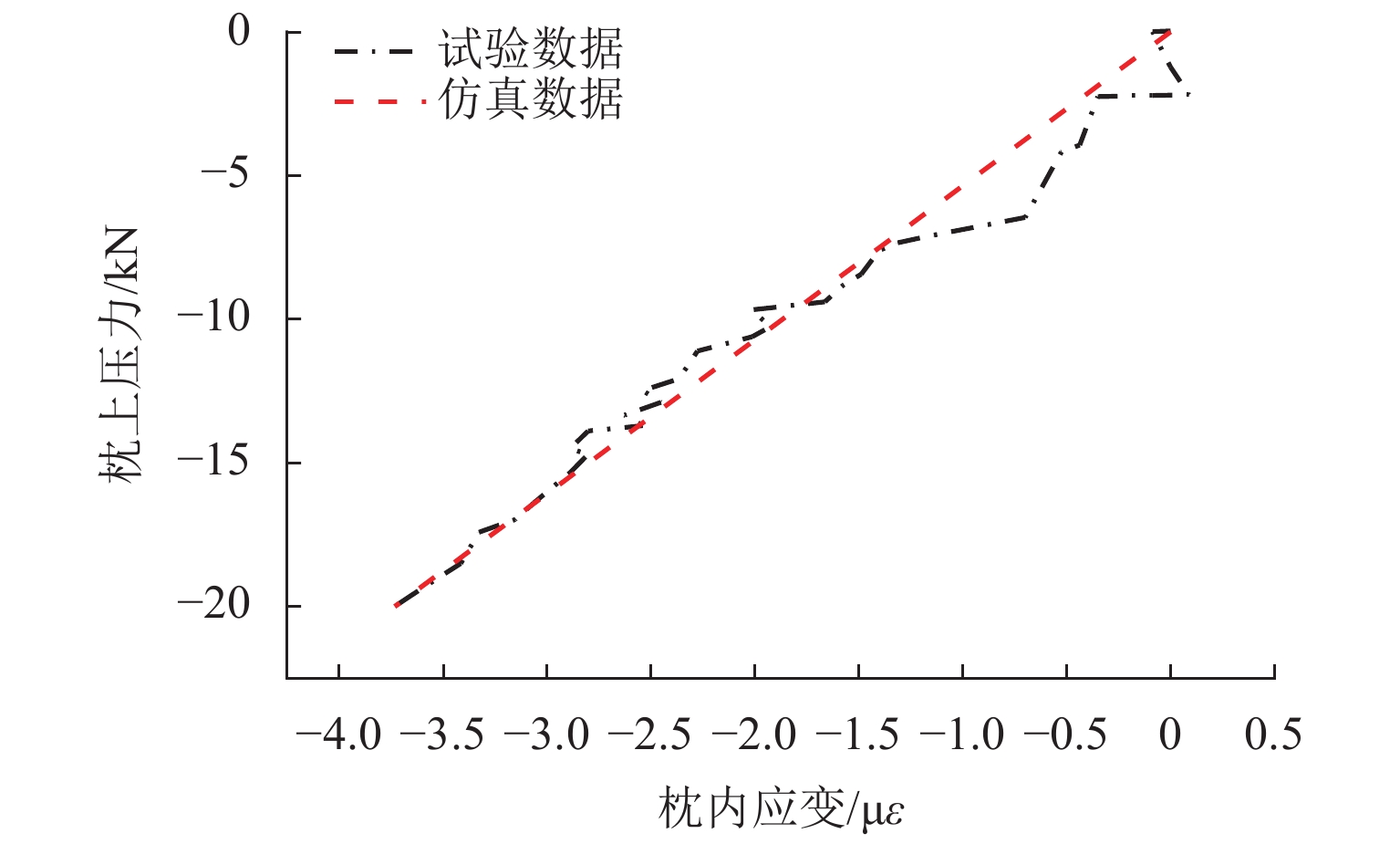

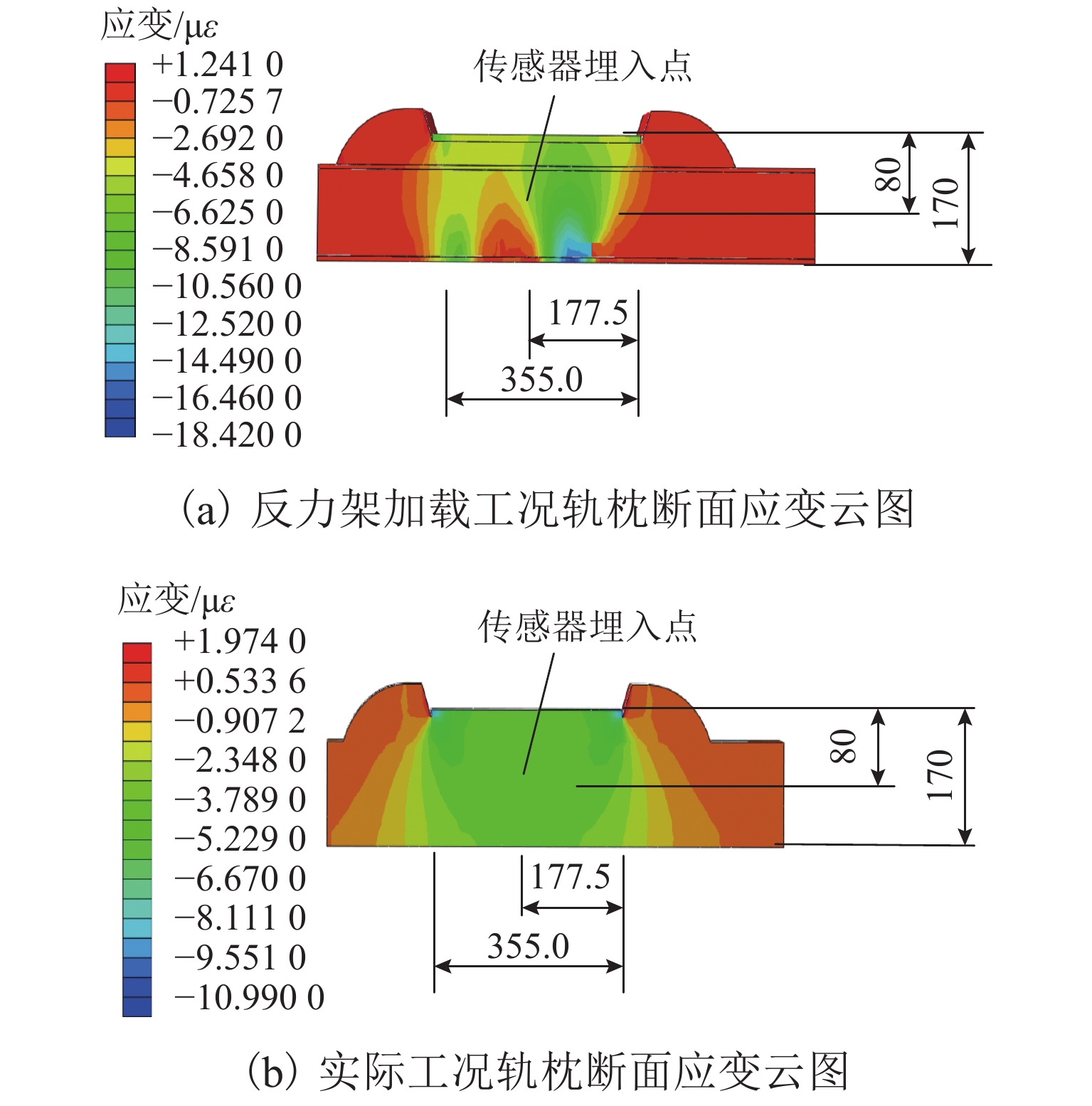

为探寻双块式无砟轨道枕上压力的长期监测方法,以CRTSⅠ型双块式轨枕为研究对象,首次利用埋入式光纤光栅传感器研究了双块式轨枕内部应变值和枕上压力的线性关系. 首先,在轨枕制造阶段埋入FRP-OF光纤光栅应变传感器,用于测试轨枕内部应变变化;其次,通过反力架和千斤顶对轨枕进行静力加载标定,分析轨枕表面加载力和轨枕内部应变的线性关系;最后,通过有限元仿真进行验证和修正. 结果表明:在轨枕表面施加的载荷和轨枕内部光纤光栅应变传感器的测试值具有良好线性关系,将此线性斜率确定为标定系数(4.90~5.28 kN/μ

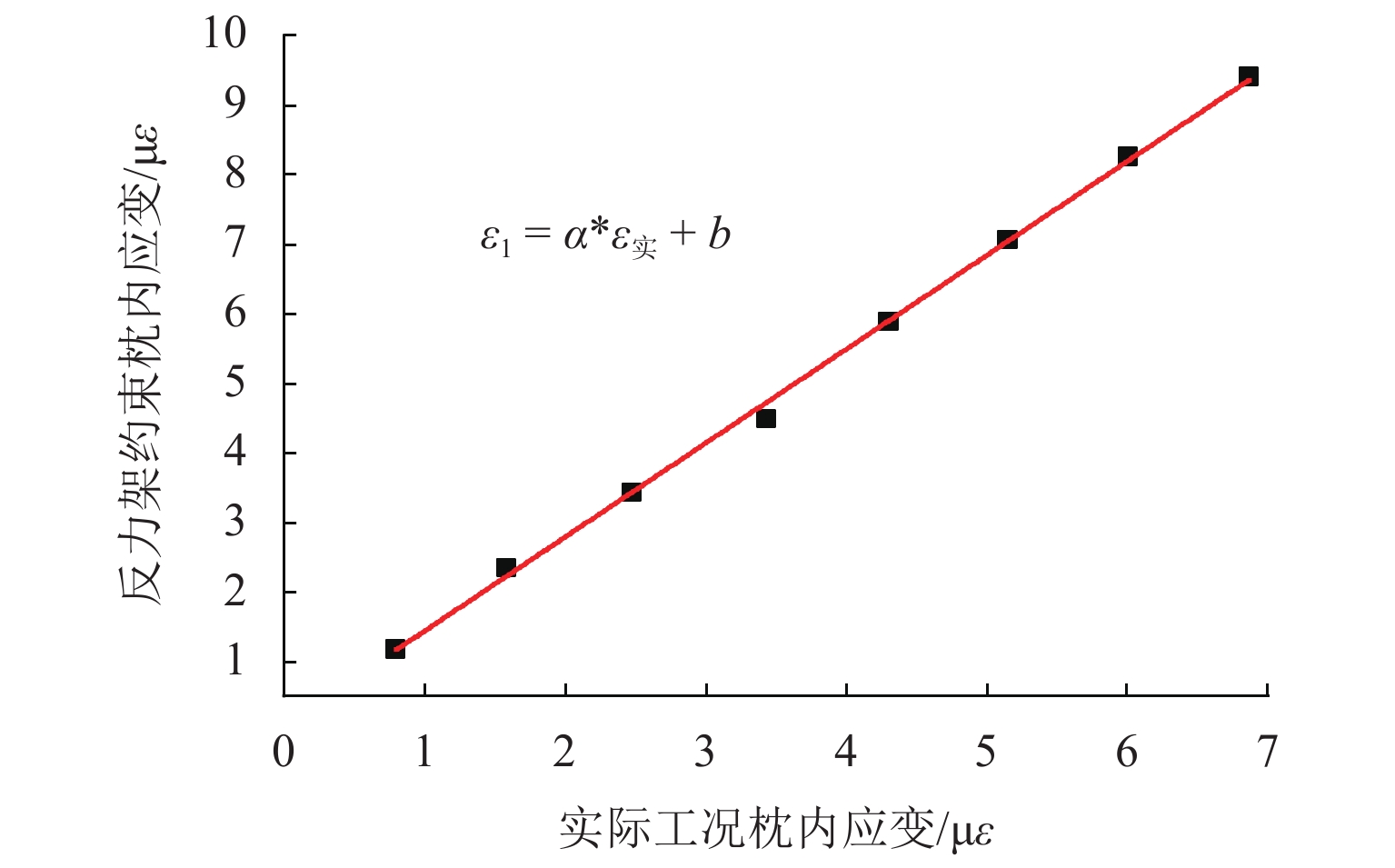

ε ),仿真数据与实测数据的误差在5%以内;对比轨枕在反力架约束和在道床板约束两种不同边界条件工况下的枕内应变,修正了枕上压力计算式,提出了一种基于双块式轨枕内部应变的枕上压力计算方法,并在高速铁路运营线路上测得枕上压力约为30~42 kN;该方法为高速铁路轮轨荷载传递研究、无砟轨道结构的强度计算理论和方法的完善以及列车轮对状态监测提供重要依据.Abstract:In order to explore the long-term monitoring method of bi-block ballastless track sleeper pressure, this paper took the CRTSⅠ bi-block sleeper as the research object and studied the linear relationship between the internal strain values and the sleeper pressure by using the embedded fiber Bragg grating sensor. Firstly, the fiber reinforced polymer-optical fiber (FRP-OF) strain sensor was embedded in the sleeper at the manufacturing stage. Secondly, the sleeper was calibrated under static load by the reaction rack and jack, and the linear relationship between the surface loading force and the internal strain of the sleeper was analyzed. Finally, the finite element simulation was used for verification and correction. The results show that the load applied on the sleeper surface has a good linear relationship with the measured value of the FRP-OF strain sensor inside the sleeper. The slope of this linearity is determined as the calibration coefficient, with a range of about 4.90–5.28 kN/μ

ε . The error rate between simulation data and measured data is within 5%. The internal strains of the sleeper are compared under two different boundary conditions: reaction frame constraint and track slab constraint, and the equation for calculating sleeper pressure is corrected. As a result, a calculation method of sleeper pressure based on the internal strain of a bi-block sleeper is presented, and the sleeper pressure measured on a high-speed railway operating line is about 30–42 kN. This method provides an important basis for studying the wheel/rail force transfer, improving strength calculation theory and method of ballastless track structures, and monitoring the condition of wheels of high-speed railways. -

表 1 FRP-OF应变传感器技术参数

Table 1. Technical parameters of FRP-OF strain sensor

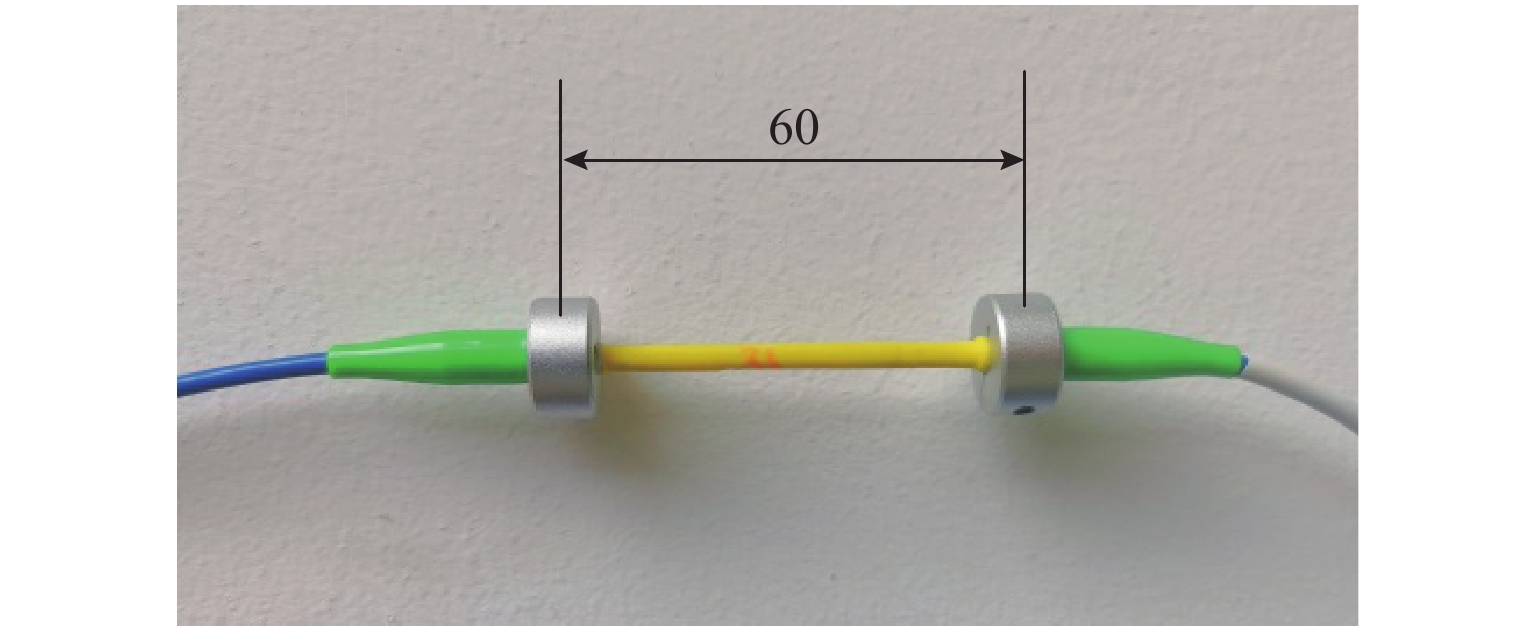

传感器技术参数 数值 量程/με −1500~3 000 分辨率/με ±0.1 测量精度/% 0.5 应变系数/ (pm·με) 0.8~1.2 线性度/% 99.9 重复性误差/% ≤0.5 中心波长/nm 1528~1568 反射率/% ≥90 标距尺寸/mm 60 工作温度范围/℃ −30~80 表 2 标定试验的荷载值为20 kN时的数据

Table 2. Data obtained at load of 20 kN in calibration test

轨枕块

编号枕内应变

平均值/με枕内应变-枕

上压力斜率

平均值/

(kN·με−1)枕内应变-枕

上压力截距

平均值/kN1# 3.7 5.03 0.61 2# 3.6 4.98 1.11 3# 3.9 4.90 0.73 4# 3.9 4.93 0.76 5# 3.9 4.78 0.50 6# 3.7 5.10 0.69 7# 3.6 5.28 0.10 8# 3.7 5.21 1.14 表 3 有限元模型材料参数

Table 3. Material parameters of finite element model

部件 材料 弹性

模量/GPa泊松比 密度/

(kg·m−3)轨枕块 C60 混凝土 36.5 0.20 2640 道床板 C40 混凝土 32.5 0.24 2440 传感器 FRP 72.0 0.20 -

[1] 李闯,张银花,田常海,等. 高速铁路钢轨服役状态及病害整治研究[J]. 铁道建筑,2020,60(8): 126-129,142.LI Chuang, ZHANG Yinhua, TIAN Changhai, et al. Study on rail service status and disease treatment of rail for high speed railway[J]. Railway Engineering, 2020, 60(8): 126-129,142. [2] 张尧毅. 高铁客运专线线路病害研究分析[D]. 兰州: 兰州交通大学, 2016. [3] 张健,吴昌华,肖新标,等. 轨枕空吊对轨枕动态性能的影响[J]. 西南交通大学学报,2010,45(2): 203-208.ZHANG Jian, WU Changhua, XIAO Xinbiao, et al. Effect of unsupported sleepers on sleeper dynamic response[J]. Journal of Southwest Jiaotong University, 2010, 45(2): 203-208. [4] 杨俊斌,刘学毅,刘永孝,等. Ⅰ型轨道板端离缝对轨道结构及车辆动力特性的影响[J]. 西南交通大学学报,2014,49(3): 432-437,512.YANG Junbin, LIU Xueyi, LIU Yongxiao, et al. Influence of seam in type Ⅰ slab ends on dynamic characteristics of track and vehicle[J]. Journal of Southwest Jiaotong University, 2014, 49(3): 432-437,512. [5] 梁佳乐. 高速铁路无砟轨道结构监测研究[D]. 重庆: 重庆交通大学, 2018. [6] 周扬,丁军君,李芾,等. 轮轨作用力测试方法的研究进展[J]. 铁道标准设计,2019,63(3): 38-44.ZHOU Yang, DING Junjun, LI Fu, et al. Research and development of wheel/Rail force testing method[J]. Railway Standard Design, 2019, 63(3): 38-44. [7] 金鑫,金新灿,龚明,等. 基于轮轴动应力测试的轮轨力识别与分析[J]. 北京交通大学学报,2012,36(4): 173-177.JIN Xin, JIN Xincan, GONG Ming, et al. Wheel-rail force identification and analysis based on wheelset dynamic stress testing[J]. Journal of Beijing Jiaotong University, 2012, 36(4): 173-177. [8] 宫雪. 轮轴结合法测力轮对研究[D]. 北京: 北京交通大学, 2017. [9] ZHANG S L, KOH C G, KUANG K S C, et al. Proposed rail pad sensor for wheel-rail contact force monitoring[J]. Smart Materials and Structures, 2018, 27(11): 115041.1-115041.9. [10] SADEGHI J. Field investigation on dynamics of railway track pre-stressed concrete sleepers[J]. Advances in Structural Engineering, 2010, 13(1): 139-151. doi: 10.1260/1369-4332.13.1.139 [11] 宋颖,杜彦良,孙宝臣. 压电传感技术在轮轨力实时监测中的应用探讨[J]. 振动与冲击,2010,29(1): 228-232,248.SONG Ying, DU Yanliang, SUN Baochen. Application of piezoelectric sensing technology in real-time monitoring of wheel/rail interaction[J]. Journal of Vibration and Shock, 2010, 29(1): 228-232,248. [12] 张政. 光纤光栅传感技术在高速铁路轨道状态监测中的应用[J]. 铁道建筑,2016(5): 77-81.ZHANG Zheng. Application of fiber Bragg grating sensing technology to monitoring of high speed railway track condition[J]. Railway Engineering, 2016(5): 77-81. [13] 潘建军. 光纤传感轨道状态监测的研究与应用[D]. 武汉: 武汉理工大学, 2012. [14] 代鑫. 基于光纤光栅的高速铁路轨道结构监测方法及关键技术研究[D]. 武汉: 武汉理工大学, 2013. [15] 孙高盼,闫连山,邵理阳,等. 基于光纤光栅的钢轨受力状态监测技术研究[J]. 传感器与微系统,2016,35(1): 69-71.SUN Gaopan, YAN Lianshan, SHAO Liyang, et al. Research on technology of rail stress status monitoring based on fiber grating[J]. Transducer and Microsystem Technologies, 2016, 35(1): 69-71. [16] LAM H F, WONG M T, YANG Y B. A feasibility study on railway ballast damage detection utilizing measured vibration of in situ concrete sleeper[J]. Engineering Structures, 2012, 45: 284-298. doi: 10.1016/j.engstruct.2012.06.022 [17] 孟汇. 光纤光栅传感器酸碱耐久性研究[D]. 武汉: 武汉理工大学, 2013. [18] WEI C L, LAI C C, LIU S Y, et al. A fiber Bragg grating sensor system for train axle counting[J]. IEEE Sensors Journal, 2010, 10(12): 1905-1912. doi: 10.1109/JSEN.2010.2049199 [19] 张兆亭,闫连山,王平,等. 基于光纤光栅的钢轨应变测量关键技术研究[J]. 铁道学报,2012,34(5): 65-69.ZHANG Zhaoting, YAN Lianshan, WANG ping, et al. Key techniques for rail strain measurements based on fiber Bragg grating sensor[J]. Journal of the China Railway Society, 2012, 34(5): 65-69. [20] 高亮,周陈一,张东风,等. 光纤光栅在轮轨作用力监测中的应用研究[J]. 北京交通大学学报,2019,43(1): 88-95.GAO Liang, ZHOU Chenyi, ZHANG Dongfeng, et al. Research on the application of wheel-rail contact forces monitoring using fiber bragg grating[J]. Journal of Beijing Jiaotong University, 2019, 43(1): 88-95. [21] BUTLER L J, XU J L, HE P, et al. Robust fibre optic sensor arrays for monitoring early-age performance of mass-produced concrete sleepers[J]. Structural Health Monitoring, 2018, 17(3): 635-653. doi: 10.1177/1475921717714615 [22] BUTLER L J, GIBBONS N, HE P, et al. Develop of self-sensing concrete sleepers for next-generation rail infrastructure[C]//ICE Institution of Civil Engieers. Cambridge: ICE Virtual Library, 2016: 15-20. [23] 徐金龙. 基础设施高性能分布式光纤监测与状态评估方法研究[D]. 哈尔滨: 哈尔滨工业大学, 2018. [24] 张鲁顺. 高速铁路无砟轨道列车荷载传递特征及机理研究[D]. 北京: 北京交通大学, 2020. [25] 马昆林,万镇昂,龙广成,等. 板式轨道充填层SCC疲劳损伤本构模型[J]. 铁道学报,2020,42(11): 139-145.MA Kunlin, WAN Zhen’ang, LONG Guangcheng, et al. Fatigue damage constitutive model of slab track filling layer SCC[J]. Journal of the China Railway Society, 2020, 42(11): 139-145. -

下载:

下载: